Preparation method of copper-clad plate

A copper clad laminate and copper foil technology, applied in chemical instruments and methods, layered products, lamination devices, etc., can solve problems such as resin void defects, difficult industrial production applications, and inability to apply industrial production, etc., to improve thickness uniformity and consistency, the preparation method is simple and easy, and the effect of improving the problem of thin thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

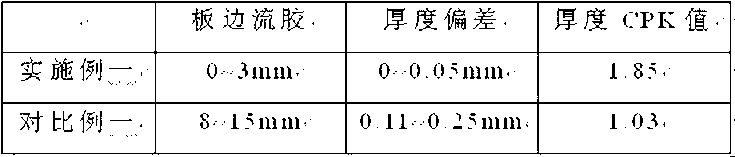

Embodiment 1

[0030] A method for preparing a copper clad laminate, comprising the steps of:

[0031] (1) Take 4 prepregs (RC content: 55%), and stack a 35-micron copper foil on both sides to obtain a prepreg combination;

[0032] (2) Take at least one group of the above-mentioned prepreg combinations, and the upper and lower surfaces of each combination are laminated with mirror steel plates;

[0033] (3) Take at least one group of the above-mentioned prepregs and put them between the upper and lower heating plates of the laminator to prepare for lamination and bonding;

[0034] (4) In the melting stage of the lamination process, the surroundings of the prepreg are heated, so that the glue around the prepreg reaches a high elastic state before the glue in the middle, and the high elastic state is that the relative curing degree is more than 60%;

[0035] (5) According to the conventional step lamination operation, the copper clad laminate can be obtained.

[0036] During the lamination p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com