High-temperature gel lubricant composition and preparation method of same

A technology of gel lubricant and composition, which is applied in the field of high-temperature gel lubricant composition and its preparation, can solve the problems of low gel phase to sol phase transition temperature, limit the use of gel lubricant at high temperature, etc., and achieve excellent Anti-friction and anti-wear performance, high temperature resistance performance, and the effect of improving bearing capacity

Inactive Publication Date: 2017-12-22

LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

View PDF4 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the gel lubricants reported above also have some problems, such as the low transition temperature from the gel phase to the sol phase (generally 60-80°C), which greatly limits the high-temperature use of gel lubricants

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0036] Preparation of 500SN gel: First, 1 wt% HTG8 was added to 99 wt% 500SN, heated and mechanically stirred to fully dissolve, and cooled to obtain a high-temperature gel lubricant composition.

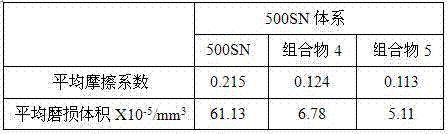

[0037] Table 7

[0038]

Embodiment 2

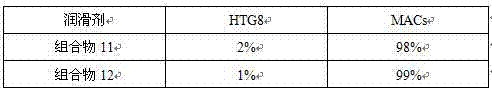

[0040] Table 8

[0041]

Embodiment 3

[0043] Table 9

[0044]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

Login to View More

Abstract

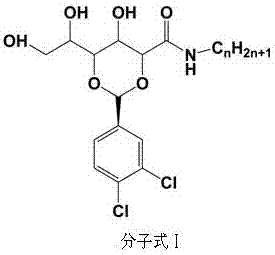

The invention discloses a high-temperature gel lubricant composition and a preparation method of same. The composition is composed of, by weight, 0.1-10% of super-molecule gelator and 90-99.9% of basic lubricant oil. The high-temperature gel lubricant composition, as a lubricant for a steel / steel friction pair, can significantly improve tribological property of blank lubricant oil at high temperature, so that bearing capacity of the lubricant oil is greatly increased. The composition has excellent friction- reducing and anti-wearing performance and high-temperature resistance.

Description

technical field [0001] The invention relates to a high-temperature gel lubricant composition and a preparation method thereof. Background technique [0002] With the rapid development of modern industry, energy consumption is getting faster and faster. According to statistics, among the energy consumed by mechanical equipment, friction consumes 30% of the primary energy, and 80% of equipment damage is caused by lubrication failure. Therefore, with the improvement of energy saving and environmental protection requirements, the use of high-efficiency lubricants is one of the main ways to reduce friction and wear of mechanical equipment. At present, lubricating oil and grease are widely used in daily life and industrial production as the main lubricants. However, there are still some problems in the process of their use, such as leakage, creep, volatilization of lubricating oil, poor cooling effect of lubricating grease, long-term use of oil separation, and lubrication failure...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C10M133/16C10M169/04C10N30/06C10N30/08C10N50/10

CPCC10M133/16C10M169/04C10M2203/045C10M2205/0285C10M2205/163C10M2207/2805C10M2215/082C10M2229/0415C10N2030/06C10N2030/08C10N2050/01C10N2050/10

Inventor 周峰王玉荣蔡美荣于强亮刘维民

Owner LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com