Method and device for preparing film coating micronano texture

A preparation device, micro-nano technology, applied in the direction of micro-structure devices, manufacturing micro-structure devices, coatings, etc., can solve the problems of increasing the difficulty of micro-nano texture design and manufacturing, achieve high-efficiency thin-film coating deposition, improve light reduction Friction and anti-wear performance, the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

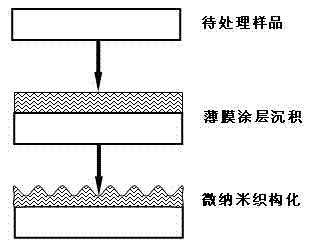

[0024] Embodiment 1: The preparation method includes preliminary preparation, film coating deposition, micro-nano texture preparation and post-treatment, and its steps are as follows:

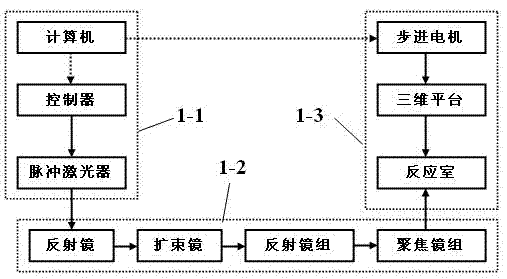

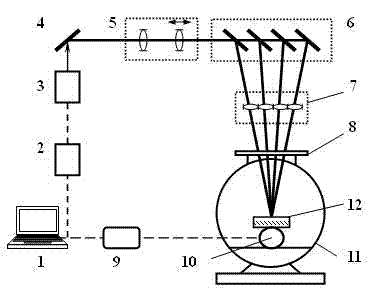

[0025] Preliminary preparations: first prepare the smooth samples required for the preparation of thin film coating micro-nano textures, establish the multi-beam pulse laser micro-nano texture processing system device, and prepare the three steps required to establish the multi-beam pulse laser micro-nano texture processing system device. Large module components, three major module components are pulse laser module 1-1, optical transmission module 1-2, precision scanning module 1-3, according to pulse laser module 1-1, optical transmission module 1-2, precision scanning module 1- 3 sequentially connected;

[0026] Thin film coating deposition: control the scanning speed of the multi-beam pulsed laser on the sample surface from 0.01 to 10mm / s, adjust the chemical reaction speed of the reactive g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com