Linear nozzle for electrostatic spinning

An electrospinning and linear technology, applied in filament/thread forming, textile and paper making, fiber processing, etc., can solve the problems of inability to spin out nanofibers at the same time, high injection voltage threshold, unstable preparation process, etc., and achieve structural Simple, low-cost, high-thickness consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

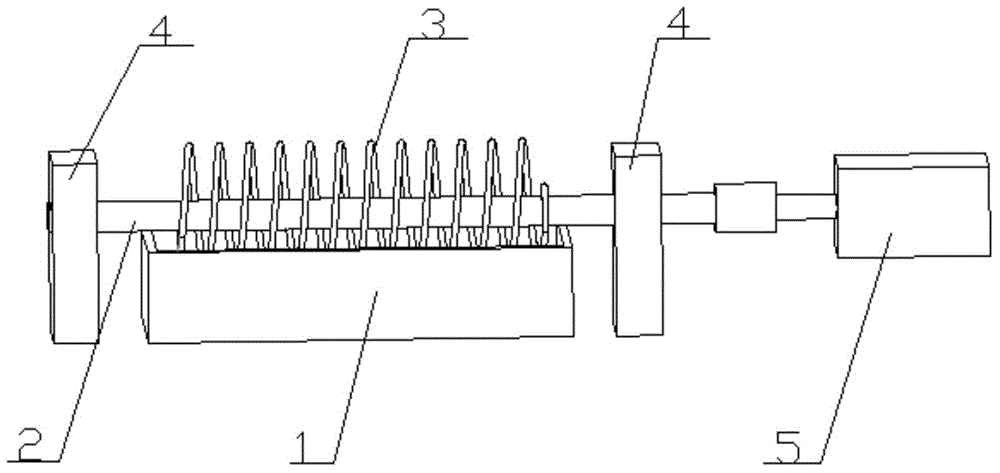

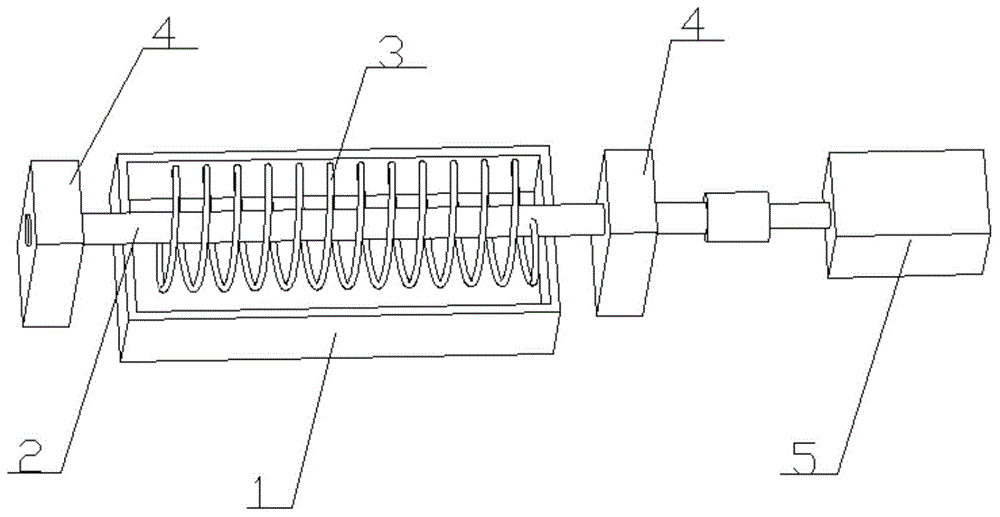

[0013] see Figure 1~3 , the embodiment of the present invention is provided with solution tank 1, rotating shaft 2, spiral metal ring 3, support base 4, driving device 5; The upper surface of described solution tank 1 is open, and rotating shaft 2 is arranged on the top of solution tank 1, and rotating shaft can conduct electricity and connect externally In the high-voltage electrostatic generating device, the two ends of the rotating shaft 2 are connected to the driving device 5, and the left and right sides of the rotating shaft 2 are respectively fixed on the support base 4.

[0014] The rotating shaft can be made of metal material, and the rotation speed of the rotating shaft can be 5-15 r / min.

[0015] The supporting seat can be made of insulating material, and the supporting seat is connected with the rotating shaft by ceramic bearings.

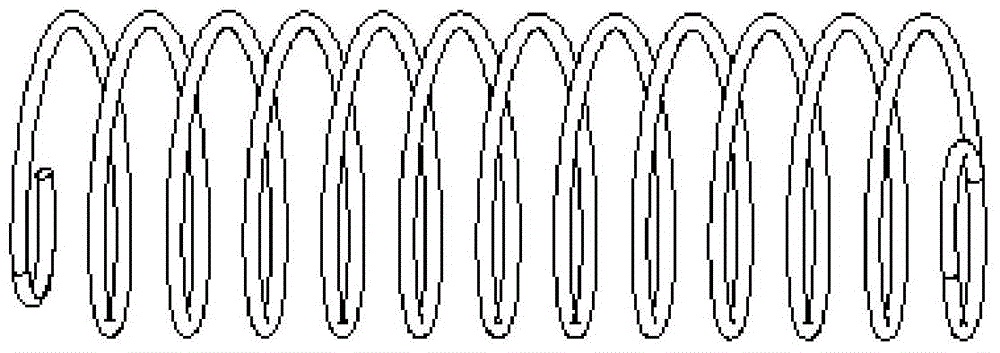

[0016] The spiral metal ring can be wound into a spring shape by a metal wire with a diameter of 1-5 mm, and the diameter of the spi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com