Electrostatic spraying process for aluminum alloy profiles

An aluminum alloy profile, electrostatic spraying technology, applied in metal material coating process, coating, device for coating liquid on the surface, etc., can solve the problems of unsatisfactory coating adhesion, poor wear resistance, etc., to reduce friction coefficient, acid resistance improvement, and the effect of enhancing compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

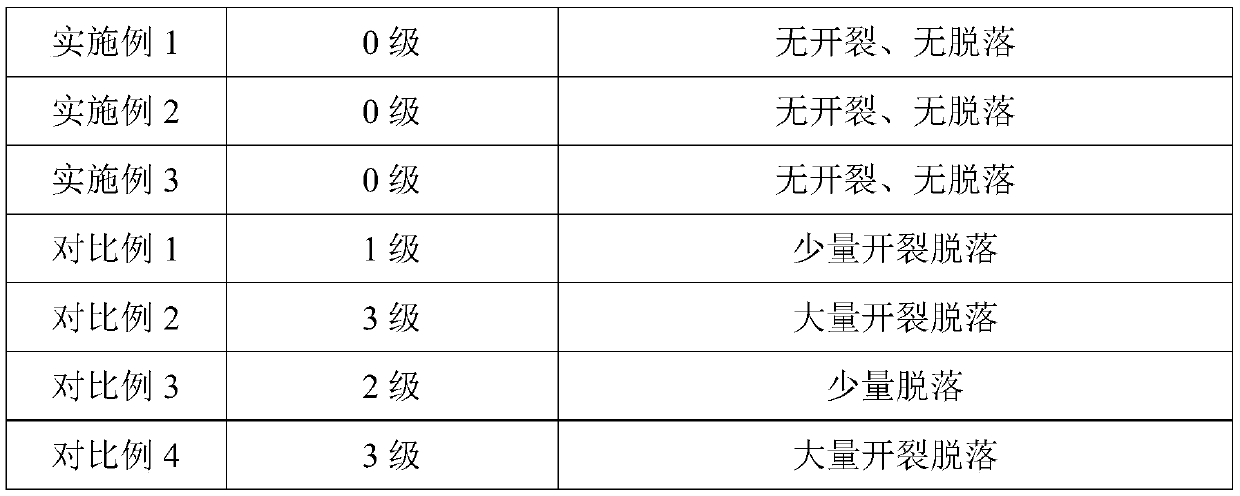

Embodiment 1

[0041] Embodiment 1, a kind of electrostatic spraying process of aluminum alloy profiles

[0042] The electrostatic spraying process of the aluminum alloy profile, the steps are as follows:

[0043]S1 Grind the surface of the aluminum alloy twice, use 400# water sandpaper for the first time, and use 800# water sandpaper for the second time, spray water, spray temperature is 55°C, spray pressure is 0.1MPa, spray time For 1min, blow dry to get the workpiece to be processed;

[0044] S2 Place the workpiece obtained in step S1 in a degreasing agent to degrease, soak for 1 min, and then spray the degreasing agent on the surface of the workpiece to be treated. The spraying temperature is 55°C, the spraying pressure is 0.1 MPa, and the spraying time is 1 to 3 minutes. , and then spray and wash the surface of the workpiece to be treated, the spray temperature is 60°C, the spray pressure is 0.1MPa, the spray time is 1min, and the degreased workpiece is obtained;

[0045] S3 Soak the ...

Embodiment 2

[0058] Embodiment 2, a kind of electrostatic spraying process of aluminum alloy profiles

[0059] The electrostatic spraying process of the aluminum alloy profile, the steps are as follows:

[0060] S1 Grind the surface of the aluminum alloy twice, use 400# water sandpaper for the first time, and use 800# water sandpaper for the second time, spray water, spray temperature is 70°C, spray pressure is 0.1MPa, spray time For 3min, blow dry to get the workpiece to be processed;

[0061] S2 Place the workpiece obtained in step S1 in a degreasing agent to degrease, soak for 3 minutes, and then spray the degreasing agent on the surface of the workpiece to be treated. The spraying temperature is 65°C, the spraying pressure is 0.1MPa, and the spraying time is 1 to 3 minutes. , and then spray and wash the surface of the workpiece to be treated, the spray temperature is 70°C, the spray pressure is 0.1MPa, and the spray time is 3min to obtain the degreased workpiece;

[0062] S3 Soak the...

Embodiment 3

[0073] Embodiment 3, a kind of electrostatic spraying process of aluminum alloy profiles

[0074] The electrostatic spraying process of the aluminum alloy profile, the steps are as follows:

[0075] S1 Grind the surface of the aluminum alloy twice, use 400# water sandpaper for the first time, and 800# water sandpaper for the second time, spray water, spray temperature 65℃, spray pressure 0.1MPa, spray time For 2min, blow dry to get the workpiece to be processed;

[0076] S2 Put the workpiece obtained in step S1 in a degreasing agent to degrease, soak for 2 minutes, then spray the degreasing agent on the surface of the workpiece to be treated, the spraying temperature is 60 ° C, the spraying pressure is 0.1 MPa, and the spraying time is 2 minutes, then Spray and wash the surface of the workpiece to be treated, the spray temperature is 65°C, the spray pressure is 0.1MPa, and the spray time is 2min to obtain the degreased workpiece;

[0077] S3 Soak the degreased workpiece obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com