Shield machine main bearing sealing grease and preparation method thereof

A technology for sealing grease and main bearings, which is applied in the field of sealing grease, and can solve the problem that water resistance and pumpability cannot be taken into account at the same time, water resistance and pumpability need to be improved, and the gap between anti-friction and anti-wear performance and lubricity and other problems, to achieve good water resistance and pumpability, excellent anti-friction and anti-wear performance, and outstanding lubricating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The shield machine main bearing sealing grease in the present embodiment has the following components and mass percentages: 18% of 32# mechanical hydraulic oil; 25% calcium base grease; 15% polyisobutylene; 2% NDZ-105 (titanate coupling agent); 35% nano-graphite; 5% wood fiber, the length of which is 0.5-6mm.

[0023] Preparation method: put 32# mechanical hydraulic oil, calcium base grease, polyisobutylene, and NDZ-105 into the kneader in turn, stir and knead for 0.5-1h; In the machine, stir for 0.5h; finally put in wood fiber, stir and knead for 1-2h.

Embodiment 2

[0025] The main bearing sealing grease of the shield machine in the present embodiment has the following components and mass percentages: 15% mineral oil; 30% lithium-based grease; 12% polypropylene alcohol; 5% OL-AT1618 (aluminum-titanium composite coupling agent ); 30% nano-graphite; 8% flax fiber, the length of which is 0.5-6mm.

[0026] Preparation method: put mineral oil, lithium base grease, polypropylene alcohol, OL-AT1618 into the kneader in turn, stir and knead for 0.5-1h; then put nano-graphite into the kneader in batches according to the ratio of 5:3:2 , Stir for 1h; finally put in flax fiber, stir and knead for 1-2h.

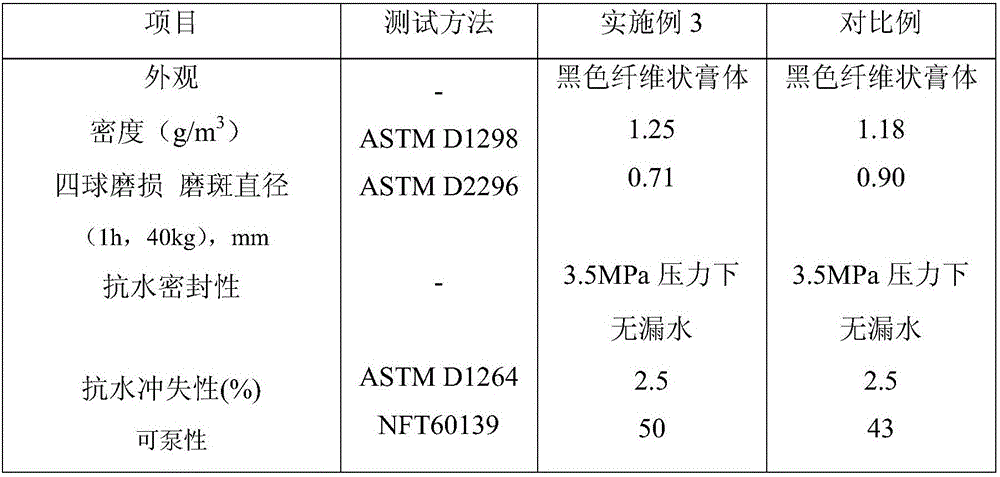

Embodiment 3

[0028] The main bearing sealing grease of the shield machine in this embodiment has the following components and mass percentages: 28% corn oil; 20% extreme pressure lithium-based grease; 20% polyisobutylene; 2% OLAT-1618; 25% nano disulfide Molybdenum; 5% flax fiber, the length of which is 0.5-6mm.

[0029] Preparation method: put corn oil, extreme pressure lithium base grease, polyisobutylene, OL-AT1618 into the kneader in turn, stir and knead for 0.5-1h; then put nano molybdenum disulfide into the In the kneader, stir for 1 hour; finally put flax fiber in, stir and knead for 1-2 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com