Coating method of light-emitting diode fluorescent powder

A phosphor and LED chip technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of difficult selection of dam colloids, difficult implementation of packaging links, limited application scope, etc., to reduce light loss and achieve high transparency. , the effect of wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

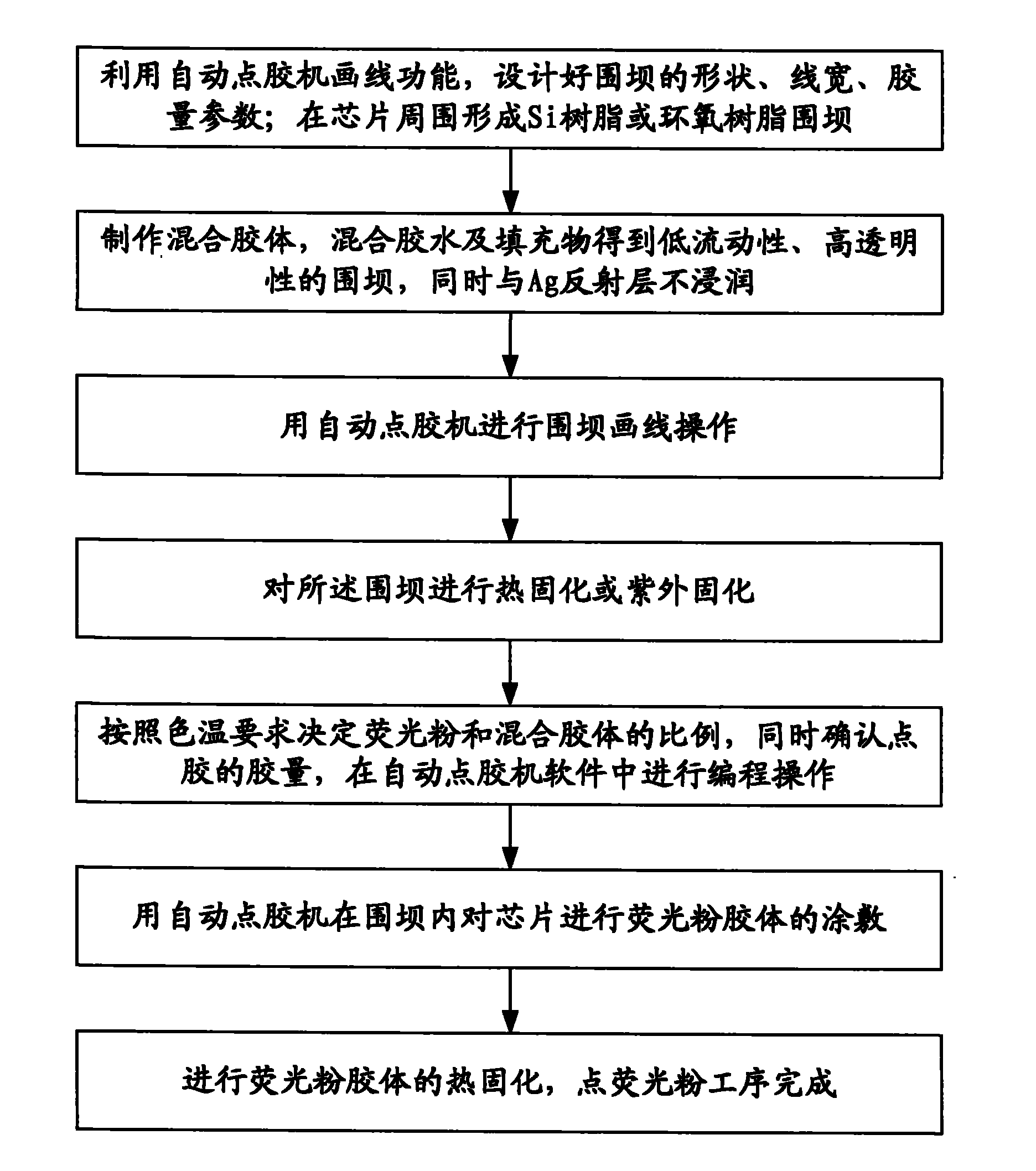

[0049]The invention provides a technique for partially coating fluorescent powder on an LED chip. After the LED chip is solidified and wire-bonded on the power-type bracket, the precision automatic dispensing equipment with a robotic arm is used to draw a colloid "dam" around the chip. The glue used is visible light transparent glue, and the Ag reflection of the reflective bowl The layer is not wetted, and its fluidity is reduced by using nano-SiO2 material. Formed colloidal "dams" are formed by heat curing or UV curing. Then dot an appropriate amount of fluorescent powder glue in the middle of the dam. Curing again to obtain LEDs with phosphor powder partially coated on the chip.

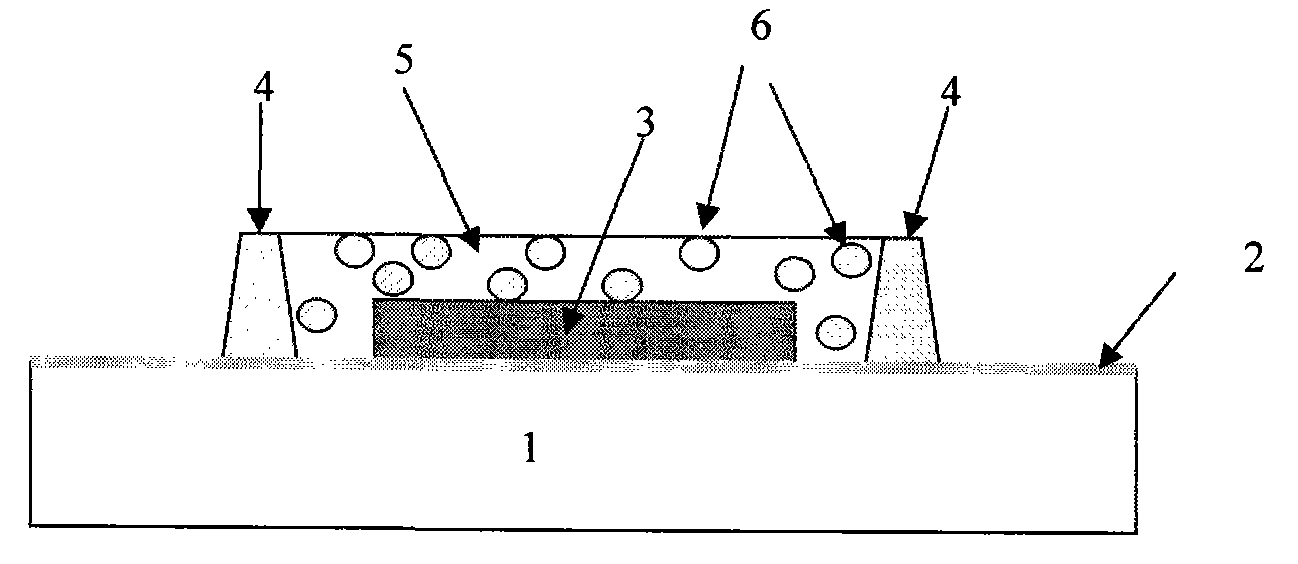

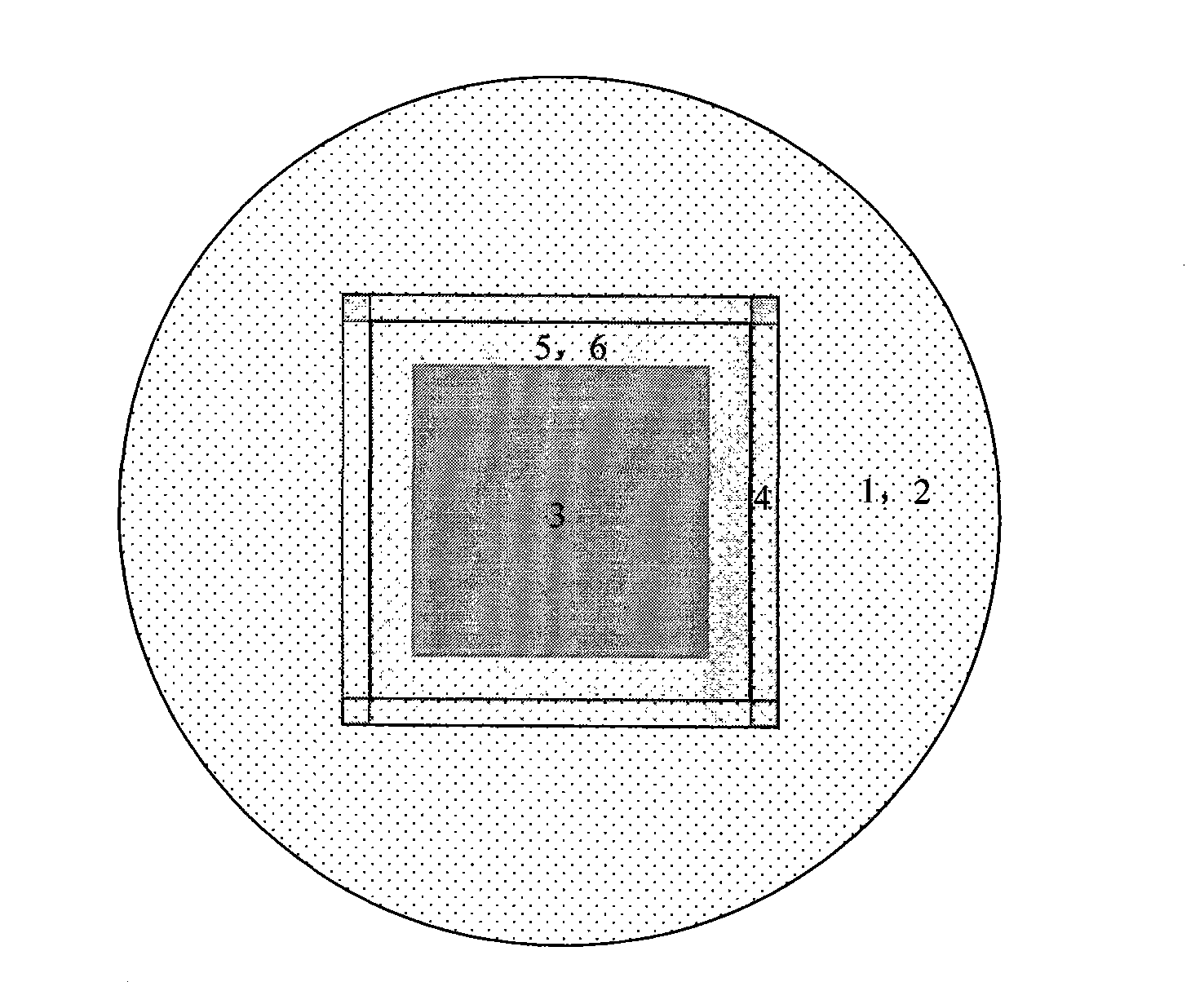

[0050] Figure 1a It is a cross-sectional structure diagram of phosphor powder partially coated on the LED chip. Ag reflector 2 is plated on the heat sink 1 of the power LED bracket, and the base material of the heat sink is generally Cu. The power LED chip 3 is fixed on the Ag surface of the he...

Embodiment 2

[0071] Embodiment 1 illustrates a typical implementation method of the present invention. However, in some special cases, higher requirements are placed on the reliability of the coated phosphor. Therefore a second embodiment is given. Such as Figure 3a , shown in 3b, it differs from Embodiment 1 in that a layer of Si resin 6' is added between the chip 3 and the phosphor adhesive layer 5,6, in order to ensure the uniformity of the thickness of the protective layer Si resin 6', We added an additional 4' of dam.

[0072] In this embodiment, the specific preparation steps of the coating method of LED phosphor powder are as follows:

[0073] (1) Use the "line drawing" function of the automatic glue dispenser to design the shape of the dam shown in Figure 3, the line width, the amount of glue and other parameters. Two dams are formed around the chip, and the height and width of the dam close to the chip are smaller than the outer "dam". The height of the inner layer "dam" is ...

Embodiment 3

[0084] With the improvement of LED chip manufacturing and packaging level, multi-chip integration has become an important direction of packaging applications. Therefore, we give a third embodiment based on multi-chip local phosphor glue dispensing. Such as Figure 4a , 4b As shown, it is different from Embodiment 1 in that it realizes the "dam" of multi-chips. For specific preparation steps, please refer to Example 1.

[0085] For multi-chip packaging, due to the mutual mixing of excitation light and fluorescence between chips, the yellow circle measured by ordinary dispensing methods is not obvious, which meets the requirements for ordinary lighting. However, when the liquid crystal display has strict requirements on the thickness of the backlight source, the local color difference will still affect the display quality. Therefore, this problem can be solved in the form of multi-chip dam packaging. For multi-chip dams, since adjacent chip dams can be shared, the number of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com