Rolling-use water base nano lubricant based on graphene oxide (GO) and preparation method thereof

A lubricant and graphene technology, applied in the field of rolling lubrication, can solve problems such as weakened wear resistance, achieve the effects of reducing surface roughness, improving contact surface quality, and reducing friction and wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

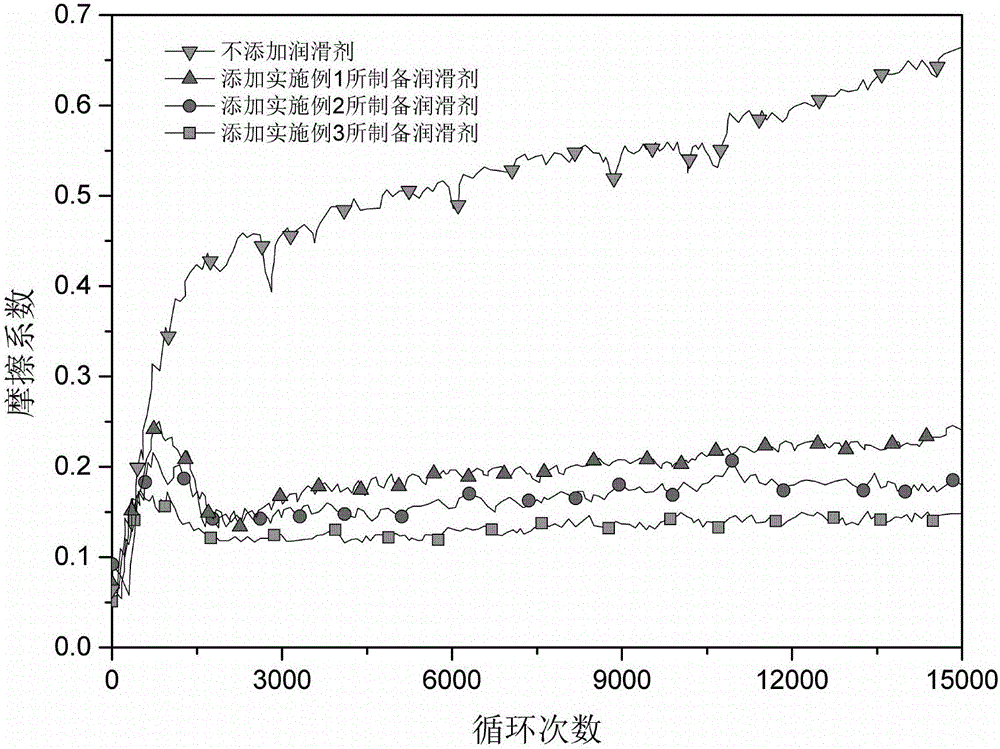

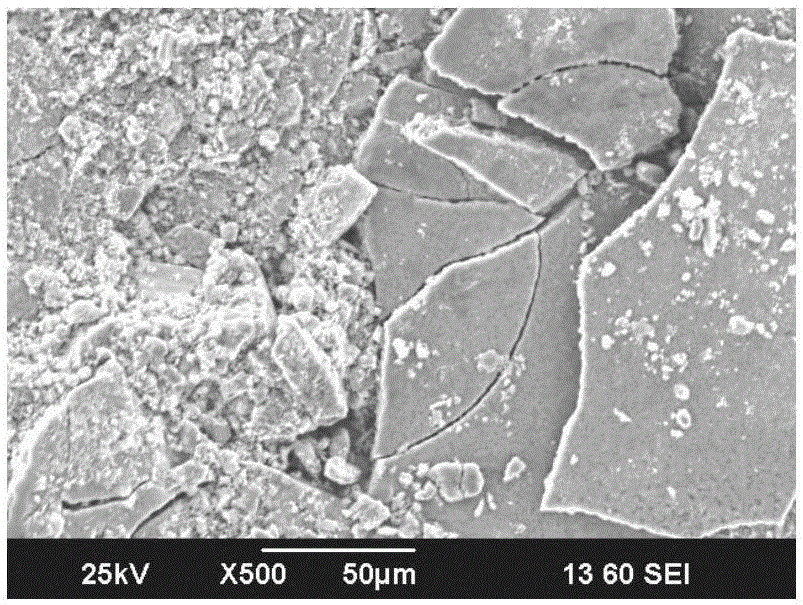

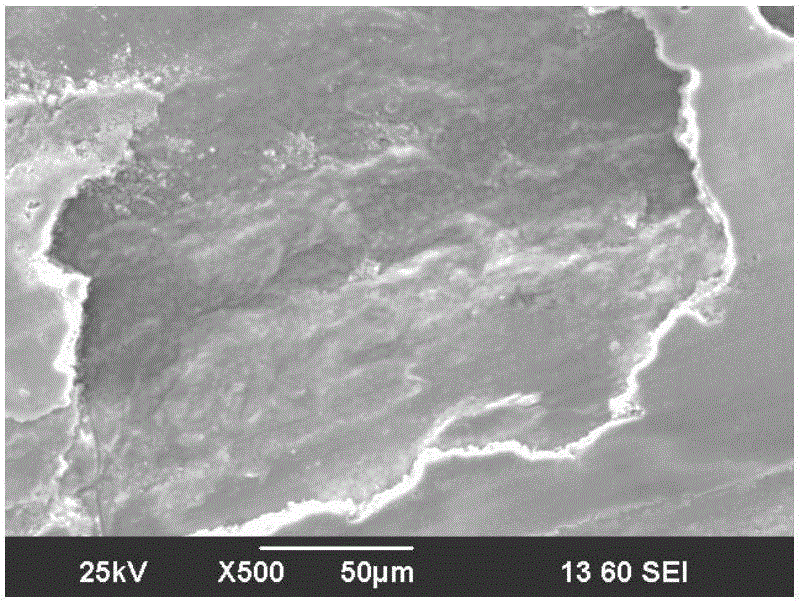

[0034] Such as Figure 1-Figure 5 As shown, the present invention provides a water-based nano-lubricant based on graphene oxide rolling and a preparation method thereof.

[0035] The lubricant includes 88%-93% deionized water, 4%-6% polyphosphate, 1%-2% polyvinylpyrrolidone, 2%-4% oxide nanopowder and 0.01%-0.05% graphene oxide , the structure of the graphene oxide is as follows:

[0036]

[0037] The polyphosphate includes sodium hexametaphosphate and potassium hexametaphosphate, the oxide nanopowder includes boron oxide and titanium dioxide, and the particle diameter specification of the boron oxide and titanium dioxide is 40nm. After surface modification, the graphene oxide is a reagent-grade freeze-dried single-layer graphene oxide with a particle diameter of 50 nm.

[0038] A kind of preparation method based on graphene oxide rolling water-based nano-lubricant, described method comprises the steps:

[0039] 1) Firstly, polyphosphate is added into deionized water to ...

Embodiment 1

[0046] Step 1: Weigh 45.0 g of sodium hexametaphosphate, add 915 ml of constant-temperature deionized water at a temperature of 30° C., and stir evenly to obtain a primary solution;

[0047] Step 2: raise the temperature of the primary solution to 40°C and keep it at a constant temperature, add 19.8g of polyvinylpyrrolidone into it, stir vigorously for 30 minutes to obtain a clear liquid;

[0048] Step 3: Weighing 20.0 g of surface-modified titanium dioxide nanoparticles with a particle diameter of 40 nm, vigorously stirring for 30 minutes to uniformly disperse them in the above solution;

[0049] Step 4: Weigh 0.2g graphene oxide, add it to the above solution, and stir to make the graphene oxide disperse evenly;

[0050] Step 5: Ultrasonic dispersion in a water bath for 100 minutes to completely disperse the graphene oxide and prevent further agglomeration of nanoparticles to obtain a finished product.

Embodiment 2

[0052] Step 1: Weigh 45.0 g of sodium hexametaphosphate, add 895 ml of constant temperature deionized water at a temperature of 30° C., and stir evenly to obtain a primary solution;

[0053] Step 2: raise the temperature of the primary solution to 40°C and keep it at a constant temperature, add 19.8g of polyvinylpyrrolidone into it, stir vigorously for 30 minutes to obtain a clear liquid;

[0054] Step 3: Weighing 40.0 g of surface-modified titanium dioxide nanoparticles with a particle diameter of 40 nm, vigorously stirring for 30 minutes to uniformly disperse them in the above solution;

[0055] Step 4: Weigh 0.2g graphene oxide, add it to the above solution, and stir to make the graphene oxide disperse evenly;

[0056] Step 5: Ultrasonic dispersion in a water bath for 100 minutes to completely disperse graphene oxide and prevent further agglomeration of nanoparticles to obtain a finished product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com