Patents

Literature

466results about How to "Improve tribological properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

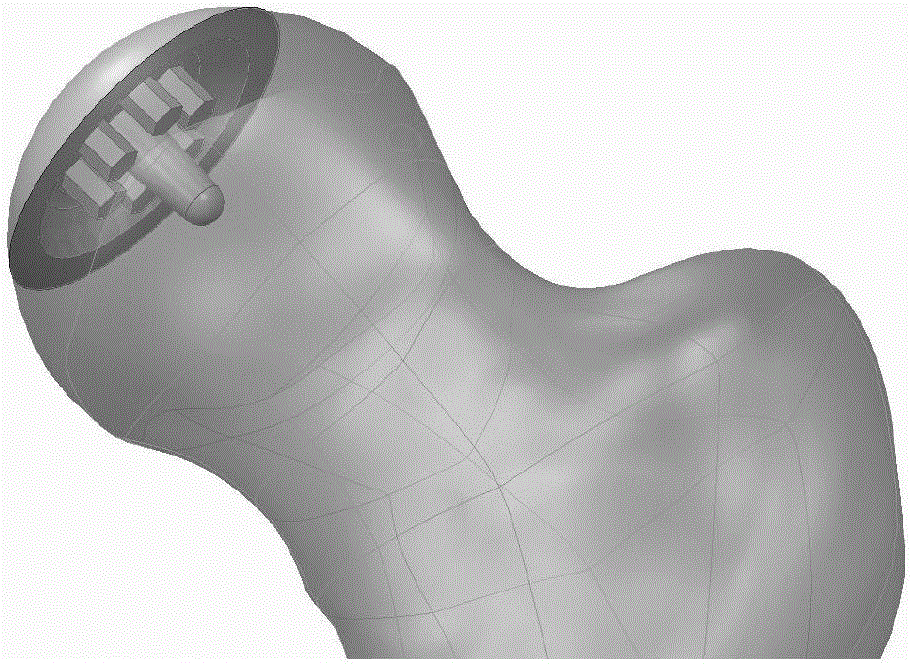

Implantable joint prosthesis

InactiveUS20020035400A1Improve wear resistanceImprove tribological propertiesDiagnosticsJoint implantsRange of motionIntervertebral disc

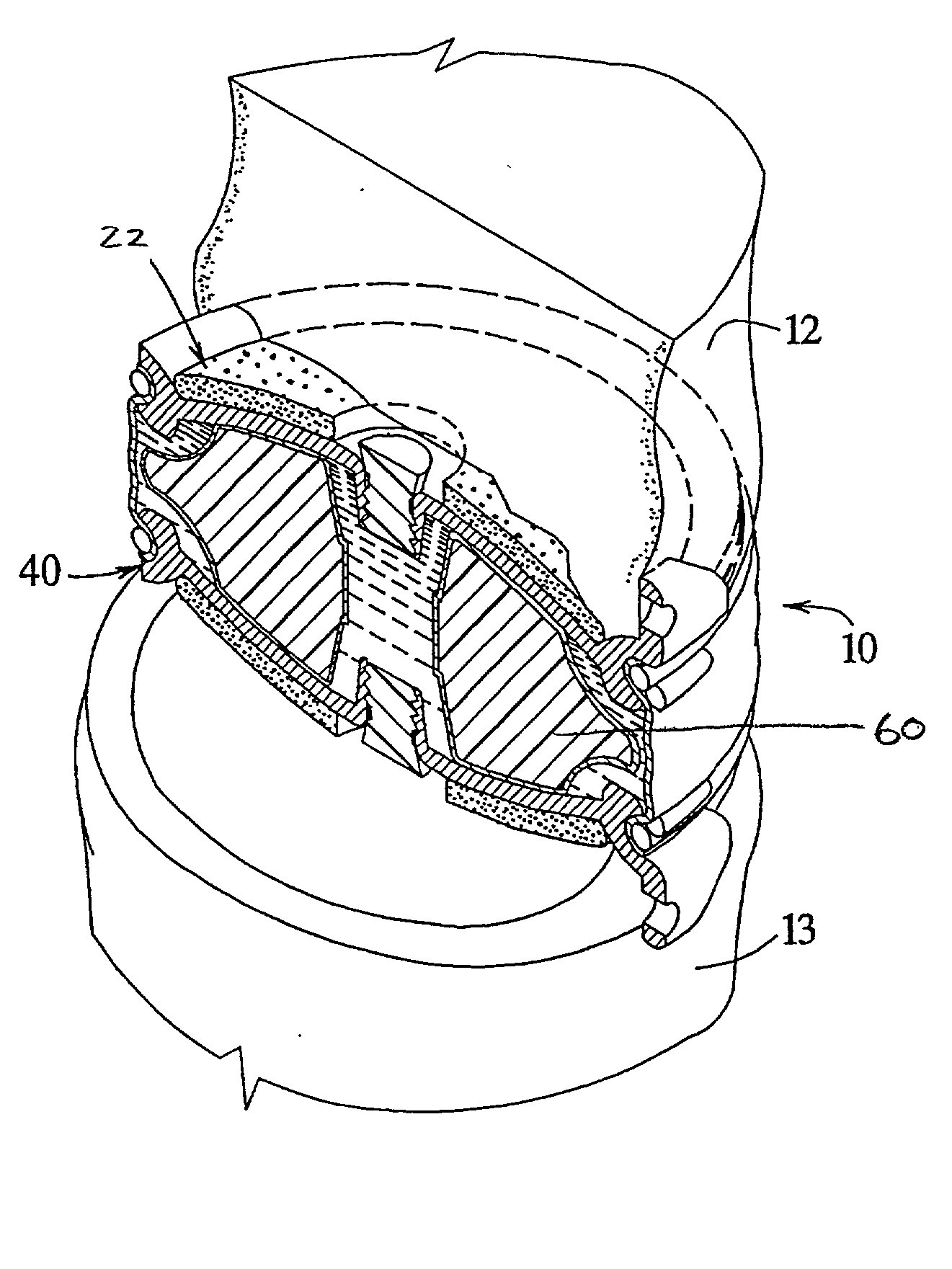

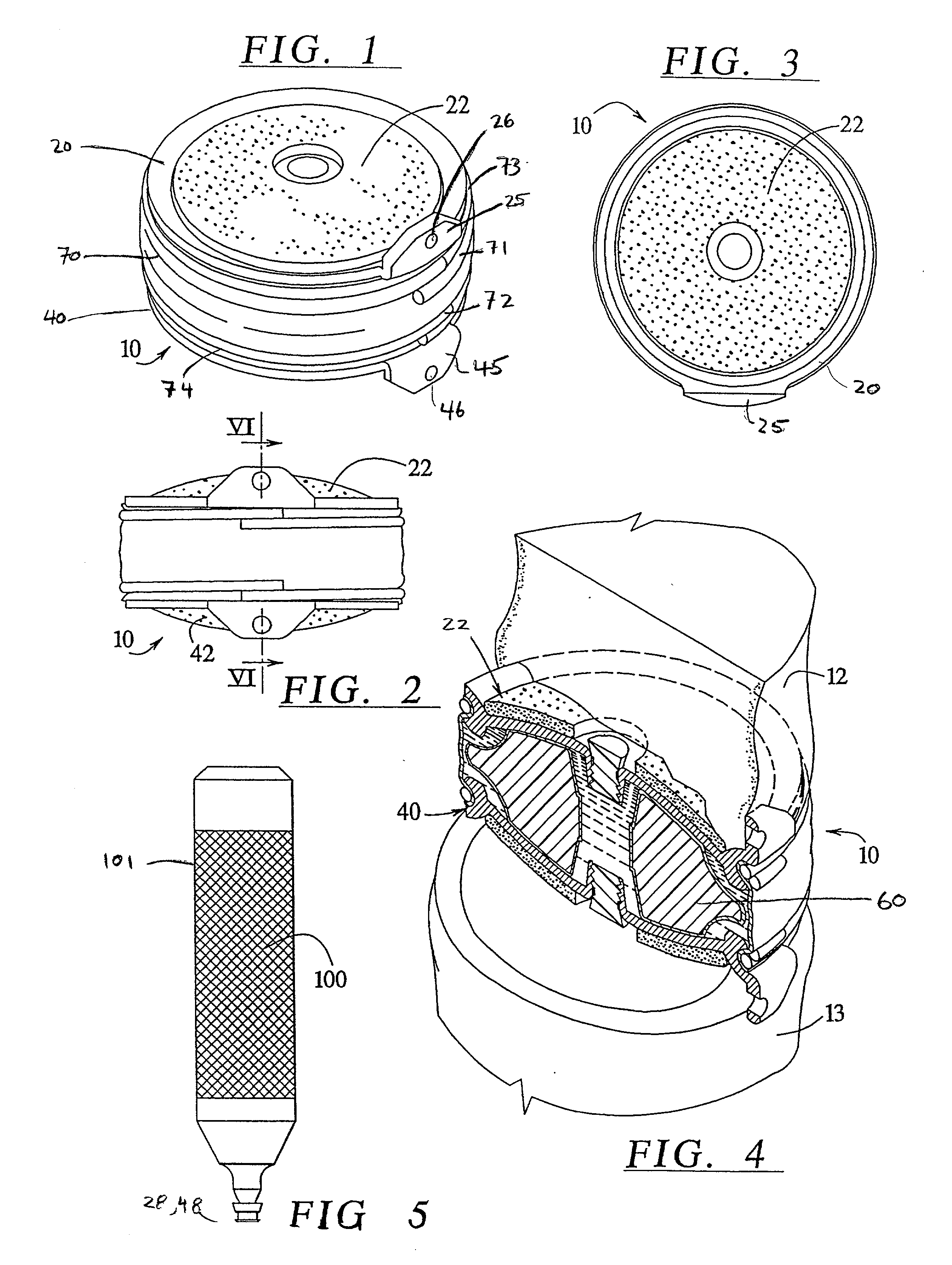

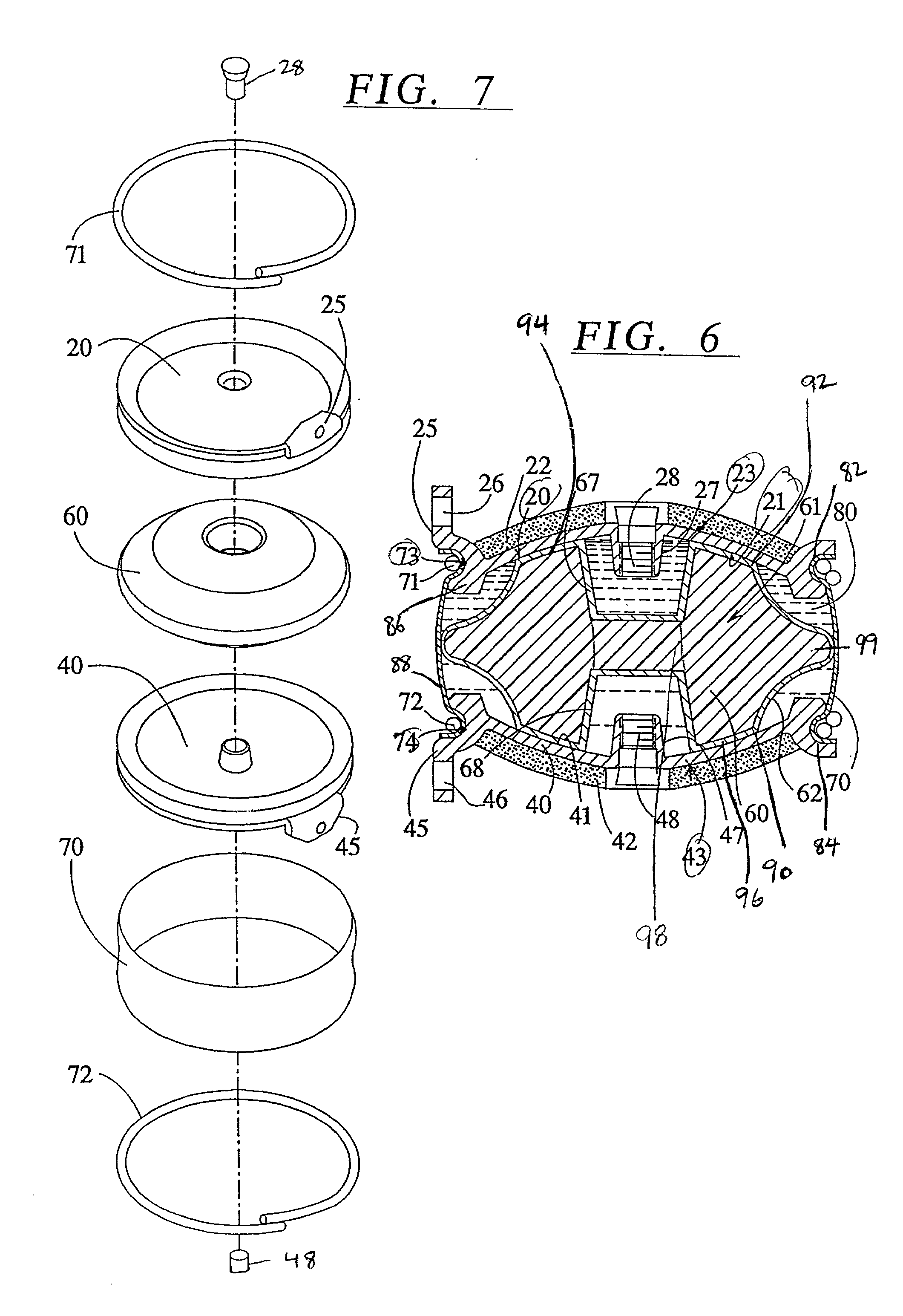

The invention relates to a surgical implant that provides an artificial diarthroidal-like joint, suitable for use in replacing any joint, but particularly suitable for use as an intervertebral disc endoprosthesis. The invention contains two rigid opposing shells, each having an outer surface adapted to engage the surfaces of the bones of a joint in such a way that the shells are immobilized by friction between their outer surfaces and the surfaces of the bone. These outer surfaces are sufficiently rough that large frictional forces strongly resist any slippage between the outer surface and the bone surfaces in the joint. They may be convex, and when inserted into a milled concavity, are immediately mechanically stable. Desirably, the outer surfaces of the shells are adapted to allow for bony ingrowth, which further stabilizes the shells in place. The inner surfaces of the shells are relatively smooth, and adapted to slide easily across a portion of the outer surface of a central body disposed between the shells. The central body has a shape that cooperates with the shape of the inner surface of the shell so as to provide a range of motion similar to that provided by a healthy joint. A flexible sheath extends between edges of the opposing shells. The inner surface of this sheath, together with the inner surfaces of the rigid shells, defines a cavity encasing the central body. At least a portion of this cavity is filled with a fluid lubricant, further decreasing the frictional force between inner surfaces of the shell and the surface of the central body.

Owner:SPINAL DYNAMICS CORP

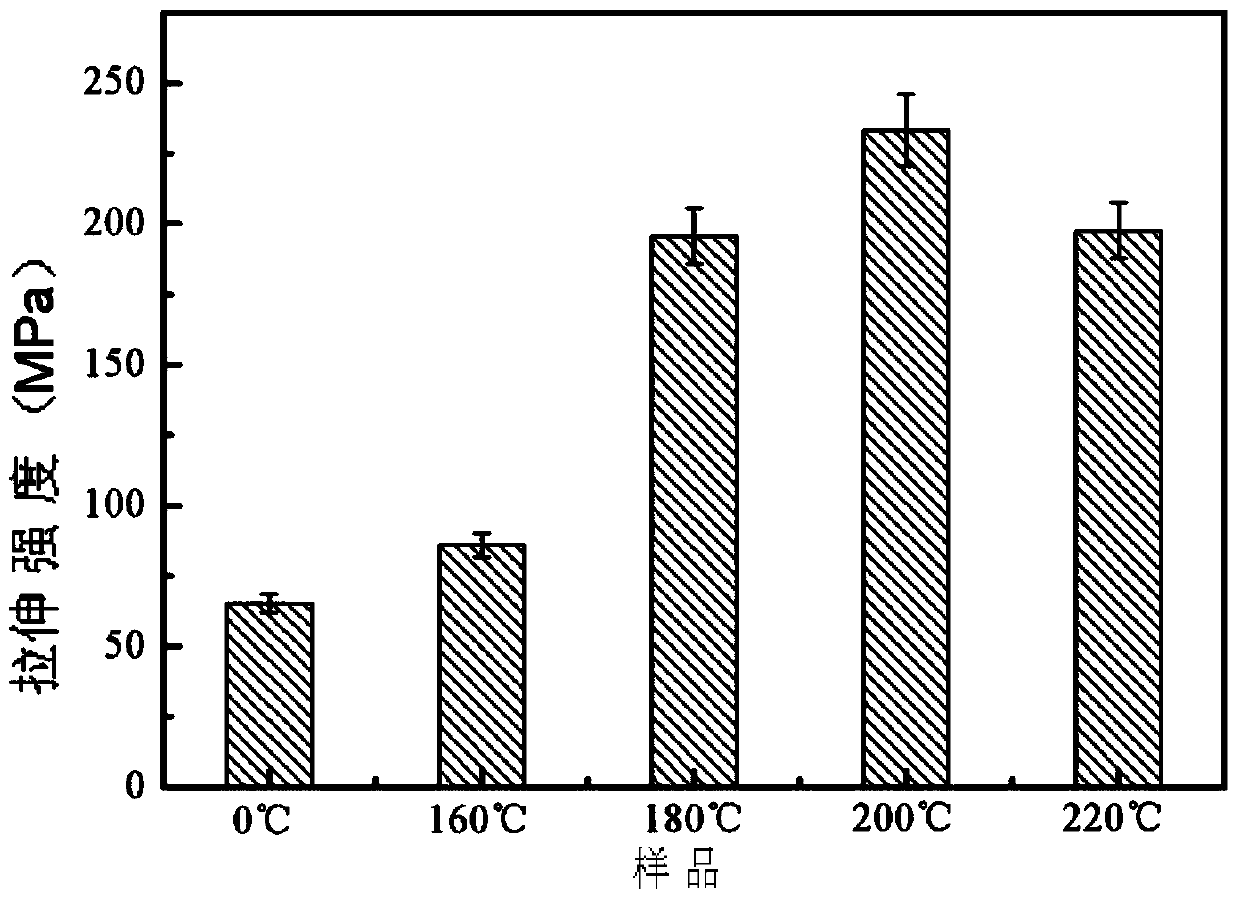

High-silicon aluminum alloy cylinder sleeve material and preparation method thereof

InactiveCN101457318AImprove mechanical propertiesImprove tribological propertiesRefining (metallurgy)Manufacturing technology

The invention discloses a high silicon aluminum alloy cylinder sleeve material and a manufacturing method thereof., Ingredients of the material by weight percent are as follows: Si: 18.0%-25.0%; Fe: 3.5%-6.0%; Ni: 1%-2%; Cu: 1.5%-3.0%; Mg: 0.5%-1.0%; Mn: 0.5%-1.5%; V: 0.1%-0.5%; Sr: 0.05%-0.15%; and the balance of Al. The manufacturing method thereof comprises the following steps: 1, composition design and accurate mixture which uses an intermediate alloy for quantitative mixture; 2, smelting, covering and refining; 3, injection deposition; 4, extrusion processing; 5, heat treatment; 6, mechanical processing and honing processing. The material and the manufacturing method lead the high silicon aluminum alloy products to have high comprehensive mechanical property characteristics which are superior to mechanical property characteristics of cast iron cylinder sleeve material, have frictional property which are superior to frictional property of steel and cast iron cylinder sleeve material, and have great compatibility with thermophysical property of aluminum piston alloy material, thereby obviously narrowing the gap for cylinder matching. The manufacturing method is characterized in that: the manufacturing process of injection deposition is employed, which serves as a primary means in manufacturing the high silicon aluminum alloy, is superior to the powder metallurgy process and the die-casting process, and can use conventional processing equipment and process conditions.

Owner:NO 52 INST OF CHINA NORTH IND GRP CORP

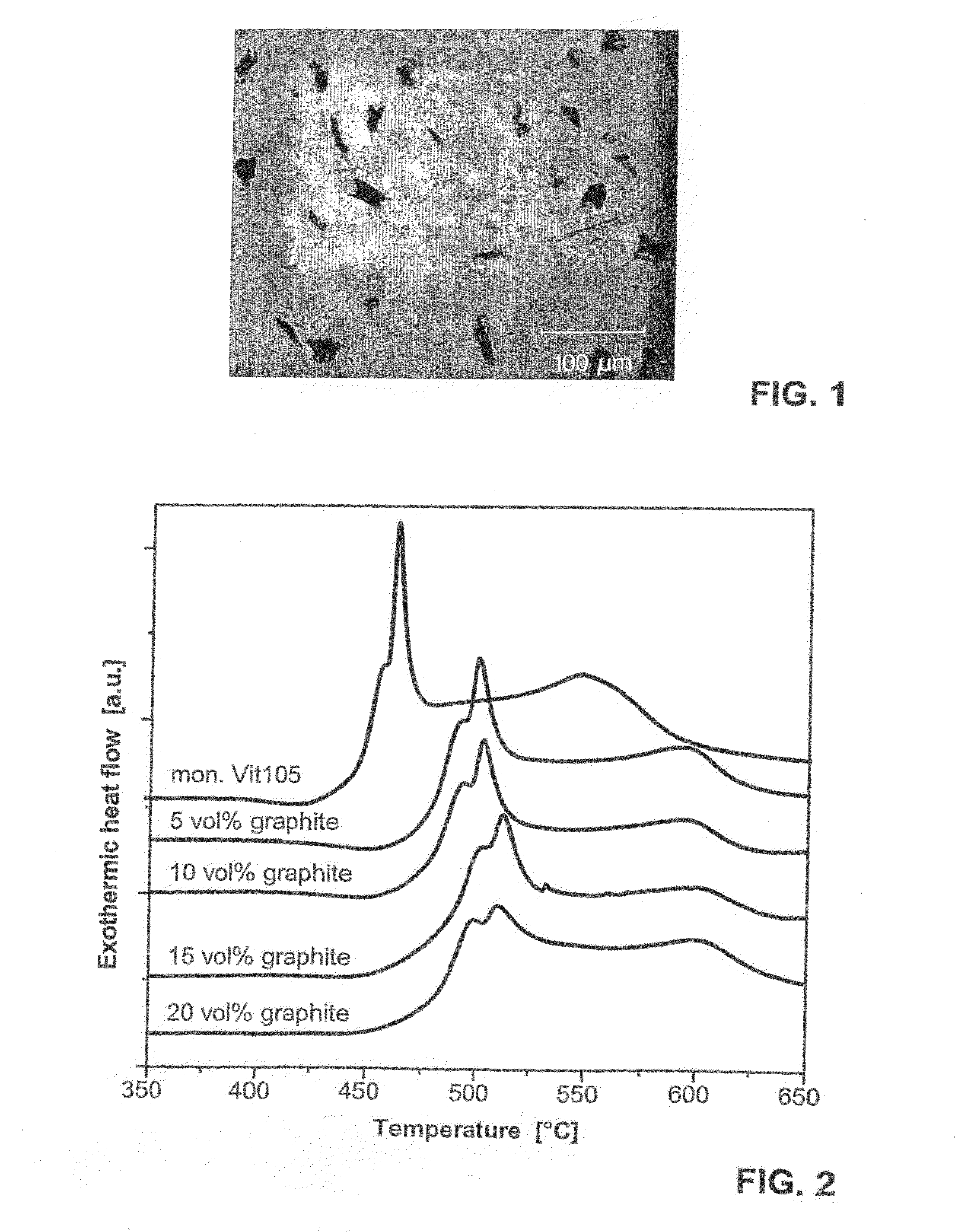

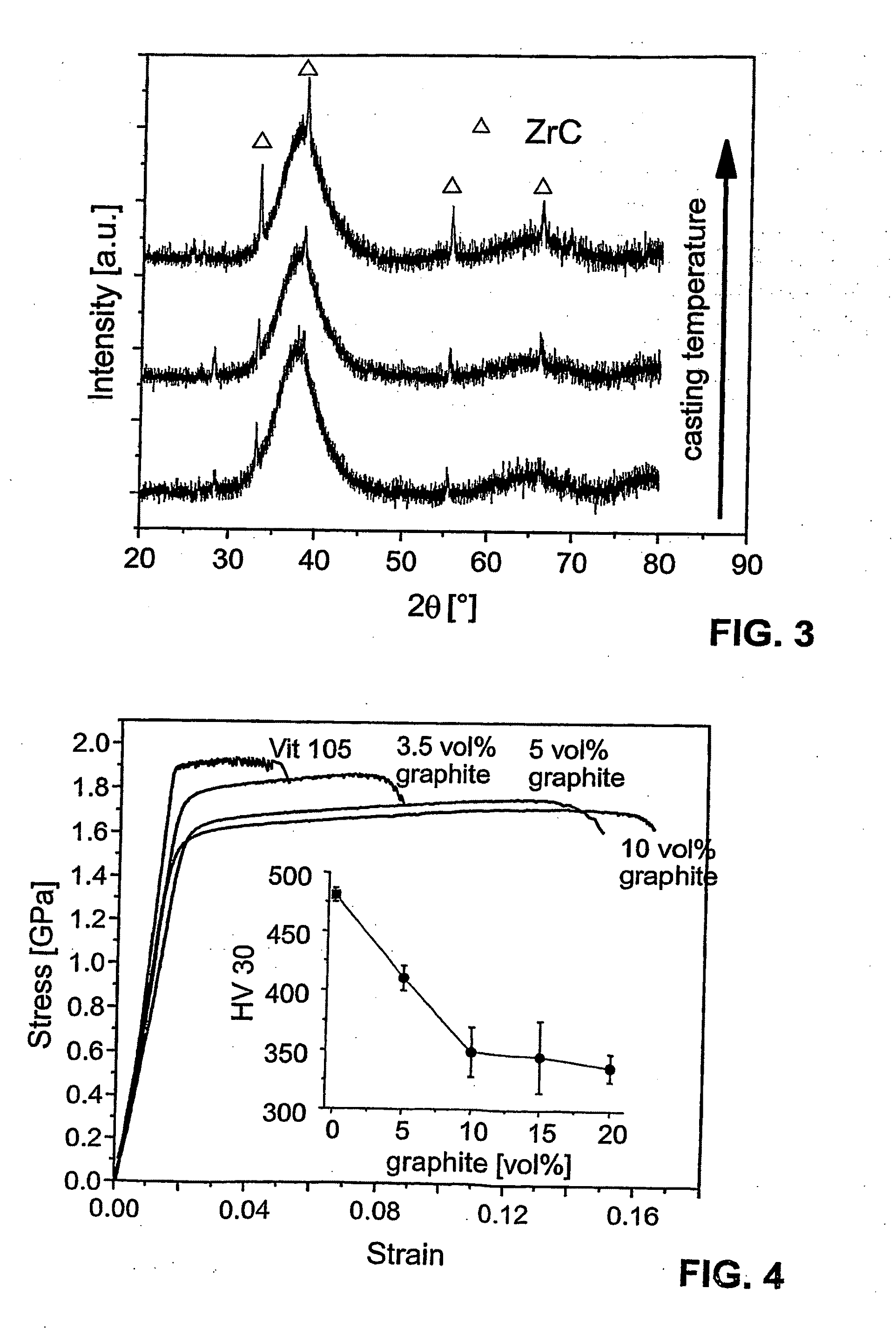

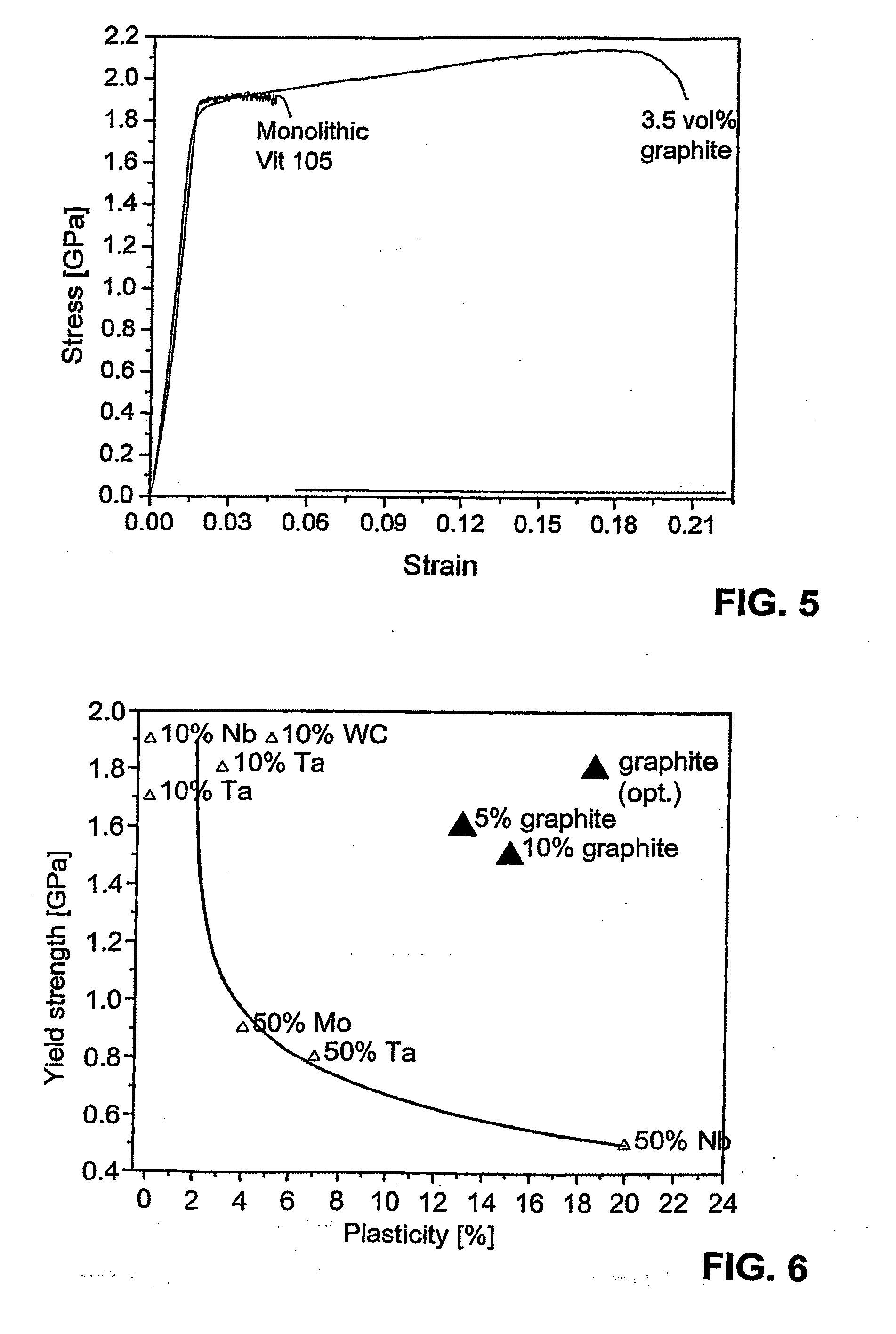

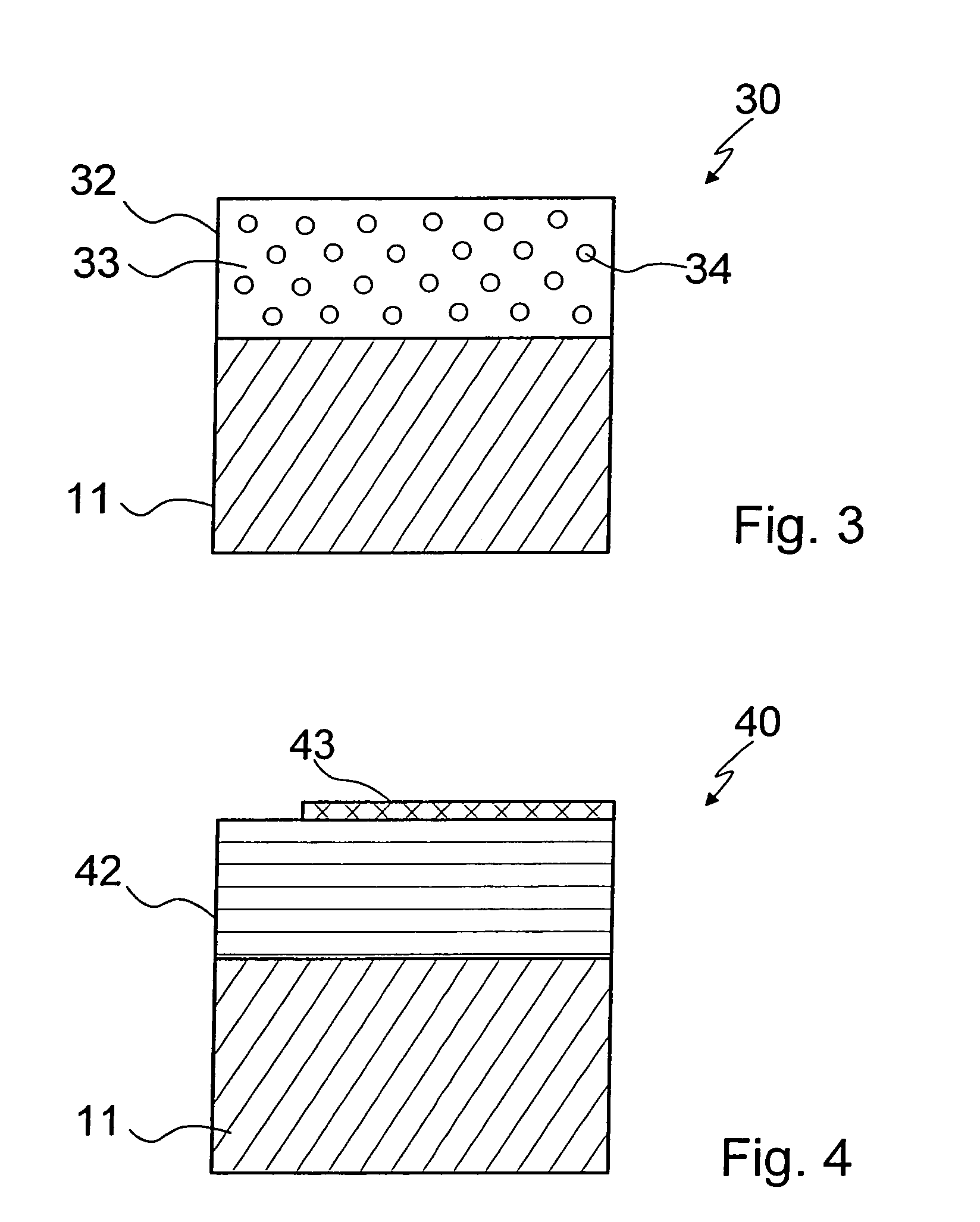

Bulk Metallic Glass/Graphite Composites

A composite material based on a bulk metallic glass is disclosed. In an amorphous alloy phase forming a substantially continuous matrix, a second phase comprising graphite particles is embedded. The alloy is preferably zirconium based. The particles may have a carbide surface layer, which may be formed phase comprising carbide particles may also be present. The composite material has high plasticity, high yield strength, good elasticity and low coefficient of friction, which renders it a good candidate for applications like joints, frictional bearings or Springs.

Owner:ETH ZZURICH

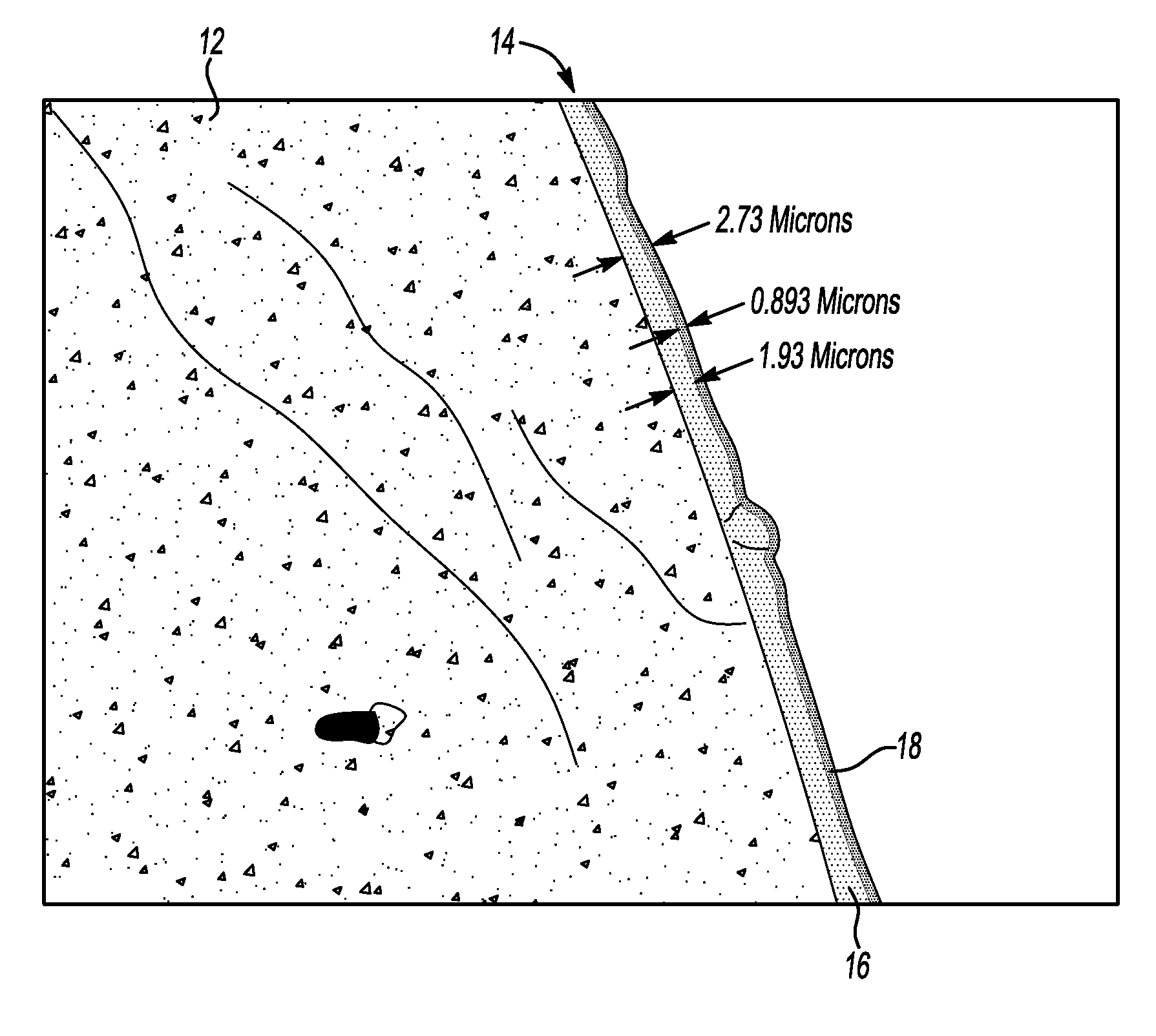

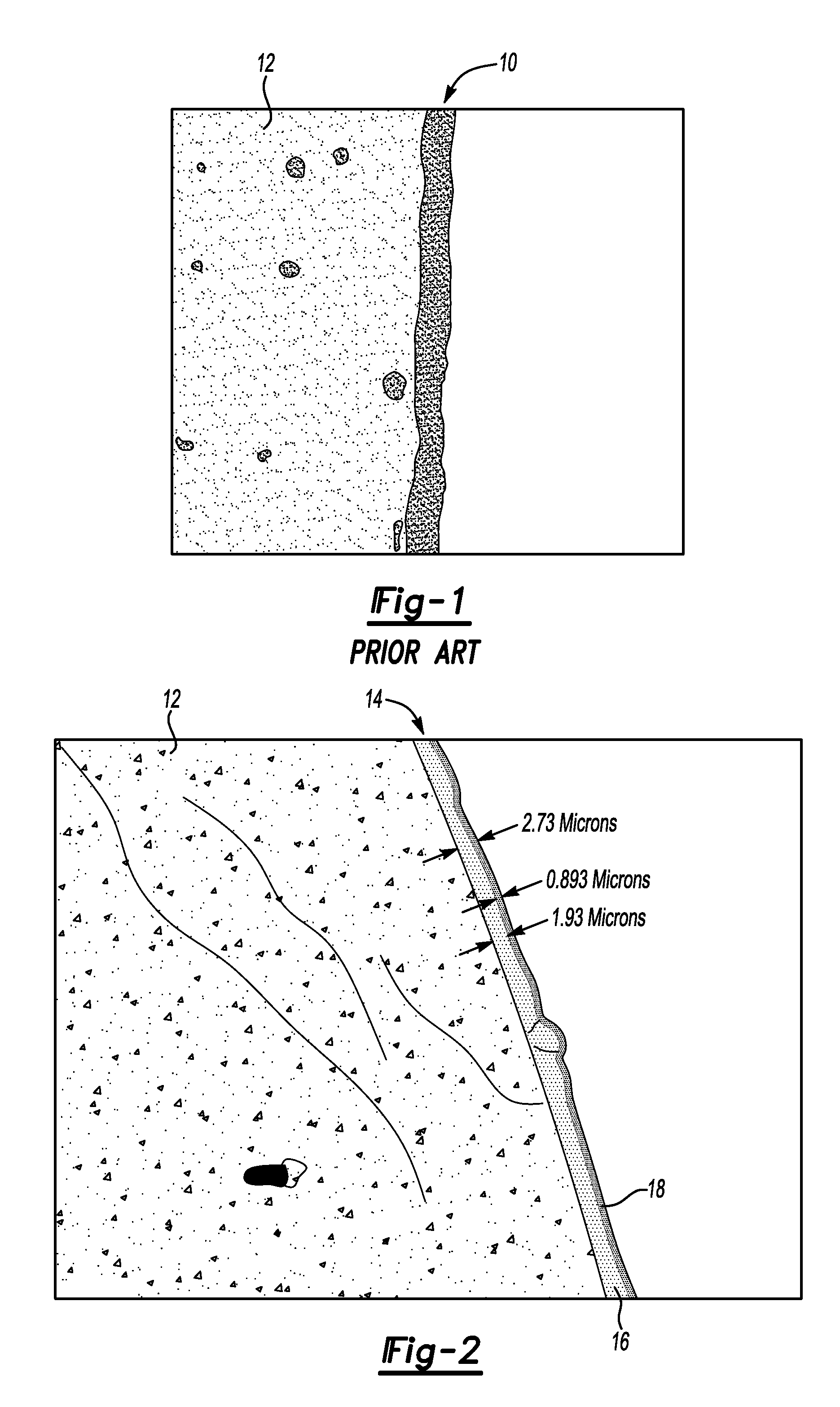

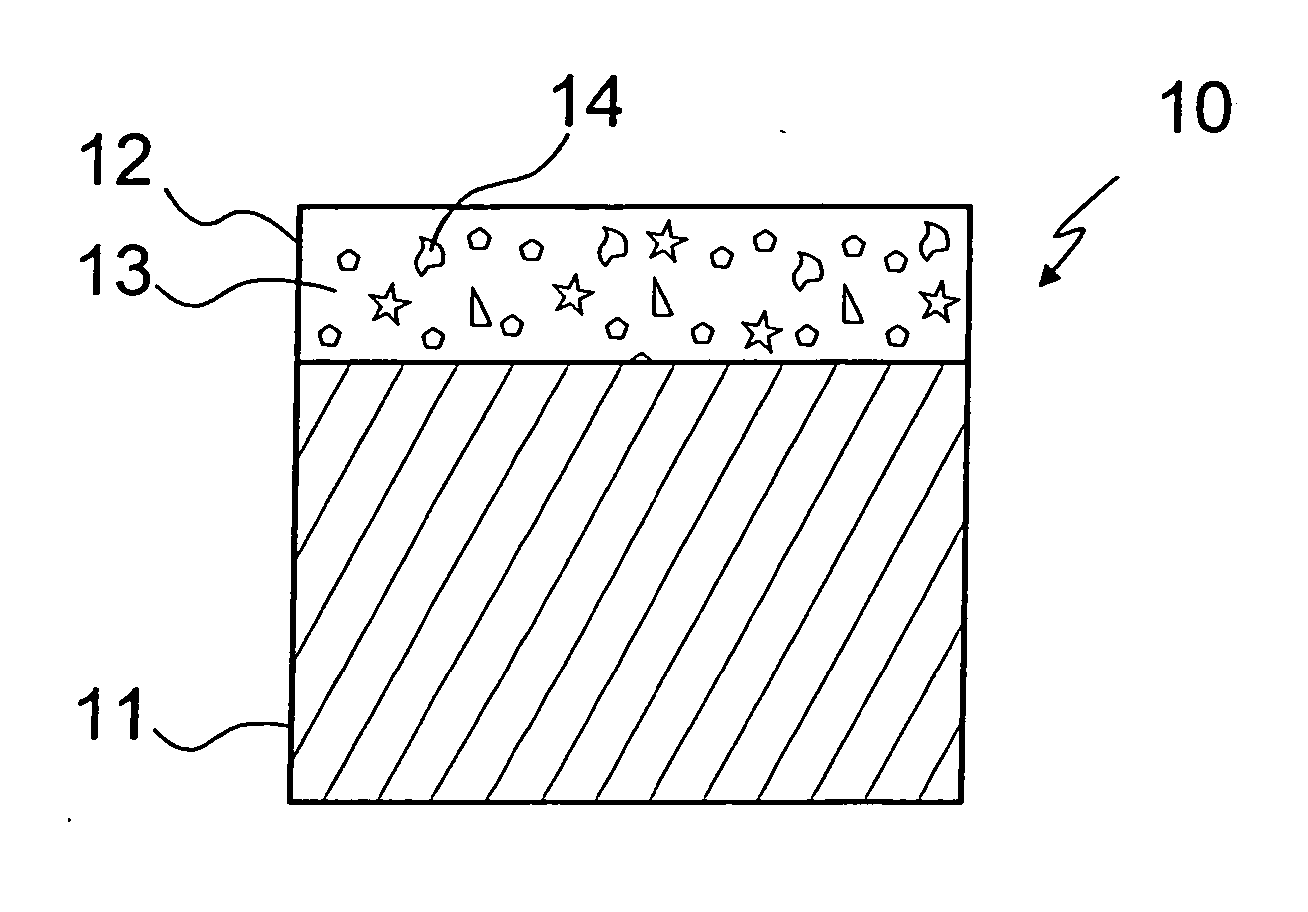

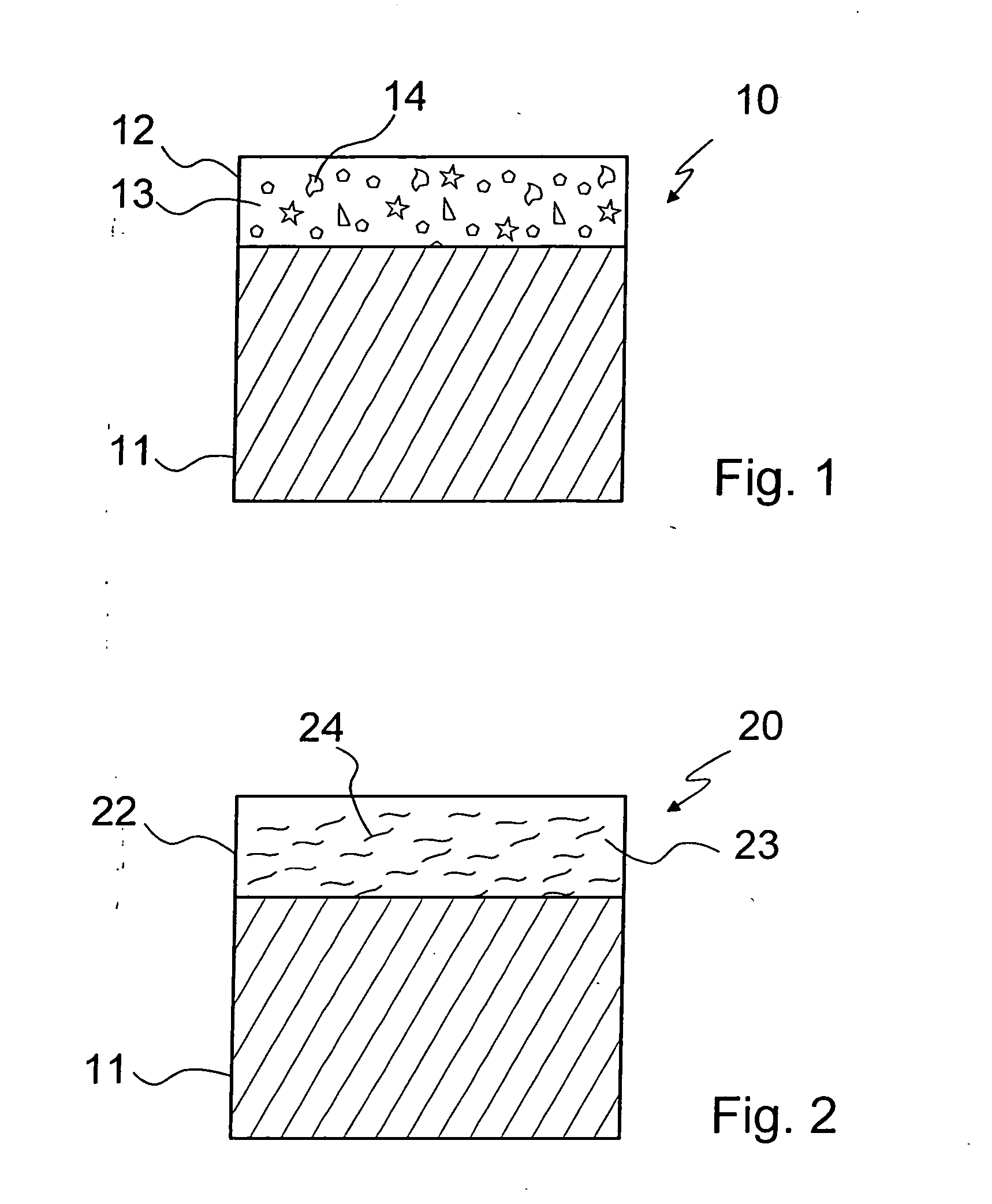

Friction- and wear-reducing coating

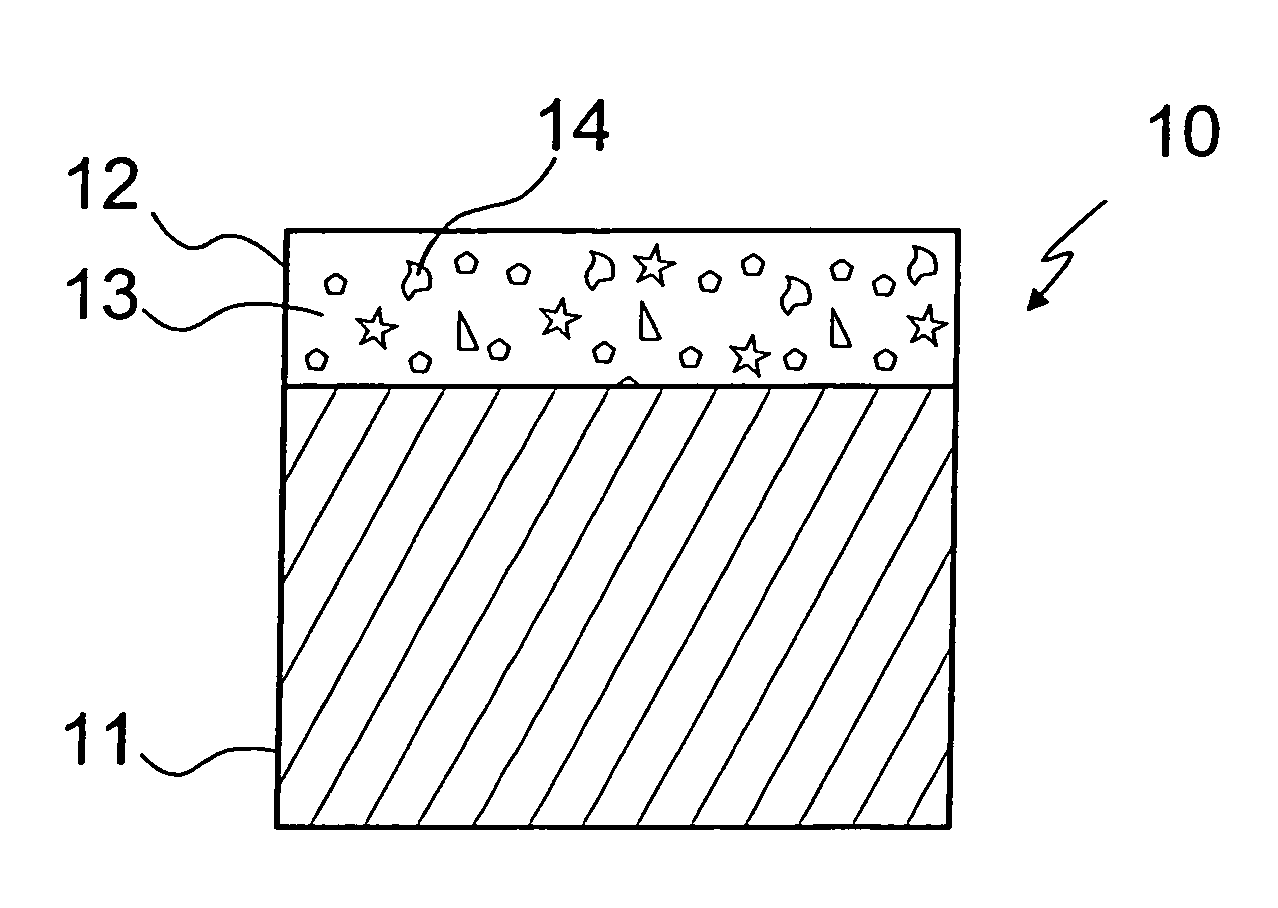

InactiveUS20100028641A1Improve tribological propertiesImprove performanceSynthetic resin layered productsVacuum evaporation coatingAlloyHardness

A coating includes a first layer of a ceramic alloy and a second layer disposed on the first layer and including carbon. The coating has a hardness of from 10 to 20 GPa and a coefficient of friction of less than or equal to 0.12. A method of coating a substrate includes cleaning the substrate, forming the first layer on the substrate, and depositing the second layer onto the first layer to thereby coat the substrate.

Owner:EATON CORP

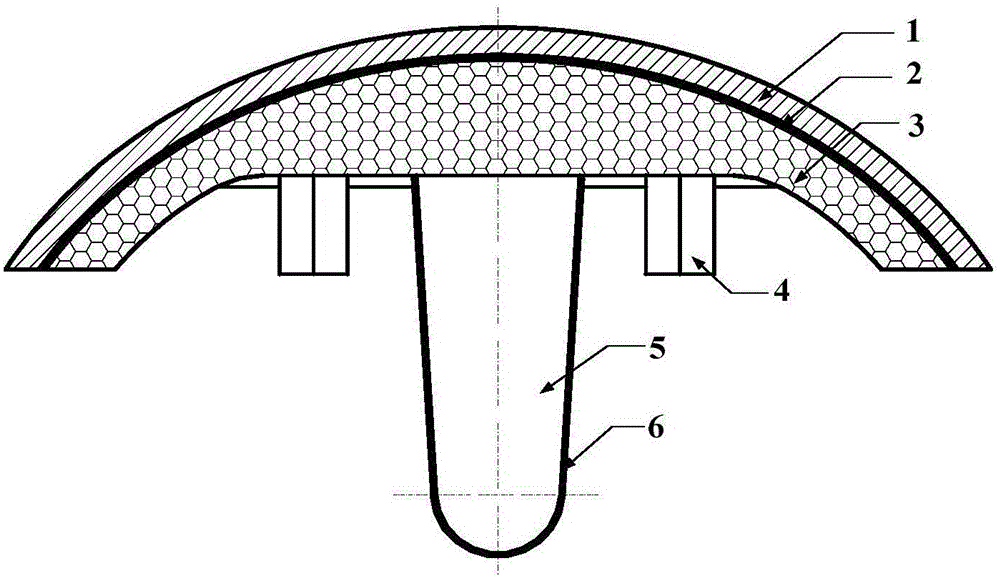

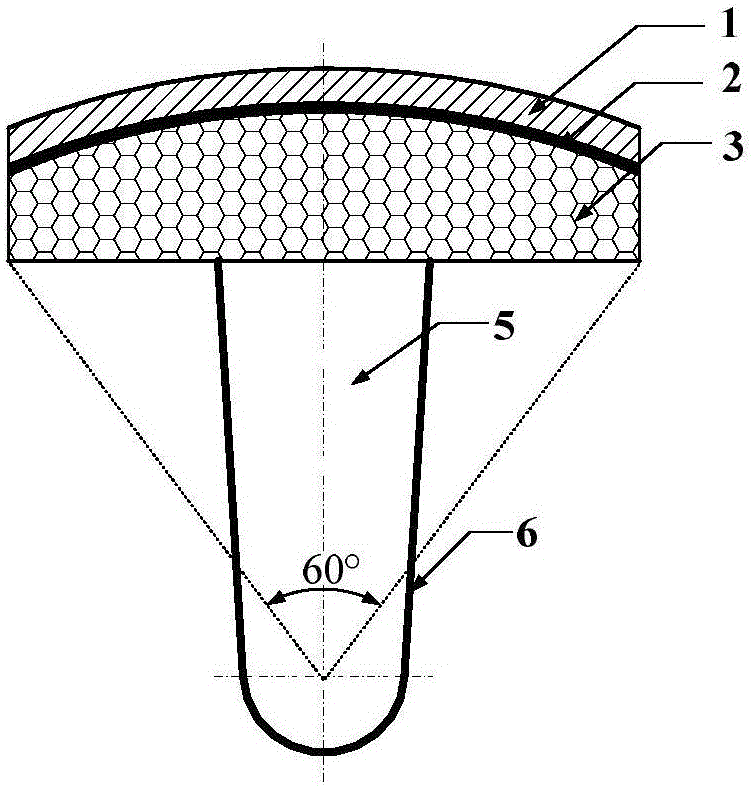

Biomimetic artificial hip joint with internal growth function

ActiveCN105105875AImprove tribological propertiesImprove fault toleranceJoint implantsHip jointsArticular surfacesBiomechanics

The invention discloses a biomimetic artificial hip joint with an internal growth function. The joint is composed of an artificial cartilage layer, an interface bonding layer and a porous bracket, wherein the artificial cartilage layer and the porous bracket have elliptic surfaces; the surface wrapping angle of the joint is 60-120 degrees; when the wrapping angle is 80-120 degrees, 3-6 convex columnar bodies, which are uniformly distributed, are designed on the inner surface of a prosthesis along the peripheral direction; a porous coating with biological activity is prepared on the outer surface of a femoral component and materials of the coating have gradient changes from inside to outside; the porous bracket is designed into a porous structure with gradient according to a finite element optimization result, and the pore diameter is 300-800 microns; the porosity is 20%-85%. According to the biomimetic artificial hip joint disclosed by the invention, bone mass and biomechanical characteristics of thigh bones can be kept to the greatest extent; the biomimetic artificial hip joint has good mechanical properties and tribological properties; the growth of bone cells is induced or promoted so as to guarantee effective interface bonding intensity between a prosthesis implantation material and a natural bone, the stability of the planted prosthesis is improved and the service life is prolonged.

Owner:XI AN JIAOTONG UNIV

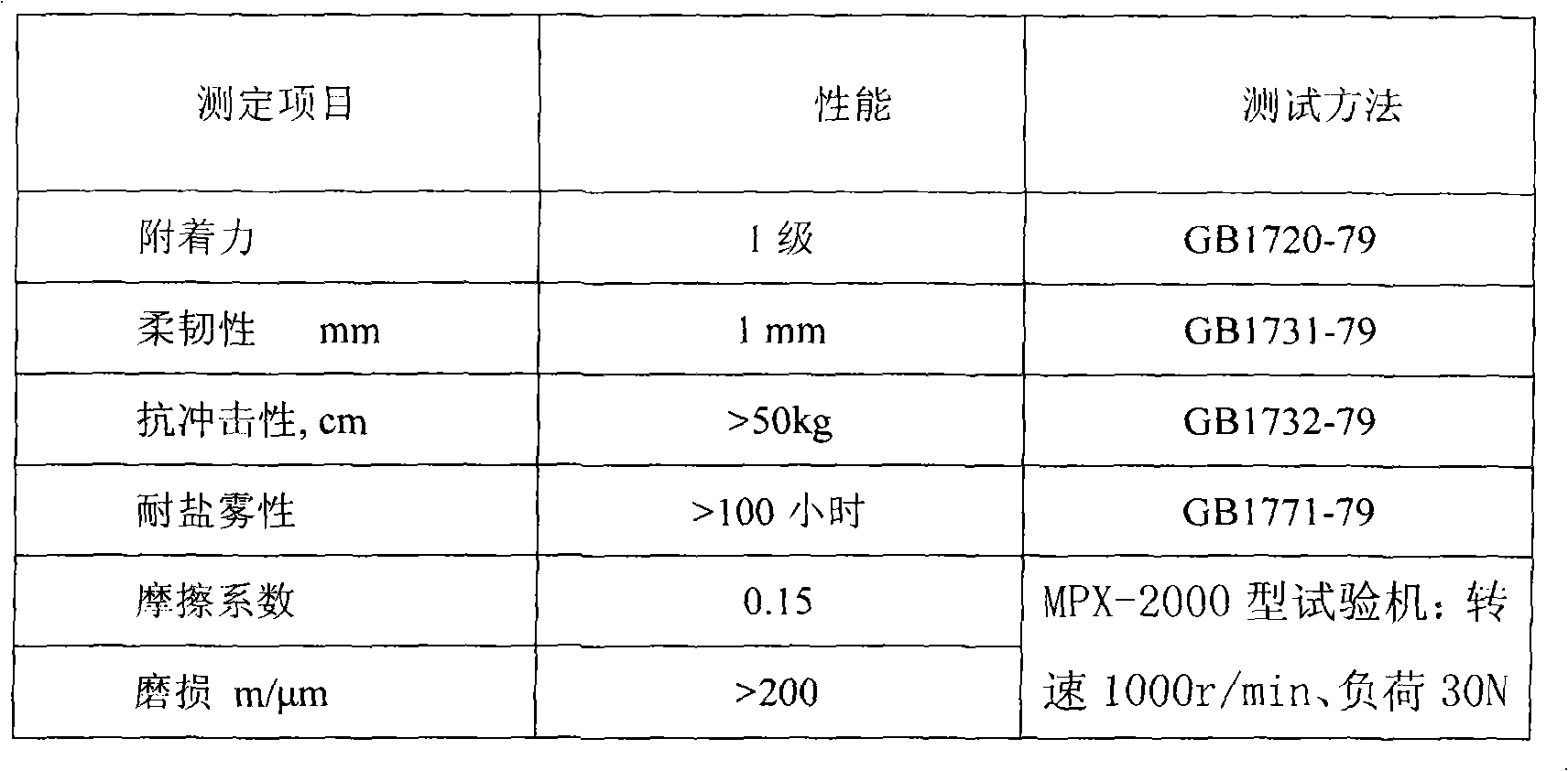

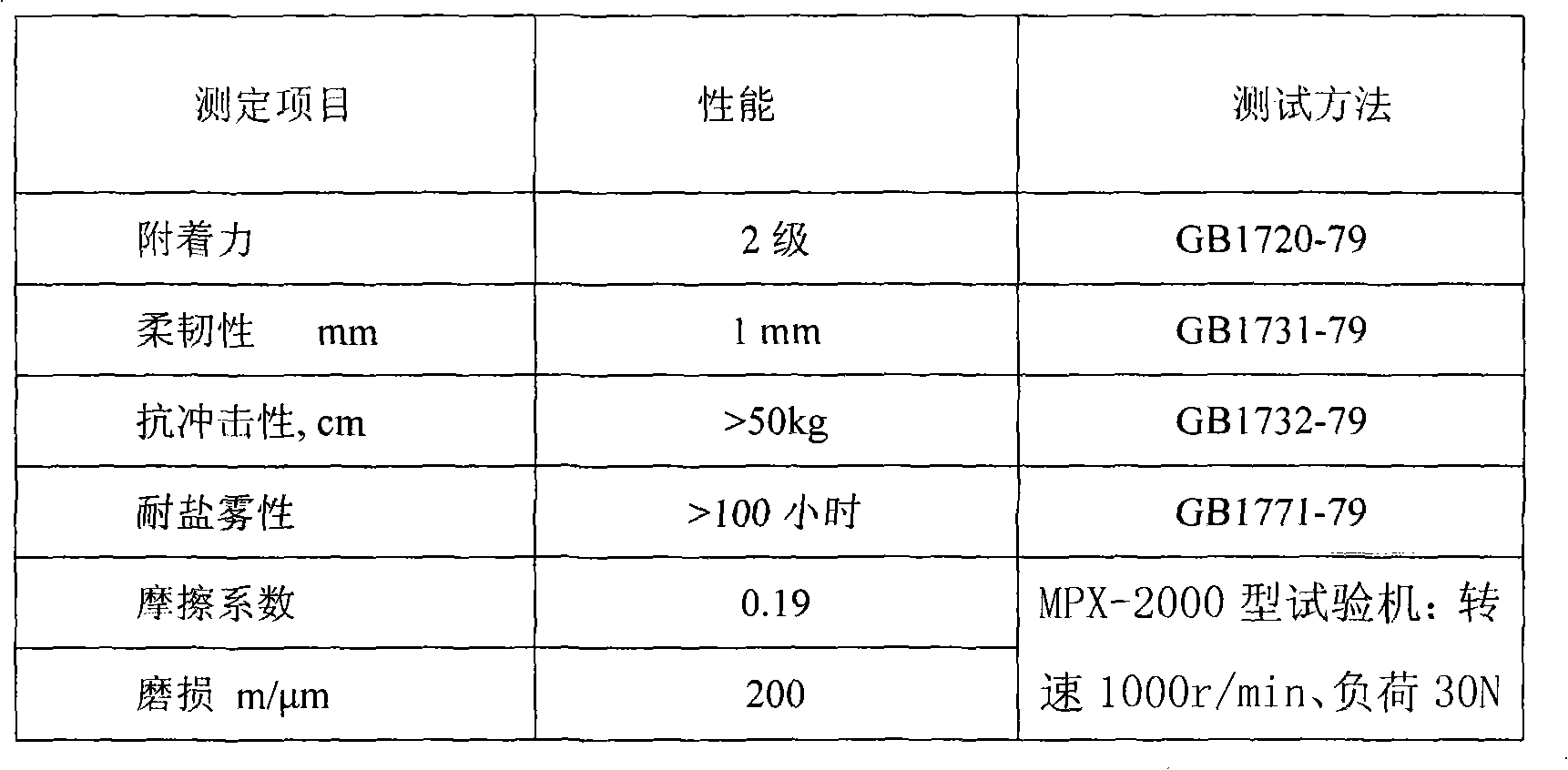

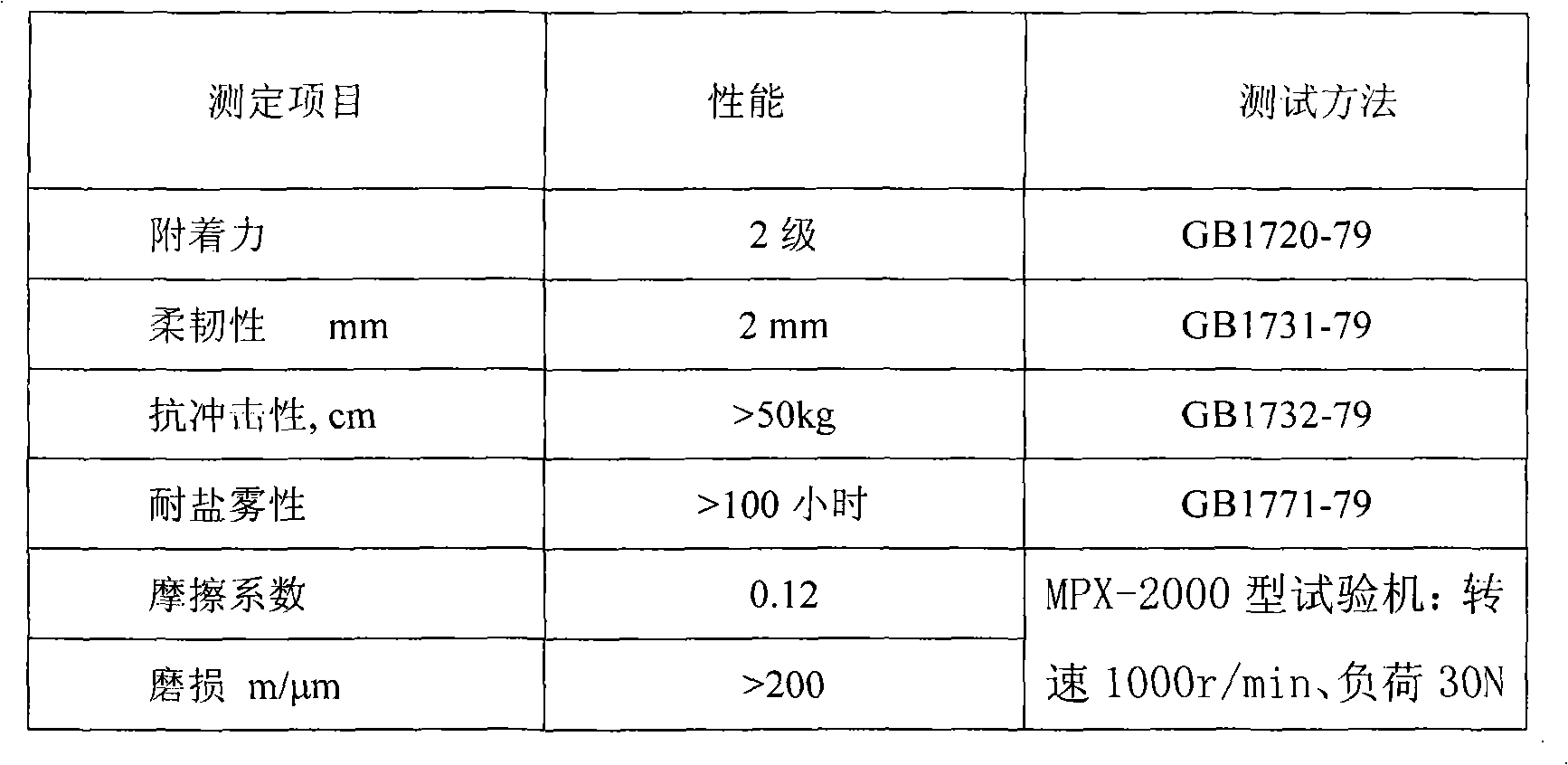

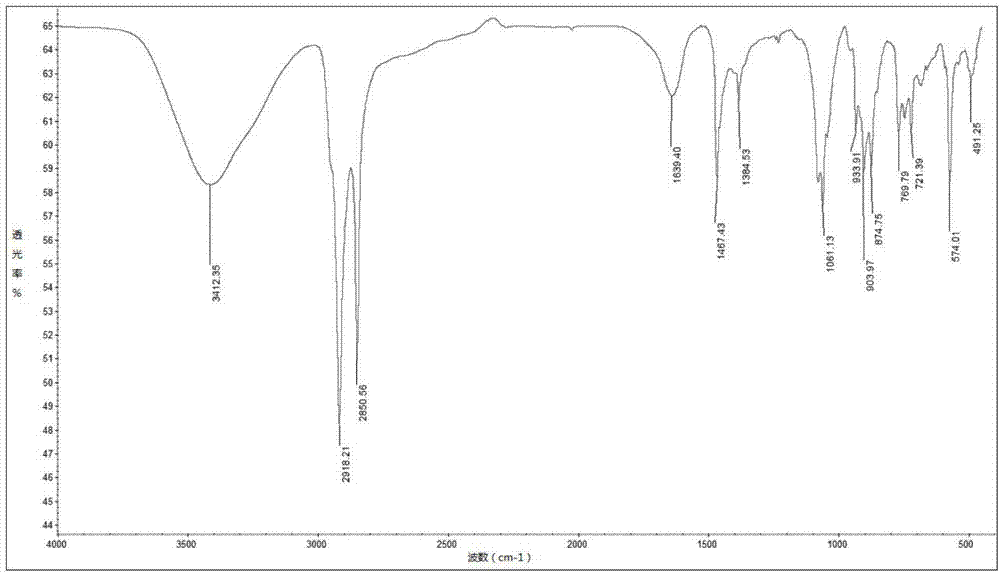

Dry film lubricant based on modified epoxy resin and preparation method thereof

ActiveCN101838576AEmission reductionImprove tribological propertiesEpoxy resin coatingsLubricant compositionWater basedEpoxy

The invention discloses a dry film lubricant based on modified epoxy resin and characterized by comprising the following components: 100 to 120 parts of epoxy resin, 1 to 5 parts of inorganic nano-particles, 0.1 to 0.5 part of coupling agent, 20 to 60 parts of lubricant, 10 to 20 parts of anti-wear agent, 1 to 4 parts of dispersing agent, 10 to 30 parts of absolute alcohol and 0 to 20 parts of deionized water. The method for preparing the dry film lubricant comprises the following steps: firstly, carrying out surface modification on the inorganic nano-particles by the coupling agent; then, adding the modified inorganic nano-particles to the epoxy resin to obtain the modified water-based epoxy resin nano-emulsion; adding the dispersing agent to the mixture of the lubricant and the anti-wear agent drop by drop; then, adding the mixture to the modified water-based epoxy resin nano-emulsion, and evenly mixing; and further adding the deionized water to adjust the viscosity of coatings, thus obtaining the dry film lubricant based on the modified epoxy resin. The invention has the advantages of low emission of organic volatile substances, good frictional properties, strength, toughness, weather resistance, corrosion resistance and other overall properties and simple preparation process.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

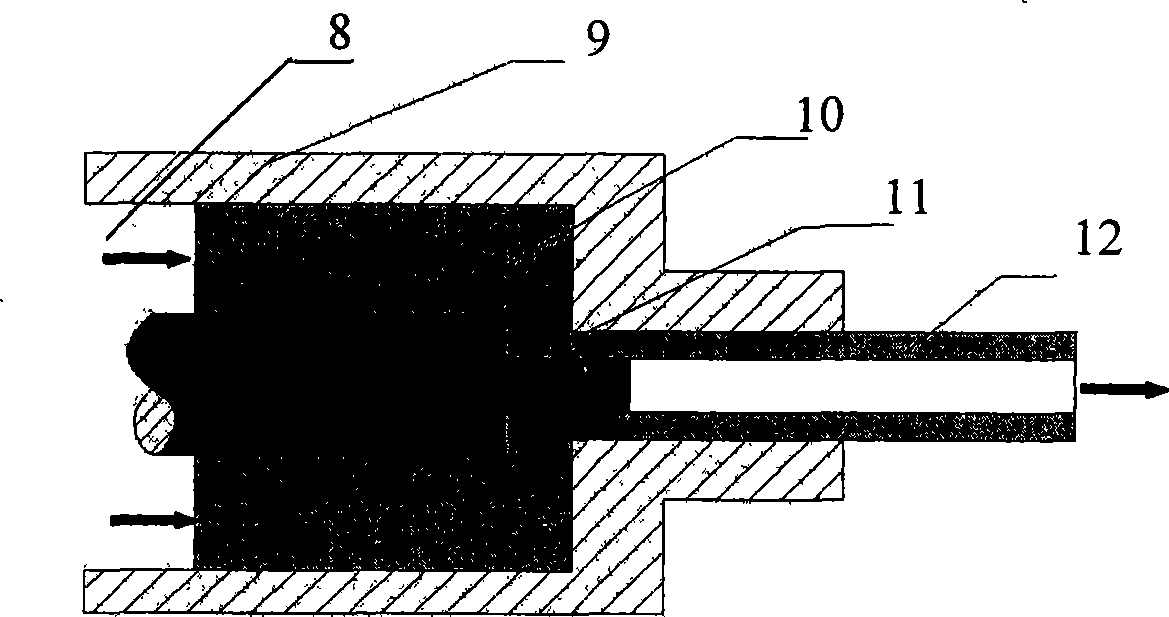

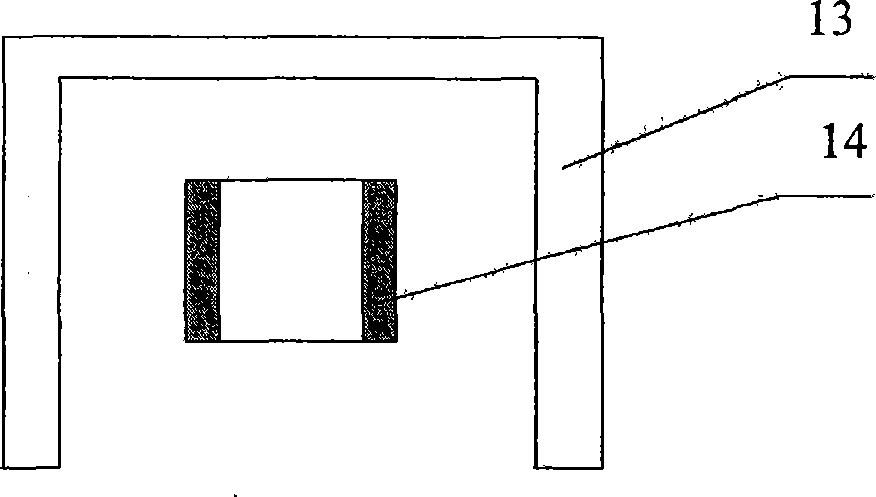

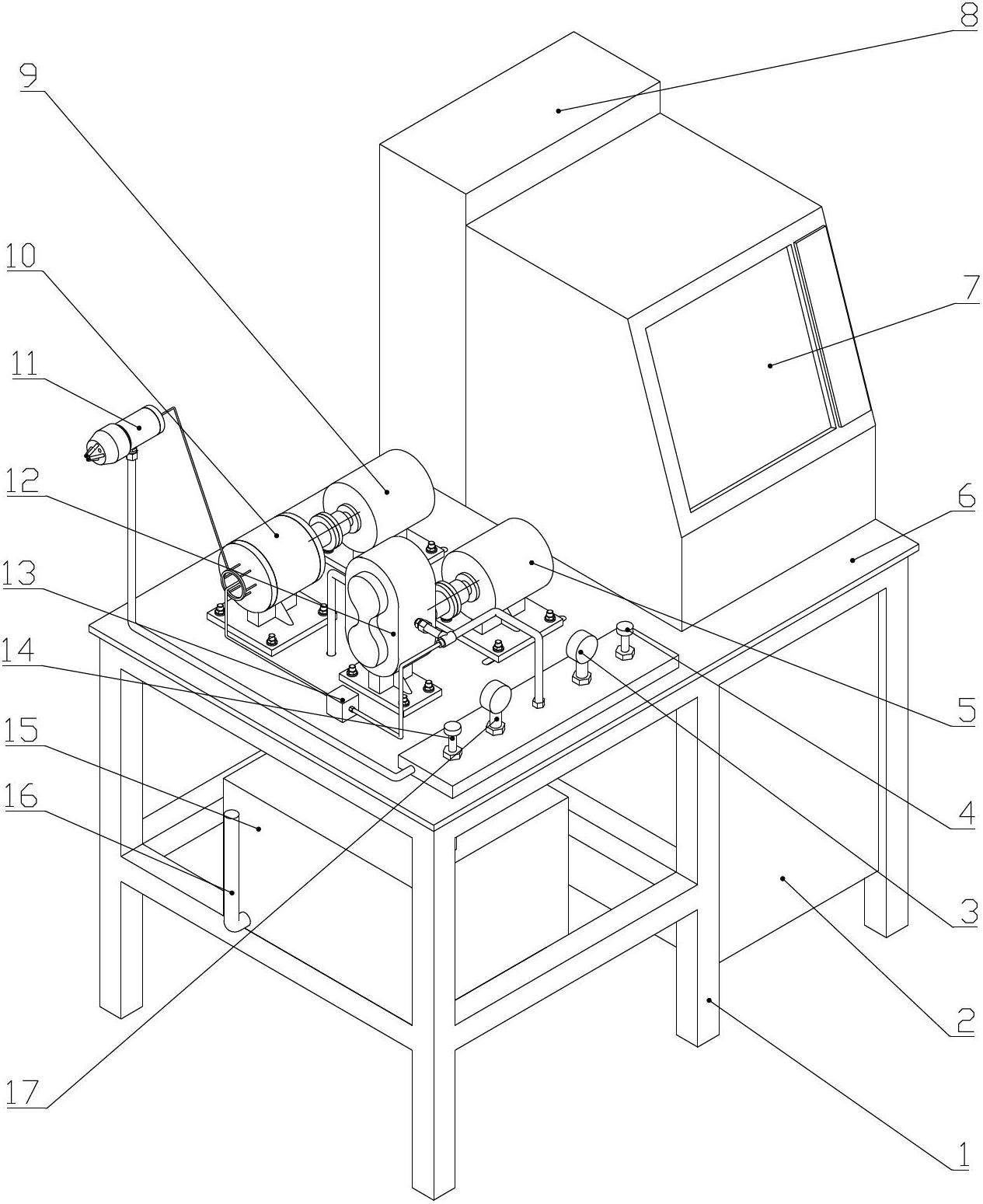

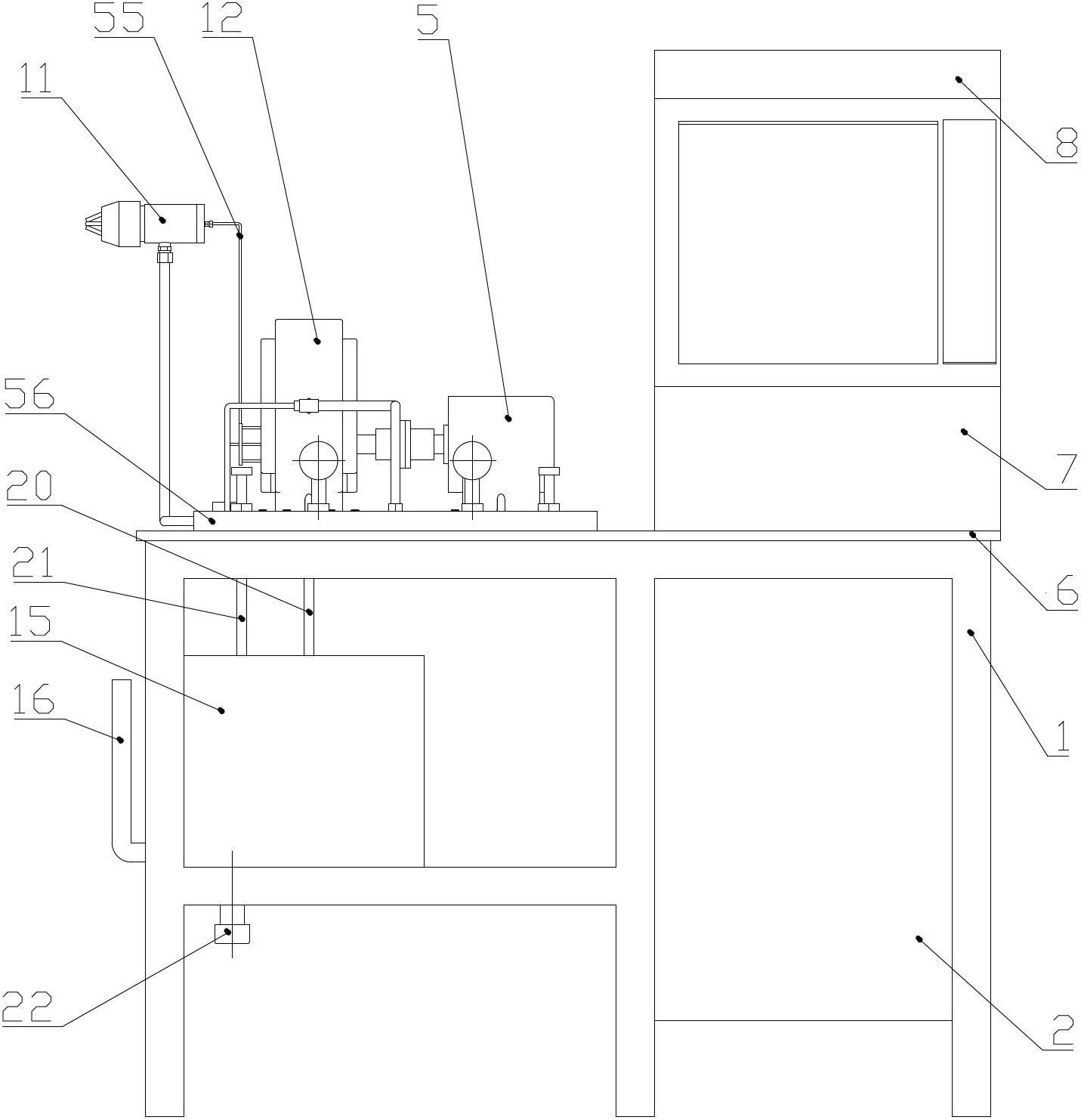

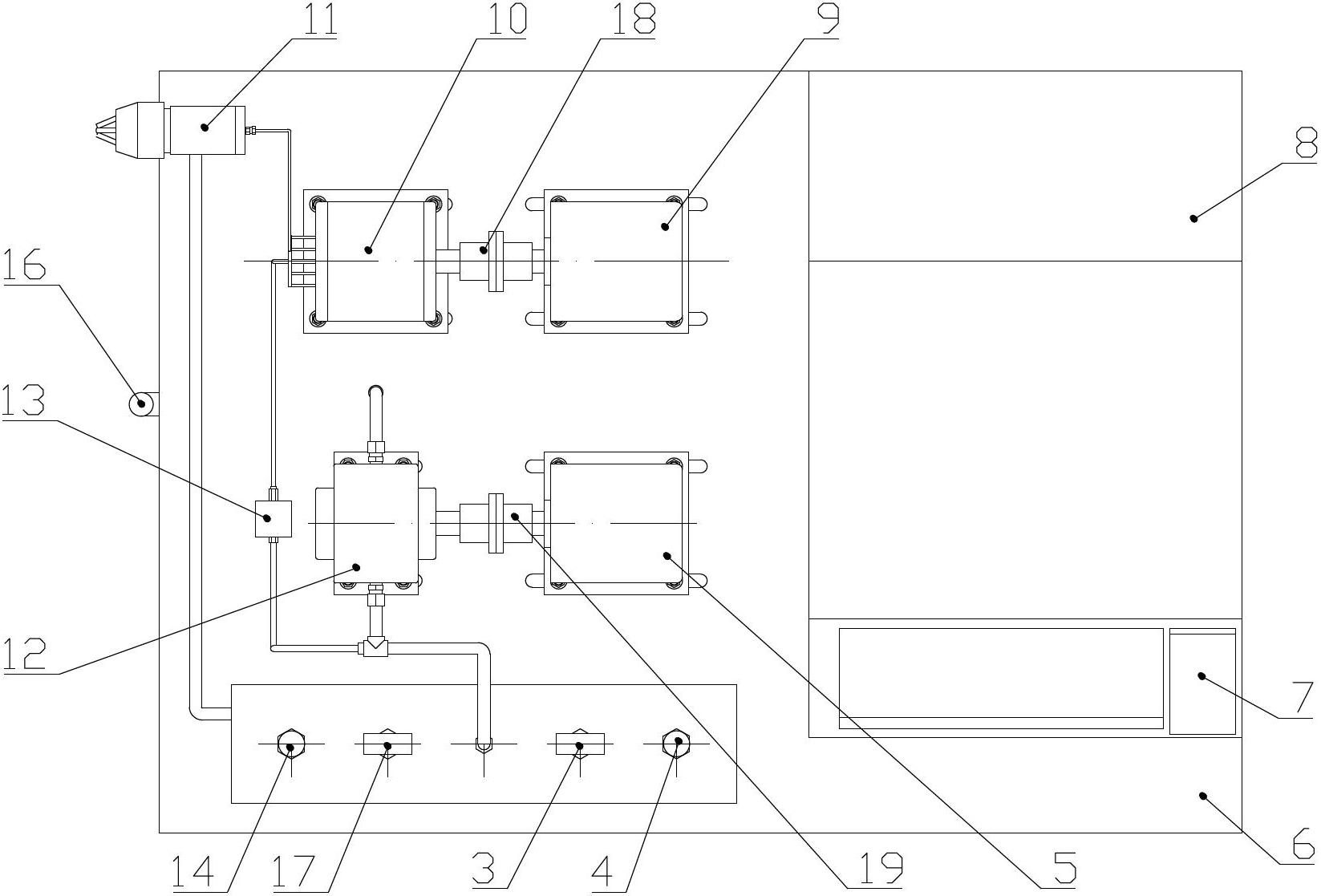

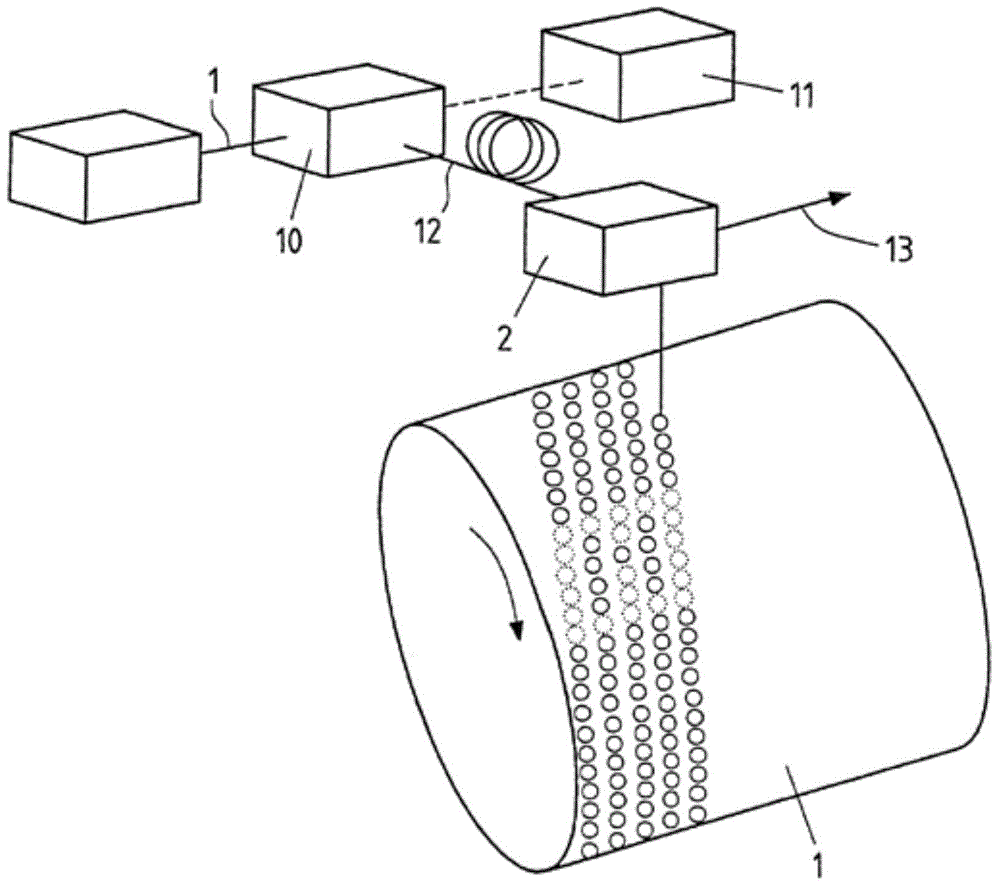

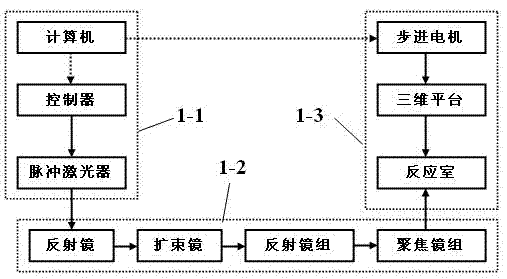

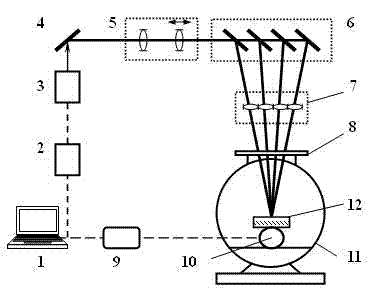

Nanoparticle jet flow minimum quantity lubrication grinding lubricant supply system

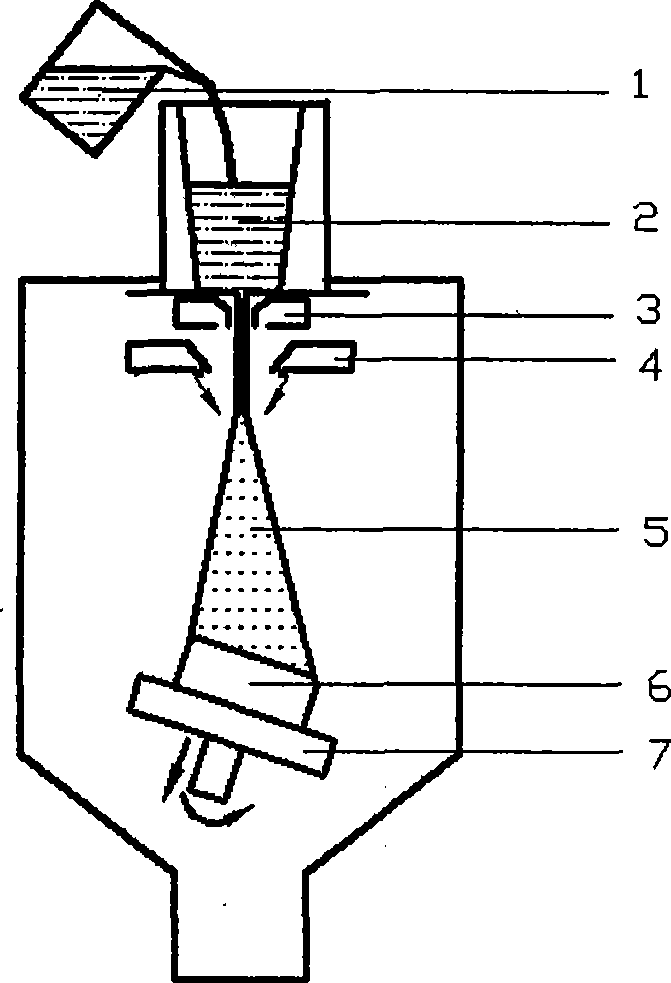

ActiveCN102658526APlay the role of cooling and lubricationImprove thermal conductivityGrinding/polishing safety devicesJet flowNanoparticle

The invention relates to a nanoparticle jet flow minimum quantity lubrication grinding lubricant supply system. A minimum quantity lubrication grinding lubricant is prepared by adding nanoscale solid particles into a degradable grinding liquid, the lubricant is turned into pulse liquid drops with fixed pressure, variable pulse frequency and invariant liquid drop diameter, and the pulse liquid drops are sprayed into a grinding region in the form of jet flow under the action of an air isolating layer formed by high-pressure gas. The system has all advantages of a minimum quantity lubrication technology, has higher cooling performance and excellent tribological characteristic, and plays an important role; and grinding burn is avoided effectively, the workpiece surface quality is enhanced, and efficient, low-consumption, environment-friendly, resource-economic, low-carbon and clean production is realized.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY +1

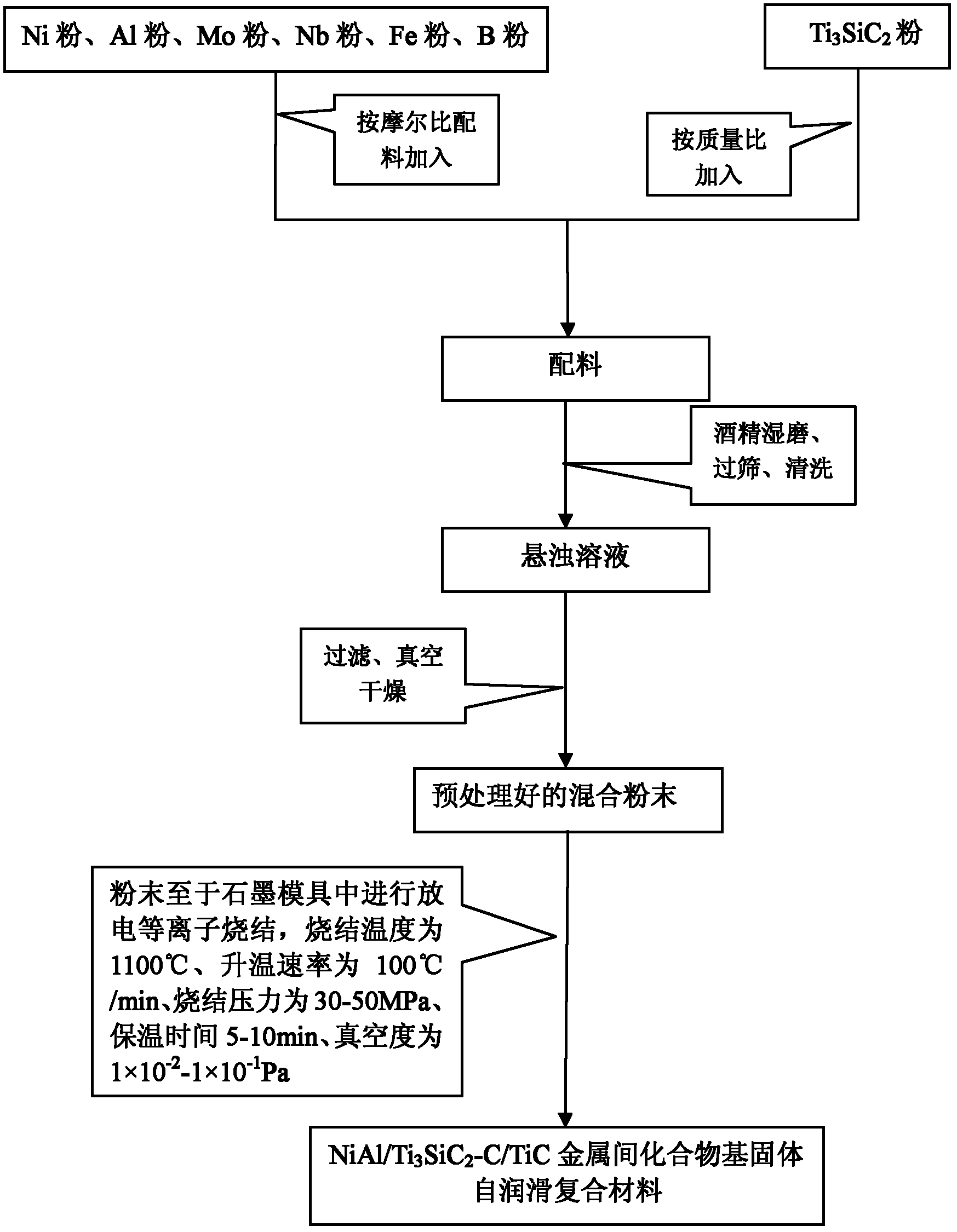

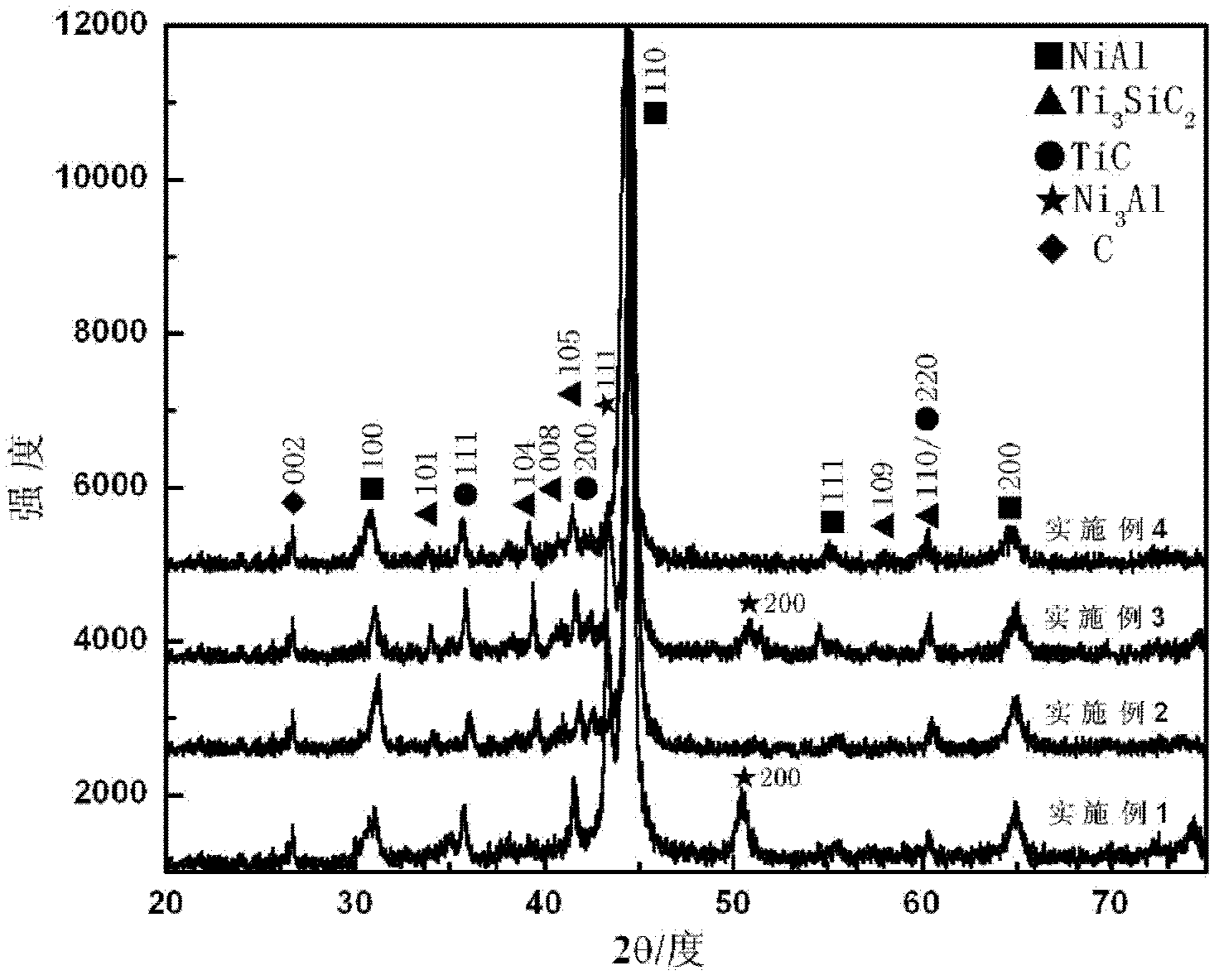

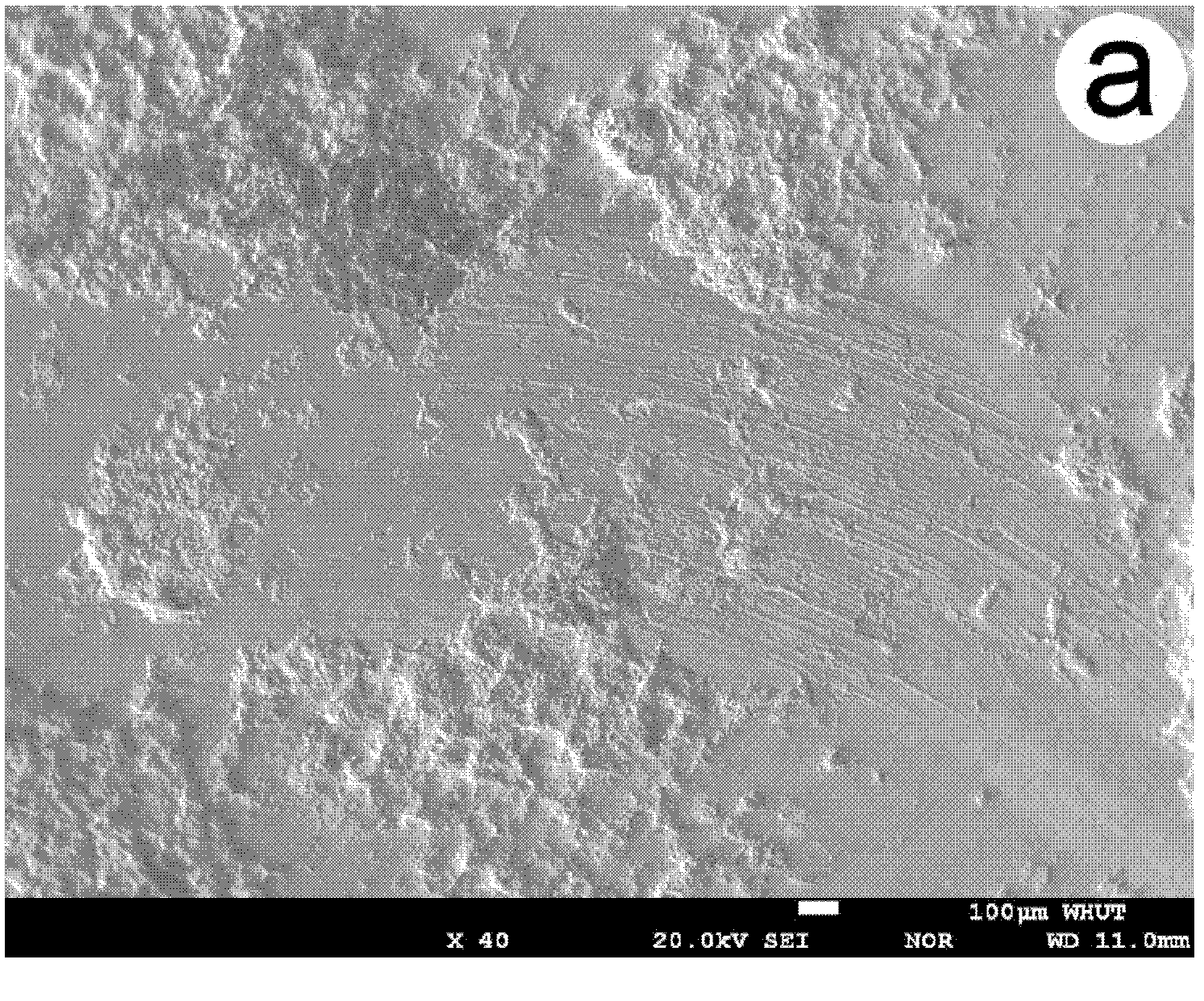

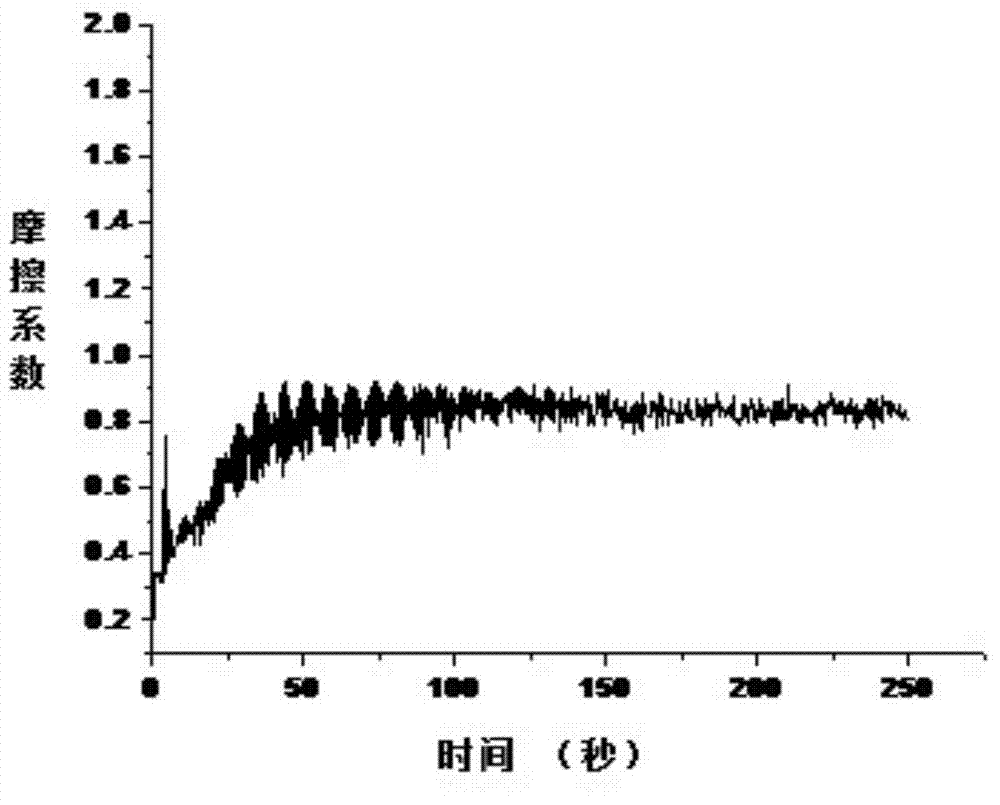

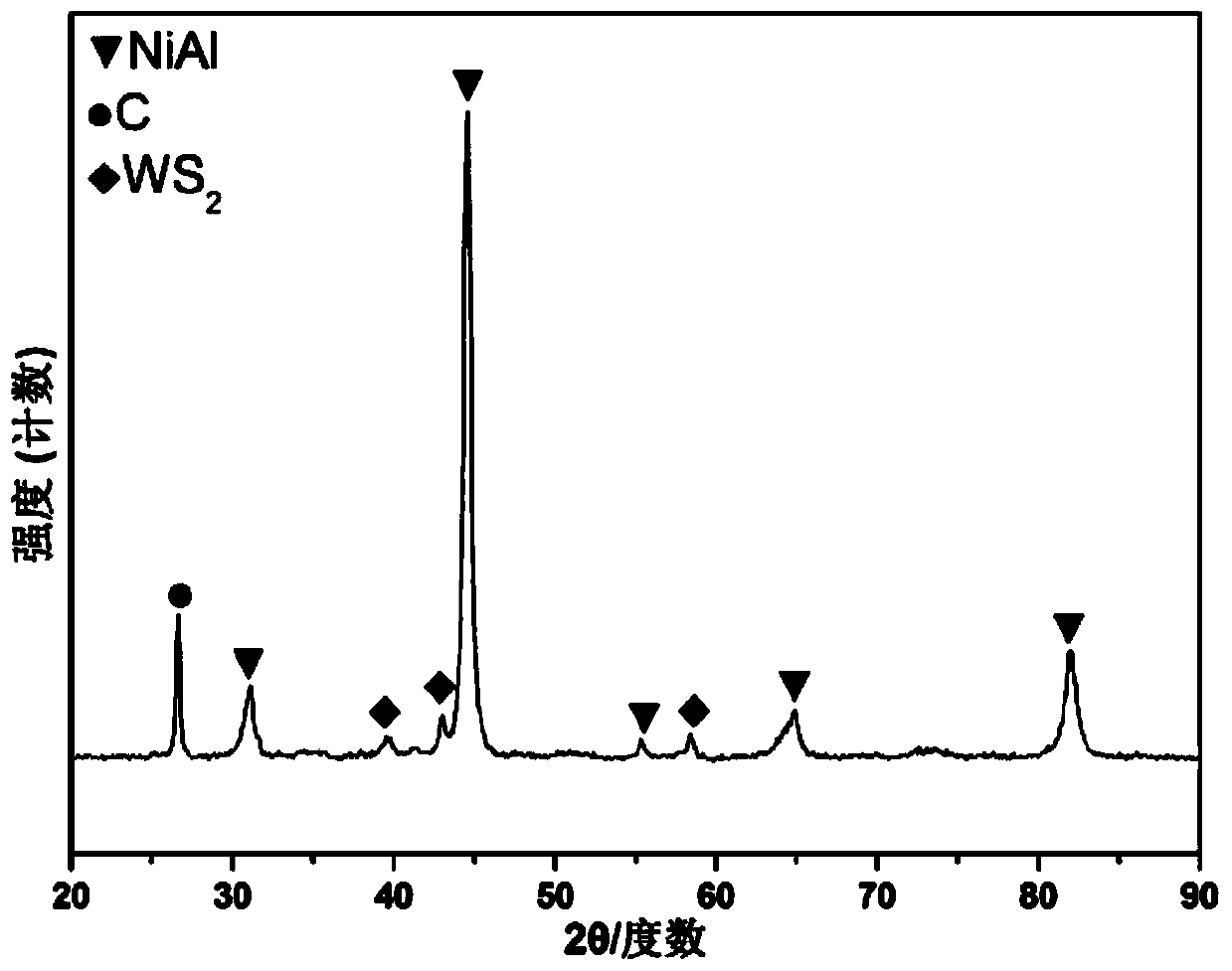

NiAl intermetallic base solid self-lubricating composite material and preparation method thereof

The invention relates to a preparation method of a NiAl intermetallic base solid self-lubricating composite material containing Ti3SiC2 and C binary composite lubrication phase and wild phase TiC. The NiAl intermetallic base solid self-lubricating composite material is prepared from Ni powder, Al powder, Mo powder, Nb powder, Fe powder, B powder and Ti3SiC2 powder, wherein the molar ratio of Ni: Al: Mo: Nb: Fe: B=48: 50: 1: 1: 0.5: 0.02, and the addition quantity of the Ti3SiC2 powder is 5-20 weight percent of the total weight of the Ni powder, the Al powder, the Mo powder, the Nb powder, theFe powder and the B powder. The NiAl / Ti3SiC2-C / TiC intermetallic base solid self-lubricating composite material synthesized by the method has novel component design (intermetallic matrix+ composite lubrication phase+ wild phase), high density, good tribological properties and stable technological parameters. The preparation process is fast and simple, and the method is easily operated and is suitable for preparing NiAl intermetallic base solid self-lubricating composite materials with high performance.

Owner:WUHAN UNIV OF TECH

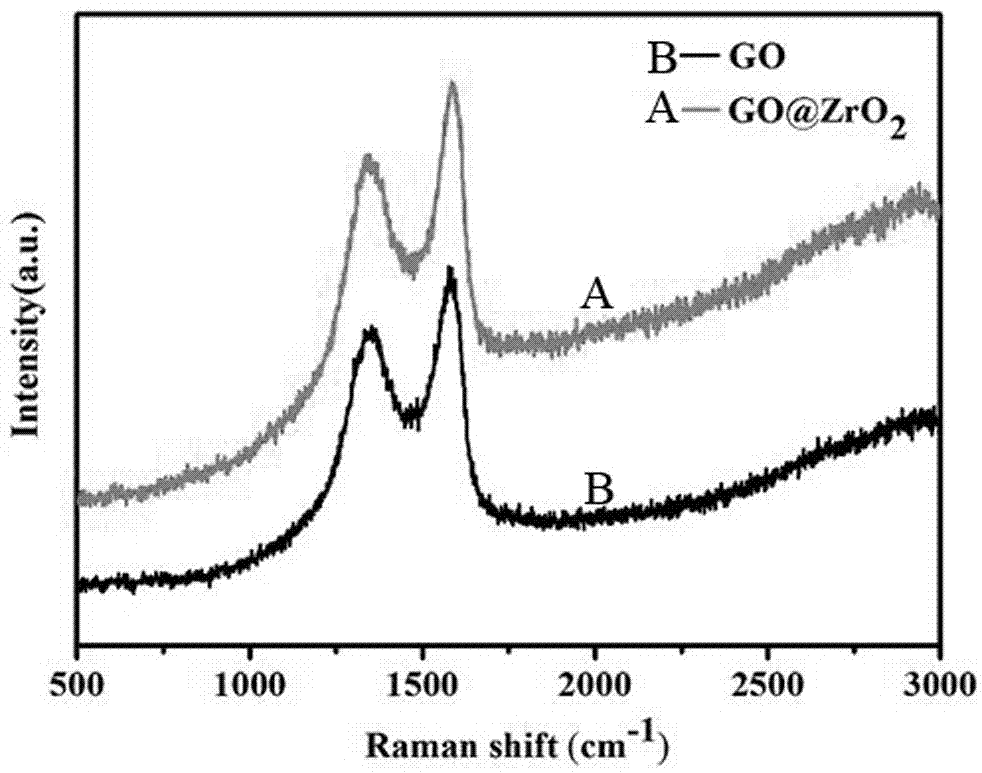

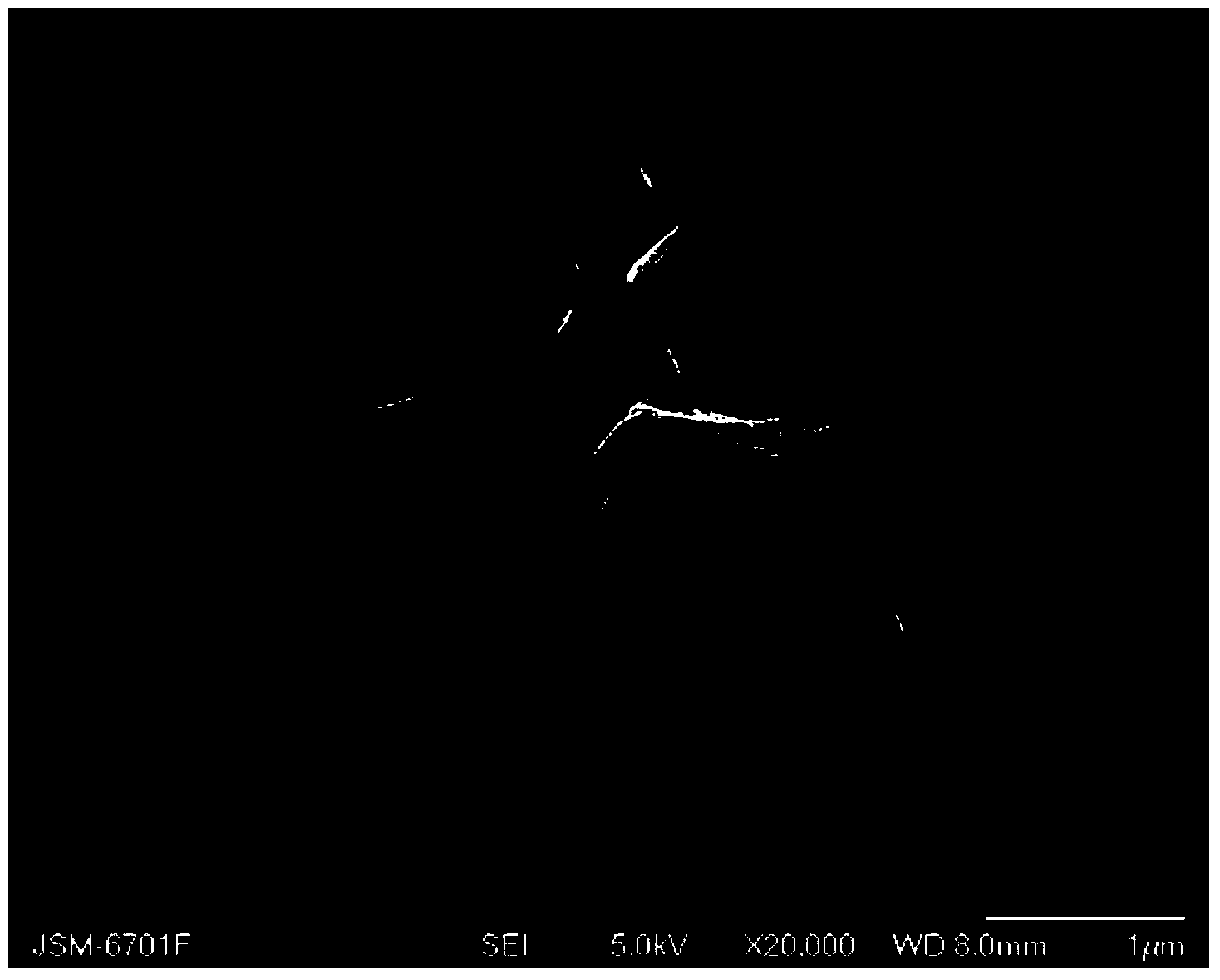

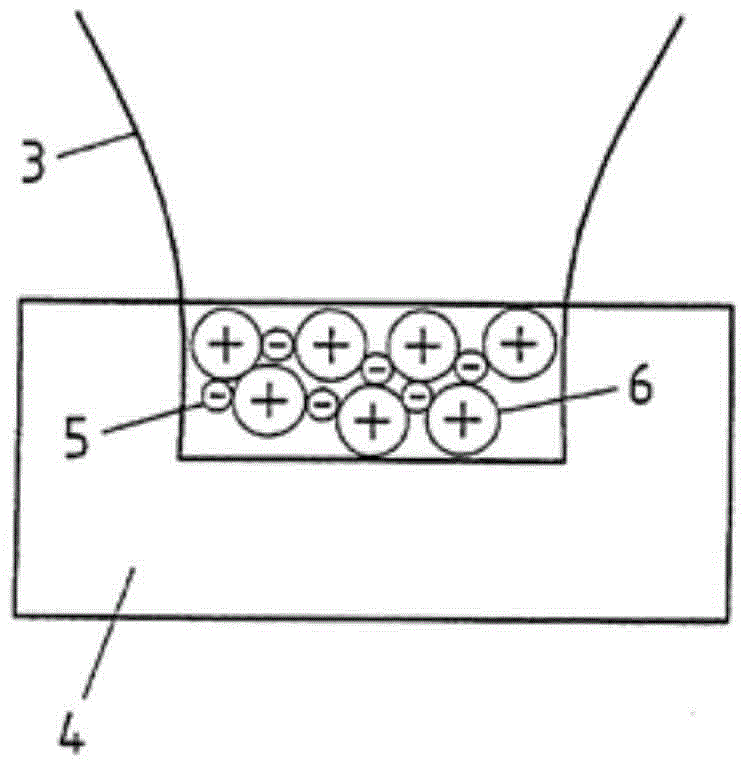

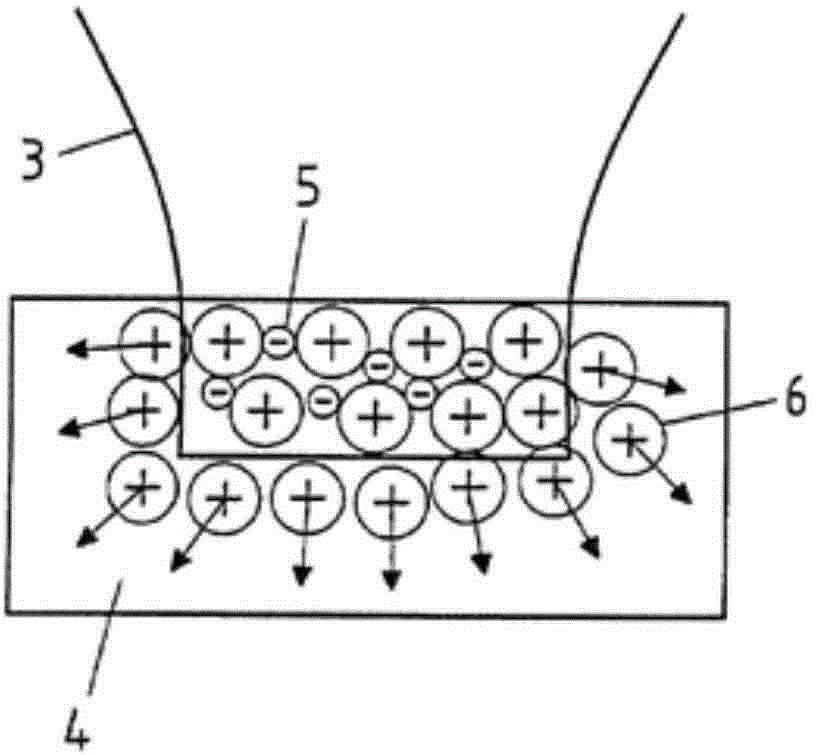

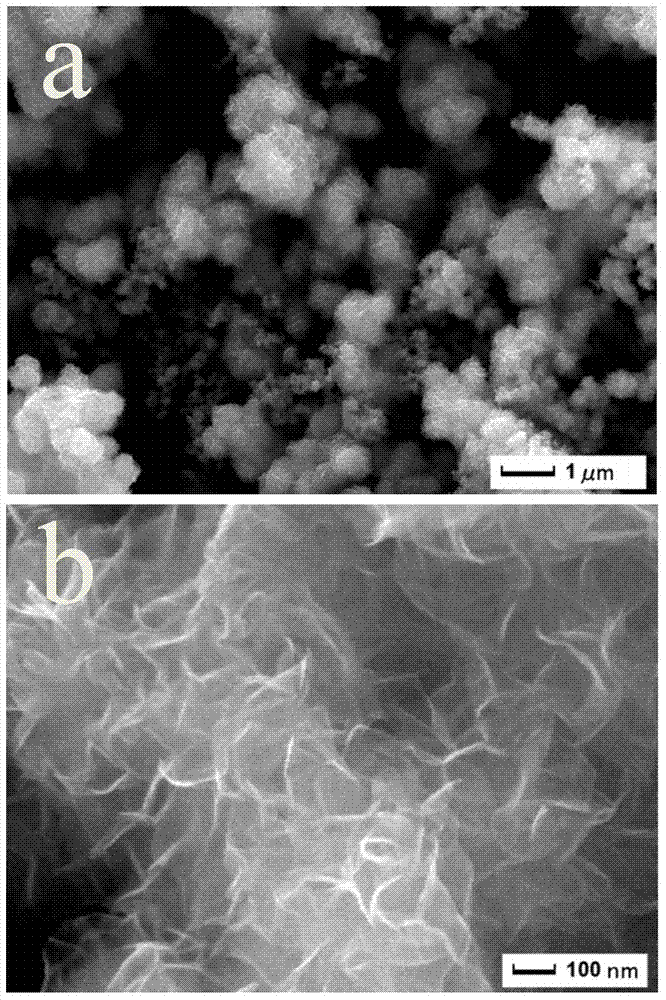

Nanoparticle/graphene oxide composite modified high polymer material and preparation thereof

ActiveCN107880484AImprove mechanical propertiesImprove tribological propertiesPolymer scienceOxide composite

The invention belongs to the field of high polymer composites and particularly relates to a nanoparticle / graphene oxide composite modified high polymer material and a preparation method thereof. The composite is prepared from nanoparticle / graphene oxide composite particles and a macromolecular polymer matrix, wherein the nanoparticle / graphene oxide composite particles are synthesized with an electrostatic self-assembly method, that is, an amino modified nanoparticle dispersion liquid is ionized to have positive charges while graphene oxide contains a large quantity of carboxyls and hydroxyls and is ionized to have negative charges, particles with positive and negative charges are sufficiently contacted, and electrostatically self-assembled nanoparticle and graphene oxide composite particles are obtained. The prepared nanoparticle / graphene oxide composite modified high polymer material has excellent mechanical and tribological performance, is simple and efficient to prepare and has goodapplication prospects in automobiles, aerospace, electronic and electrical engineering, machinery, weapons and other fields.

Owner:ZHONGBEI UNIV

Prepn of self-assembled superthin polymer film

InactiveCN1403494AInnovativeGood solvent resistanceMaterial nanotechnologyPolymer scienceLubrication

The present invention is the preparation process of one kind of superthin polymer film. Filming material is first synthesized via free radical copolymerization and superthin polymer film with different surface property is then prepared by means of self-assembling technological process. The process is simple and the prepared superthin polymer film has friction reducing and wear resisting effect and may be used in the lubrication and protection of mini electromechanical system.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

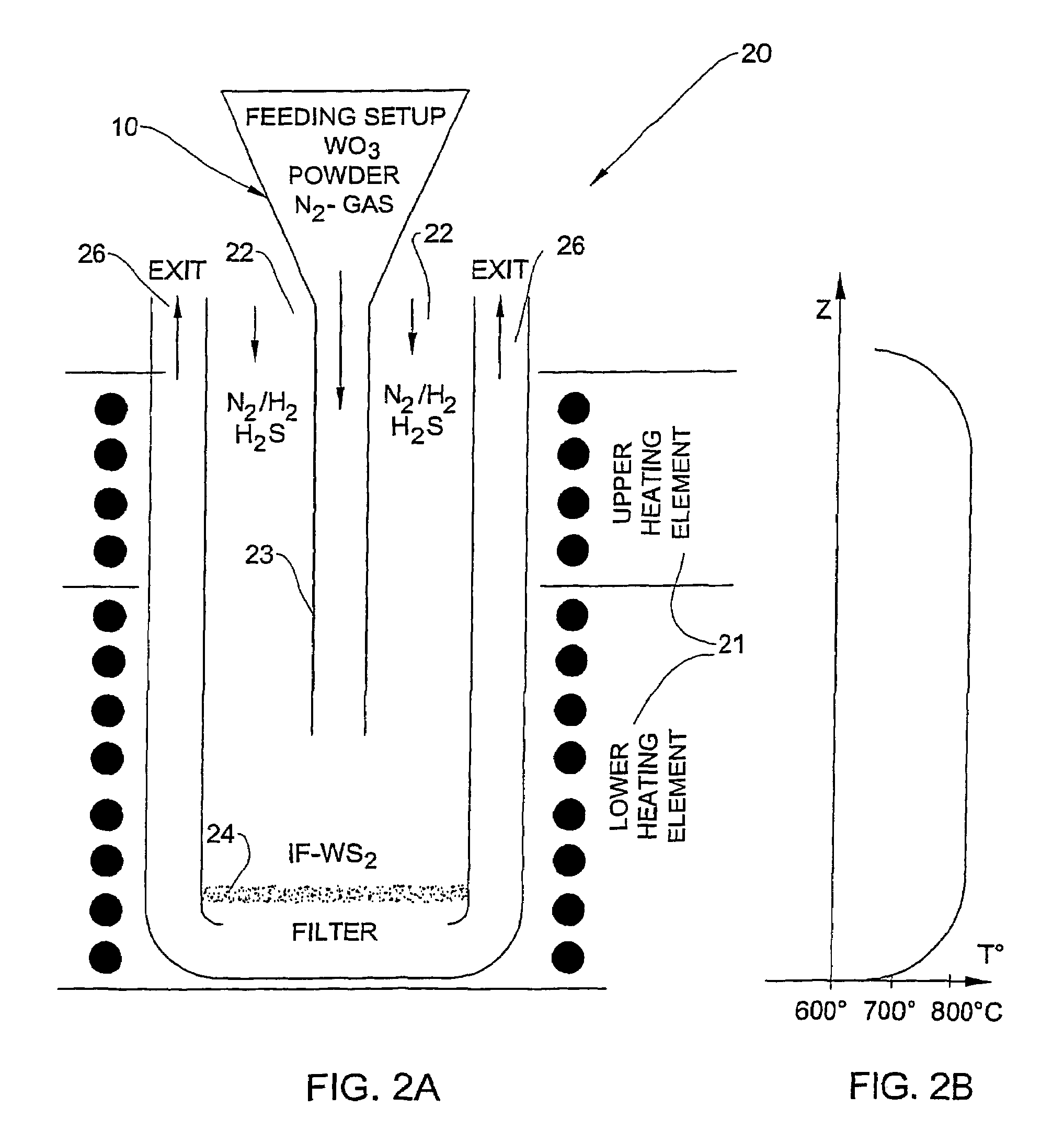

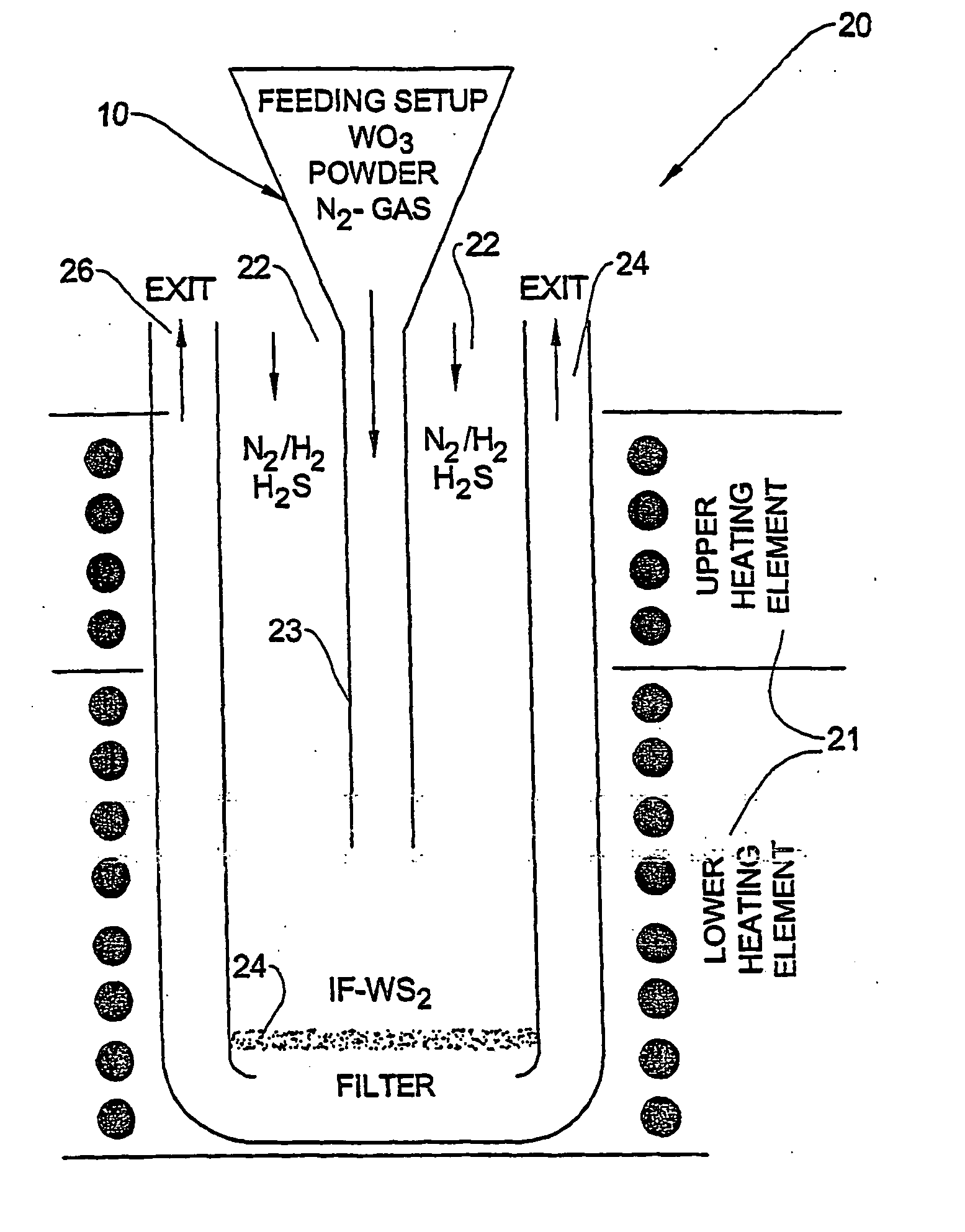

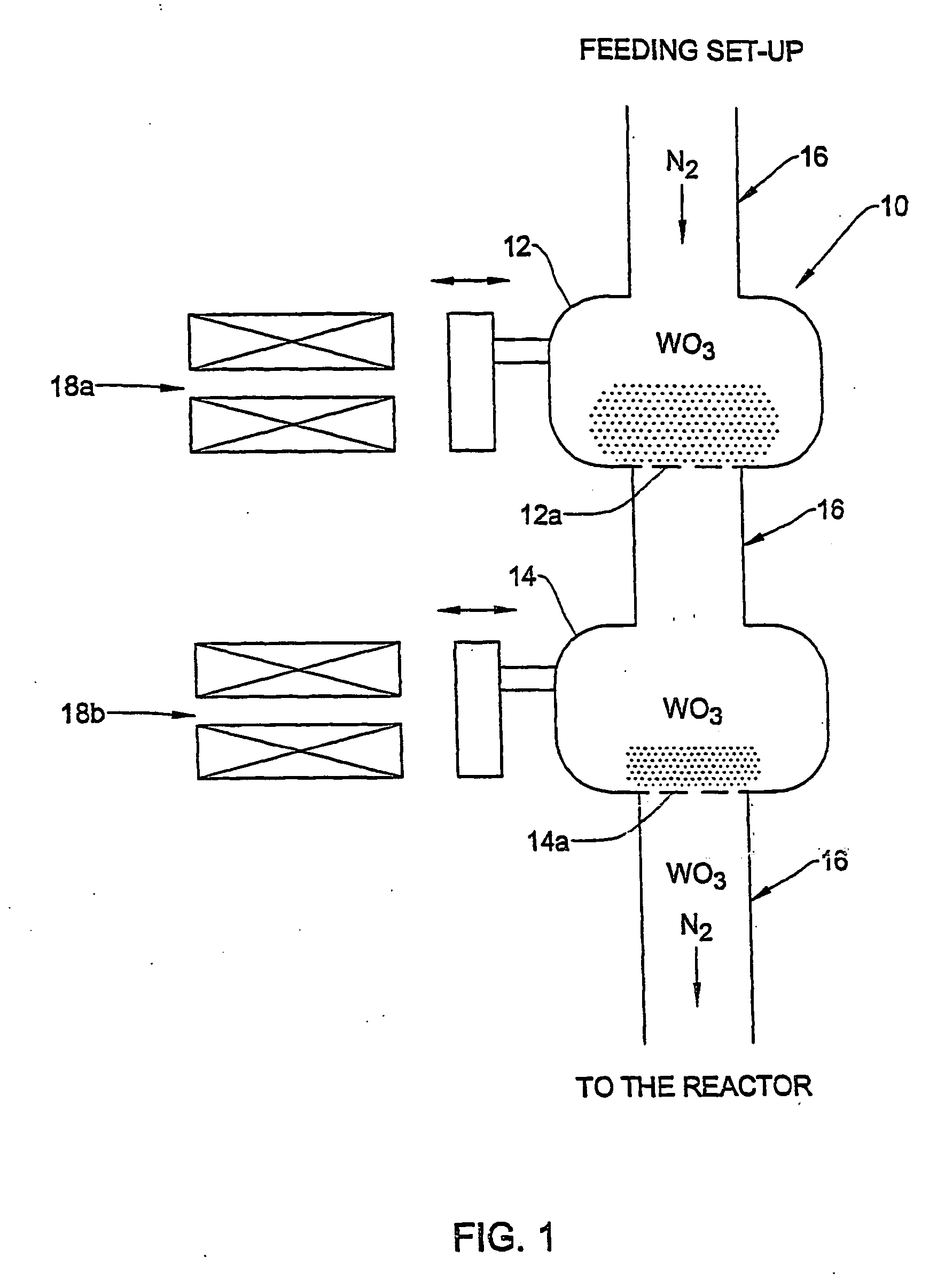

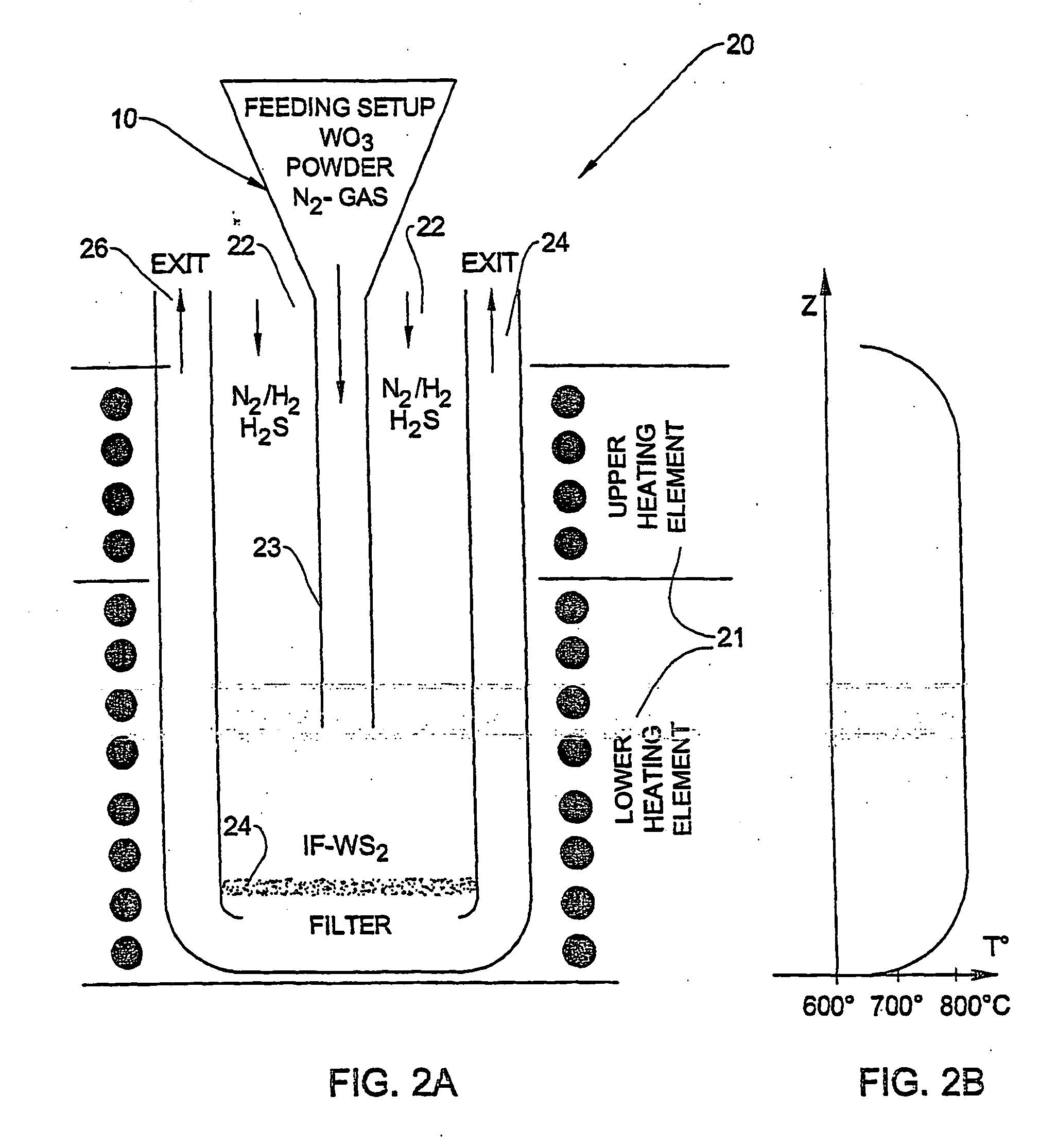

Reactors for producing inorganic fullerene-like tungsten disulfide hollow nanoparticles and nanotubes

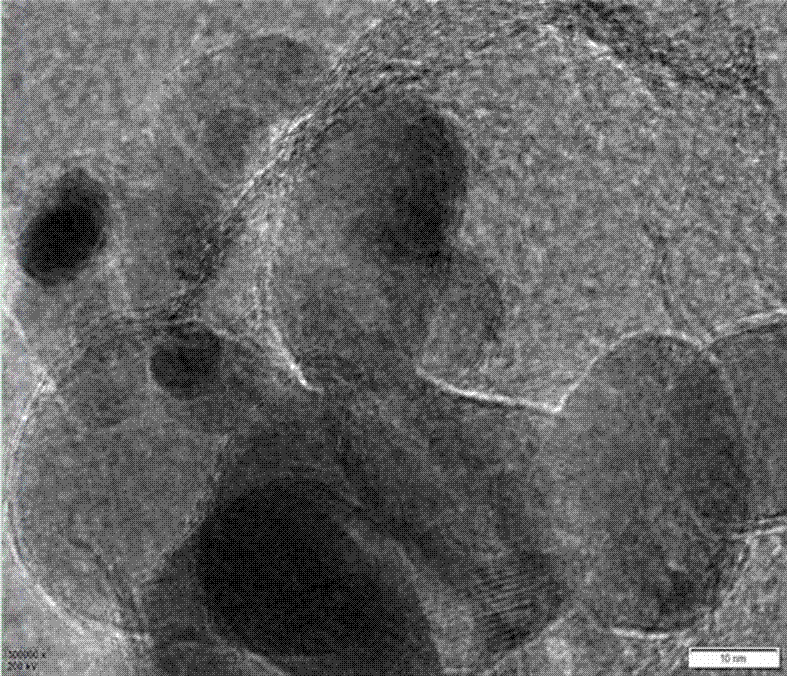

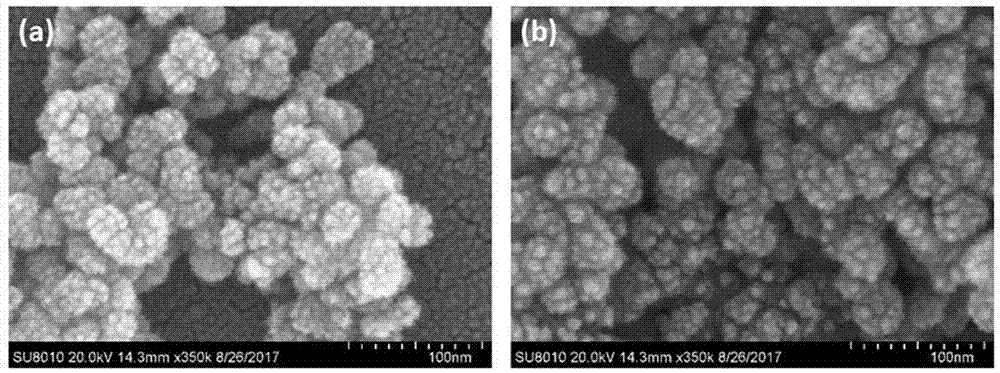

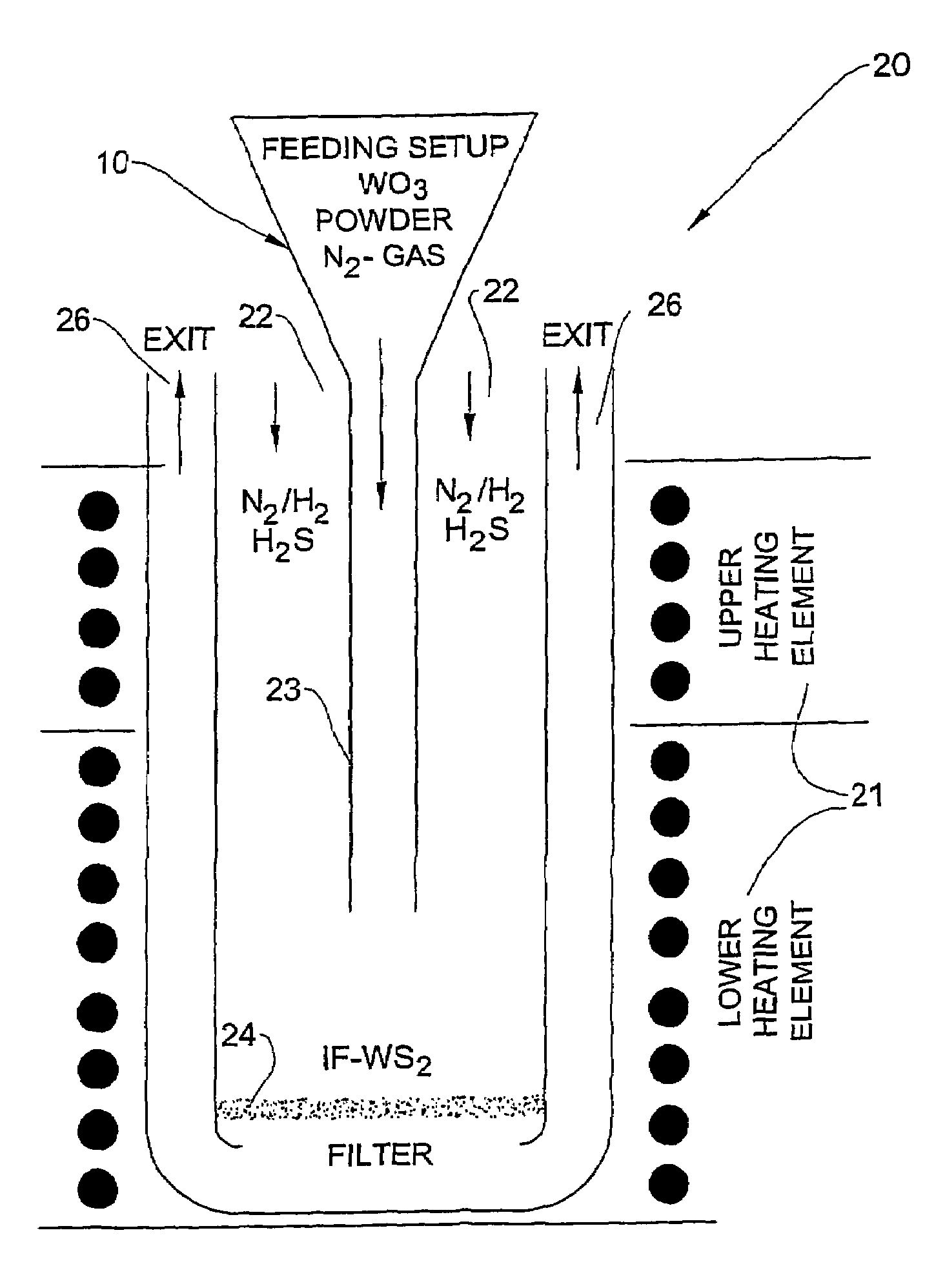

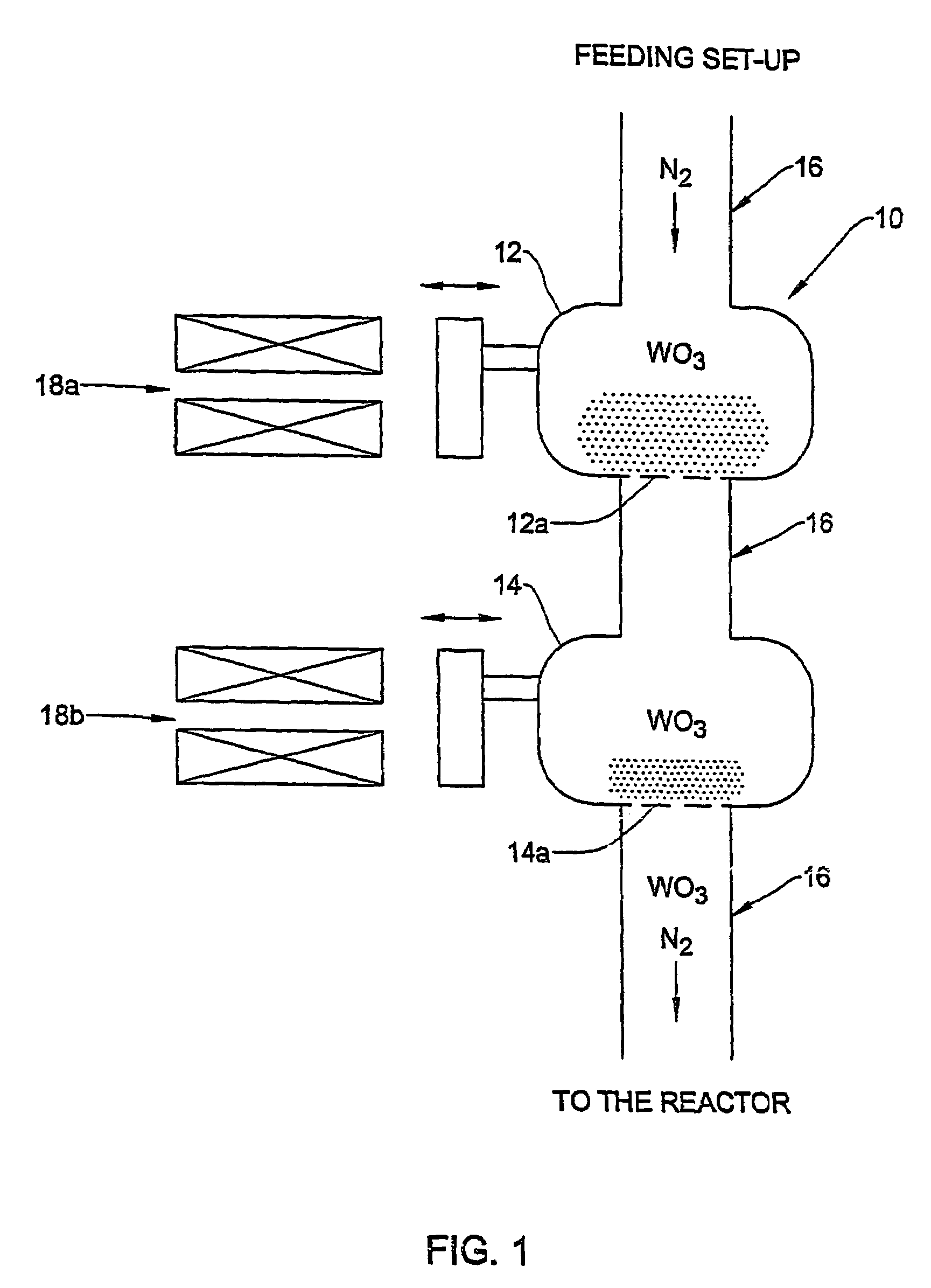

InactiveUS7524481B2Uniform spherical shapeUniform size distributionMaterial nanotechnologyNanostructure manufactureTemperature controlNanoparticle

The present invention is related to an apparatus for the production of inorganic fullerene-like (IF) nanoparticles and nanotubes. The apparatus comprises a chemical reactor, and is further associated with a feeding set up and with a temperature control means for controlling the temperature along the reaction path inside the reactor so as to maintain the temperature to be substantially constant. The invention is further directed to a method for the synthesis of IF-WO3 nanoparticles having spherical shape and having a size up to 0.5 mu m and nanotubes having a length of up to several hundred mu m and a cross-sectional dimension of up to 200 nanometer.

Owner:YEDA RES & DEV CO LTD

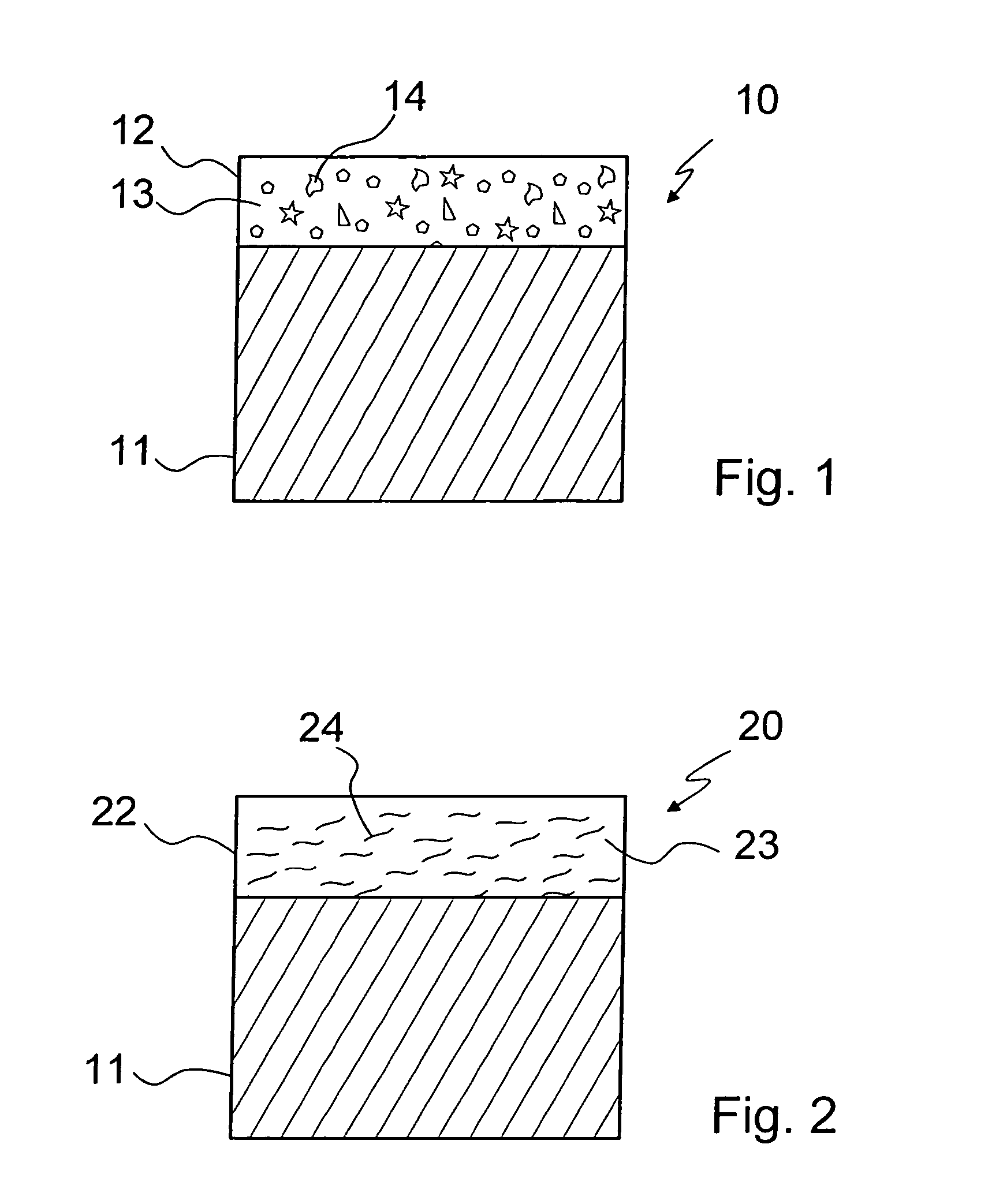

Electrical contact

InactiveUS20060105641A1Reduce coefficient of frictionIncrease wear resistanceContact materialsElectrically conductive connectionsEngineeringMetallic substrate

An electric contact, in particular an electric contact of a plug-in connector, has a metallic substrate to which a contact layer is applied. The contact layer is arranged as a structured layer.

Owner:ROBERT BOSCH GMBH

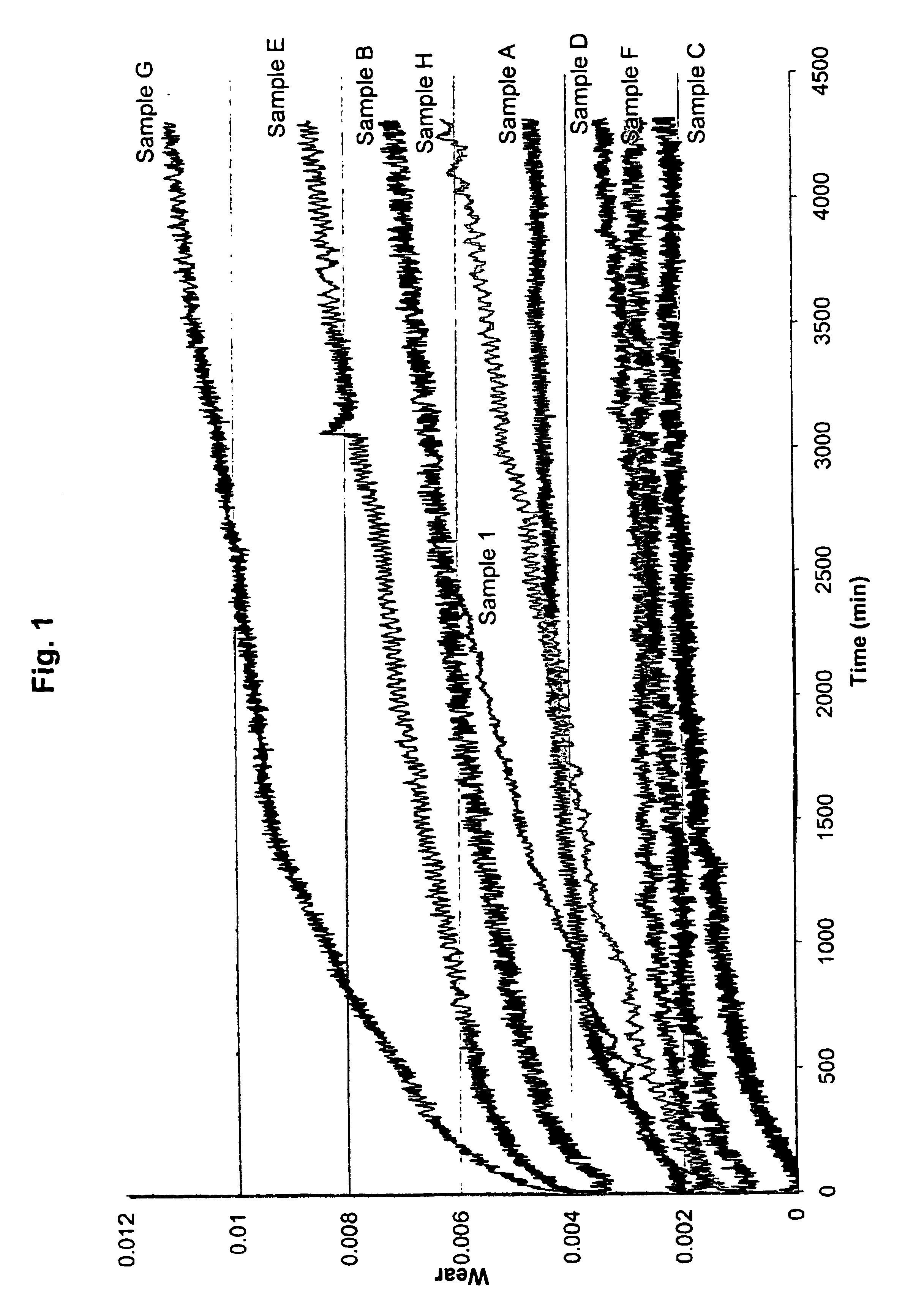

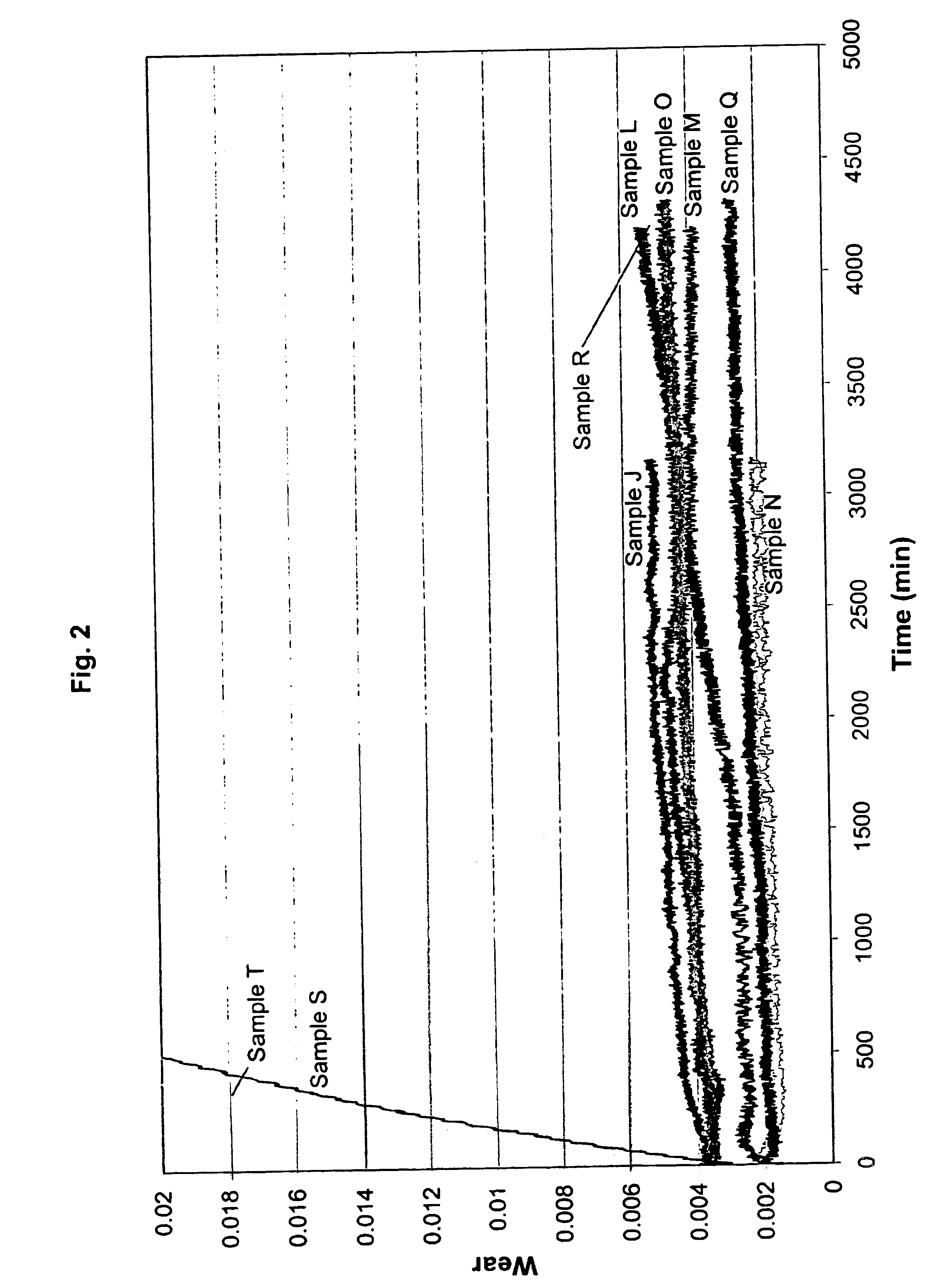

Compositions containing polyphenylene ether and/or polystyrene having improved tribological properties and methods for improving tribological properties of polyphenylene ether and/or polystyrene compositions

InactiveUS6887938B2Improve tribological propertiesImprove wear resistanceSpecial tyresOrganic dyesLinear low-density polyethylenePolystyrene

Internally lubricated polymer compositions containing a styrene- and / or polyphenylene ether-containing polymer, an olefin-containing polymer, and a compatibilizer are provided. The olefin-containing polymer, which is present in the compositions in about 3 to about 30 weight percent, provides internal lubrication and improves the tribological properties of the compositions compared with the styrene- or polyphenylene ether-containing polymer alone, as determined by wear measurements. Preferred compositions exhibit wear factors less than about 130×10−11n mm5 / Pa-m. A preferred composition includes a blend of polystyrene / polyphenylene ether, linear low density polyethylene, and styrene-ethylene-butadiene-styrene. Methods are also provided for improving tribological properties of styrene- and / or polyphenylene ether-containing base polymers by incorporating into the base polymers at least one olefin-containing polymer and at least one compatibilizer, or by incorporating at least one substantially halogen-free internal lubricant.

Owner:SHPP GLOBAL TECH BV

Preparation method of textured diamond-like carbon composite film for water lubrication

ActiveCN101748370AImprove stabilityImprove anti-friction and anti-wear propertiesVacuum evaporation coatingSputtering coatingDiamond-like carbonComposite film

The invention discloses a preparation method of a textured diamond-like carbon composite film for water lubrication. In the invention, by adopting a laser surface micro-processing technology, a microtexture appearance molding can be obtained on the surface of a workpiece, and a film can be obtained on the surface of the workpiece by plating a titanium transition layer and doping a diamond-like carbon film of titanium after the workpiece is plasma-cleaned by a magnetic control sputtering deposition technology. The film greatly enhances the stability and the antifriction and abrasion resistance performance of the conventional diamond-like carbon film under the condition of water lubrication with the friction coefficient reduction reaching up to 40 percent and the abrasion resistance enhanced by 1-3 times. The invention is suitable for surface protection and strengthening of a transmission friction pair of a mechanical sealing ring, a thrust bearing and other machines under the water-consuming environment, and the service life is prolonged.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

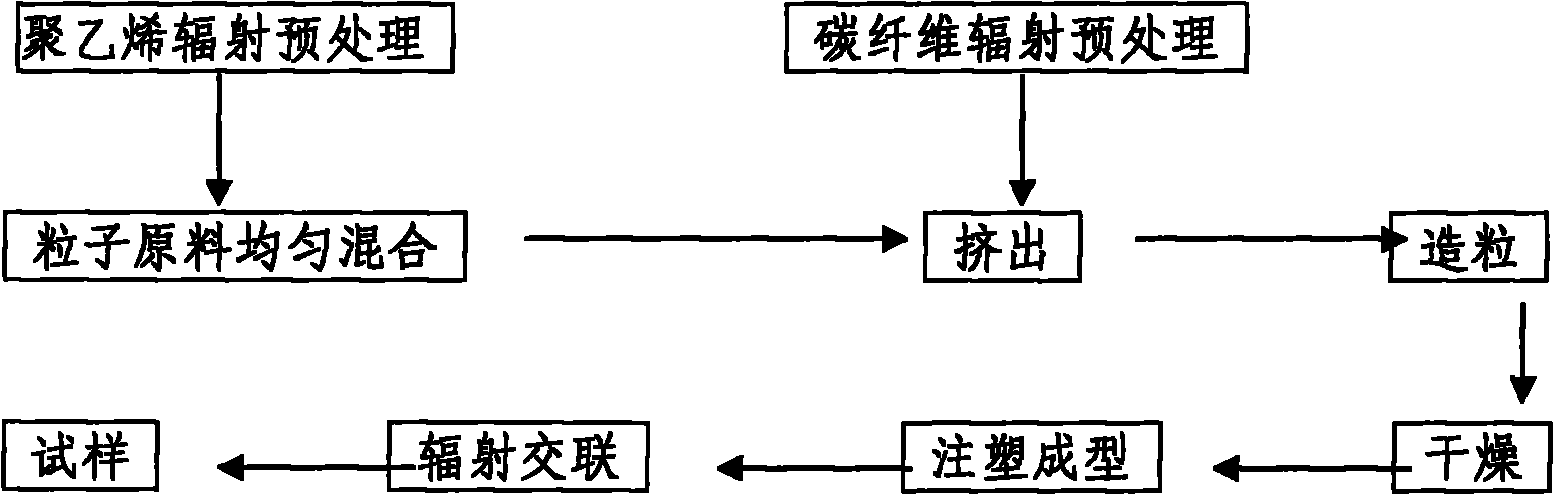

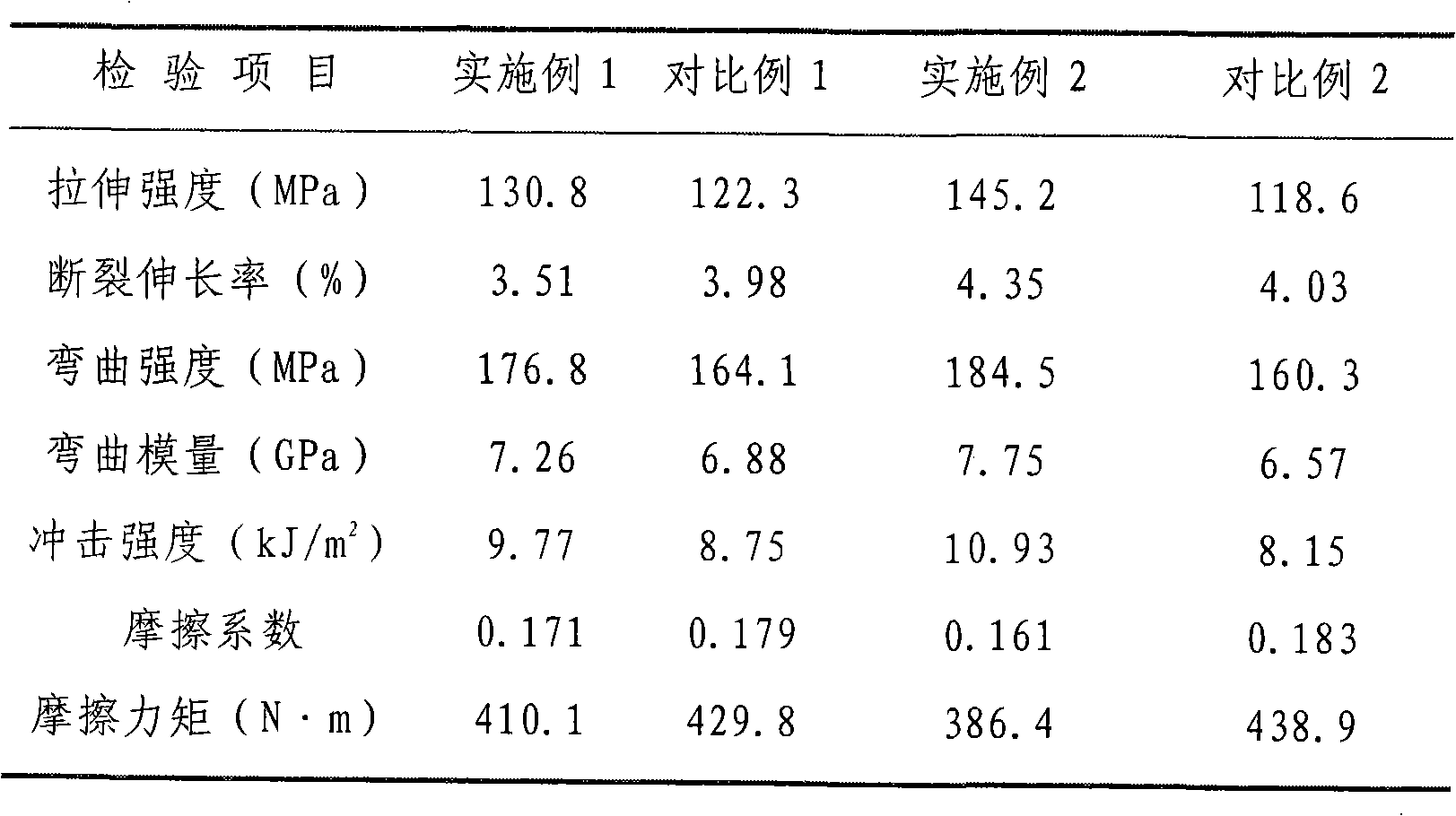

Wear-resistant self-lubricating nylon compound material and method for preparing same

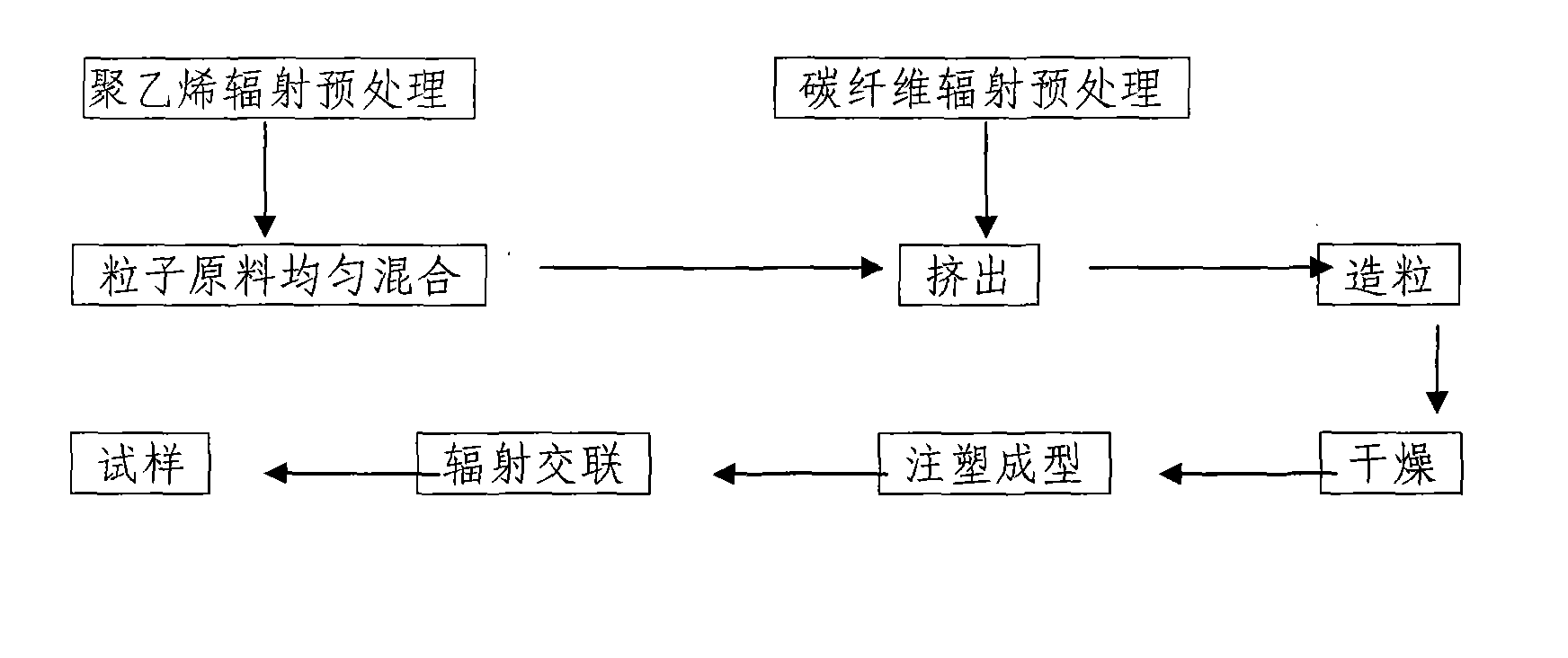

The invention discloses a wear-resistant self-lubricating nylon compound material and a method for preparing the same, and belongs to the technical field of macromolecular materials. The wear-resistant self-lubricating nylon compound material comprises the following raw materials in part by weight: 100 parts of nylon, 10 to 30 parts of carbon fiber, 5 to 15 parts of polyethylene, 2 to 4 parts of compatilizer, 0.5 to 3 parts of irradiation sensitizer, 0.1 to 0.3 part of antioxidant and 5 to 15 parts of polytetrafluoroethylene. The preparation method comprises the following steps: irradiation pretreatment of carbon fibers and polyethylene, preparation of nylon / polytetrafluoroethylene / carbon fiber compound materials, irradiation crosslinking modification of nylon / polytetrafluoroethylene / carbon fiber compound materials and the like. The wear-resistant self-lubricating nylon compound material possesses excellent wear-resistant property, self-lubricating property and physical mechanical property and high size stability and heat resistance, and can be widely applied in fields of self-lubricating bearings, shaft sleeves, mechanical cams, gears, sucker rod couplings, oil-free lubricating materials and the like.

Owner:河南省科学院同位素研究所有限责任公司

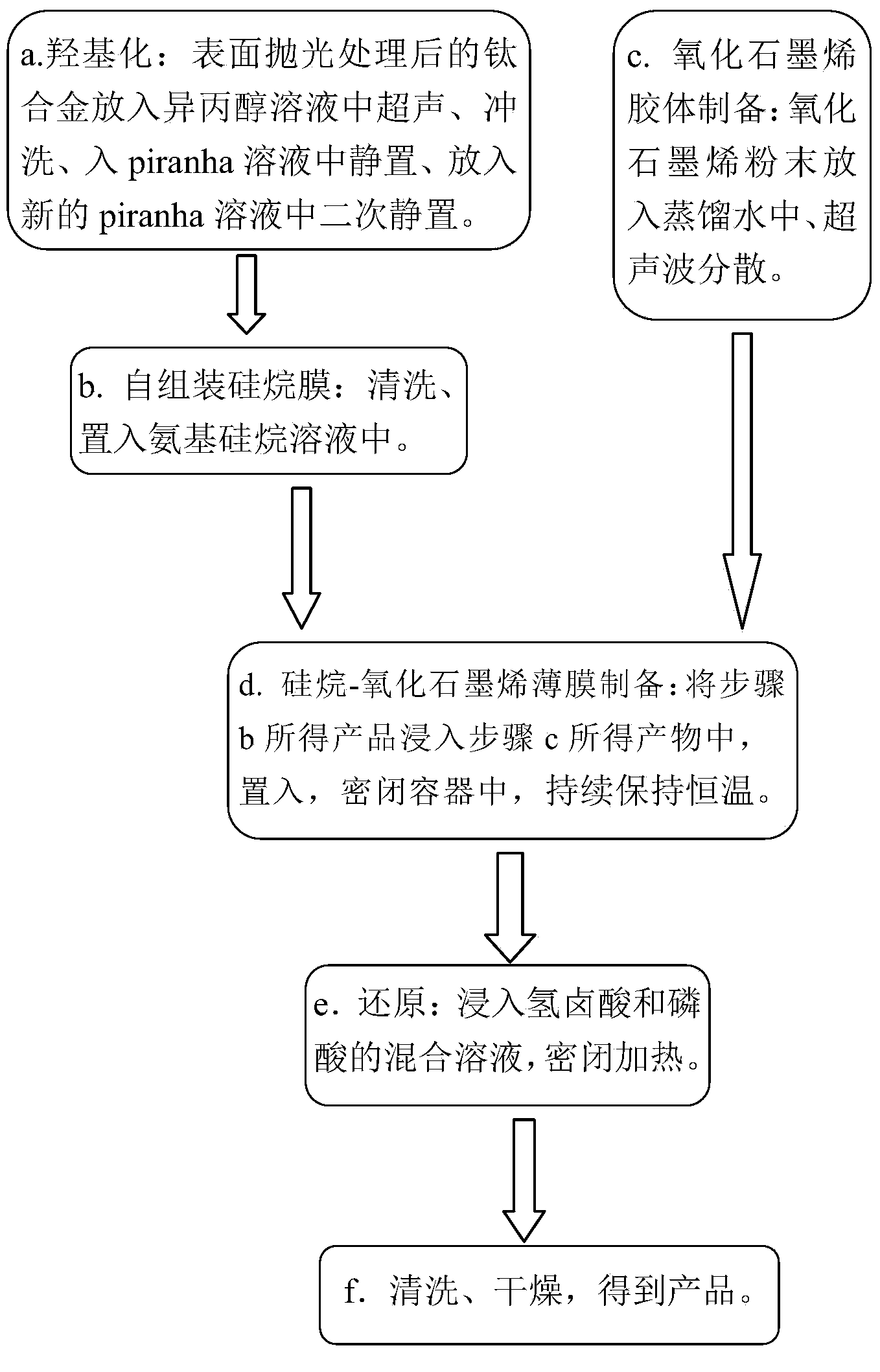

Method for preparing graphene film on surface of titanium alloy

InactiveCN104018145AReduce coefficient of frictionHigh strengthSolid/suspension decomposition chemical coatingHydrogen halideSilanes

The invention discloses a method for preparing a graphene film on the surface of titanium alloy. The method specifically comprises the following steps of putting a medical titanium alloy into a piranha solution and carrying out hydroxylation treatment, and then putting into an amino silane solution, and self-assembling a silane film; carrying out ultrasonic treatment on graphene oxide powder to obtain a stable graphene oxide colloid; immersing the titanium alloy of which the surface is attached with the silane film in the graphene oxide colloid to prepare a silane-graphene oxide film; and finally, reducing the graphene oxide film with hydrogen halide acid, and drying to obtain the reduced graphene oxide composite film. The method disclosed by the invention is simple and causes no harm to experiment operators, and the obtained film has the advantages of good integrity, high strength, low coefficient of friction and excellent wear resistance and is expected to become a medical joint material.

Owner:SHANGHAI JIAO TONG UNIV

Flat product made of metal material, in particular a steel material, use of such a flat product, and roll and method for producing such flat products

ActiveCN104884180AGood formabilityImprove spray appearanceRollsOther manufacturing equipments/toolsThin metalMetallic materials

A flat product made of a metal material has been provided with deterministic surface texture which has a plurality of depressions which have a depth in the range of from 2 to 14 μm, wherein the depressions are designed to be I-shaped, H-shaped, cross-shaped, C-shaped or X-shaped, and wherein the surface texture has a peak count RPc in the range of from 45 to 180 l / cm, an arithmetic mean roughness Ra in the range of from 0.3 to 3.6 μm, and an arithmetic mean waviness Wsa in the range of from 0.05 to 0.65 μm. A roll which is particularly suitable for producing such a flat product has a deterministic surface texture which has a plurality of overlapping dimples, which are arranged such that they delimit a double-I-shaped, H-shaped, cross-shaped, C-shaped or X-shaped material texture in the roll surface, and wherein the surface texture of the roll, measured in the direction of the roll axis, is characterized by a peak count RPc in the range of from 80 to 180 l / cm, an arithmetic mean roughness Ra in the range of from 2.5 to 3.5 μm and an arithmetic mean waviness Wsa in the range of from 0.08 to 1.0 μm.

Owner:THYSSENKRUPP STEEL EURO AG

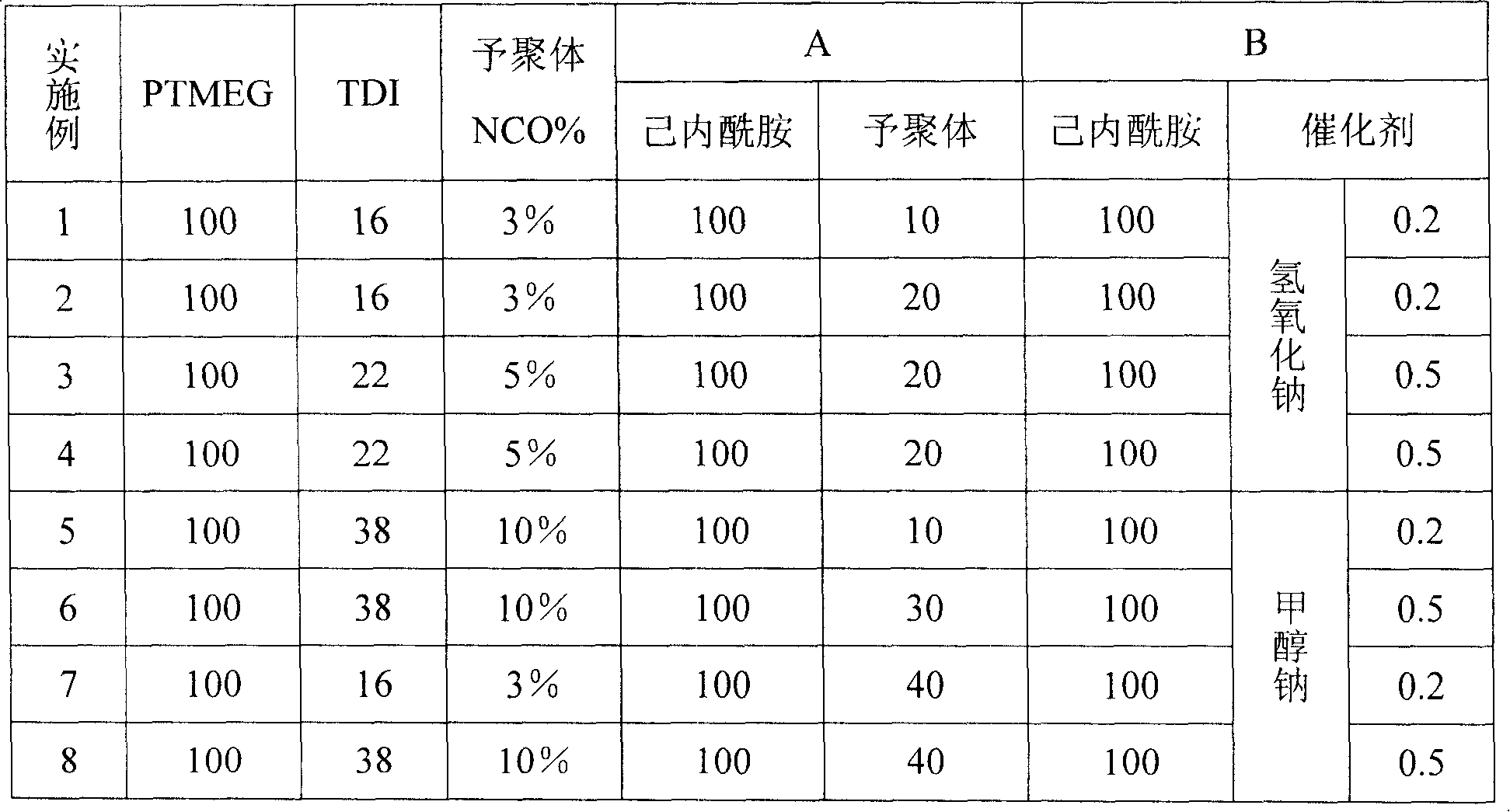

Method for producing polyurethane toughness-reinforcing cast form nylon composite material

InactiveCN101195706AHigh mechanical strengthIncreased tensile elongation at breakNylon materialToughness

The invention relates to a preparation method of polyurethane plasticizing monomer casting nylon compound material. The material is made through pouring the raw material of polyurethane prepolymer, and caprolactam, etc. The main performance of the material is characterized in that the mechanical strength is improved, the tensile fracture elongation rate is increased along with increasing of the use amount of the polyurethane prepolymer, the impact strength is enhanced along with the increasing of the use amount of the polyurethane prepolymer, and the tribology performance and the antistatic performance are improved remarkably.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Reactors for producing inoraganic fullerene-like tungsten disulfide hollow nanoparticles and nanotubes

InactiveUS20040105808A1Uniform spherical shapeUniform size distributionMaterial nanotechnologyNanostructure manufactureNanometreTungsten disulfide

The present invention is related to an apparatus for the production of inorganic fullerene-like (IF) nanoparticles and nanotubes. The apparatus comprises a chemical reactor, and is further associated with a feeding set up and with a temperature control means for controlling the temperature along the reaction path inside the reactor so as to maintain the temperature to be substantially constant. The invention is further directed to a method for the synthesis of IF-WO3 nanoparticles having spherical shape and having a size up to 0.5 mu m and nanotubes having a length of up to several hundred mu m and a cross-sectional dimension of up to 200 nanometer.

Owner:YEDA RES & DEV CO LTD

Wide temperature zone self-lubricating nickel-chromium alloy base composite material and preparation method thereof

InactiveCN101078071AGood mechanical propertiesLower coefficient of friction and wear rateNitrogen gasHot press

A kind of self-lubricating nickel chromium alloy group compound material with wide temperature band and the preparation method of it. The components and the mass percent of them are: Ni: 36.8-57.6%, Cr: 9.2-14.4%, Mo: 9.0-15.0%, Al: 2.0- 6.0%, Ti: 3.0-8.0%, B: 0.08%, MoS2: 6.0-15.0%, rare-earth compound: 2.0-8.0%. The preparation method contain the following steps: The powders of the above components according to the above mass percent will be uniformly mixed in ball crusher or mortar. The powders uniformly mixed will be chill pressed to mould and then will be put into the graphite mould to be hot pressed to mould in a vacuum thermocompressor. The process is as following: firstly, to be vacuumized to 2X10-5-8X10-5Pa, and to inflate N2 to protect them, and then the temperature will be increased to 1200-1280deg.C, a positive pressure 12-16MPa will be added when the temperature has got, to preservate the temperature and the press for 20-30min. From normal temperature to 700deg.C, the patent own lots of advantages, such as the mechanical strength of it is high, the oxidation resistance is high. The tribology ability of it is well, and it can be used to resolve the running problem of all kinds of hot engine and other high temperature machine and the lubricating problem of packing parts in wide temperature band range.

Owner:NANJING UNIV OF SCI & TECH

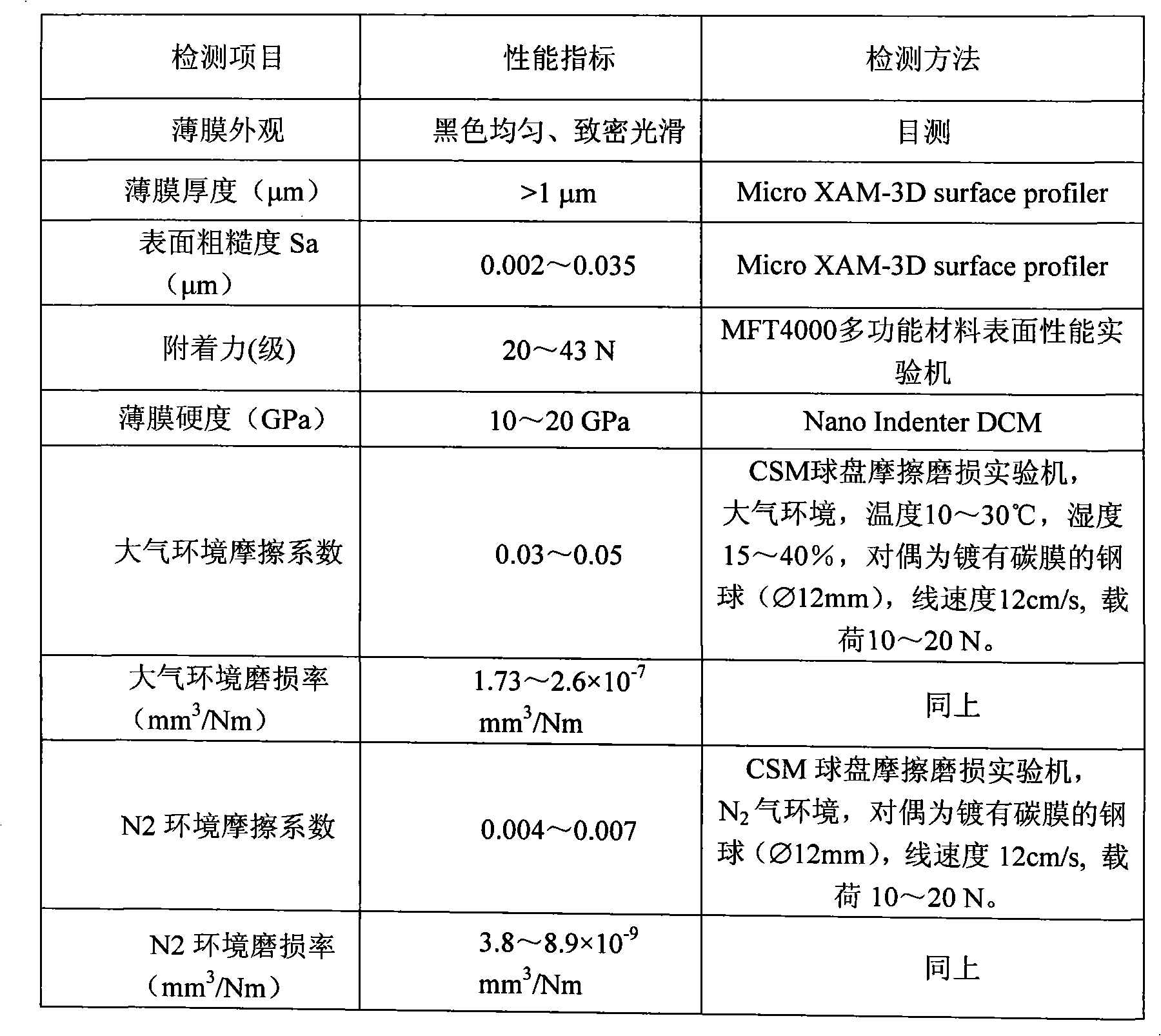

Method for preparing ultra-lubricating compound carbon film material

InactiveCN101665942AIncrease energy densityHas super lubricating propertiesVacuum evaporation coatingSputtering coatingCarbon filmFrictional coefficient

The invention discloses a method for preparing an ultra-lubricating compound carbon film material on base metal. The method is characterized in that: a silicon transition layer is formed on a metallicsubstrate by the unbalanced magnetic control sputtering method, and the hydrogen containing carbon film material is prepared by a pulse biasing voltage assistant radio frequency inductively coupled plasma chemical vapor deposition method. The film material can be firmly bonded to the metallic substrate and shows extremely excellent tribological property with a frictional coefficient of 0.03 to 0.05 and a wear rate of 1.73 to 2.6*10<-7>mm<3> / Nm in the atmospheric environment and a frictional coefficient of 0.004 to 0.007 and a wear rate of 3.8 to 8.9*10<-9>mm<3> / Nm in an atmosphere of inert gas such as N2 and the like. Therefore, the problem of the poor bonding force between the carbon film material and the metallic substrate is solved, and the carbon film material of the invention has a wide application prospect in various fields such as high tech precision machinery, electric information technology and the like.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

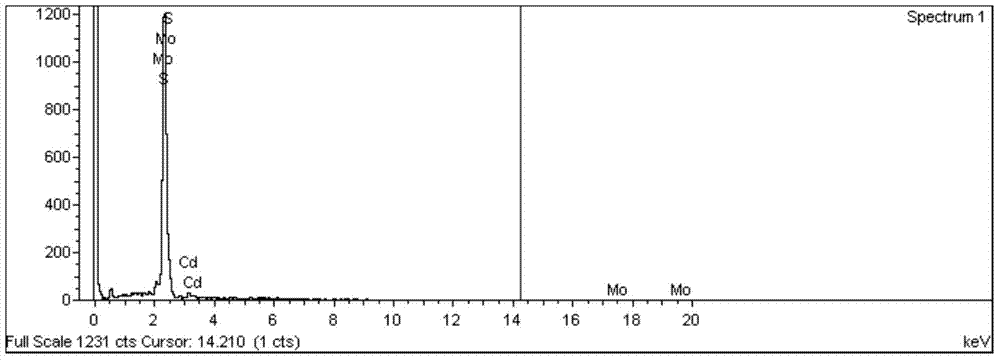

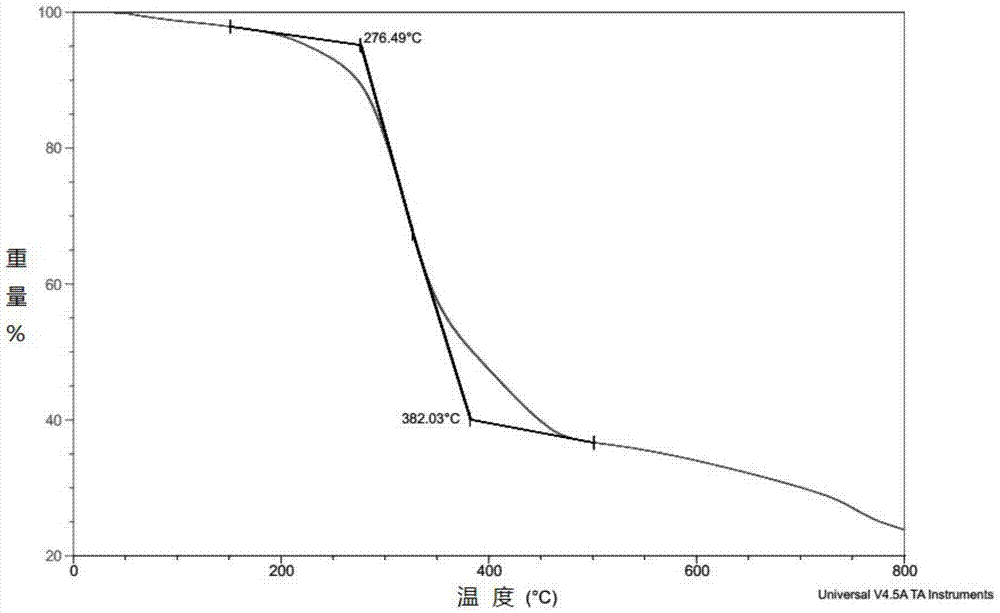

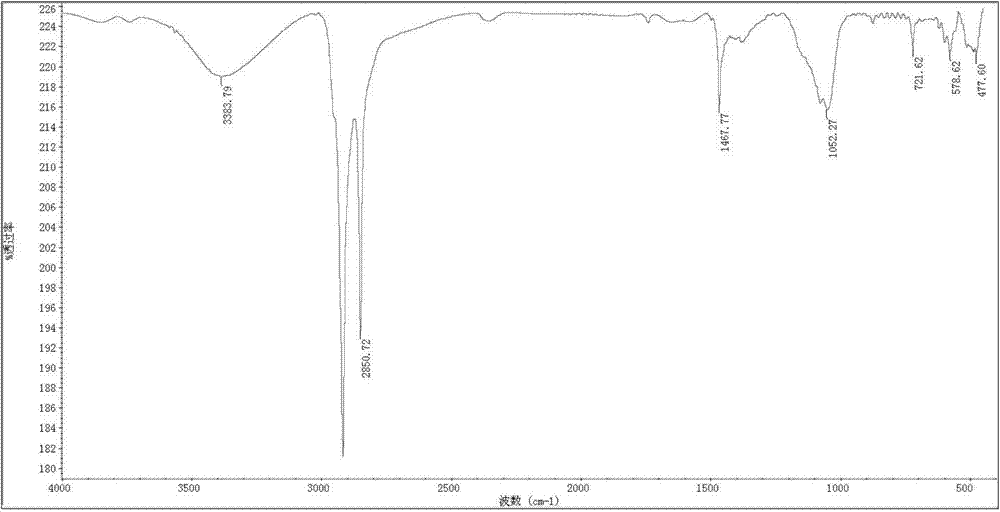

Preparation method of cadmium-doped molybdenum disulfide nano lubricating additive

ActiveCN103613138AHigh specific surface areaExcellent tribological propertiesMaterial nanotechnologyMolybdenum sulfidesTribologyMolybdenum disulfide

The invention discloses a preparation method of a cadmium-doped molybdenum disulfide nano lubricating additive, which is characterized by comprising the following steps: (1) dissolving (NH4)2MO4, Na2S, a reducer and a soluble cadmium salt in deionized water to obtain a mixture solution for later use; (2) transferring the solution obtained in the step (1) into a stainless steel reaction kettle, sealing, reacting at 130-260 DEG C for 24 hours, and cooling to room temperature to obtain the reaction product; and (3) separating the reaction product, washing, and drying to obtain the flower-structure Cd-doped MoS2 nanosheets assembled from nanosheets. The method has the advantages of simple technique and low cost; and the prepared product has the advantages of high purity, high yield, high specific area and favorable tribological performance.

Owner:ZHENJIANG COLLEGE

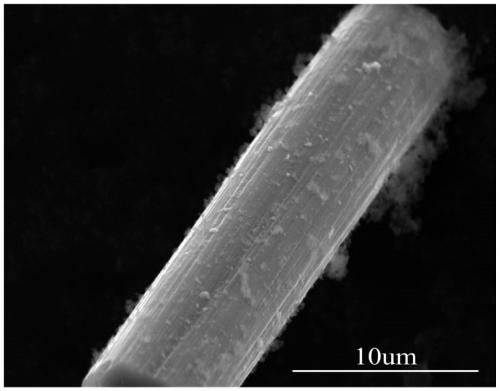

Preparation method of carbon cloth with nanoparticle modified surface

InactiveCN104179002AIncrease oxygen contentHigh bonding strengthPhysical treatmentCarbon fibresSio2 nanoparticleVacuum drying

The invention relates to a preparation method of carbon cloth with the nanoparticle modified surface. The method comprises the steps of putting carbon cloth into an acetone solution, saturating, and drying the carbon cloth after the saturating in the air to obtain a sample A; putting the sample A and concentrated nitric acid into a hydrothermal reaction kettle; putting the hydrothermal reaction kettle into a homogeneous reactor for oxidization, cleaning the taken carbon cloth, and finally carrying out vacuum drying to obtain a sample B; putting the sample B and a silica sol solution into a reaction kettle, and carrying out reaction in a microwave hydrothermal reaction instrument; cooling a reaction system to the room temperature, and washing the sample B taken from the reaction system; finally, carrying out the vacuum drying to obtain the carbon cloth with the nanoparticle modified surface. According to the method, SiO2 nanoparticles can be evenly deposited on the surface of the carbon cloth efficiently; the prepared carbon cloth with the nanoparticle modified surface is high in surface oxygen content; the uniformity of a reticular polymer formed by a linear polymer through cross-linking action in the sulfidation process can be improved; and therefore, the carbon cloth has the superior self-lubricating property, mechanical strength and tribological property.

Owner:SHAANXI UNIV OF SCI & TECH

Electrical contact

InactiveUS7294028B2Reduce coefficient of frictionImprove wear resistanceContact materialsElectrically conductive connectionsContact layerEngineering

Owner:ROBERT BOSCH GMBH

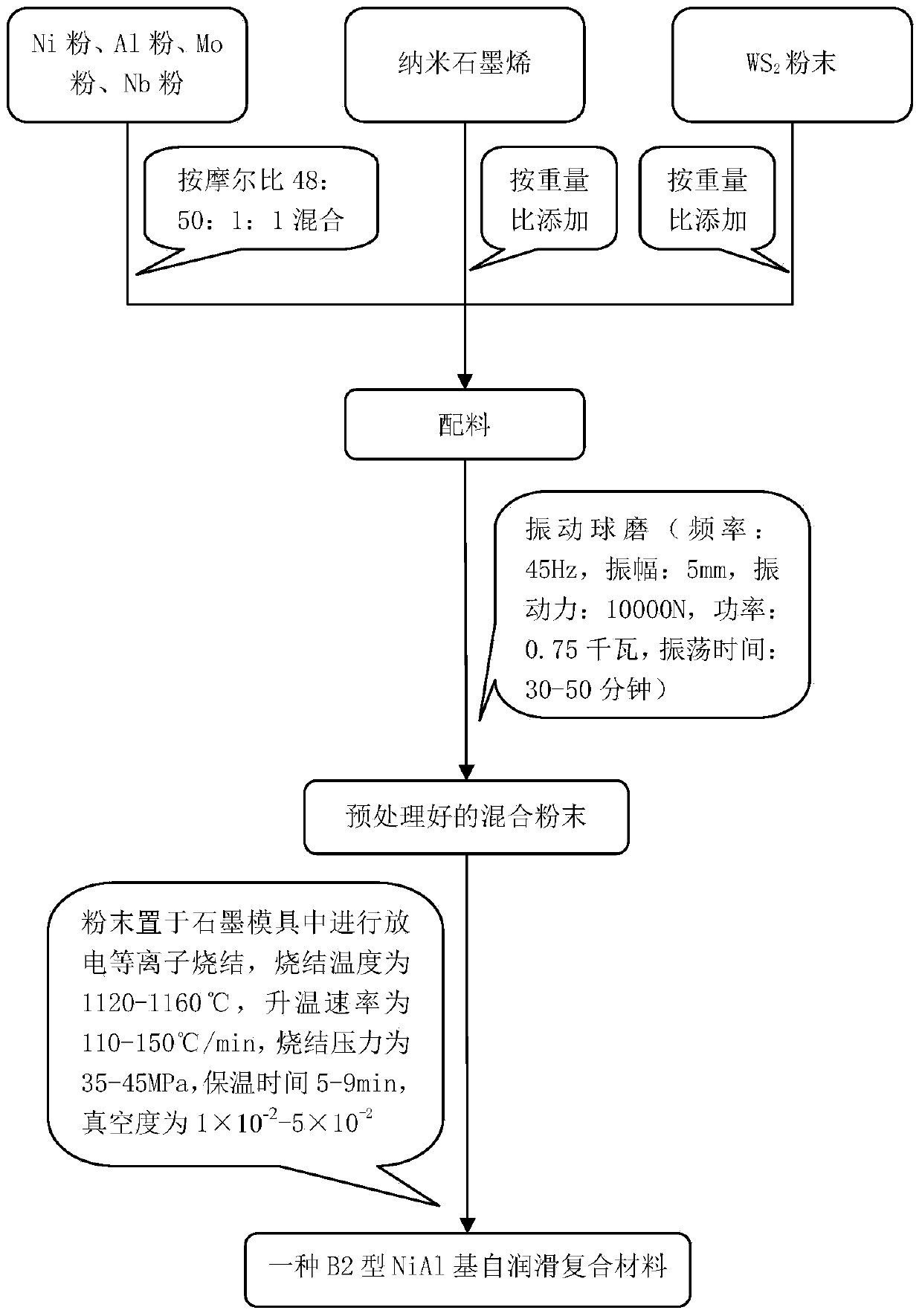

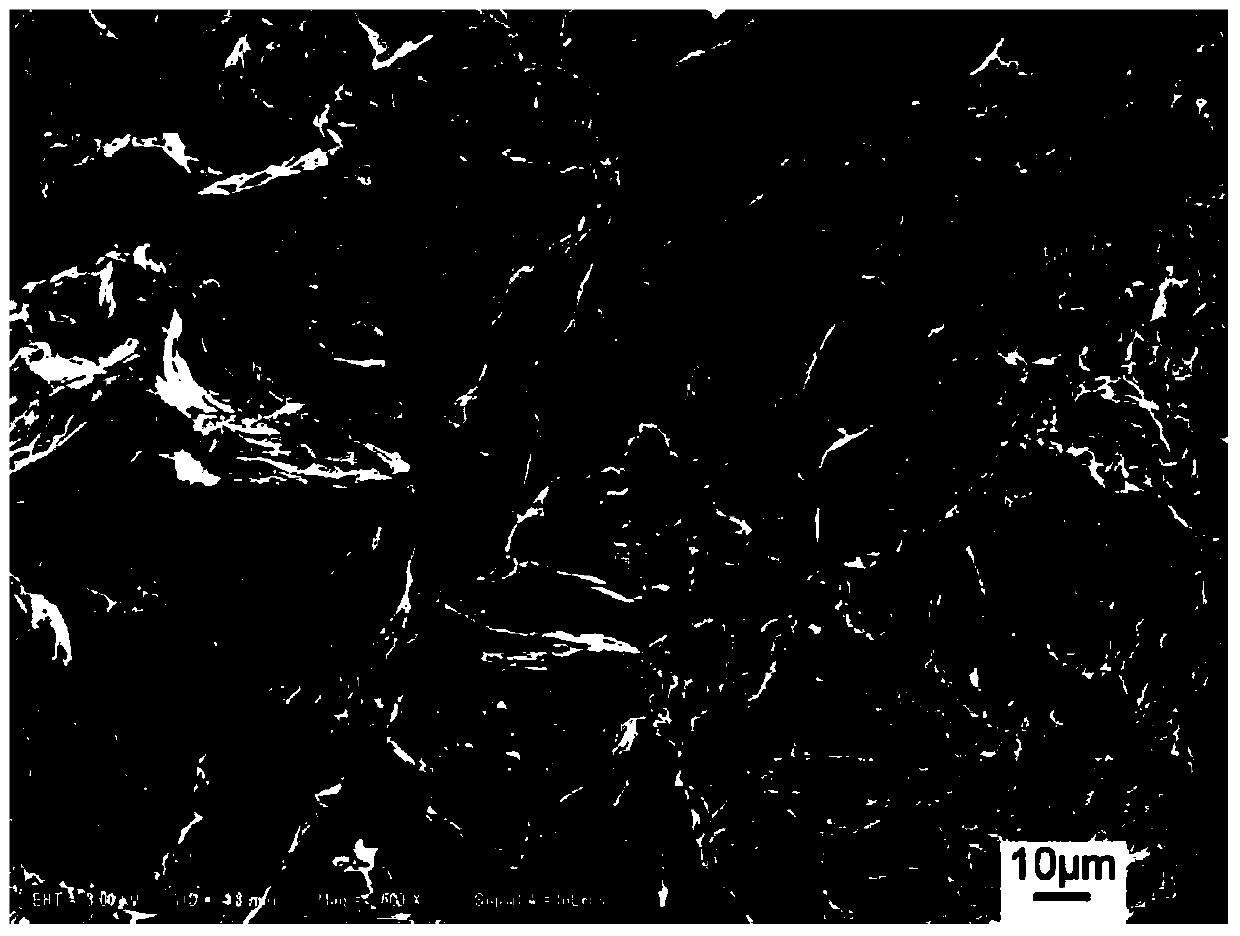

B2 type NiAl-based self-lubricating composite materials and preparing method thereof

The invention provides B2 type NiAl-based self-lubricating composite materials and a preparing method thereof. The method comprises the following steps that (1) Ni powder, Al powder, Mo powder, Nb powder, nano grapheme and WS2 powder are selected according to proportion, and ingredients are obtained; (2) the ingredients are placed in a vibration ball mill for dry grinding, the inner wall of a vibration ball milling tank is made of Teflon, vibration frequency is 45 Hz, amplitude is 5 mm, vibration force is 10000 N, vibration time is 30 minutes-50 minutes, and preprocessed mixed powder is obtained; and (3) the preprocessed mixed powder is placed in a graphite mould with the inner diameter of 20 mm, and then under the vacuum condition, a spark plasma sintering method is used for the B2 type NiAl-based self-lubricating composite materials. The self-lubricating composite materials obtained through the method are high in purity and good in compactness and have good tribology performance. In addition, through the spark plasma sintering method, sintering temperature is lowered, sintering time is shortened, the steps are simple and convenient to achieve, and large-scale batch production can be well achieved.

Owner:重庆三木汽车部件有限公司

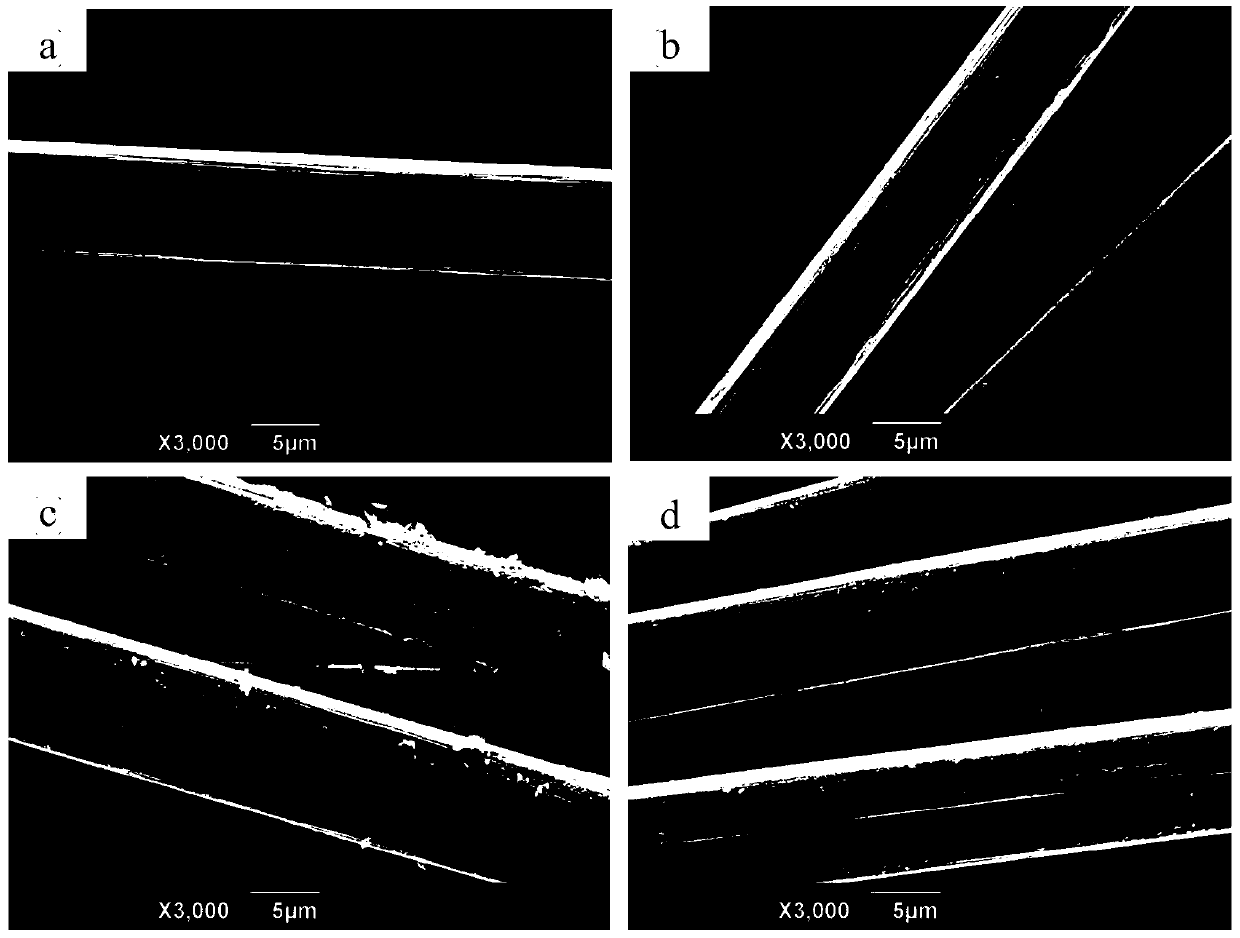

Reinforced poly-ether-ether-ketone composite material with nano SiO2 chemically grafted to surfaces of carbon fibers and preparation method of material

The invention discloses a reinforced poly-ether-ether-ketone composite material with nano SiO2 chemically grafted to the surfaces of carbon fibers and a preparation method of material. The composite material is prepared from, by weight, 65-100 parts of poly-ether-ether-ketone, 5-30 parts of the carbon fibers, 0-10 parts of the nano SiO2, 0.5-3 parts of gamma-aminopropyl triethoxysilane and 0.5-3 parts of gamma-glycidyl ether oxypropyl trimethoxysilane. According to the composite material, modified carbon fibers are obtained by chemically grafting the nano SiO2 to the surfaces of the carbon fibers, so that the interface bonding performance between the carbon fibers and matrix resin is improved. Meanwhile, the modified carbon fibers are added into PEEK matrix as a reinforcing filler to improve the mechanical performance and wear resistance of PEEK and reduce the friction coefficient and wear rate of the material so that the modified-carbon-fiber-reinforced PEEK-based composite material can be applicable to extreme working conditions such as high speed, heavy loads and oil-free lubrication.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Non-sulfur and non-phosphorus organic molybdenum compound and preparation method and application thereof

InactiveCN104844656AImprove thermal stabilityImprove tribological propertiesAdditivesGroup 6/16 organic compounds without C-metal linkagesOrganic solventSulfur

The invention provides a non-sulfur and non-phosphorus organic molybdenum compound and preparation method and application thereof. The structural formula is shown in the formula, wherein R is a C1-C30 linear or branched alkyl or cycloalkyl. The preparation method comprises the step of reacting hydroxyalkyl amine with ammonium molybdate tetrahydrate in the presence of an organic solvent and a catalyst. The organic molybdenum compound provided by the present invention can be used as a lubricating oil additive and has good antiwear and extreme-pressure properties.

Owner:SHANGHAI JIAO TONG UNIV

Method and device for preparing film coating micronano texture

InactiveCN102418082AImprove anti-friction and anti-wear propertiesControllable texture sizeDecorative surface effectsNanotechnologySurface engineeringChemical reaction

The invention relates to a method and a device for preparing a film coating micronano texture and belongs to a film coating of surface engineering. The preparation method comprises the steps of preparing at early stage, depositing the film coating, preparing the micronano texture and performing aftertreatment. The special device is a multi-beam pulse laser micronano texture processing system device. The multi-beam pulse laser micronano texture processing system device comprises a pulse laser module, an optical path transmission module and a precise scanning module which are connected with one another sequentially. The invention has the advantages that: the method and the device are convenient in processing and high in efficiency; preparation for the film coating deposition micronano texture on the surface of a material is realized by one laser source; the process is simple, and easy to control; the prepared samples are not subjected to a complex posttreatment process; the application range is wide; ultraviolet pulse laser has the characteristics of large photon energy and short wavelength and can perform precise micronano texture treatment on any materials; chemical reaction of various gases can be induced; and film coating deposition can be performed efficiently.

Owner:CHINA UNIV OF MINING & TECH

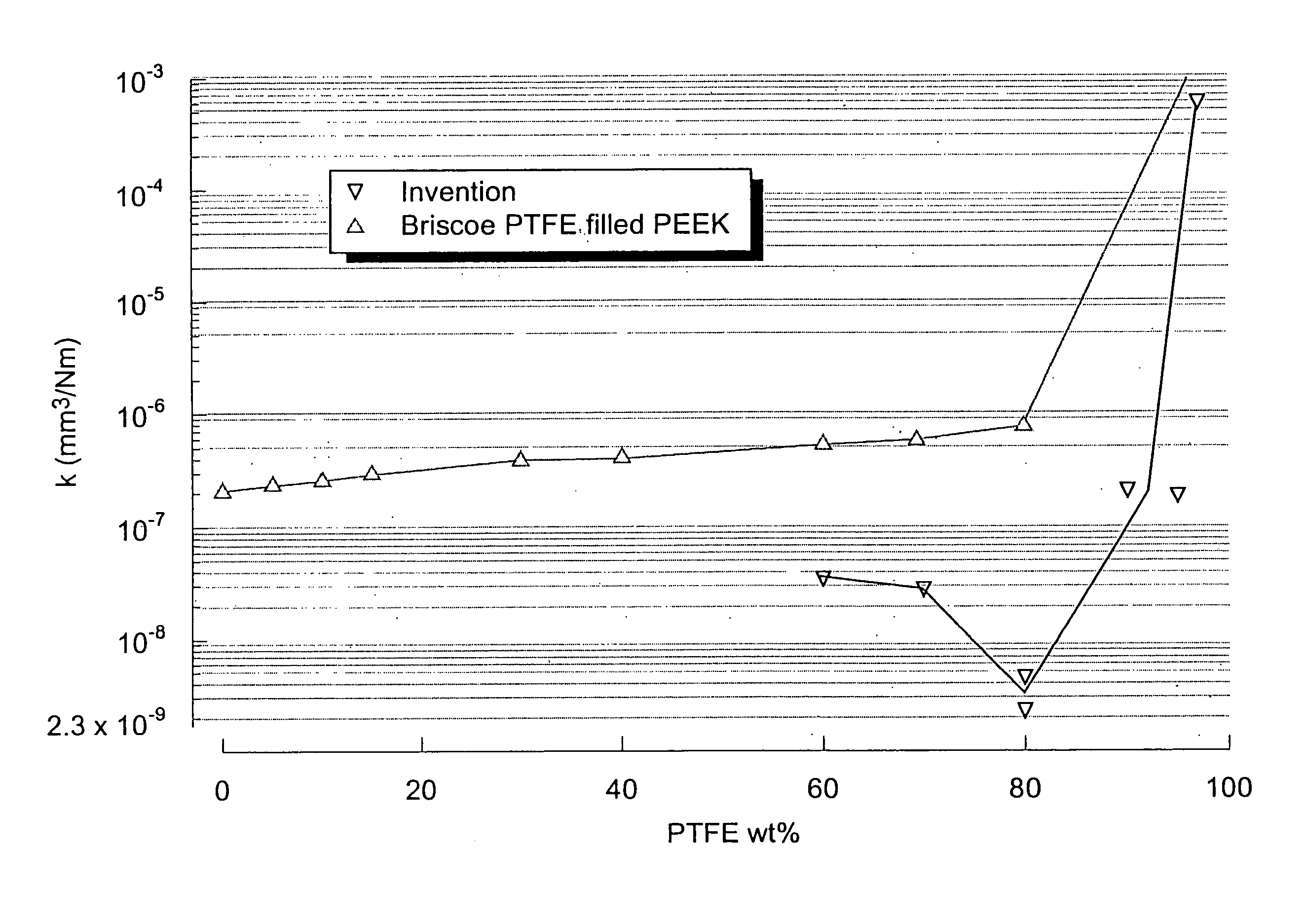

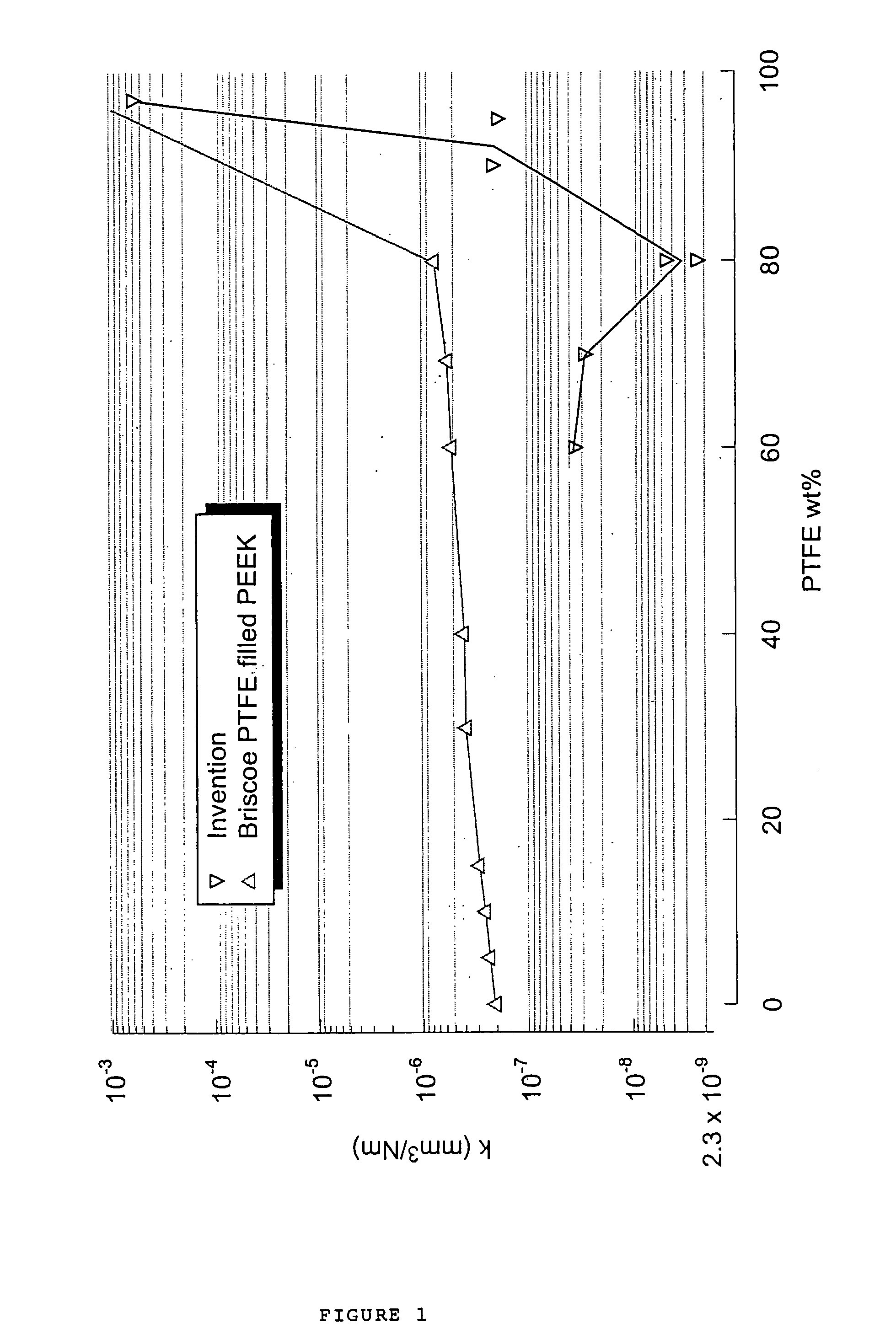

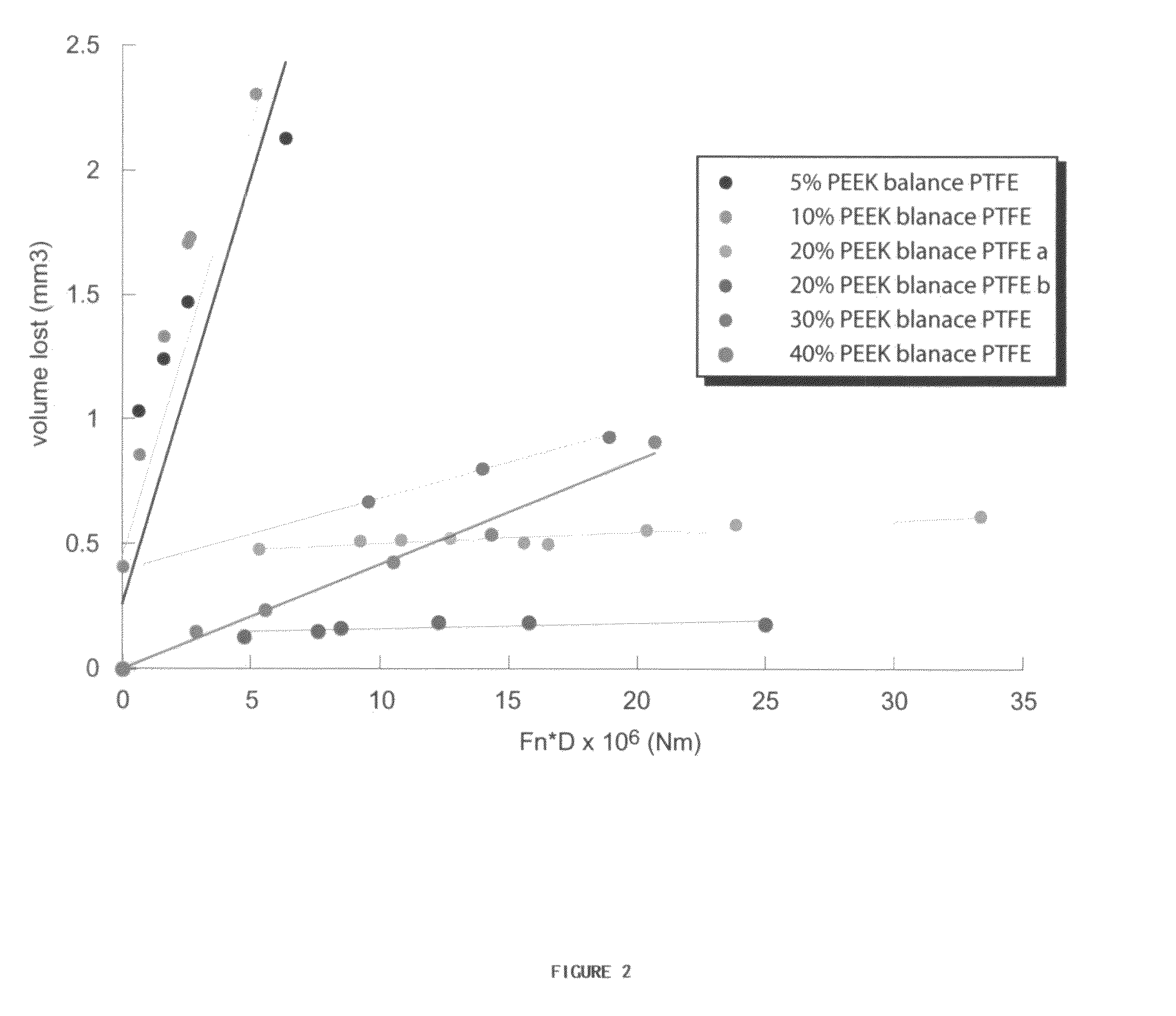

Low friction and low wear polymer/polymer composites

InactiveUS7314646B2Improve tribological propertiesReduce wearCoatingsSpecial surfacesPolymer sciencePolyether ether ketone

A composite material having superior tribological properties includes a first polymer being a transfer film forming polymer and a second polymer mixed with the first polymer. The first polymer is at least 10 weight % of the composite and the composite provides a wear rate of <10−7 mm3 / Nm and an average friction coefficient of said composite no more than 0.15. The first polymer can be PTFE and the second polymer a polyaryletherketone (e.g., PEEK). A method of forming composites includes the steps of providing a plurality of transfer film forming polymer particles and second polymer particles, and molding or extruding the particles at a temperature sufficient to allow softening and mobilization of at least one of the transfer film forming polymer particles and the plurality of strengthening phase polymer particles to form an interconnected network, wherein the composite formed provides a wear rate of <10−7 mm3 / Nm.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

Preparation of metal doped diamond-like surface ion liquid lubricant self-assembled lubricating film

InactiveCN101463466AImprove tribological propertiesExcellent friction reductionVacuum evaporation coatingSputtering coatingCarbon filmDiamond-like carbon

The invention discloses a method for preparing a metallic contamination adamantine surface ionic liquid lubricant self-assembly lubricative film. The method takes ionic liquid lubricant as raw material, adopts magnetron sputtering equipment to prepare a metallic contamination adamantine carbon film and assembles the liquid lubricant film which is stable, uniform and ordered on the carbon film. The method is characterized in that the preparation process is operated at normal temperature, and the requirements for the material and the shape of a substrate are lower; the film is stable and uniform, and has lower surface roughness; the film also has good performances on antifriction, wear resistance and adhesion resistance. The test of friction and wear proves that the ionic liquid lubricant and adamantine has good combining performance and better performances on antifriction, wear resistance and adhesion resistance, so that the lubricative film is expected to become the effective means of solving the problems of protecting and lubricating materials I the technical fields such as space machinery, information technology, etc.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com