Vegetable oil based ionic liquid microemulsion type nano lubricating oil and preparation method thereof

An ionic liquid and vegetable oil-based technology, applied in the field of lubricating oil, can solve the problems of poor dispersion stability and complicated dispersion process, and achieve the effects of high dispersion, reduced production cost, and simplified production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

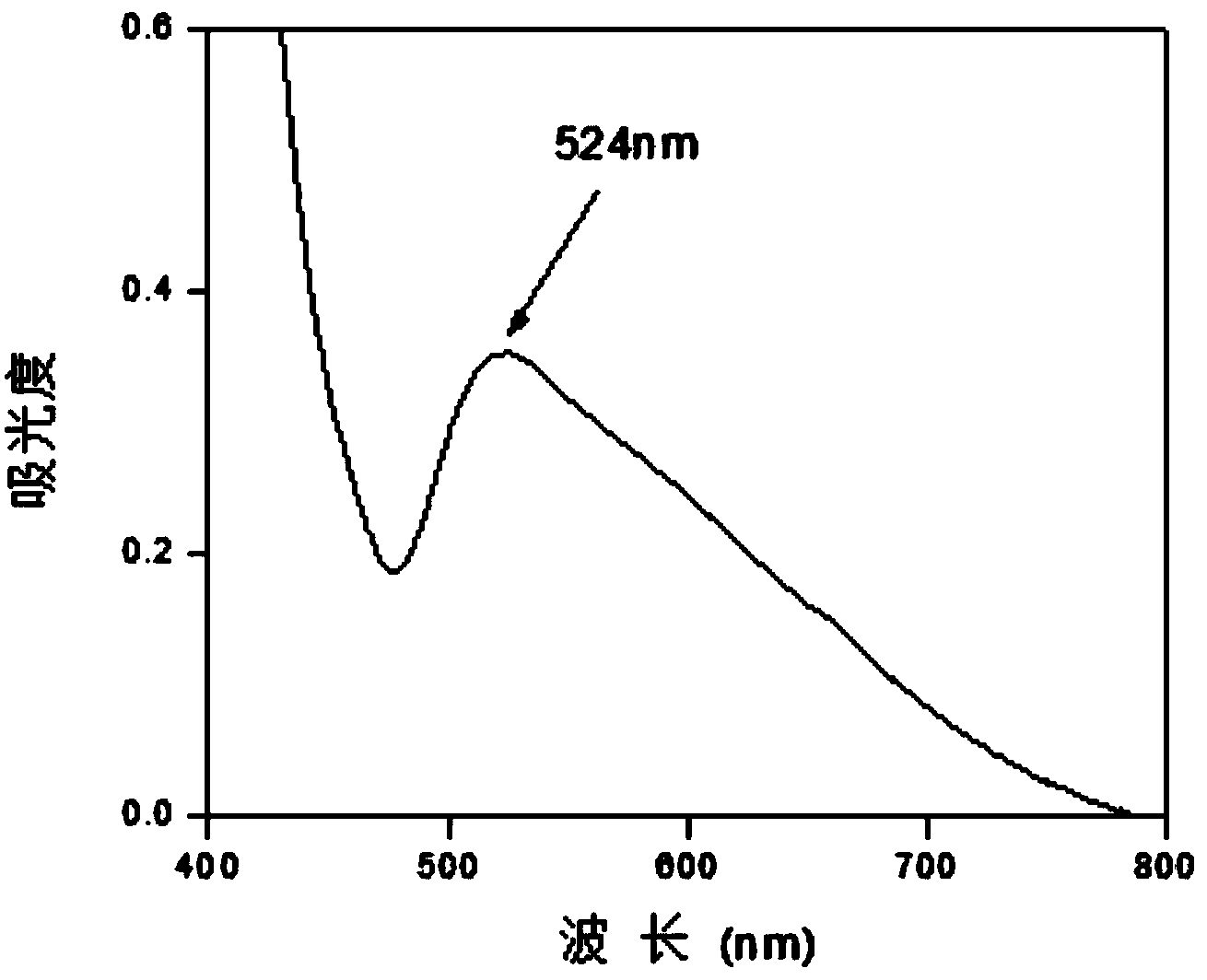

Image

Examples

Embodiment 1

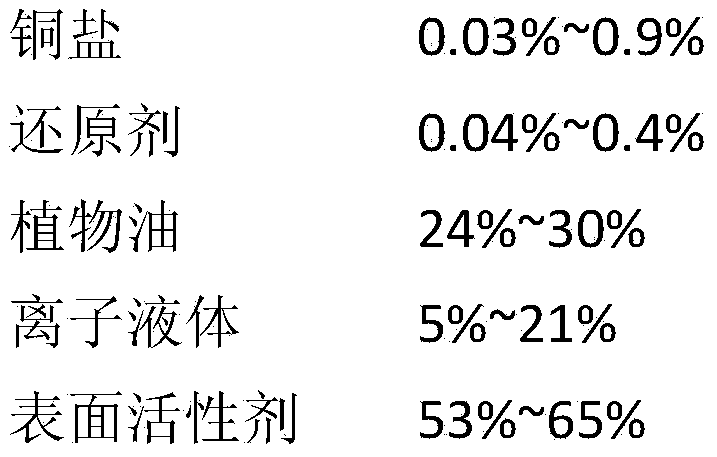

[0028] (1) Weigh raw materials according to the following weight percentages: cuprous chloride 0.9%, hydrazine 0.4%, rapeseed oil 24.3%, 1-butyl-3-methyl-imidazole hexafluorophosphate 20.7%, hexadecyl Trimethylammonium bromide 53.9%.

[0029] (2) Dissolve cuprous chloride in rapeseed oil at 90° C. and stir at 300 rpm, and stir for 5 minutes to obtain component A.

[0030] (3) Dissolve reduced hydrazine in 1-butyl-3-methyl-imidazolium hexafluorophosphate at 75°C and stir at 300 rpm, and stir for 5 minutes to obtain component B.

[0031] (4) Add the surfactant hexadecyltrimethylammonium bromide to the component A at 90° C. and 300 rpm under stirring conditions, and stir for 5 minutes to obtain the component C.

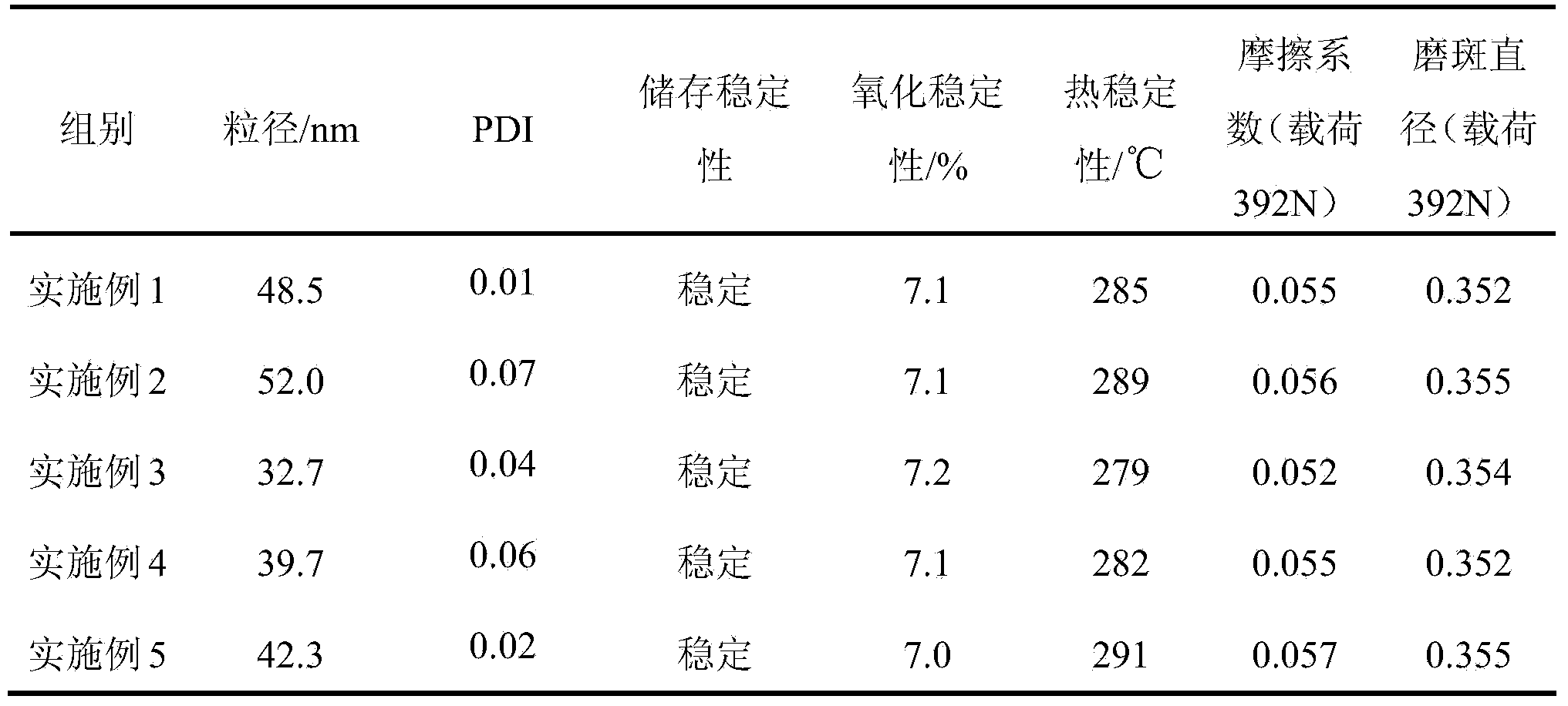

[0032] (5) Under the condition of 85° C. and 300 rpm stirring, component B was evenly added dropwise to component C, and after constant temperature reaction for 6 hours, a vegetable oil-based ionic liquid microemulsion nano-lubricating oil containing nano-copper particl...

Embodiment 2

[0035] (1) Weigh raw materials according to the following weight percentages: anhydrous copper chloride 0.03%, ascorbic acid 0.04%, castor oil 29.2%, 1-butyl-3-methyl-imidazole tetrafluoroborate 5.7%, octylbenzene Base polyoxyethylene ether 65%.

[0036] (2) Dissolve anhydrous copper chloride in castor oil at 20° C. and stir at 1200 rpm, and stir for 8 minutes to obtain component A.

[0037] (3) Dissolve ascorbic acid in 1-butyl-3-methyl-imidazolium tetrafluoroborate at 22°C and stir at 1200 rpm, and stir for 8 minutes to obtain component B.

[0038] (4) Add surfactant octylphenyl polyoxyethylene ether to component A at 50° C. and stirring at 1200 rpm, and stir for 8 minutes to obtain component C.

[0039] (5) Under the condition of 20° C. and 1200 rpm stirring, component B was evenly added dropwise to component C, and after constant temperature reaction for 1 hour, a vegetable oil-based ionic liquid microemulsion nano-lubricating oil containing nano-copper particles was obta...

Embodiment 3

[0042] (1) Weigh raw materials according to the following weight percentages: 0.5% of anhydrous copper sulfate, 0.2% of sodium borohydride, 26.8% of soybean oil, 13% of 1-butyl-3-methylimidazolium bromide, bis(2-ethyl Sodium hexyl) succinate sulfonate 59.5%.

[0043] (2) Dissolve anhydrous copper sulfate in soybean oil at 55° C. and 750 rpm under stirring conditions, and stir for 10 minutes to obtain component A.

[0044] (3) Dissolve sodium borohydride in 1-butyl-3-methylimidazolium bromide at 50°C and stir at 750 rpm, and stir for 10 minutes to obtain component B.

[0045] (4) Add the surfactant sodium bis(2-ethylhexyl) succinate sulfonate to component A under stirring conditions of 20°C and 750 rpm, and stir for 10 minutes to obtain component C.

[0046] (5) Under the condition of stirring at 58° C. and 750 rpm, component B was evenly added dropwise to component C, and after constant temperature reaction for 3 hours, a vegetable oil-based ionic liquid microemulsion nano-lu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com