Warp arrangement method of 2.5D copying woven sleeve and copying machine woven sleeve

A copying machine and warp technology, applied in the direction of fabrics, textiles, textiles and papermaking, etc., can solve the problems of reducing the performance of fabrics, unevenness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0038] A 2.5D cylindrical profiling woven cover is prepared by using gradient cloth warp. The warp used in the cylindrical profiling woven cover is 480Tex×1 strand of high-strength glass fiber, the weft is 480Tex×1 strand of high-strength glass fiber, the theoretical thickness of the cylindrical profiling woven cover is 3mm, and the cylinder diameter 70mm, length 200mm, equal diameter along the length direction. The fabric structure is a 2.5D woven shallow cross-bending structure, the warp density of the fabric is 9 threads / cm, and the weft density is 3.3 threads / cm.

[0039] The weaving method of described woven cover comprises the following steps:

[0040] The first step, determine the total row number n=200 of fabric warp yarn according to fabric perimeter, determine the total number of layers m=10 of fabric warp yarn according to fabric thickness;

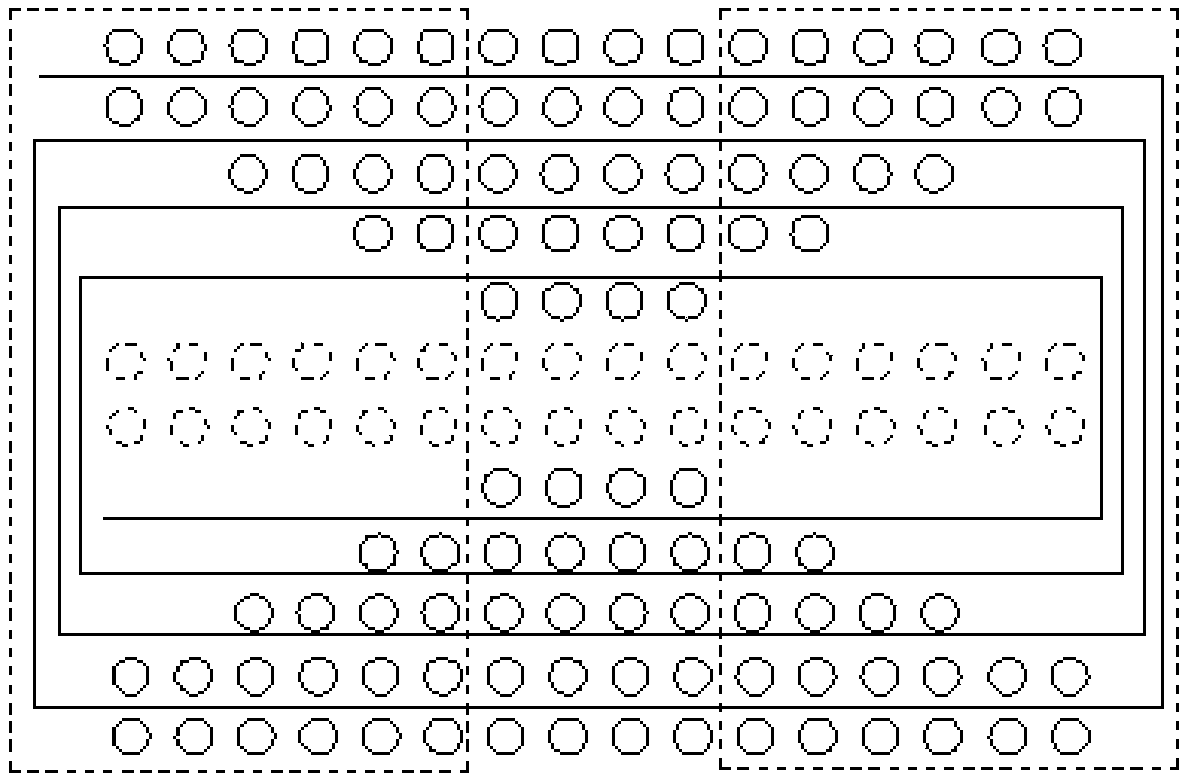

[0041] The second step, the main warp yarn arrangement: the warp yarns are arranged in the upper 5 layers and the lower 5 l...

Embodiment approach 2

[0047] Embodiment 2 is basically the same as Embodiment 1, except that the fabric structure is a 2.5D woven shallow cross-linked structure, and the weft yarn weaving method is as follows:

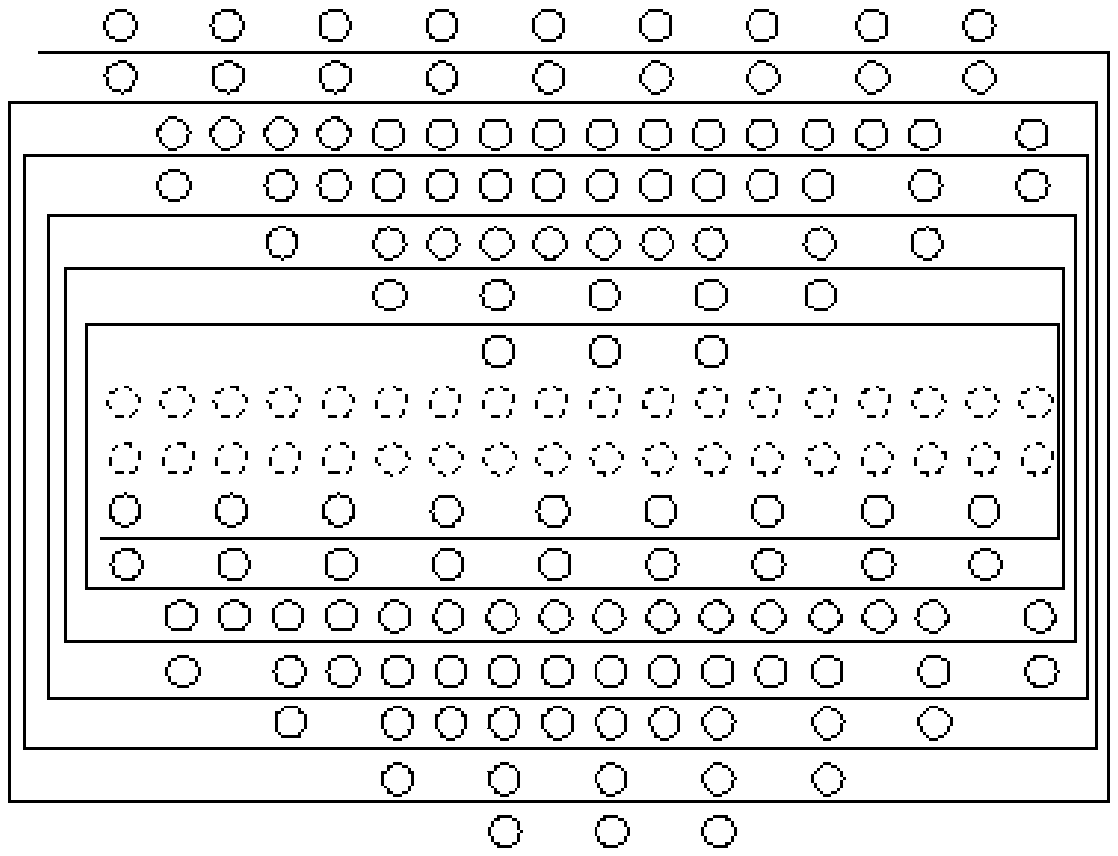

[0048] The first step, the first weft introduction: adjust the front and rear heald frames to the position where the front heald frame is higher than the two heald eyes of the rear heald frame, and the position after the yarn movement is as follows: figure 2 As shown, the introduction method of the weft yarn is the same as that of the first weft in Embodiment 1, and will not be repeated here.

[0049] The second step, the second weft introduction: adjust the front and rear rows of heald frames so that the front and rear heald frames are in the same position, and the position after the yarn moves is as follows: figure 1 As shown, the introduction method of the weft yarn is the same as that of the second weft in Embodiment 1, and will not be repeated here.

[0050] The third step, the third...

Embodiment approach 3

[0054] A 2.5D conical profiling woven sleeve is prepared by using gradient cloth warp. The warp used in the woven cover is 480Tex×1 strand of high-strength glass fiber, the weft is 480Tex×2 strand of high-strength glass fiber, the thickness of the 2.5D woven cone is 3.0mm, and the diameter of the large end of the fabric is Φ=400± 1mm, the diameter of the small end is Φ=0mm. The fabric structure is a 2.5D woven shallow cross-linked structure, the number of warp yarns is designed to be 4 layers, the warp density of the fabric is 9 threads / cm, and the weft density is 4.0 threads / cm.

[0055] The weaving method of described woven cover comprises the following steps:

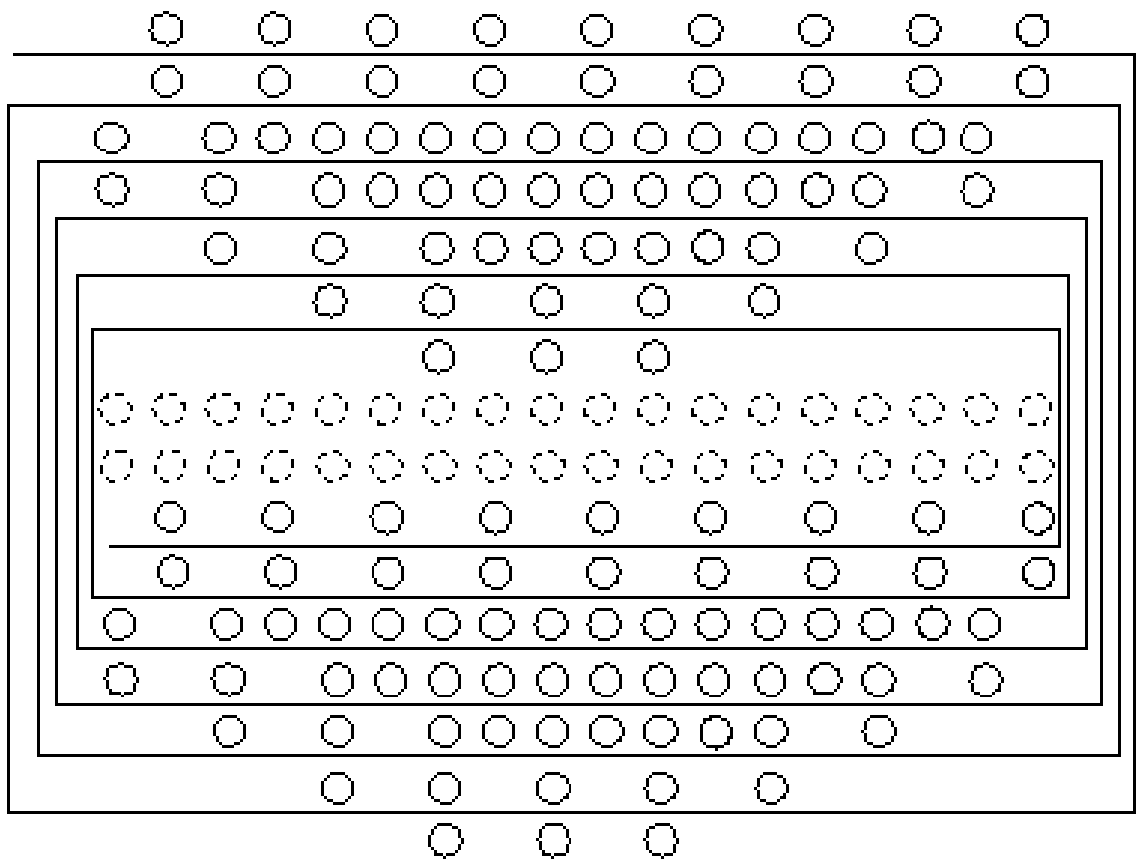

[0056] The first step, determine the total row number n=1132 of fabric warp yarn according to fabric circumference, determine the total number of layers m=8 of fabric warp yarn according to fabric thickness;

[0057] The second step, the main warp yarn arrangement: the warp yarns are arranged in the upper 4 layers ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com