Heat-coating elevator steel wire rope grease and preparation method thereof

A steel wire rope grease, coating technology, applied in the field of grease, can solve the problems of poor film formation, poor metal adhesion, protection and auxiliary braking, etc., to achieve the effect of improving friction coefficient, strong metal adhesion, and improving safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

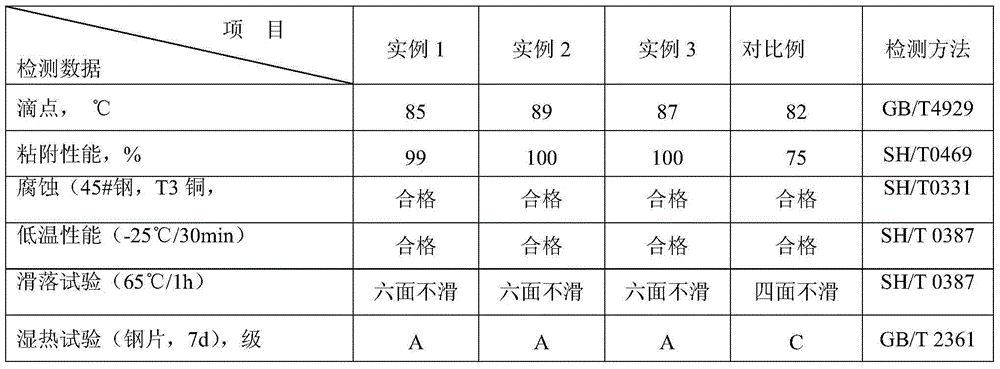

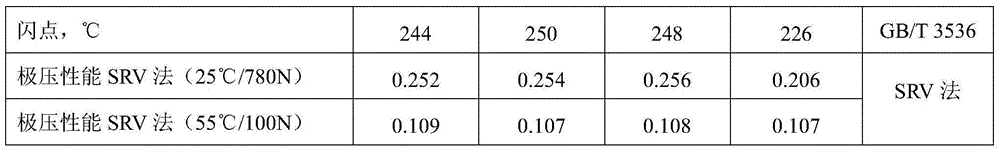

Examples

preparation example Construction

[0057] The present invention also provides a preparation method (one-step complete thickening process) of hot-coated elevator wire rope grease, comprising the steps of:

[0058] 1) Add 3-7% microcrystalline wax, 3-10% amide thickener, and 10-20% friction enhancer to 60-83% mineral oil and mix in sequence. The temperature is controlled between 145-150°C and the 0.5~1h;

[0059] 2) Start stirring after the microcrystalline wax melts, control the stirring speed at 200-300r / min, and the stirring time is not less than 2.5h;

[0060] 3) Cool down to 110-120°C, add 1-8% antirust agent, stir for 1-1.5 hours, and fill;

[0061] Wherein, the aromatic hydrocarbon content of the mineral oil described in step 1) is between 35% and 85%, and the kinematic viscosity at 100°C is between 30% and 80mm 2 / s; step 1) to step 3) each percentage is a mass ratio.

[0062] Wherein, in a preferred embodiment of the method for preparing hot-coated elevator steel wire rope grease of the present invent...

Embodiment a

[0072] The present embodiment provides a kind of preparation method of thermal coating type elevator wire rope grease, comprises the following steps (the following percentages are mass ratios):

[0073] 1) Add 3% microcrystalline wax, 3% amide thickener, and 10% friction enhancer to 83% mineral oil in turn and mix them. The temperature is controlled at 145°C and left to rest for 0.5h;

[0074] 2) Start stirring after the microcrystalline wax melts, control the stirring speed at 200r / min, and stir for 2.5h;

[0075] 3) Cool down to 110°C, add 1% rust inhibitor, stir for 1 hour, and fill;

[0076] Wherein, the aromatic hydrocarbon content of the mineral oil described in step 1) is 35%, and 100 ℃ kinematic viscosity is 30mm 2 / s; the microcrystalline wax is 70# microcrystalline wax; the amide thickener is oleic acid amide; the friction enhancer is rosin resin; the rust inhibitor is barium sulfonate.

[0077] According to the hot-coated elevator steel wire rope grease prepared b...

Embodiment b

[0081] The present embodiment provides a kind of preparation method of thermal coating type elevator wire rope grease, comprises the following steps (the following percentages are mass ratios):

[0082] 1) Add 7% microcrystalline wax, 10% amide thickener, and 20% friction enhancer to 60% mineral oil in order to mix, control the temperature at 150°C, and let stand for 1 hour;

[0083] 2) Start stirring after the microcrystalline wax melts, control the stirring speed at 300r / min, and stir for 4 hours;

[0084]3) Cool down to 120°C, add 3% rust inhibitor, stir for 1.5h, and fill;

[0085] Wherein, the aromatic hydrocarbon content of the mineral oil described in step 1) is 85%, and 100 ℃ kinematic viscosity is 80mm 2 / s; the microcrystalline wax is 80# microcrystalline wax; the amide thickener is erucamide; the friction enhancer is rosin modified phenolic resin; the rust inhibitor is sulfonic acid sodium.

[0086] According to the hot-coated elevator steel wire rope grease prep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| drop melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com