Patents

Literature

276results about How to "No unevenness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

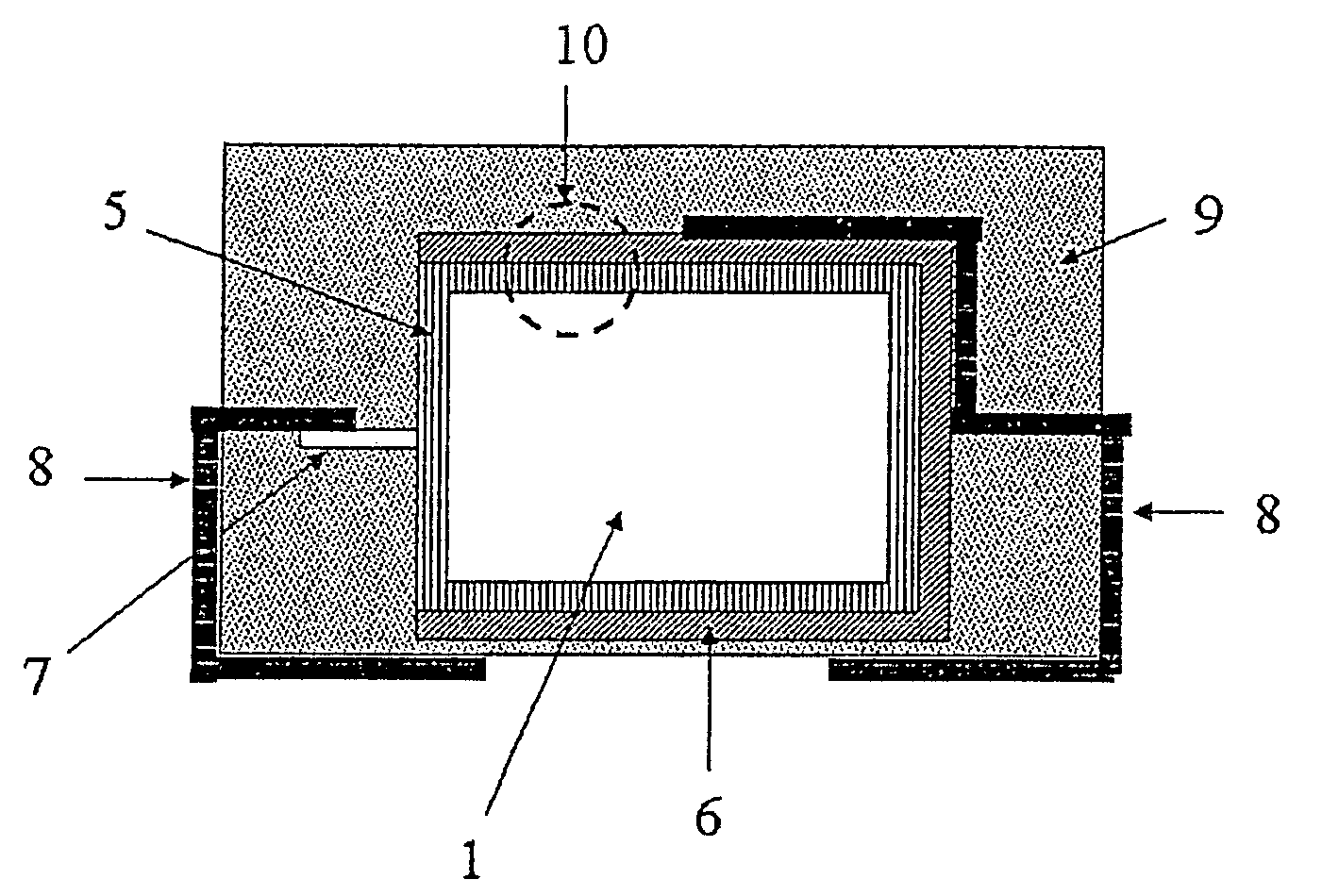

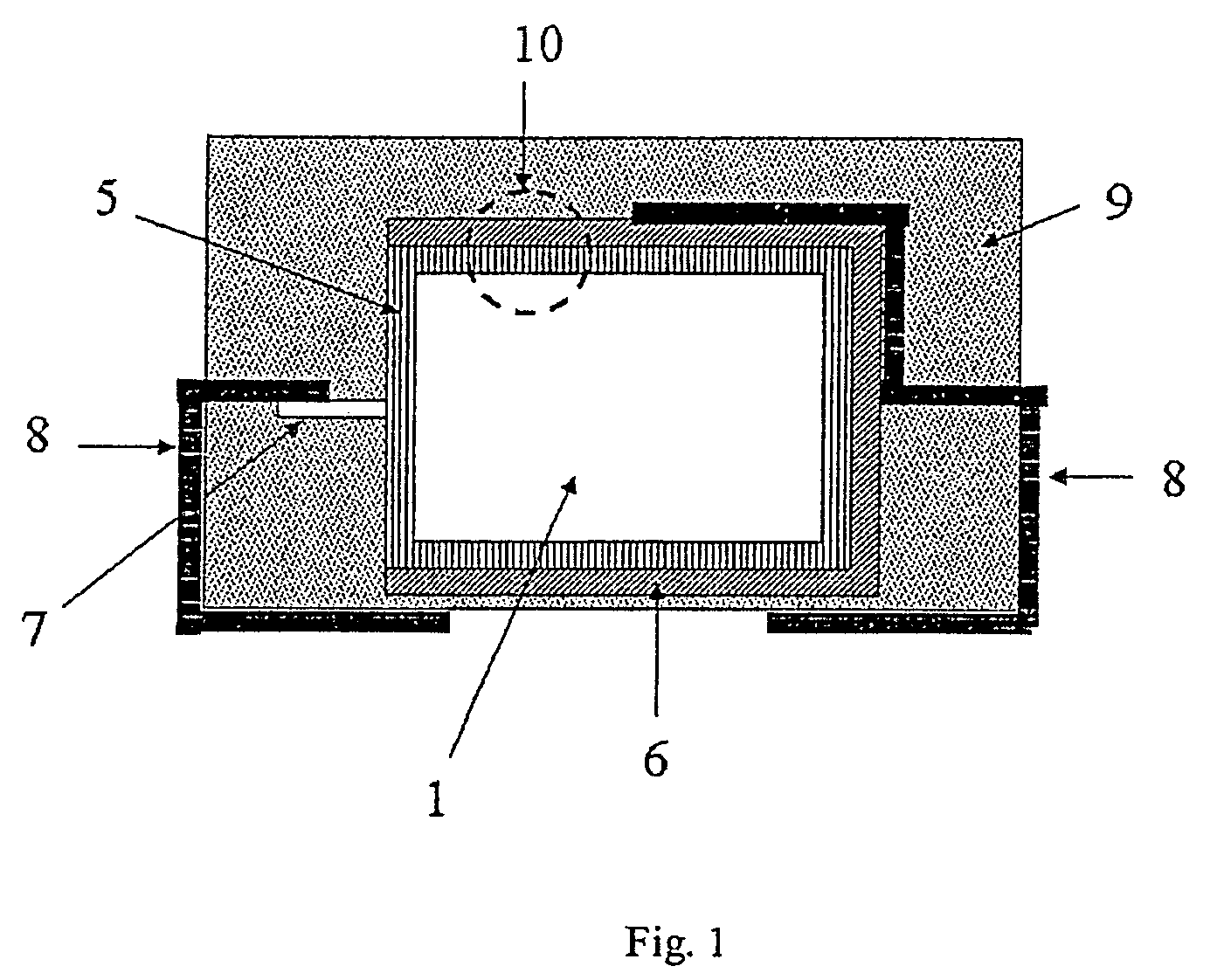

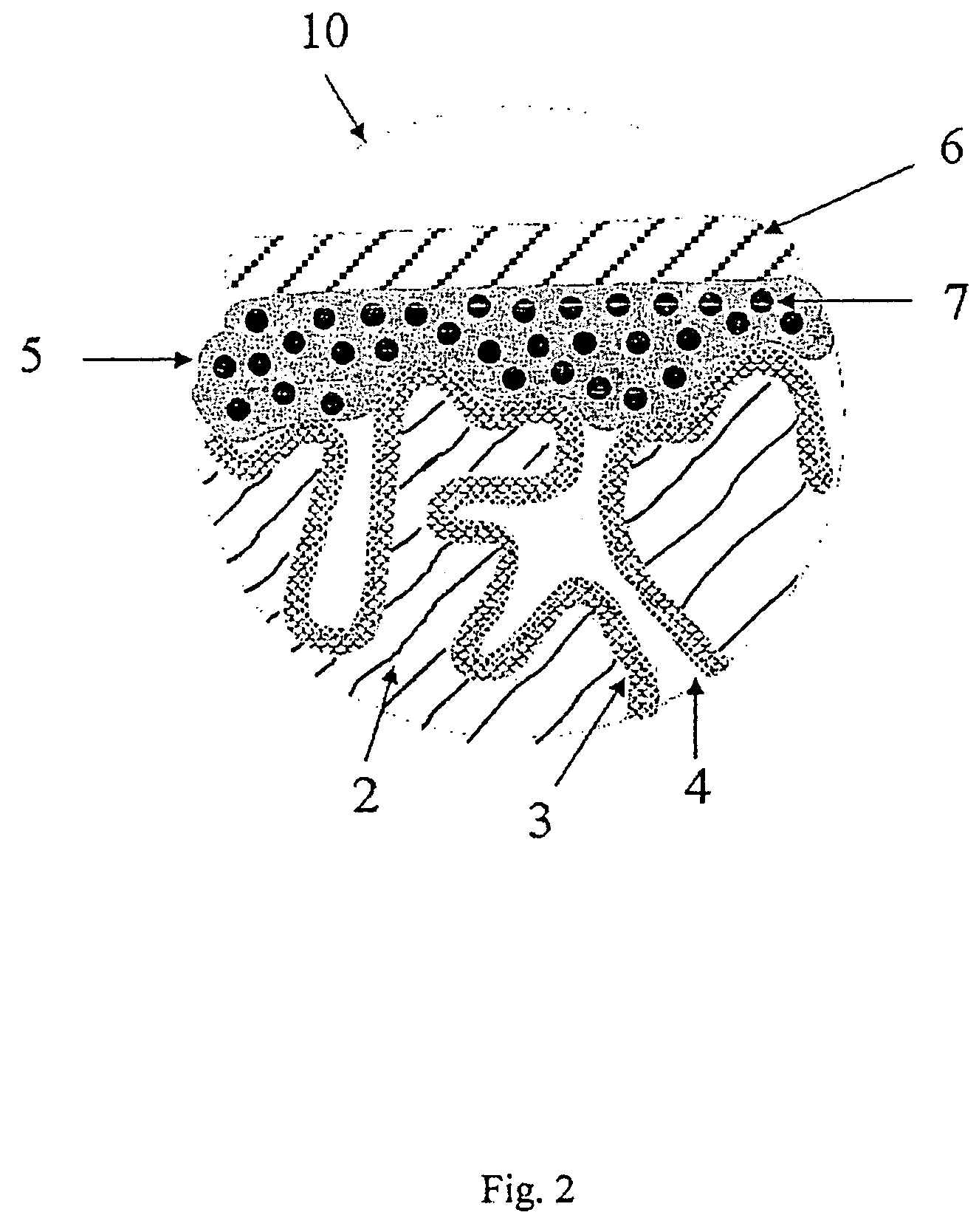

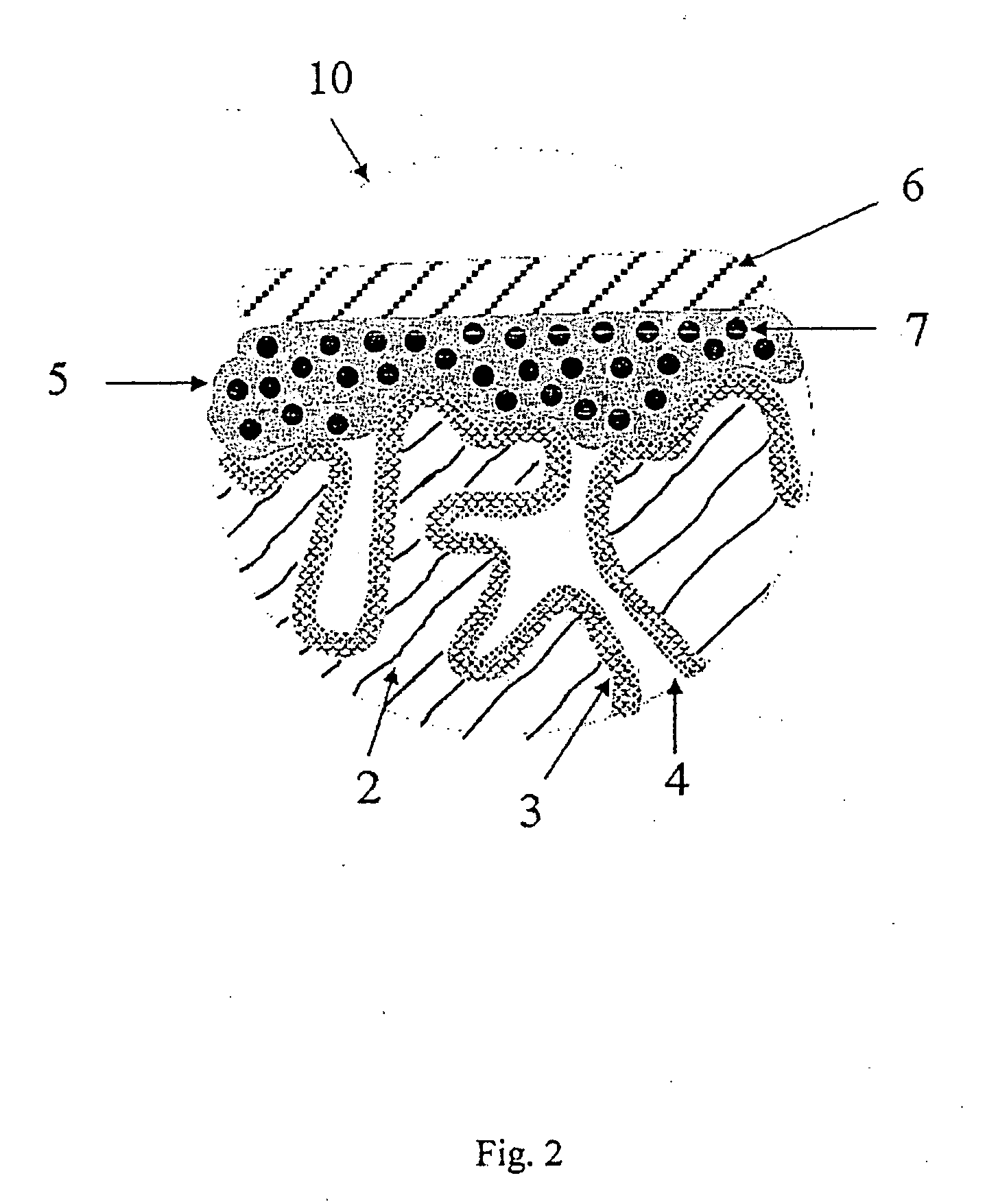

Electrolytic capacitors with a polymeric outer layer and process for the production thereof

ActiveUS7411779B2Lower equivalent series resistanceIncrease coverageHybrid capacitor electrolytesSolid electrolytic capacitorsElectrolysisConductive polymer

The invention relates to a process for the production of electrolytic capacitors with low equivalent series resistance and low residual current consisting of a solid electrolyte made of conductive polymers and an outer layer containing conductive polymers, to electrolytic capacitors produced by this process and to the use of such electrolytic capacitors.

Owner:HERAEUS PRECIOUS METALS GMBH & CO KG

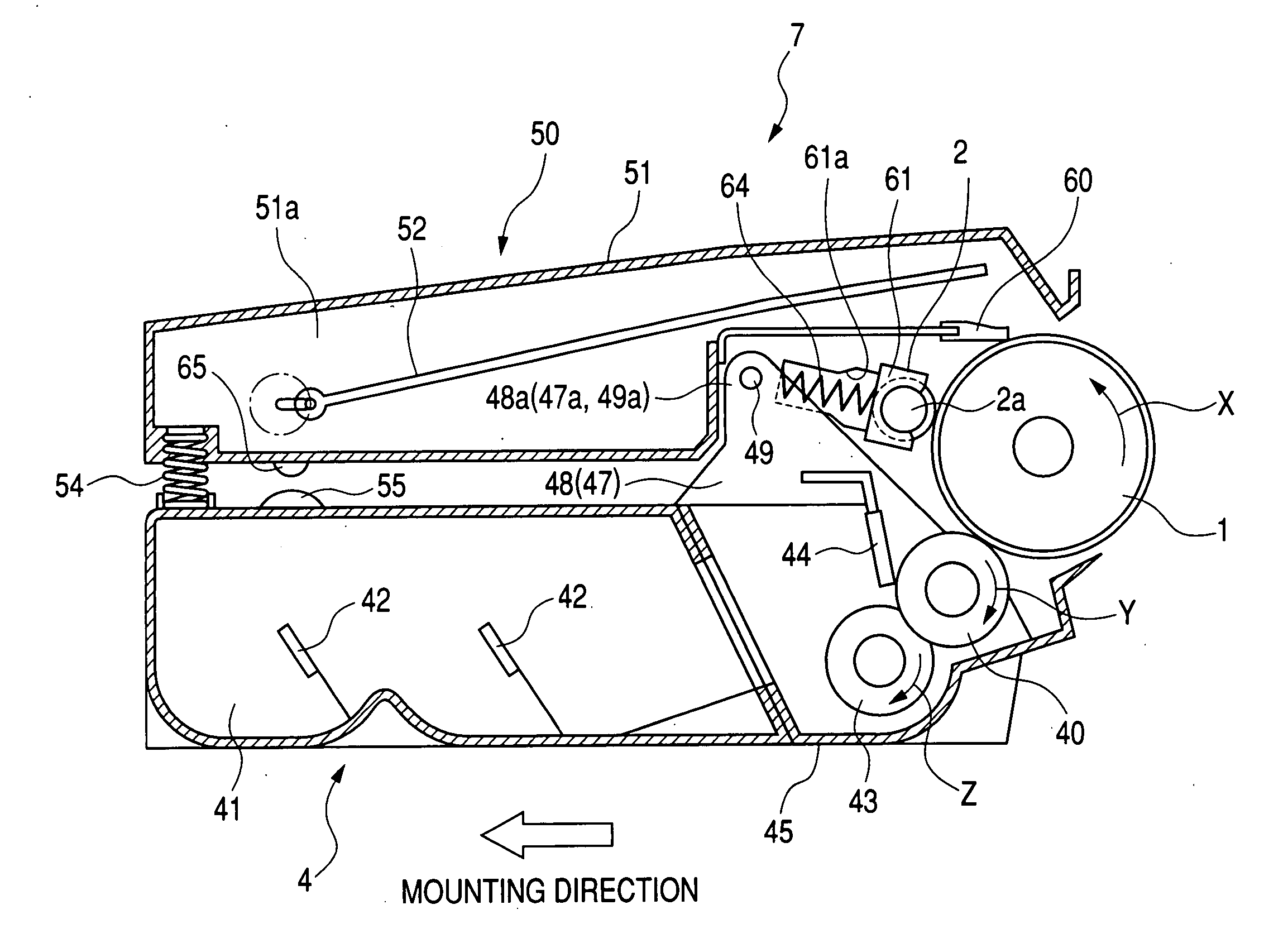

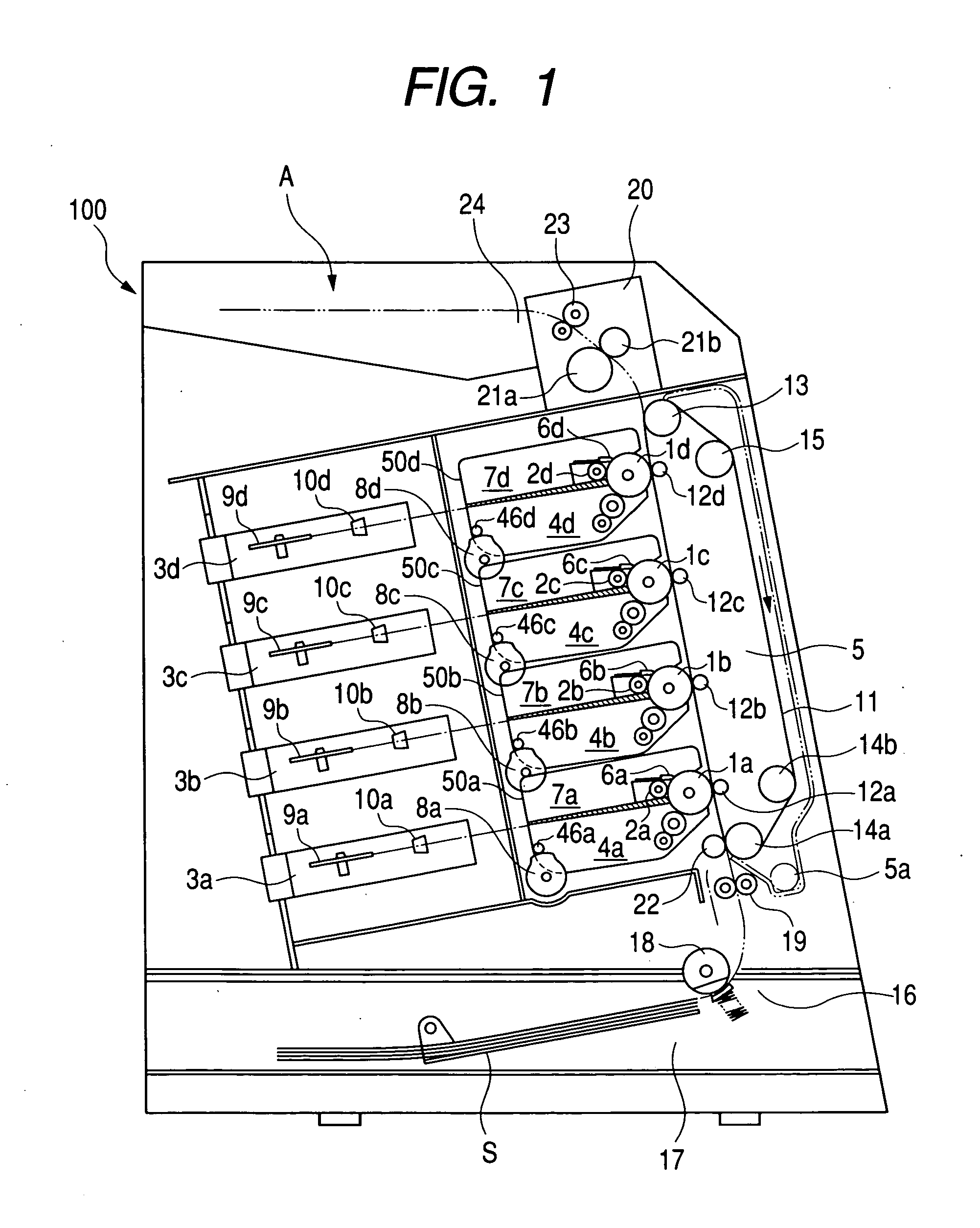

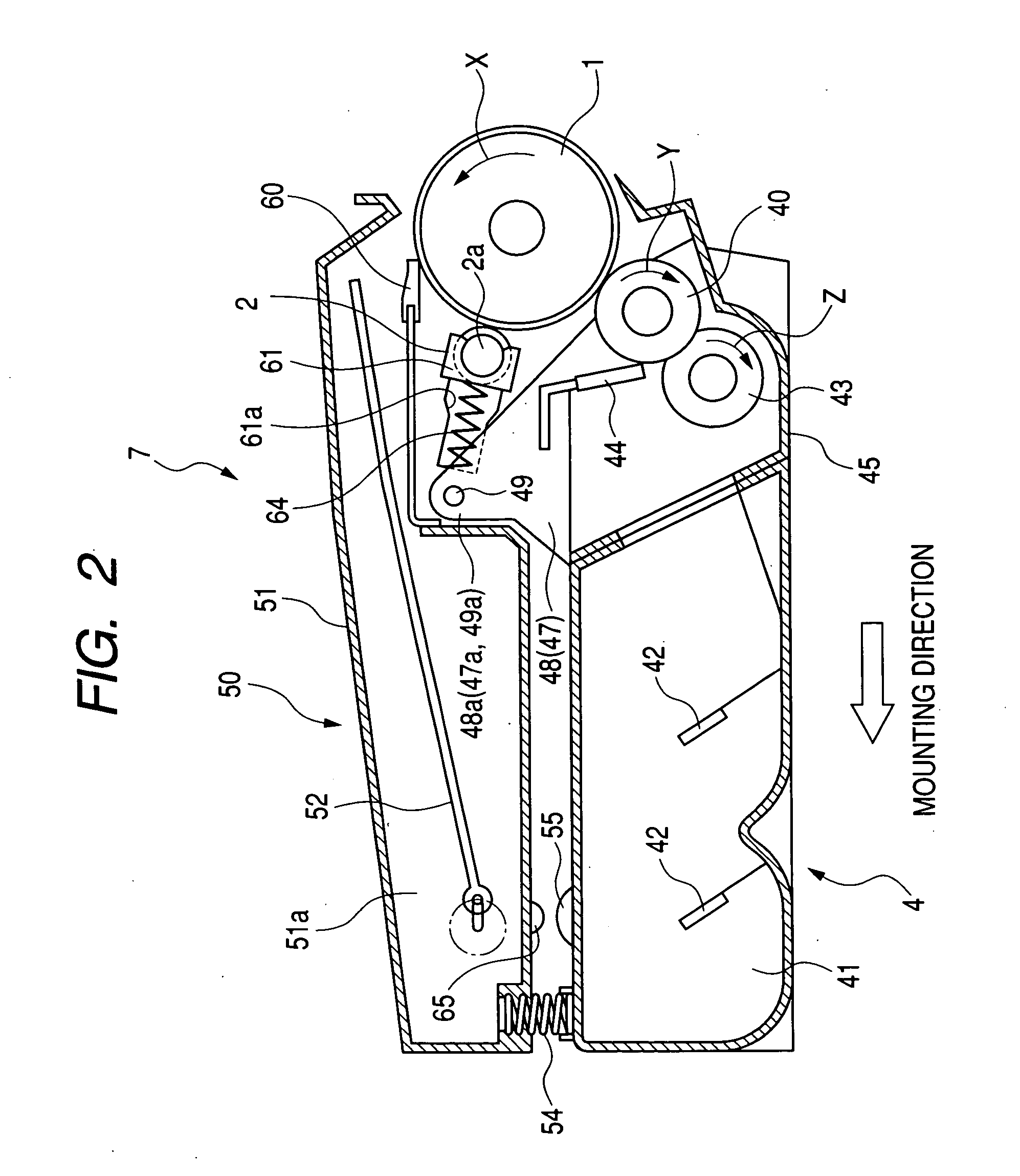

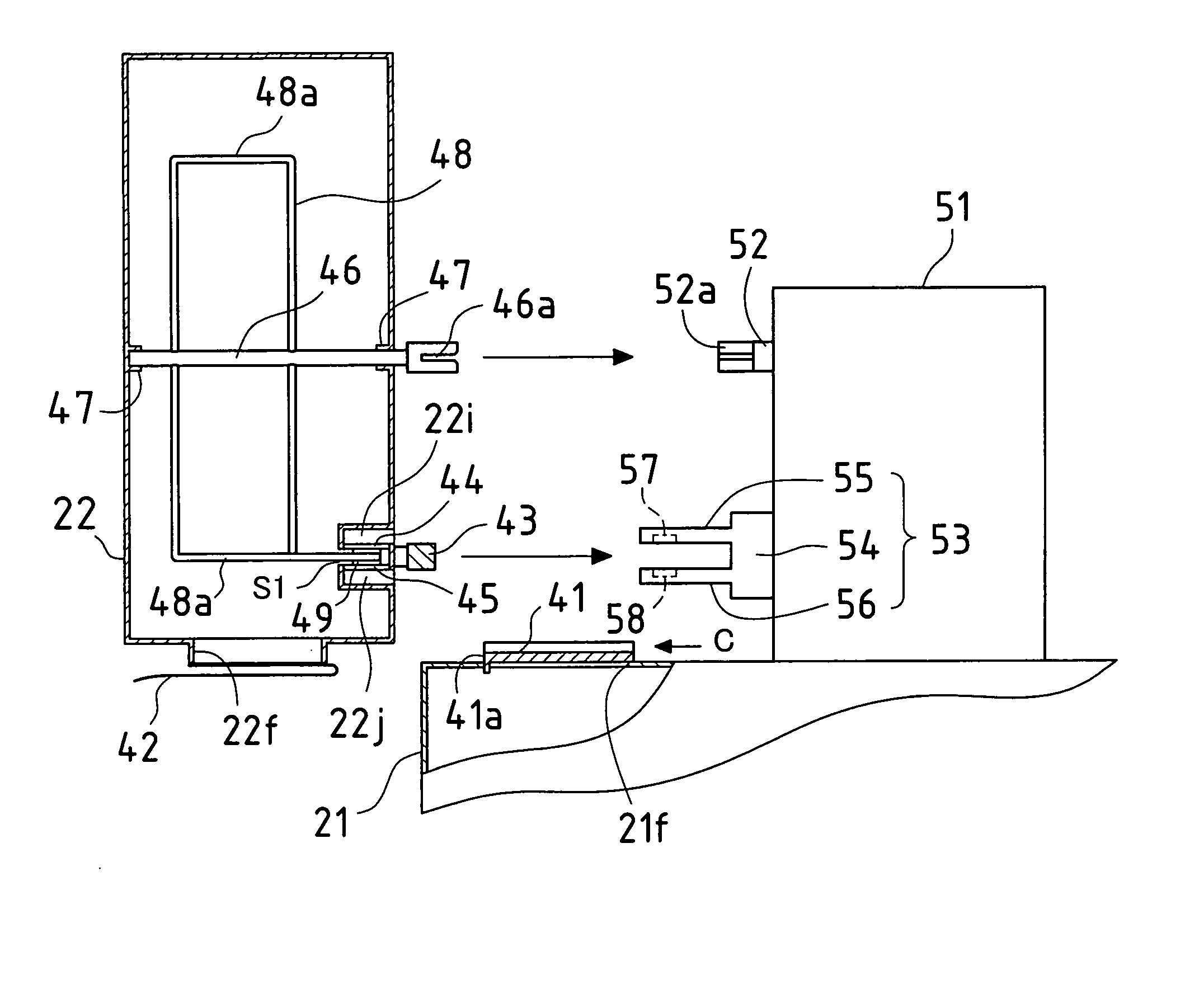

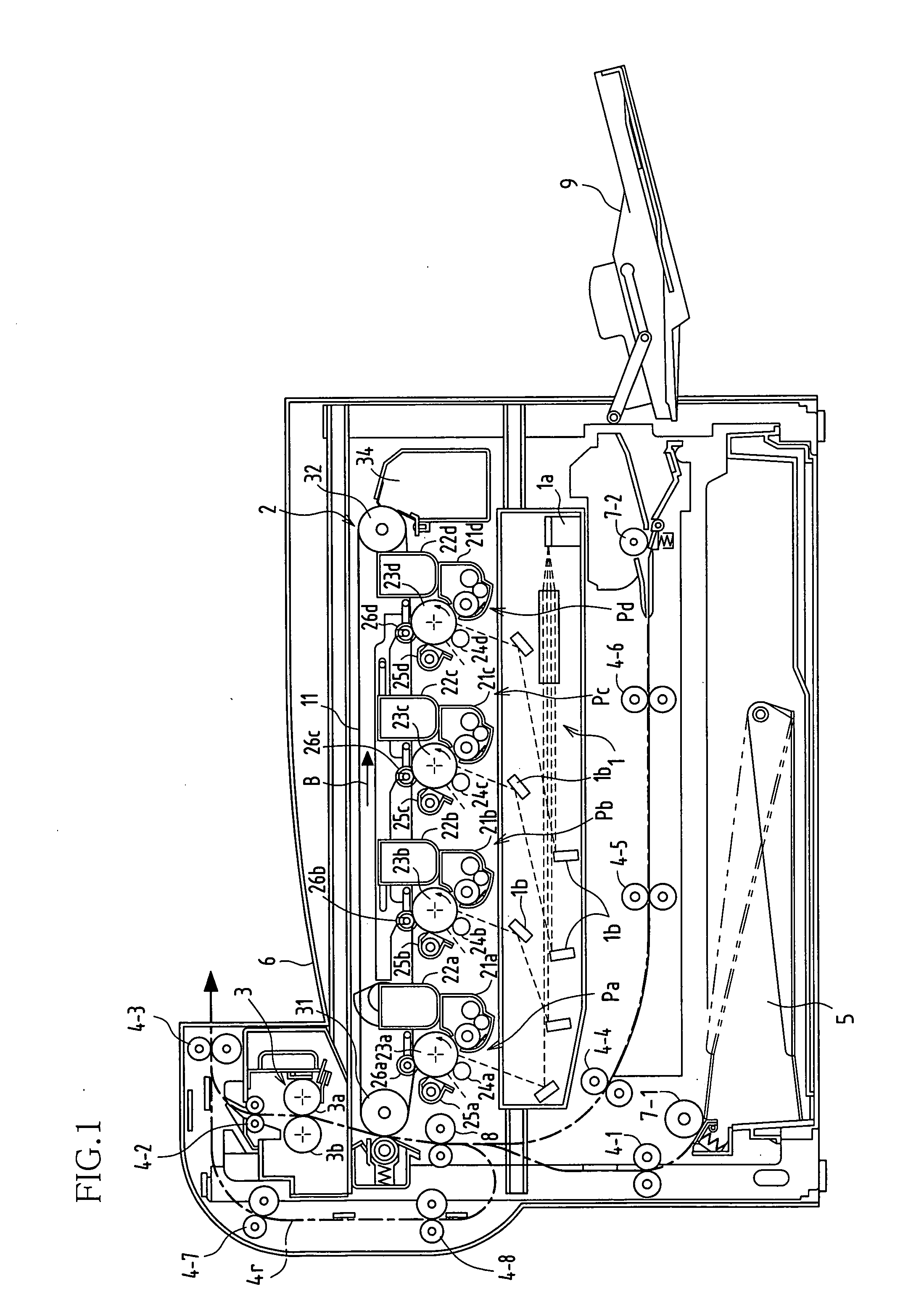

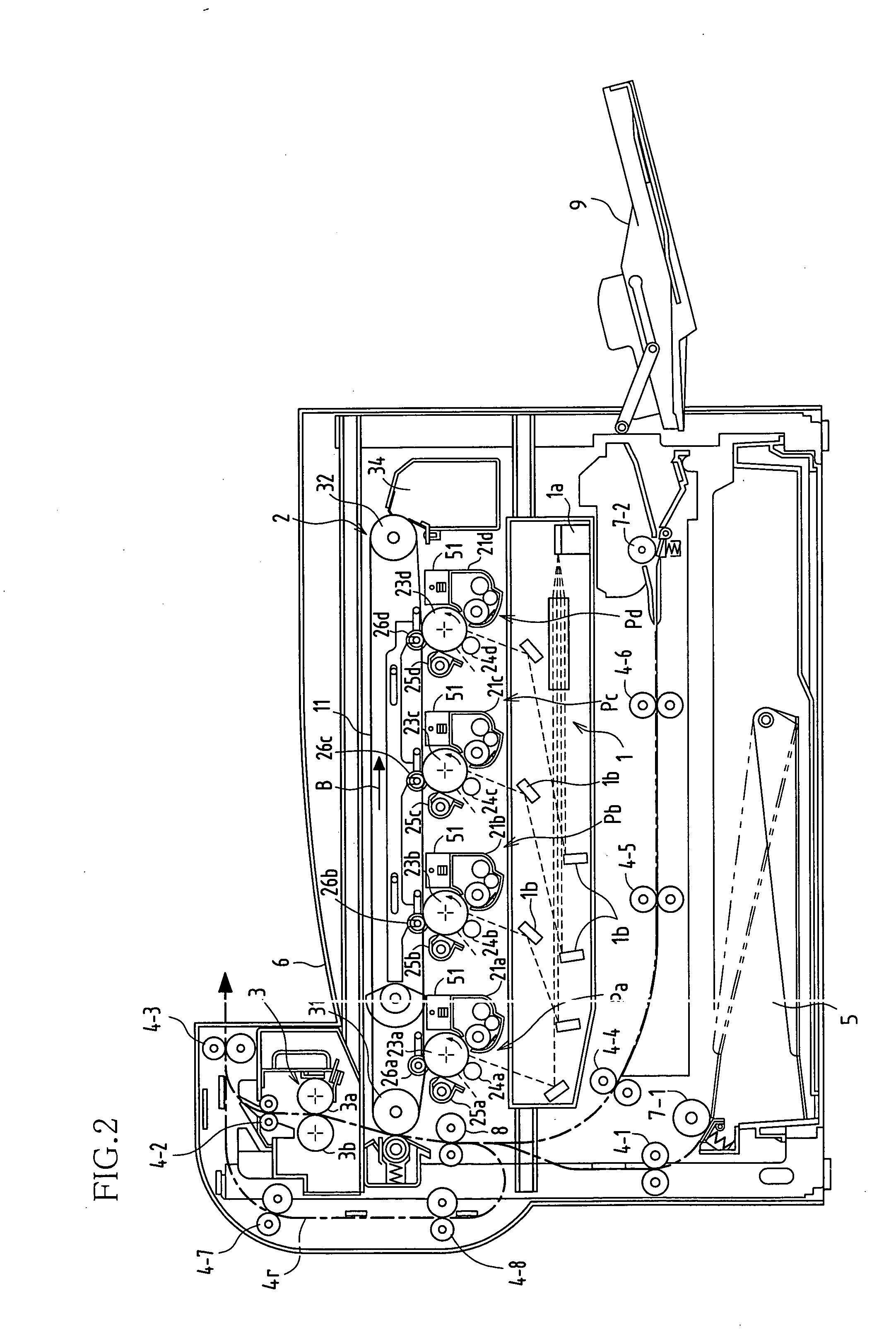

Process cartridge and electrophotographic image forming apparatus

InactiveUS20050069342A1Inexpensive and space-savingEasy constructionElectrographic process apparatusCorona dischargeImaging equipmentBiomedical engineering

A process cartridge and an electrophotographic image forming apparatus in which both a developing member and a charging member are separable from an electrophotographic photosensitive member by changing the swinging attitudes of a photosensitive member unit and a developing unit, thereby making it possible to obtain, with a simple construction, a stable image free from unevenness or transversal streaks.

Owner:CANON KK

Electrolytic capacitors with a polymeric outer layer and process for the production thereof

ActiveUS20070171597A1Good edge coverageSimple and reliably reproducibleHybrid capacitor electrolytesSolid electrolytic capacitorsCapacitanceElectrolysis

The invention relates to a process for the production of electrolytic capacitors with low equivalent series resistance and low residual current consisting of a solid electrolyte made of conductive polymers and an outer layer containing conductive polymers, to electrolytic capacitors produced by this process and to the use of such electrolytic capacitors.

Owner:HERAEUS PRECIOUS METALS GMBH & CO KG

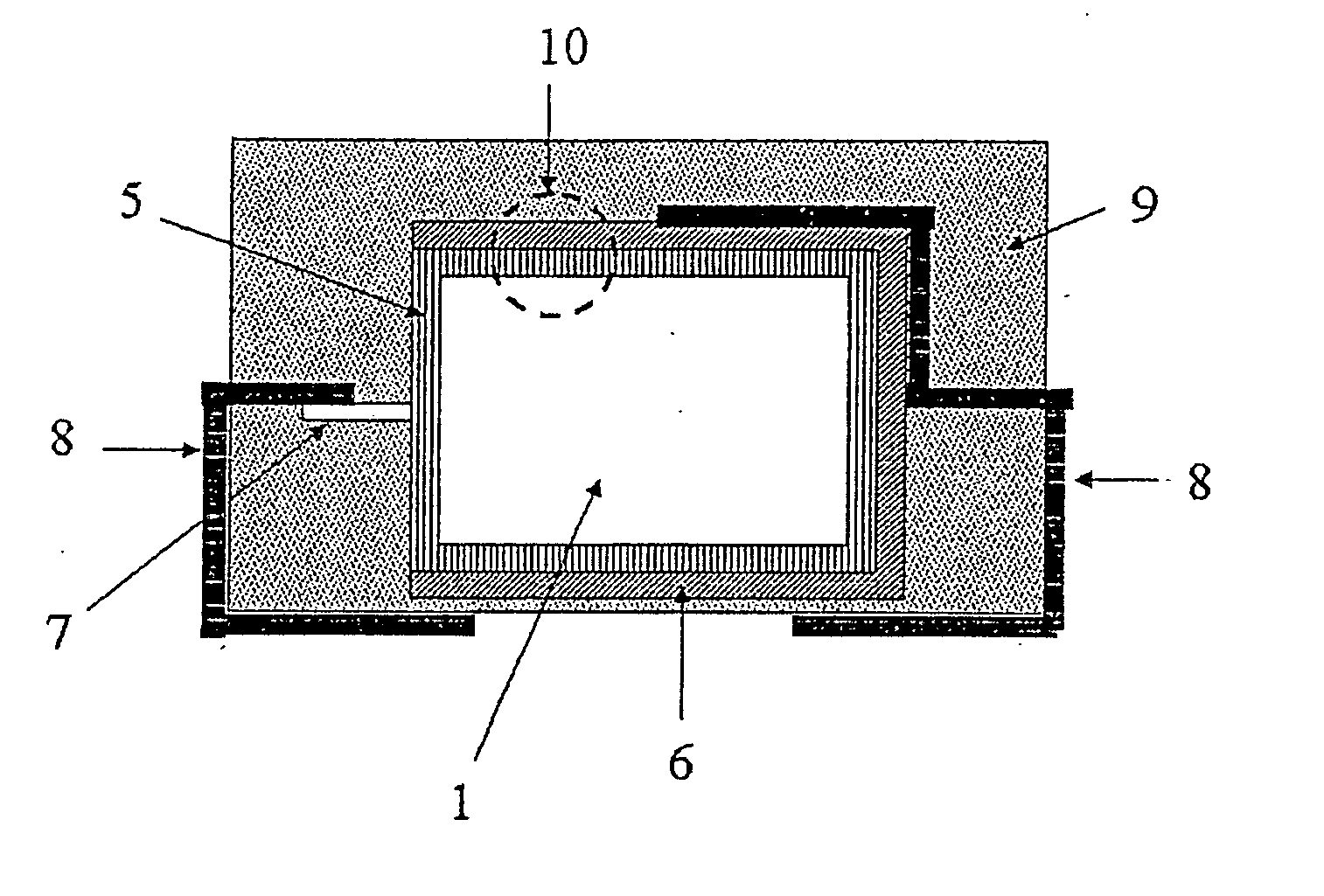

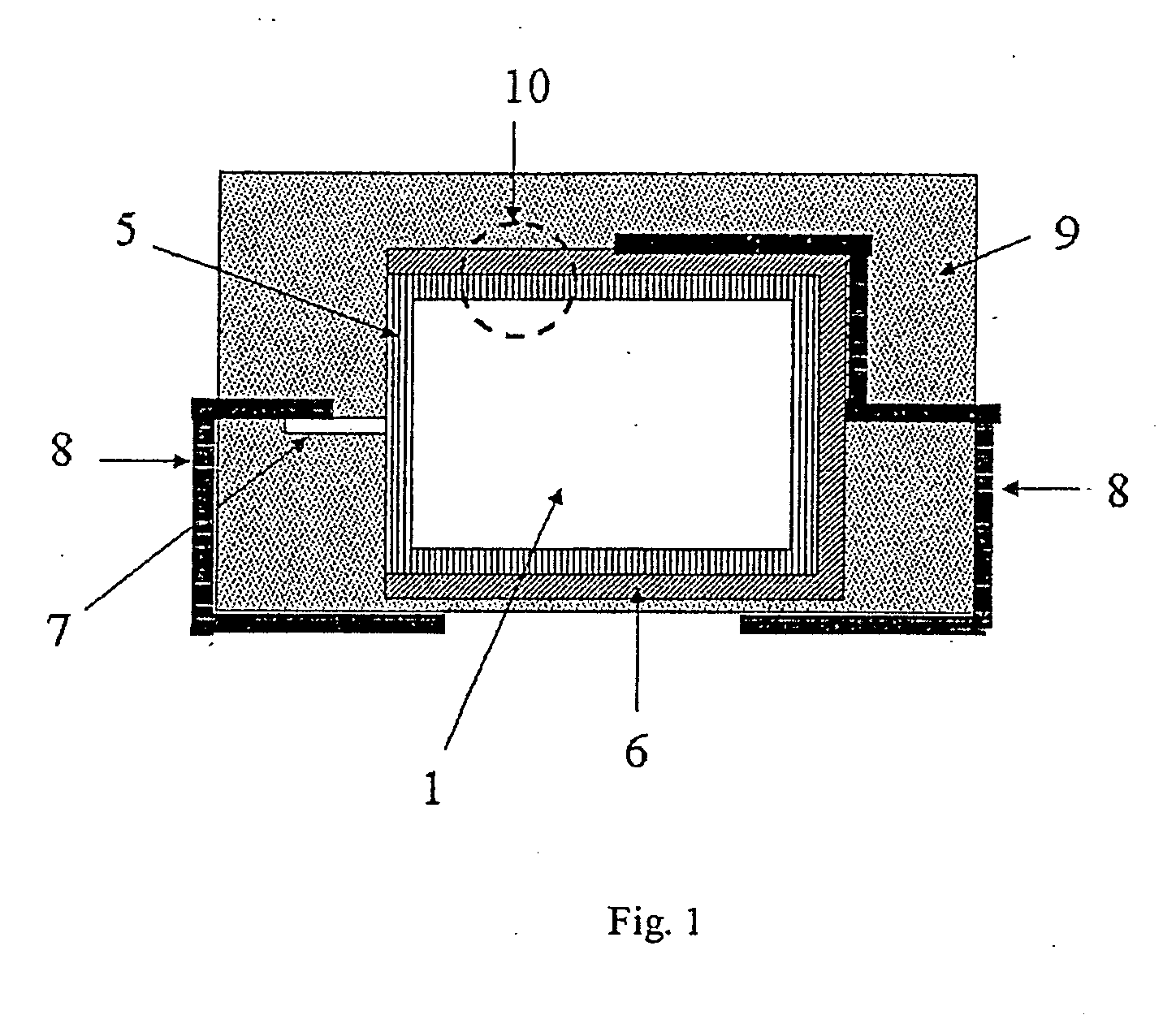

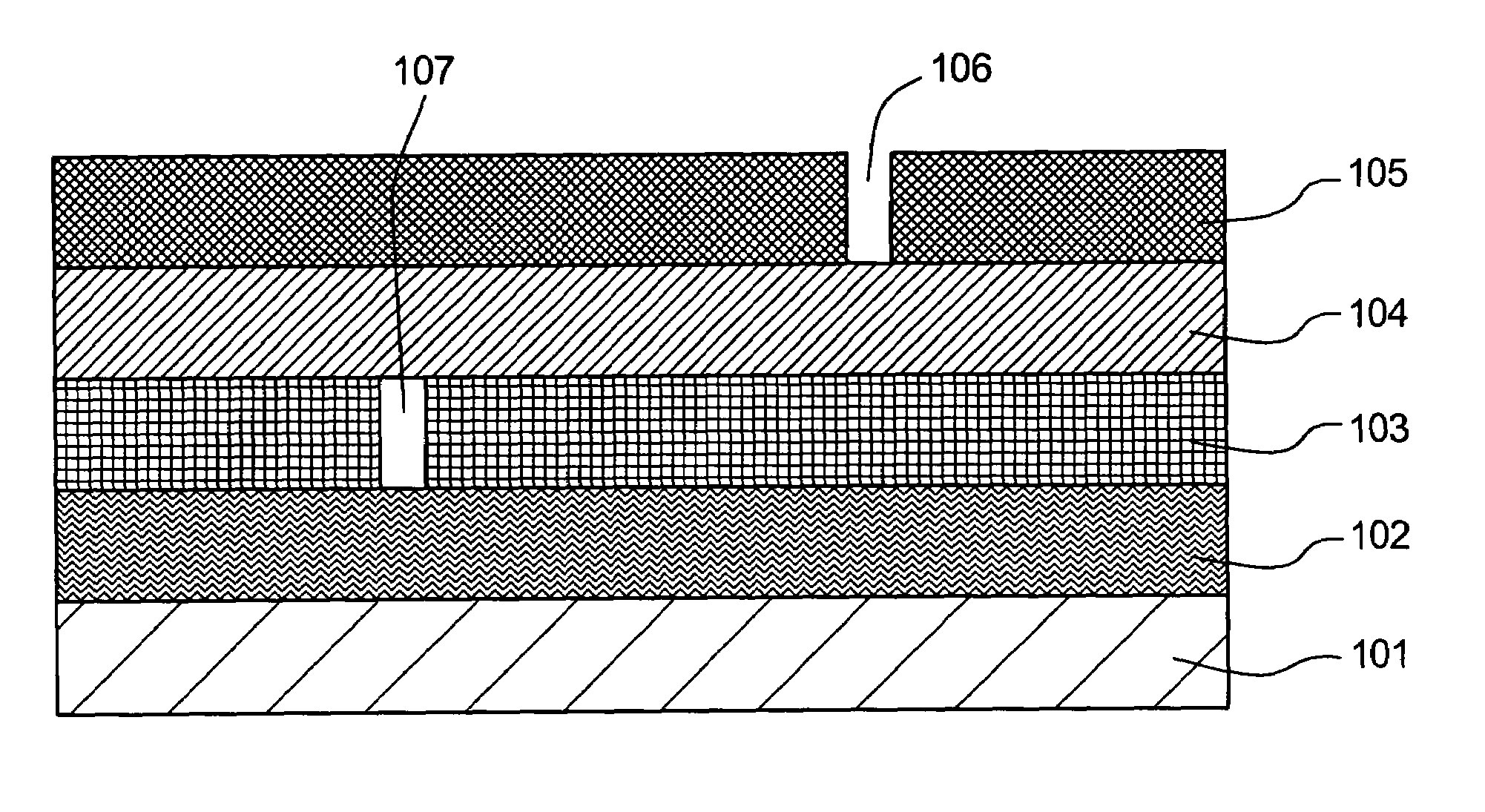

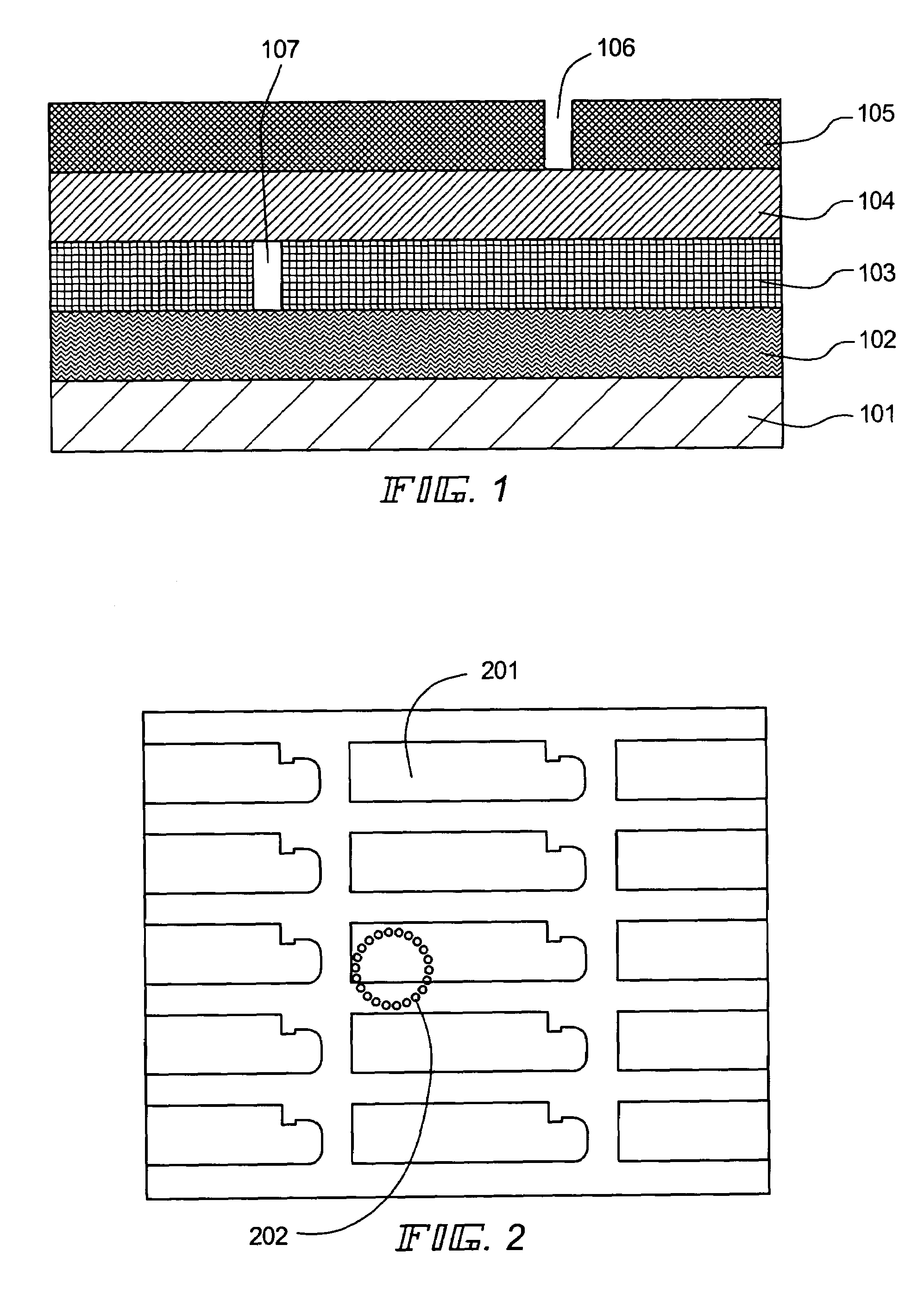

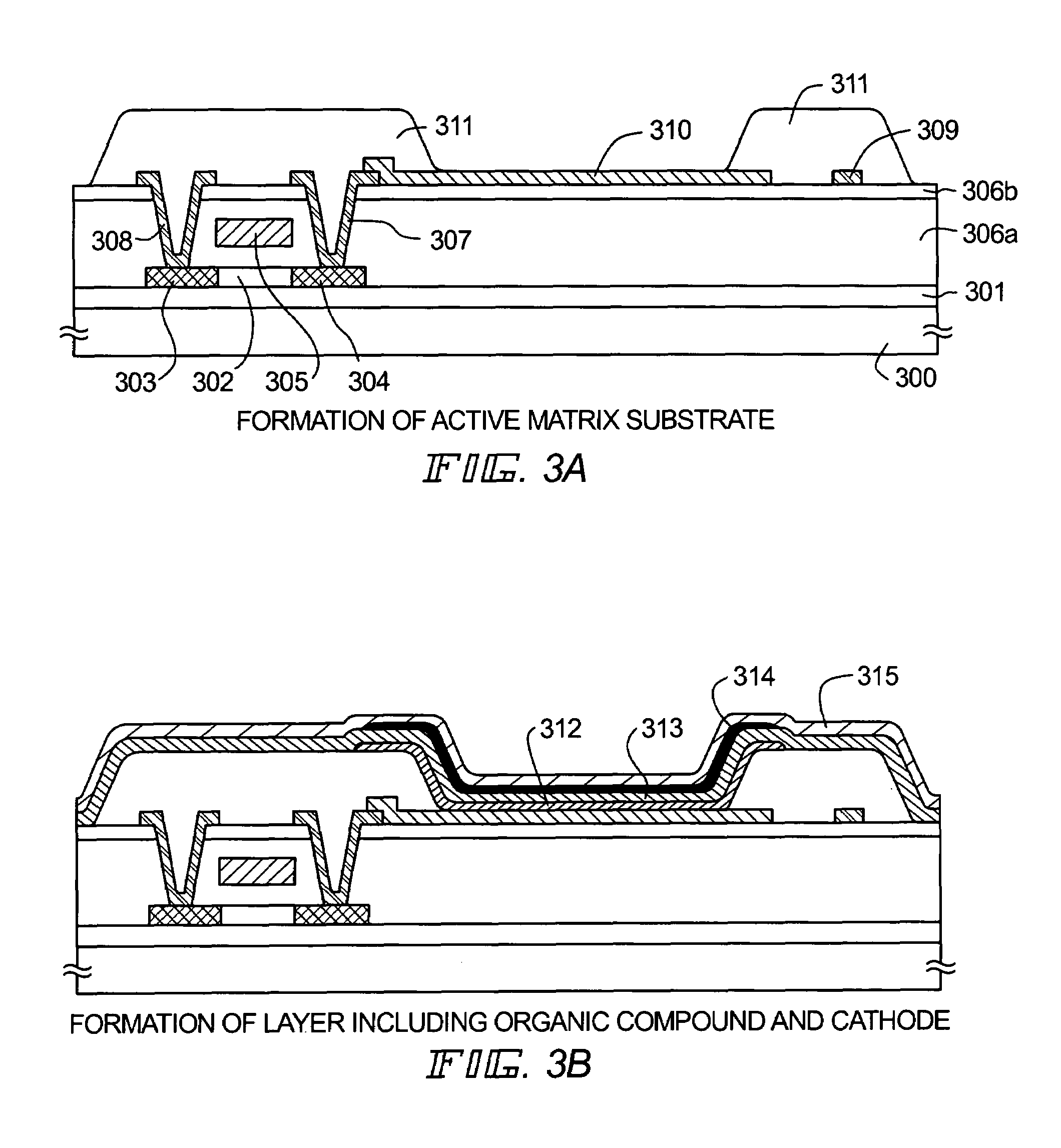

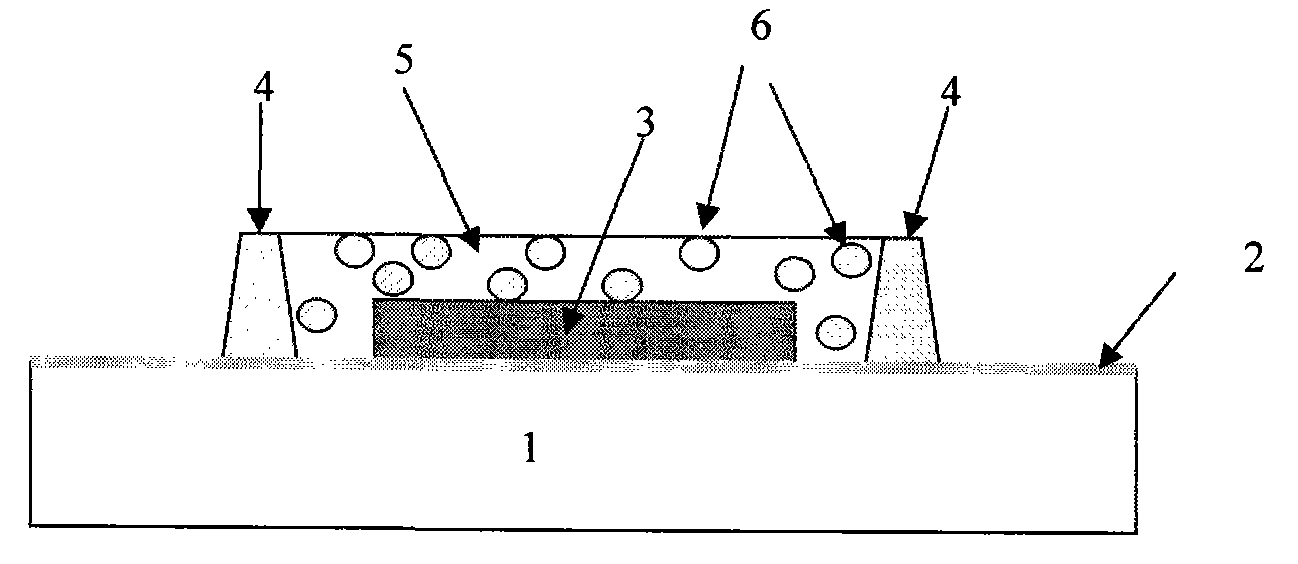

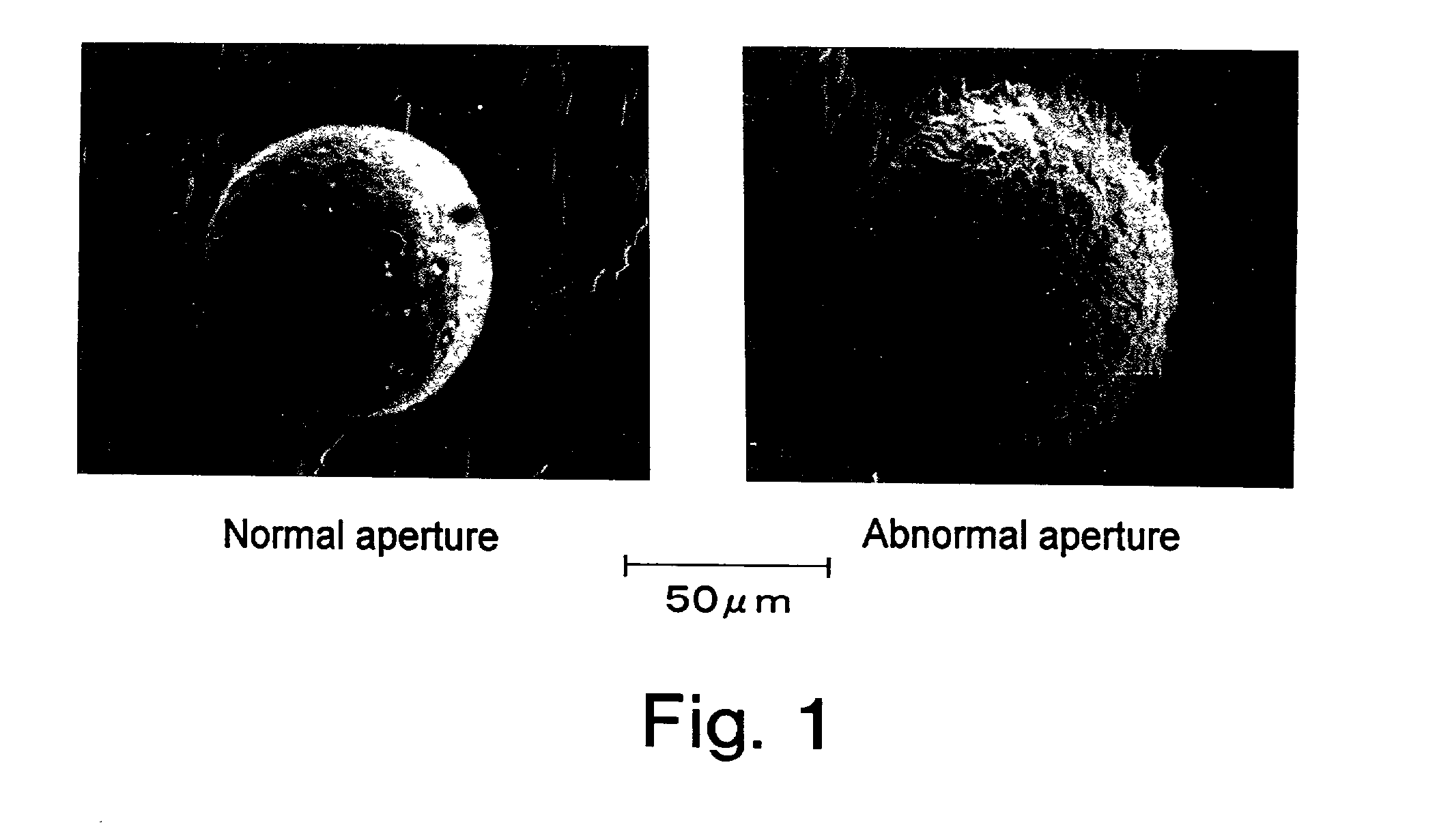

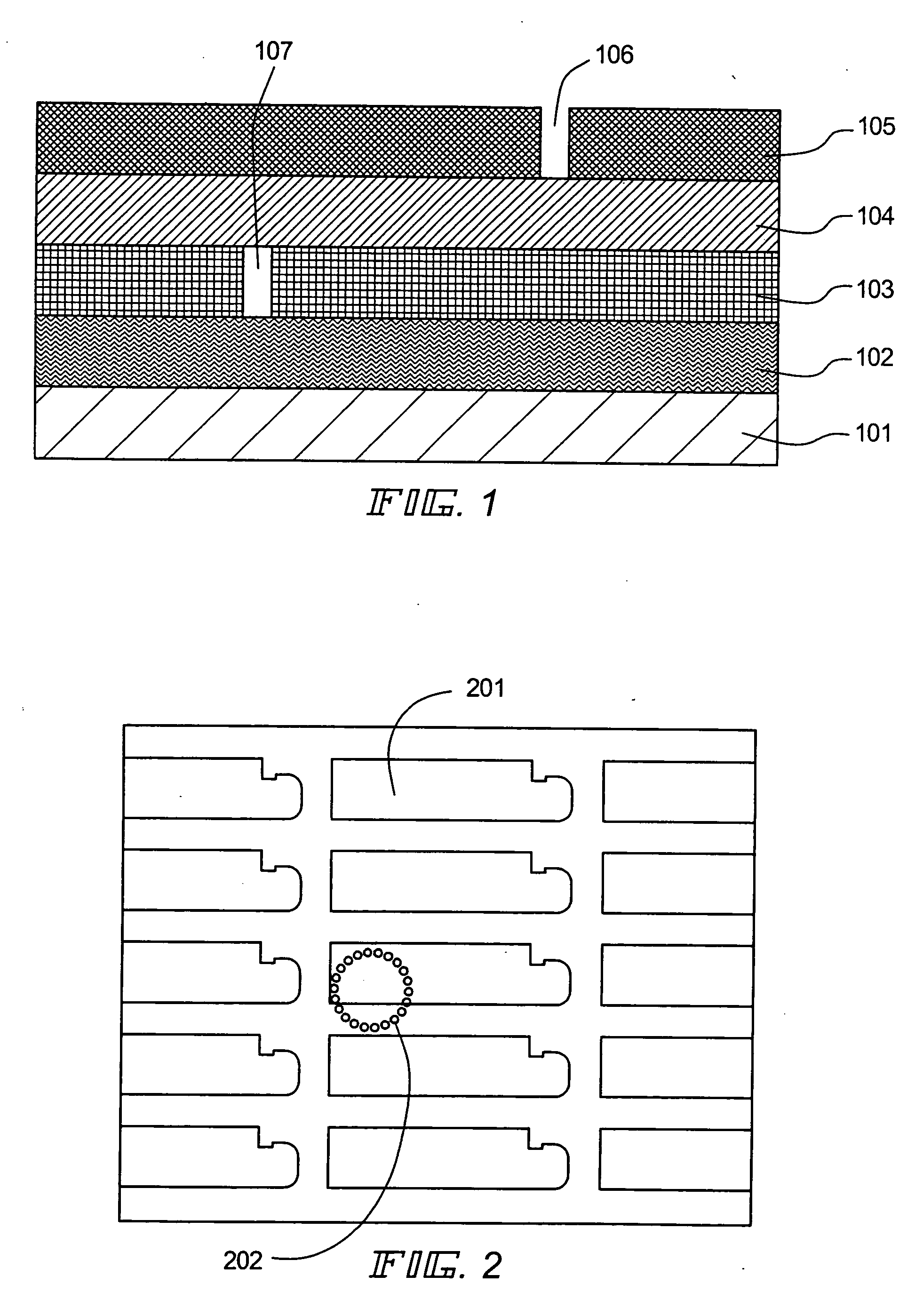

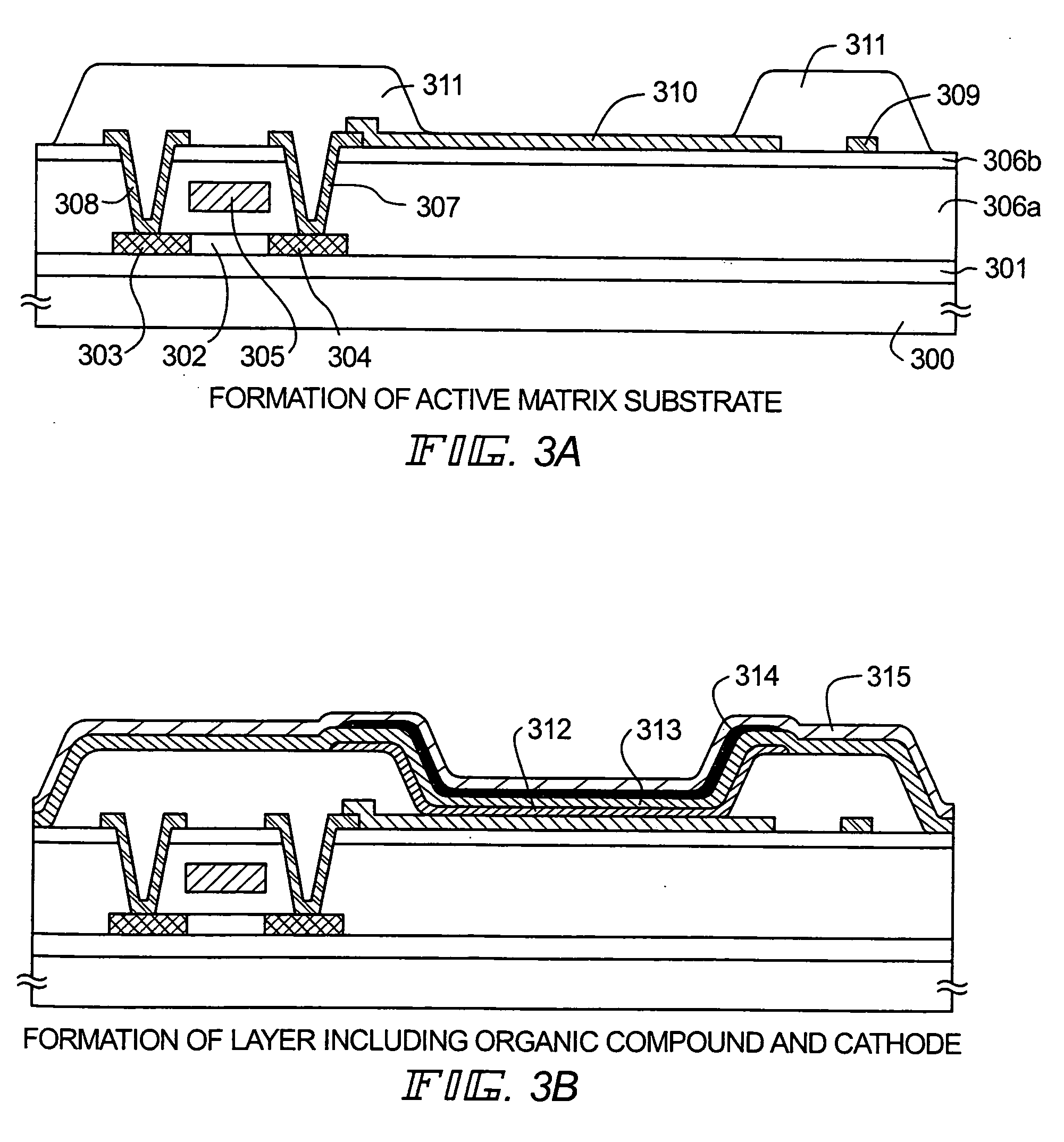

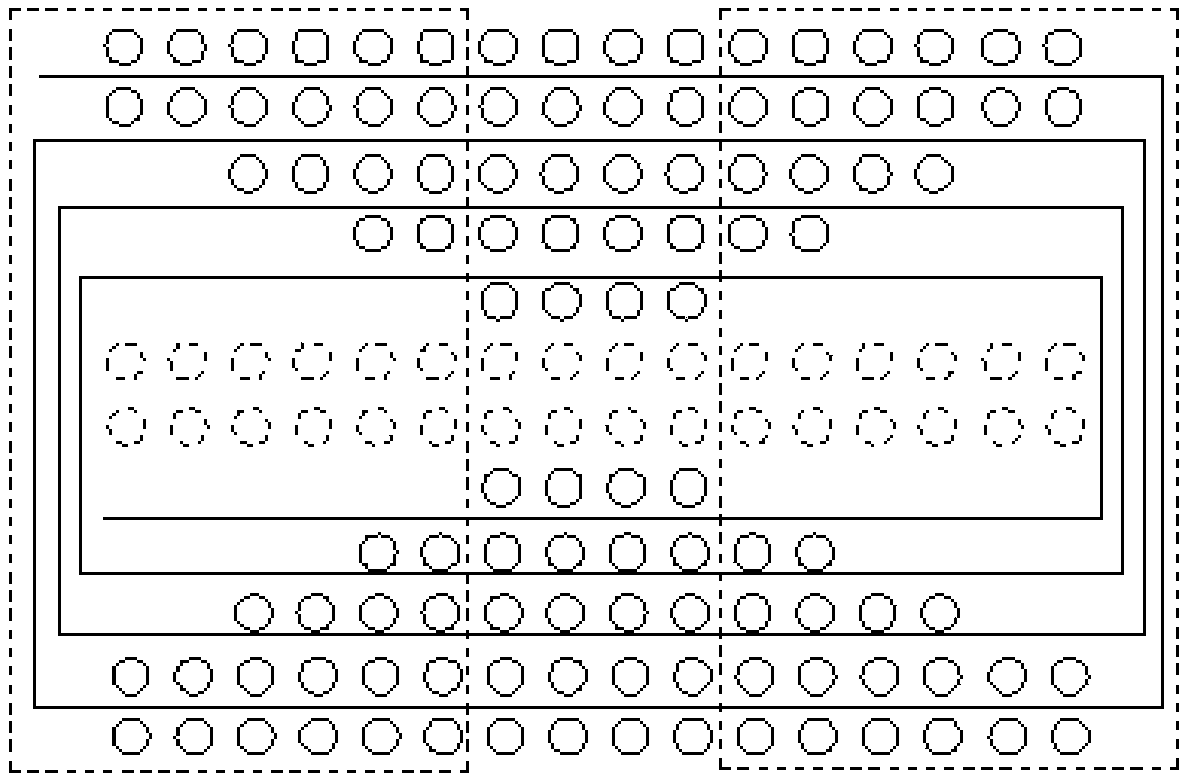

Light-emitting device having electrode formed by laminate of at least first inorganic film, organic film, and second inorganic film and method for manufacturing the same

InactiveUS7045822B2Reduce pinholesImprove reliabilityDischarge tube luminescnet screensElectroluminescent light sourcesOrganic filmDark spot

The present invention provides an organic light-emitting element where a lower electrode, an organic compound layer and an upper electrode are laminated on a substrate, wherein the upper electrode of the organic EL element is formed by a laminate of at least a conductive first inorganic film, a conductive organic film and a conductive second inorganic film, in order to suppress the occurrence of dark spot, so that the occurrence of pinholes in the upper electrode leading to dark spots is suppressed. Here, pinholes refer to holes in the upper electrode that penetrate upper electrode from the organic compound layer underneath to the atmosphere above.

Owner:SEMICON ENERGY LAB CO LTD

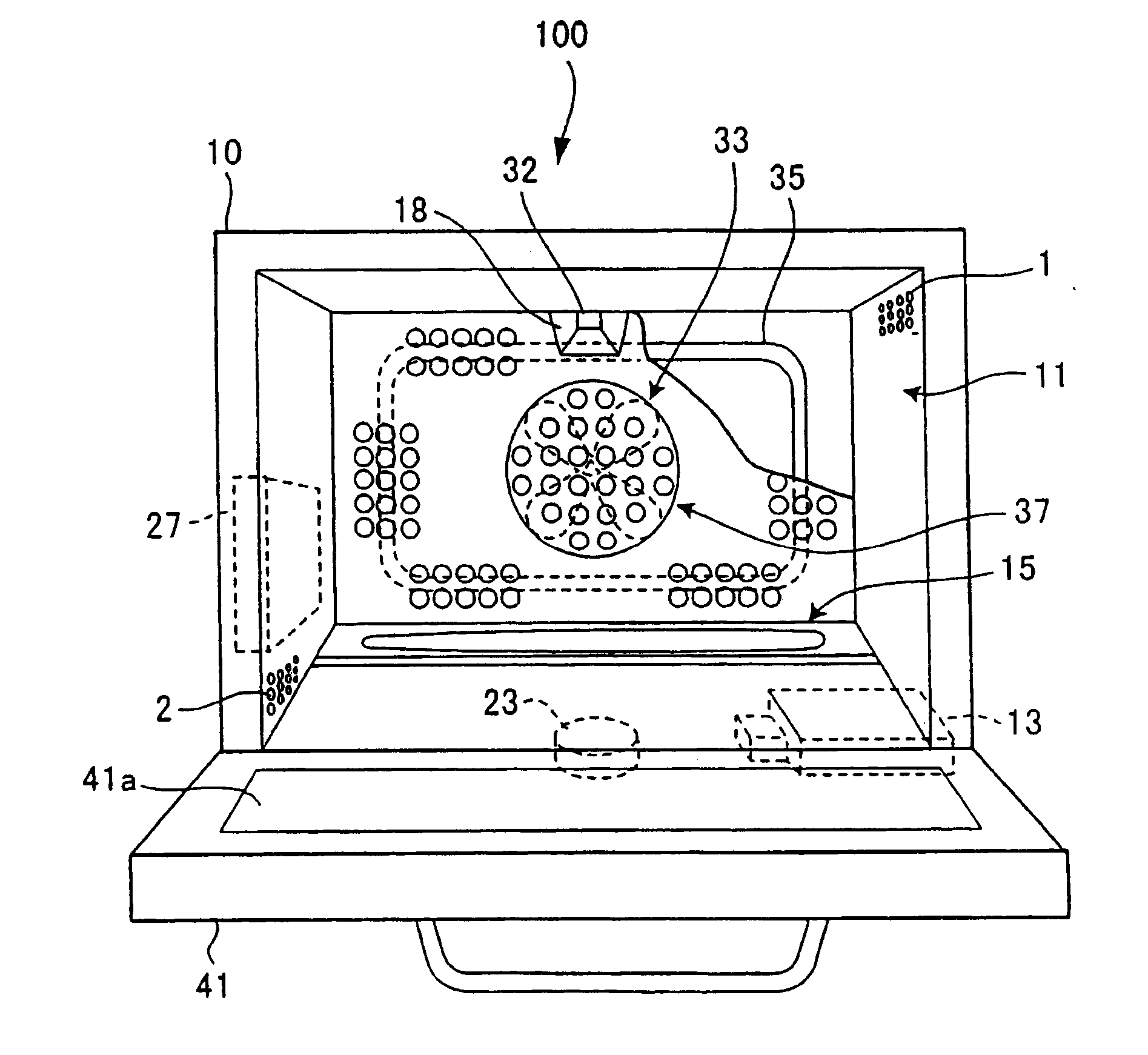

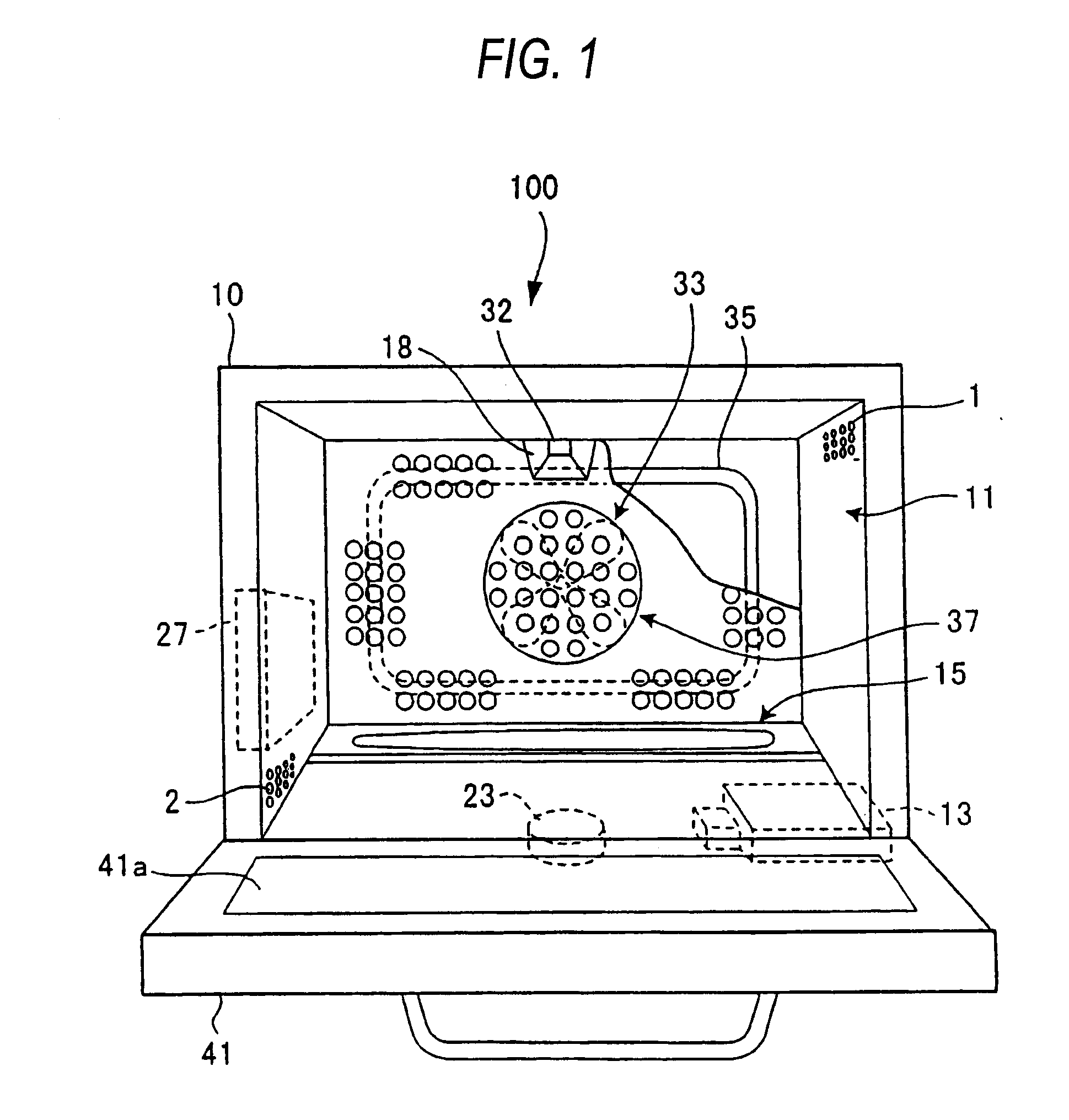

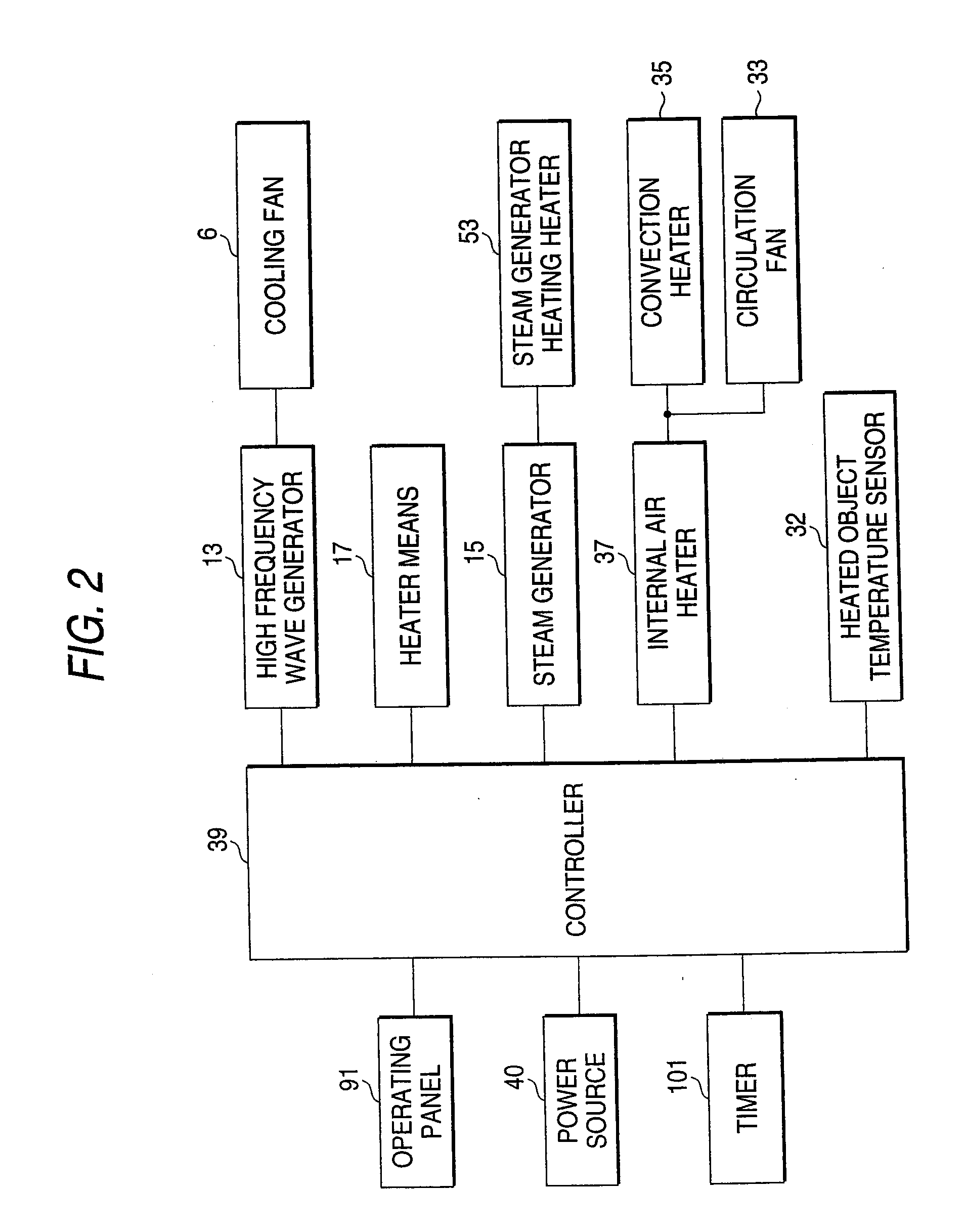

Thawing method

InactiveUS20070029311A1No unevennessDomestic stoves or rangesLighting and heating apparatusDewHigh frequency

To provide a thawing method wherein a frozen commodity can be thawed, in a short time, from the inside with no unevenness. The thawing method, which thaws a frozen commodity by high frequency heating, includes: a first high frequency heating step in which the frozen commodity is high frequency heated to the vicinity of a melting temperature; a temperature detection step which measures the temperature of the frozen commodity during the first high frequency heating step and detects that the measured temperature has reached the melting temperature; a steam supplying step which starts a steam supply when the melting temperature is detected in the temperature detection step, thus forming a film of dew condensation on the surface of the frozen commodity; and a second high frequency heating step in which the frozen commodity is high frequency heated after the start of the steam supplying step.

Owner:PANASONIC CORP

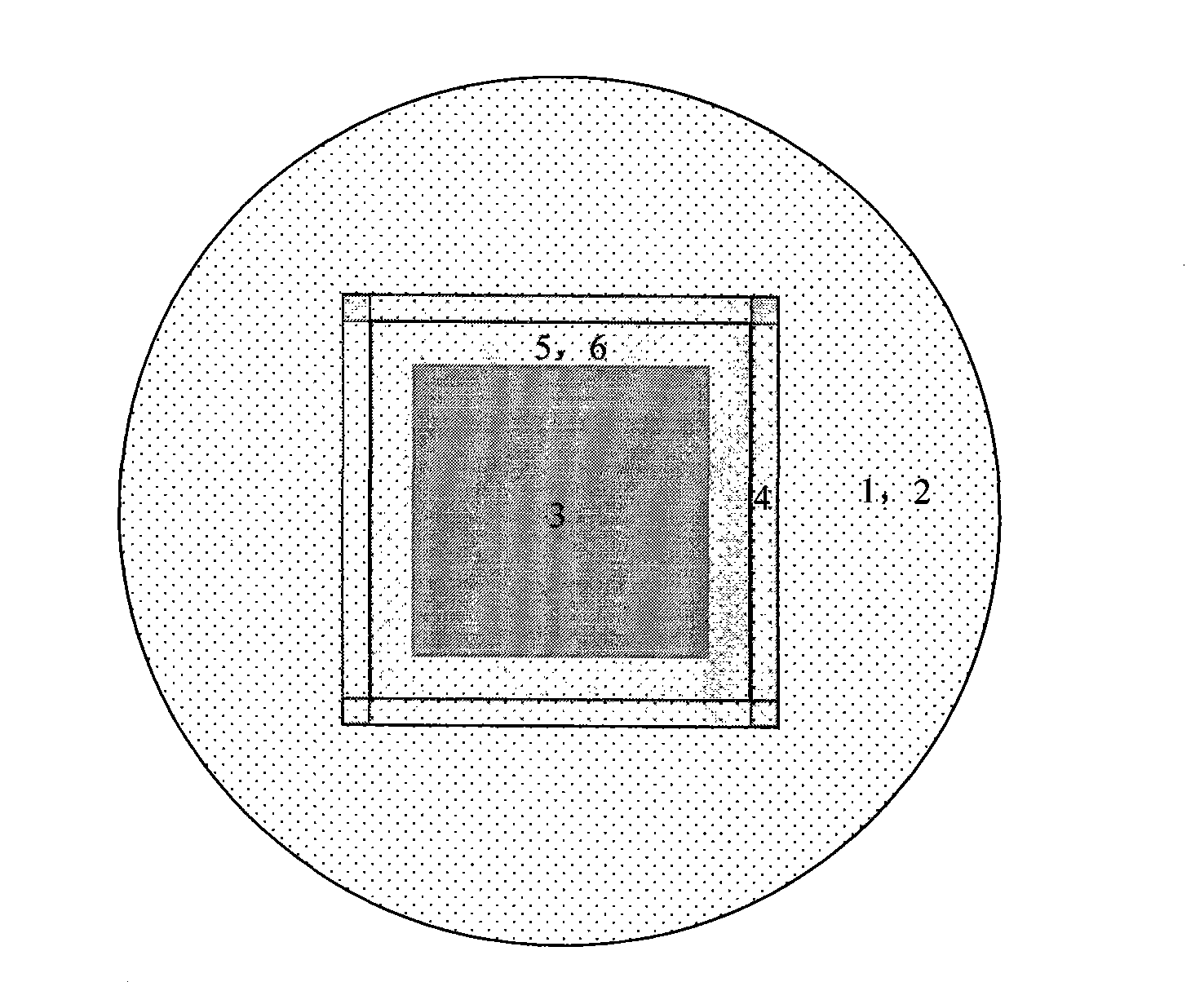

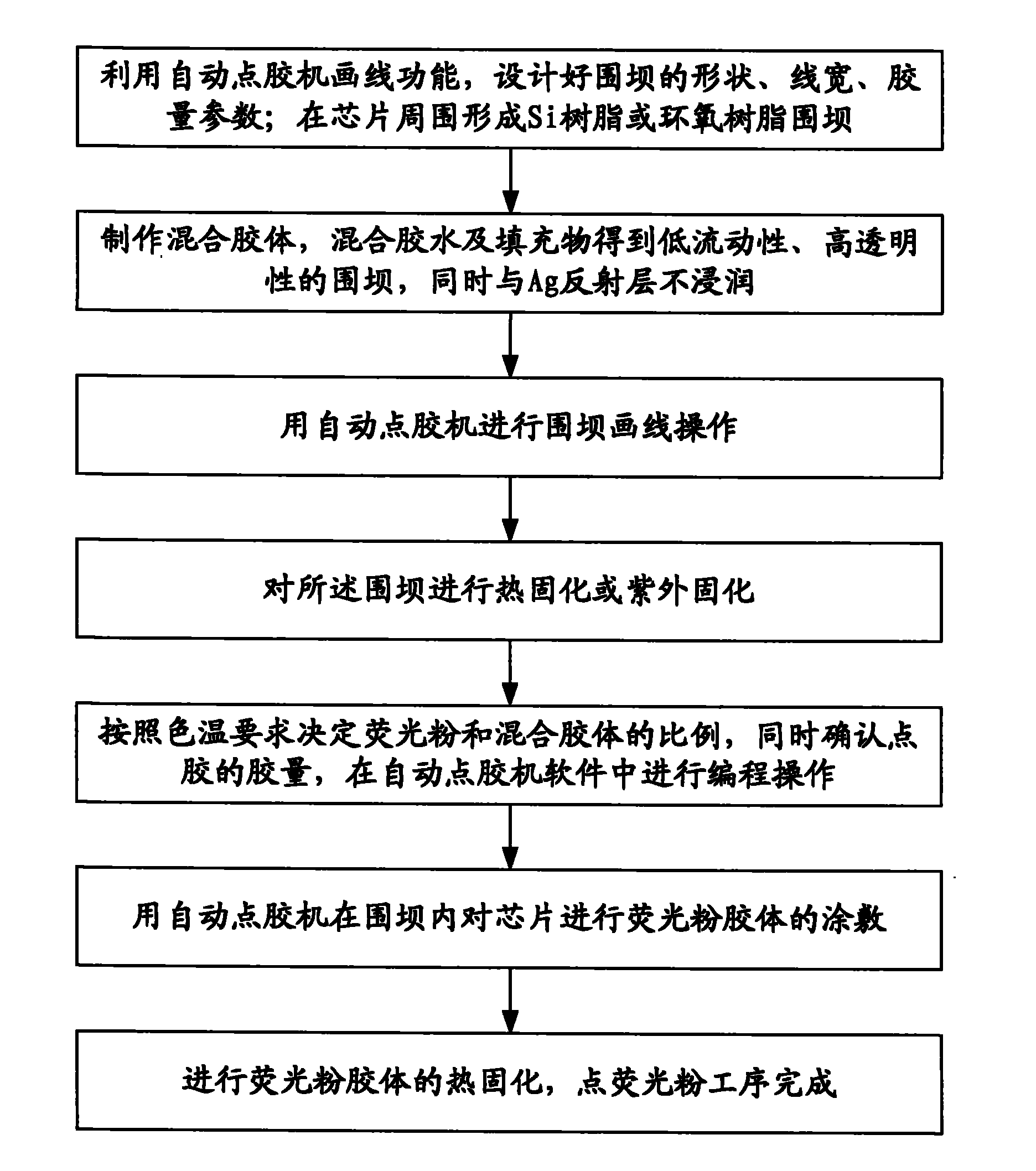

Coating method of light-emitting diode fluorescent powder

The invention discloses a coating method of light-emitting diode (LED) fluorescent powder. The method comprises the following steps: performing crystal- bonding and wire-bonding of a LED chip on a support, using a precision automatic adhesive-dispensing device with a robot arm to draw colloidal box dam around the chip; forming a colloidal box dam through hot curing or ultraviolet curing; dispensing a defined amount of fluorescent powder adhesive in the box dam; and curing again to obtain the LED, wherein fluorescent powder is coated on part of the chip. By using the method of the invention, the uniformity of light colour of the white LED can be increased; and the adhesive thickness round the chip can be accurately controlled by using the box dam, thus the effect of white light-mixing in all directions is controlled, and yellow ring, blue ring and other non-uniform phenomena can not appear.

Owner:江苏米优光电科技有限公司

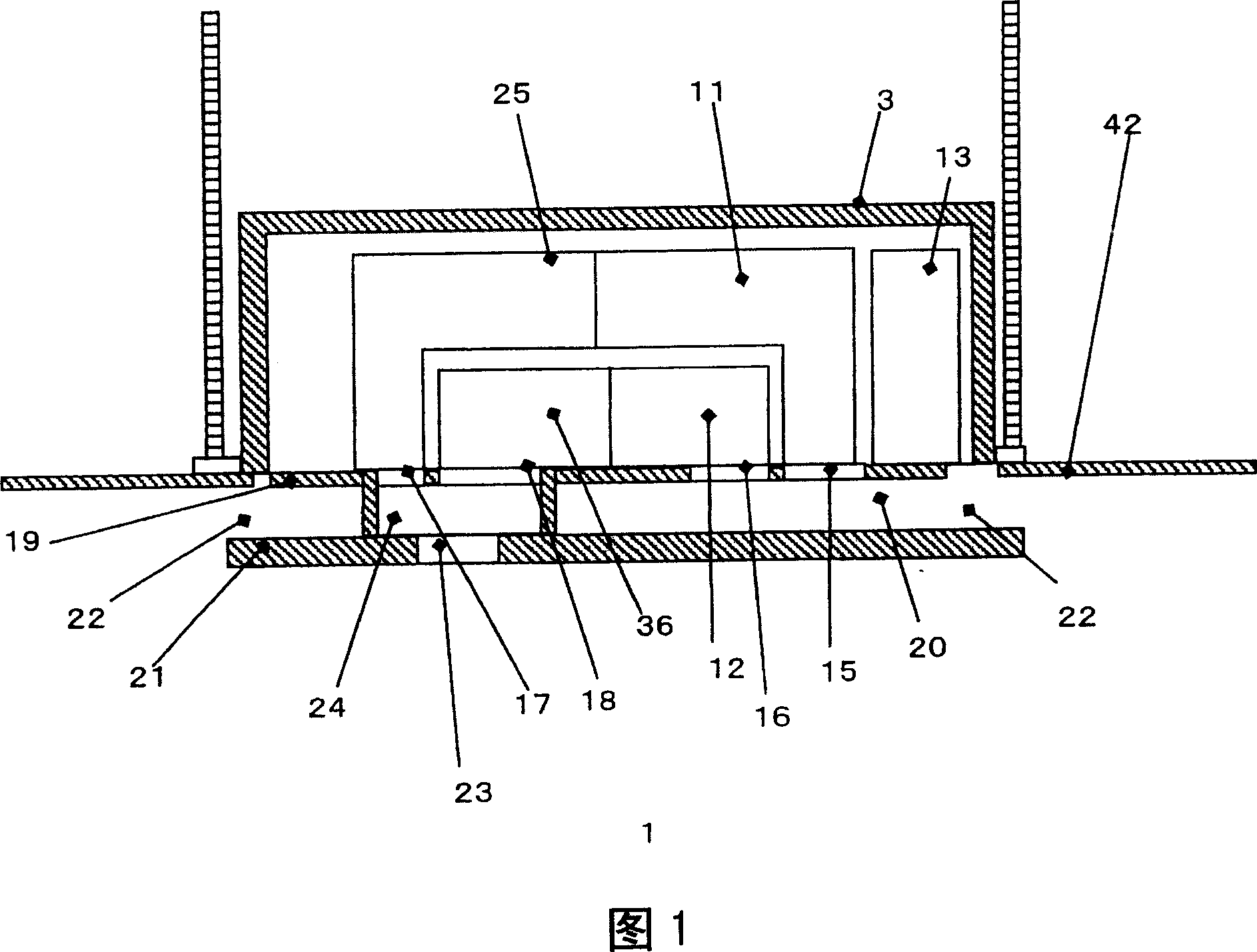

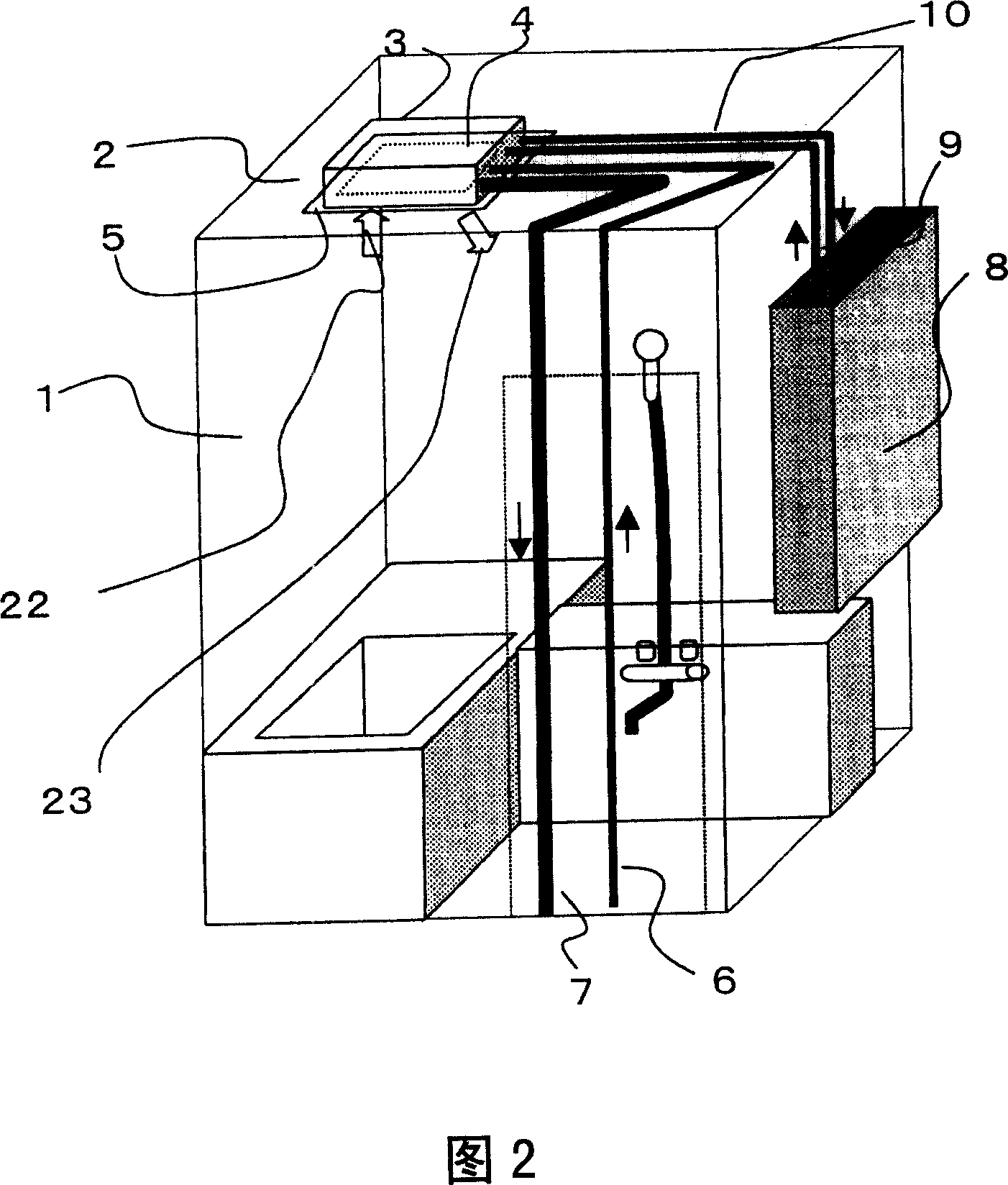

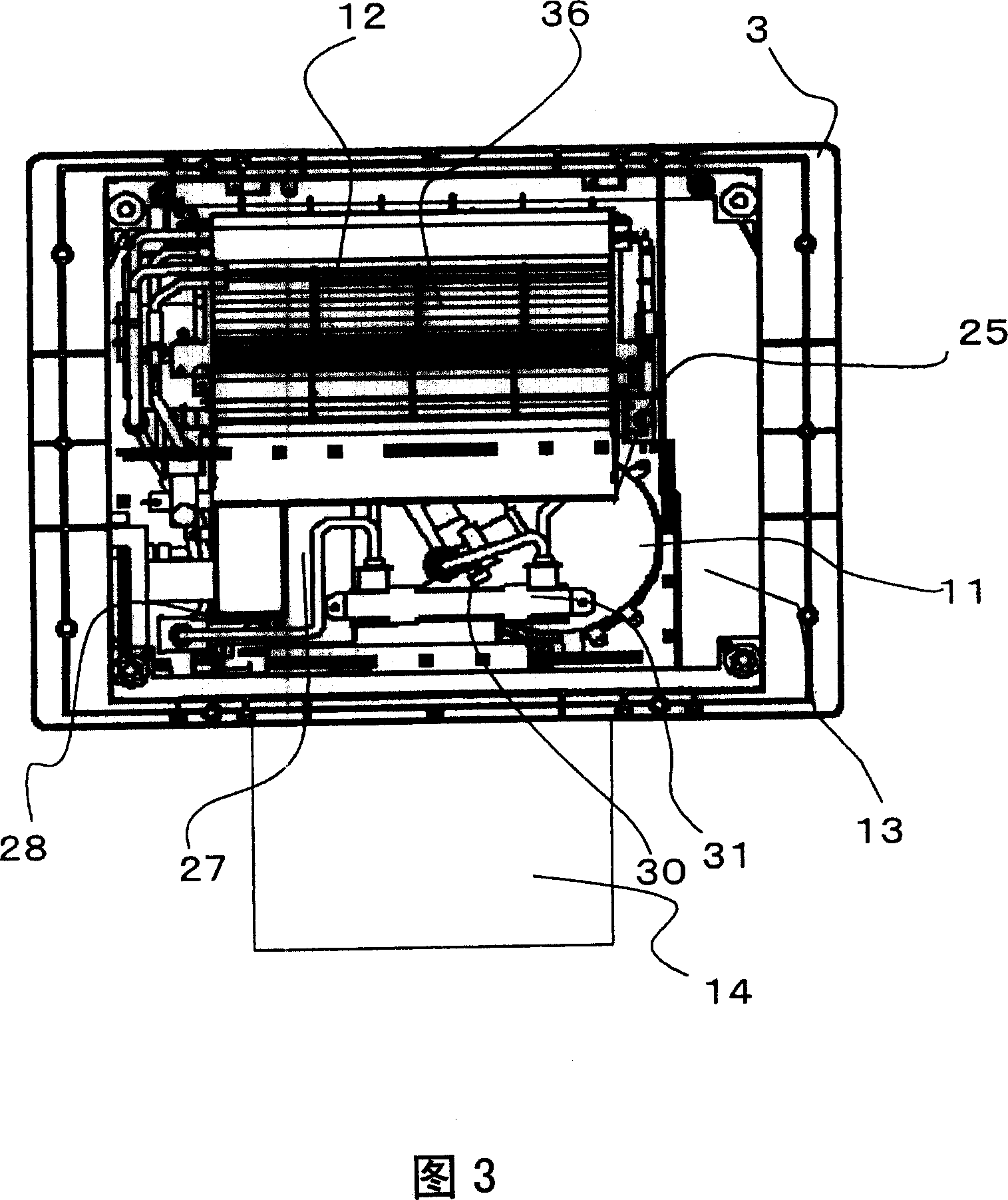

Saunas arrangement

ActiveCN101112344AExcellent temperature and humidity distributionEfficient actionBathing devicesWater supplyGas supply

The present invention provides a sauna device which can obtain the uniform temperature and humidity. The sauna device includes: a heating air supply part (36), which transfers the air which is heated by a heating part (12) to heat the air; a humidifying part (11); a humidifying air supply part (25), which transfers the air which is humidified by the humidifying part (11); a suction inlet (22); and an exhaust outlet (23), wherein, the confluence of the heated air from the heating air supply part (36) and the humidified air from the humidifying air supply part (25) is in front of the exhaust outlet (23), and then the air after the heating and humidifying is exhausted from the exhaust outlet (23), so the present invention can get the sauna device which can obtain the uniform temperature and humidity.

Owner:PANASONIC CORP

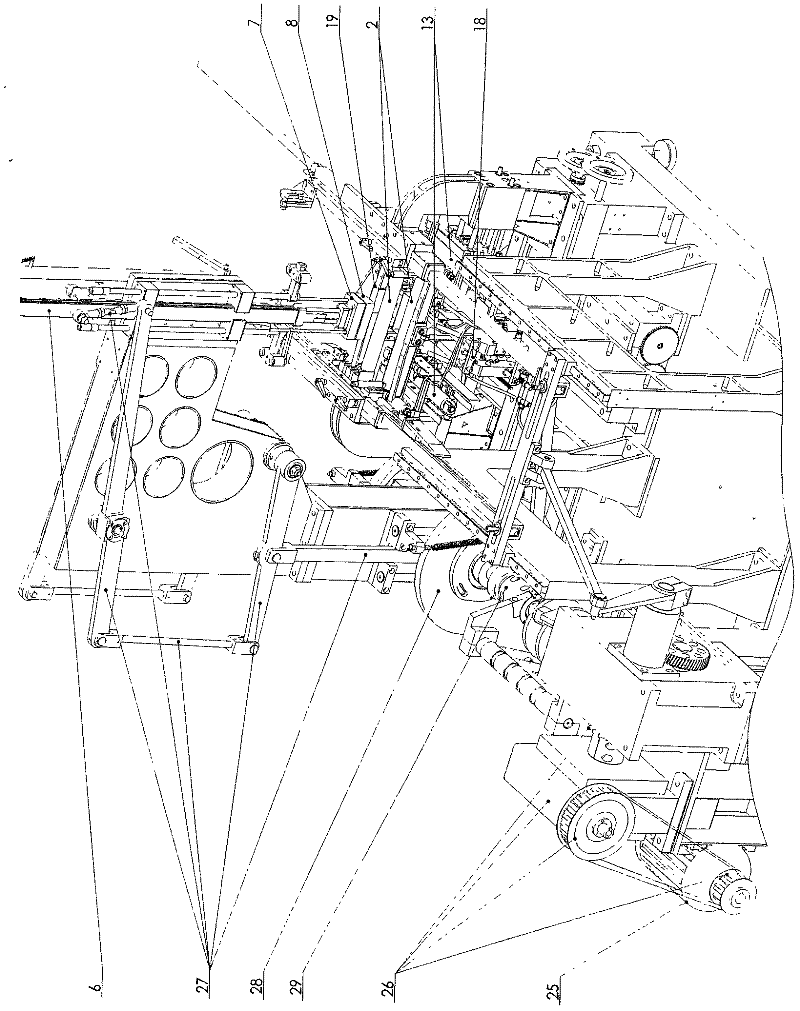

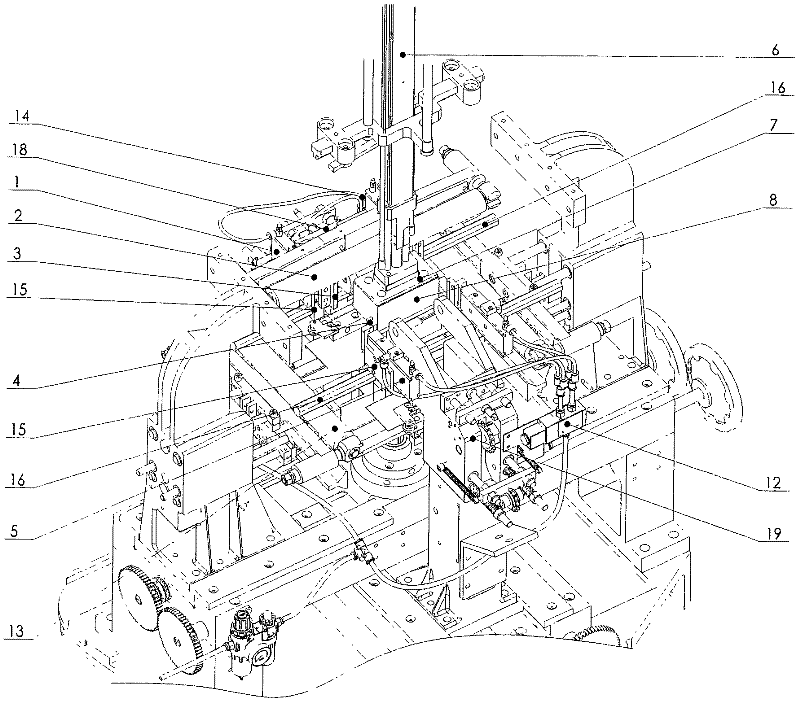

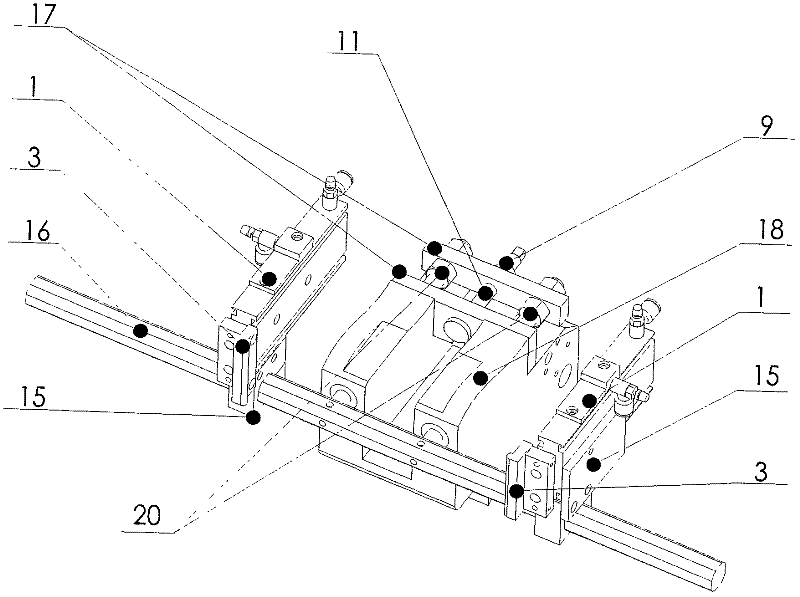

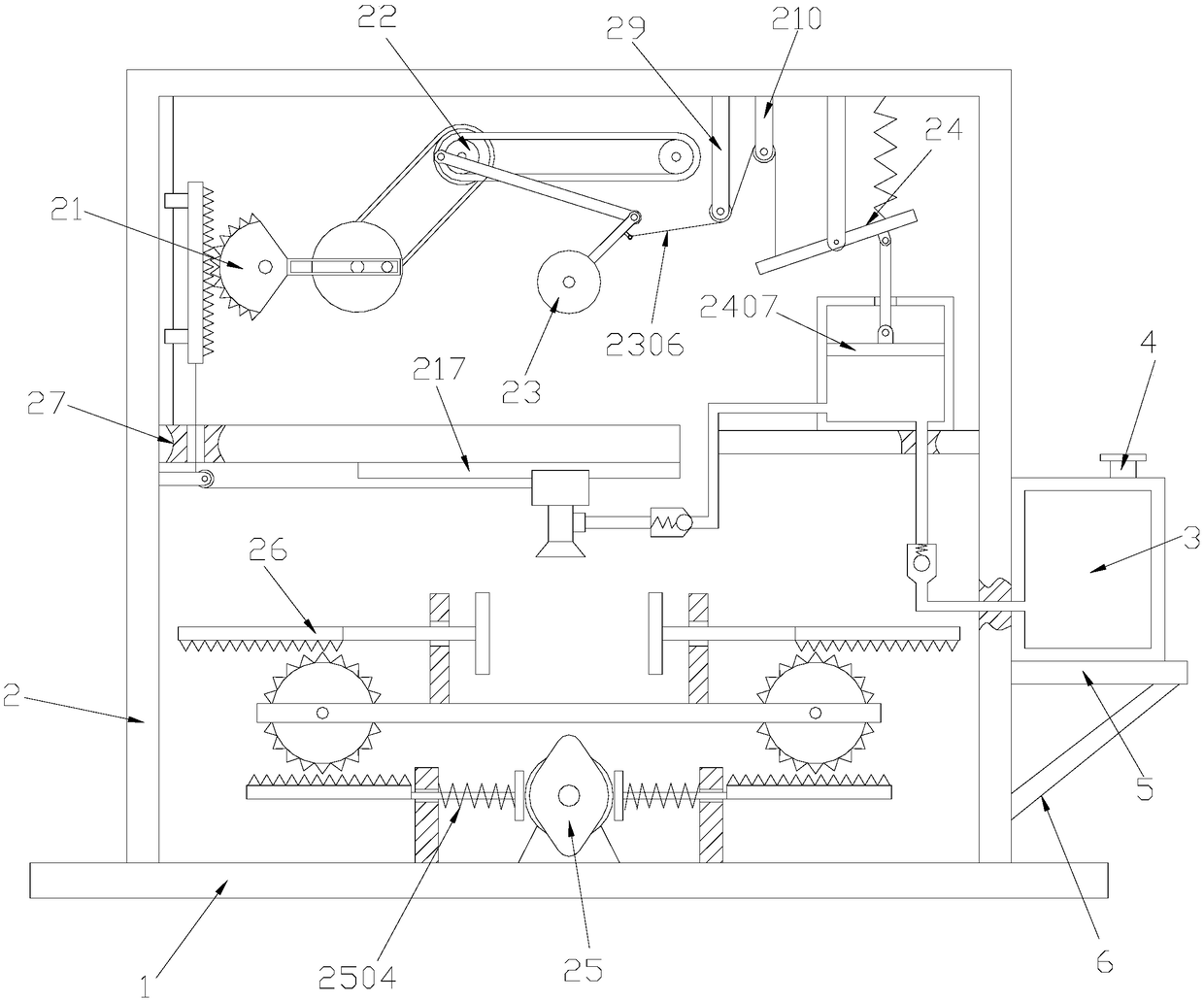

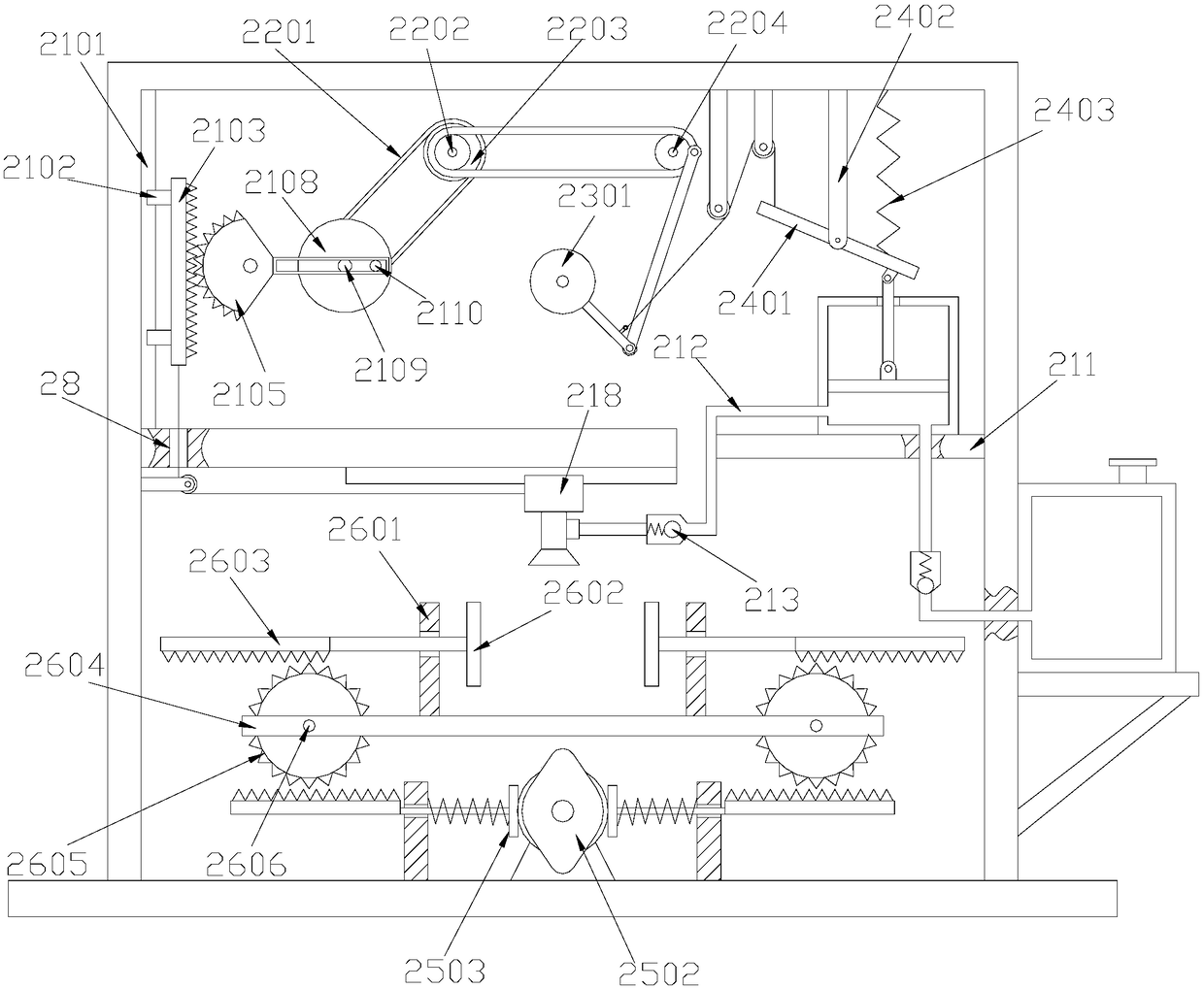

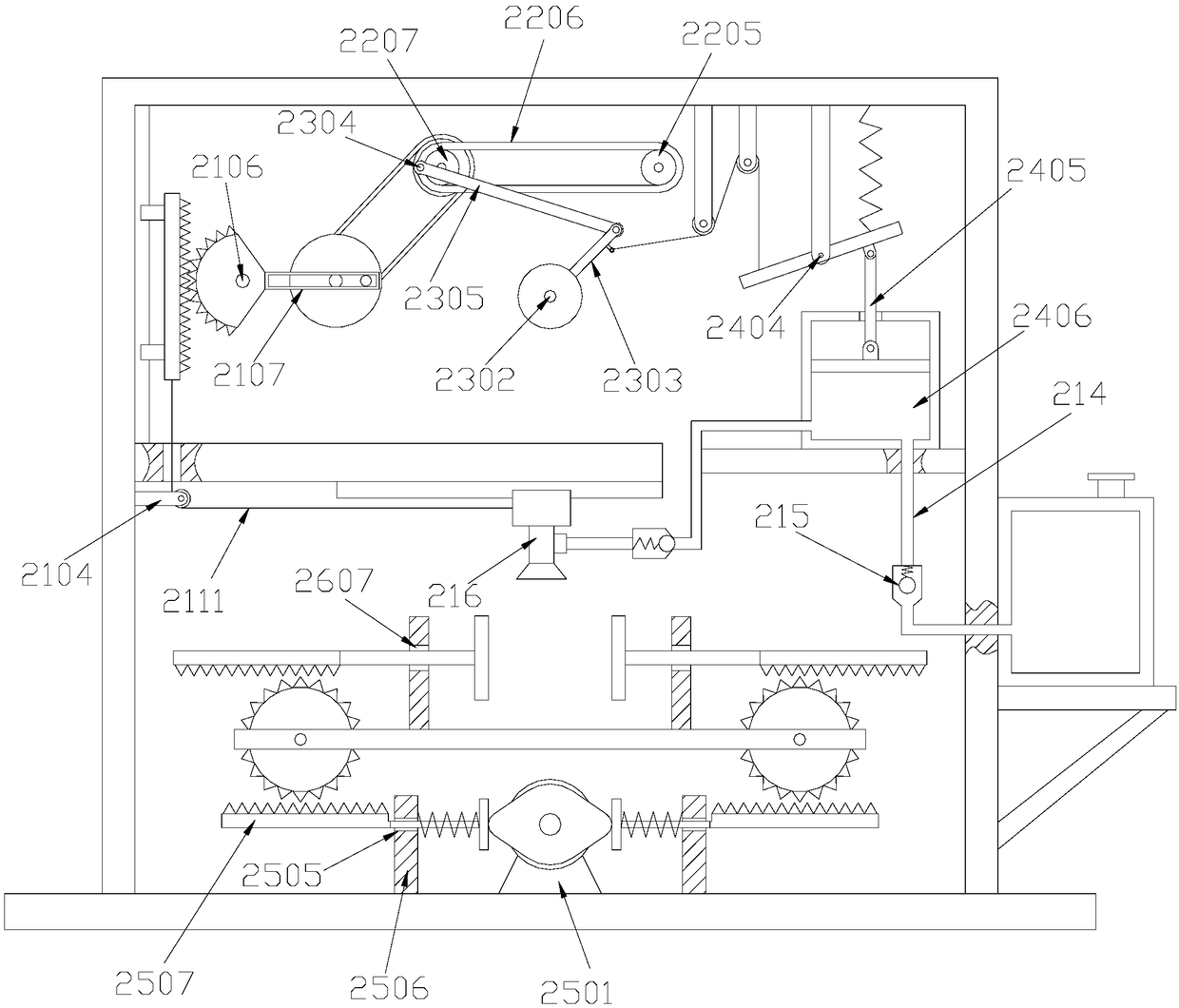

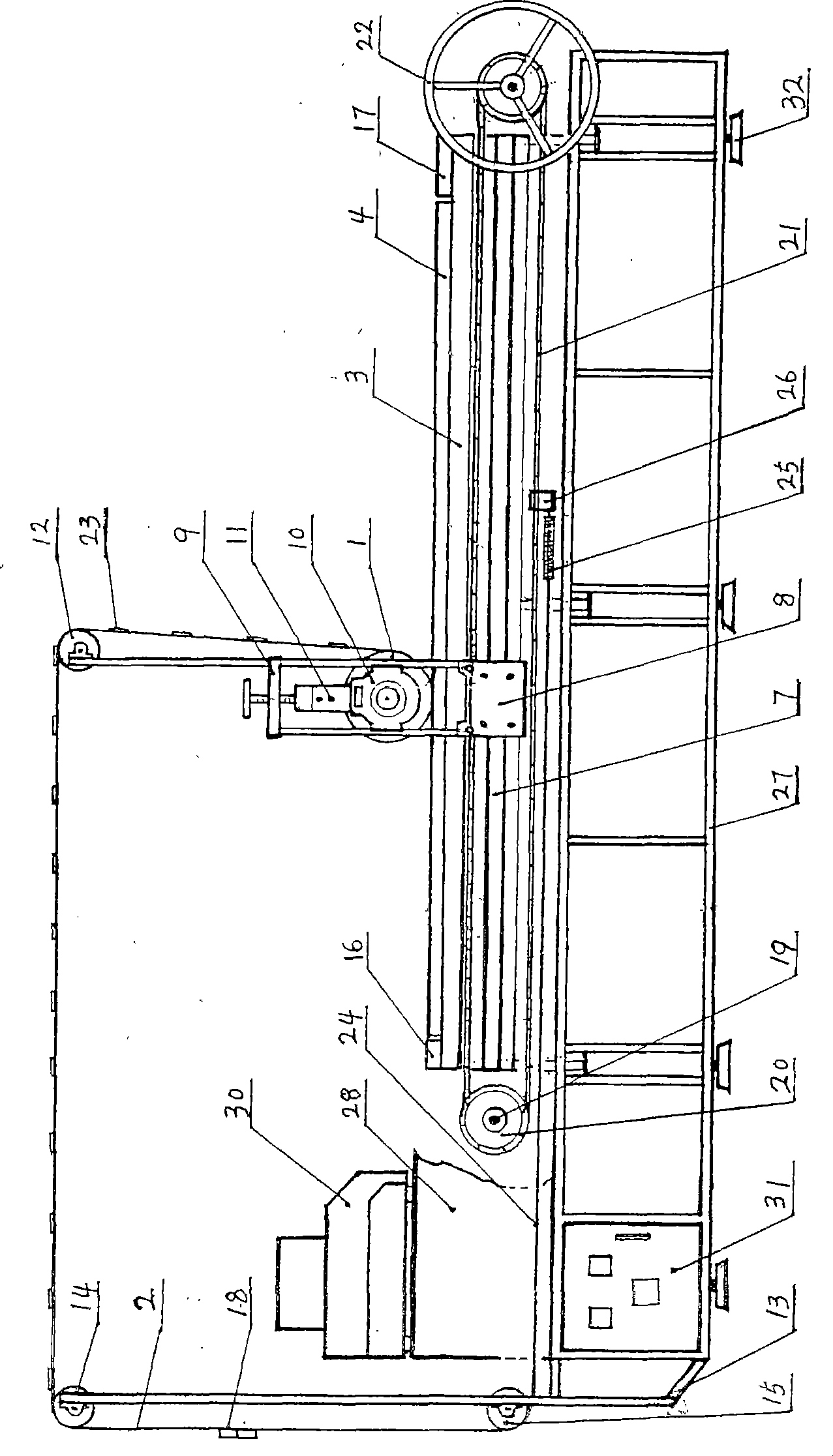

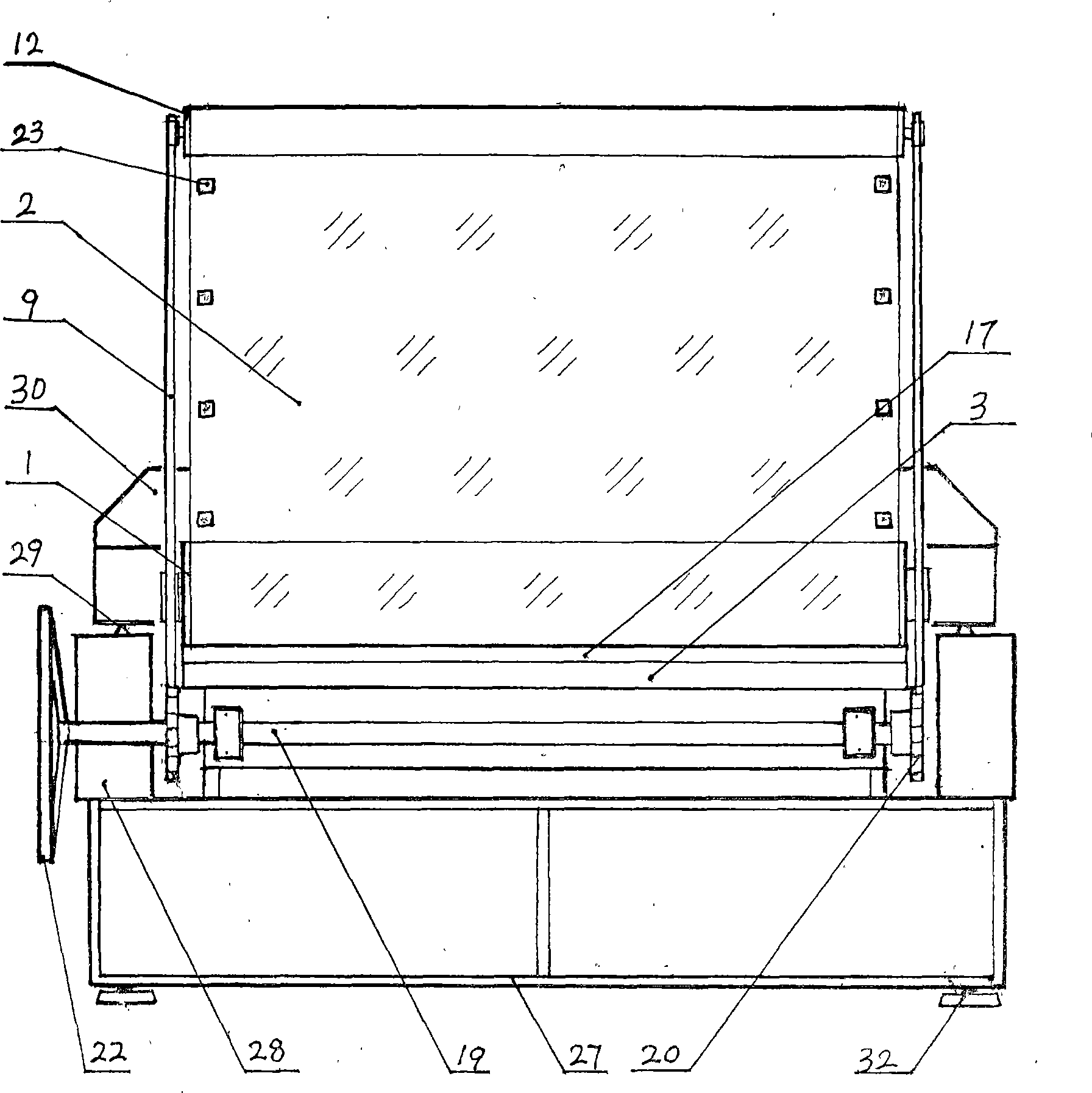

Fully edge turning method for tissues of blank boxes and fully edge turning mechanism adopting fully edge turning method

InactiveCN102490394AFlat sidewaysImprove overall aestheticsContainer making machineryPistonEngineering

A fully edge turning method for tissues of blank boxes is applied to a paper box forming machine and includes steps of conveying the tissues of a blank box from top to bottom after the tissues are positioned and adhered, realizing control by front edge turning tools and rear edge turning tools via expansion and contraction of front edge turning cylinders and rear edge turning cylinders, realizing first front box wide full edge turning and then second rear box wide full edge turning for edge turning portions of the tissues, completely overlaying and covering first fully turned edges by second fully turned edges, and realizing comprehensive edge turning of the blank box in the width direction. A fully edge turning mechanism adopting the fully edge turning method is characterized in that the front box wide edge turning cylinders (1) are mounted at two lateral edges of a front box wide working seat (18), the front box wide edge turning tools (3) are mounted at outer ends of piston rods of the front box wide edge turning cylinders, the rear box wide edge turning cylinders (5) are mounted at two lateral edges of a rear box wide working seat (19), and the rear box wide edge turning tools (4) are mounted at outer ends of piston rods of the rear box wide edge turning cylinders. By the aid of the fully edge turning method and the fully edge turning mechanism, lateral surfaces of the blank box in the width direction look flat and thick, and cannot be uneven, the integral attractiveness of a paper box is improved, and requirements of high-end customers are met completely.

Owner:浙江中科包装机械有限公司

Lacquering device for wooden toy

The invention discloses a lacquering device for a wooden toy. The lacquering device structurally comprises a bottom plate, a shell, a lacquer feeding hole, a lacquer tank, a first supporting plate anda ribbed plate, wherein the bottom of the shell is vertically mounted at the top of the bottom plate in a welded connection manner; the first supporting plate is horizontally arranged; the left end of the first supporting plate is vertically mounted on the right side surface of a right side plate of the shell in a welded connection manner; one end of the ribbed plate is welded with the right endof the bottom of the first supporting plate; and the other end of the ribbed plate is mounted at the bottom of the right side surface of the right side plate of the shell in a welded connection manner. According to the structure of the lacquering device, a shower nozzle is fixed on a sliding block, can do reciprocating motion, can spray lacquer on the wooden toy on a clamping device, and can spraylacquer on the surface of the toy uniformly to avoid an uneven phenomenon that stripes are generated by lacquer on the surface of the toy and enable lacquer on the surface of the toy to be bright andeven, so that the appearance of the toy is improved.

Owner:邓秋婷

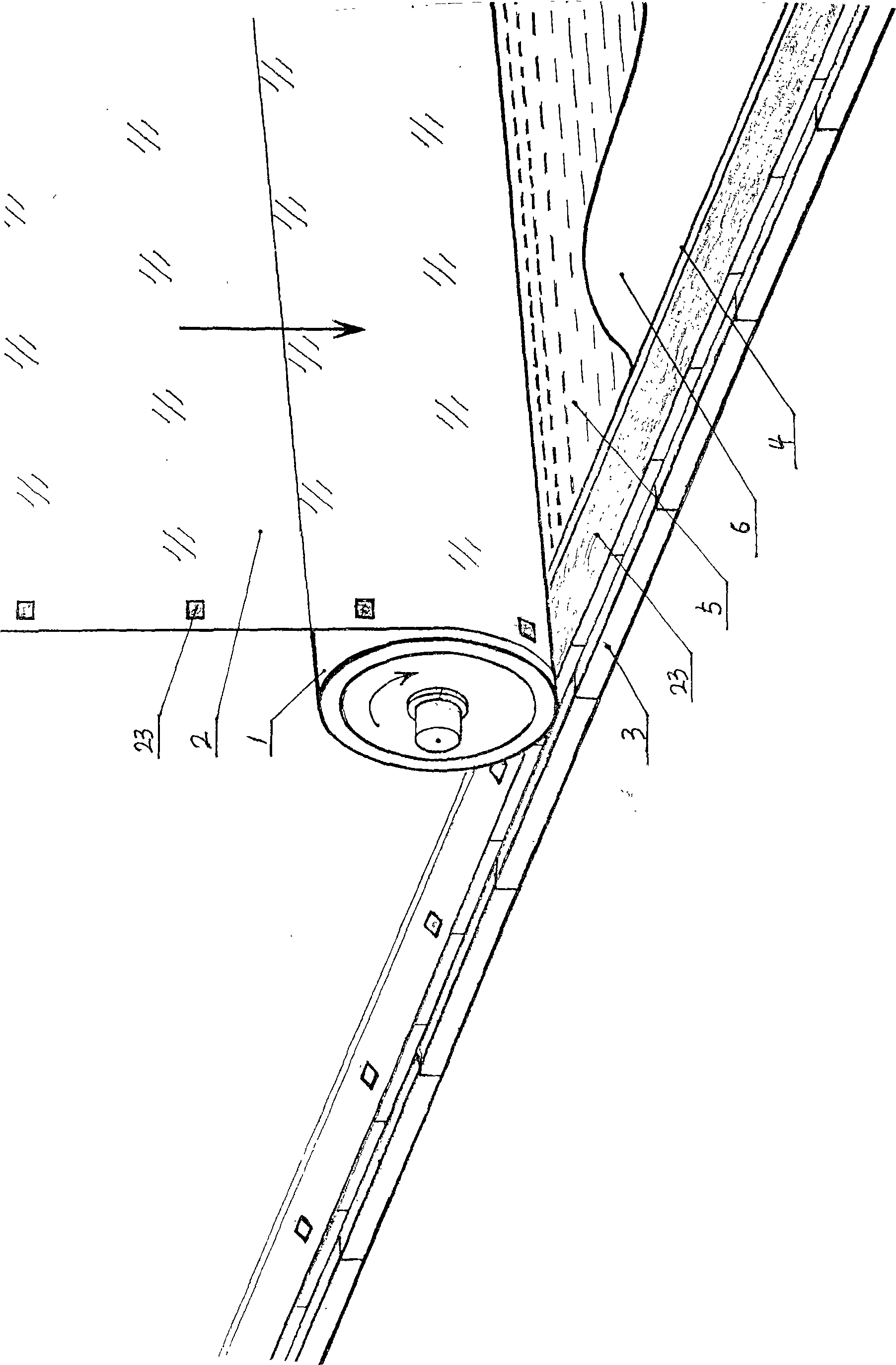

Method and device for coating and curing ultraviolet curing coating

InactiveCN101518774AHigh coating densitySimple compositionPretreated surfacesCoatingsUltravioletMaterials science

The invention relates to a method and a device for coating and curing ultraviolet cured coating, in particular to a method and a device for coating and curing coating on the surface of an object with ultraviolet. The method comprises the following steps: an objected to be coated with ultraviolet cured coating on the surface is placed flat; the ultraviolet cured coating is coated on the surface of the object; the surface of an press roll passes by a transparent coating, and the press roll is cooperatively arranged above the object; the press roll shifts relative to the object, rotationally rolls, presses, spreads and evenly coats the ultraviolet cured coating, and conveys and coats the transparent coating on the surface of the object; the ultraviolet cured coating under the transparent coating is cured under the irradiation of an ultraviolet lamp with ultraviolet rays penetrating the transparent coating; and the transparent film is uncovered, with the result that the ultraviolet cured coating is cured on the surface of the object. The invention has the advantages of low manufacturing cost, high degree of finish, good effect, reliable running, easy operation, and the like.

Owner:秦皇岛洛克维德新材料技术有限公司

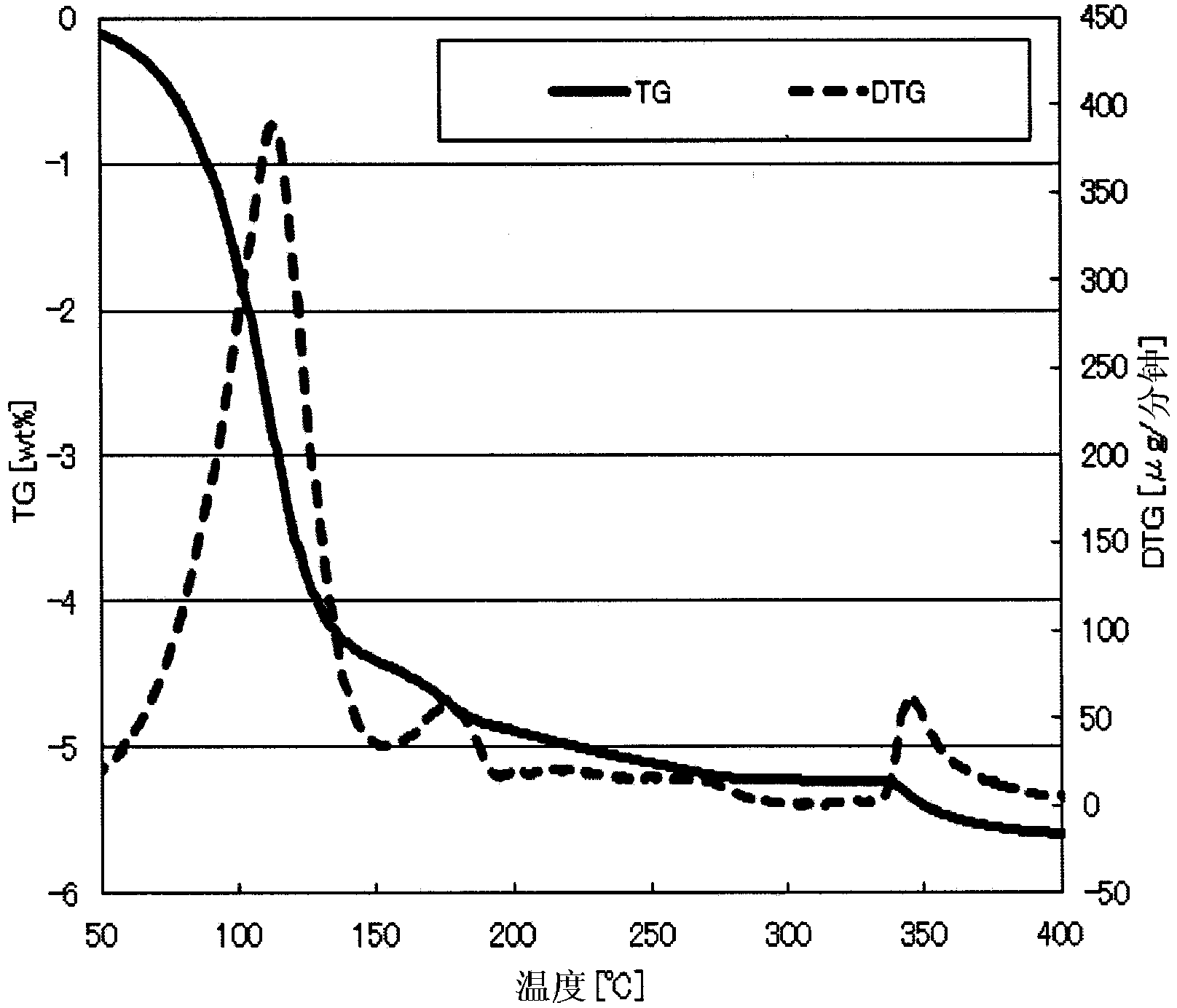

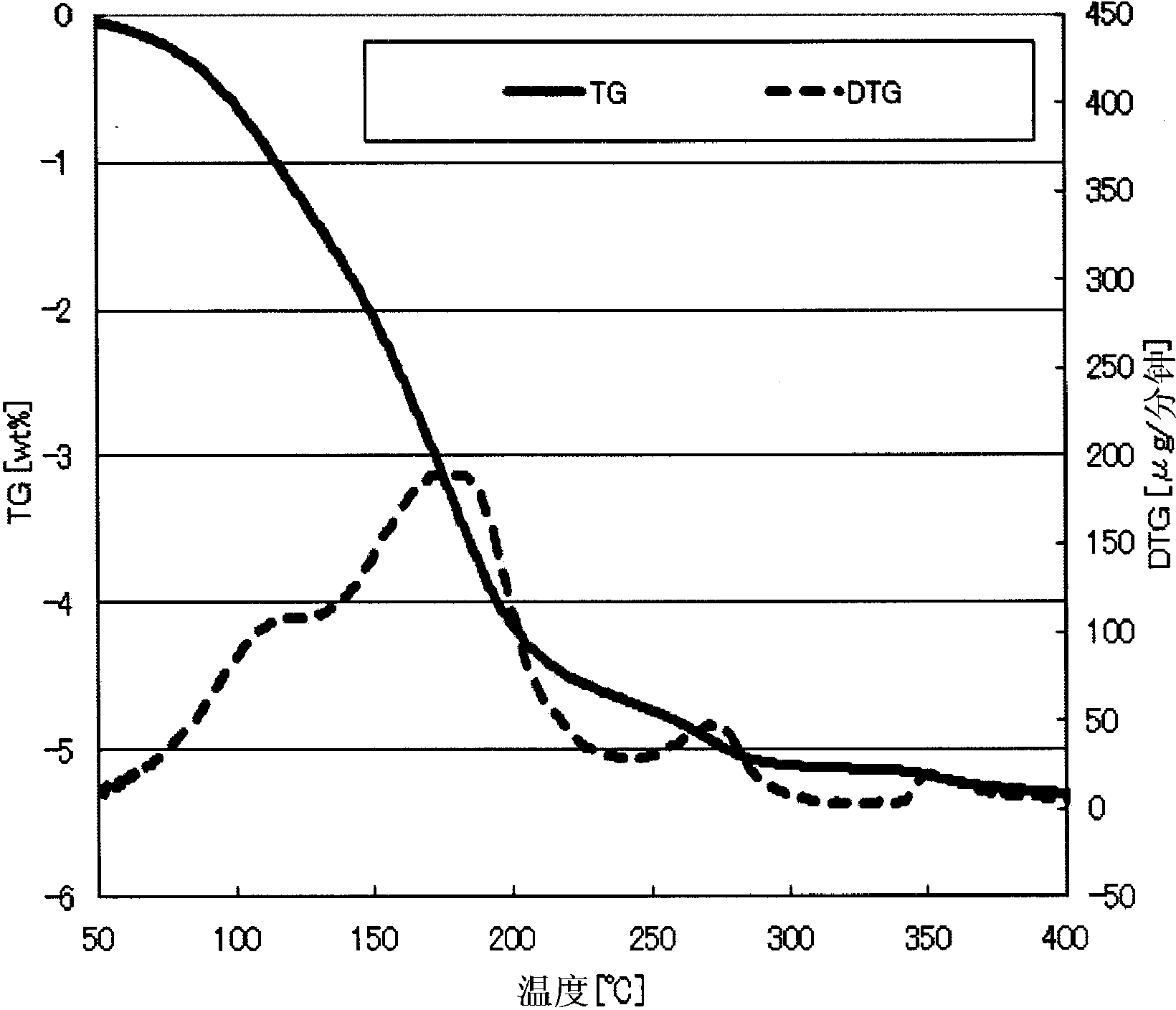

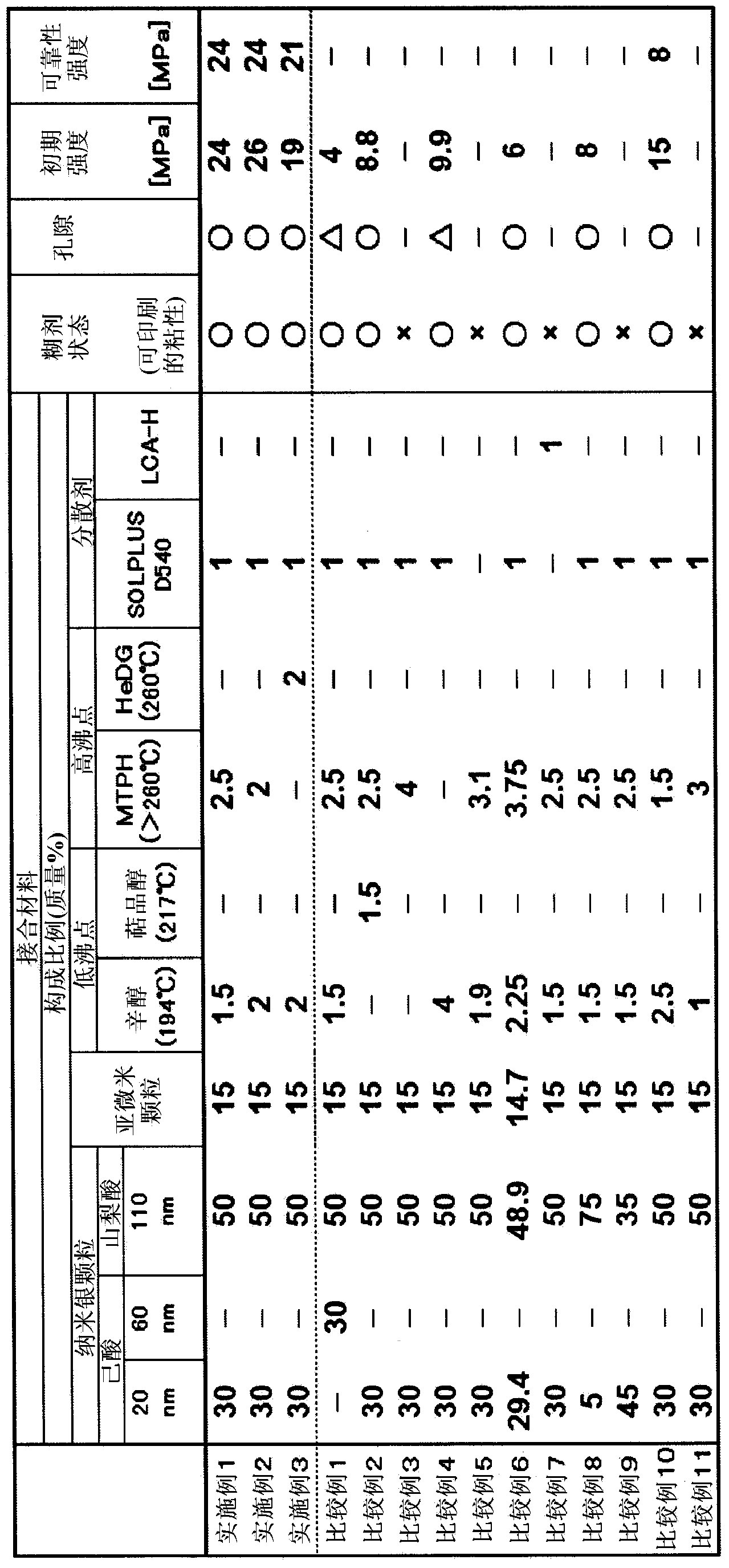

Bonding material and bonding method in which said bonding material is used

InactiveCN104066534AImprove reliabilityIncrease contentTransportation and packagingWelding/cutting media/materialsIn planeCarbon number

The purpose of the present invention is to enable highly-reliable bonding of bonding surfaces to be carried out such that the occurrence of uneven drying at the center and ends of the bonding surfaces, which occurs in-plane on a bonding layer in a desolvation process of a preliminary drying step, is reduced, thereby ensuring that the bonding surfaces do not detach even if repeatedly exposed to heat shock after bonding. This bonding material, which solves the aforementioned problem, is characterized by being covered by organic matter with a carbon number of six or less, comprising main silver particles, and covered by organic matter with a carbon number of six or less, comprising nano silver particles having an average primary particle size of 10 to 30 nm, and sub silver particles. The bonding material is further characterized by containing nano silver particles with an average primary diameter of 100 to 200 nm, two types of solvents with different boiling points, and a dispersant.

Owner:DOWA ELECTRONICS MATERIALS CO LTD

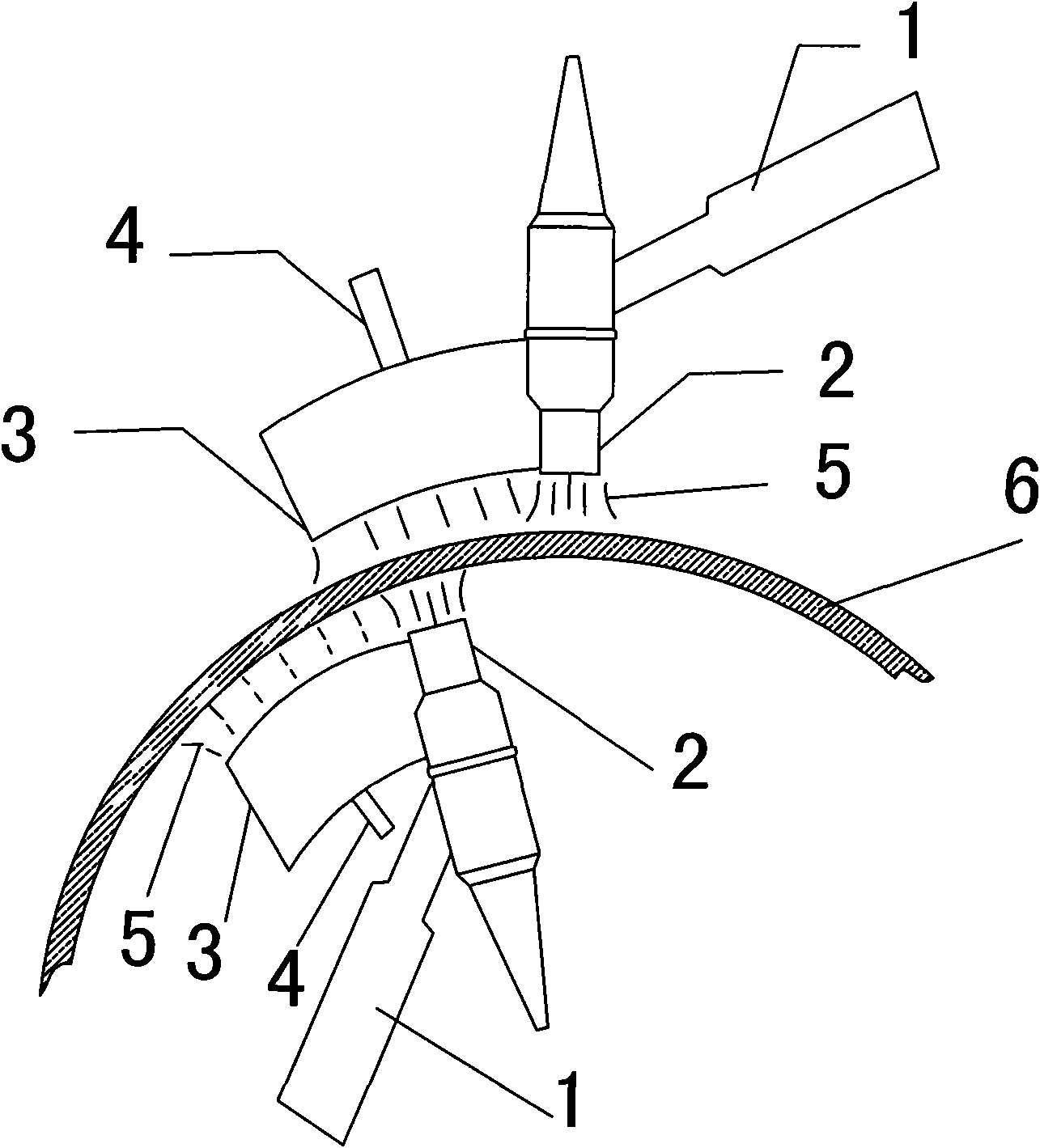

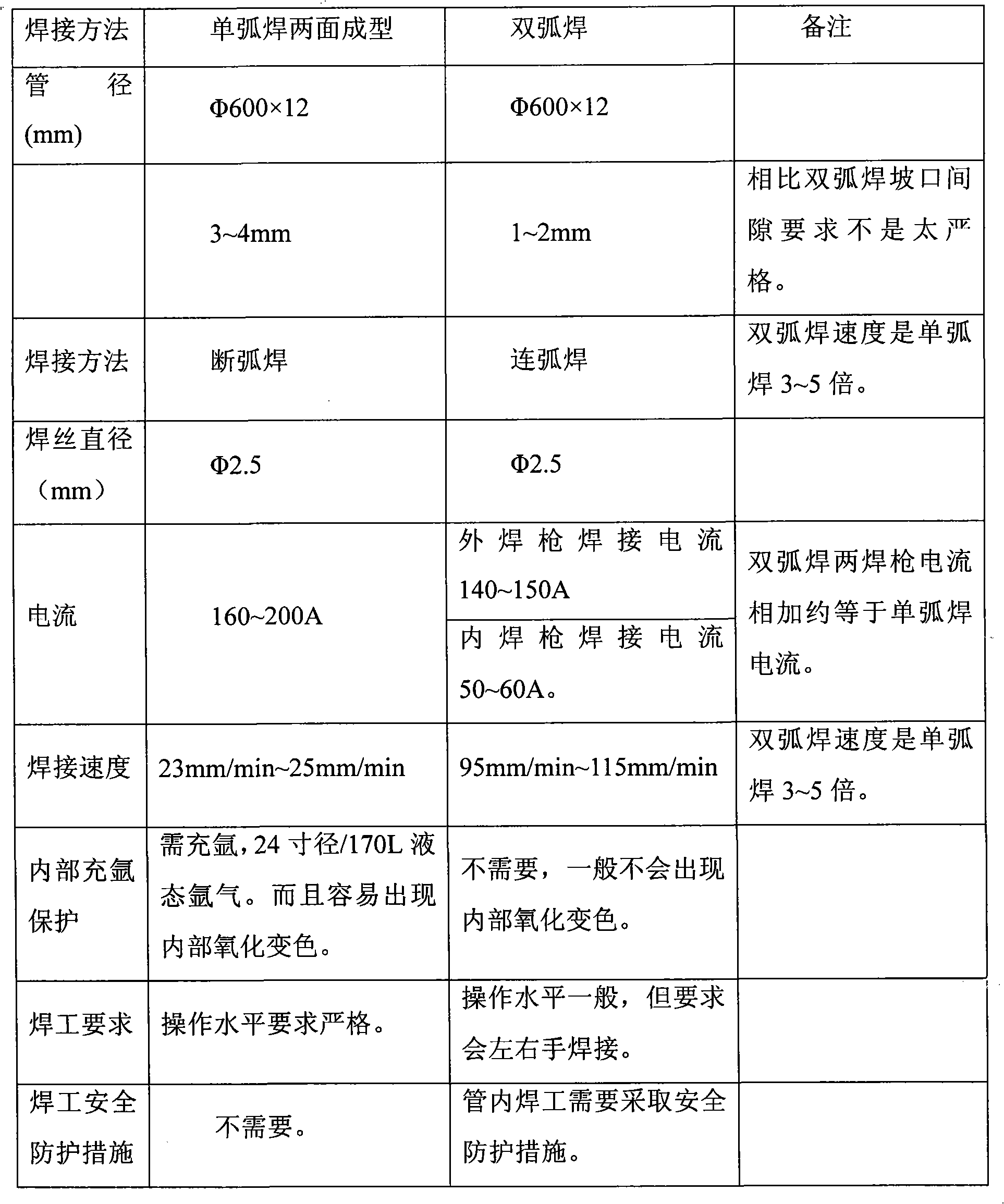

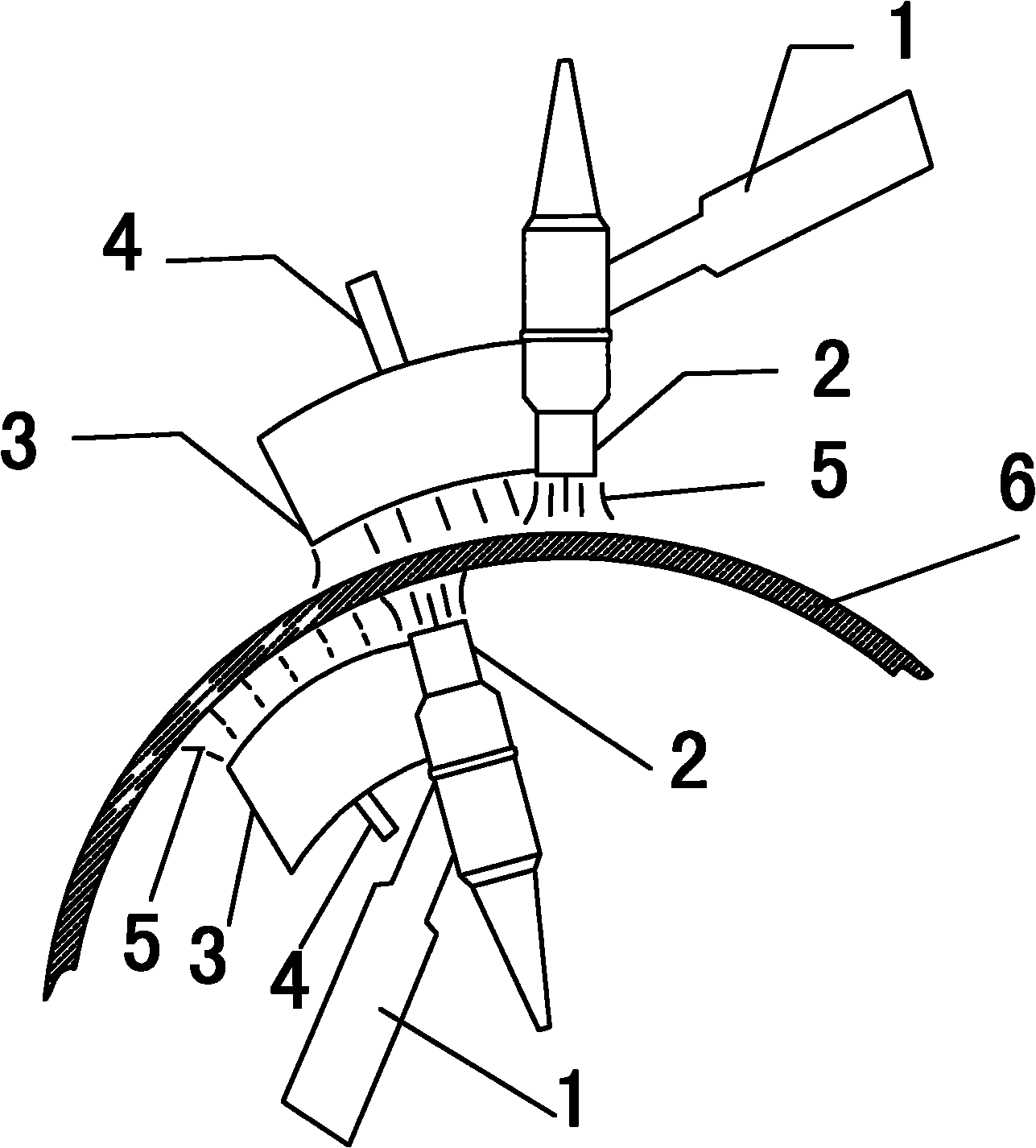

Bottom sealing twin arc welding method of large-caliber industrial pure titanium pipelines

ActiveCN102069274ANo protectionPlay a protective effectArc welding apparatusTubular articlesPower flowNonferrous metal

The invention relates to a bottom sealing twin arc welding method of large-caliber industrial pure titanium pipelines, which belongs to the technical field of pipeline welding and is suitable for root welding of large-caliber (phi is larger than or equal to 600mm) titanium pipelines, equipment and other non-ferrous metals. The method comprises the following steps of: cleaning greasy dirt and oxides on the surfaces of solder wires and weldments; chamfering pipelines; fitting up the pipelines, wherein the fitting-up gap is 1-2mm; and welding the titanium pipelines by simultaneously using two welding guns inside and the outside the titanium pipelines, wherein argon tungsten arc welding guns with protection dragging covers are adopted, during welding, the welding gun nozzles are in the front, and the protective dragging covers are on the back; and the argon flow of the outer welding gun nozzle is 25-30L / min, the argon flow of the inner welding gun nozzle is 15-20L / min, the argon flow of the dragging cover of the outer welding gun is 25-35L / min, the argon flow of the dragging cover of the inner welding gun is 25-30L / min, and the current of the outer welding gun is 140-160A. The method has the advantages of easy control of welding line molding quality, high welding speed, energy and raw material saving, and the like, wherein the welding speed is 3-5 times as fast as single arc welding.

Owner:SINOPEC TENTH CONSTR

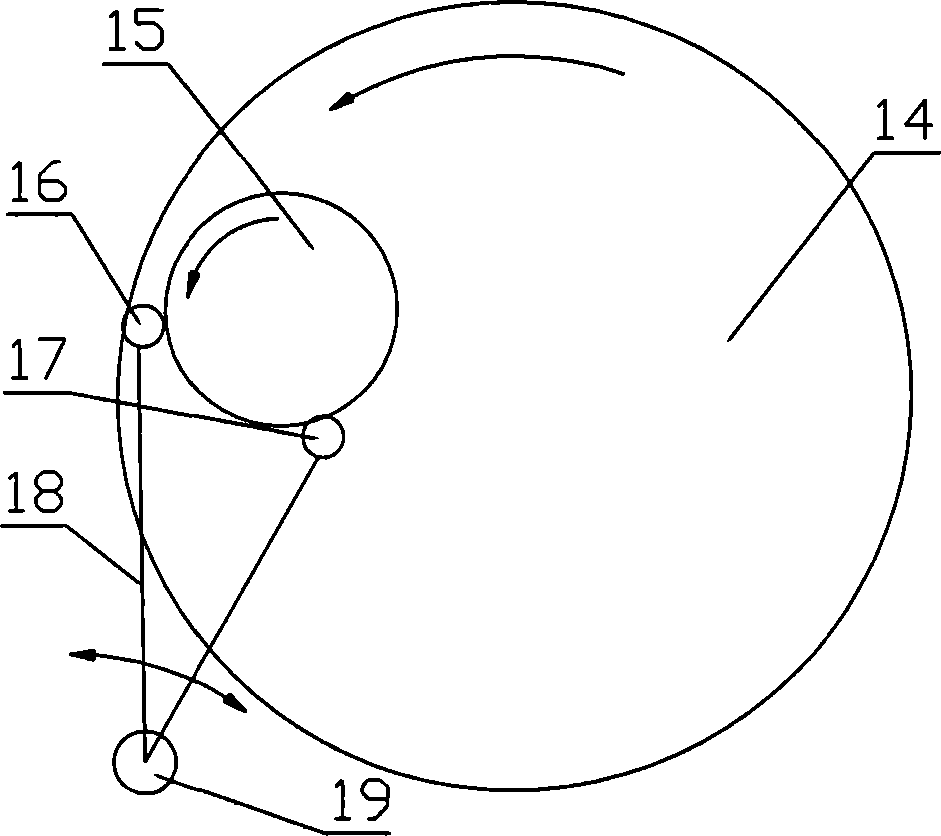

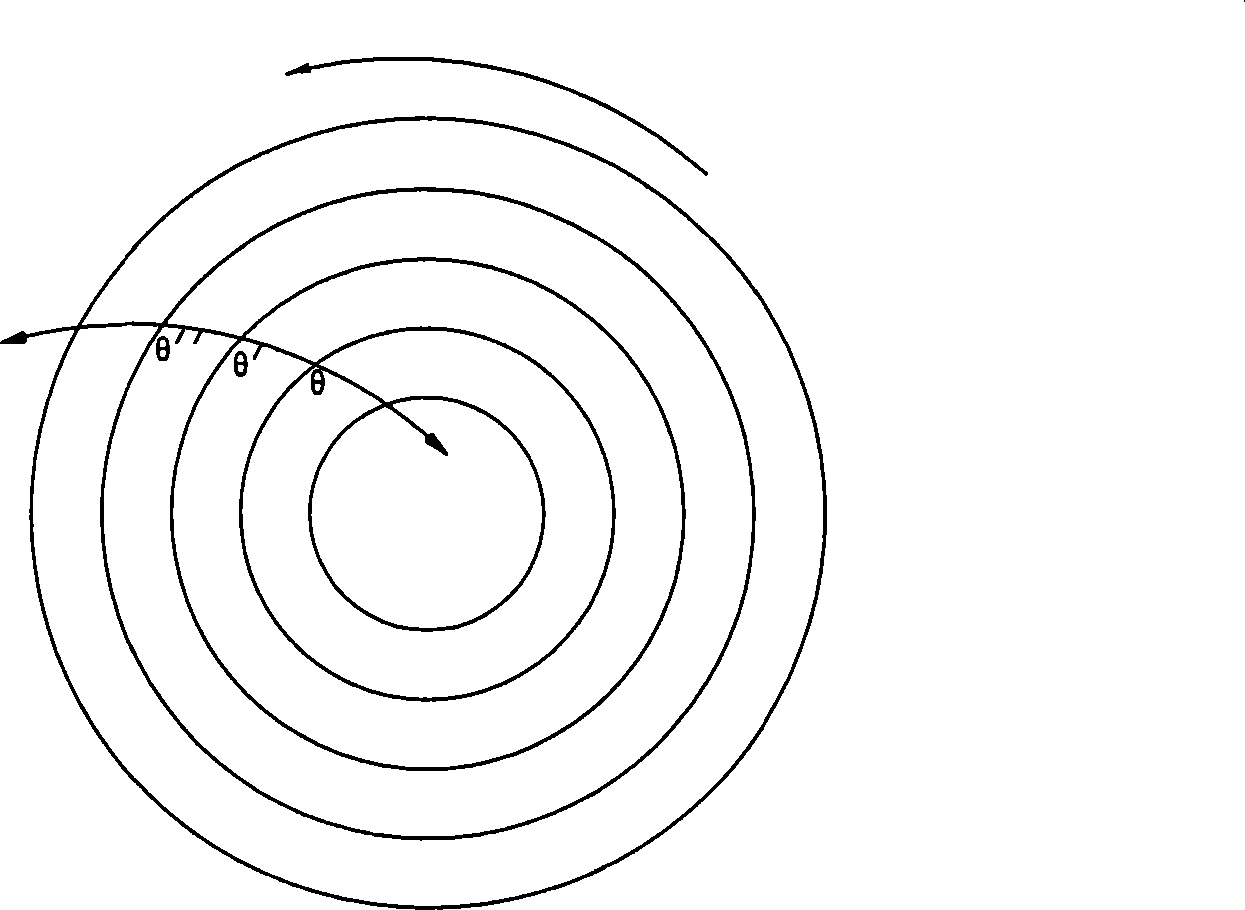

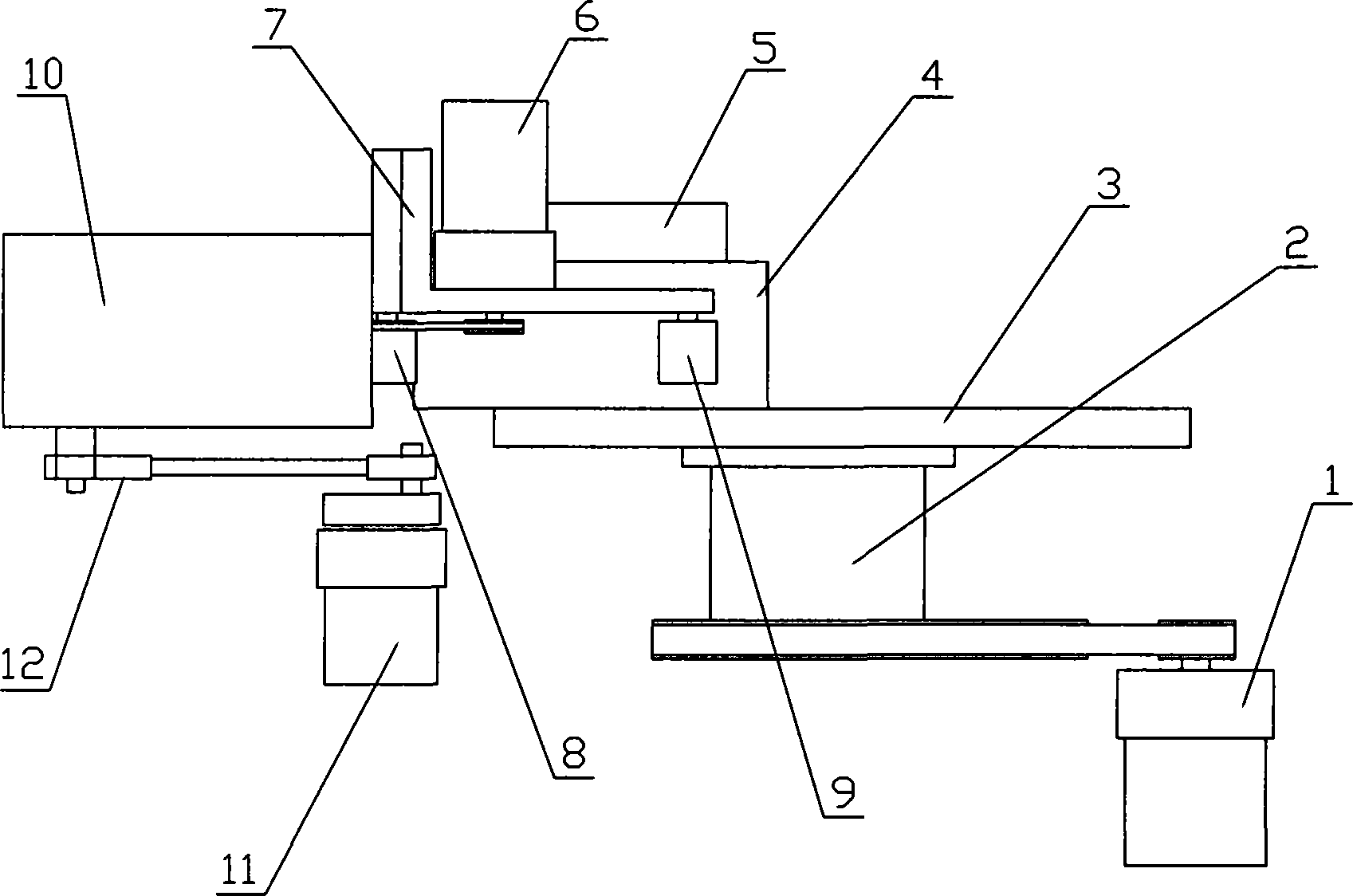

Reciprocating straight-line and rotating motion grinding polishing device

InactiveCN101249632AEvenly distributedNo unevennessPolishing machinesSemiconductor/solid-state device manufacturingCircular discEngineering

The invention relates to a grinding polishing device for reciprocating linear and rotary motion, in particular to a material processing device. The device comprises a grinding polishing pad, a rotary body, a driving motor of grinding polishing pad, a material loading tray, a support of the material loading tray, a driving support guide wheel, a driven support guide wheel, a guide wheel driving motor, a linear guide rail seat, a guide rail driving motor, an eccentric dial pole and a trimming ring, wherein, the material loading tray bonded to grinded material is arranged face to face on the plane of the grinding polishing pad; the grinding polishing pad is connected with the driving motor of grinding polishing pad; the rotary body is connected with the grinding polishing pad; the external diameter of the material loading tray is sleeved with the trimming ring, which is placed between the driving support guide wheel and the driven support guide wheel; the support of the material loading tray is connected in parallel with the linear guide rail seat, which is connected with the guide rail driving motor through the disc eccentric dial pole on the main shaft of the driving motor. The device solves the problems of large concave and convex 'heart-height' sheet of the grinded materials, low flatness of the sheet, and poor parallelism.

Owner:SHENYANG CAIJIA MECHANICAL EQUIP

Fe-Ni alloy shadow mask blank with excellent etch perforation properties and method for manufacturing the same

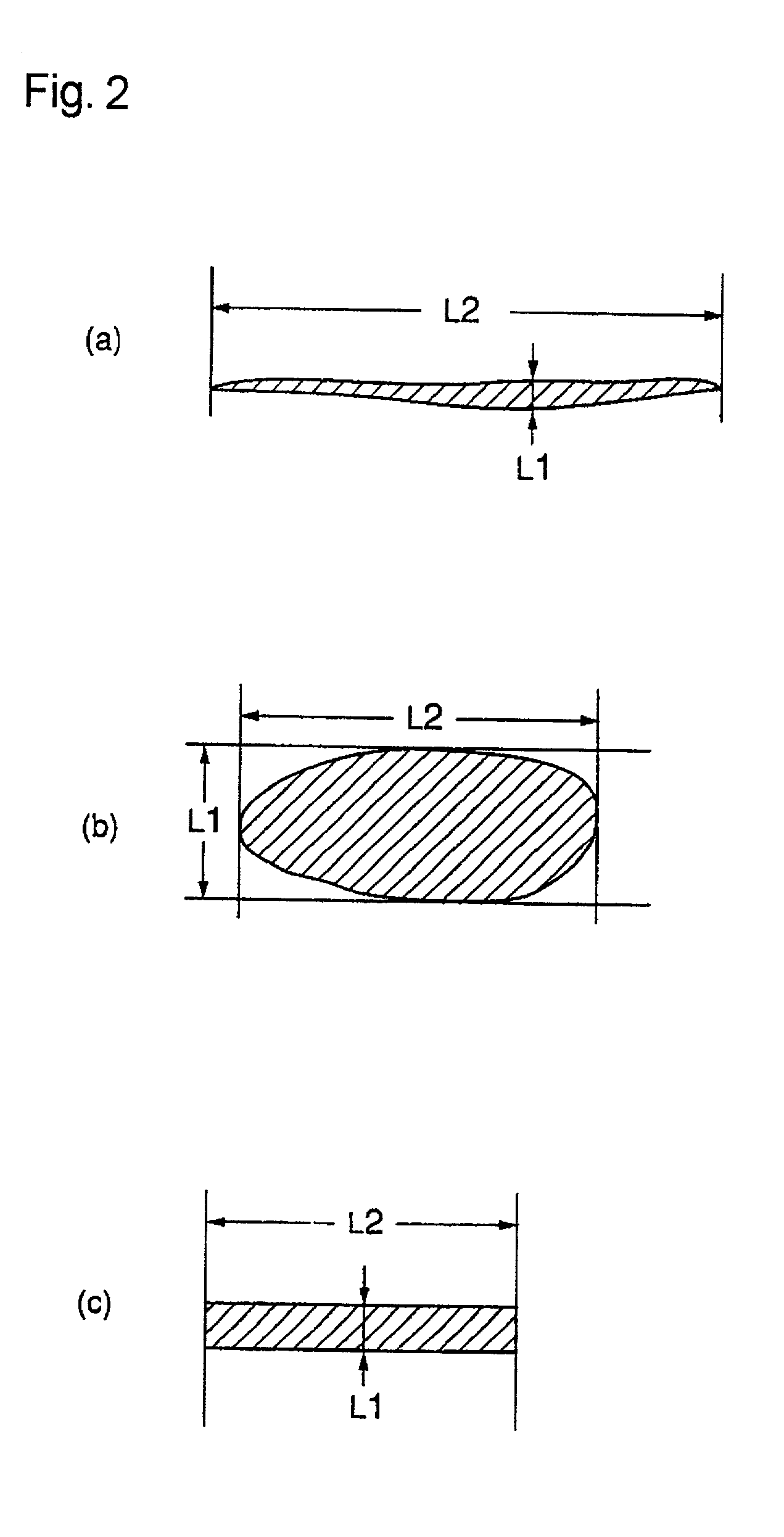

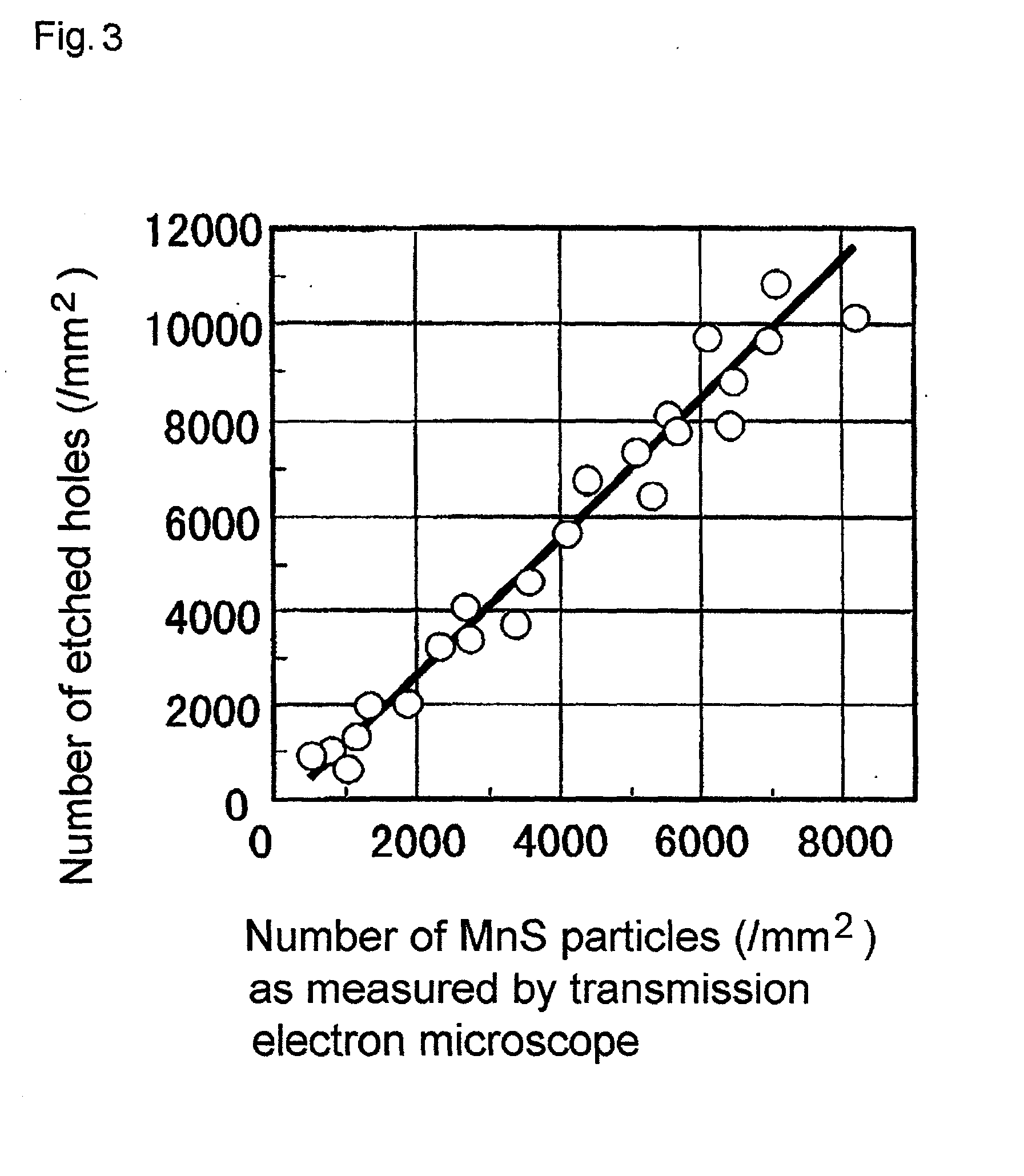

InactiveUS20010047839A1Reduce unevennessNo unevennessCathode ray tubes/electron beam tubesFurnace typesMean diameterReduction ratio

A shadow mask blank of Fe-Ni alloy which exhibits excellent uniformity of diameter of apertures formed by perforation with etching for the passage of electron beams, consisting of 34-38% Ni, 0.05-0.5% Mn, 4-20 ppm S, and the balance Fe and no more than specified limits of C, Si, Al, and P, with MnS inclusions 50-1,000 nm in diameter dispersed at the density of at least 1,500 / mm2 or simply with etched holes 0.5-10 mum in diameter emerging at the density of at least 2,000 / mm2 when the blank is immersed in a 3% nitric acid-ethyl alcohol solution at 20° C. for 30 seconds. A method of manufacturing the blank comprises hot rolling of a slab of the Fe-Ni alloy, cooling, recrystallization annealing, cold rolling, etc. under controlled conditions: e.g., hot rolling the slab at 950-1,250° C. to 2-6 mm thick, cooling the stock in the range of 900-700° C. at the rate of 0.5° C. / second, continuously passing the stock through a heating furnace at 850-1,100° C. for recrystallization annealing to adjust the mean diameter of the recrystallized grains to 5-30 mum, and performing the cold rolling before the final recrystallization annealing at a reduction ratio of 50-85% and the final cold rolling at a reduction ratio of 10-40%.

Owner:JX NIPPON MINING & METALS CO LTD

Coten base enamel and glazeslip thereof

The invention relates to coten base enamel and glazeslip thereof. The contents of some ingredients in the chemical component of coten are excessive for production of the enamel and are unbeneficial to the quality of a product; the key for overcoming the adverse factors is to determine suitable special base enamel capable of ensuring the enamel quality and the physicochemical property. The coten base enamel comprises the following components: 57.80-59.30 parts of SiO2, 32.06-2.70 parts of Al2O3, 1.80-2.80 parts of K2O, 10.98-11.35 parts of Na2O, 12.76-16.05 parts of B2O3, 2.80-1.00 parts of Li2O2, 3.80-4.80 parts of CaO, 0.60-1.50 parts of CoO, 1.401-2.00 parts of NiO, 0.20-0.80 part of Fe2O3 and 1.40-2.00 parts of MnO. The coten base enamel is utilized as an acid resistant and anticorrosive coten heat transfer element coating.

Owner:HARBIN TIANLU ENAMEL

Two-side front jacquard satin towel and weaving process thereof

The invention discloses a two-side front jacquard satin towel and a weaving process thereof. The two-side front jacquard satin towel is formed by weaving warp yarns and weft yarns, the warp yarns are divided into four layers, the ground warps of the upper two warp yarn layers and the weft yarns are woven to form a front side pattern texture, the looped warps of the lower two warp yarn layers and the weft yarns are woven to form a reverse side pattern texture, the front pattern texture and the reverse side pattern texture are connected into a whole body through a plurality of uniformly-distributed tying textures formed by the looped warps and the weft yarns, the weft density of the weft yarns is 80-90 / cm, and the tying texture is wefted by 5-15. The double sides of the towel have different patterns or the same pattern, so that the towel can reach a new level in visual appearance, the new pattern development field is opened up, and compared with the traditional double-color weft satin jacquard towel, the two-side front jacquard satin towel has high level and has high market competitive power.

Owner:SUNVIM GROUP

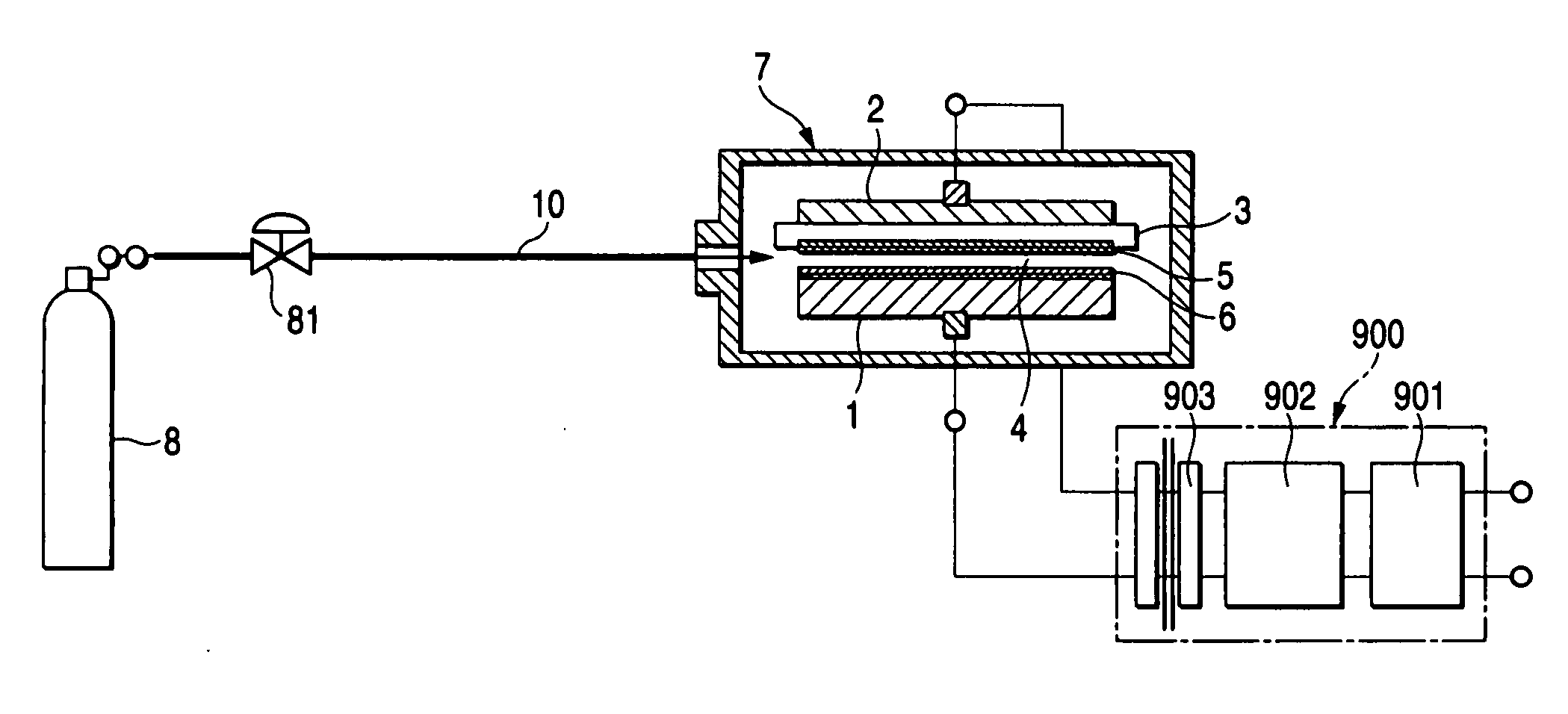

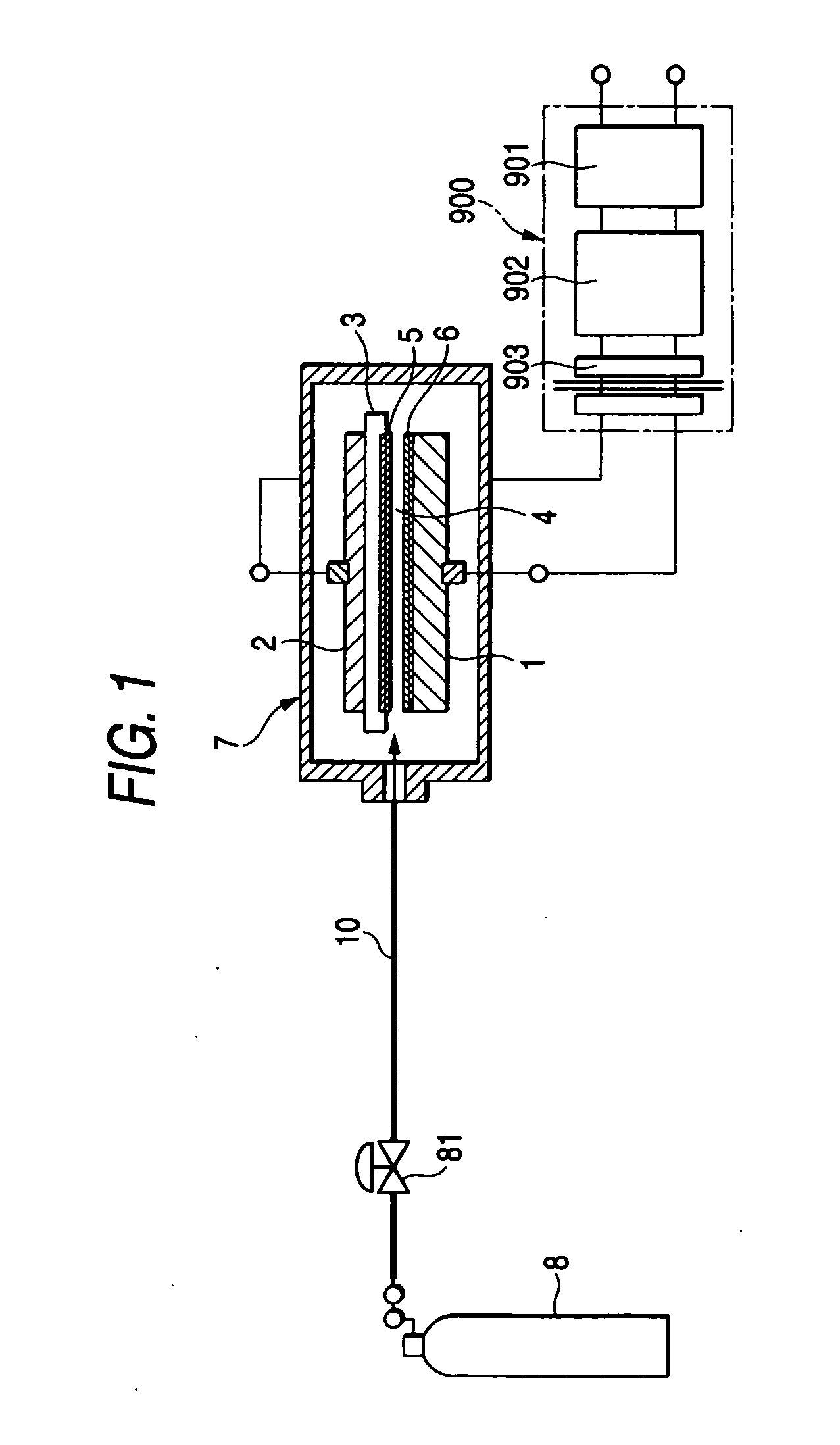

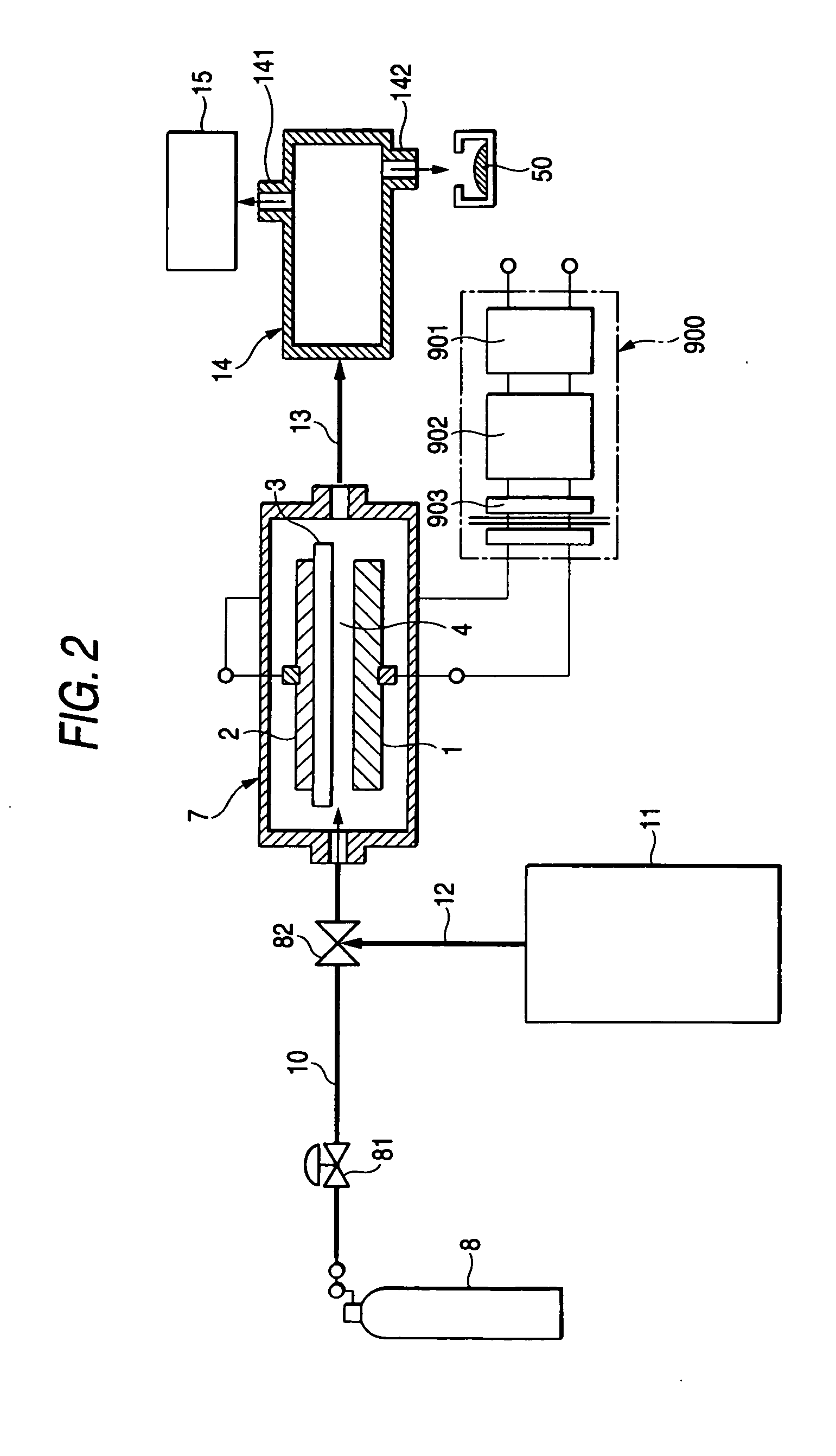

Photocatalyst Material Producing Method and Photocatalyst Material Producing Apparatus

ActiveUS20080251012A1Low costEasy to produceSpark gapsPretreated surfacesHigh concentrationChemical reaction

This invention provides a new photocatalyst material producing apparatus and photocatalyst material producing method that can produce a large quantity of photocatalyst material of high quality by a chemical reaction in light high-field plasma in a highly oxidative high-concentration ozone medium state, instead of systems to produce a photocatalyst material by PVD and CVD, which are conventional dry deposition methods.In a photocatalyst material producing method and photocatalyst material producing apparatus according to this invention, a pair of facing electrodes are provided via a dielectric material in a discharge gap where gas mainly containing oxygen gas is supplied, and an AC voltage is applied between the electrodes to generate dielectric barrier discharge (silent discharge or creeping discharge) in the discharge gap. Thus, oxygen gas containing ozone gas is created and a metal or metal compound is modified to a photocatalyst material by the dielectric barrier discharge.

Owner:TOSHIBA MITSUBISHI-ELECTRIC IND SYST CORP

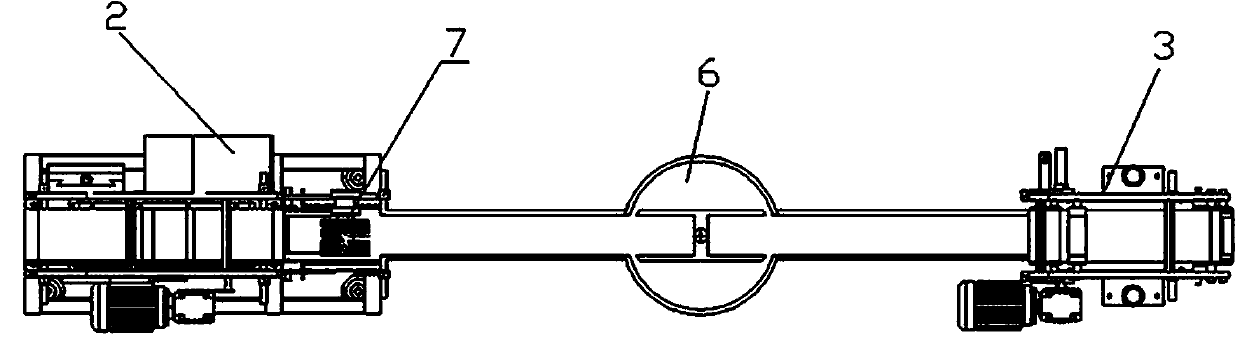

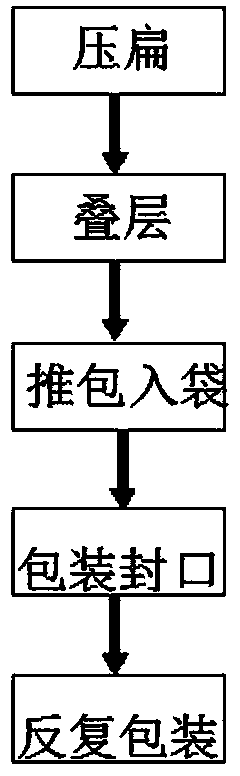

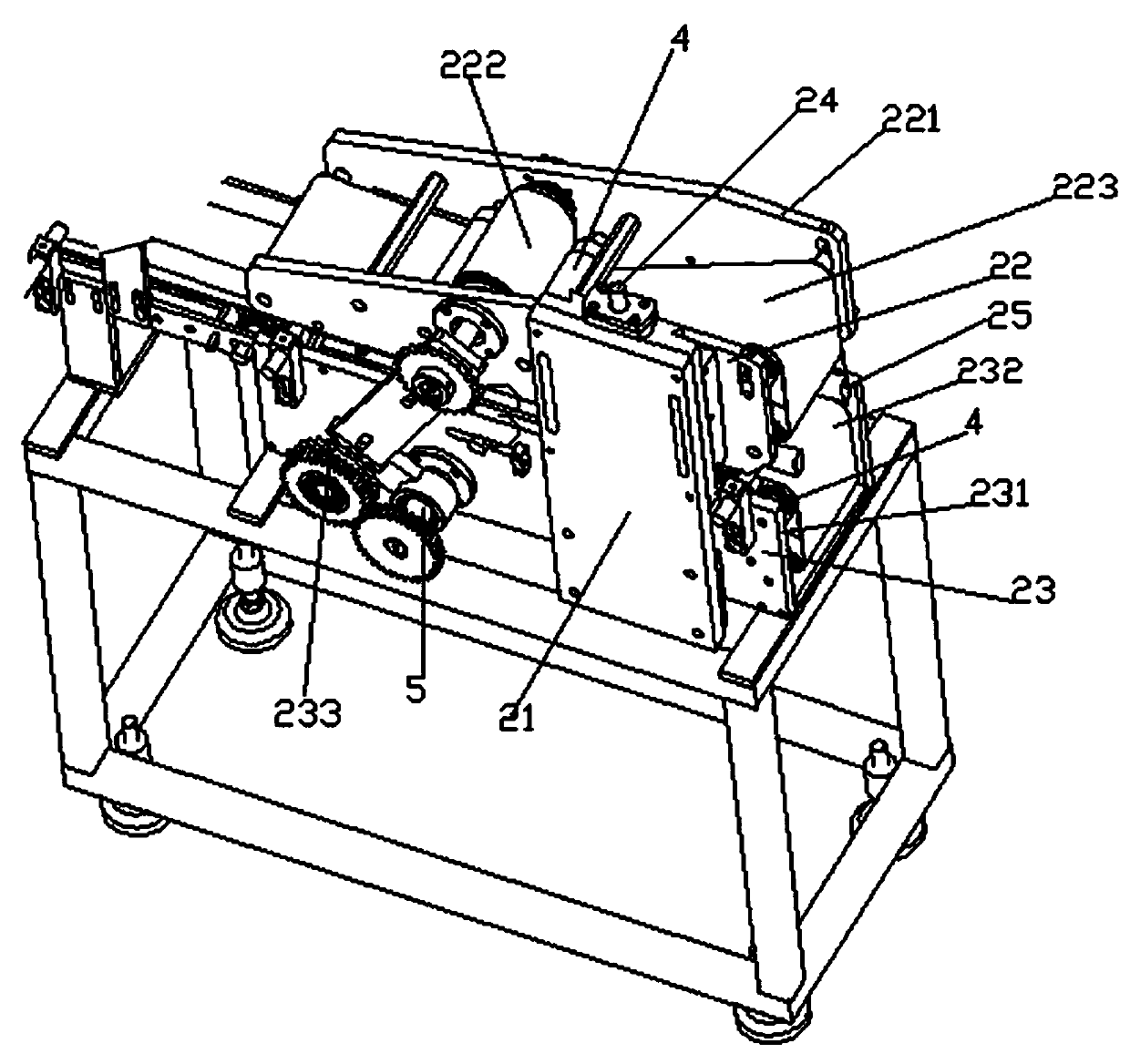

Packaging method of flat rolled toilet paper

The invention discloses a packaging method of flat rolled toilet paper, and relates to the technical field of tissue packaging. The packaging method includes the steps of flattening, laminating, pushing packages into bags, packaging, sealing and packaging repeatedly. According to the packaging method, flattening is conducted on a paper roll twice, the paper roll is flattened and shaped completely, the situations of jumping and warping can be avoided, automatic laminating processing can be achieved, laminating packaging is completed automatically, and packaging operation is completed efficiently.

Owner:上海松川峰冠包装自动化有限公司

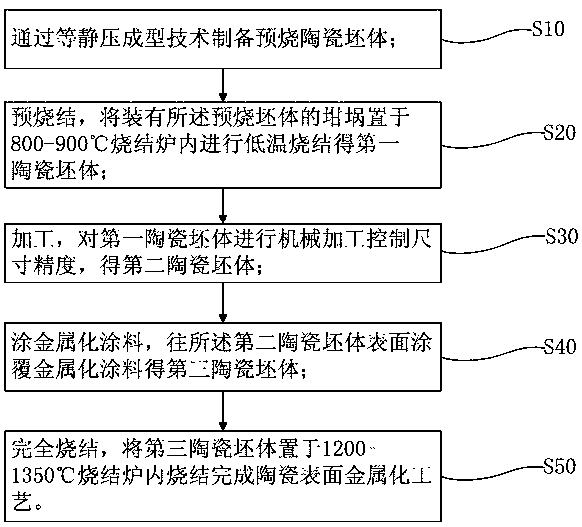

Ceramic surface metallization process

The invention provides a ceramic surface metallization process. The process comprises the following steps: preparing a pre-sintered green body through the isostatic pressing technology; performing pre-sintering: placing a crucible containing the pre-sintered green body into a sintering furnace with a temperature of 800-900 DEG C, and carrying out low-temperature sintering to obtain a first ceramicgreen body; performing processing: performing mechanical processing on the first ceramic green body by controlling dimensional accuracy to obtain a second ceramic green body; coating a metallizationlayer: coating the surface of the second ceramic green body with a metallization coating; and performing complete sintering: placing the third ceramic green body into a sintering furnace with a temperature of 1200-1350 DEG C for sintering to complete the ceramic surface metallization process. The ceramic surface metallization process overcomes shortcomings of the prior art, the preparation methodis simple, and a bonding strength between ceramic and a metal surface is large.

Owner:泰州市光明电子材料有限公司

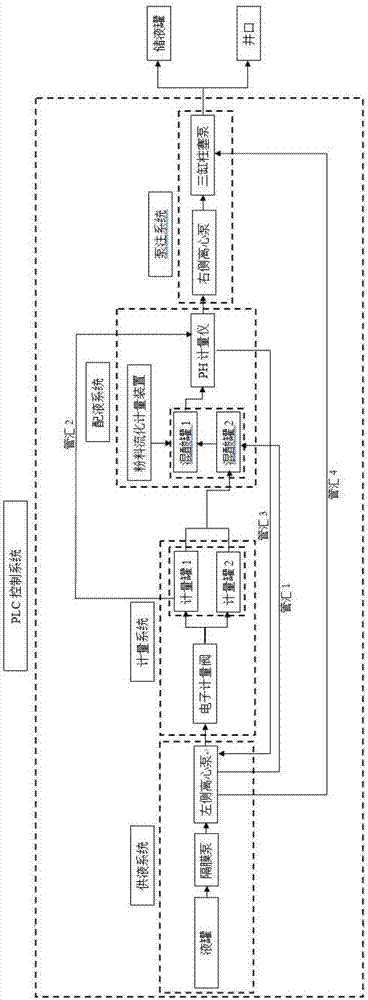

Integrated skid-mounted continuous mixing device and technology for acid liquor

InactiveCN107335377ANo unevennessEasy to transportFlow mixersTransportation and packagingControl systemPneumatic valve

The invention discloses an integrated skid-mounted continuous mixing device for acid liquor. The device is controlled by a PLC control system and integrates functions of a balance pumper and an acid mixing device. A liquor supply system comprises a liquor tank and a left centrifugal pump unit which are sequentially connected, a metering system comprises an electronic metering valve and a metering tank unit which are sequentially connected, a liquor preparing system comprises a powder fluidization metering device, an acid mixing tank and a PH meter unit which are sequentially connected, a pumping system comprises a right centrifugal pump and a three-cylinder plunger pump unit which are sequentially connected, a process manifold comprises pipelines or pipes and pneumatic valves, and the liquor supply system, the metering system, the liquor preparing system and the pumping system are connected through the manifold. The device has the benefits as follows: continuous mixing is realized; mixing of solid phase and liquid phase chemical materials, well washing, continuous acid injection, plug removal operation and the like are finished by the same vehicle; the device can be transported and used on field sites conveniently; the device can realize continuous and uniform liquor preparation and is high in speed; precise control and detection of preparation effect can be realized; liquor preparation can be finished automatically according to site requirements.

Owner:CNPC BOHAI DRILLING ENG

Remaining toner detection apparatus and image forming apparatus provided with same

ActiveUS20050117921A1Accurately determinedAccurate measurementElectrographic process apparatusLevel indicators by physical variable measurementImage formationEngineering

A pair of indentations is formed with a vertical spacing on a side wall of a toner cartridge, respective translucent windows are arranged on opposing upper and lower surfaces of the indentations protruding into the toner cartridge, and a light-emitting element and a light-receiving element of a remaining toner sensor are inserted to the indentations such that the light-emitting element and the light-receiving element of the remaining toner sensor face each other via the translucent windows of the indentations. When there is sufficient toner remaining in the toner cartridge, there is toner in the space between the transparent plates, and the space between a light-emitting diode and a phototransistor is blocked such that light is not incident on the phototransistor, whereas when there is little toner remaining in the toner cartridge, there is no toner in the space between the transparent plates, and the light is incident on the phototransistor via the space between the light-emitting diode and the photoresistor.

Owner:SHARP KK

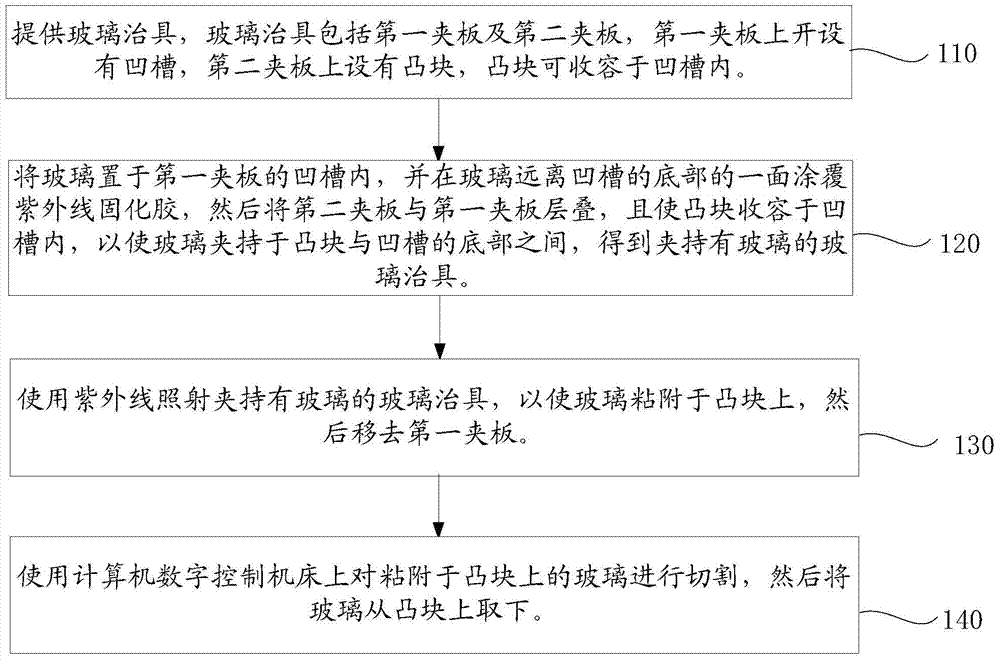

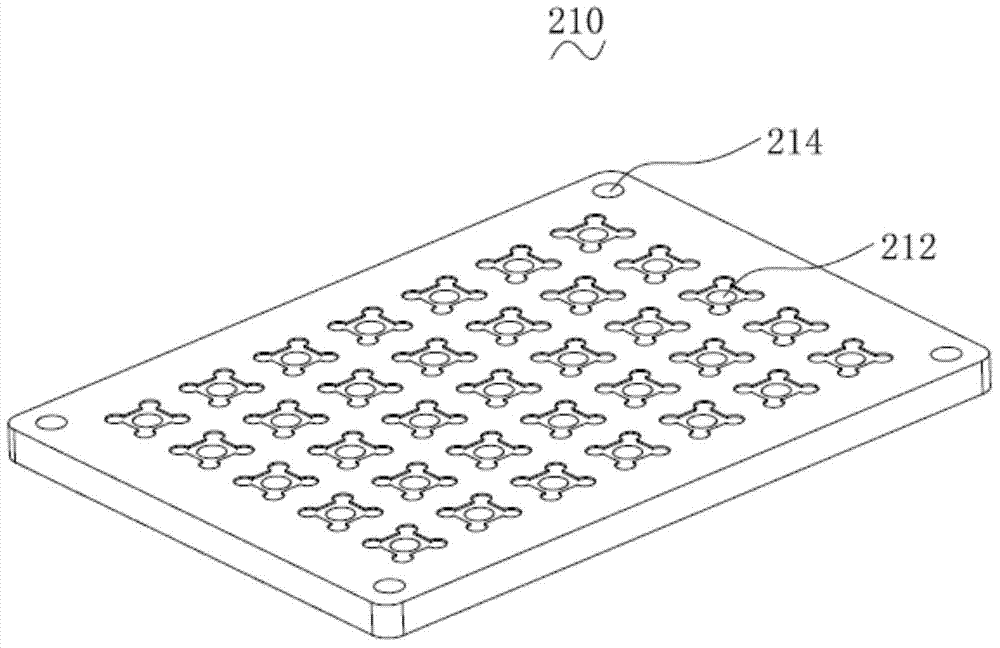

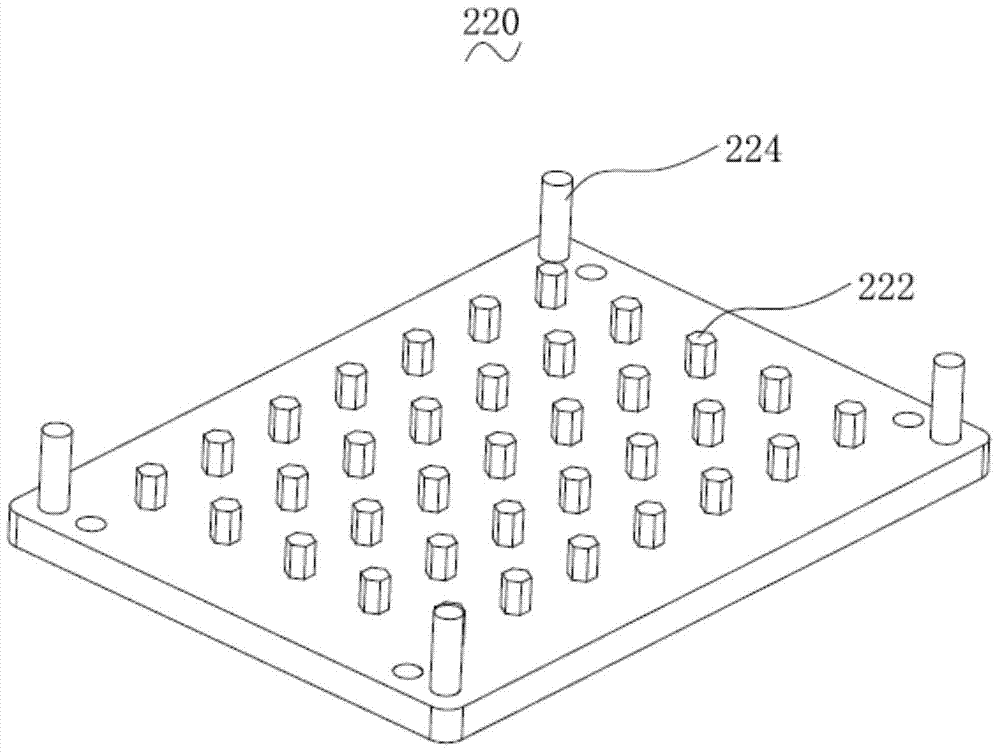

Processing method of glass eyeglass of camera

ActiveCN103936274AEasy to processImprove processing efficiencyGlass severing apparatusGlass productionNumerical controlUV curing

A processing method of a glass eyeglass of a camera comprises the following steps: providing a glass jig comprising a first clamping plate and a second clamping plate, wherein the first clamping plate is provided with a groove, the second clamping plate is provided with a projection, and the projection can be accommodated in the groove; putting glass in the groove of the first clamping plate, coating one surface of the bottom of the glass far from the groove with an ultraviolet-curable adhesive, laminating the first clamping plate and the first clamping plate, and allowing the projection to be accommodated in the groove to make glass clamped between the projection and the bottom of the groove in order to obtain a glass clamped glass jig; irradiating the glass clamped glass jig with ultraviolet ray to make the glass adhered to the projection, and removing the first clamping plate; and cutting the glass adhered on the projection by using a computer numerical control machine tool, and taking the glass off the projection. The processing efficiency of the processing method of the glass eyeglass of the camera is high.

Owner:深圳市浩科投资咨询有限公司

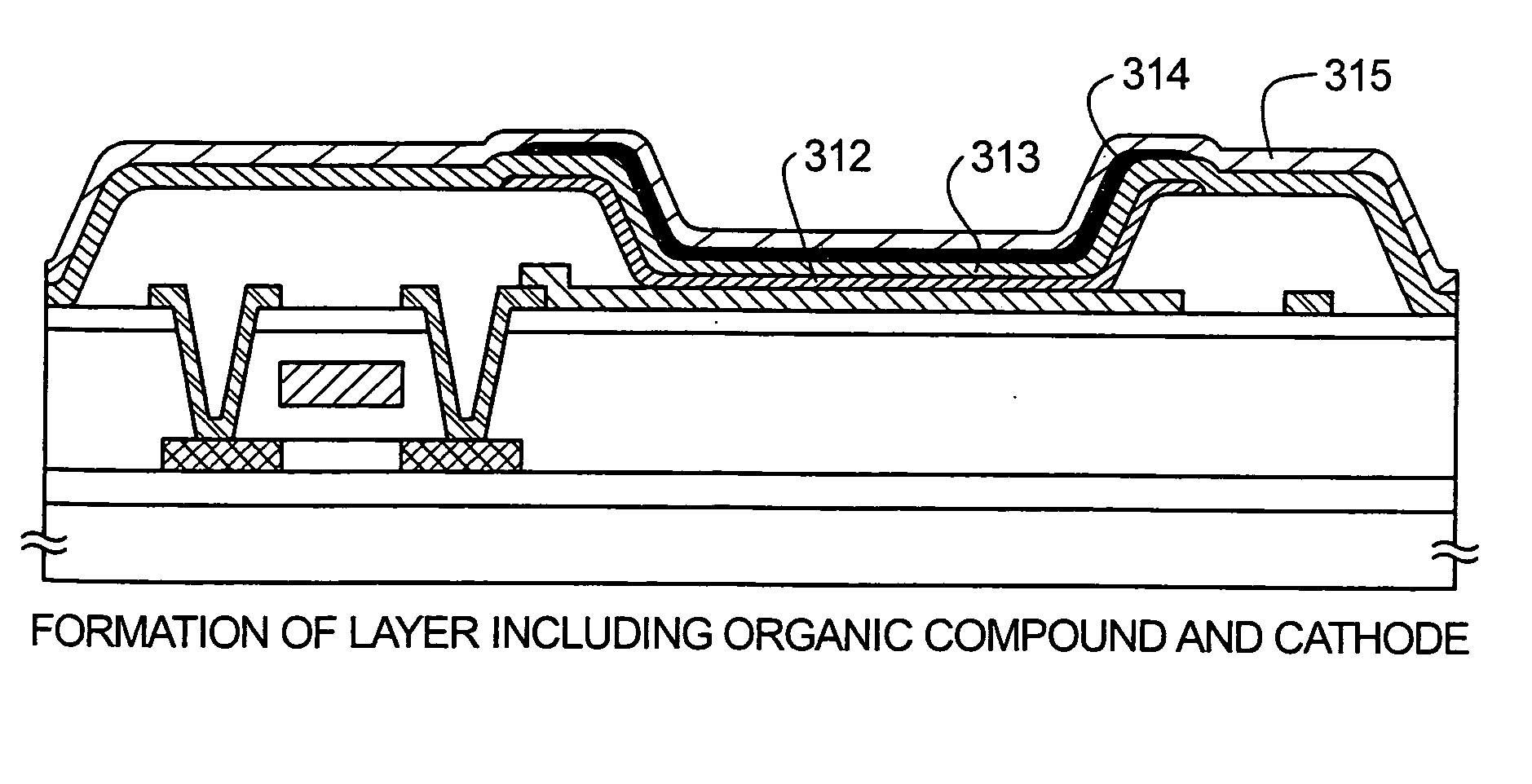

Light-emitting device and method for manufacturing the same

InactiveUS20060197081A1Reduce pinholesImprove reliabilityElectroluminescent light sourcesSolid-state devicesOrganic filmSimple Organic Compounds

The present invention provides an organic light-emitting element where a lower electrode, an organic compound layer and an upper electrode are laminated on a substrate, wherein the upper electrode of the organic EL element is formed by a laminate of at least a conductive first inorganic film, a conductive organic film and a conductive second inorganic film, in order to suppress the occurrence of dark spot, so that the occurrence of pinholes in the upper electrode leading to dark spots is suppressed. Here, pinholes refer to holes in the upper electrode that penetrate upper electrode from the organic compound layer underneath to the atmosphere above.

Owner:SEMICON ENERGY LAB CO LTD

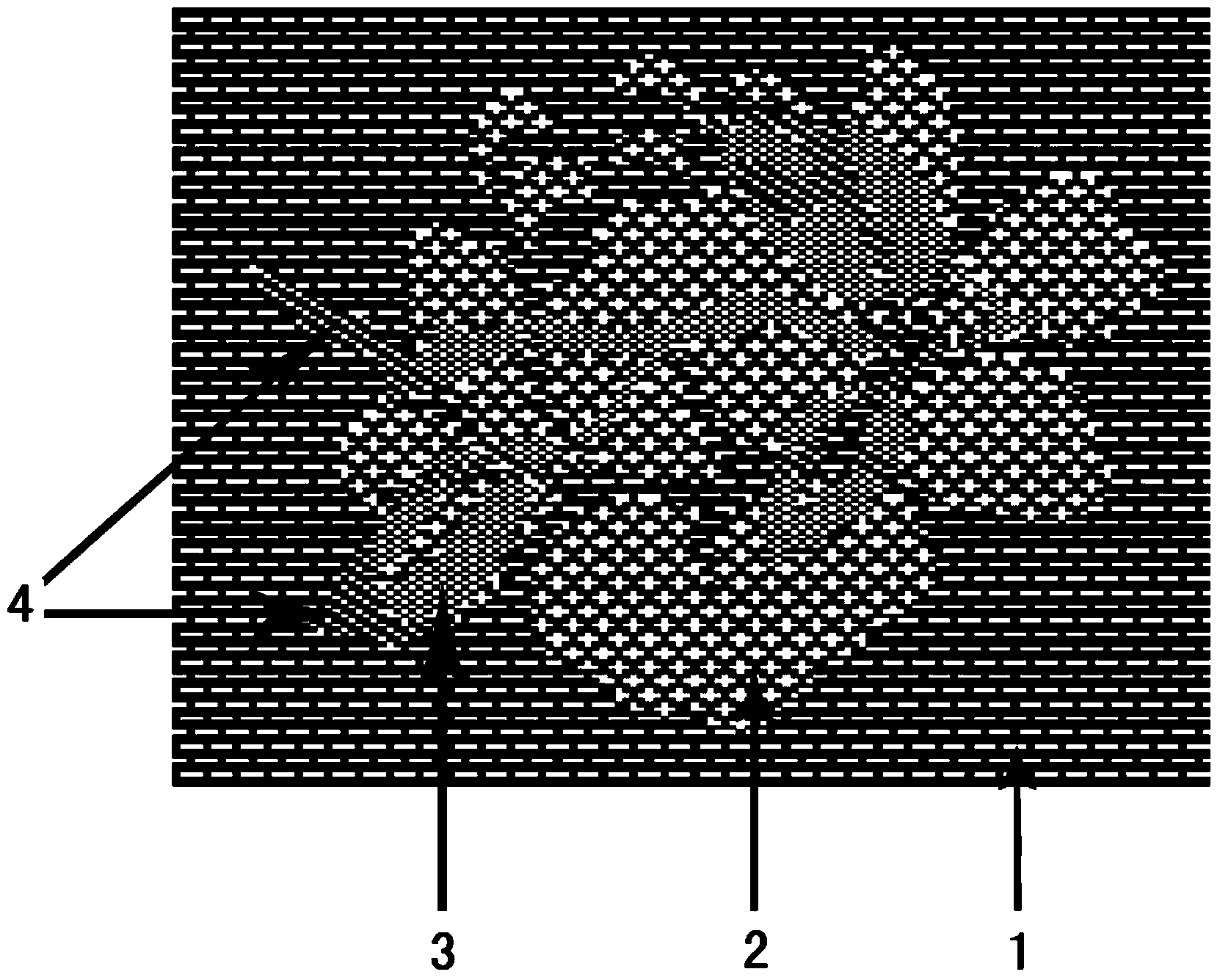

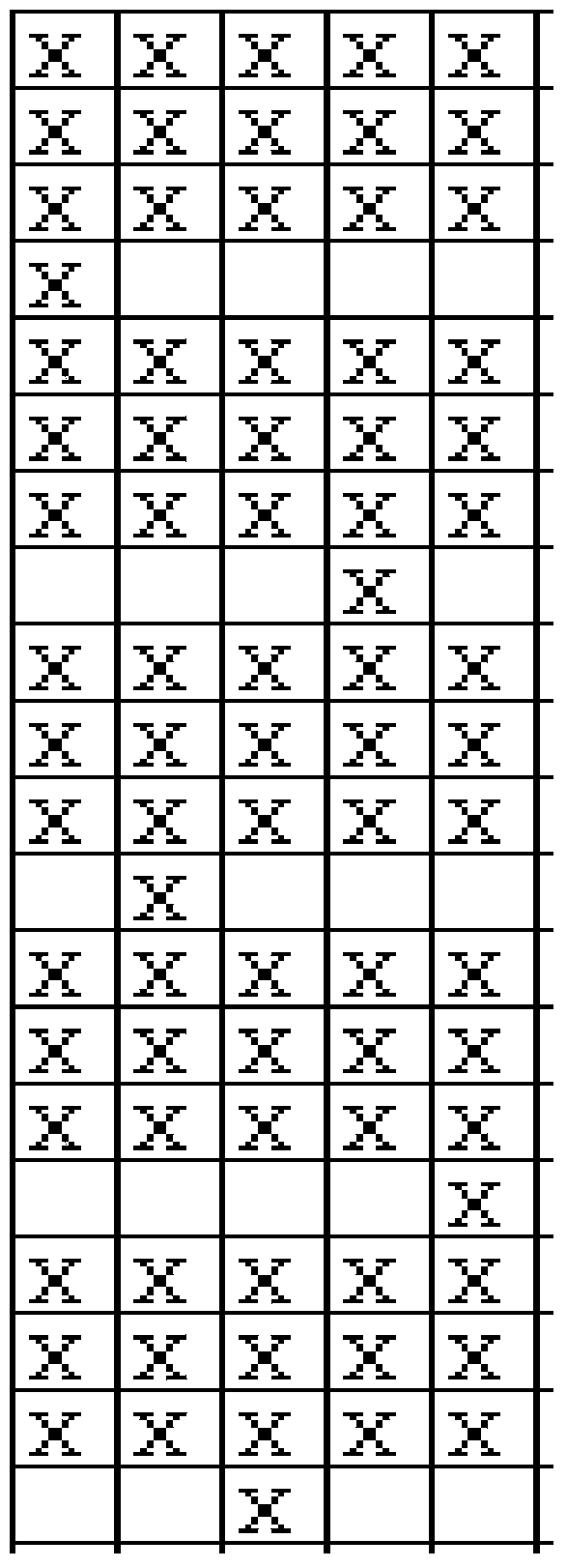

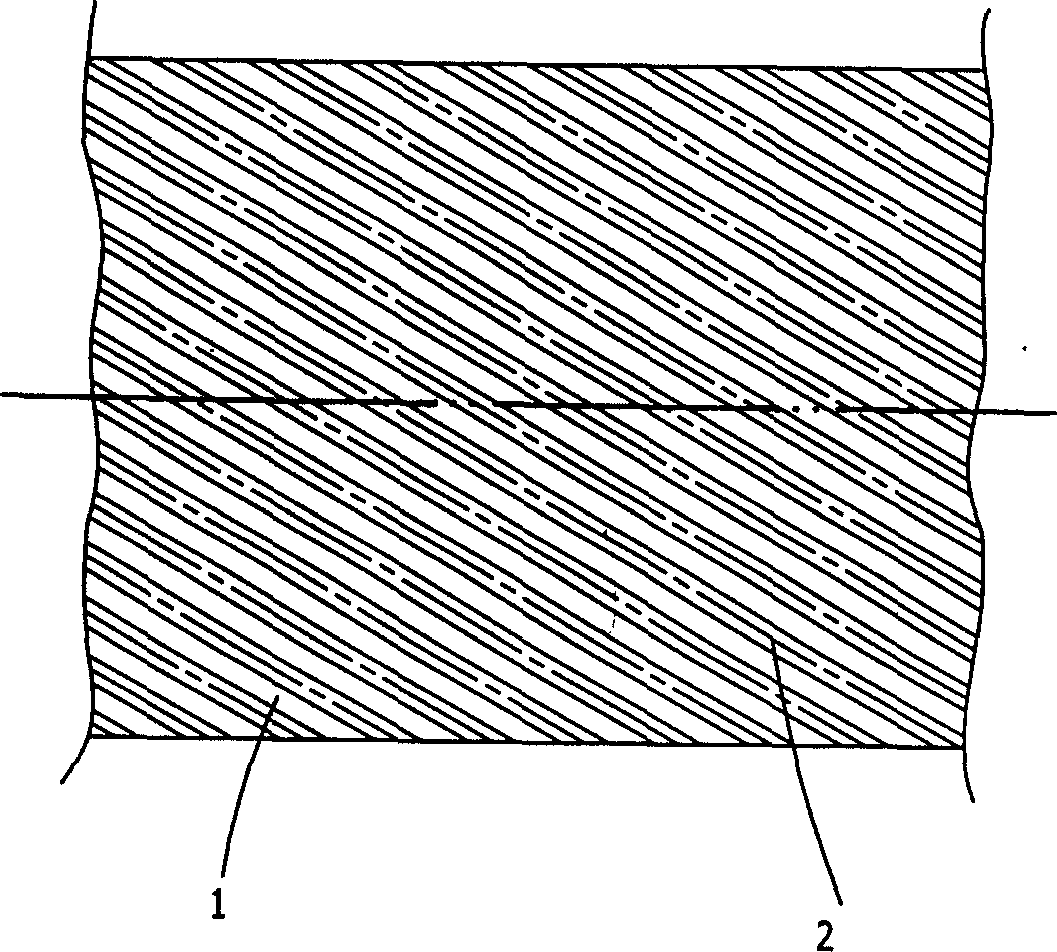

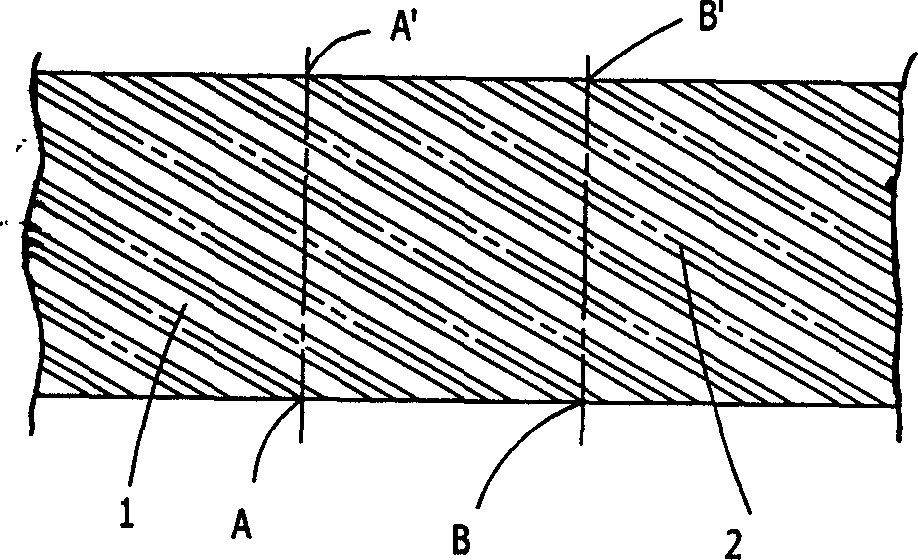

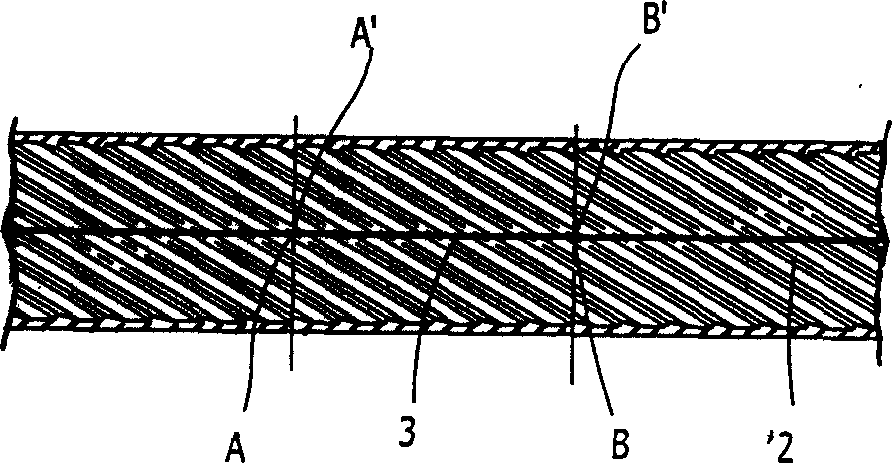

Warp arrangement method of 2.5D copying woven sleeve and copying machine woven sleeve

The invention discloses a warp arrangement method of a 2.5D copying woven sleeve and the woven sleeve woven with the method. The warp arrangement method is a gradient warp arrangement process, namely,after main warps are arranged, two rows of edge warps in one group are arranged on the two sides of the main warps from the middle to two edges respectively in a gradient descending manner, and the edge warps are decreased progressively from an inner layer to an outer layer. The 2.5D cylindrical or tapered copying woven sleeve is prepared by adopting the gradient warp arrangement process, no gasexists between an upper piece and a lower piece of the prepared woven sleeve, and the phenomenon of non-uniformity does not exist.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD

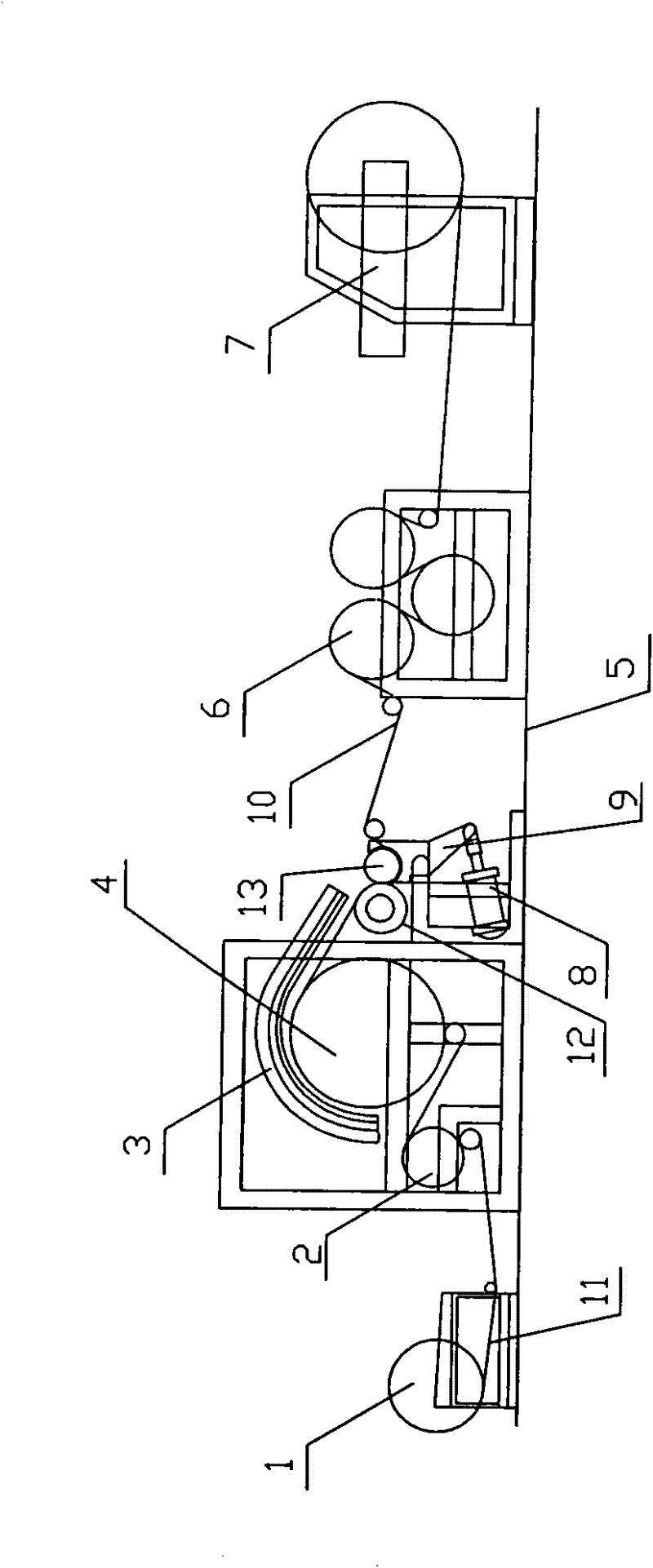

Fully automatic floor tile laying machine

The invention discloses a fully automatic floor tile laying machine, and belongs to the technical field of construction machinery. A cement discharging device 2 is arranged at the front end of the fully automatic floor tile laying machine. A cement storage tank 1 is connected to the upper end of the cement discharging device 2. A plastering device 15 is connected to the lower end of the cement discharging device 2. A first motor 9 is arranged at the rear of the cement discharging device 2. A floor tile accommodating box 3 is arranged at the rear of the first motor 9. A floor tile laying device7 is arranged at the lower end of the floor tile accommodating box 3. A second motor 10 is connected to the rear of the floor tile accommodating box 3. A compacting device 4 is connected to the rearof the second motor 10. A cement recovery box 11 is arranged at the rear of the compacting device 4. The whole fully automatic floor tile laying machine is arranged on a base 5. Walking rollers 8 arearranged at the lower end of the base 5. The fully automatic floor tile laying machine has excellent laying efficiency and laying effect.

Owner:杨帮燕

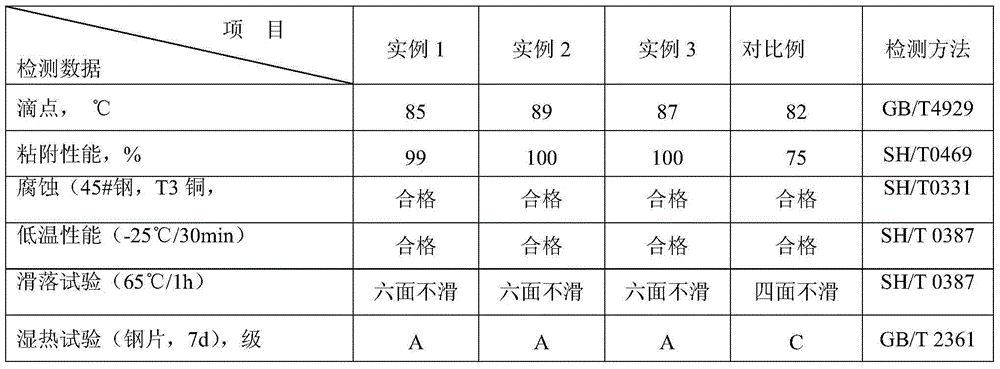

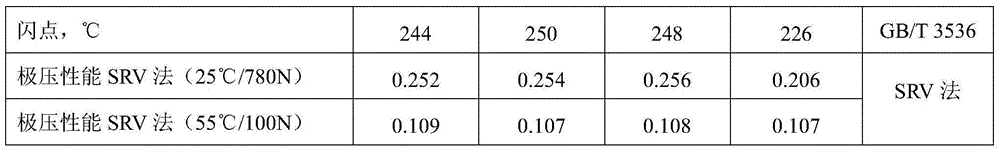

Heat-coating elevator steel wire rope grease and preparation method thereof

ActiveCN105733752APrevent slippingPrevent invasionLubricant compositionAdhesion forceMicrocrystalline wax

The invention discloses a heat-coating elevator steel wire rope grease and a preparation method thereof. The grease comprises 60-83% of high-viscosity high-aromatic-hydrocarbon-content mineral oil, 3-7% of microcrystalline wax, 3-10% of an amide thickener, 10-20% of a friction enhancing agent, and 1-8% of a rust inhibitor. The heat-coating elevator steel wire rope grease provided by the invention has good film-forming performance, metal surface adhesion force, and friction performance.

Owner:PETROCHINA CO LTD

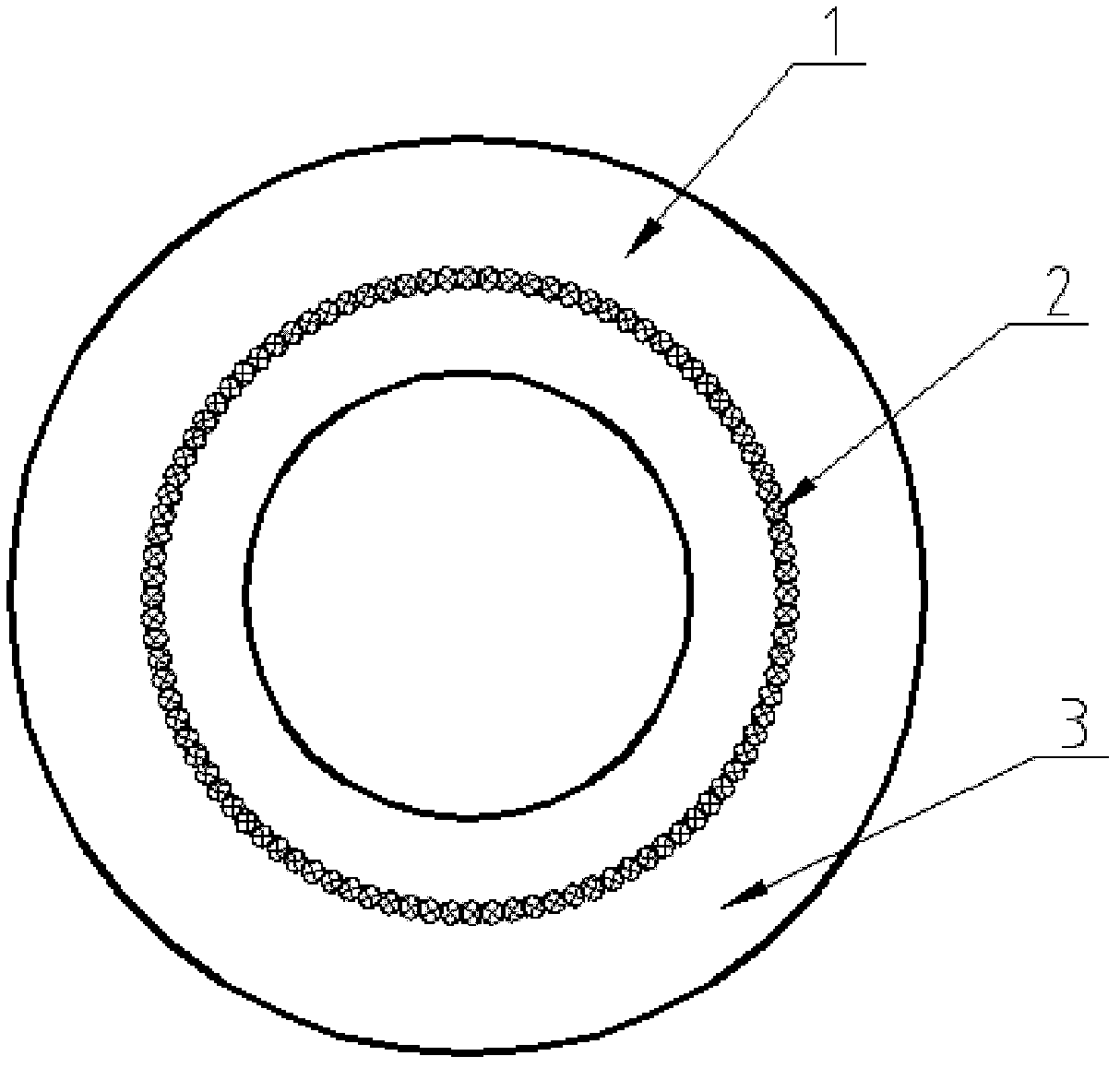

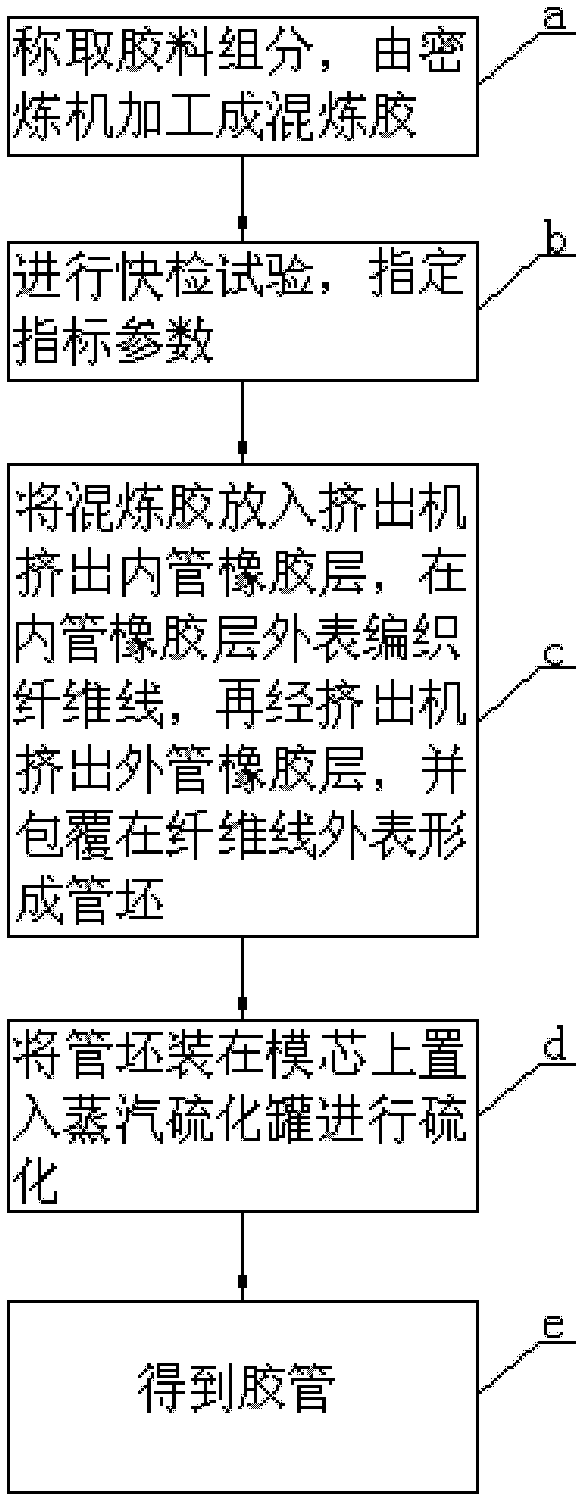

High-pressure power steering gear rubber tube and manufacturing process thereof

ActiveCN102628531AGood oil resistanceExcellent heat and aging resistanceFlexible pipesTubular articlesFiberVulcanization

The invention relates to the technical filed of automotive part manufacture, in particular to a high-pressure power steering gear rubber tube and a manufacturing process of the high-pressure power steering gear rubber tube. The high-pressure power steering gear rubber tube is formed by sequentially compositing an inner pipe rubber layer, a fiber wire enhancement layer and an outer pipe rubber layer from inside to outside. The main sizing material is chlorosulfonated polyethylene rubber (CSM). Each layer of rubber enables a banburying machine to be manufactured into rubber compounds to be compounded and extruded, two copies of fiber wires are weaved on the outer surface of the inner pipe rubber layer, then a pipe blank is formed by extruding the outer pipe rubber layer and wrapping on the surface of the fiber wire, the pipe blank is sleeved on a pipe die core to be arranged in a steam vulcanization tank for vulcanization, and the rubber pipe is obtained after depoling and level pressure of the pipe blank. The high-pressure power steering gear rubber tube has the advantages of being heat-resisting, oil-resisting, voltage-resisting, age-resisting, good in pulse performance, low in manufacture cost and high in percent of pass, and greatly meeting development requirements of modern automotives.

Owner:ZHEJIANG JUNHE RUBBER TECH

Welded steel pipes with ribs and method of manufacture

InactiveCN1570537AReduce thicknessImprove heat transfer efficiencyTubular elementsHigh rateStrip steel

The invention relates to a kind of steel tube jointing and making technique with costate pieces, rolling the coiled steel or sheet to make costate pieces, processing the technics such as clipping, intervolving, jointing to make diagonal costate pieces which are parallel to the axes of the steel pipe, with several salience in the inside of the pipe. These costate pieces form angle with the axes of the steel pipe, combined to form consecutive and parallel jointing pipe, it can be made into integrated costate pieces with screw thread. This invention has some advantages such as: having high rate of capability to cost, making costate pieces for jointing with simple measures and without the special and expensive equipments, acquiring jointing steel pipe which has high efficiency but the cost less. The costate pieces inside can be made integrated screw thread, without dead angle, easy to maintain, and easy to clean smeary and wash.

Owner:JONJEE HI TECH INDAL & COMML HLDG +1

Embossing machine

InactiveCN102260757AImprove product qualityNo unevennessLeather surface mechanical treatmentEngineeringActuator

The invention discloses an embossing machine, which comprises a heating roller, a driving roller, an embossing roller and a cooling device. The two roller surfaces are tangent or leave a gap for the leather to pass through and emboss. The cooling device is arranged behind the transmission roller and also includes a lever transmission mechanism. The supporting point of the lever transmission mechanism is connected to the embossing machine. , one end of the lever transmission mechanism is connected with the embossing roller, and the other end of the lever transmission mechanism is connected with the hydraulic device. The invention changes the movement of the embossing roller from manual adjustment to pneumatic adjustment, which saves a lot of manpower, and can maintain the pressure balance of the transmission roller and the embossing roller on the leather or bottom blank during embossing, so that the embossing roller The quality of flower products is stable, and the patterns are not uneven.

Owner:JIANGSU GUOXIN SYNTHETIC LEATHER

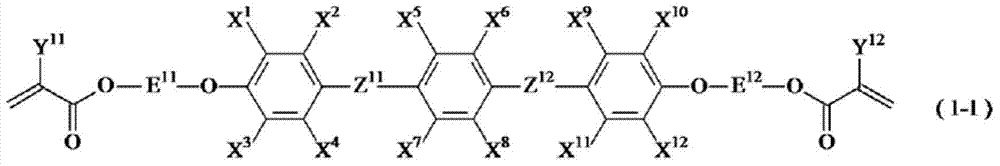

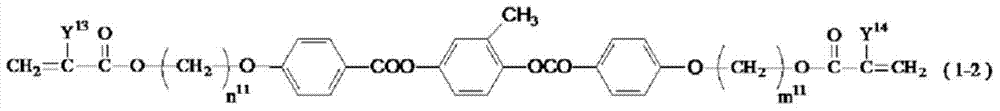

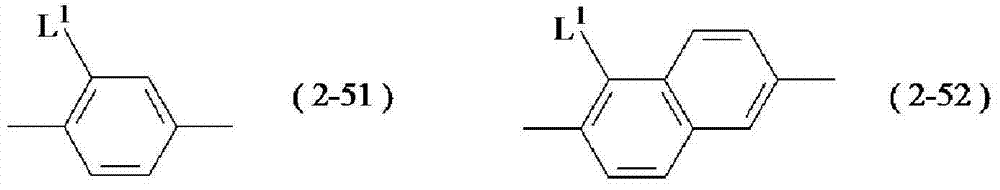

Polymerizable liquid crystal composition and thin film using same

InactiveCN103781879ALow hazeExcellent adhesionLiquid crystal compositionsPolarising elementsSolubilityLaser light

The present invention relates to a polymerizable composition which is useful as a material for liquid crystal devices, displays, optical components, coloring agents, security marking and laser light emission; and a thin film which is obtained from the polymerizable composition. The present invention provides a polymerizable liquid crystal composition which has excellent solubility in a solvent and good adhesion to a base and is capable of providing a thin film that has low haze and is free from unevenness. The present invention also provides a thin film which is obtained using the polymerizable liquid crystal composition and has excellent appearance. A composition and a thin film, which are free from unevenness and have low haze and good adhesion to a base, can be obtained at low cost by using a polymerizable liquid crystal composition of the present invention.

Owner:DIC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com