Patents

Literature

128 results about "Model quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Computer method and apparatus for adaptive model predictive control

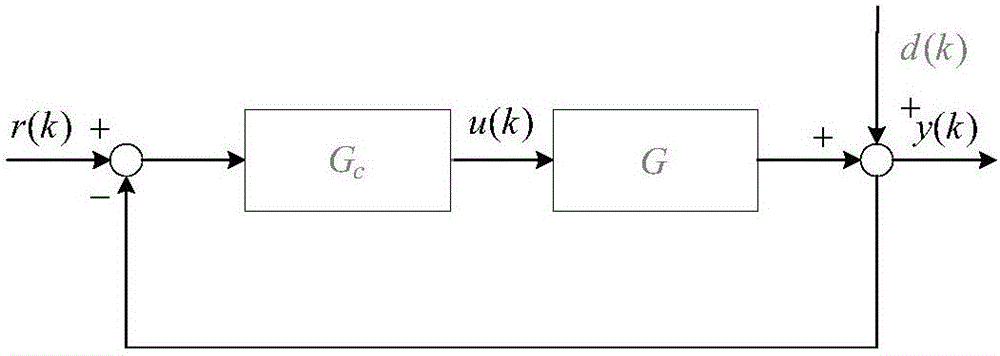

InactiveUS20070225835A1Automatically efficiently performLow costAdaptive controlControl engineeringModel quality

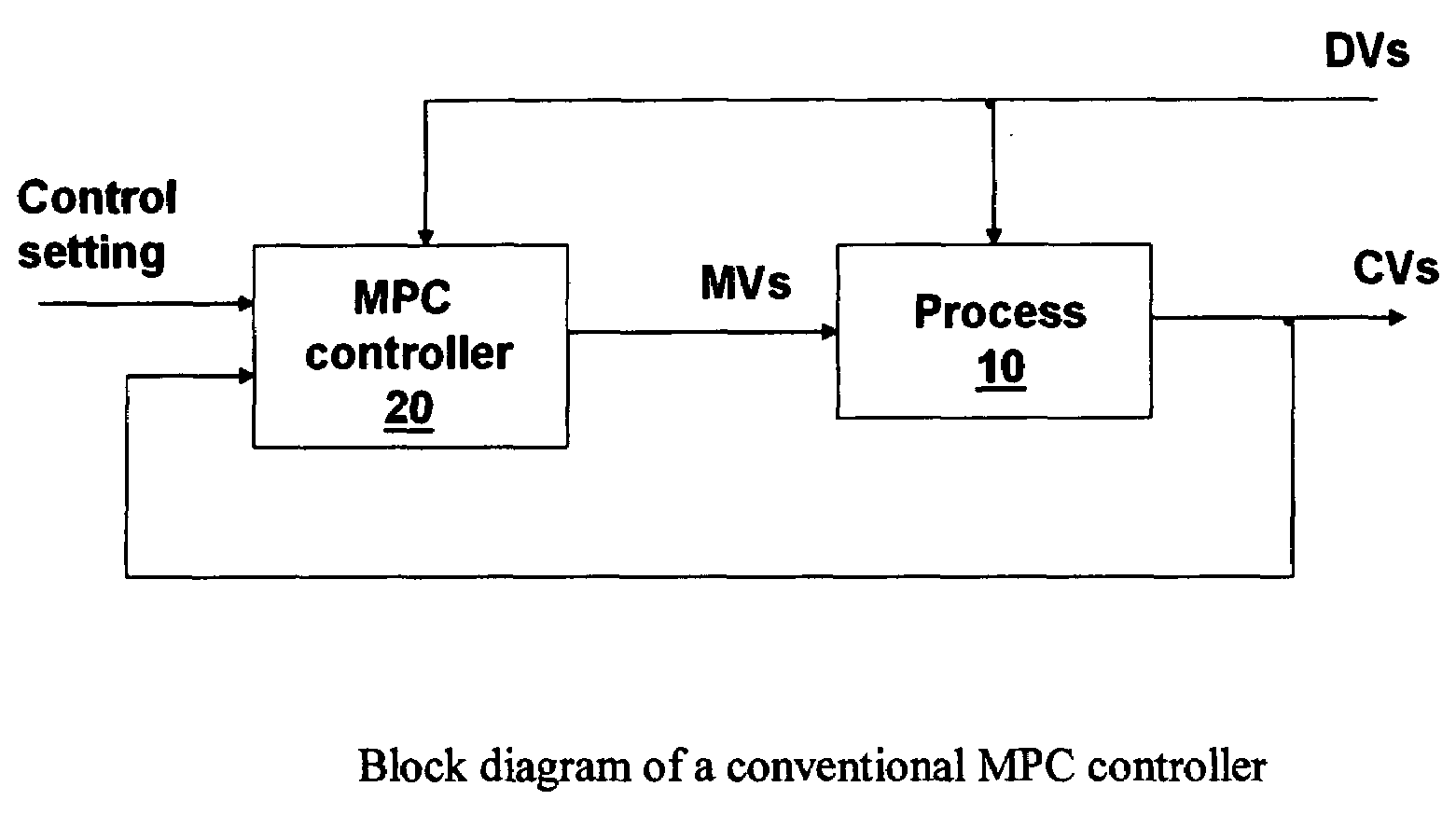

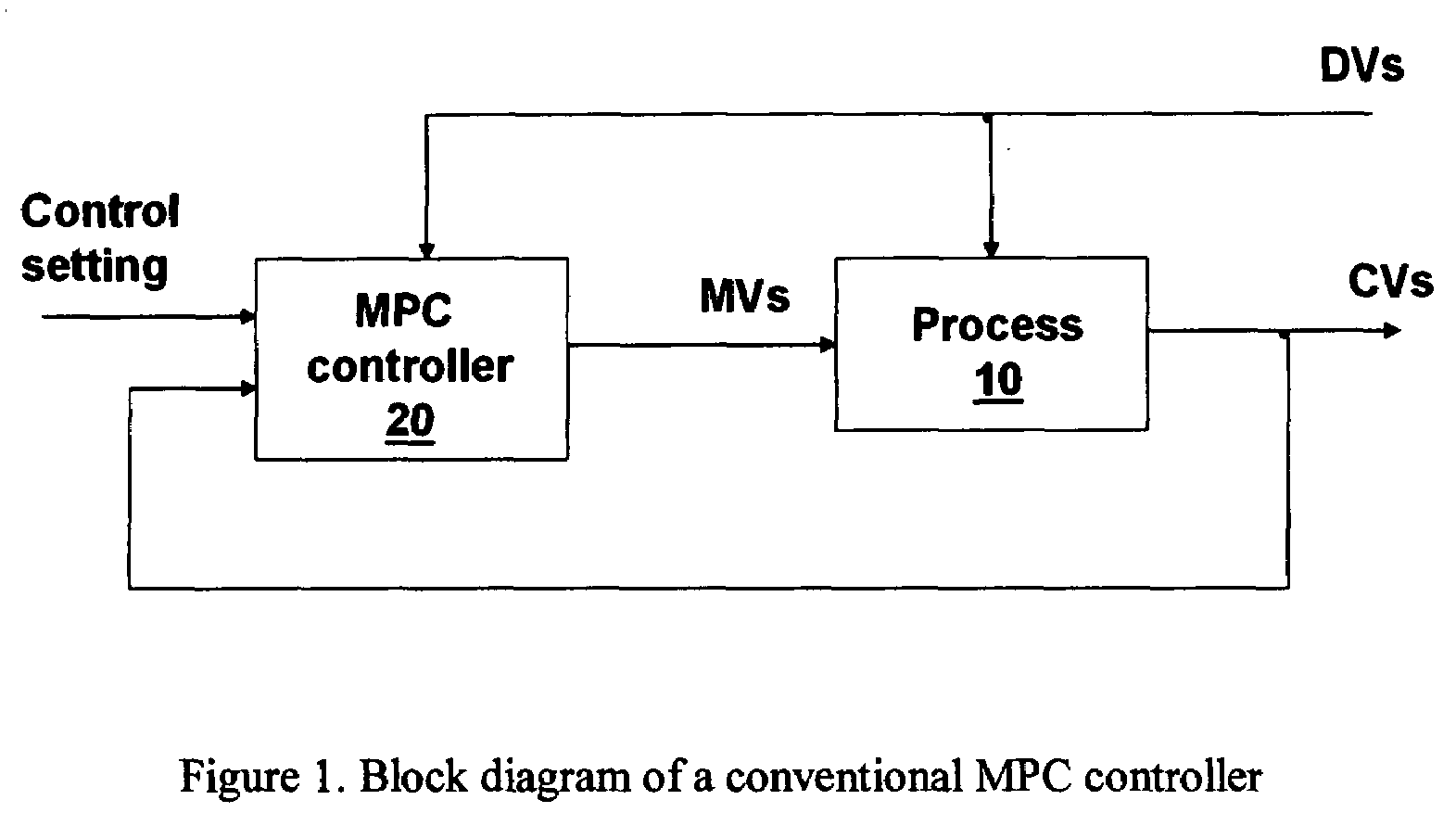

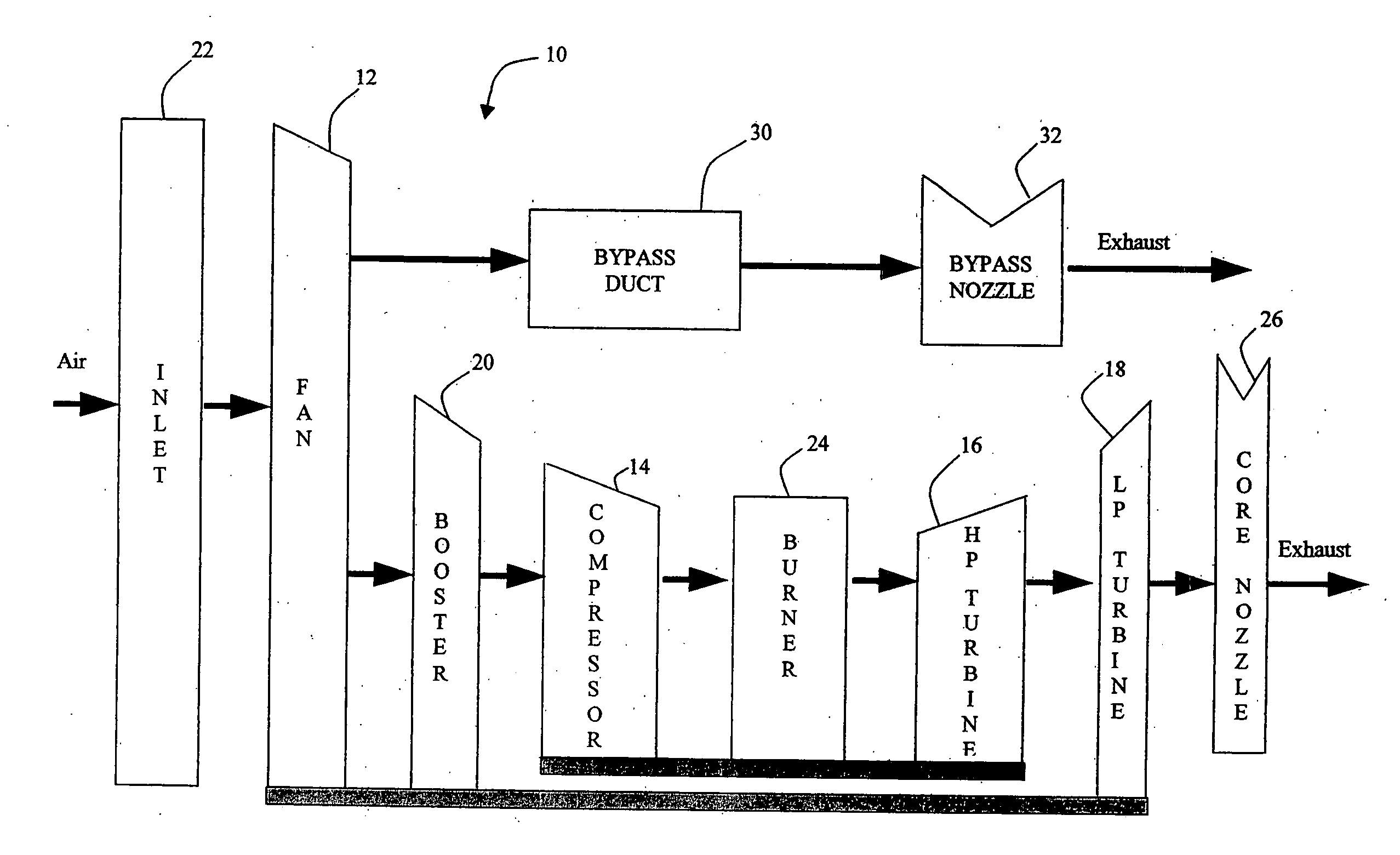

A computer method and apparatus for adaptive model predictive control (MPC) of multivariable processes is disclosed. The adaptive MPC system can perform automatic implementation for a new MPC controller, and, for an existing MPC controller, it can perform automatic maintenance when necessary. The adaptive MPC system consists of three modules: an MPC control module, an online identification module and a control monitor module. In MPC implementation, the online identification module and the MPC control module work together and perform various steps in MPC implementation automatically and efficiently. When the MPC controller is online, the control monitor module continuously monitors the MPC performance and model quality. When control performance becomes poor and considerable model degradation is detected, monitor module will start the maintenance by activating the online identification module. The identification module will re-identify the model and replace the old model. For strongly nonlinear process units, multiple models are identified and used in control.

Owner:ZHU YUCAI

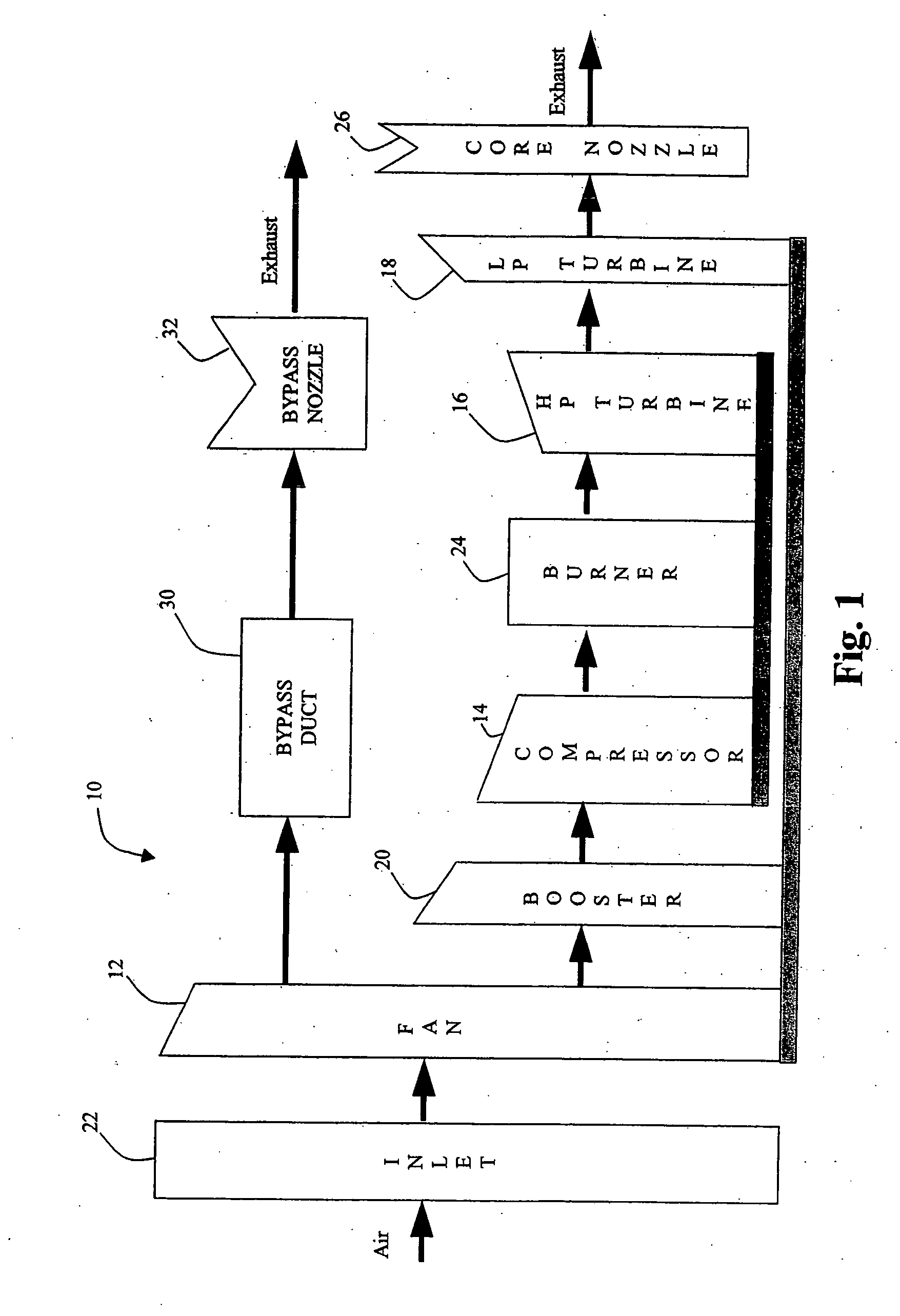

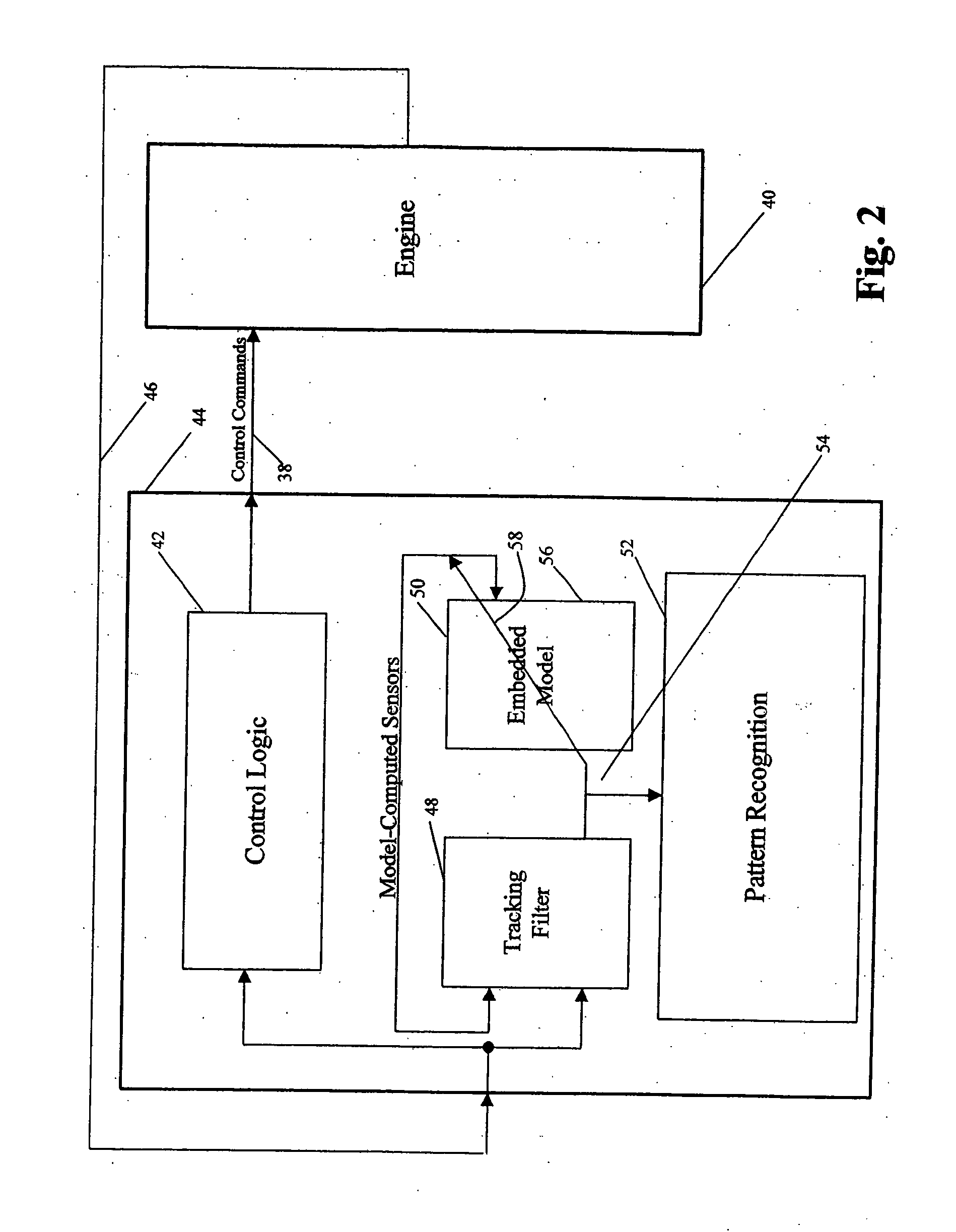

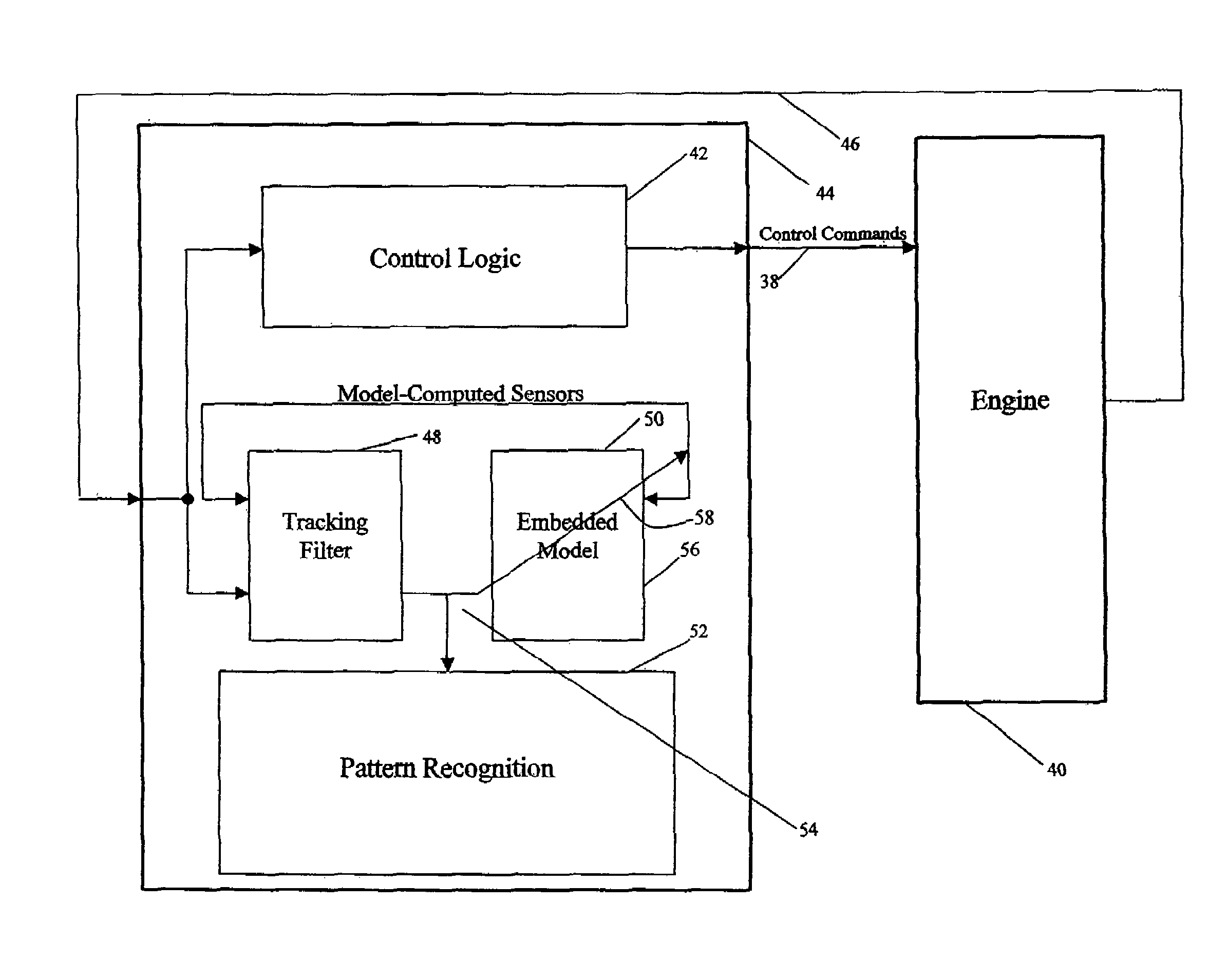

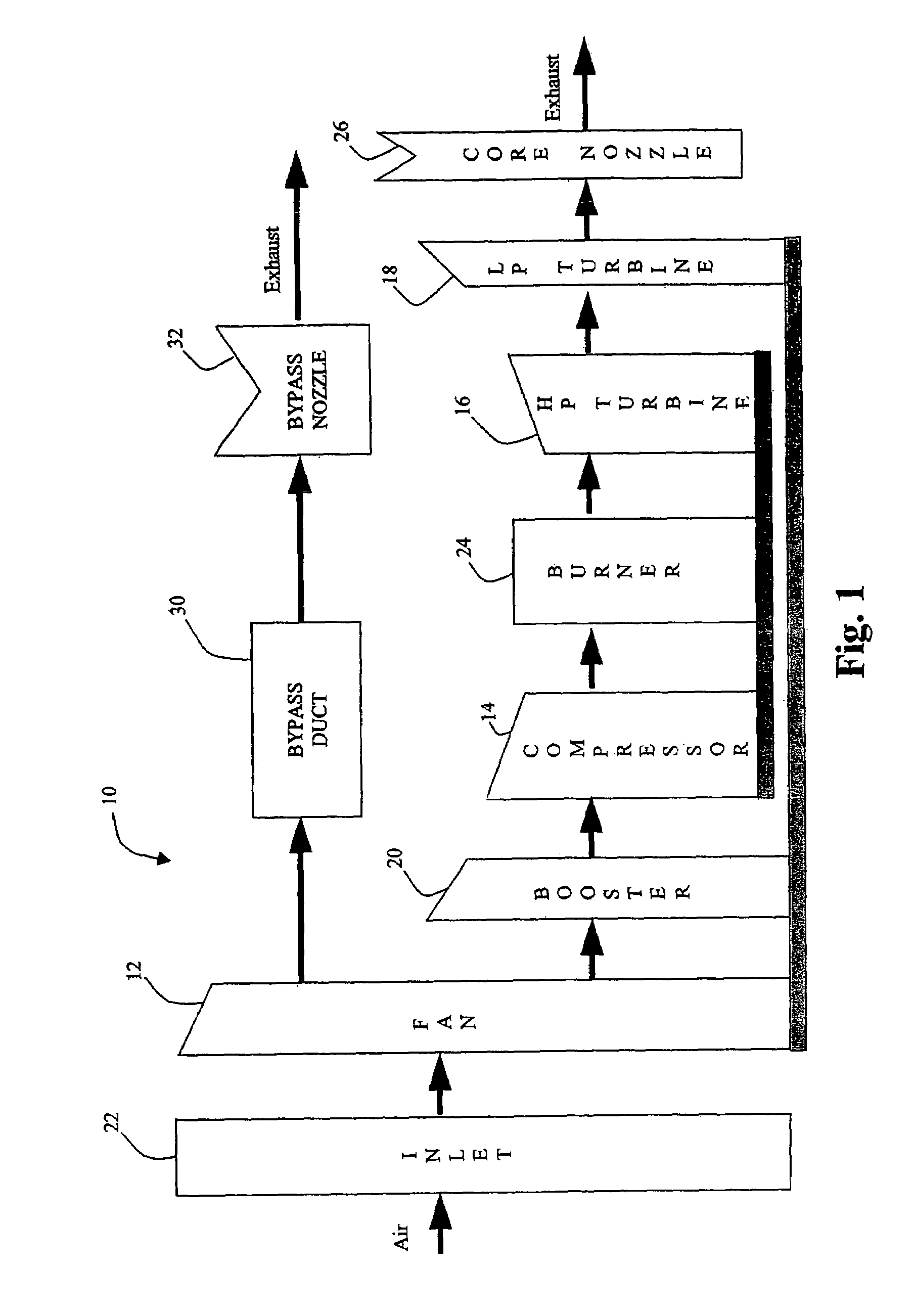

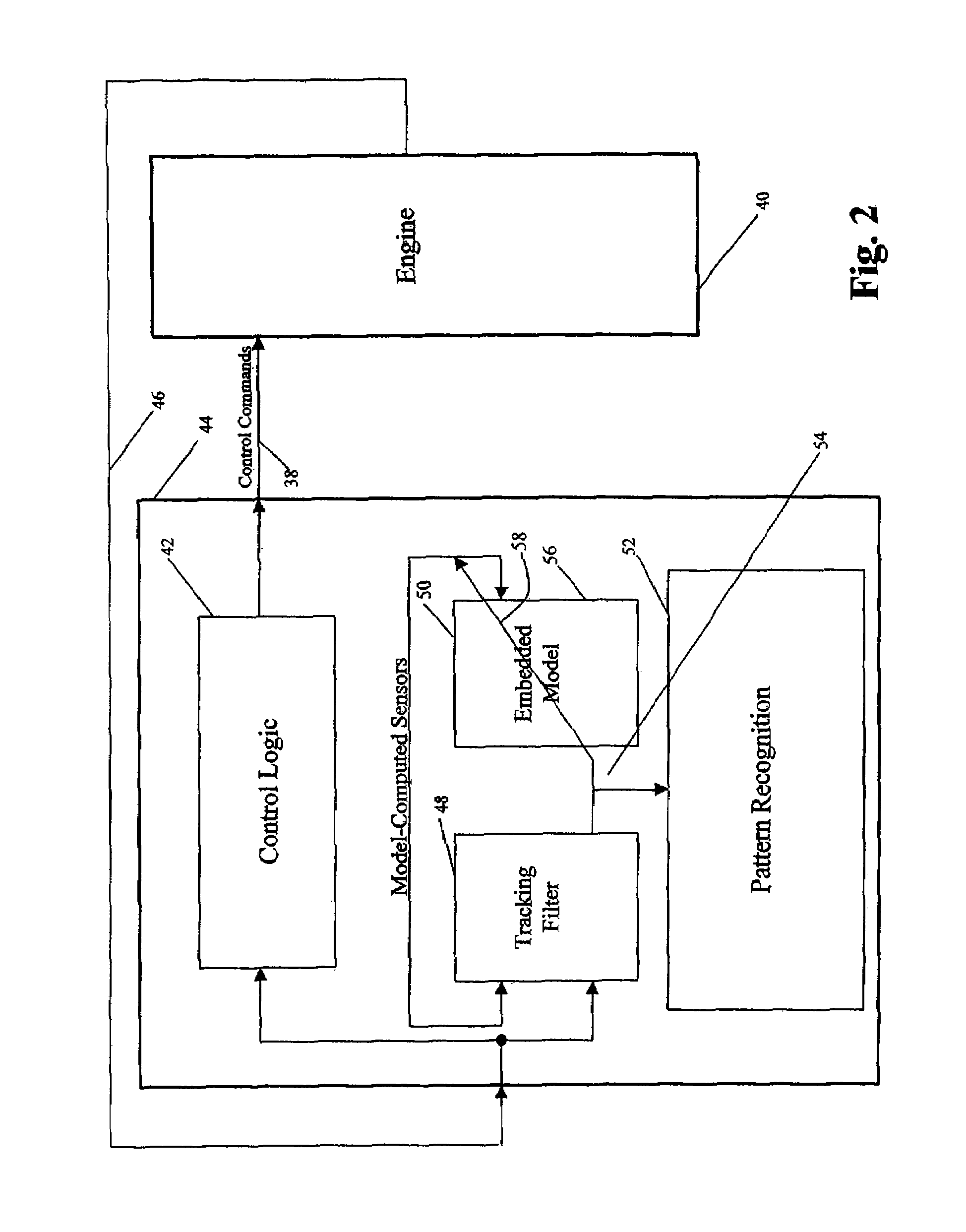

Sensor diagnostics using embedded model quality parameters

ActiveUS20070118270A1Detect failureVehicle testingAnalogue computers for vehiclesCombustorCombustion chamber

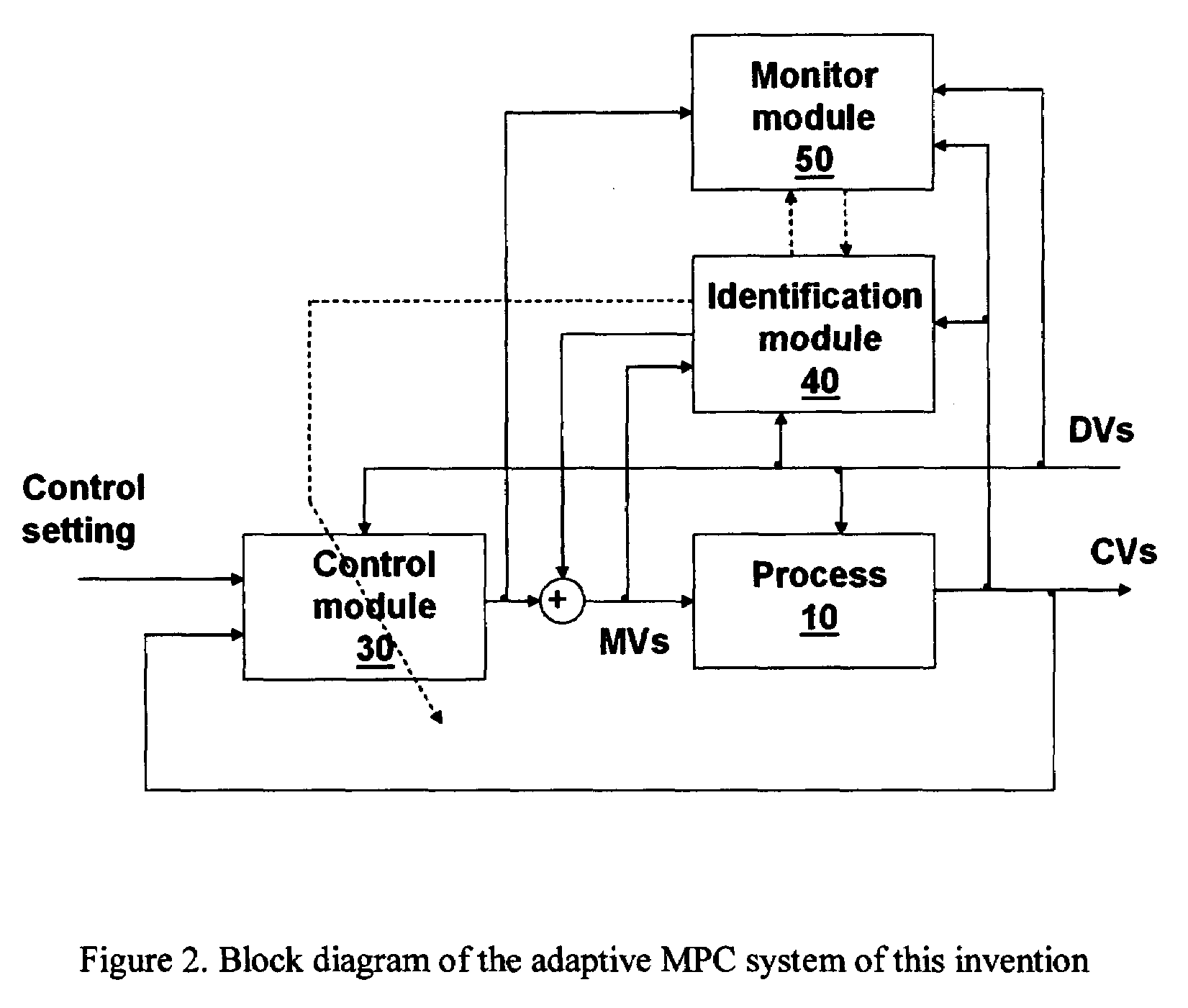

A method and system is provided for identifying in-range sensor faults in a gas turbine engine, by observing the tracked component qualities in an embedded model and recognizing anomalous patterns of quality changes corresponding to sensor errors. An embedded model of the engine is employed to estimate sensed parameters such as rotor speeds, temperatures and pressures, as well as other parameters that are computed based on input parameters. Each major rotating component of the engine, including the fan, compressor, combustor, turbines, ducts and nozzle is individually modeled. Sensor failures are detected by identifying anomalous patterns in component quality parameters. A library of anomalous patterns is provided for comparing quality parameters generated by a tracking filter with the library of anomalous patterns. If a pattern is matched, a sensor may be eliminated from the tracking filter and the estimated model parameter used to avoid corrupting the model quality parameters.

Owner:GENERAL ELECTRIC CO

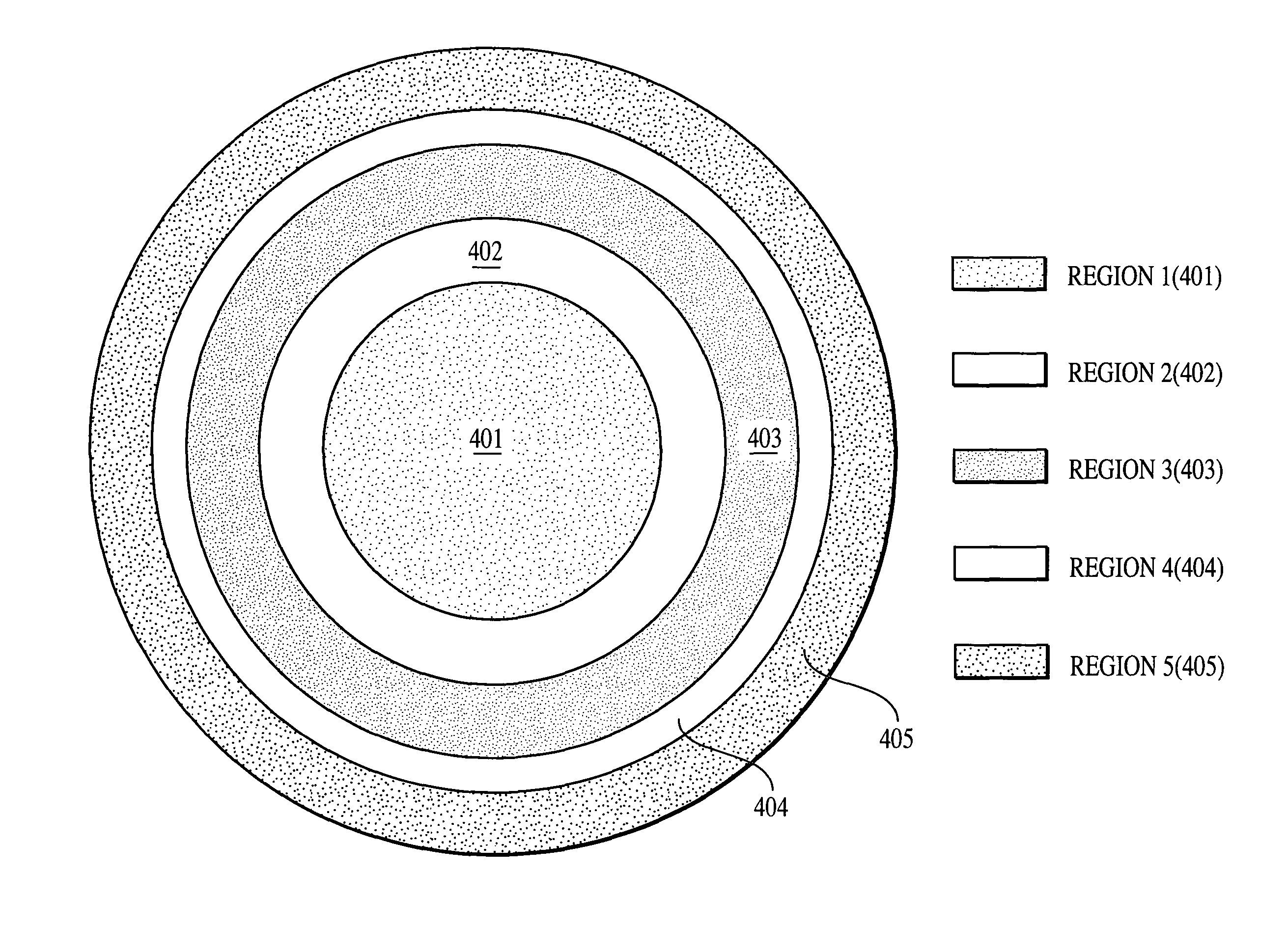

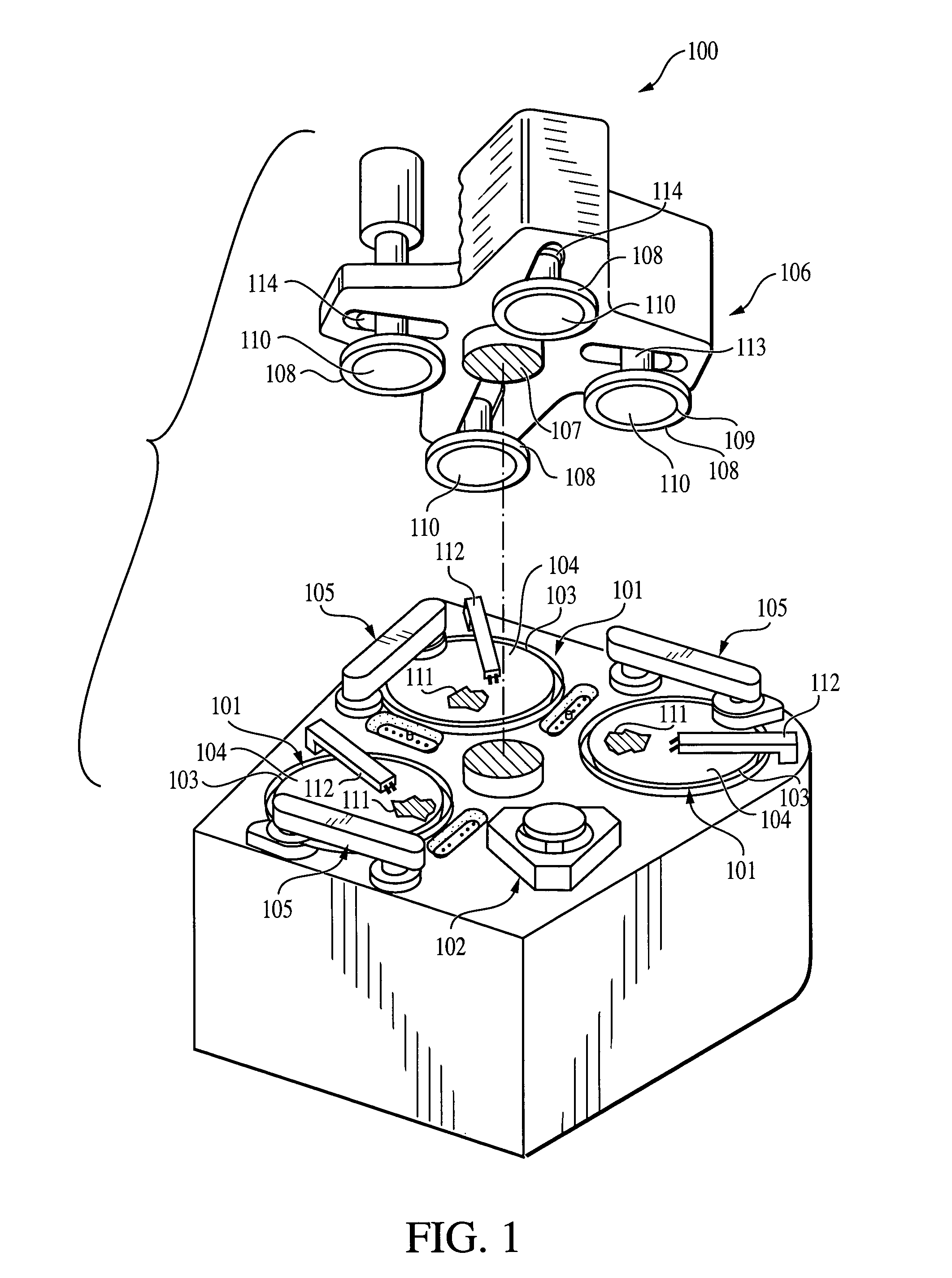

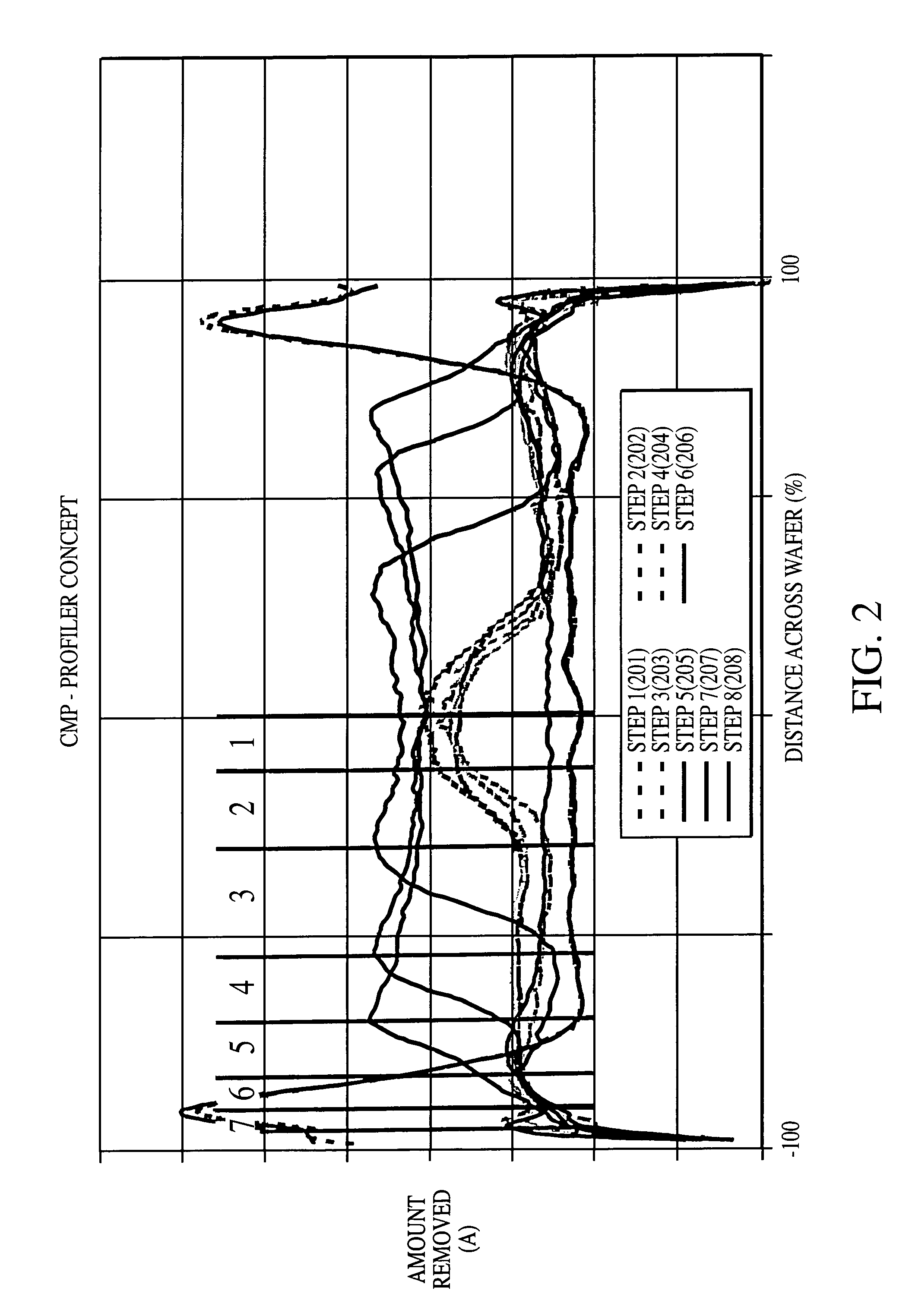

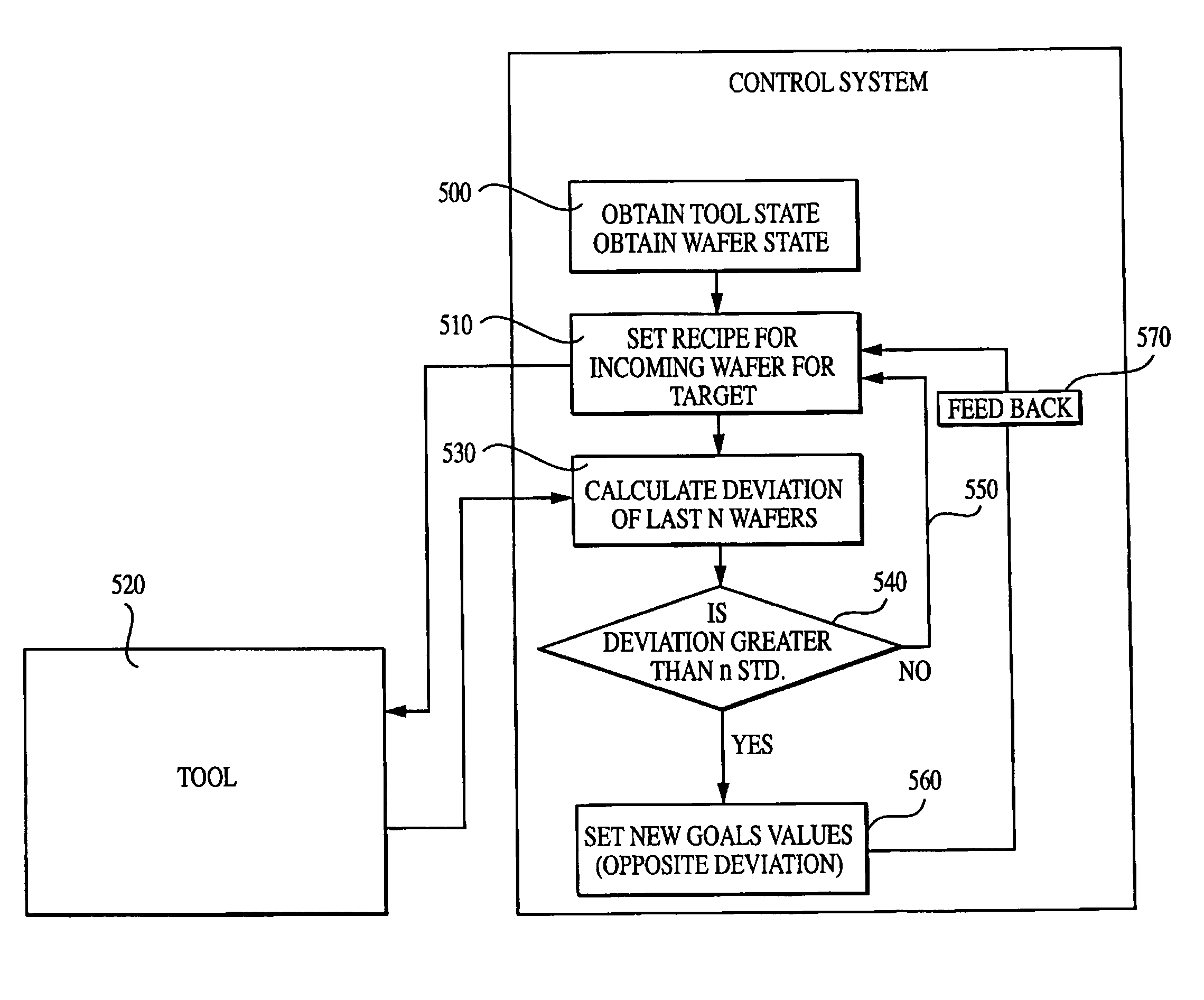

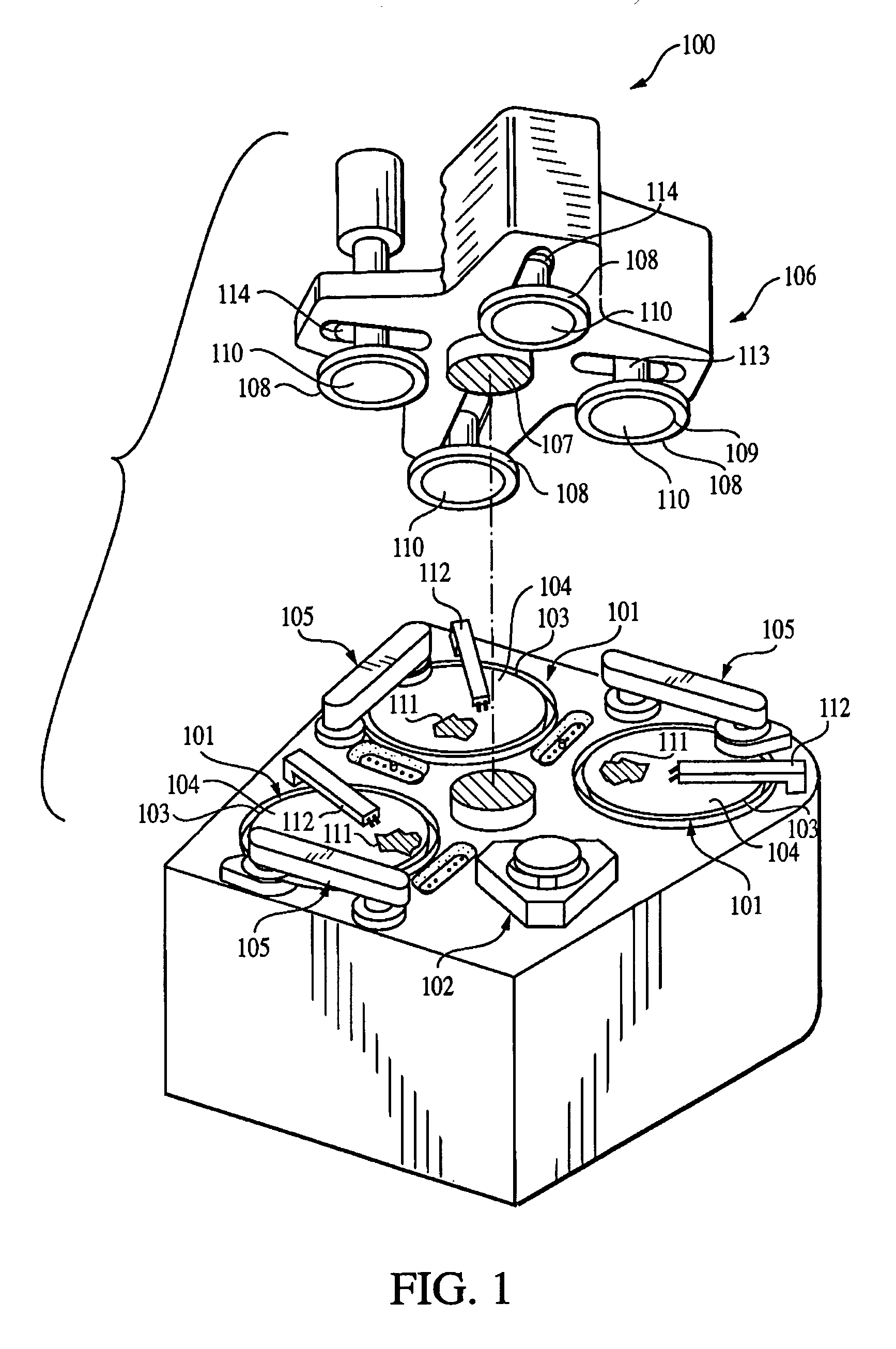

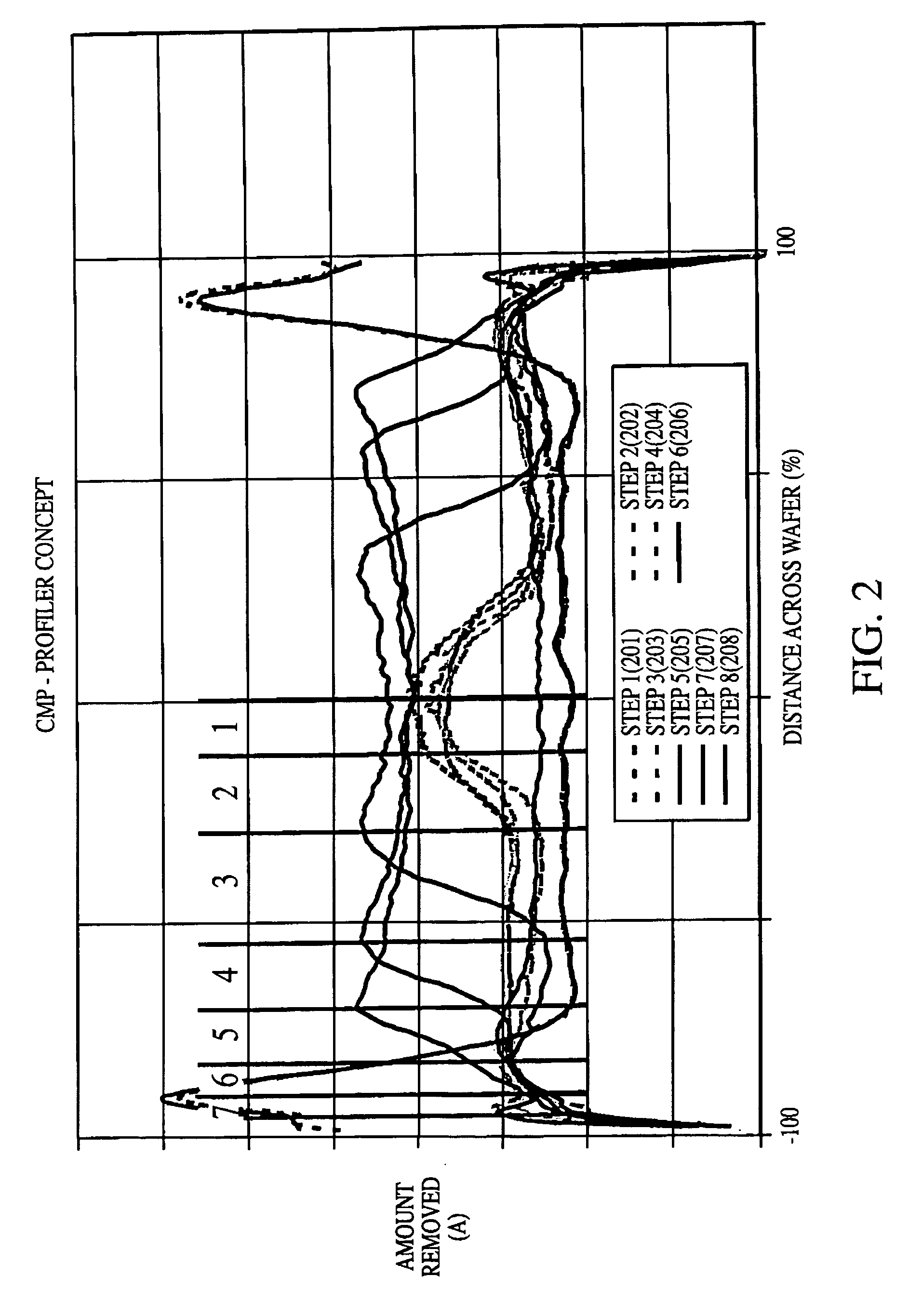

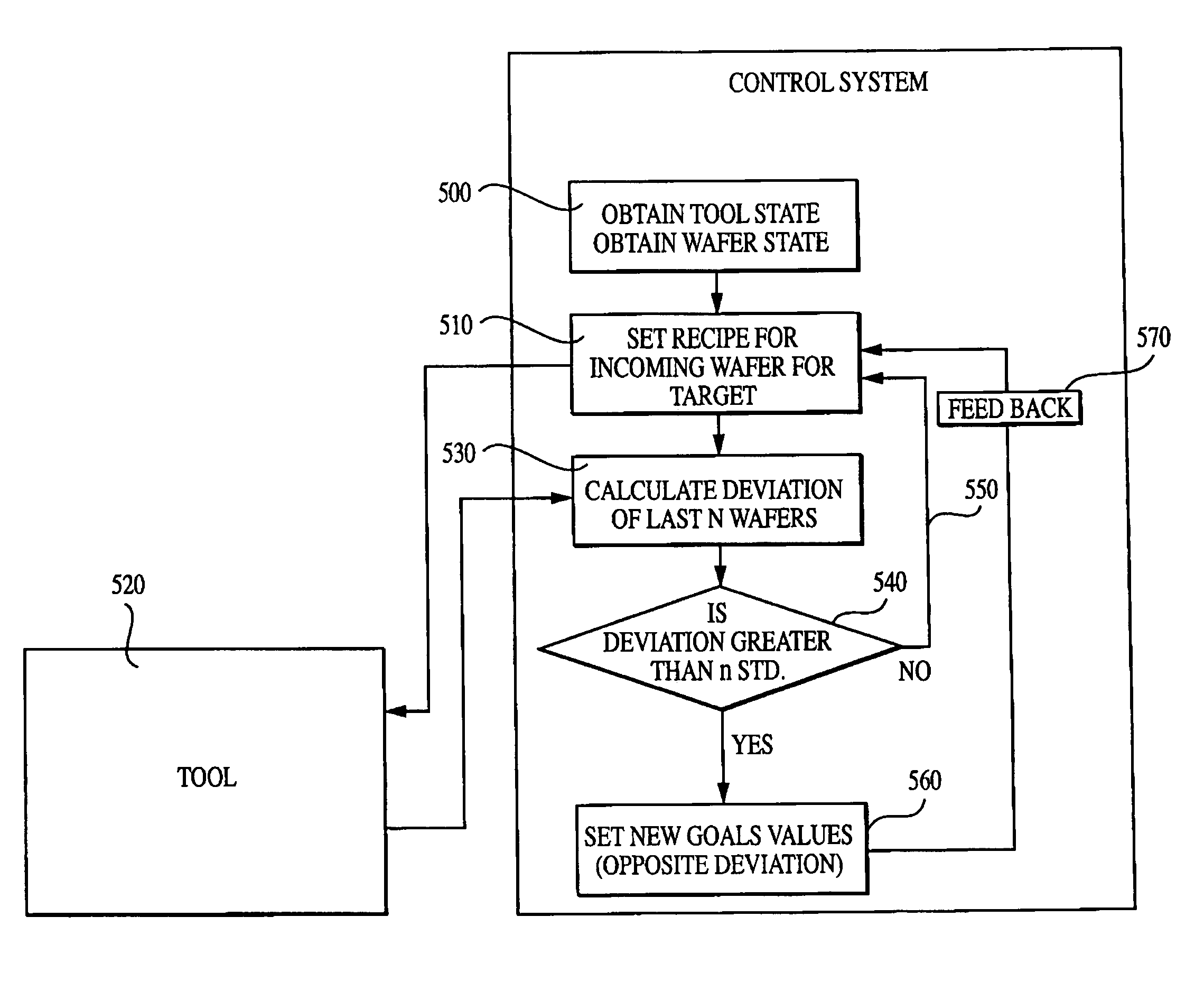

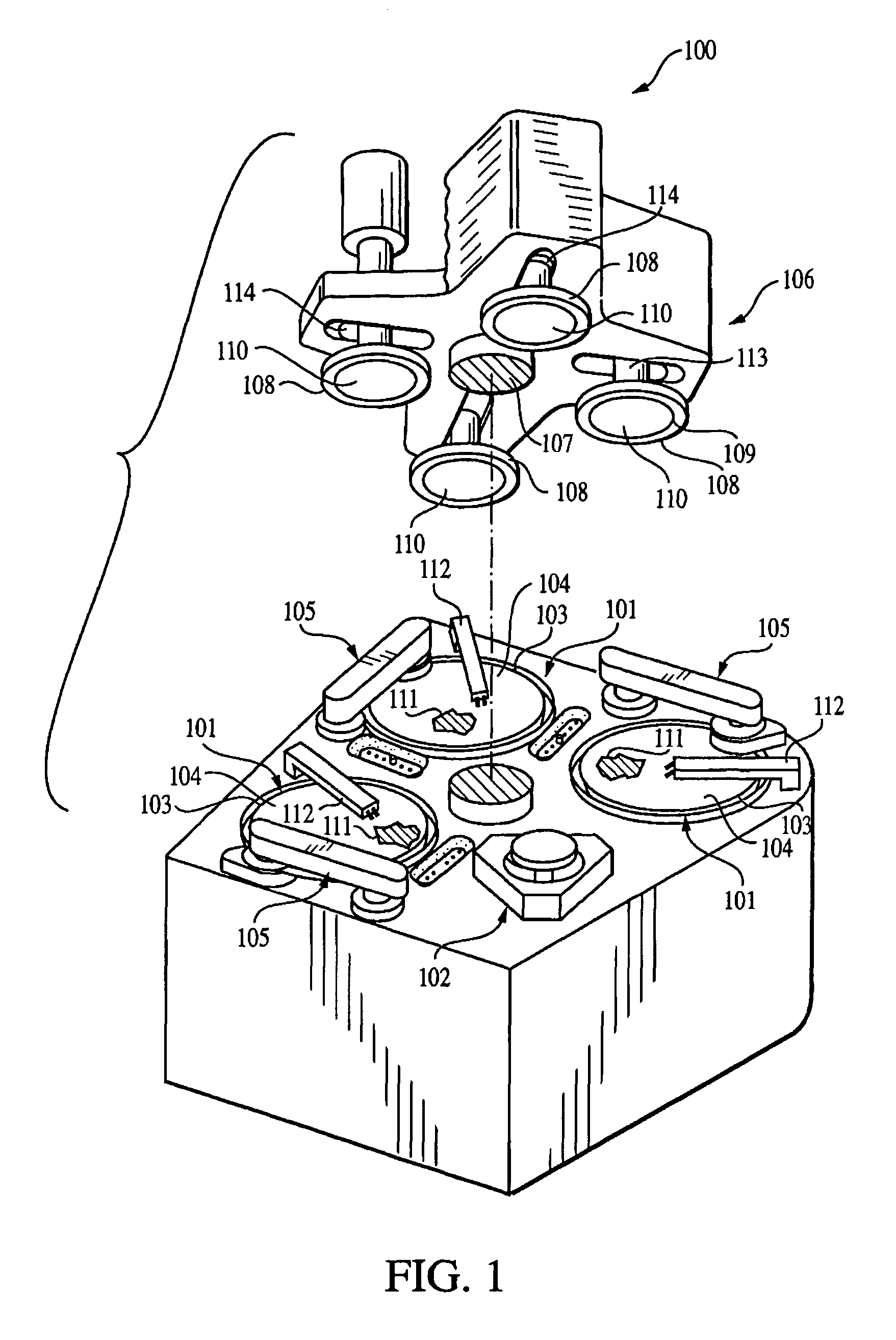

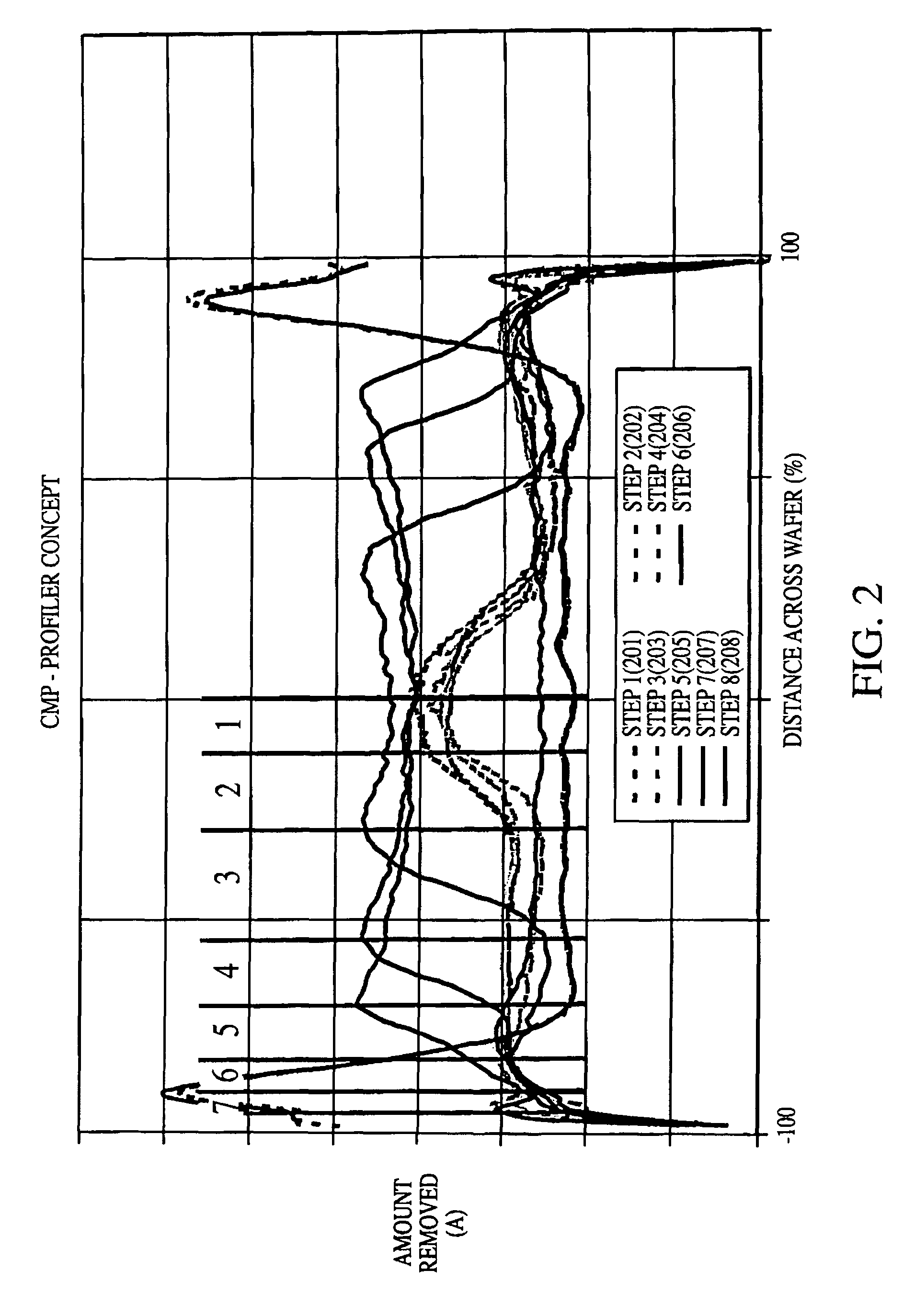

Feedback control of a chemical mechanical polishing device providing manipulation of removal rate profiles

InactiveUS7160739B2Optimal Operational ControlImprove resultsSemiconductor/solid-state device testing/measurementComputer controlMaterial removalModel quality

A method of controlling surface non-uniformity of a wafer in a polishing operation includes (a) providing a model for a wafer polishing that defines a plurality of regions on a wafer and identifies a wafer material removal rate in a polishing step of a polishing process for each of the regions, wherein the polishing process comprises a plurality of polishing steps, (b) polishing a wafer using a first polishing recipe based upon an incoming wafer thickness profile, (c) determining a wafer thickness profile for the post-polished wafer of step (b), and (d)calculating an updated polishing recipe based upon the wafer thickness profile of step (c) and the model of step (a) to maintain a target wafer thickness profile. The model can information about the tool state to improve the model quality. The method can be used to provide feedback to a plurality of platen stations.

Owner:APPLIED MATERIALS INC

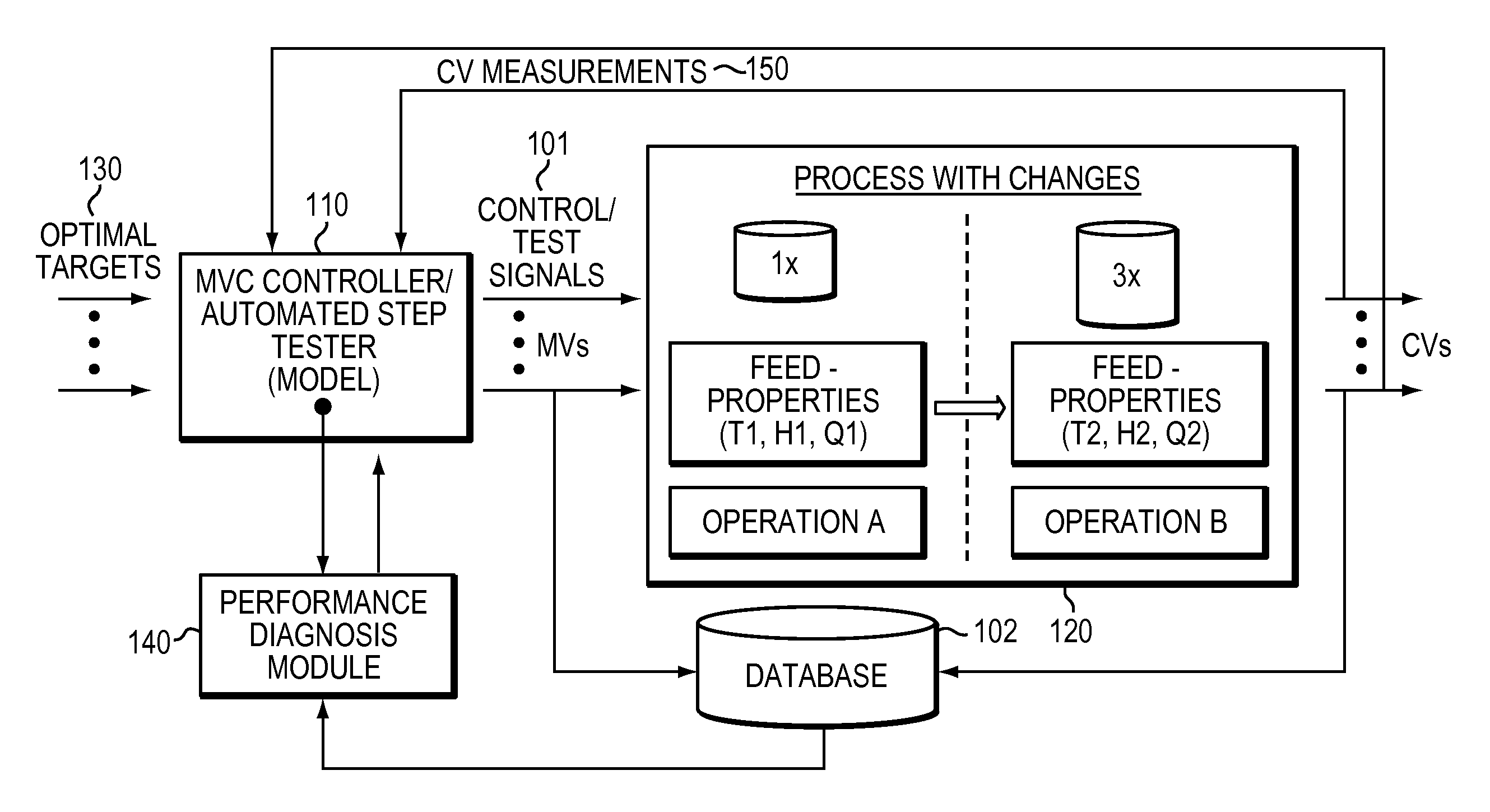

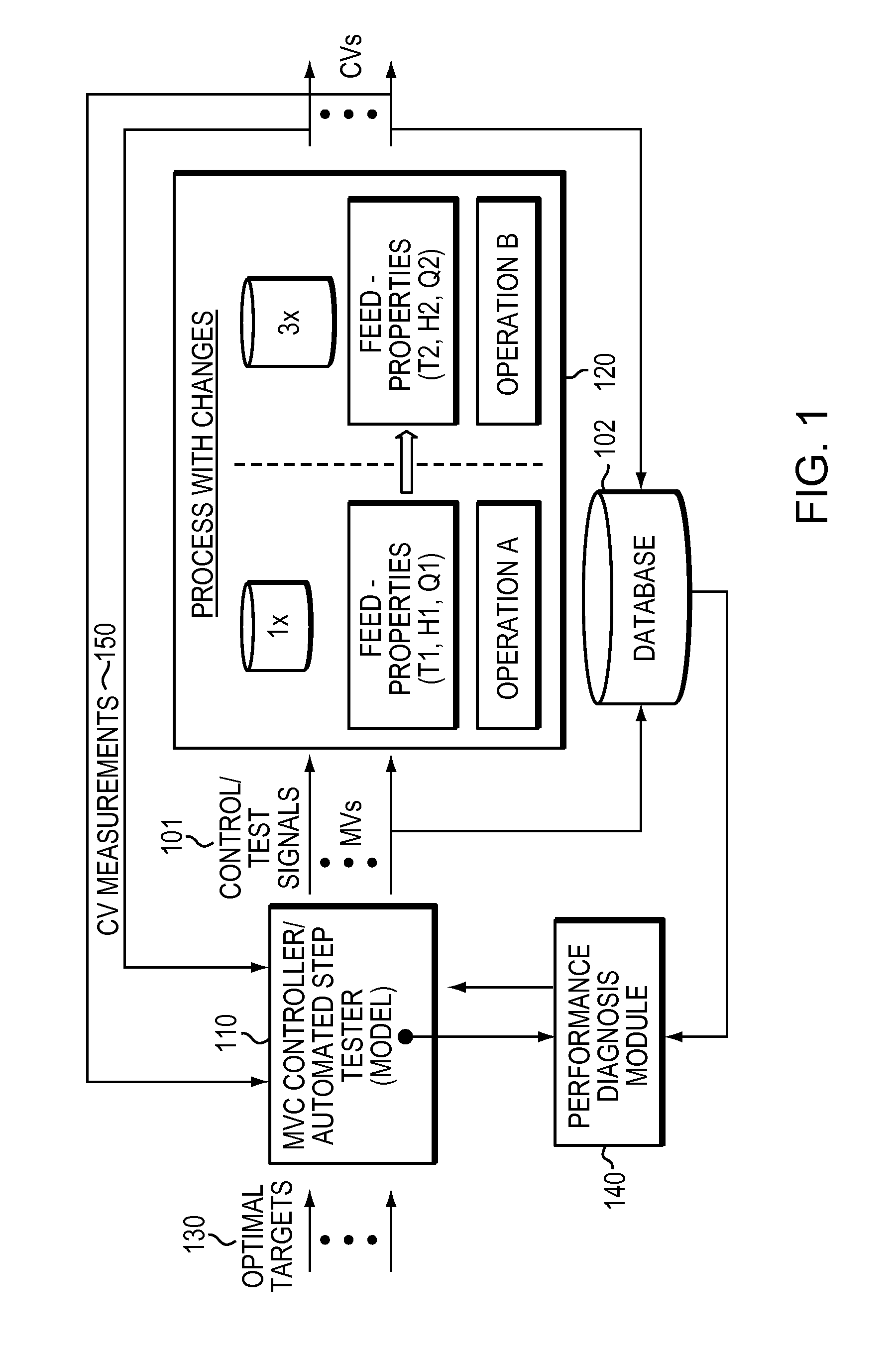

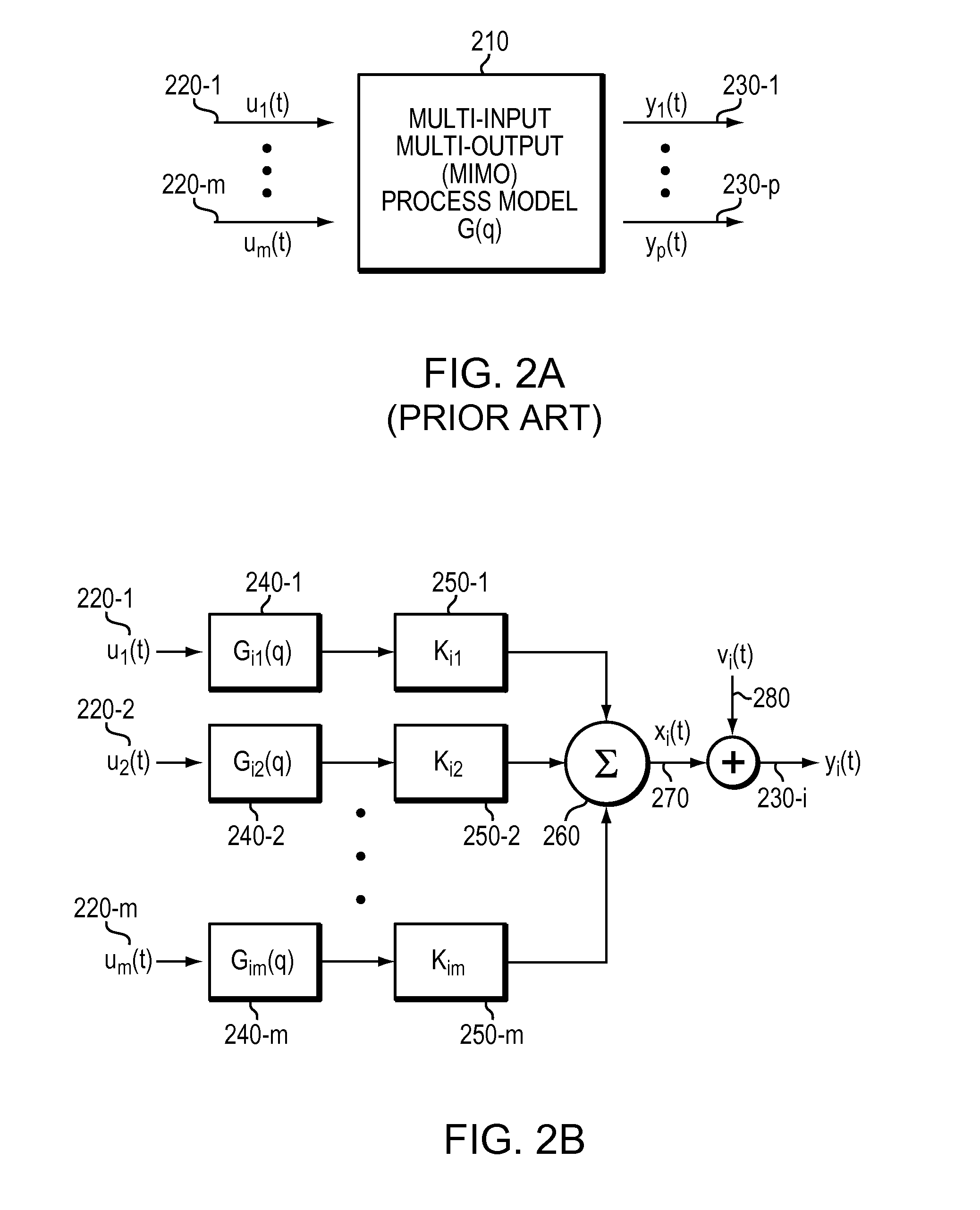

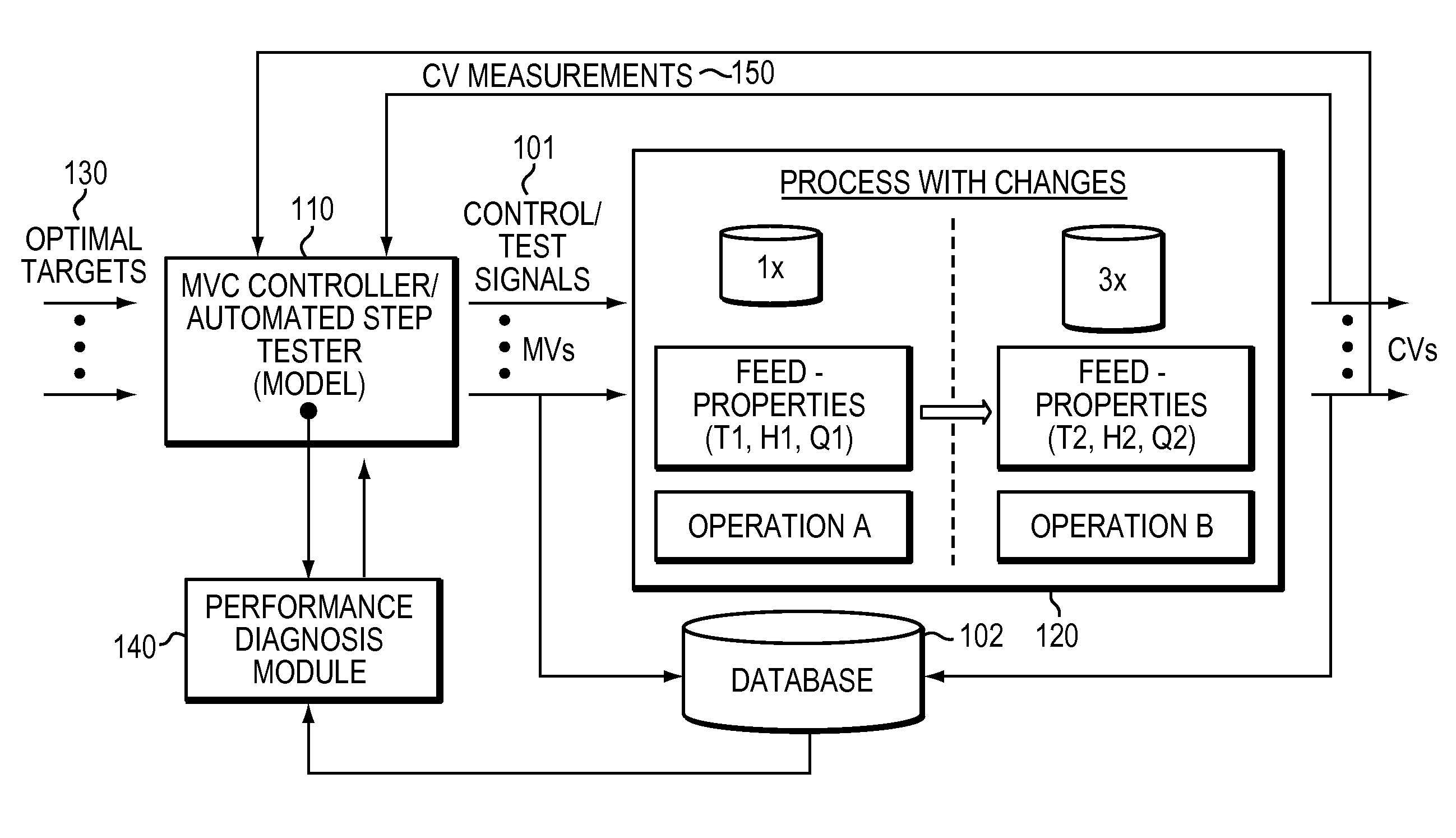

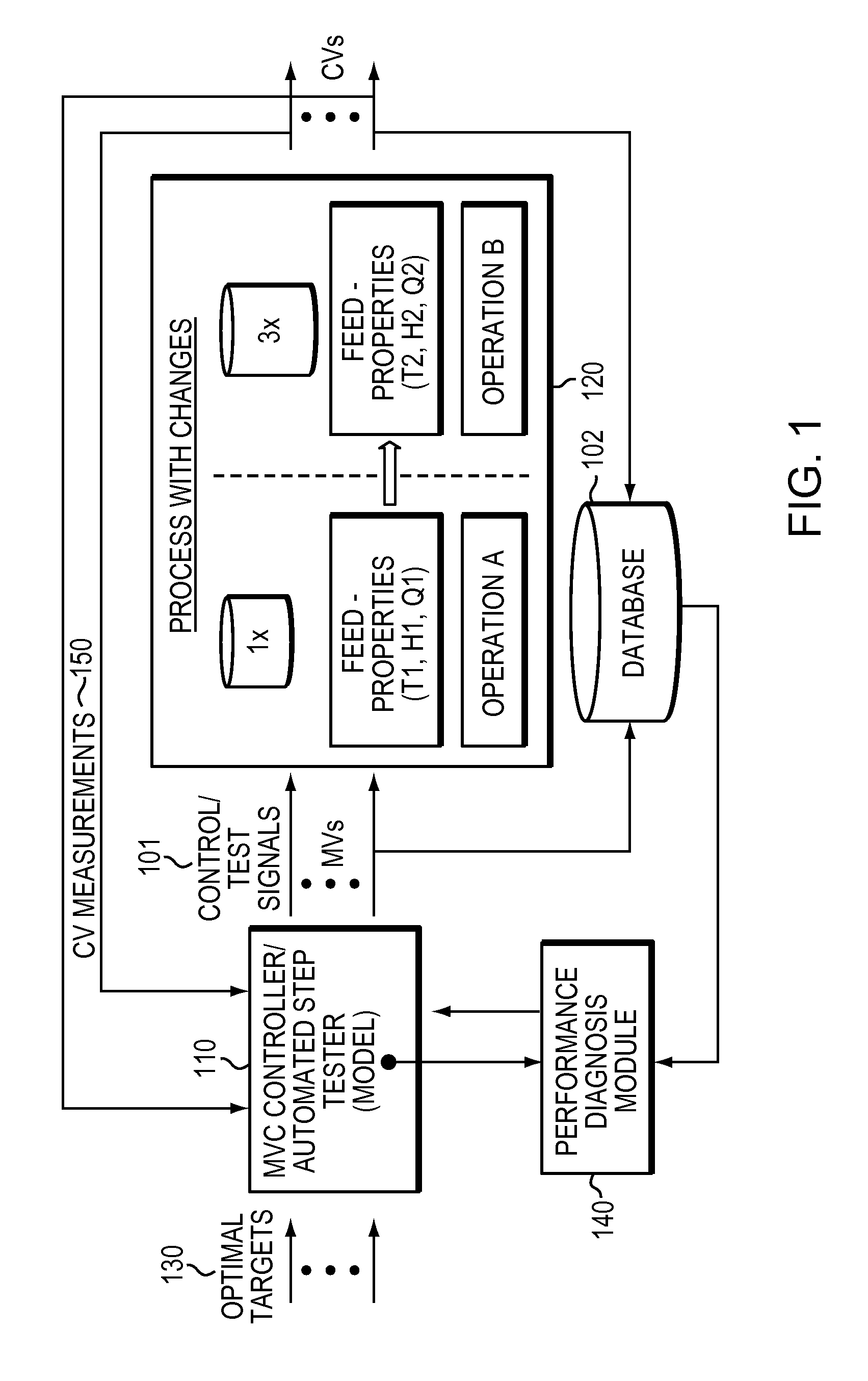

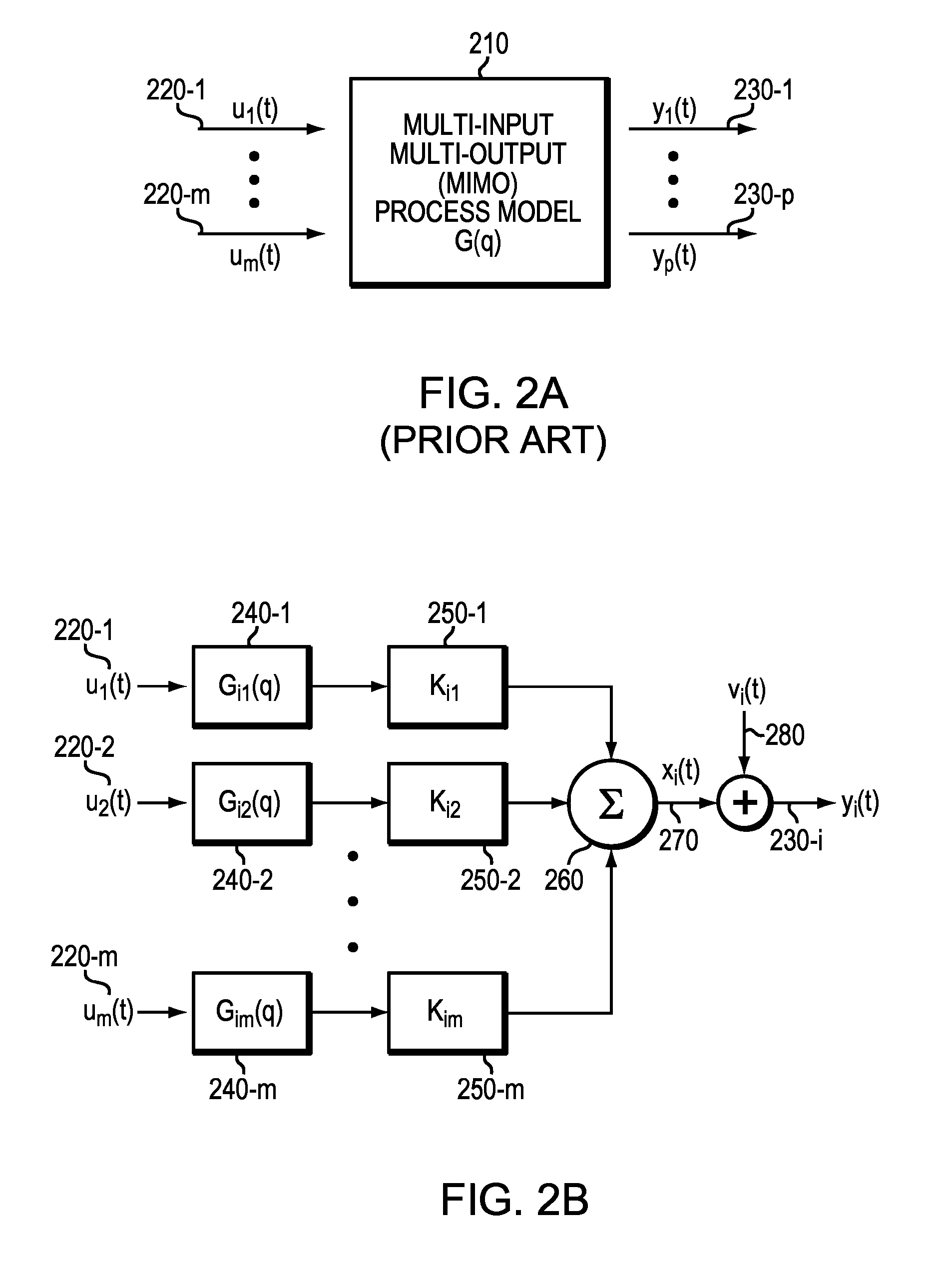

Apparatus and method for model quality estimation and model adaptation in multivariable process control

ActiveUS20110130850A1Minimize negative impactDigital differential analysersAdaptive controlModel qualityMultiple input

Apparatuses and methods for model quality estimation and model adaptation in multivariable process control are disclosed. A method for updating a multiple input multiple output (MIMO) dynamical model of a process includes perturbing the process, auditing the controller model, identifying poor performing submodels and re-testing the relevant process variables, re-identifying submodels and adapting the model online while the process continues to operate within normal operating parameters. An apparatus comprises an online multivariable controller, a tester, a database to store data corresponding to manipulated variables and controlled variables, and a performance diagnosis module configured to identify problematic submodels and adapt a model used by the controller.

Owner:ASPENTECH CORP

Apparatus and method for model quality estimation and model adaptation in multivariable process control

ActiveUS8560092B2Minimize negative impactDigital differential analysersSpecial data processing applicationsMulti inputDynamic models

Apparatuses and methods for model quality estimation and model adaptation in multivariable process control are disclosed. A method for updating a multiple input multiple output (MIMO) dynamical model of a process includes perturbing the process, auditing the controller model, identifying poor performing submodels and re-testing the relevant process variables, re-identifying submodels and adapting the model online while the process continues to operate within normal operating parameters. An apparatus comprises an online multivariable controller, a tester, a database to store data corresponding to manipulated variables and controlled variables, and a performance diagnosis module configured to identify problematic submodels and adapt a model used by the controller.

Owner:ASPENTECH CORP

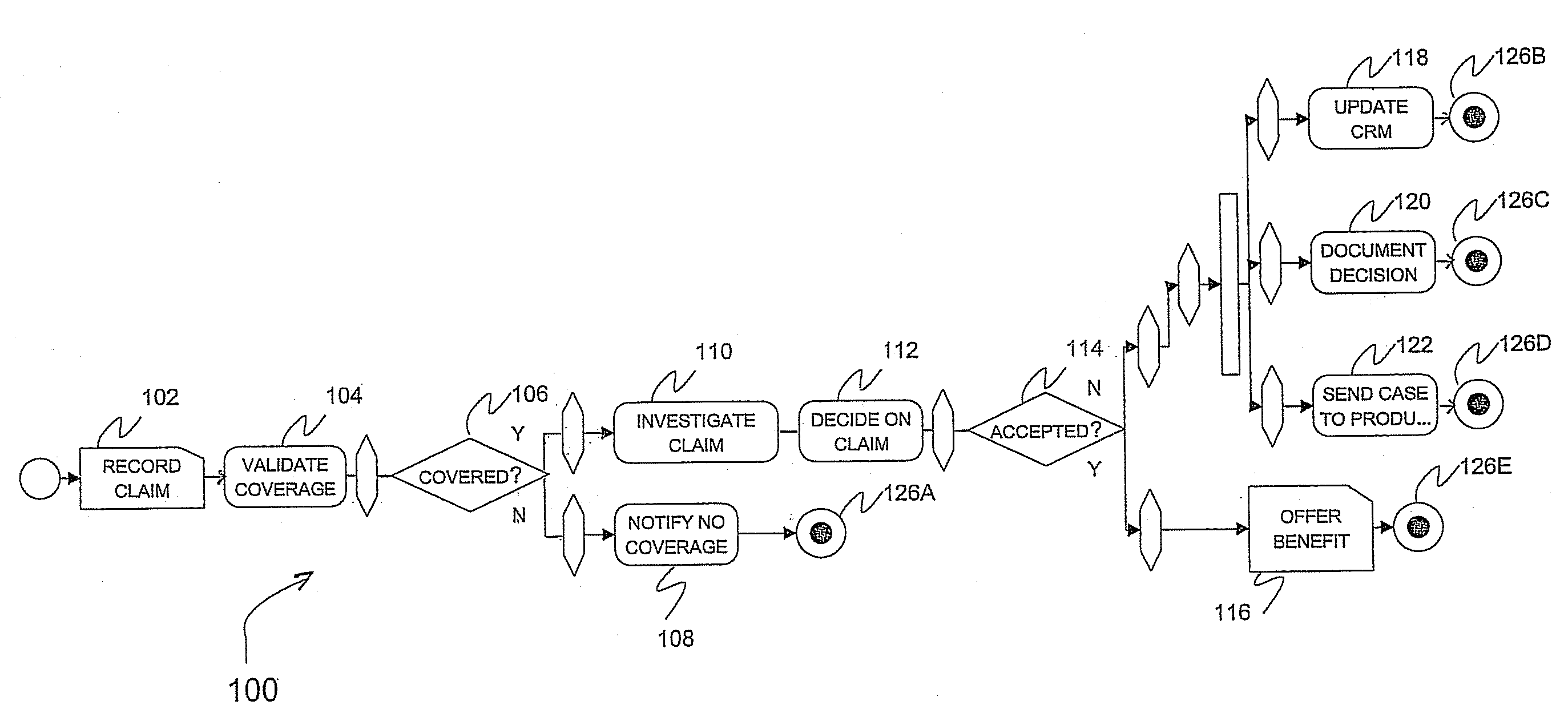

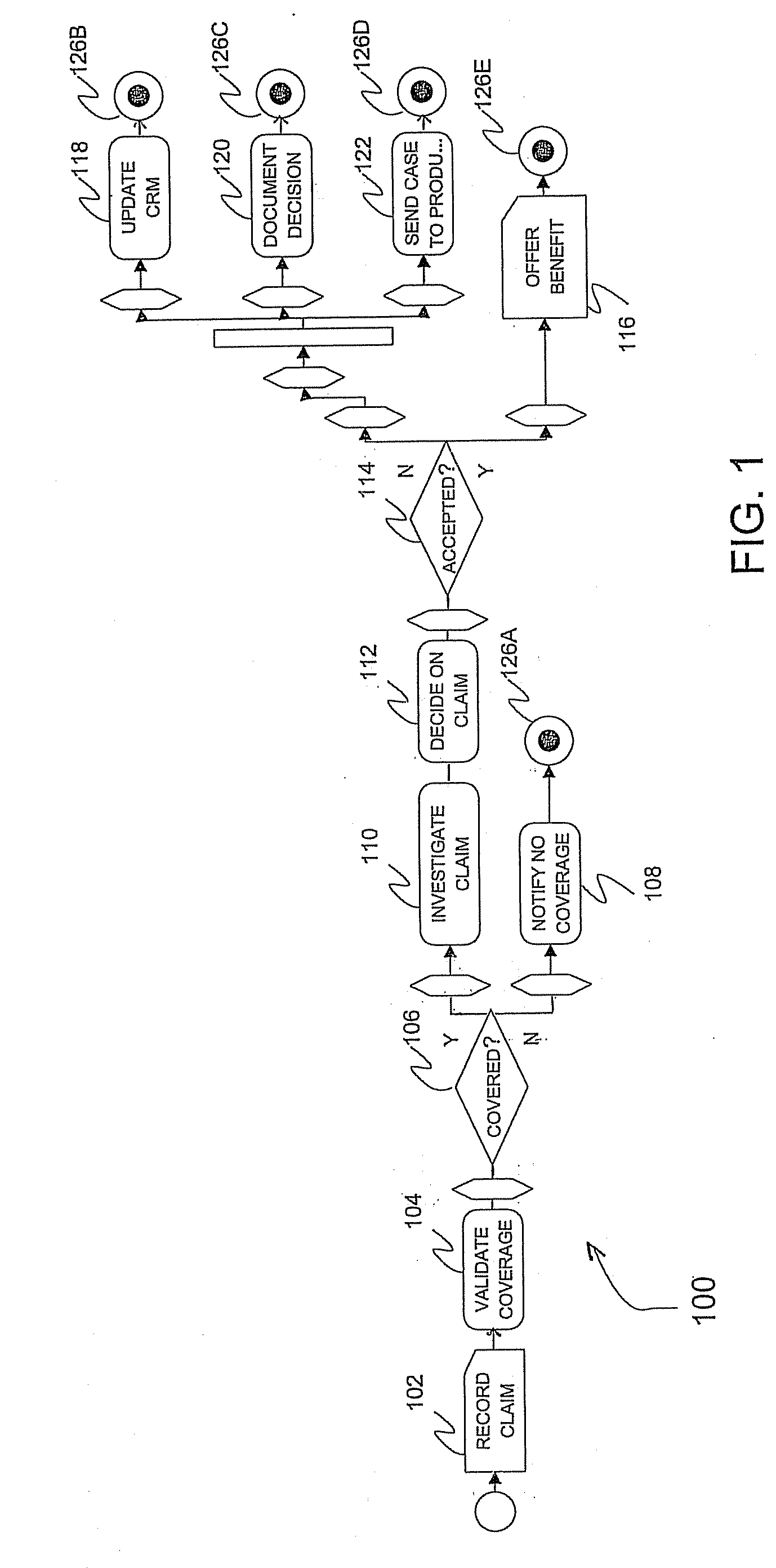

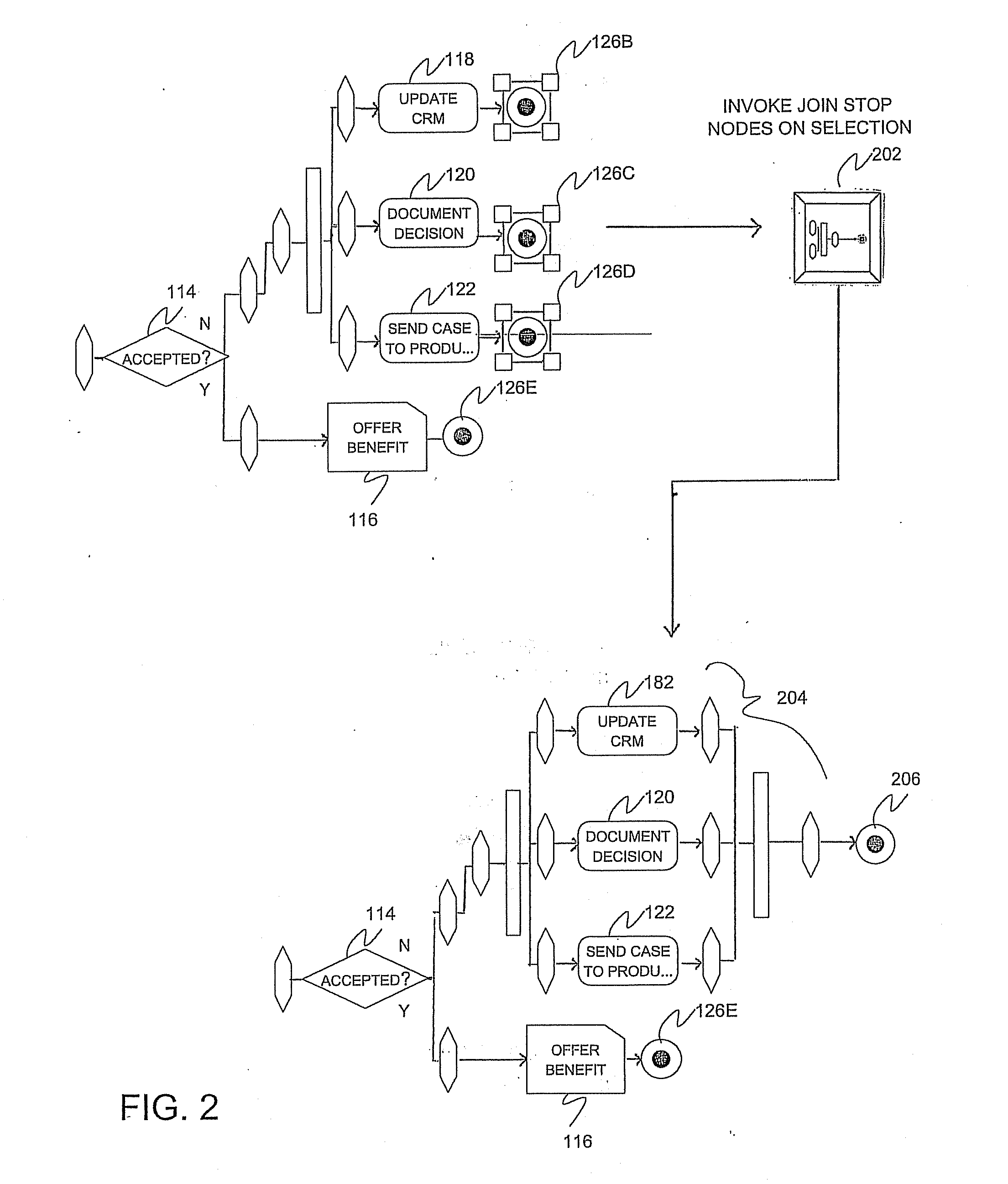

Method and system for combining quality assurance and model transformations in a business-driven development environment

InactiveUS20090150860A1ResourcesSpecific program execution arrangementsQuality assuranceDecomposition

A system for combining quality assurance and model transformations in a business-driven development environment includes a host system executing a business modeling application, a transformation framework including a transformation programming interface (TPI) and a quality assurance framework executing on top of the business modeling application, and a plurality of transformation plug-in tools in communication with the TPI. The TPI includes options for model access and traversal, model element creation / removal, model element property editing and analysis. The options are applied to the transformations, via the selected transformation plug-in tools, to a business model resulting in a modified business model that conforms to an information technology (IT)-based executable code. The quality assurance framework performs single-entry-single-exit (SESE) fragment decomposition of the modified business model, control-flow analysis, and notification to the user of any detected error conditions, the notification presented to the user with the modified business model via the TPI.

Owner:IBM CORP

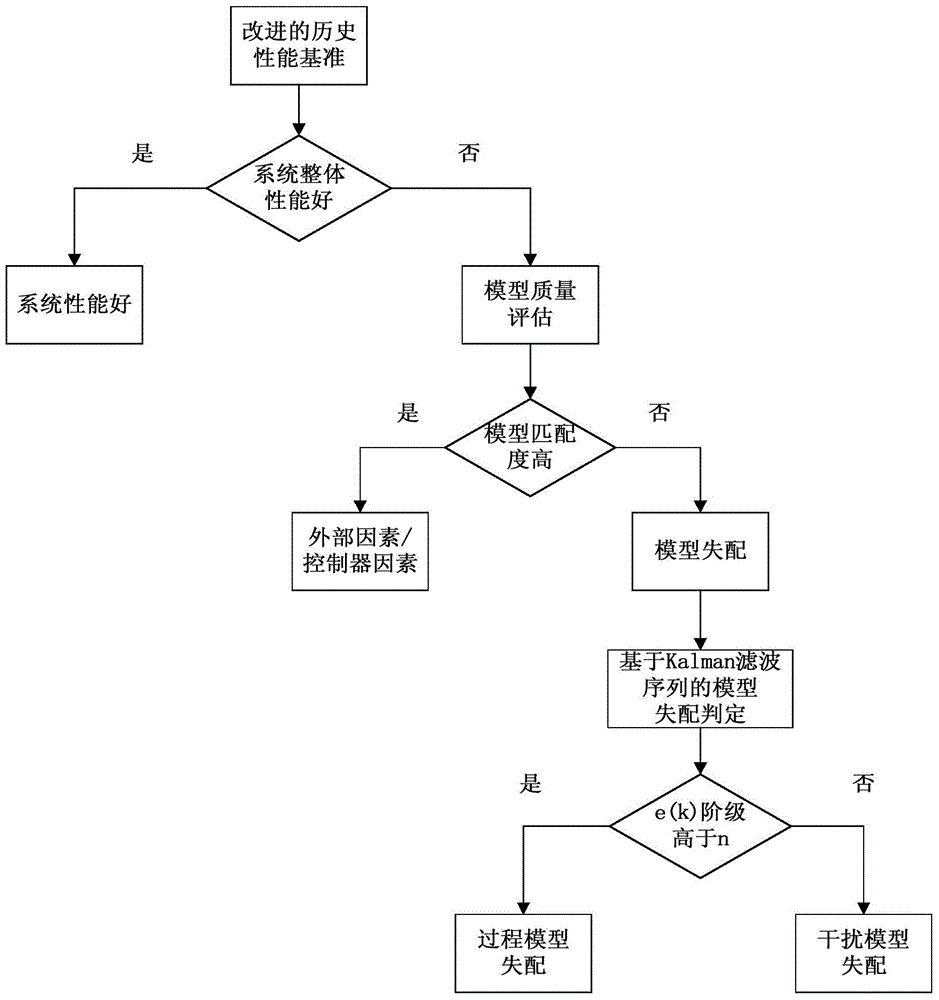

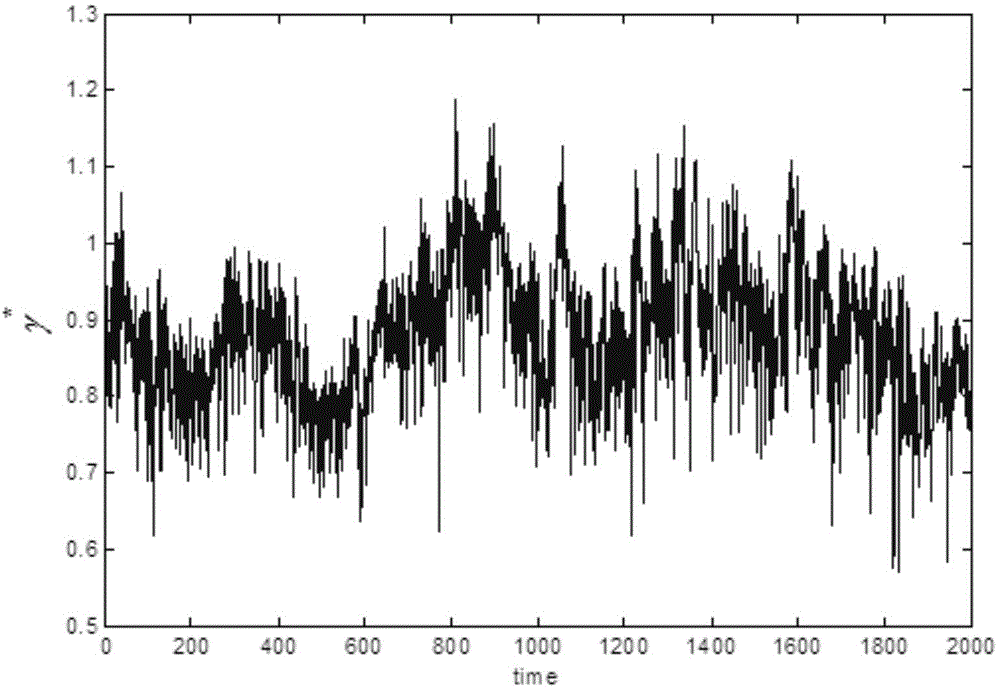

Model predictive control performance evaluation and diagnosis method

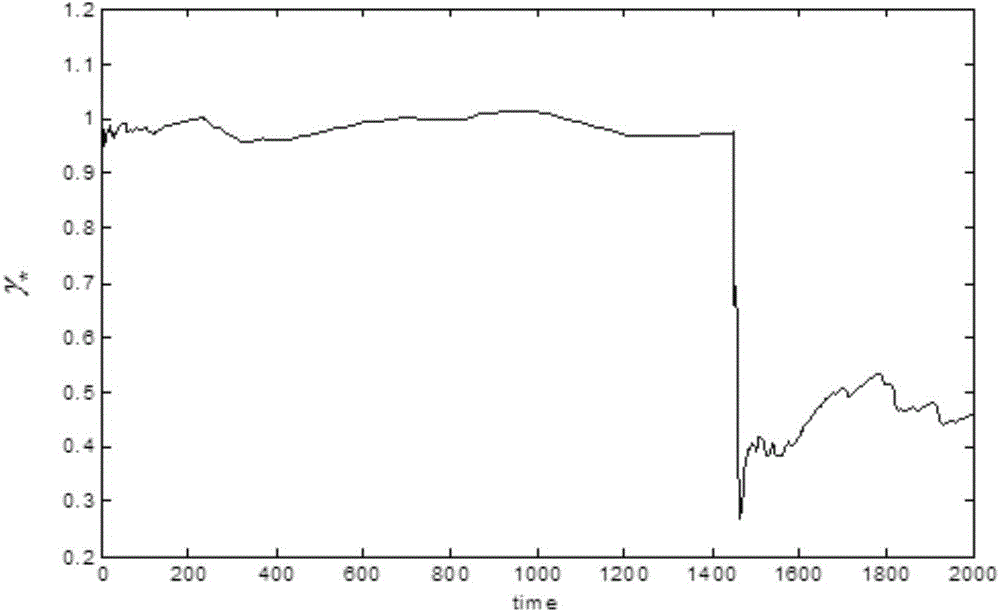

The invention discloses a model predictive control performance evaluation and diagnosis method. The method includes the steps: calculating the real-time performance value Ji and the average form Jnew of a system; selecting a segment of a data set and making the segment a historical performance benchmark value J<hist><*>; comparing the Jnew with the J<hist><*> and obtaining a system performance index [gamma]<k><*>, determining that the system performance is good if the [gamma]<k><*> is close to 1, and moving to the next step if the [gamma]<k><*> is close to 0; calculating an interference error e<0>(k), a predictive error e(k) and a model quality index [eta], and determining that the reason of deterioration of the system performance is external factors or a controller factor, otherwise, determining a system model mismatch and moving to the next step; detecting autocorrelation of an information sequence e(k), and moving to the next step if the autocorrelation of the e(k) exists, otherwise, determining that the model matching degree is good; and since n corresponding to the minimal loss function is the class of the e(k), determining a process model mismatch if the class of the e(k) is greater than the class of a process model, otherwise, determining an interference model mismatch. The overall performance of the system can be evaluated and deterioration sources of the system performance can be positioned only through closed loop input and output data.

Owner:NANJING UNIV OF TECH

Feedback control of chemical mechanical polishing device providing manipulation of removal rate profiles

InactiveUS20070102116A1Optimal Operational ControlImprove thickness uniformitySemiconductor/solid-state device testing/measurementComputer controlMaterial removalModel quality

A method of controlling surface non-uniformity of a wafer in a polishing operation includes (a) providing a model for a wafer polishing that defines a plurality of regions on a wafer and identifies a wafer material removal rate in a polishing step of a polishing process for each of the regions, wherein the polishing process comprises a plurality of polishing steps, (b) polishing a wafer using a first polishing recipe based upon an incoming wafer thickness profile, (c) determining a wafer thickness profile for the post-polished wafer of step (b), and (d) calculating an updated polishing recipe based upon the wafer thickness profile of step (c) and the model of step (a) to maintain a target wafer thickness profile. The model can information about the tool state to improve the model quality. The method can be used to provide feedback to a plurality of platen stations.

Owner:APPLIED MATERIALS INC

Sensor diagnostics using embedded model quality parameters

A method and system is provided for identifying in-range sensor faults in a gas turbine engine, by observing the tracked component qualities in an embedded model and recognizing anomalous patterns of quality changes corresponding to sensor errors. An embedded model of the engine is employed to estimate sensed parameters such as rotor speeds, temperatures and pressures, as well as other parameters that are computed based on input parameters. Each major rotating component of the engine, including the fan, compressor, combustor, turbines, ducts and nozzle is individually modeled. Sensor failures are detected by identifying anomalous patterns in component quality parameters. A library of anomalous patterns is provided for comparing quality parameters generated by a tracking filter with the library of anomalous patterns. If a pattern is matched, a sensor may be eliminated from the tracking filter and the estimated model parameter used to avoid corrupting the model quality parameters.

Owner:GENERAL ELECTRIC CO

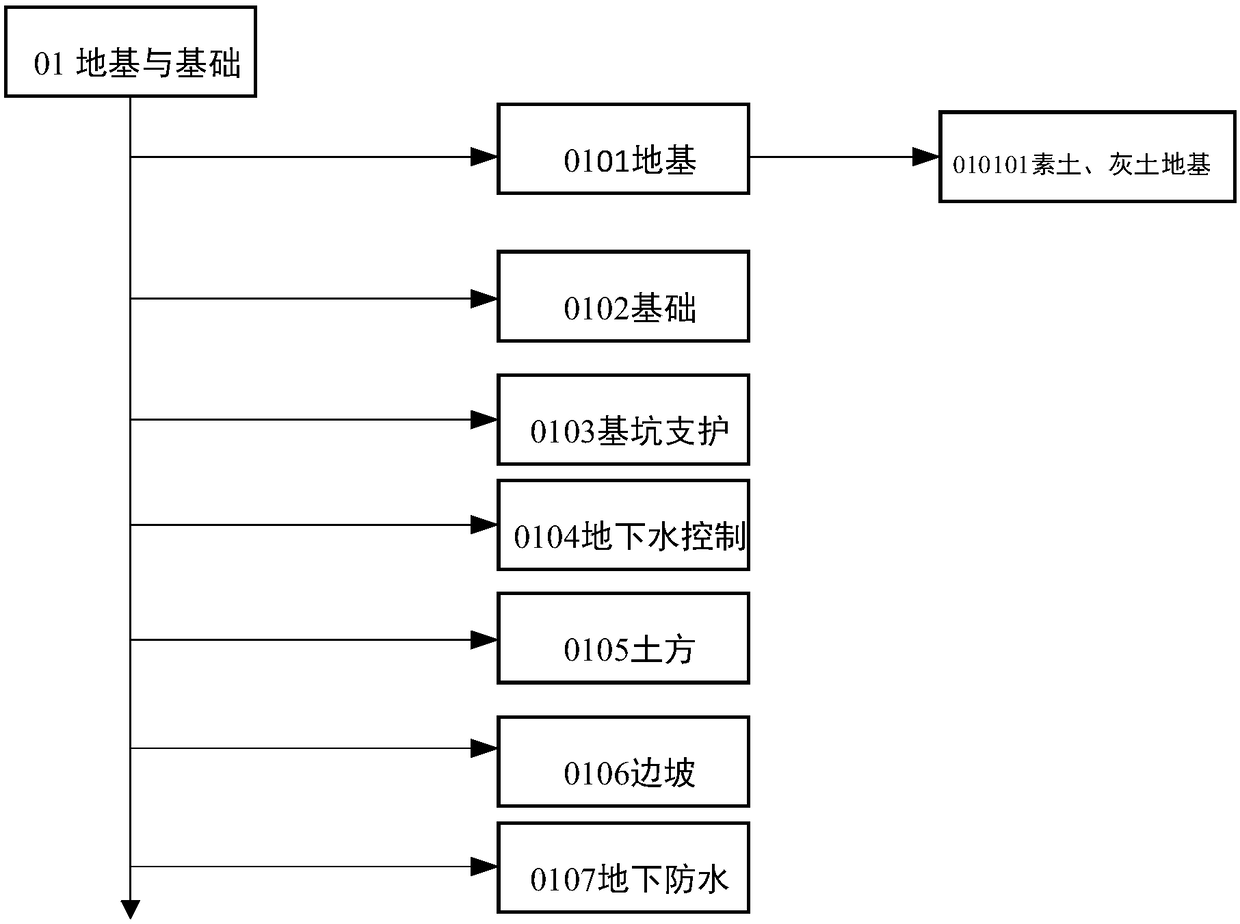

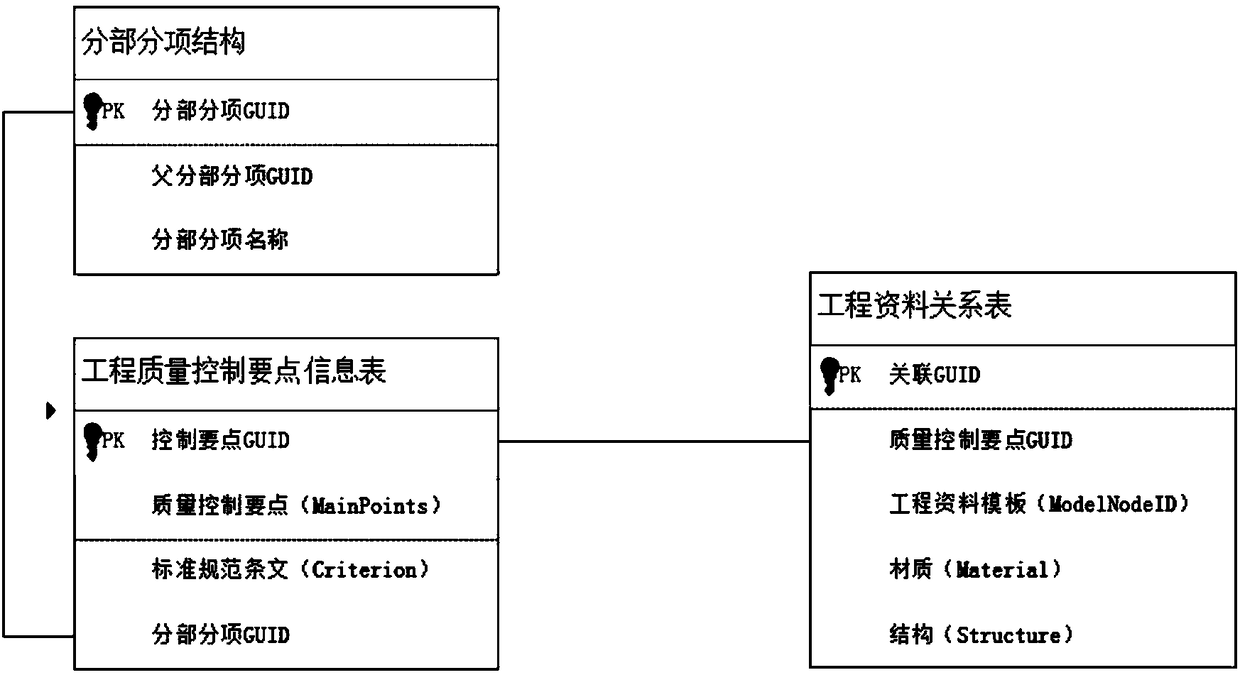

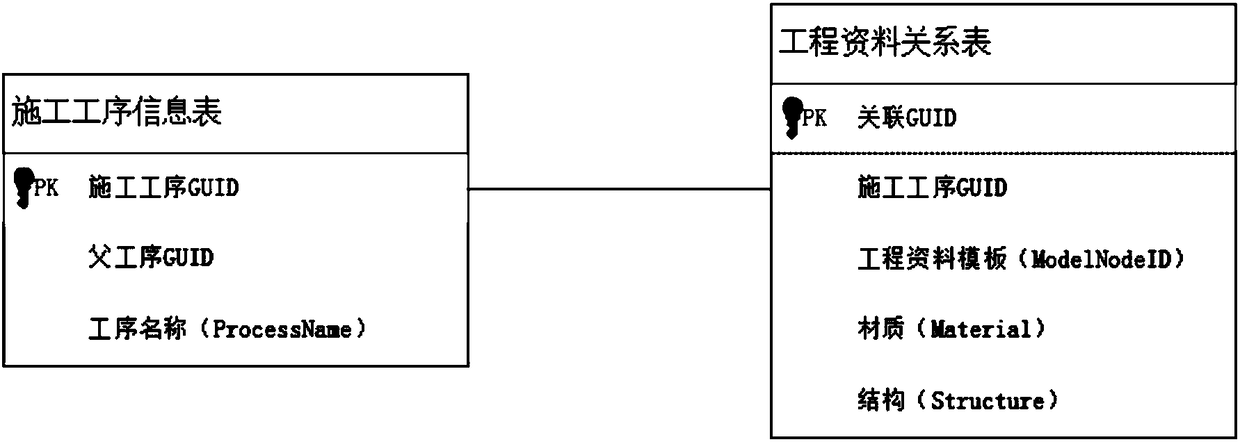

BIM-model-based quality management standardization method of building engineering

ActiveCN108376376ARealize automatic matchingImprove work efficiencyGeometric CADData processing applicationsQuality dataModel quality

The invention relates to a BIM-model-based quality management standardization method of building engineering. The method comprises: quality data standard attributes of BIM model components and / or a component group are established; a quality control key point database is established; an engineering data relationship table is associated with a construction process information table, BIM model quality data standard attributes are extended to an association database, and corresponding attribute values are extracted and written into corresponding attribute fields according to engineering data tables under all processes; when an BIM model is established, a data interface of a cloud server is invoked to obtain source data of the quality data standard attributes; the BIM model meeting the BIM model quality data standard matches an engineering quality control key point with engineering data automatically; and when engineering data are compiled, values in the corresponding database are invoked and the BIM model quality data standard attributes are inherited. According to the invention, on the basis of an implementation idea different from ones in the prior art, the technical blank of combination of the BIM and the engineering quality management is filled in by combining architectural standard specifications and the actual scene of the engineering site.

Owner:北京筑业志远软件开发有限公司

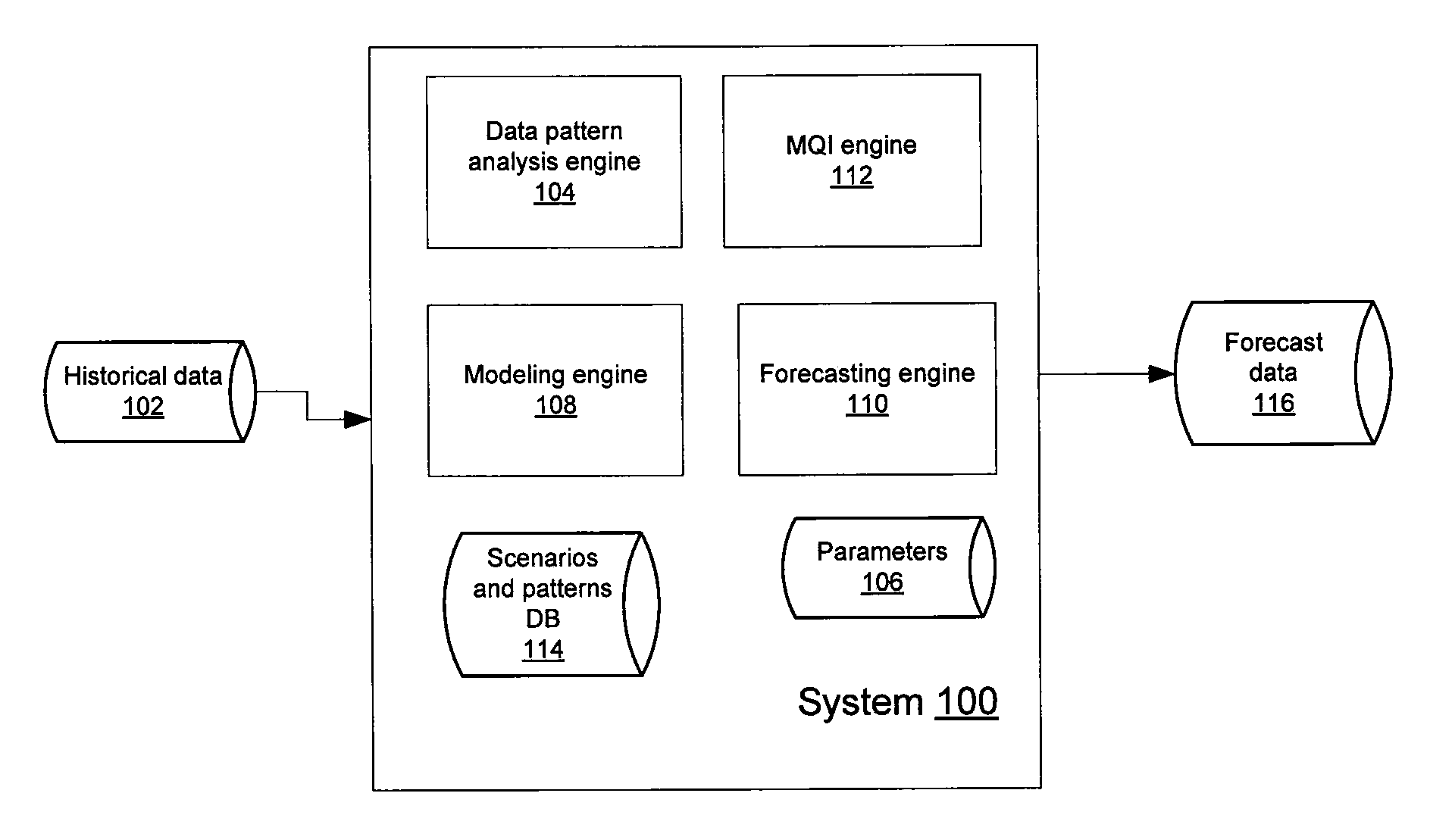

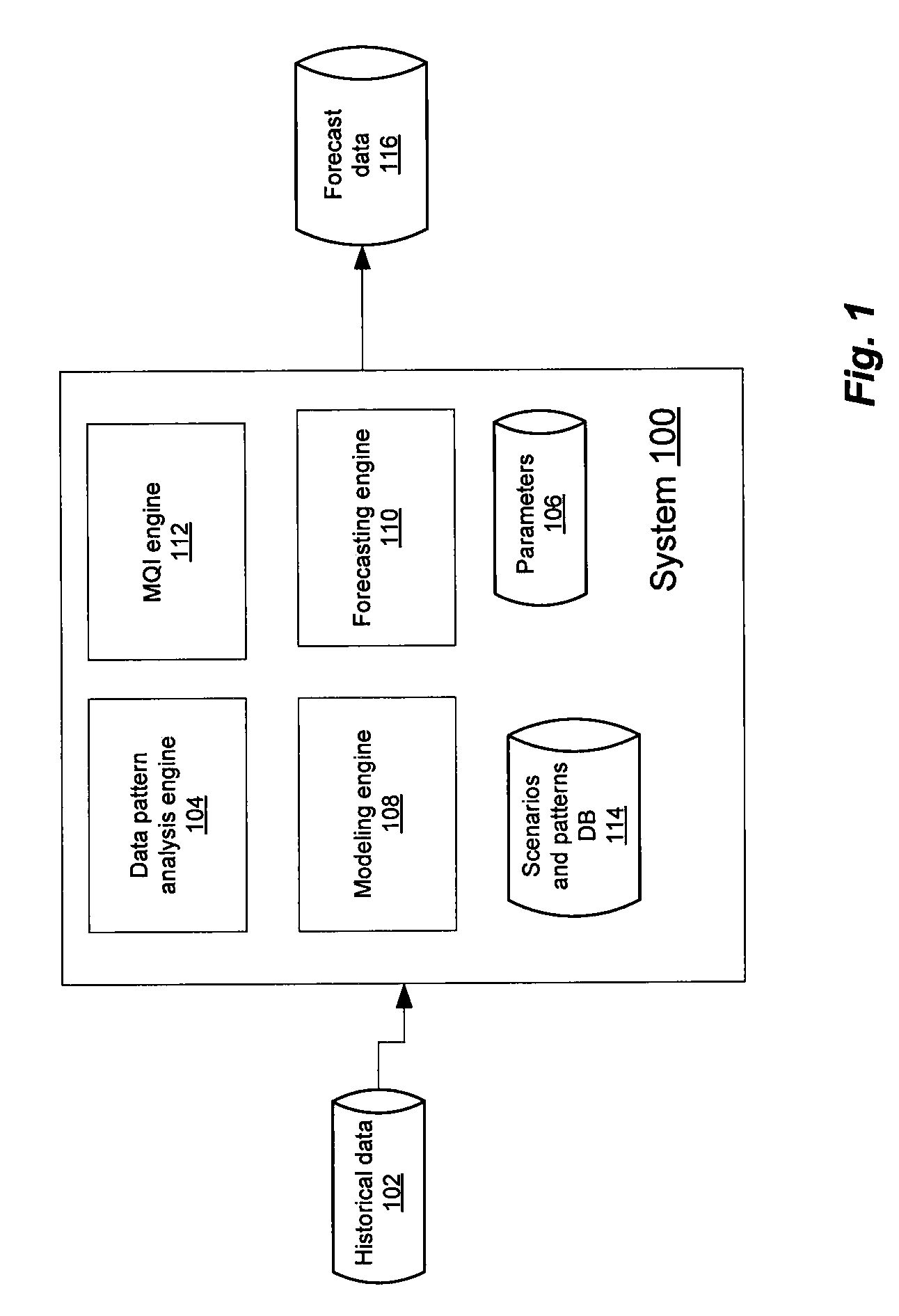

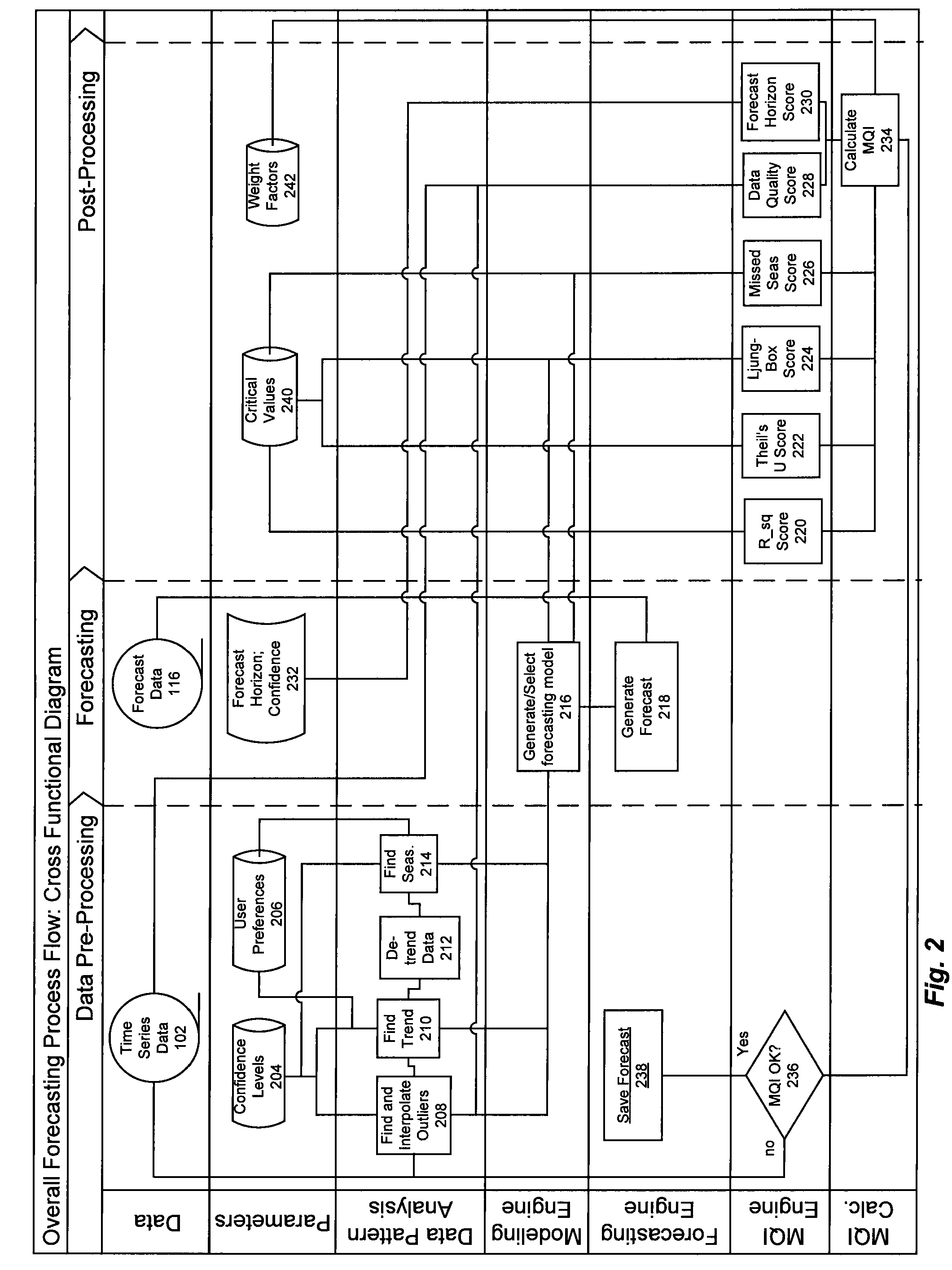

Forecast model quality index for computer storage capacity planning

ActiveUS7788127B1Rapid assessmentCommerceSpecial data processing applicationsModel qualityAssessment data

A robust, simple, application-specific way to evaluate data models and forecasts is provided for evaluating whether a forecast is trustworthy. An approach for formulating a single, summary indication of data / model / forecast quality relevant for the task at hand is described. This approach includes generating a forecast model from collected data, combining multiple model-quality parameters based on the model, computing an indication based on the combination of parameters, and evaluating the model and forecast quality based on the indication. This indication, in the form of a Model Quality Index, can also be used to compare different types of models produced by different types of analysis approaches.

Owner:LIGHTHOUSE CAPITAL PARTNERS V LP

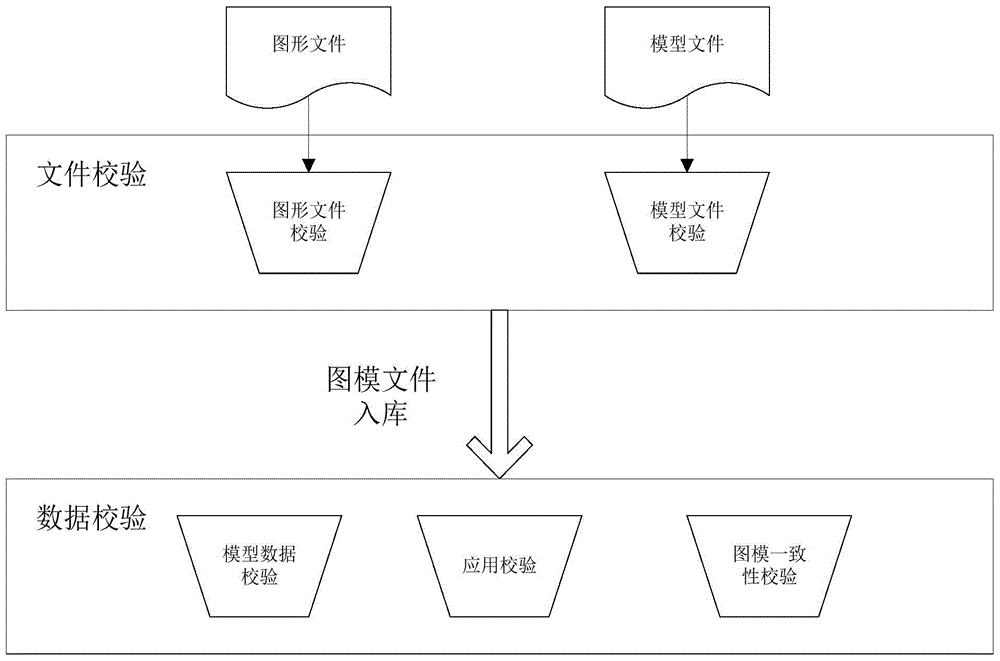

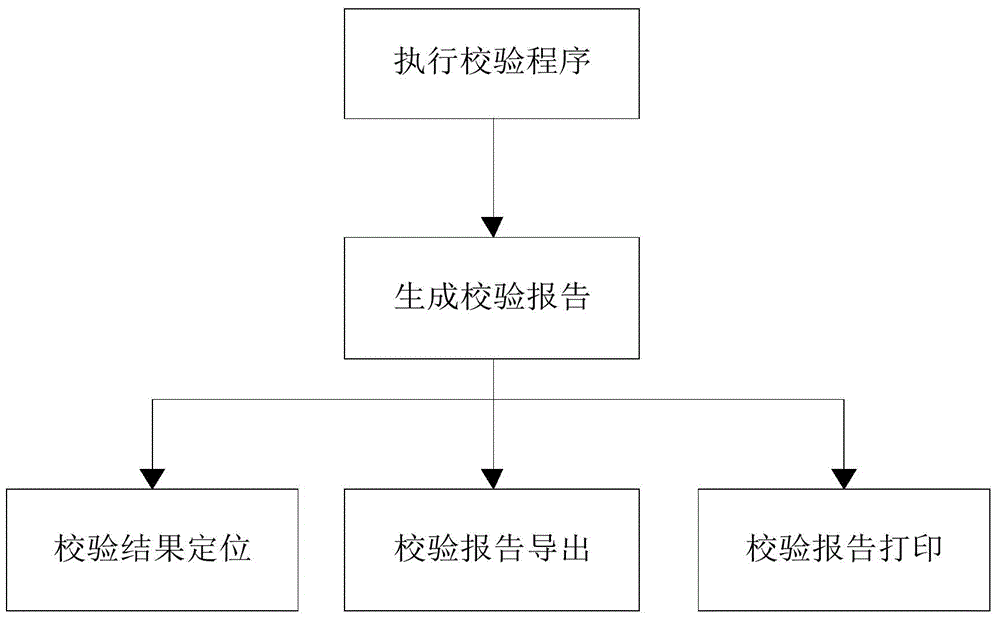

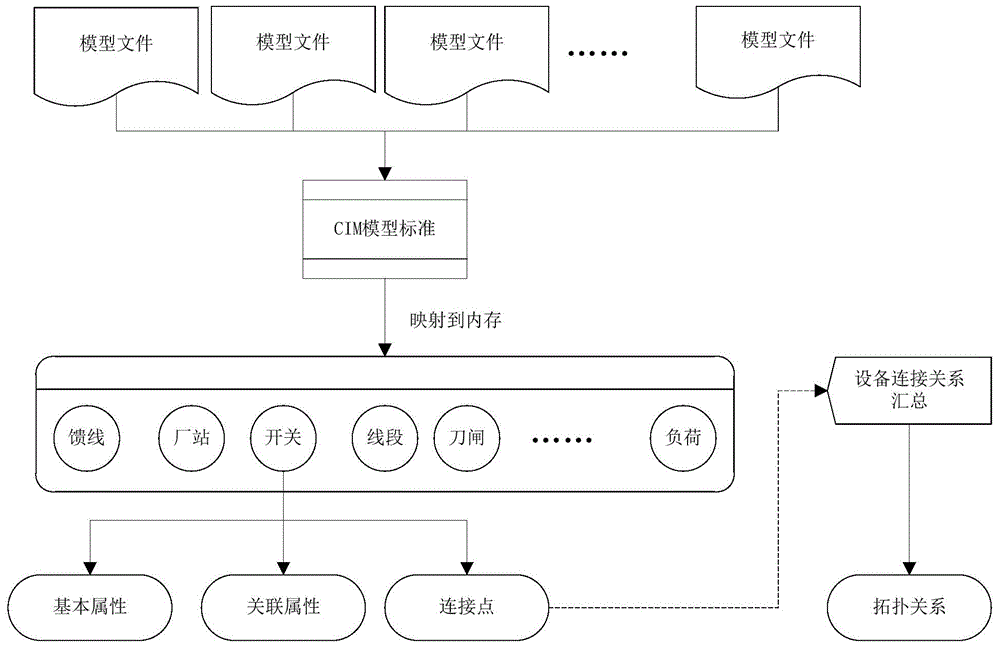

Multidimensional graphic and model quality analysis method facing power distribution network

InactiveCN104951997AImprove the efficiency of analysis and judgmentEasy to analyze and judgeData processing applicationsGraphicsSimulation

The invention discloses a multidimensional graphic and model quality analysis method facing a power distribution network. The multidimensional graphic and model quality analysis method includes steps of classifying graphic files and model files forming a power distribution network model; checking the graphic files and the model files respectively in the file checking step, and putting the graphic files and the model files into storage; checking model data, applications and graphic and model consistency respectively in the data checking step, and analyzing and checking the graphic and model quality of the power distribution network from multiple dimensions. The graphic and model quality of the power distribution network can be analyzed and checked from multiple dimensions, the graphic and model quality of the power distribution network can be conveniently and quickly analyzed by operators of the power grid, and analysis and judgment efficiency of the graphic and model quality of the power distribution network is improved.

Owner:TIANSHUI POWER SUPPLY COMPANY OF STATE GRID GANSUELECTRIC POWER +1

Tooth preparation body digital model design method

InactiveCN103886145AFlexible and convenient operation processEasy to operateSpecial data processing applicationsPersonalizationComputer-aided

The invention provides a tooth preparation body digital model design method, and belongs to the field of computer aided design digital dental treatment. The method includes the steps of data model building and preprocessing, tooth feature extraction, preparation body model parametric design and modification and model quality evaluation. Man-machine interaction is easy and convenient to achieve by means of a guide type model generation method, the automation degree is high, a tooth preparation body model meeting the requirements of various medical indexes can be smoothly generated, and individuation, parametric modification and result quality evaluation of the tooth preparation body model can be achieved. By means of the design method, tooth preparation time and treatment cost of dentists are greatly reduced, repair comfort and efficiency are improved, and the method has great application value in the field of computer aided dental preparation.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

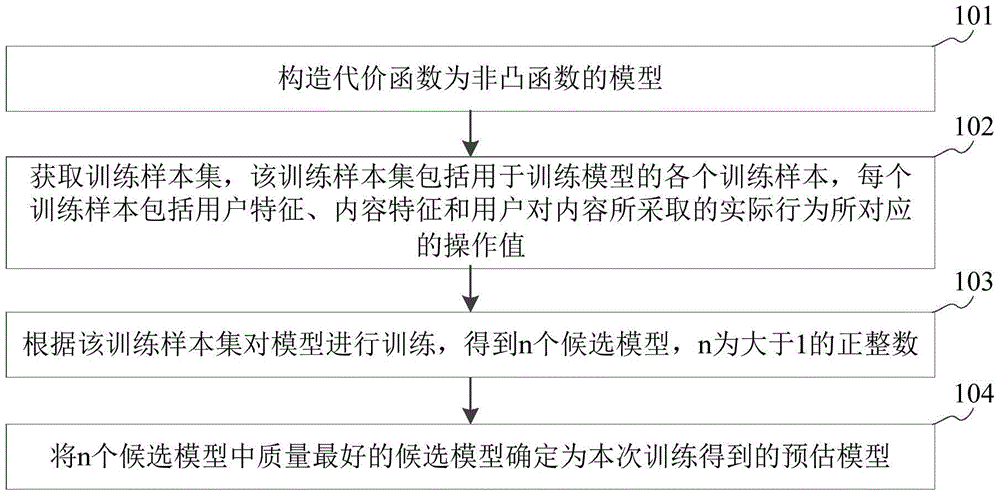

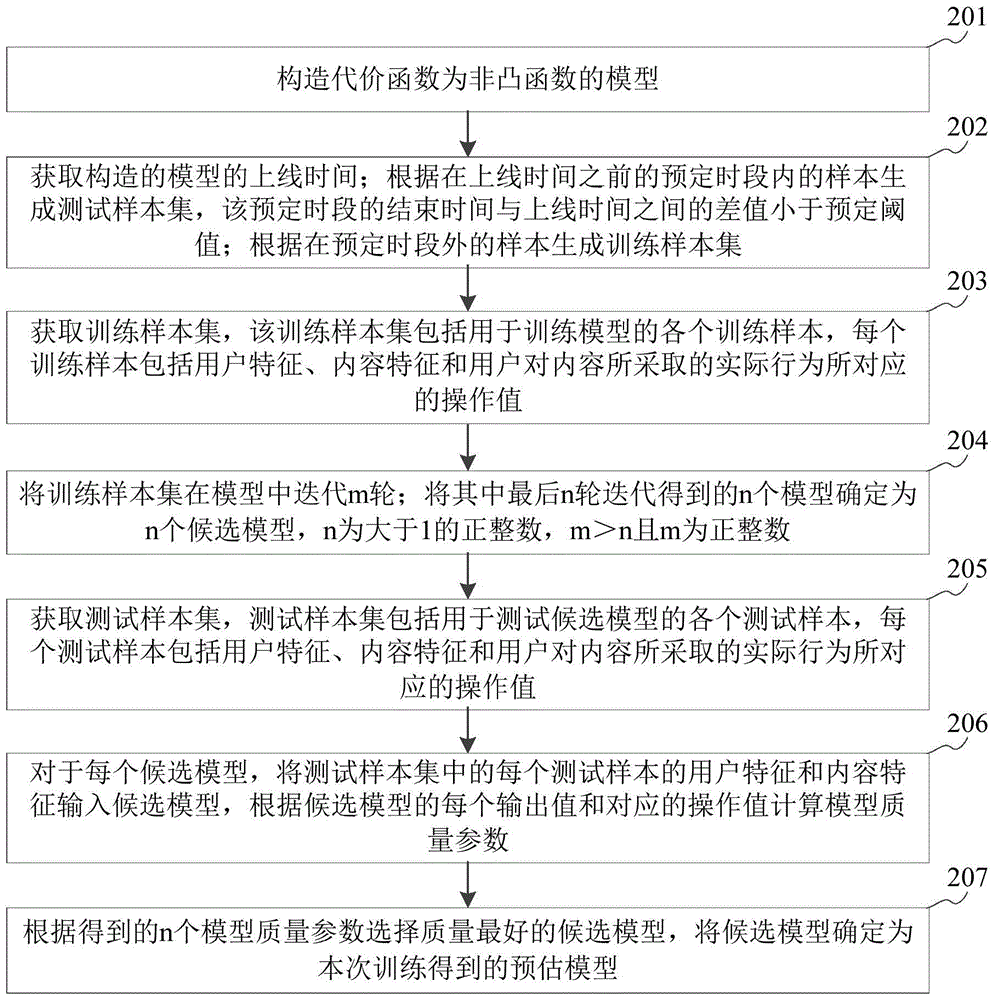

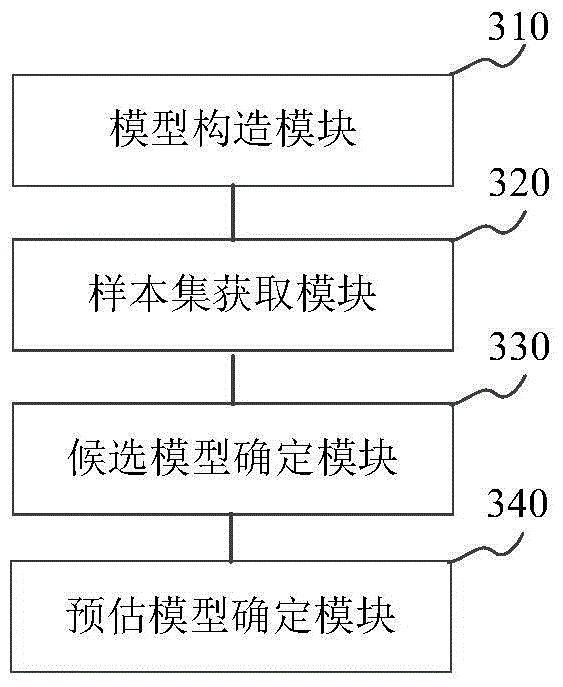

Model training method and device

The invention discloses a model training method and device, and belongs to the technical field of computers. The method comprises the following steps: constructing a cost function as a non-convex function model; obtaining a training sample set, wherein the training sample set comprises each training sample used for training the model, and each training sample comprises user characteristics, content characteristics and an operation value corresponding to practical behaviors adopted by the content; according to the training sample set, training the model to obtain n candidate models, wherein n is a positive integer which is greater than one; and determining the candidate model with the highest quality in the n candidate models as an estimated model obtained in the current training. The model training method and device solves the problem of great fluctuation of the model quality of the estimated model of which the cost function is the non-convex function, and achieves the effect that the model quality of the estimated model which is finally obtained by the training.

Owner:TENCENT TECH (SHENZHEN) CO LTD +1

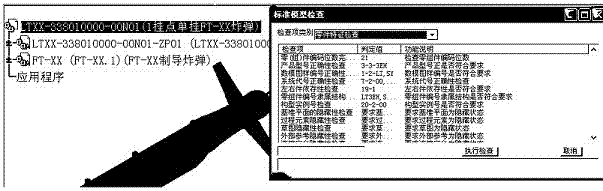

Configurable product model quality inspection method

InactiveCN107145622AValid checkEffective supervisionGeometric CADDesign optimisation/simulationVisual inspectionModel quality

The invention discloses a configurable product model quality inspection method. The method comprises the following steps that: on the basis of a model quality inspection system platform which is seamlessly integrated on CATIA (Computer-graphics Aided Three-dimensional Interactive Application) software, according to an existing digital management standard and modeling norm, carrying out user-defined configuration on check items; and then, according to the configured check items, carrying out quality inspection and an inspection result management analysis on a product model corresponding to design data in the CATIA software. Through the model quality inspection system platform, a user can carry out the user-defined configuration on the check items, and meanwhile, according to the check items configured by the user, a three-dimensional model designed in the CATIA software is subjected to the quality inspection and the inspection result management analysis. Through the model quality inspection system platform, a three-dimensional part designed through the CATIA software can be normatively, quickly and automatically subjected to quality detection so as to realize effective inspection and supervision for the quality of the three-dimensional model.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

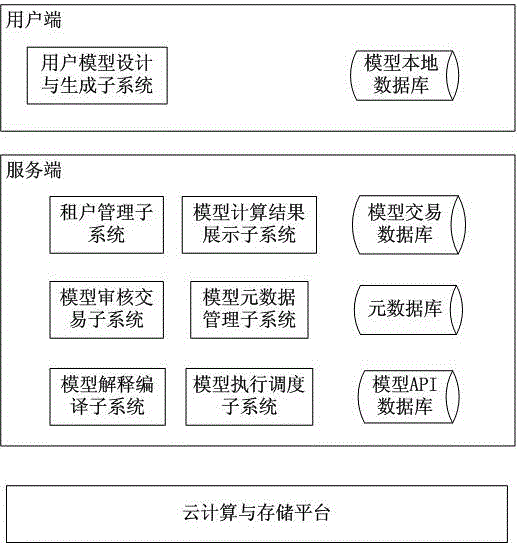

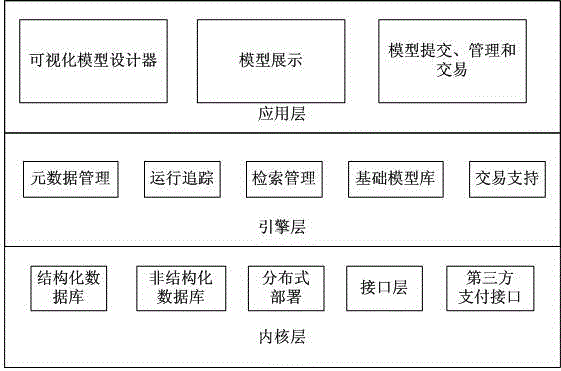

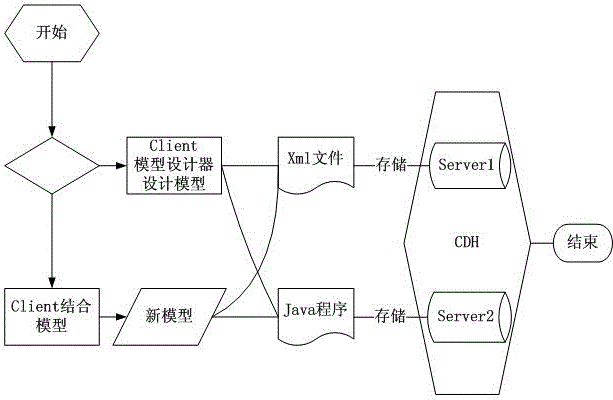

System for developing, generating and managing large-data analysis model business

ActiveCN105893522ASpecial data processing applicationsDatabase design/maintainanceModel managementMetadata management

The invention discloses a system for developing, generating and managing large-data analysis model business. The system comprises a user terminal, a server terminal and a cloud calculating and storing platform. The user terminal comprises a user-model designing and generating subsystem and a local model database. The server terminal comprises a tenant managing subsystem, a model auditing and trading subsystem, a model explaining and compiling subsystem, a model executing and dispatching subsystem, a model metadata managing subsystem, a calculated-result showing subsystem, a model trading database, a metadata base and a model API database. According to a frame, an efficient large-data operation-and-maintenance mode with centralized-distributed controllable, manageable and tradable calculating resources, model resources and storage resources is adopted, and six functions such as data-distributed data storing and calculating platform, model designing and generating, model managing and trading, model-quality auditing and verifying, model explaining and executing and tenant managing and accessing controlling are specially covered.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

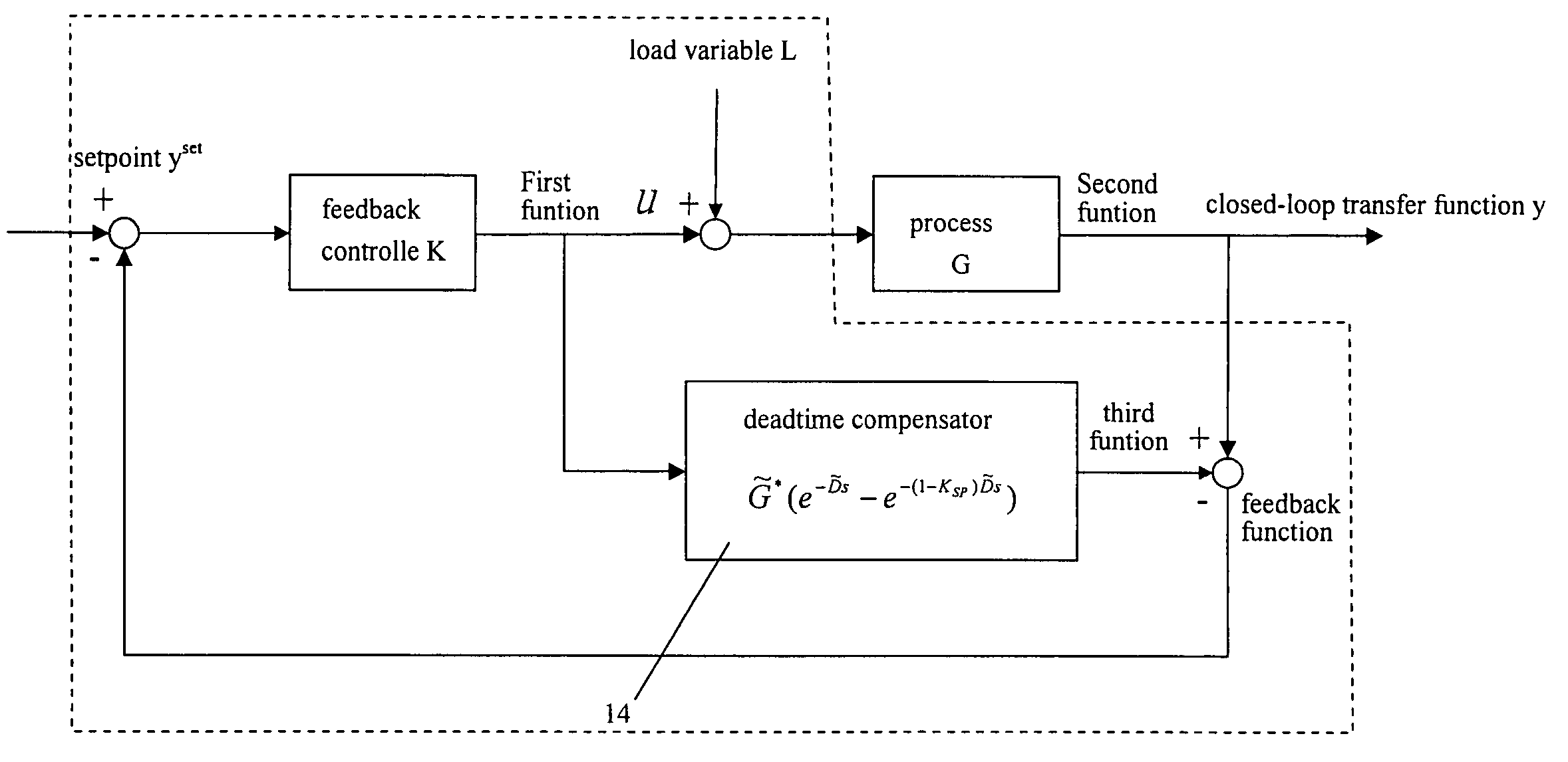

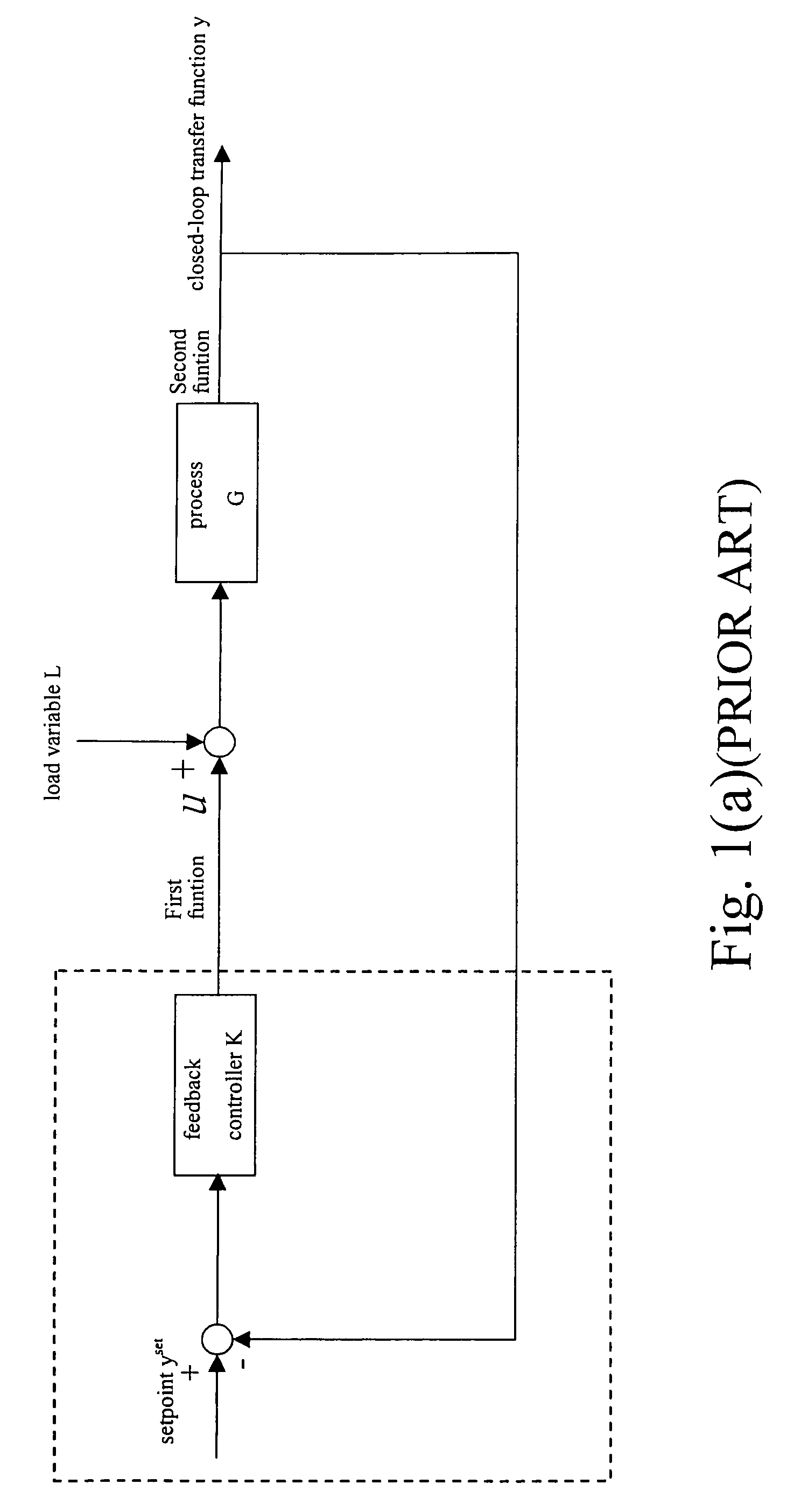

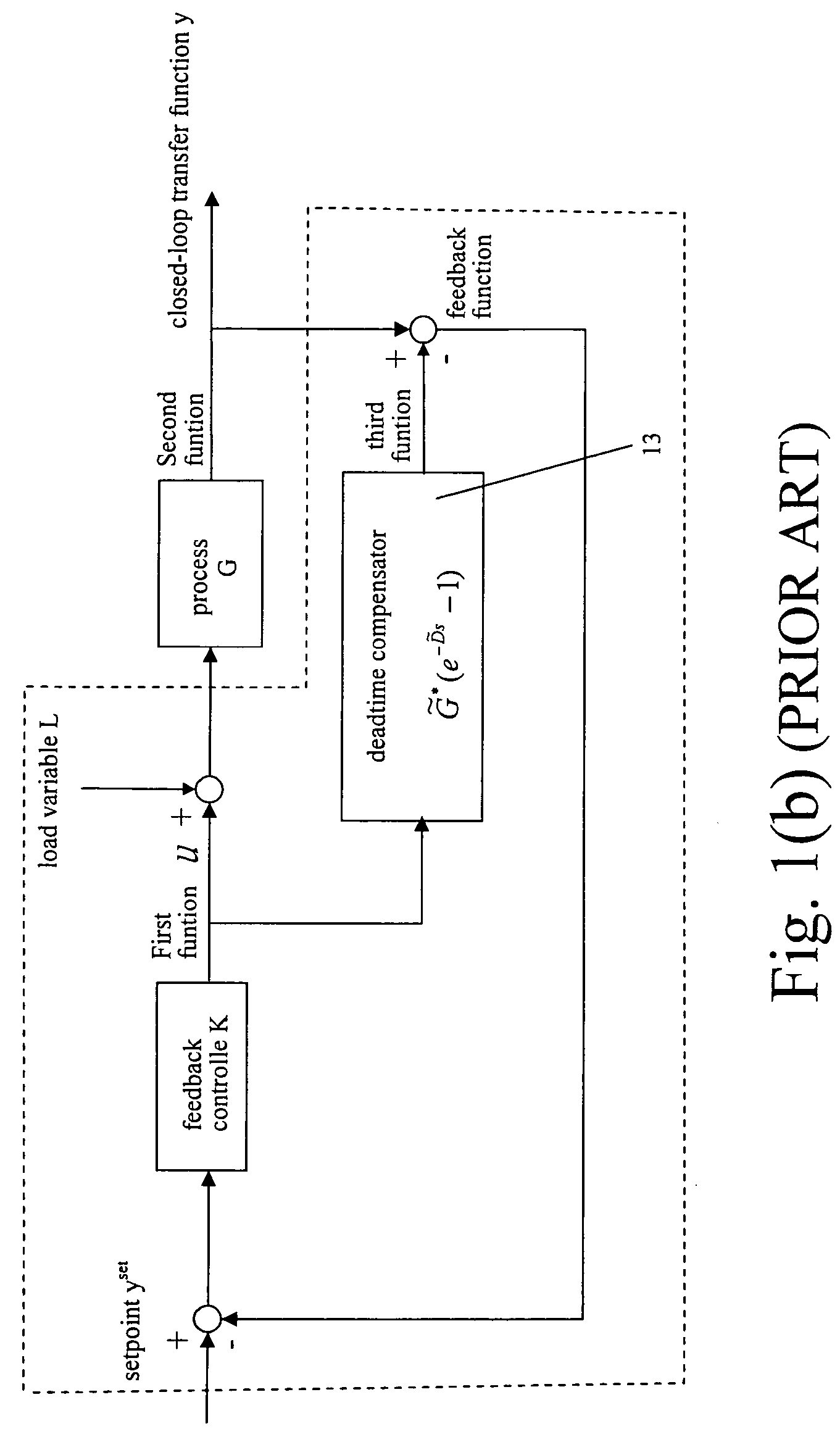

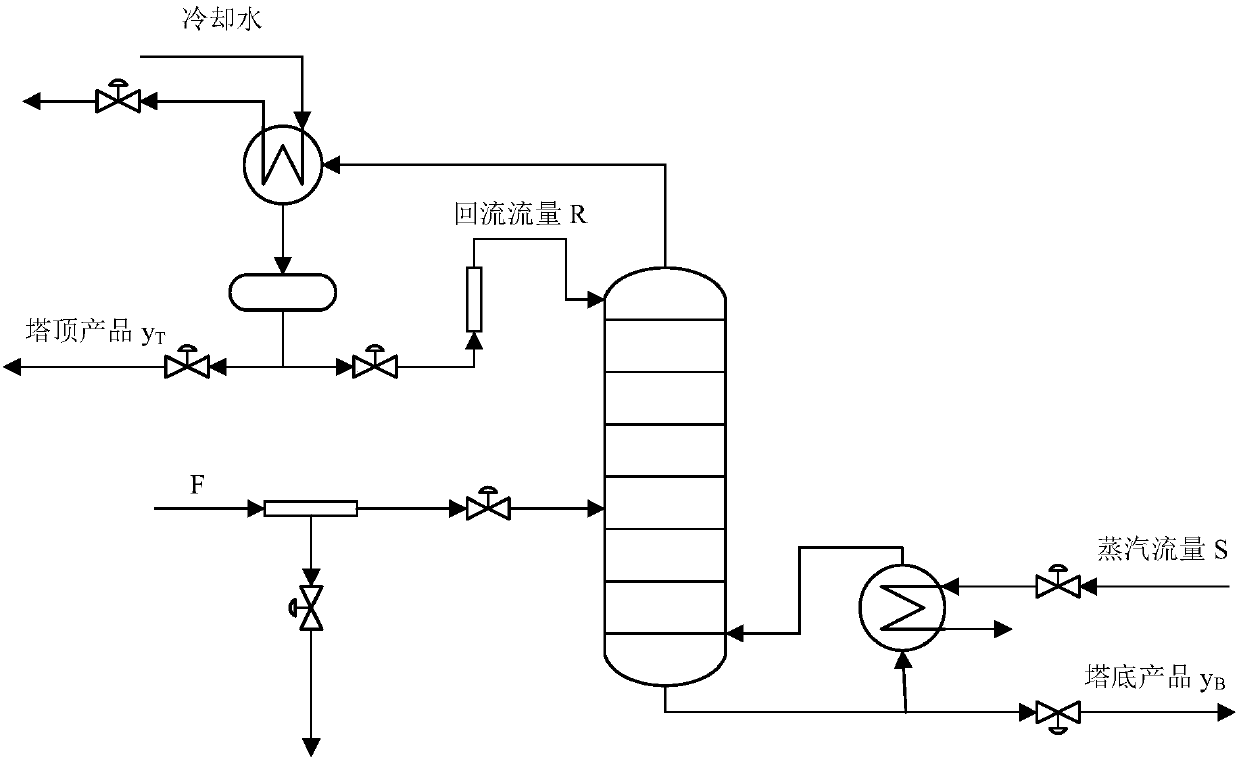

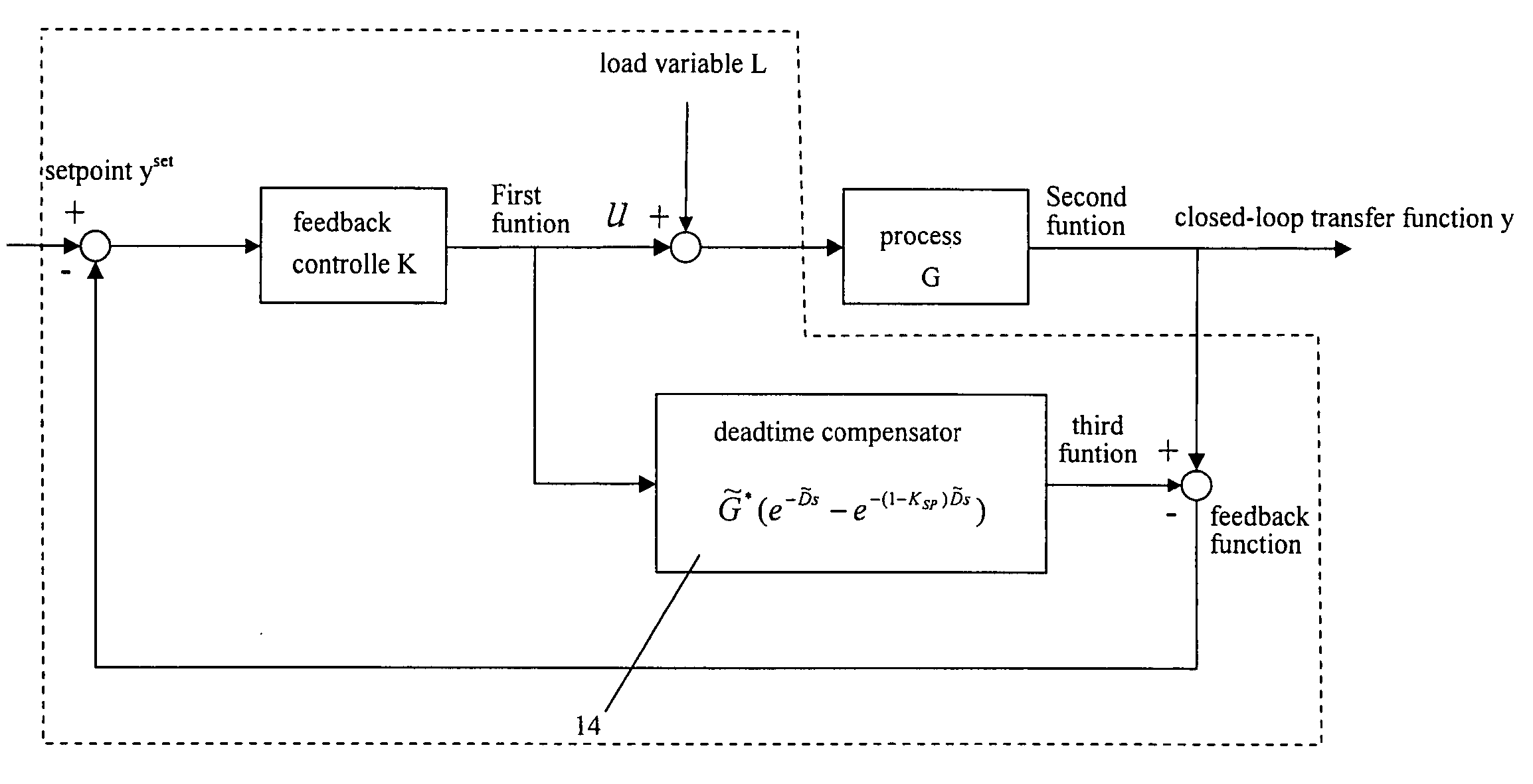

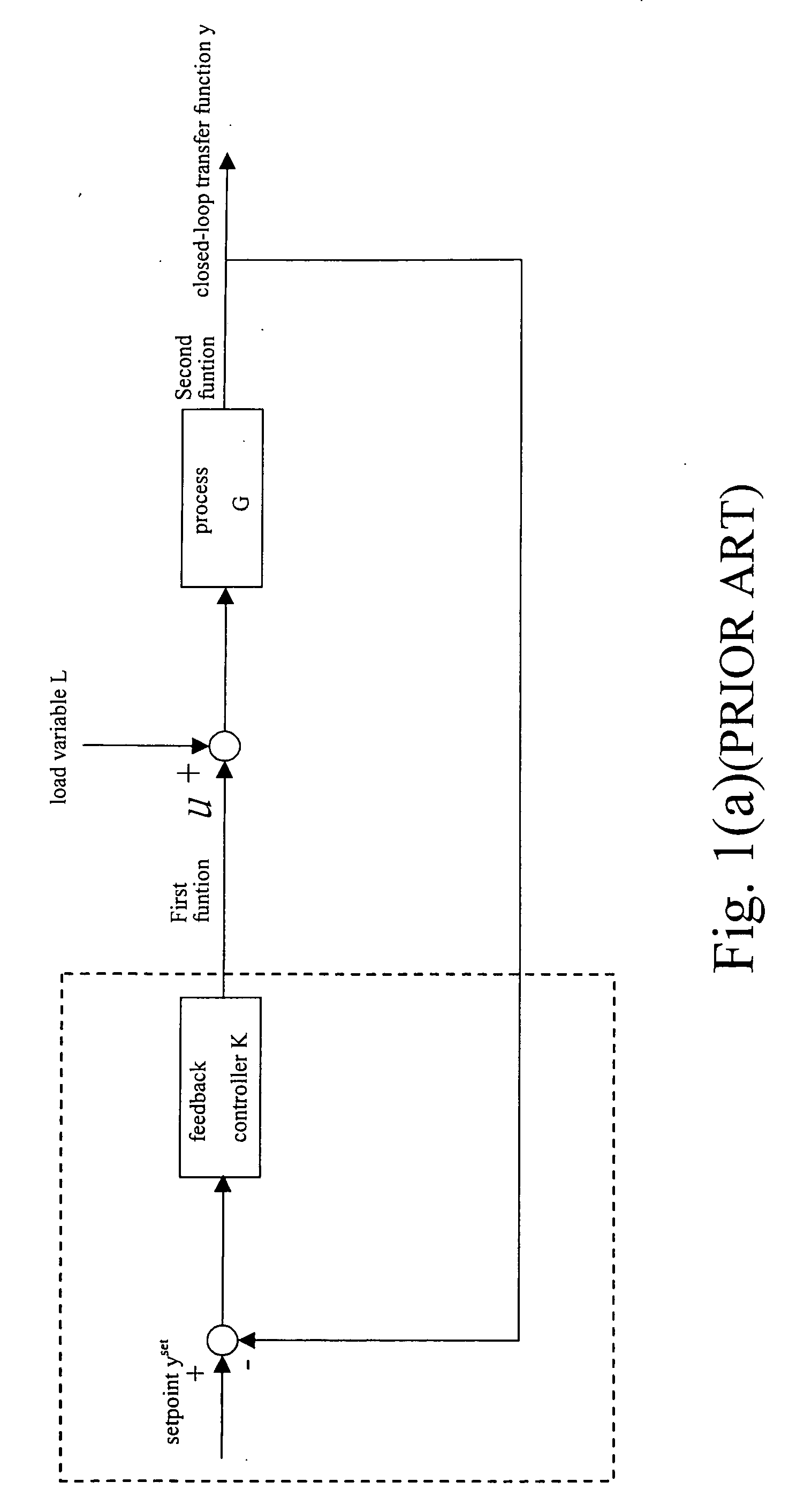

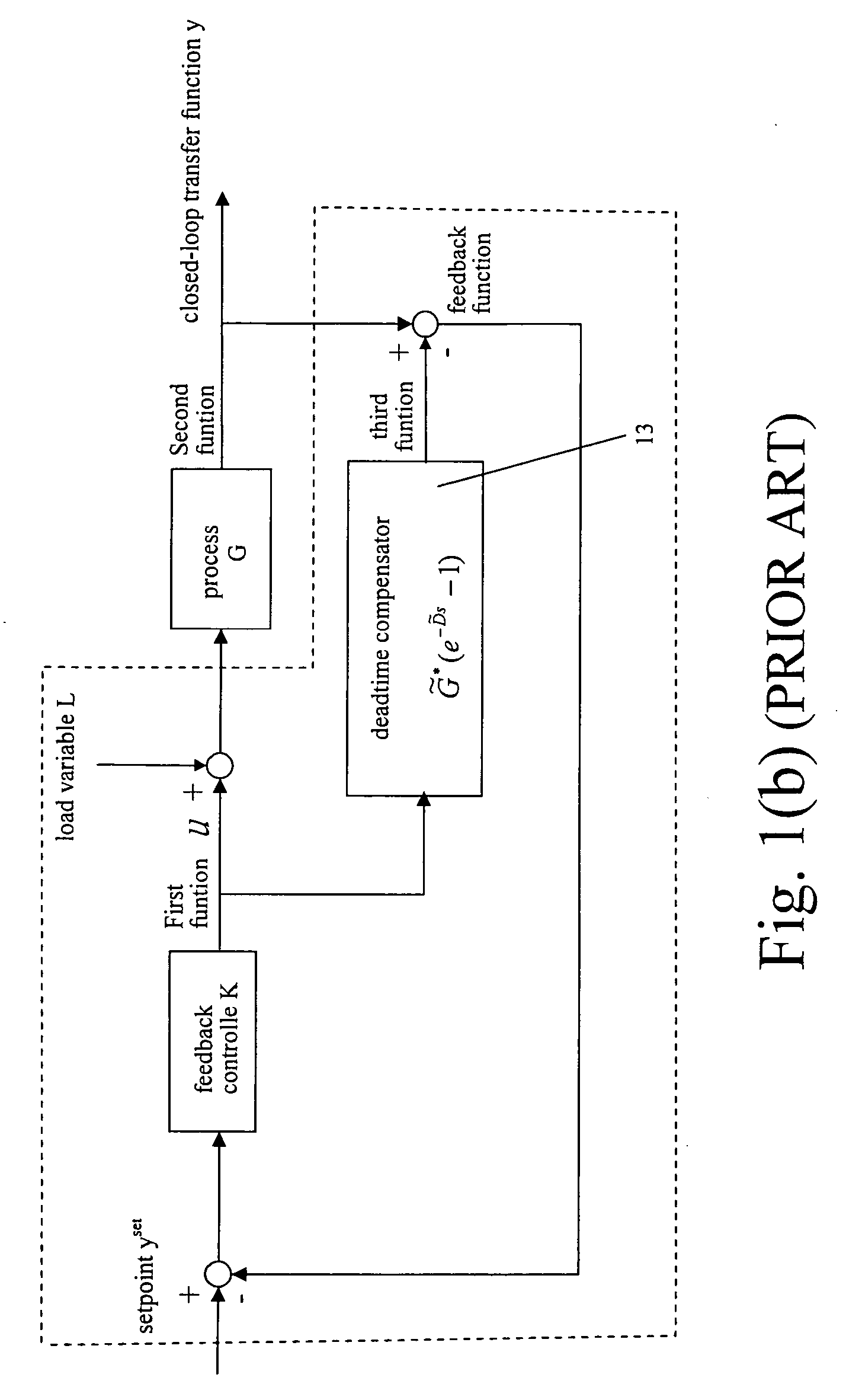

Method and apparatus for PID controller with adjustable deadtime compensation

ActiveUS7181295B2Effective regulationEasy to operateIgnition automatic controlAnti-hunting elementsModel qualitySmith predictor

In the present invention, a Smith predictor enhanced PID controller, SP-PID, is proposed. A tuning parameter Ksp is devised and the SP-PID controller would be gradually transformed from a PID controller to a Smith predictor as Ksp changes from 0 to 1. Properties of the SP-PID are explored and the design procedure is given to ensure a certain degree of robustness. Simulation results clearly indicate that the SP-PID takes advantage of the SP when small modeling error is encountered and it is gradually detuned to a PID controller, a user-friendly controller, when the model quality degrades. Moreover, the controller and its design procedure can be implemented in current process control computers with virtually no extra hardware cost.

Owner:NAT TAIWAN UNIV

Feedback control of chemical mechanical polishing device providing manipulation of removal rate profiles

InactiveUS8070909B2Optimal Operational ControlImprove thickness uniformitySemiconductor/solid-state device testing/measurementComputer controlMaterial removalModel quality

A method of controlling surface non-uniformity of a wafer in a polishing operation includes (a) providing a model for a wafer polishing that defines a plurality of regions on a wafer and identifies a wafer material removal rate in a polishing step of a polishing process for each of the regions, wherein the polishing process comprises a plurality of polishing steps, (b) polishing a wafer using a first polishing recipe based upon an incoming wafer thickness profile, (c) determining a wafer thickness profile for the post-polished wafer of step (b), and (d) calculating an updated polishing recipe based upon the wafer thickness profile of step (c) and the model of step (a) to maintain a target wafer thickness profile. The model can information about the tool state to improve the model quality. The method can be used to provide feedback to a plurality of platen stations.

Owner:APPLIED MATERIALS INC

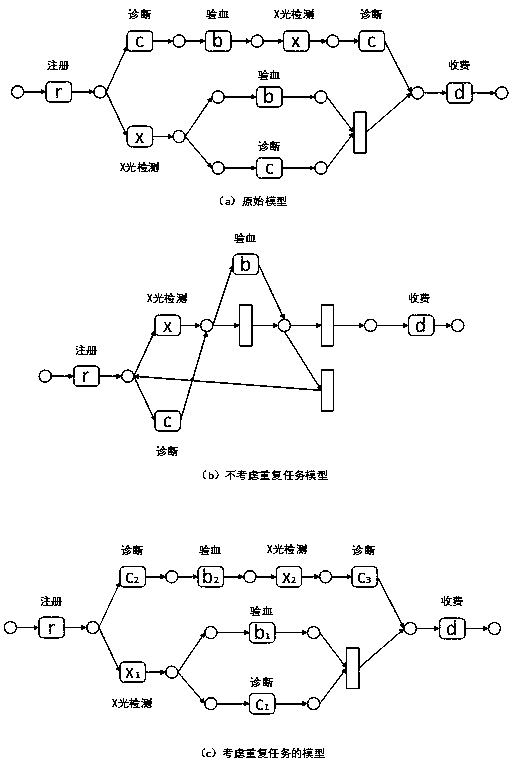

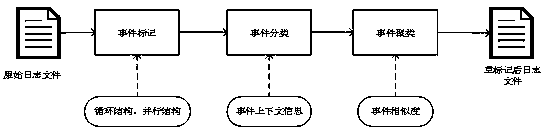

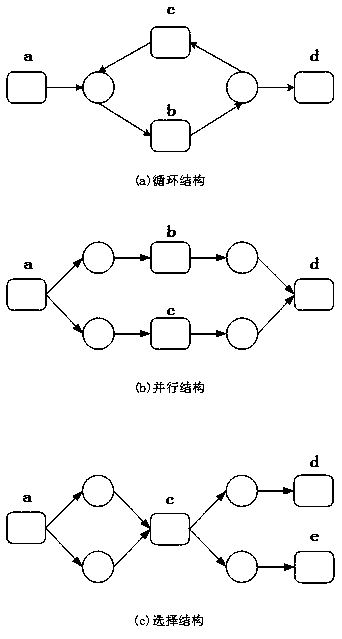

Workflow log repeated task recognition method based on relation matrix

ActiveCN107909344AHigh precisionReduce the number of divisionsOffice automationComputational modelModel quality

The invention discloses a workflow log repeated task recognition method based on a relation matrix. According to the invention, a strategy that log events are firstly classified and then clustered isadopted, in a division process, by finding a circulation and parallel structure with a stable structure, division types are reduced; in a clustering process, according to event contexts, similarity ofevery two repeated tasks in a candidate repeated task set is calculated; in the clustering process every time, model quality is calculated; and finally, after the clustering is finished, the optimalclustering scheme is selected, wherein each cluster represents one real different task. According to the invention, accuracy of following workflow model excavation can be improved.

Owner:HANGZHOU DIANZI UNIV

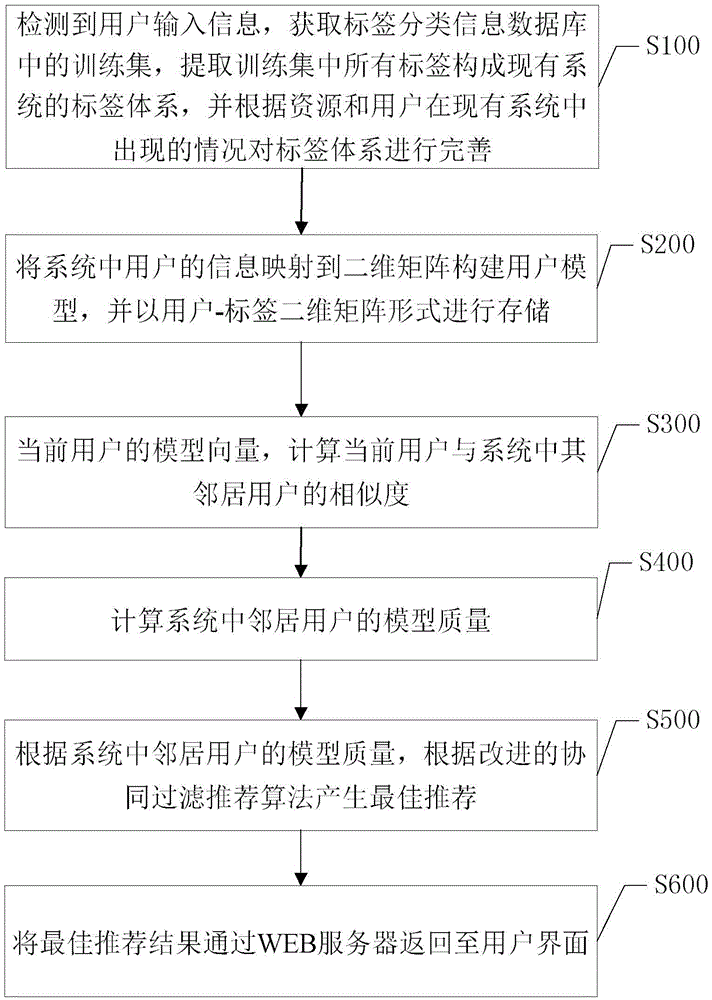

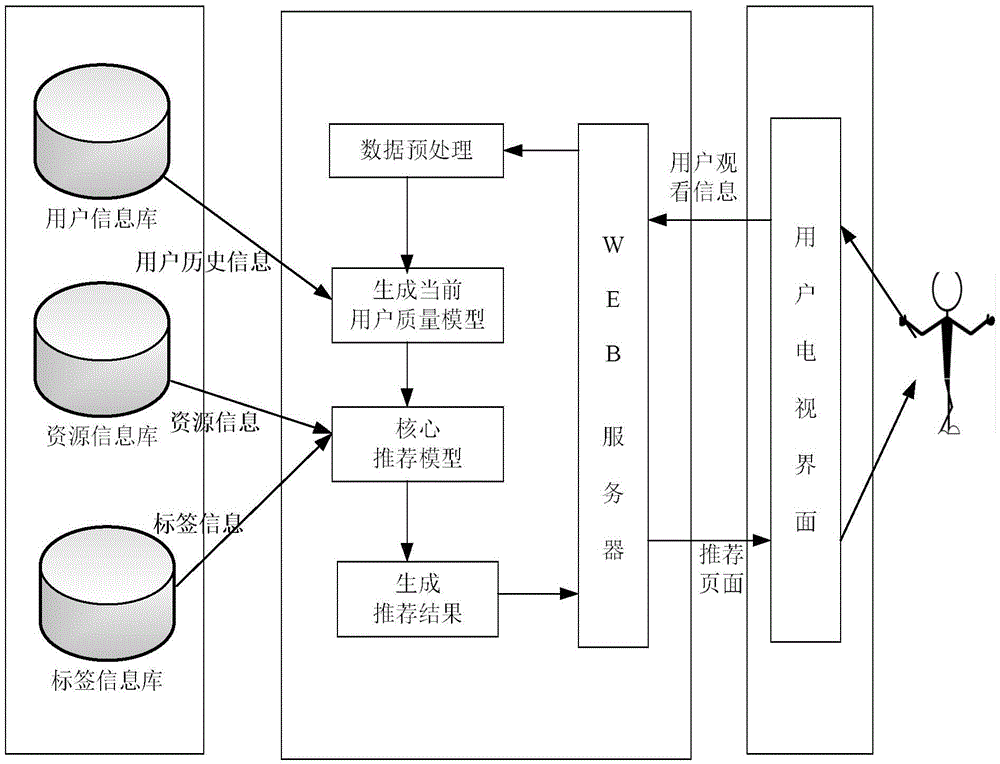

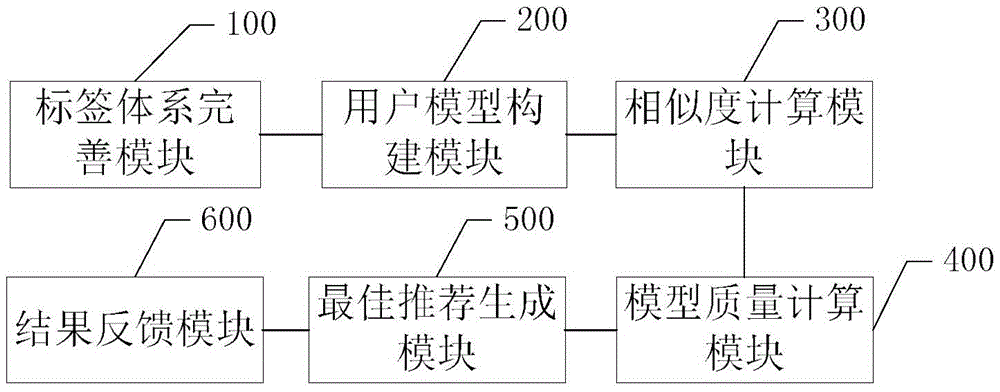

Collaborative filtering tag recommendation method and system based on user quality model

ActiveCN105426550AImplement updateFix stale issuesSpecial data processing applicationsWeb serviceModel quality

The invention discloses a collaborative filtering tag recommendation method and system based on user quality model. The collaborative filtering tag recommendation method comprises the following steps: perfecting a tag system according to situations that happen in the existing system; mapping information of users in the system into a two-dimensional matrix, so as to construct a user model, and storing the user model in the form of a user-tag two-dimensional matrix; acquiring model vectors of the current user, and calculating the degree of similarity between the current user and the neighbor user in the system; calculating model vectors of the neighbor user; according to the model vectors of the neighbor user in the system and a modified collaborative filtering recommendation algorithm, generating the best recommendation; returning the best recommendation result to the user interface through a WEB server. According to the collaborative filtering tag recommendation method and system based on the user quality model, provided by the invention, the best recommended user selection process in the conventional algorithm is optimized, the recommendation accuracy and the recall rate are improved, and evolution and updating of the current tag system in the system are facilitated; besides, according to appearing situations of users and resources in the system, proper tag sources are selected, and the problems of cold boot and single tag source are solved.

Owner:TCL CORPORATION

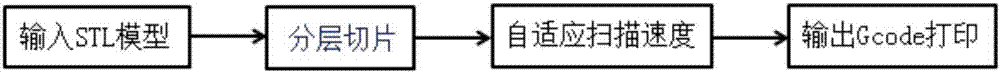

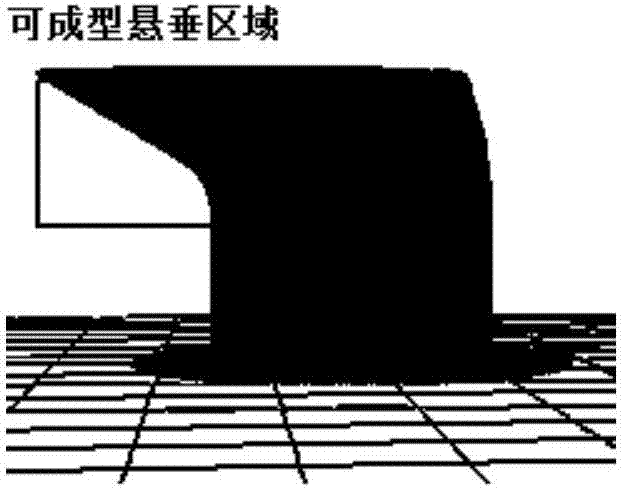

Self-adaptive scanning speed method for improving molding quality of hanging body model

The invention faces to the 3D printing field and discloses a self-adaptive scanning speed method. The self-adaptive scanning speed method of the invention comprises steps of establishing a topology structure according to normal vector information of an apex and a triangle face in an STL model to establish a topology structure, performing layered slicing processing on the STL model to obtain an enclosed two-dimensional polygonal contour and determining a moldable hanging section of each layer of the two-dimensional polygonal contour, solving scanning speed of the two-dimensional contour of this layer according to slice data of each layer, generating a universal Gcode file through a slicing engine for the 3D printer to read and print after obtaining scanning speeds of all layers. In order to improve modeling quality of the hanging body structure model and on the basis of the analysis on the affect on modeling quality by the scanning speed, the invention discloses he self-adaptive scanning speed method for improving molding quality of the hanging body model to ensure stable modeling of the mould, which not only improves printing effects and greatly saves consumption of printing materials.

Owner:HOHAI UNIV CHANGZHOU

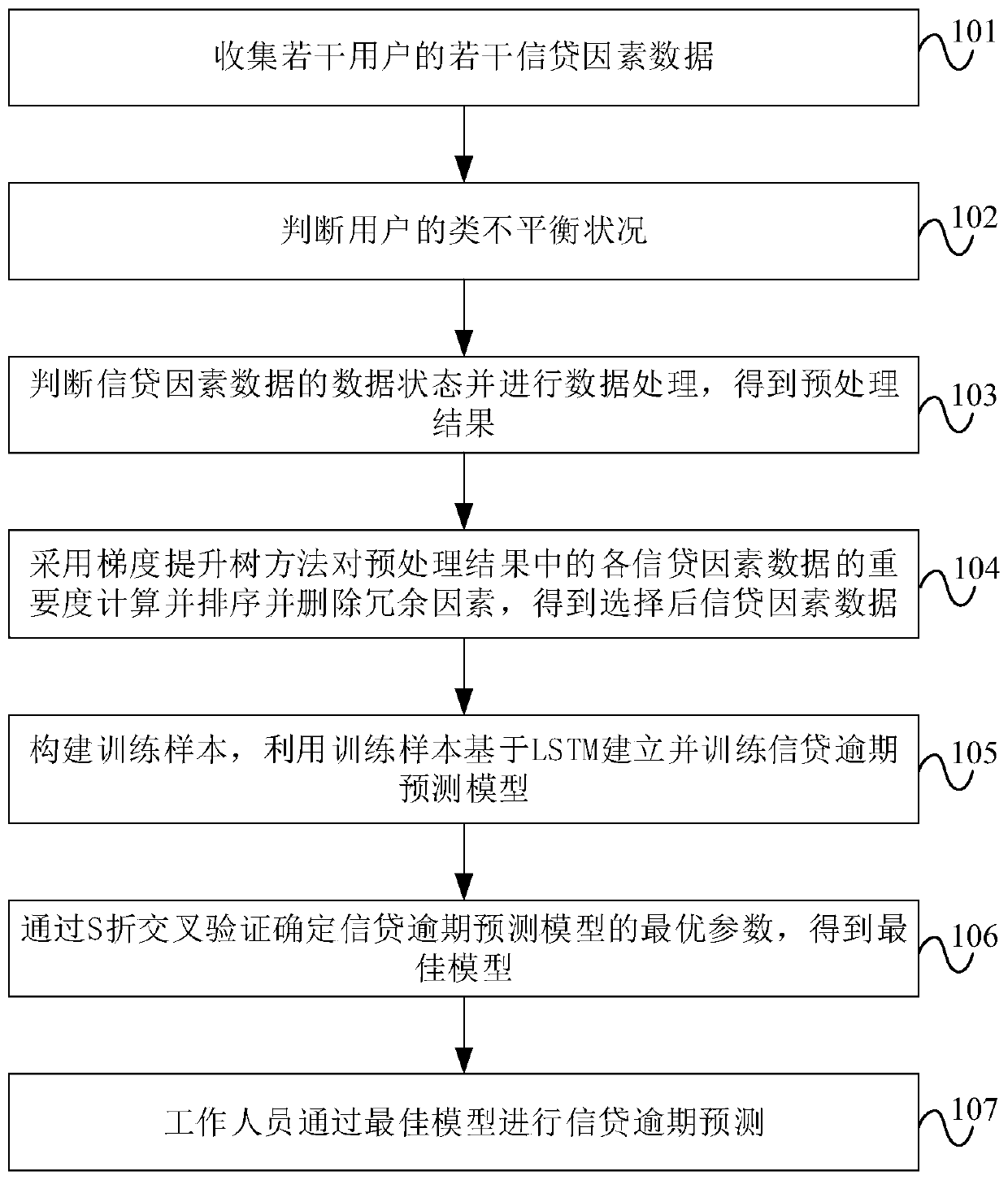

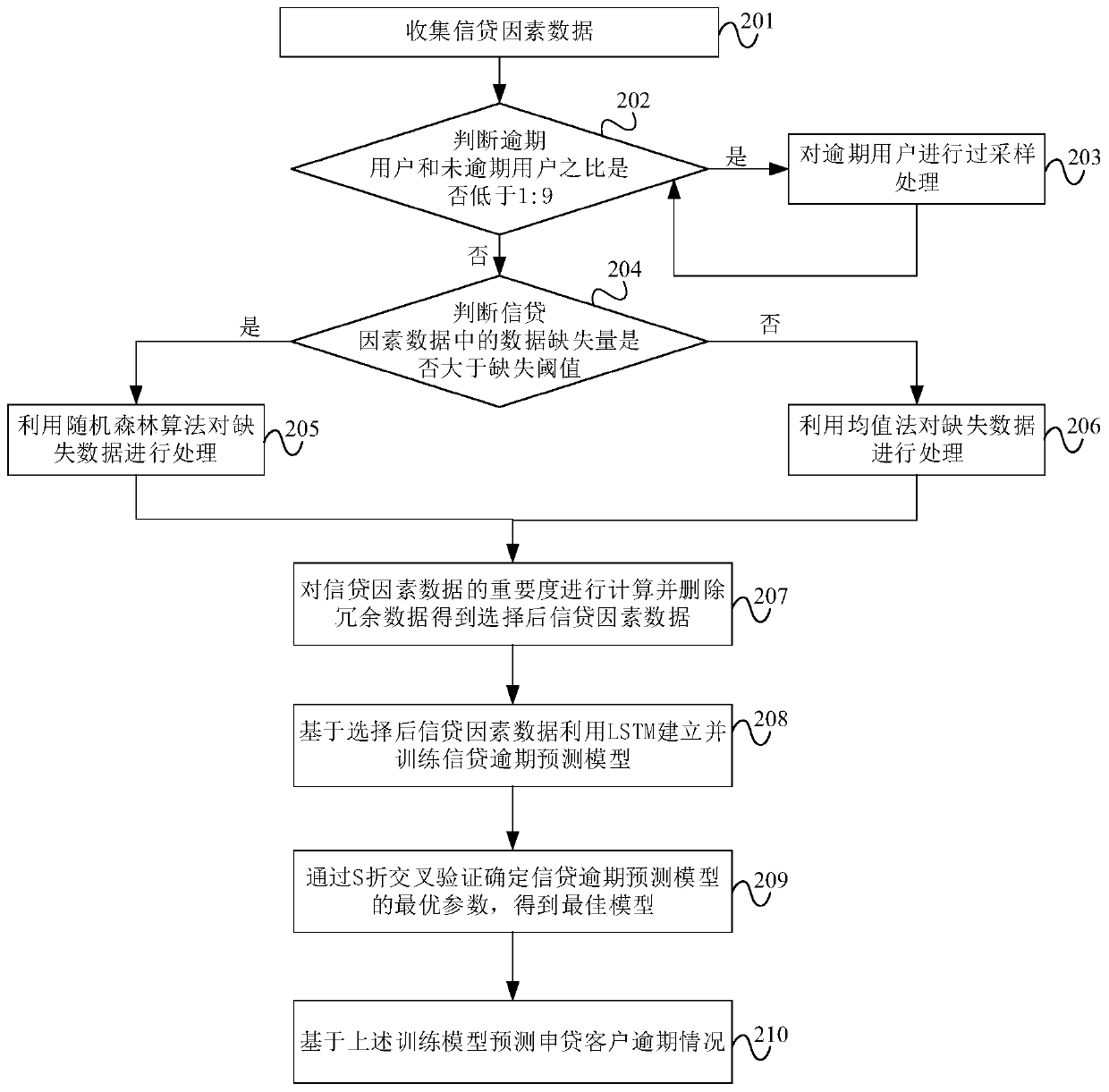

Credit prediction overdue method and system fused with machine learning

PendingCN110675243AIncrease diversityImprove data qualityFinanceCharacter and pattern recognitionOptimality modelFactor selection

The invention provides a credit overdue prediction method and system fused with machine learning, and the method comprises the steps: collecting a plurality of credit factor data, carrying out the preprocessing, carrying out the calculation and sorting of the importance of the credit factor data in a preprocessing result, and deleting redundancy, and obtaining the selected credit factor data; andconstructing a training sample based on the credit factor data, establishing and training a credit overdue prediction model by using LSTM based on the training sample, determining an optimal parameter, and performing credit overdue prediction after the optimal model is obtained. According to the invention, credit factor data is widely collected to improve comprehensiveness of credit overdue prediction; the missing training data is classified to improve the data quality; the class imbalance condition of the user is processed by using an oversampling method, and data distribution is balanced; all factors influencing credit expiration is sorted, and redundancy is eliminated, and then the reasonability of factor selection is improved; and a credit overdue prediction model is comprehensively established based on bidirectional LSTM in combination with timing sequence factors, optimal model parameters are determined through S-fold intersection, and the optimal model quality is improved.

Owner:北京银联金卡科技有限公司

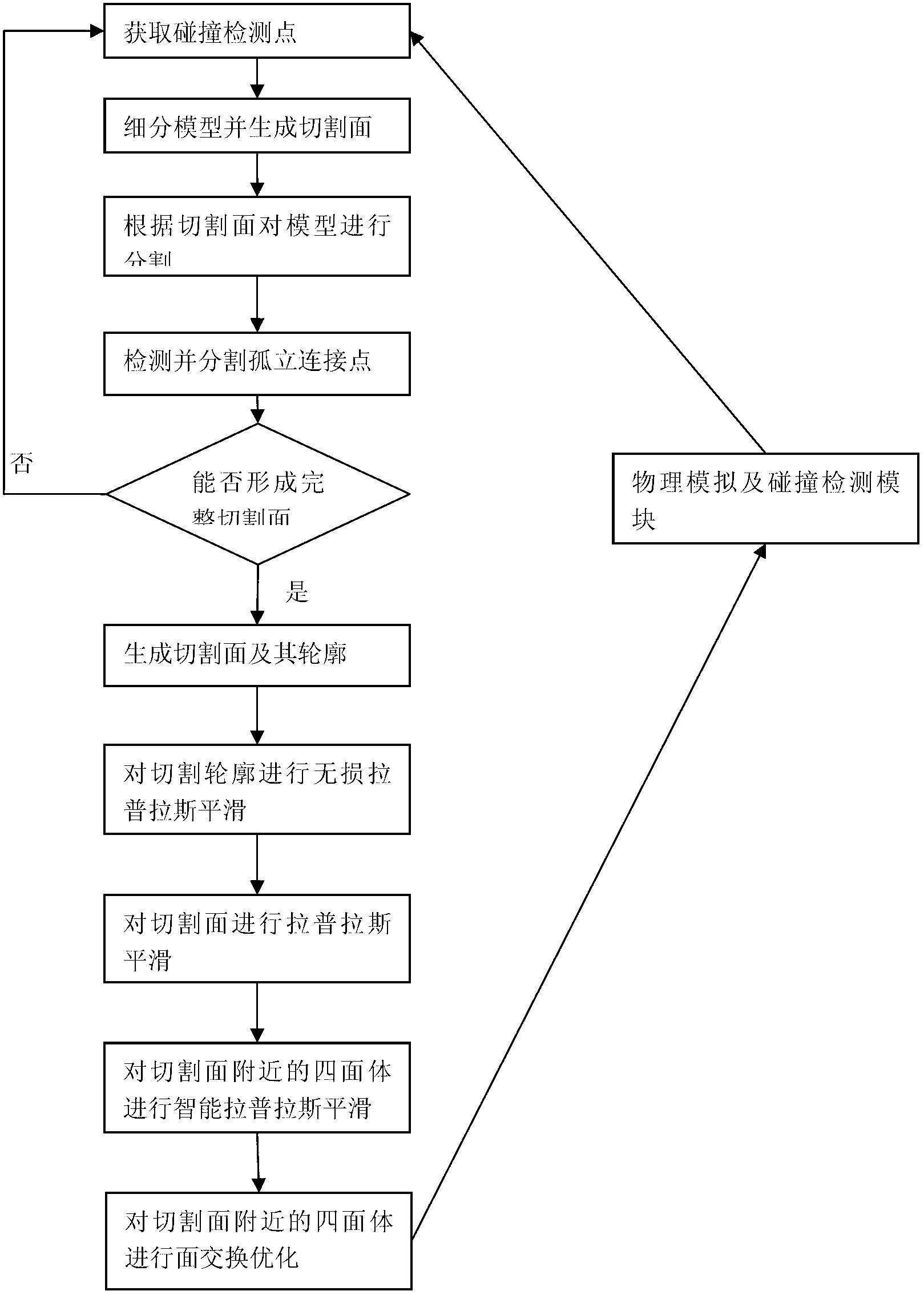

Organization model cutting method based on tetrahedron in virtual operation training system

InactiveCN103065305ANo unevennessHigh precisionImage enhancementImage analysisModel qualityComputer science

The invention relates to an organization model cutting method based on tetrahedrons in a virtual operation training system. The organization model cutting method includes the following steps: picking up a present collision point from a collision detecting system, refining a model and generating a potential cleavage plane through a potential cleavage plane generating module according to the collision point, cutting the model preliminarily through a face cleavage module, detecting whether phenomenon of isolated points exists or not through a point cleavage module, if so, conducting the cleavage on the isolated points, judging whether all nodes after cleavage form a complete tangent plane or not, generating a cutting plane and an outline of the cutting plane according to the cleavage points, conducting lossless Laplace smoothness on nodes of the outline, conducting normal Laplace smoothness on nodes of the cutting plane, conducting intelligent Laplace smoothness on nodes of all tetrahedrons inside the system, and conducting surface exchanging optimization on the internal tetrahedrons. Compared with the prior art, the organization model cutting method based on the tetrahedrons in the virtual operation training system has the advantages of being high in precision and robustness, and capable of imitating organization model cutting efficiency and keeping organization model quality, and the like.

Owner:SHANGHAI JIAO TONG UNIV

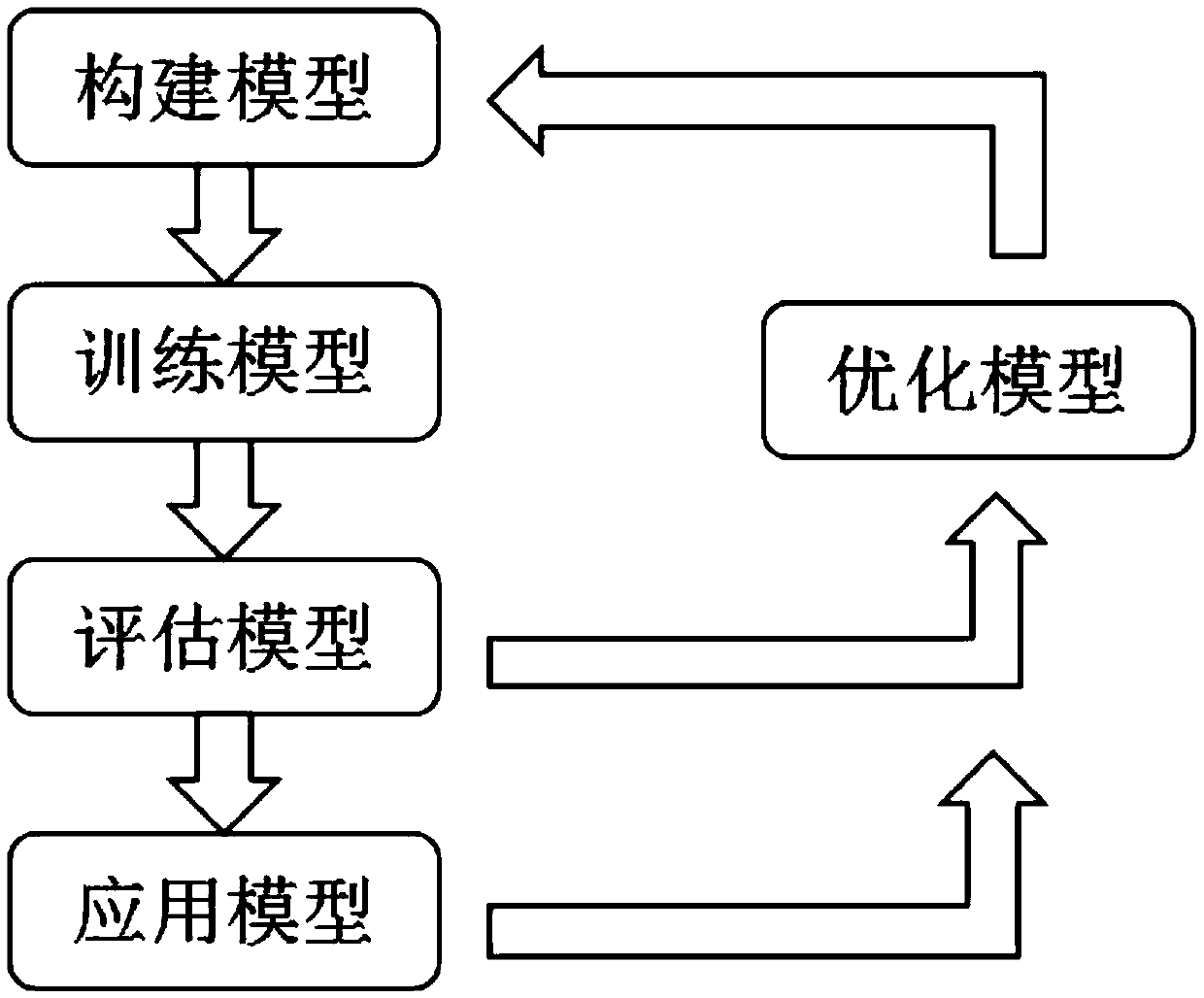

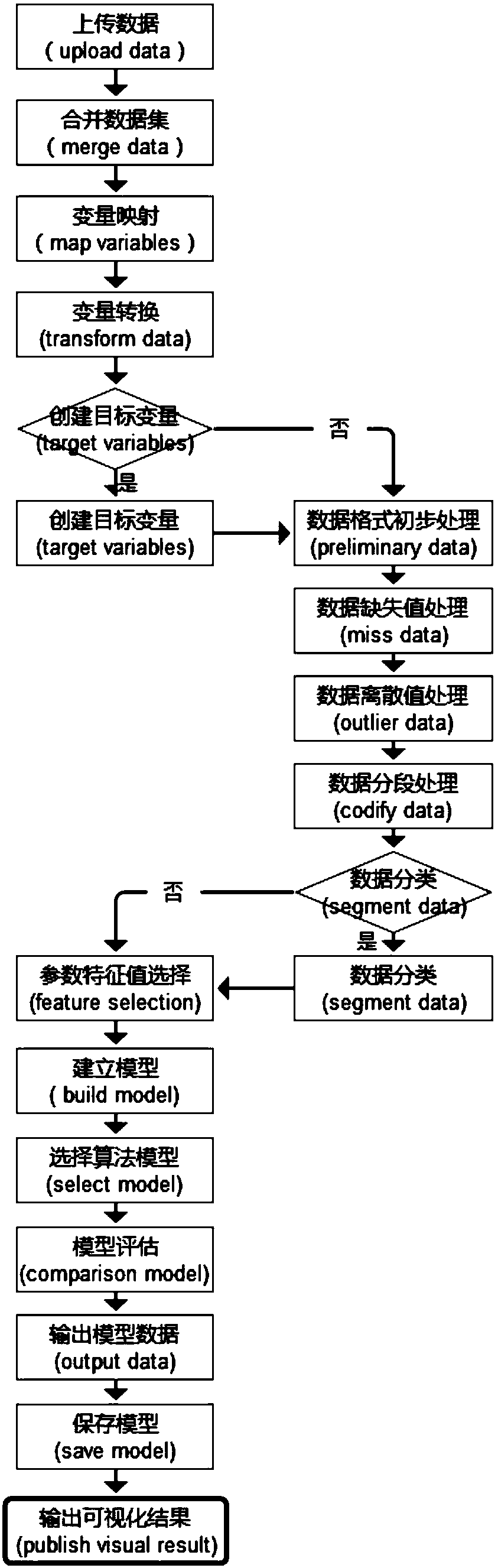

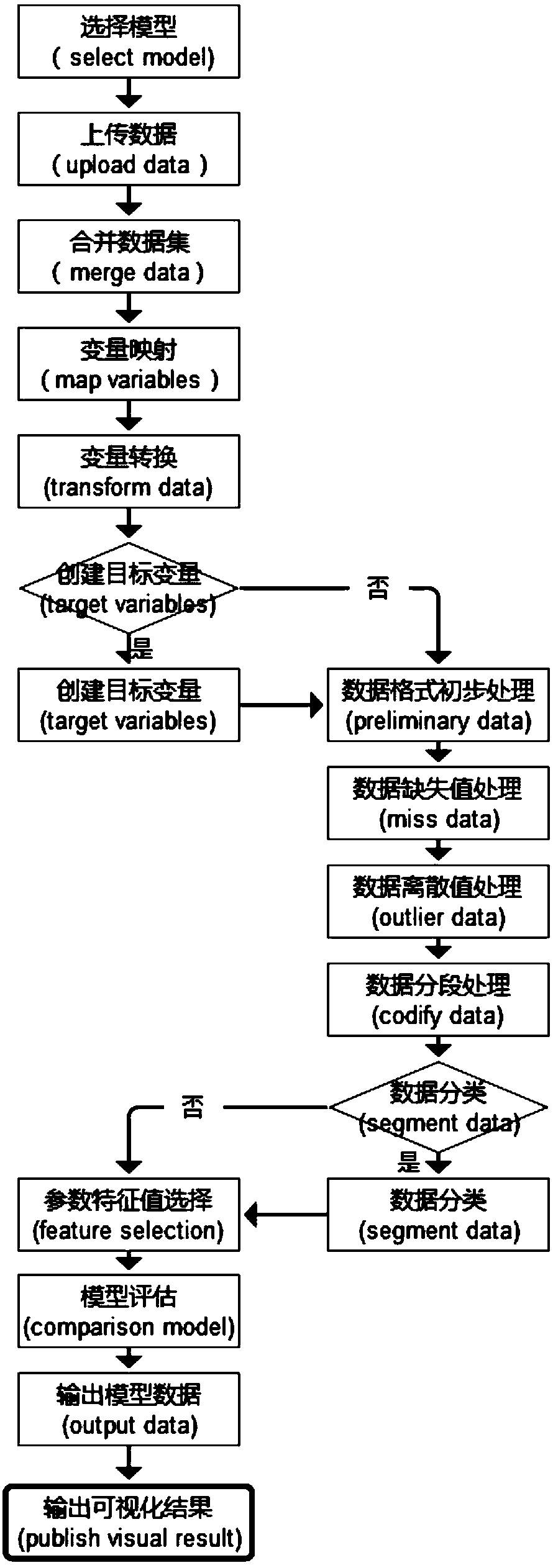

Automatic modeling method of a business service model

PendingCN109523316AThe data analysis results are accurateRealize seamless dockingDigital data information retrievalSpecial data processing applicationsData transformationSi model

The automatic modeling method of the business service model comprises the steps of constructing a model, training the model, evaluating the model and applying the model, and performing continuous dataexploration and model optimization in the process of training the model and the application model; Constructing a model: carrying out data cleaning, data mining, data conversion and data writing by uploading a training set, automatically and quickly matching an algorithm model, and providing multi-dimension assessment model quality; Training a model: training the model through the test set by using a machine learning technology; And model application: applying the model to a real business scene to verify the model, and outputting a visual chart report according to business requirements afterthe model is evaluated and optimized through a test set. The invention provides a big data technology automatic modeling method covering a data mining program module, a machine learning module and anartificial intelligence program module for the whole industry.

Owner:杭州珞珈数据科技有限公司

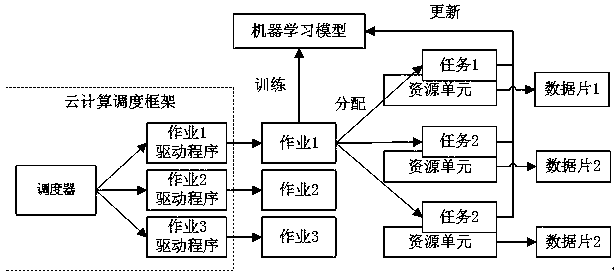

Cloud computation resource scheduling method oriented to distributed machine learning

InactiveCN108694090AImprove training effectImprove energy utilizationResource allocationTransmissionResource utilizationModel quality

The invention relates to a cloud computation resource scheduling method oriented to distributed machine learning. The method comprises the steps of establishing a model between the number of iterations and a model quality improvement through historical data for online prediction of an influence of resource allocation on the model quality improvement; and formulating a resource allocation strategyso as to achieve the effect of maximization of overall performances of multiple concurrently executed model training tasks running in a cloud computation platform. Therefore, the resource utilizationrate is improved and dynamic changes of the tasks and loads are rapidly adapted.

Owner:JIANGSU HOPERUN SOFTWARE CO LTD

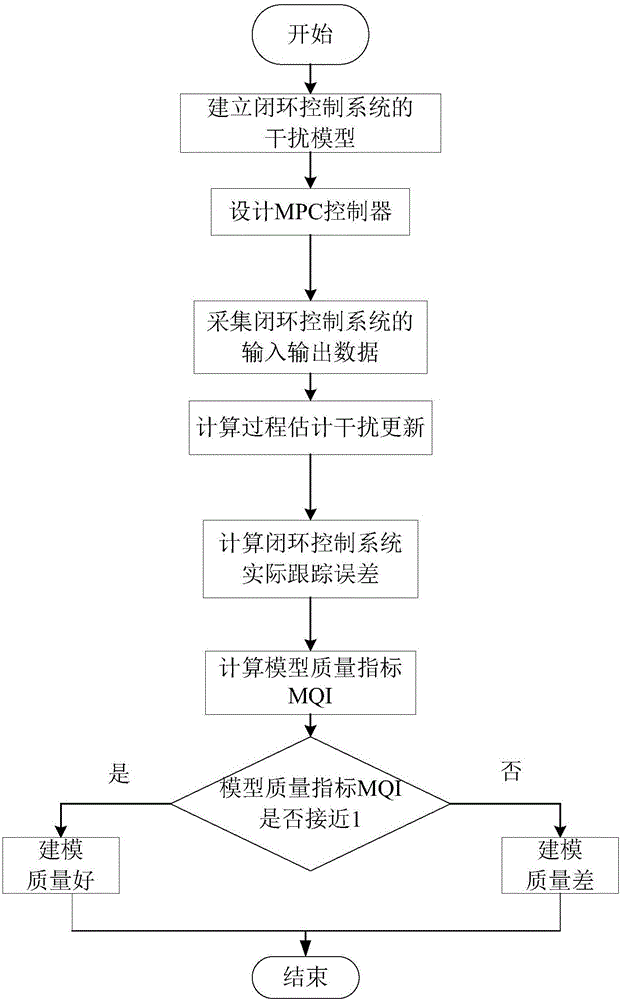

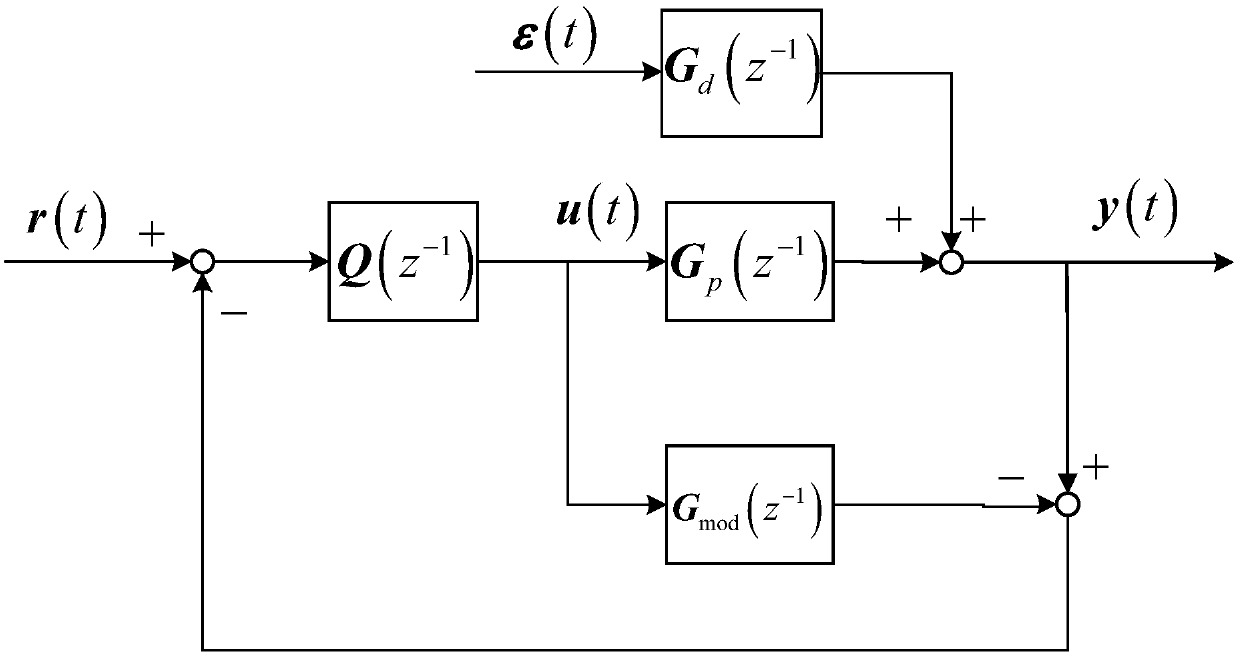

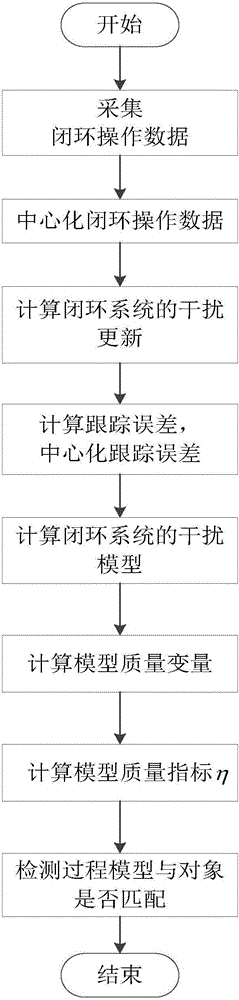

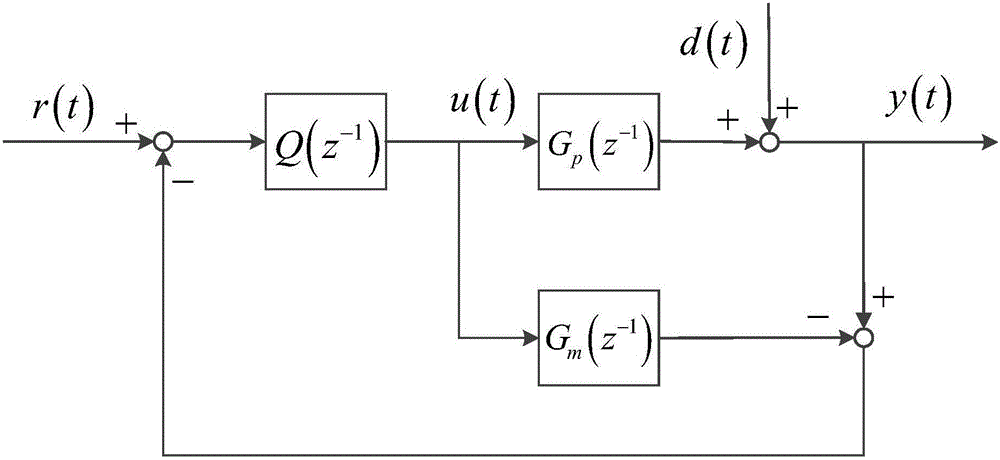

Modeling quality monitoring method for model predictive controller (MPC) with drift interference

InactiveCN105700358AHigh feasibilityConsume less resourcesAdaptive controlDynamic modelsControl system

The invention discloses a modeling quality monitoring method for a model predictive controller (MPC) with drift interference. The method comprises the following steps: an interference model for a closed loop control system is built; according to the actual condition of the closed loop control system and a given control target, a dynamic model predictive controller (MPC) for a process is designed; the interference model and the MPC are adopted for controlling the closed loop control system, and process data obtained by operation of the closed loop control system are acquired; according to the structure of the closed loop control system, orthogonal projection is carried out on process output and process input data, and process estimation interference update is acquired; according to an established reference signal of the closed loop control system and the process actual output, the actual tracking error of the closed loop control system is acquired; according to the process estimation interference update and the actual tracking error, a model quality index for the closed loop control system is acquired; and according to the structure of the closed loop control system, the model quality index is used for monitoring the modeling quality. The method of the invention has the advantages of high feasibility, few consumed resources for processing, and high evaluation result accuracy.

Owner:HUAZHONG UNIV OF SCI & TECH

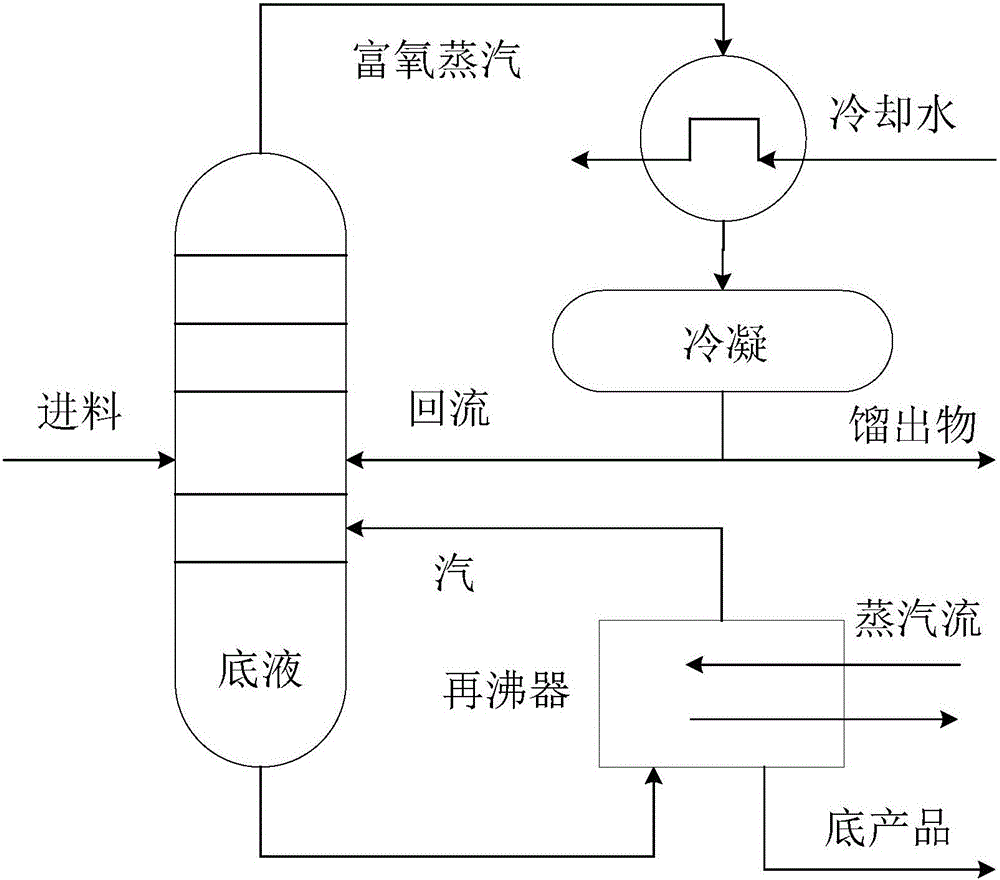

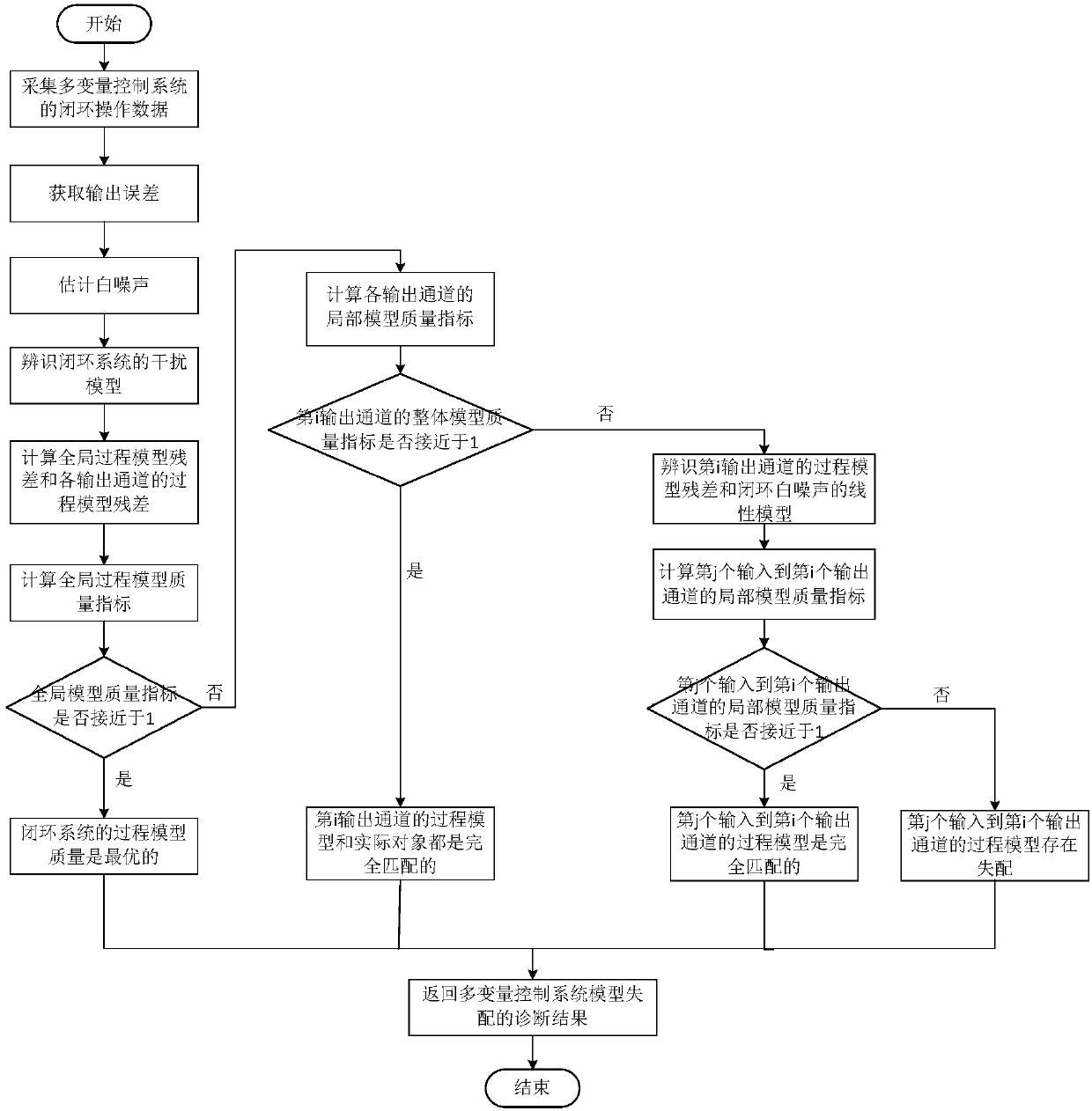

Model mismatching diagnosis method of data driven multivariable control system

InactiveCN108536127AEfficient separationAvoid economic lossElectric testing/monitoringSystem maintenanceClosed loop

The invention discloses a model mismatching diagnosis method of a data driven multivariable control system. The method comprises the following steps: according to closed loop operation data, estimating white noise, identifying an interference model, and acquiring global process model residual errors and process model residual errors of different output channels; acquiring global model quality indexes according to the white noise and the global process model residual errors, detecting overall process model mismatching of a multivariable control system according to the global model quality indexes, acquiring overall model quality indexes and partial model quality indexes according to the white noise and the process model residual errors of different output channels, confirming input / output sub-channels of model mismatching of the multivariable control system, and judging that a process model of an input / output sub-channel has serious model mismatching if a partial model quality index isapproximate to 0. By adopting the method, process model mismatching can be diagnosed under a normal operation condition in the industrial process, system maintenance cost can be lowered, and system security can be improved.

Owner:HUAZHONG UNIV OF SCI & TECH

Method and apparatus for PID controller with adjustable deadtime compensation

ActiveUS20050251272A1Effective regulationEasy to operateIgnition automatic controlAnti-hunting elementsModel qualitySmith predictor

In the present invention, a Smith predictor enhanced PID controller, SP-PID, is proposed. A tuning parameter Ksp is devised and the SP-PID controller would be gradually transformed from a PID controller to a Smith predictor as Ksp changes from 0 to 1. Properties of the SP-PID are explored and the design procedure is given to ensure a certain degree of robustness. Simulation results clearly indicate that the SP-PID takes advantage of the SP when small modeling error is encountered and it is gradually detuned to a PID controller, a user-friendly controller, when the model quality degrades. Moreover, the controller and its design procedure can be implemented in current process control computers with virtually no extra hardware cost.

Owner:NAT TAIWAN UNIV

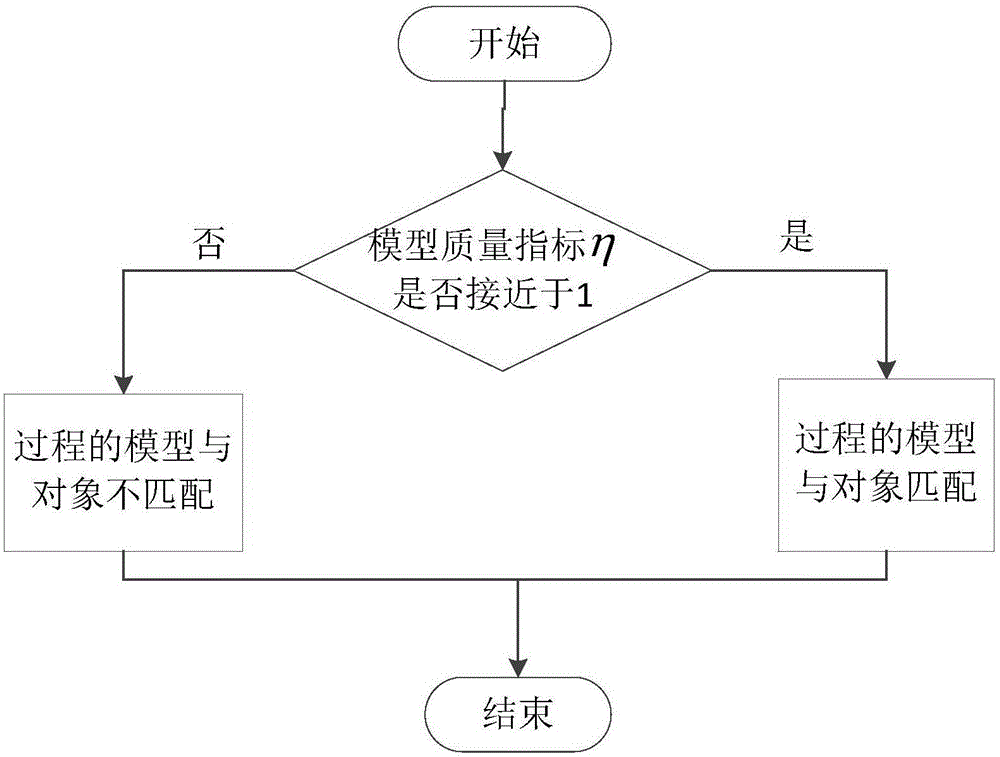

Detection method for mismatching of model of closed-loop control system and object

InactiveCN105807611AInterference updatePerformance impactAdaptive controlControl systemSystem maintenance

The invention discloses a detection method for mismatching of a model of a closed-loop control system and an object. Closed-loop data of the current system is obtained during normal operation of an industrial process. A model quality index is obtained by utilizing the data. The matching degree of the model and the object is detected according to the values of the model quality index. The more the model quality index is approximate to 1, the higher the matching degree of the model and the object is. The model quality index is insusceptible of change of adjusting parameters of the controller and the change of an interference model. By adopting the method, the mismatching of the model and the object can be removed from other elements affecting control performance effectively and influence on the control system performance by the mismatching of the model and the object can be analyzed more clearly. Besides, by adopting the method for detecting the mismatching of the model and the object, no external excitation signals are needed to add during the industrial process in normal operation. The mismatching of the model and the object can be detected in normal operation condition of the industrial process, so that the system maintenance cost is reduced and the system safety is improved.

Owner:HUAZHONG UNIV OF SCI & TECH

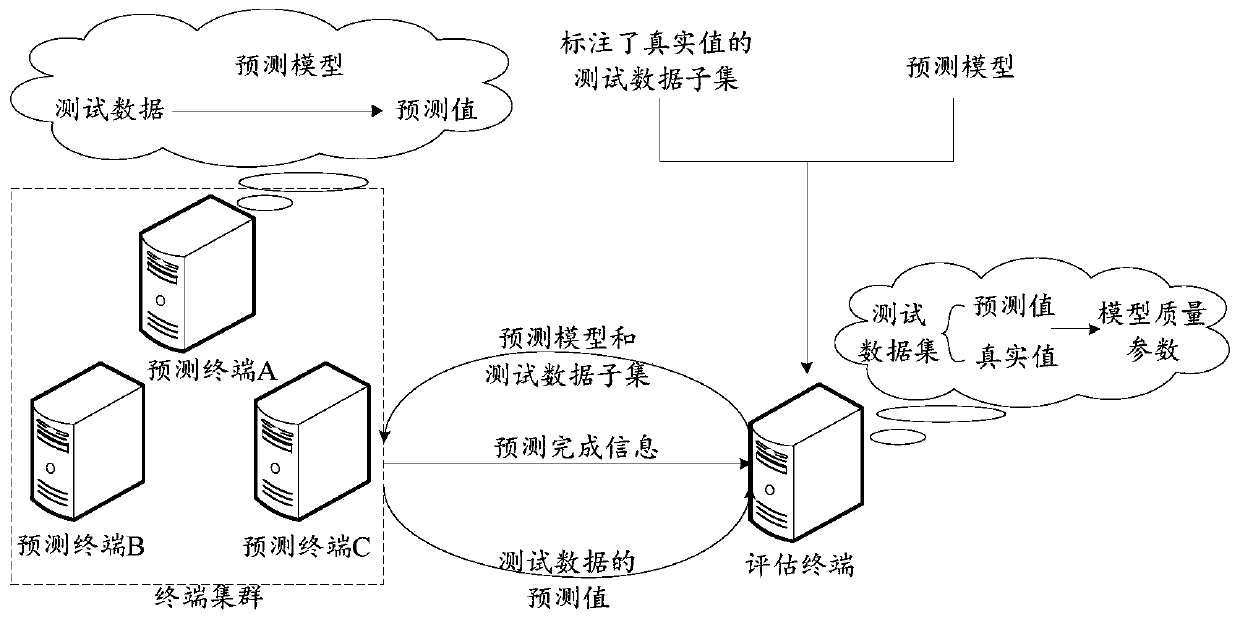

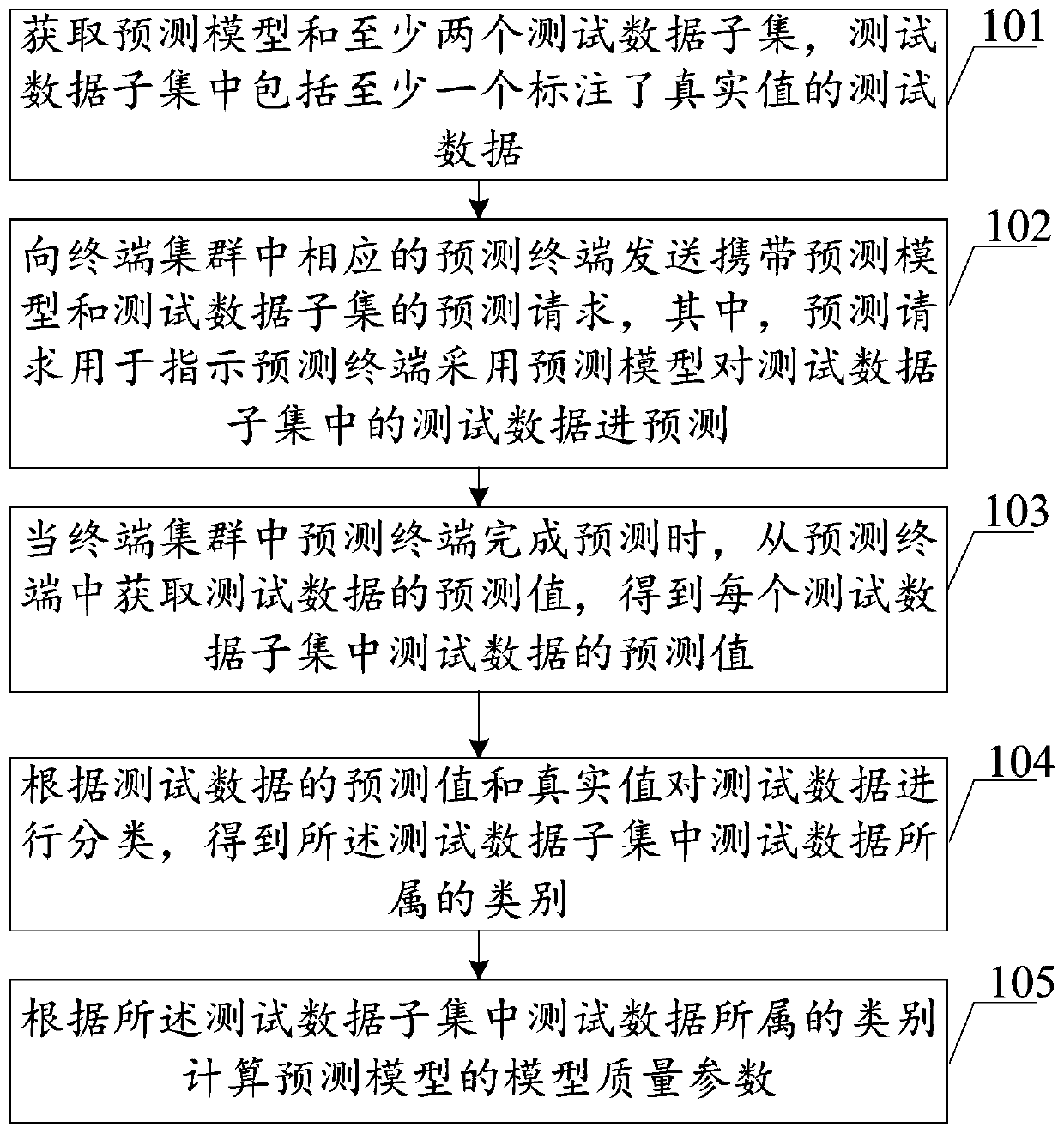

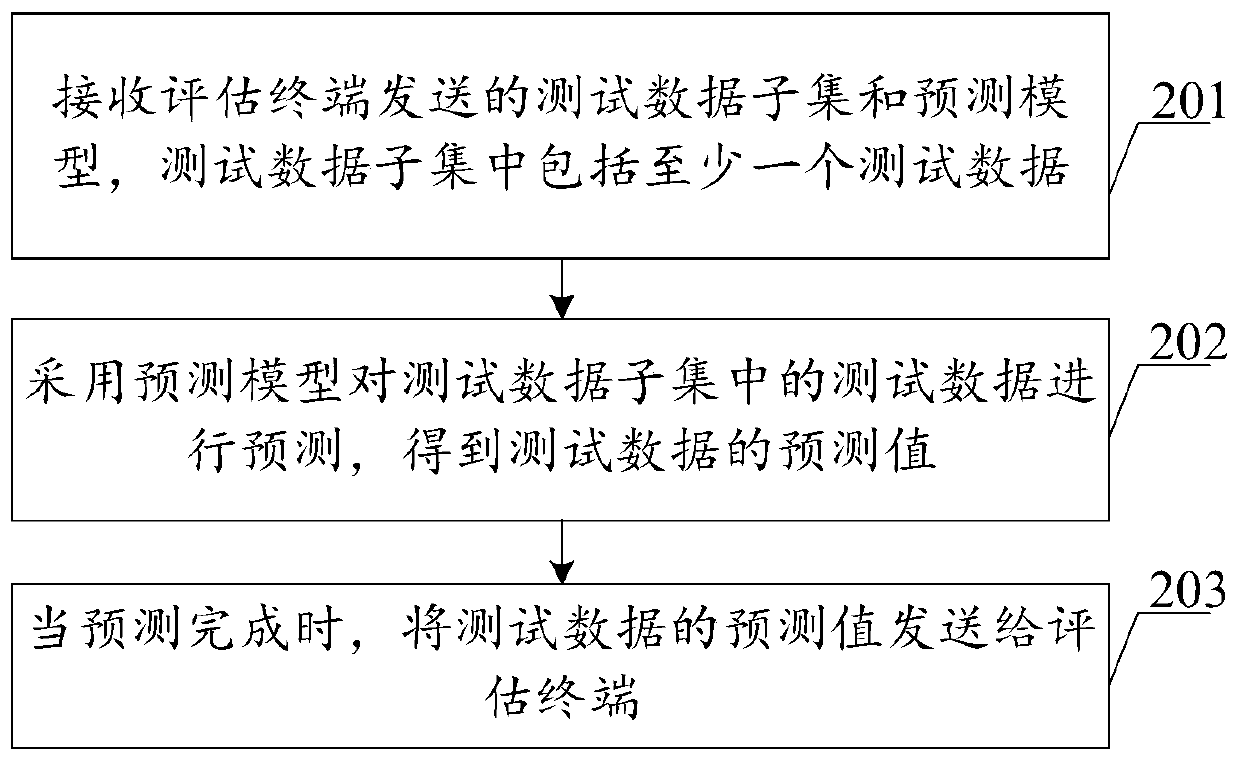

Model quality evaluation method and device

PendingCN110363427AImprove the efficiency of quality assessmentShorten operation timeResourcesMarketingModel qualityData mining

The invention discloses a model quality evaluation method and device. The method includes: obtaining a prediction model and a plurality of test data subsets, wherein each test data subset comprises atleast one piece of test data marked with a real value; sending a prediction request carrying the prediction model and the test data subset to a corresponding prediction terminal in the terminal cluster; when the prediction terminal in the terminal cluster completes prediction, obtaining a prediction value of the test data from the prediction terminal, and obtaining a prediction value of the testdata in each test data subset; classifying the test data according to the predicted value and the true value of the test data to obtain the category to which the test data in the plurality of test data subsets belongs; and calculating a model quality parameter of the prediction model according to the category to which the test data in the plurality of test data subsets belongs. According to the method, prediction is carried out in a clustering mode, and the calculation time of the prediction value is shortened, so that the model quality evaluation efficiency can be improved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com