Patents

Literature

452 results about "Coating deposition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

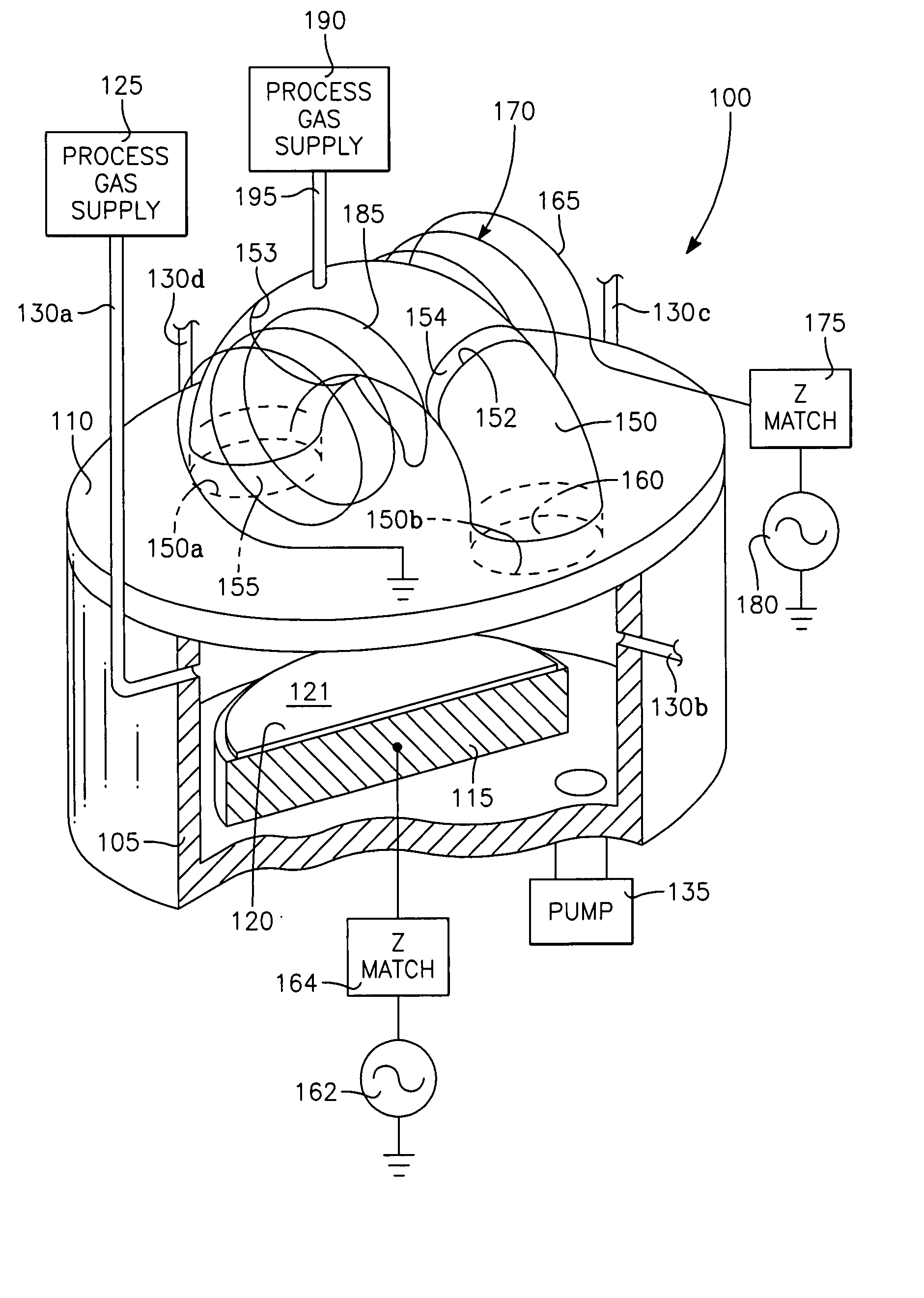

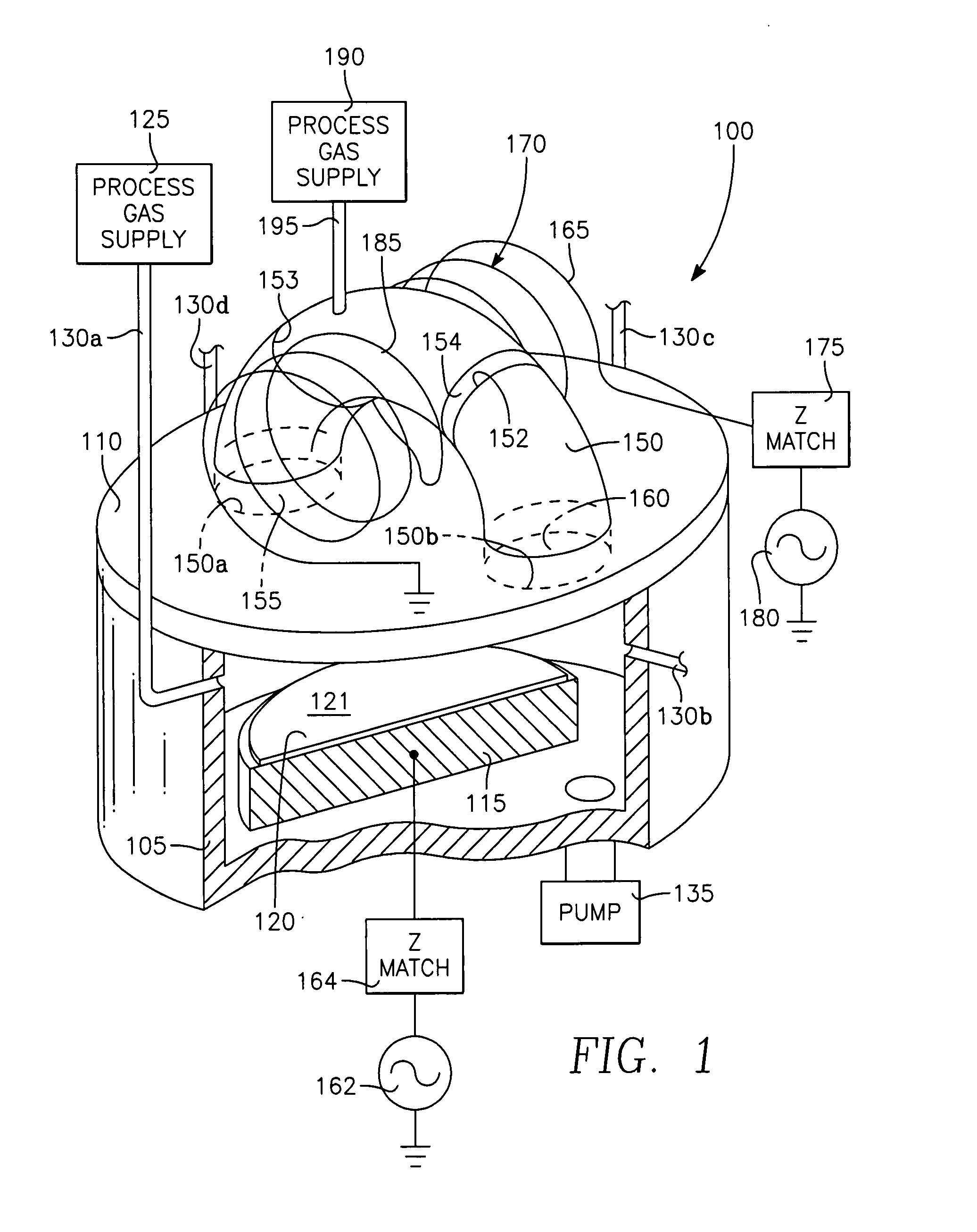

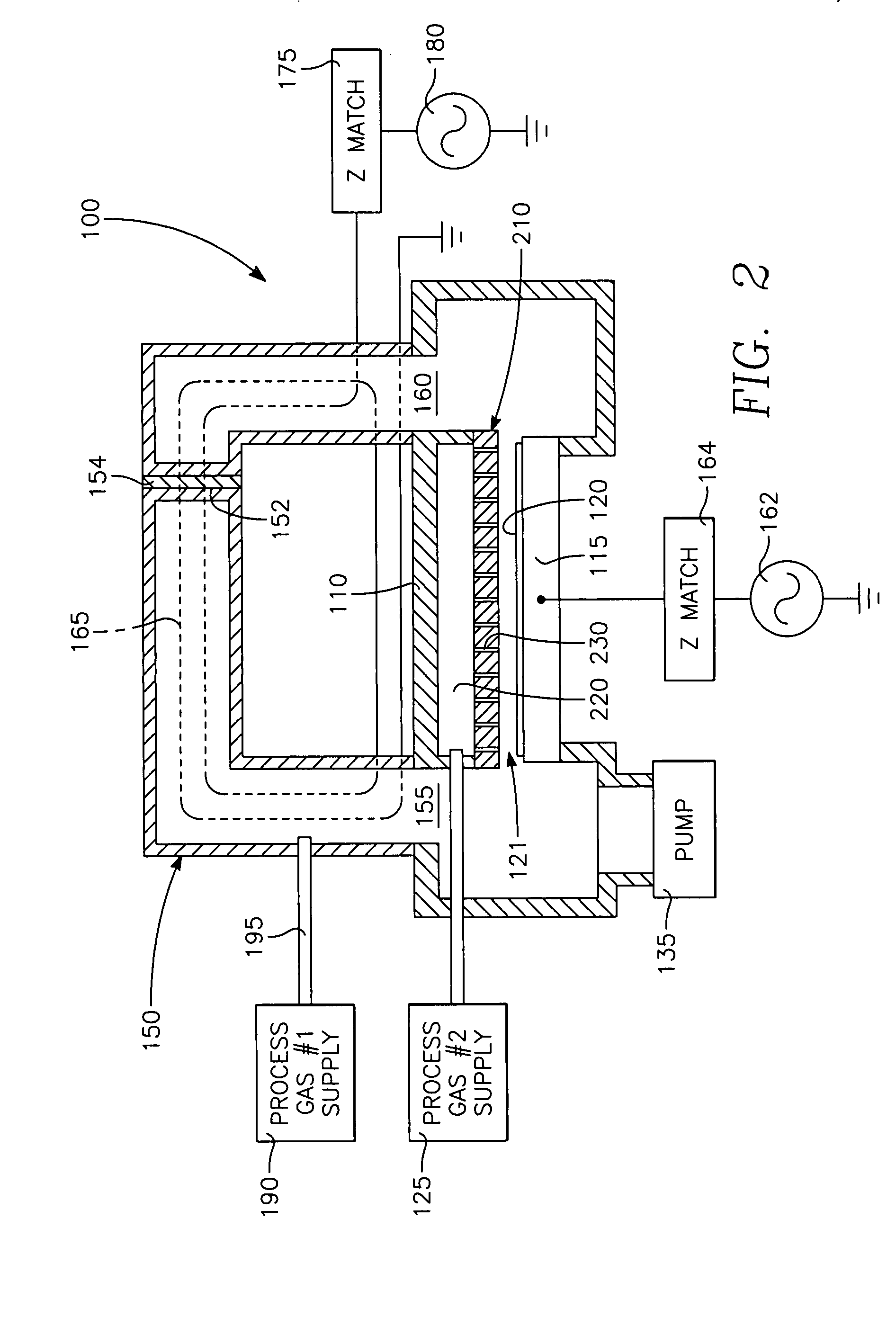

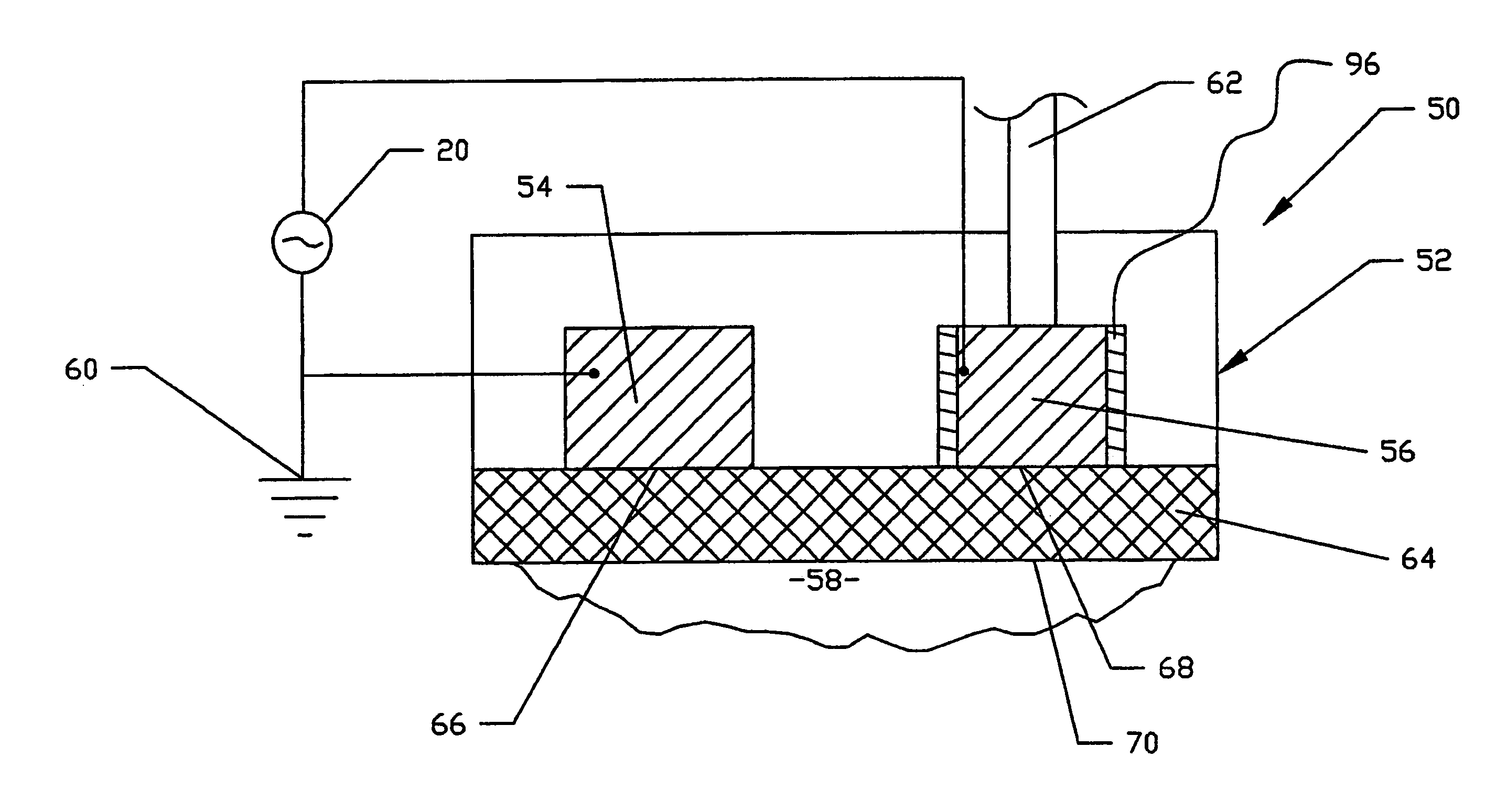

Low temperature CVD process with selected stress of the CVD layer on CMOS devices

Device-enhancing coatings are deposited on CMOS devices by successively masking with photoresist each one of the sets of N-channel and P-channel devices while unmasking or leaving unmasked the other set, and after each step of successively masking one of the sets of devices, carrying out low temperature CVD steps with a toroidal RF plasma current while applying an RF plasma bias voltage. The temperature of the workpiece is held below a threshold photoresist removal temperature. The RF bias voltage is held at a level at which the coating is deposited with a first stress when the unmasked set consists of the P-channel devices and with a second stress when the unmasked set consists of N-channel devices.

Owner:APPLIED MATERIALS INC

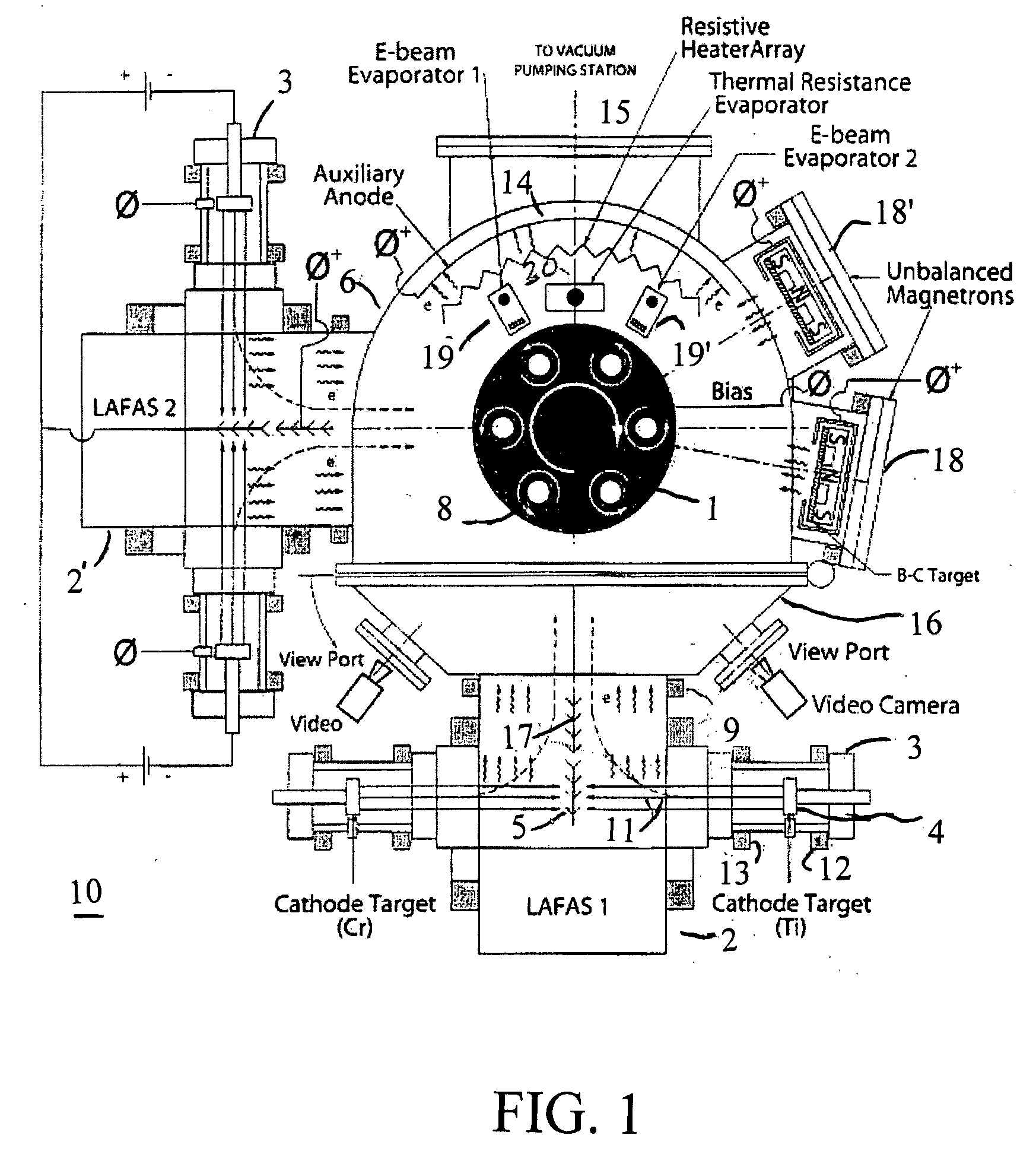

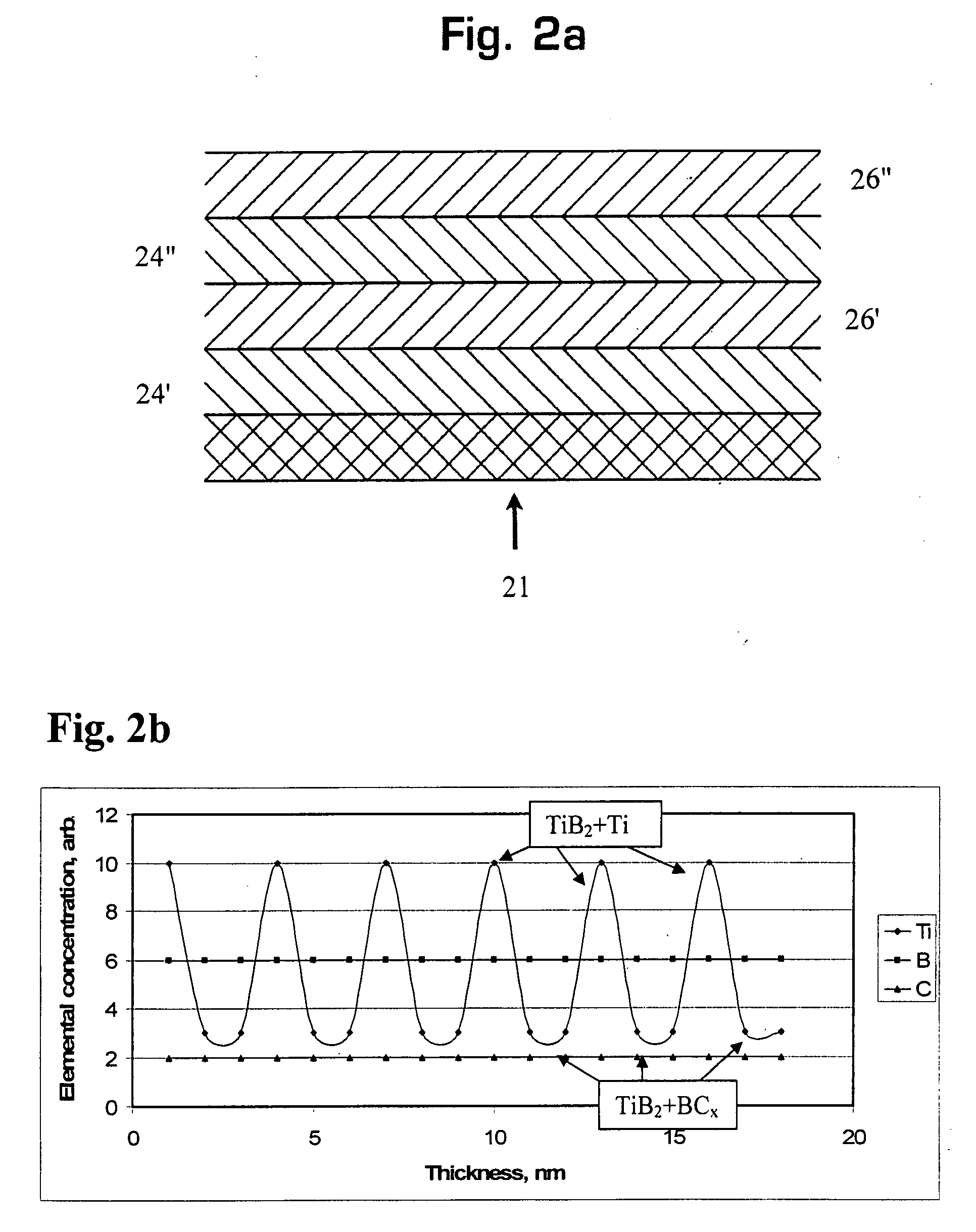

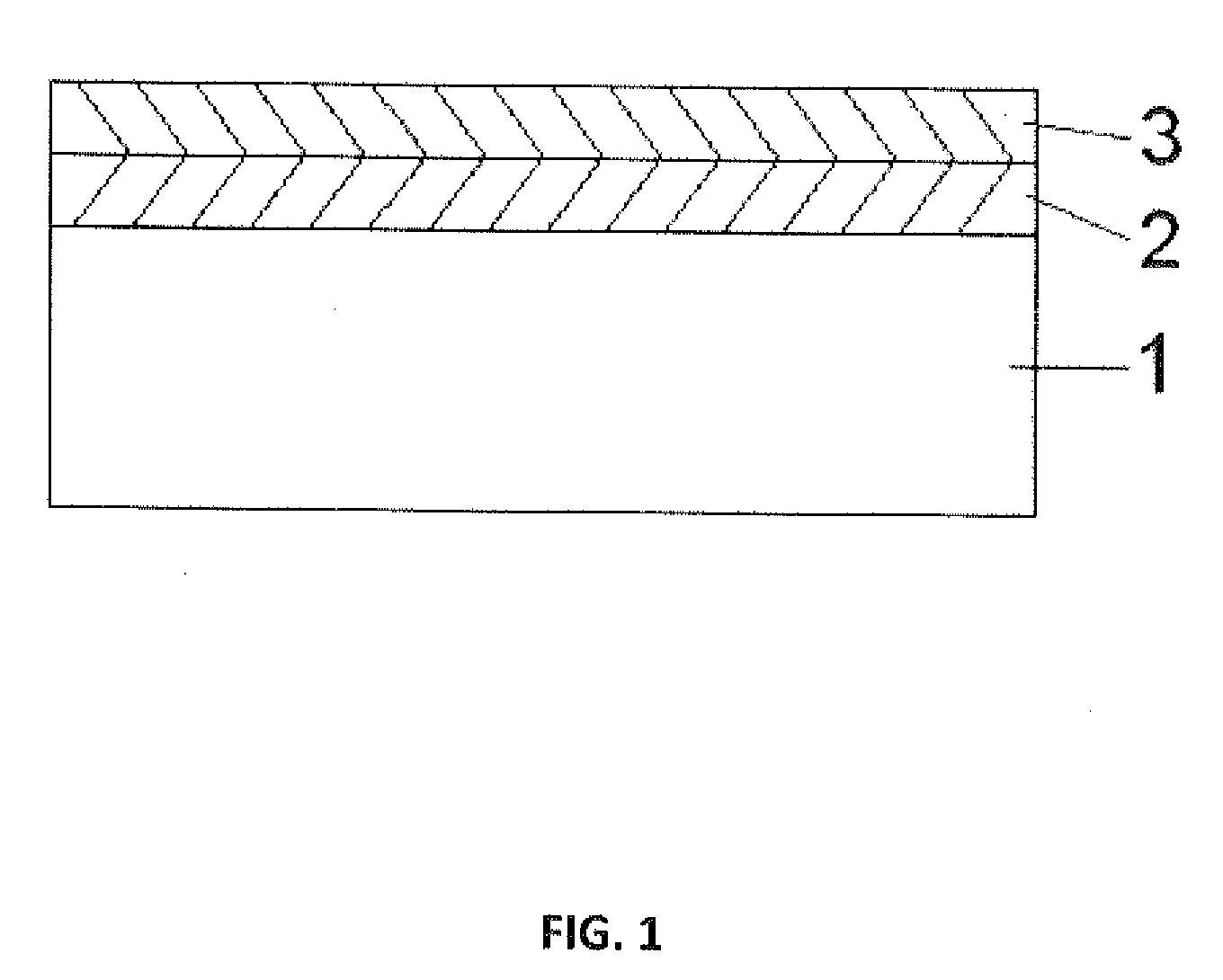

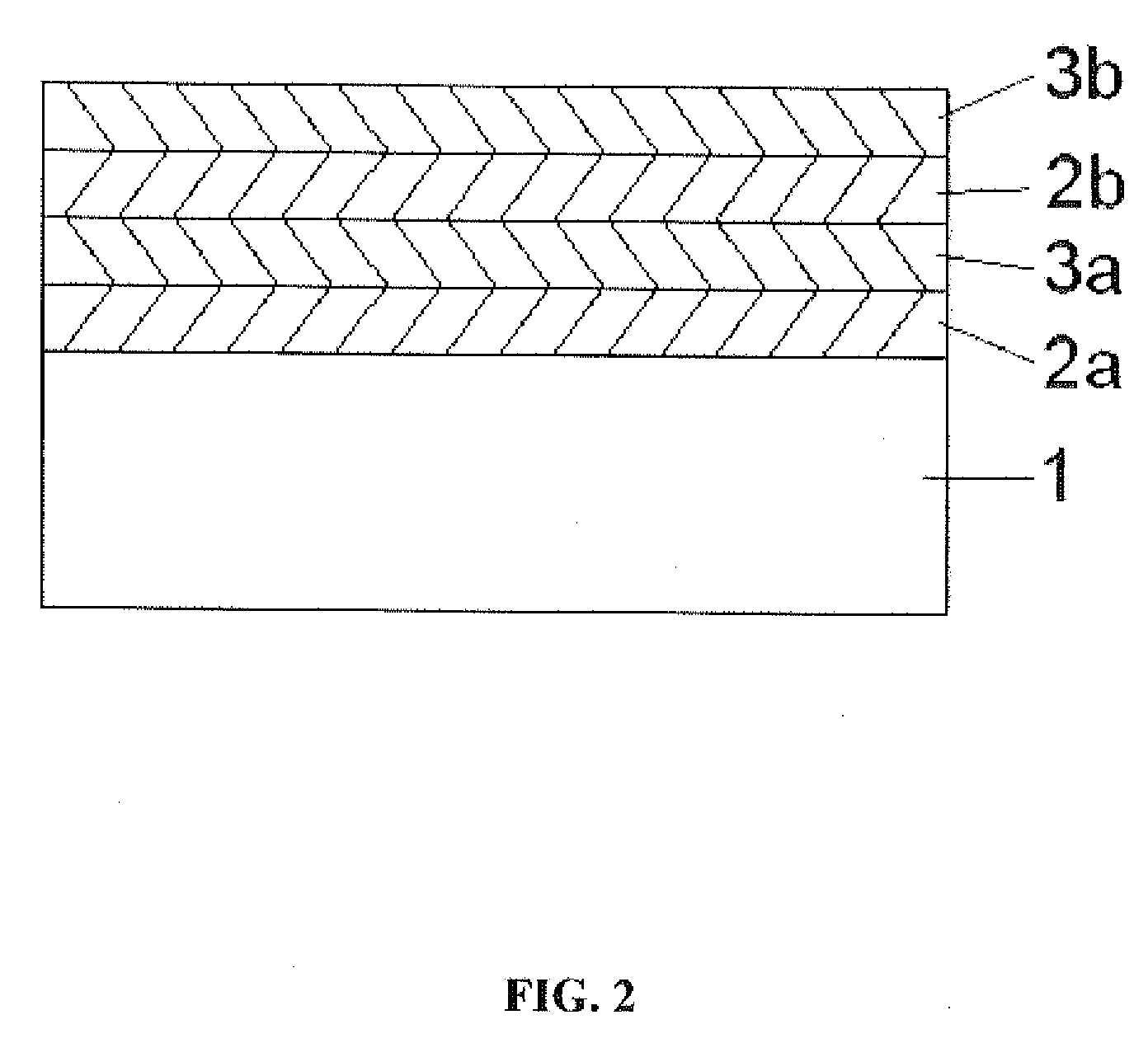

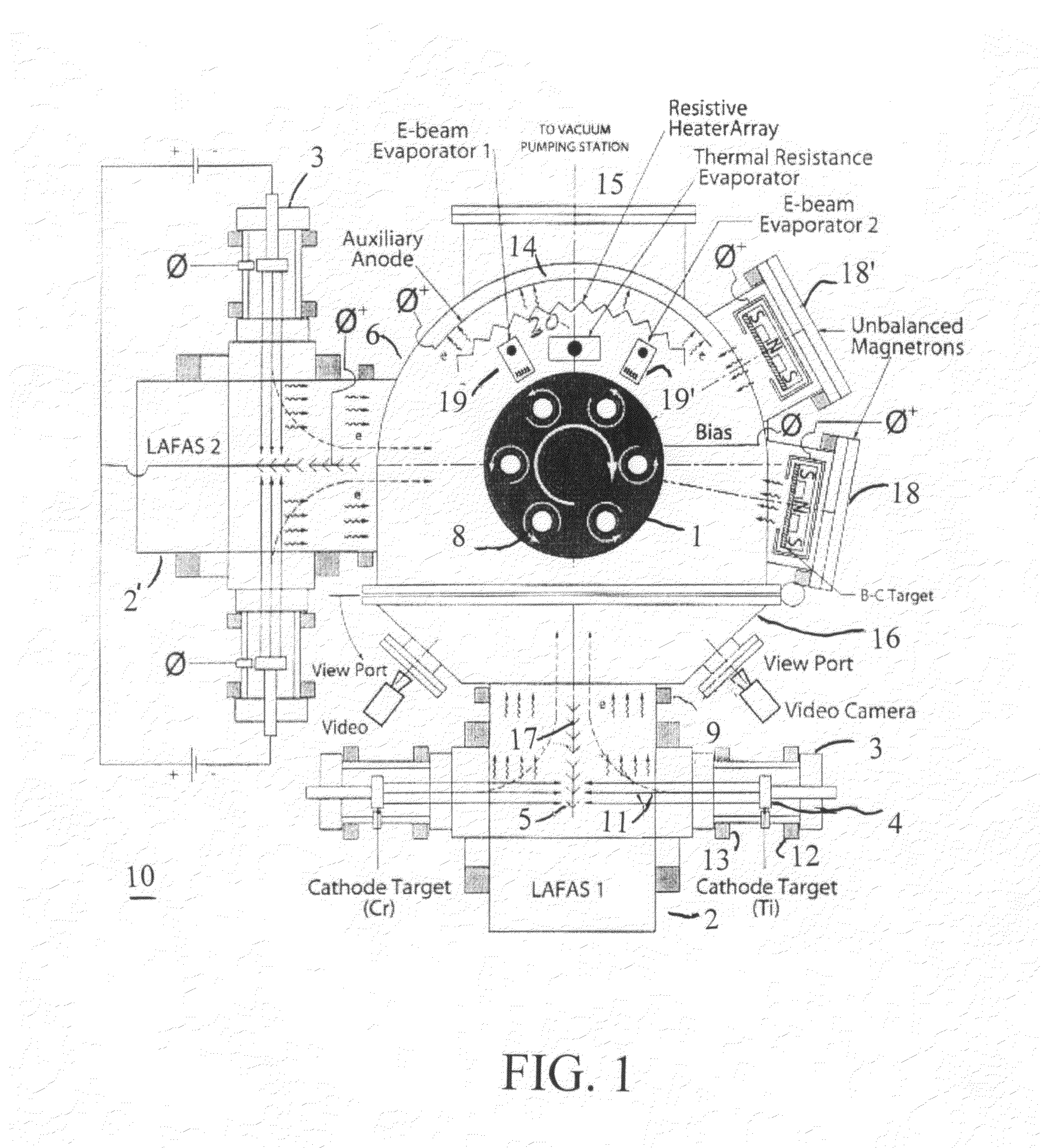

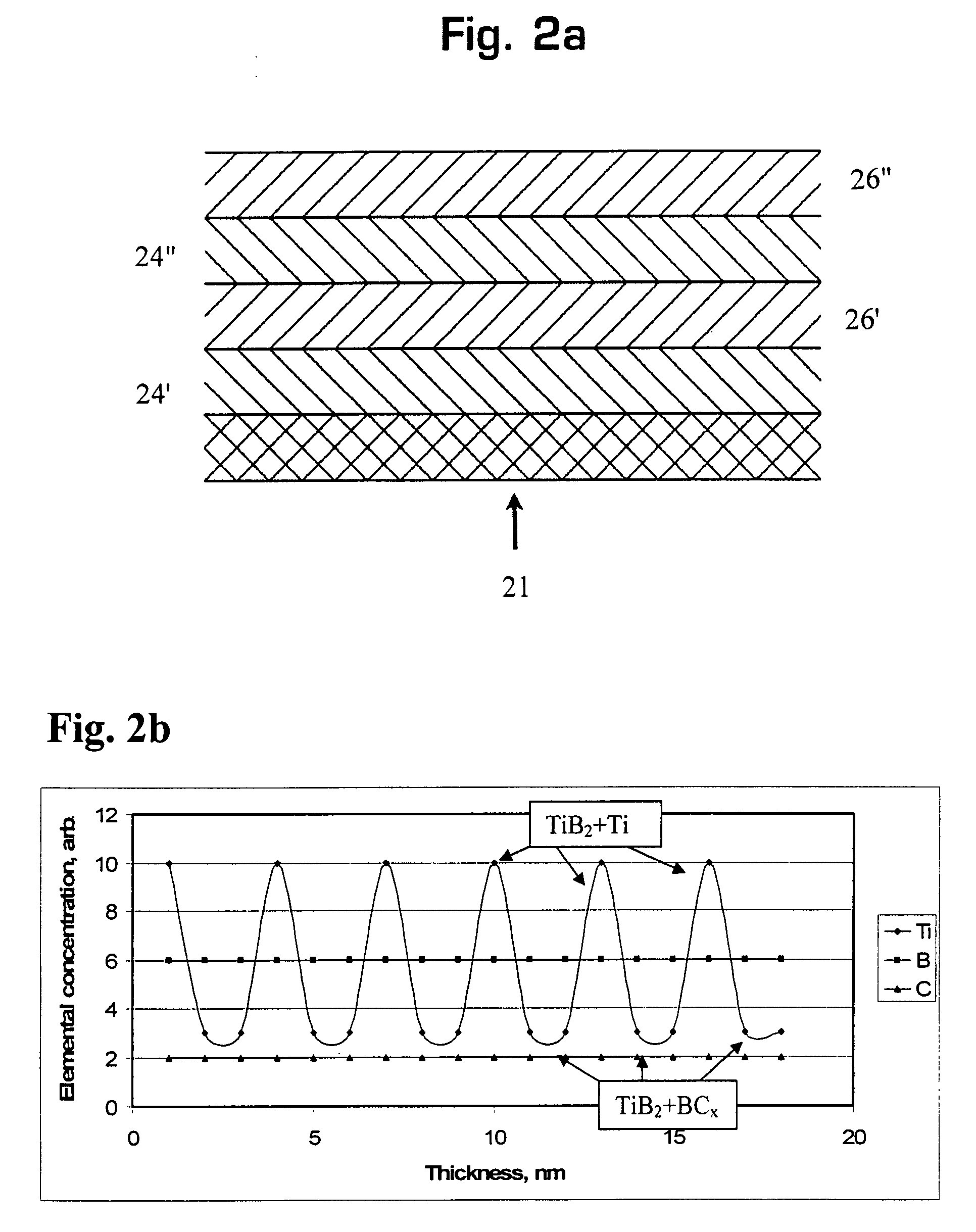

Wear resistant vapor deposited coating, method of coating deposition and applications therefor

ActiveUS20070284255A1Stable cutting edgeReduce torsion fatiguePigmenting treatmentSurgeryWear resistantShape-memory alloy

A low friction top coat over a multilayer metal / ceramic bondcoat provides a conductive substrate, such as a rotary tool, with wear resistance and corrosion resistance. The top coat further provides low friction and anti-stickiness as well as high compressive stress. The high compressive stress provided by the top coat protects against degradation of the tool due to abrasion and torsional and cyclic fatigue. Substrate temperature is strictly controlled during the coating process to preserve the bulk properties of the substrate and the coating. The described coating process is particularly useful when applied to shape memory alloys.

Owner:G&H TECH LLC

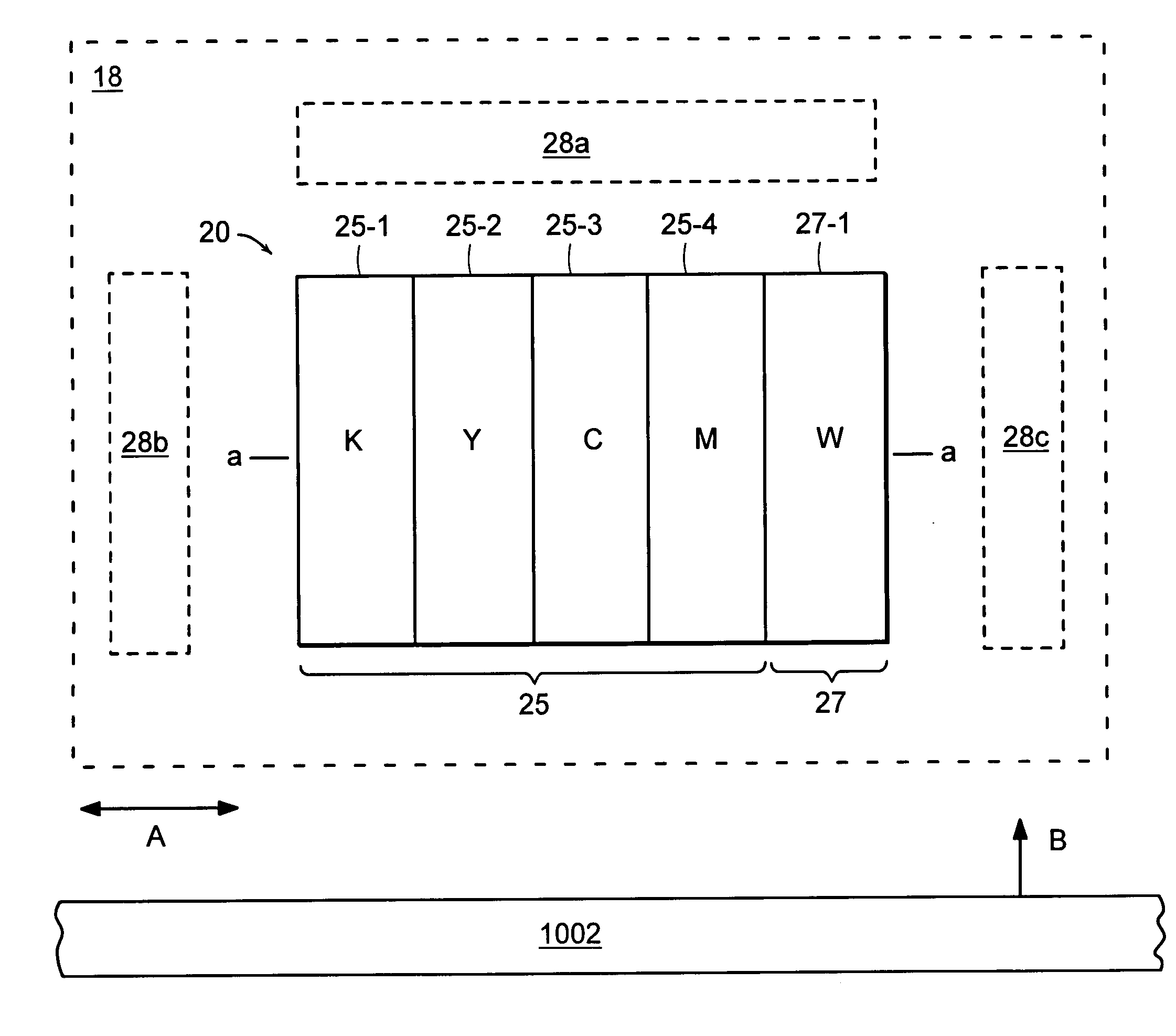

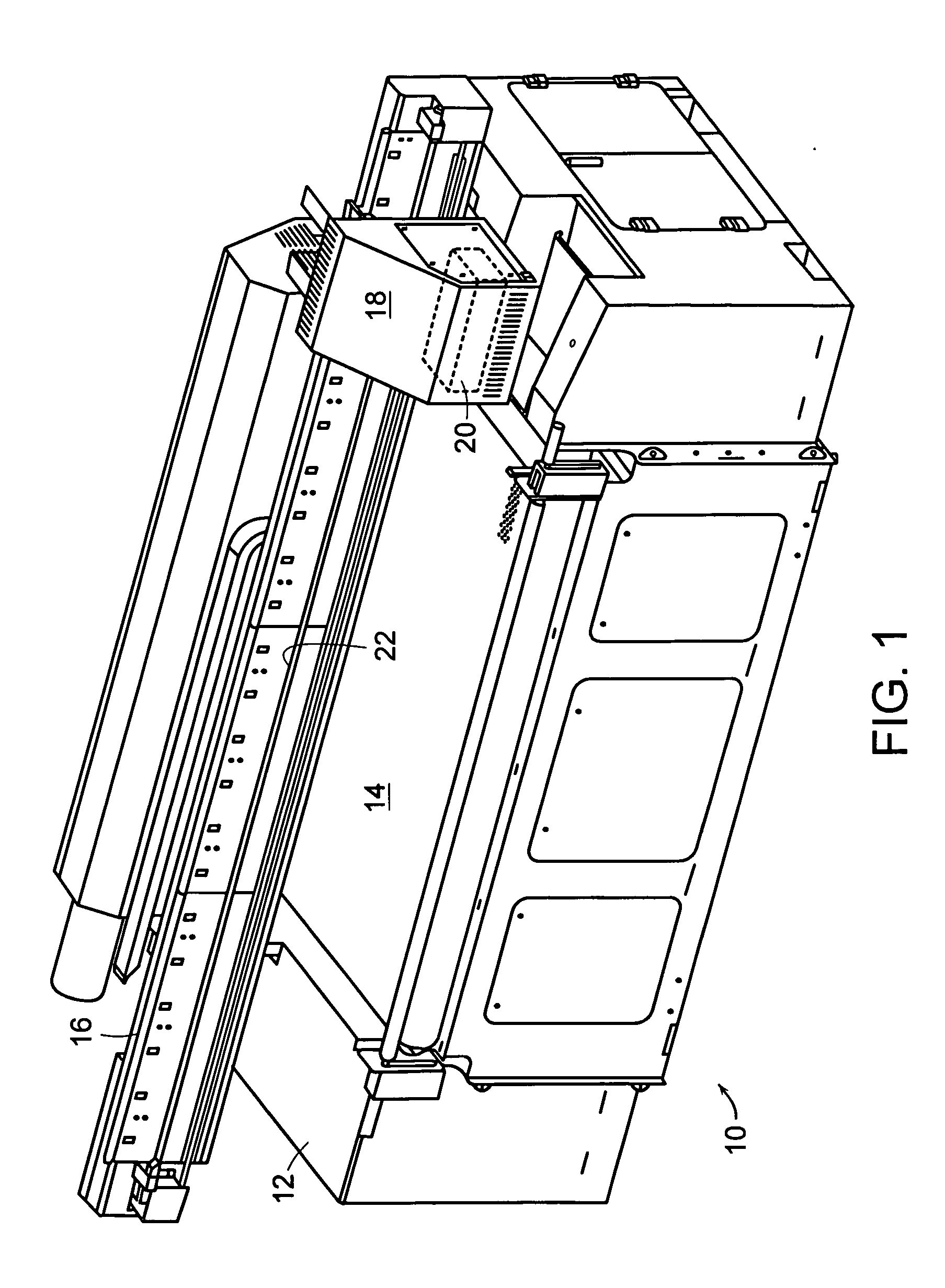

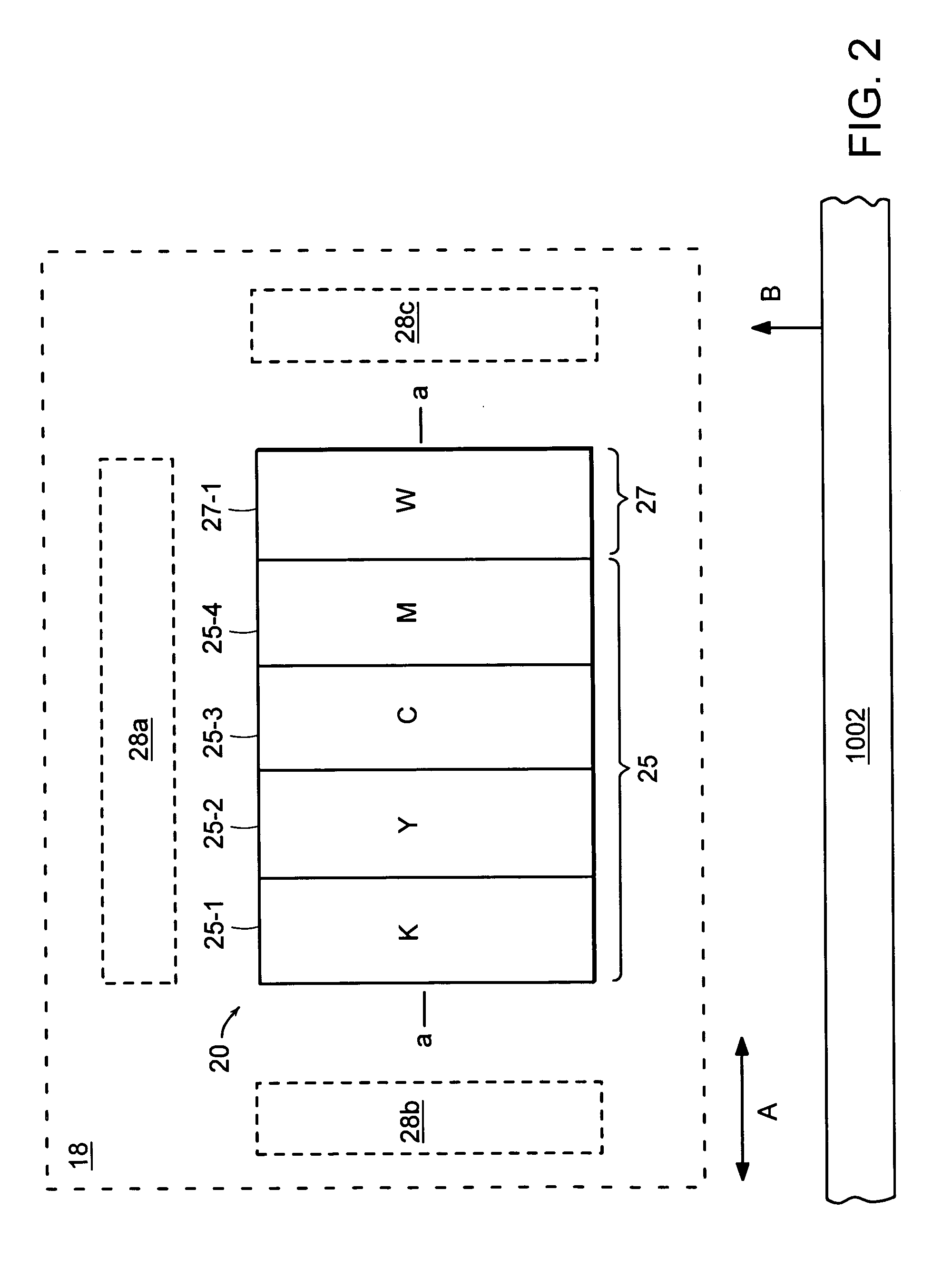

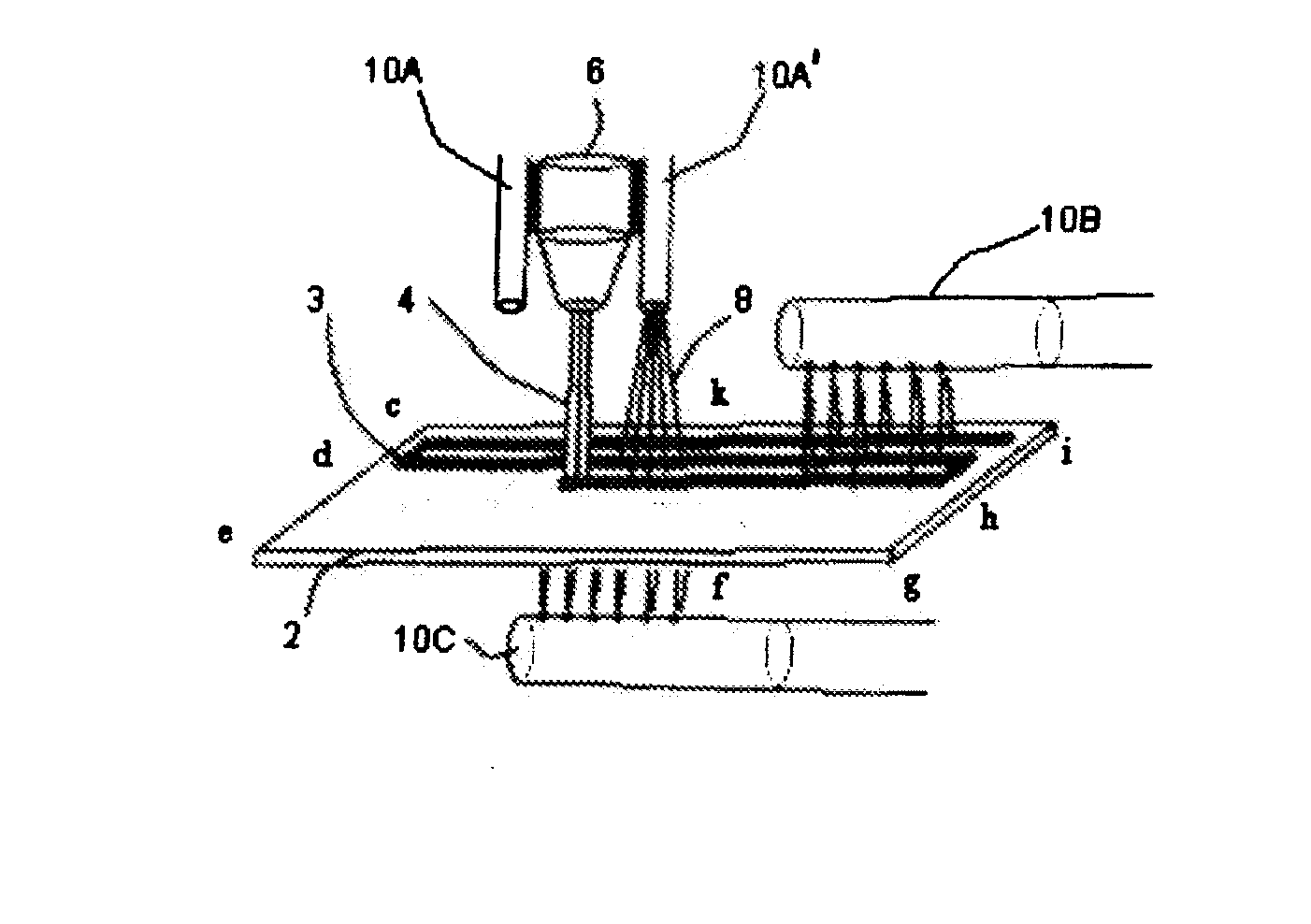

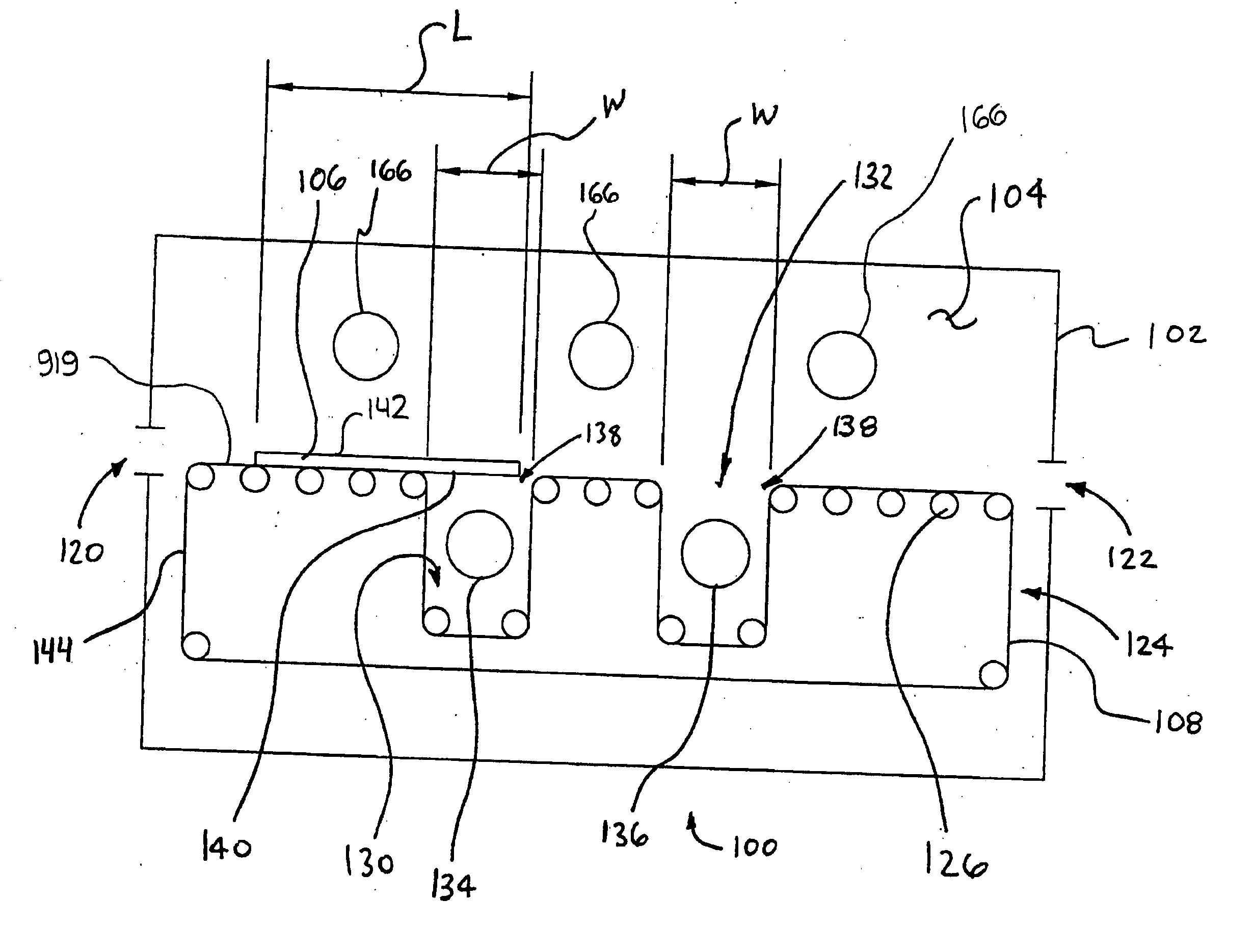

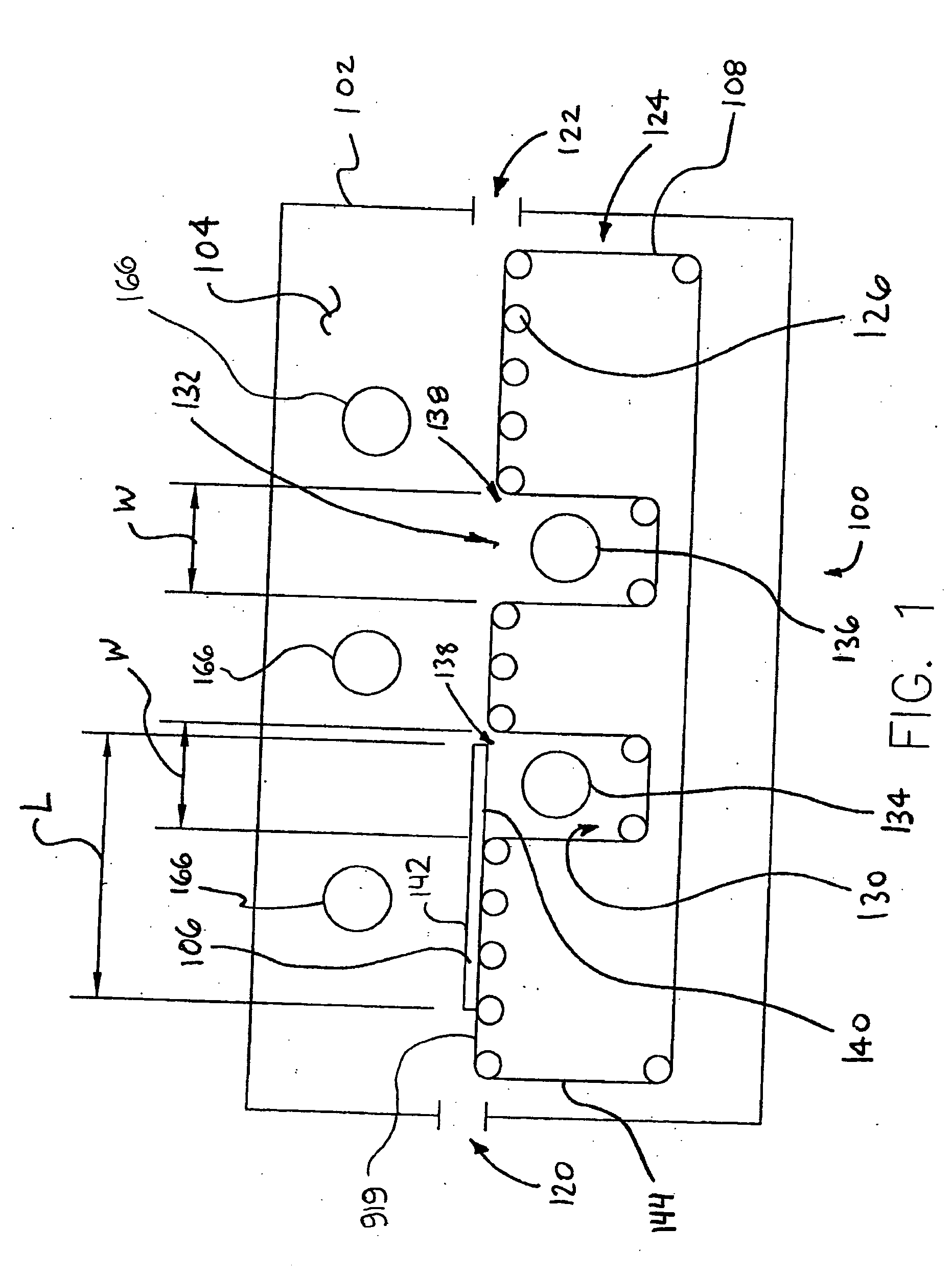

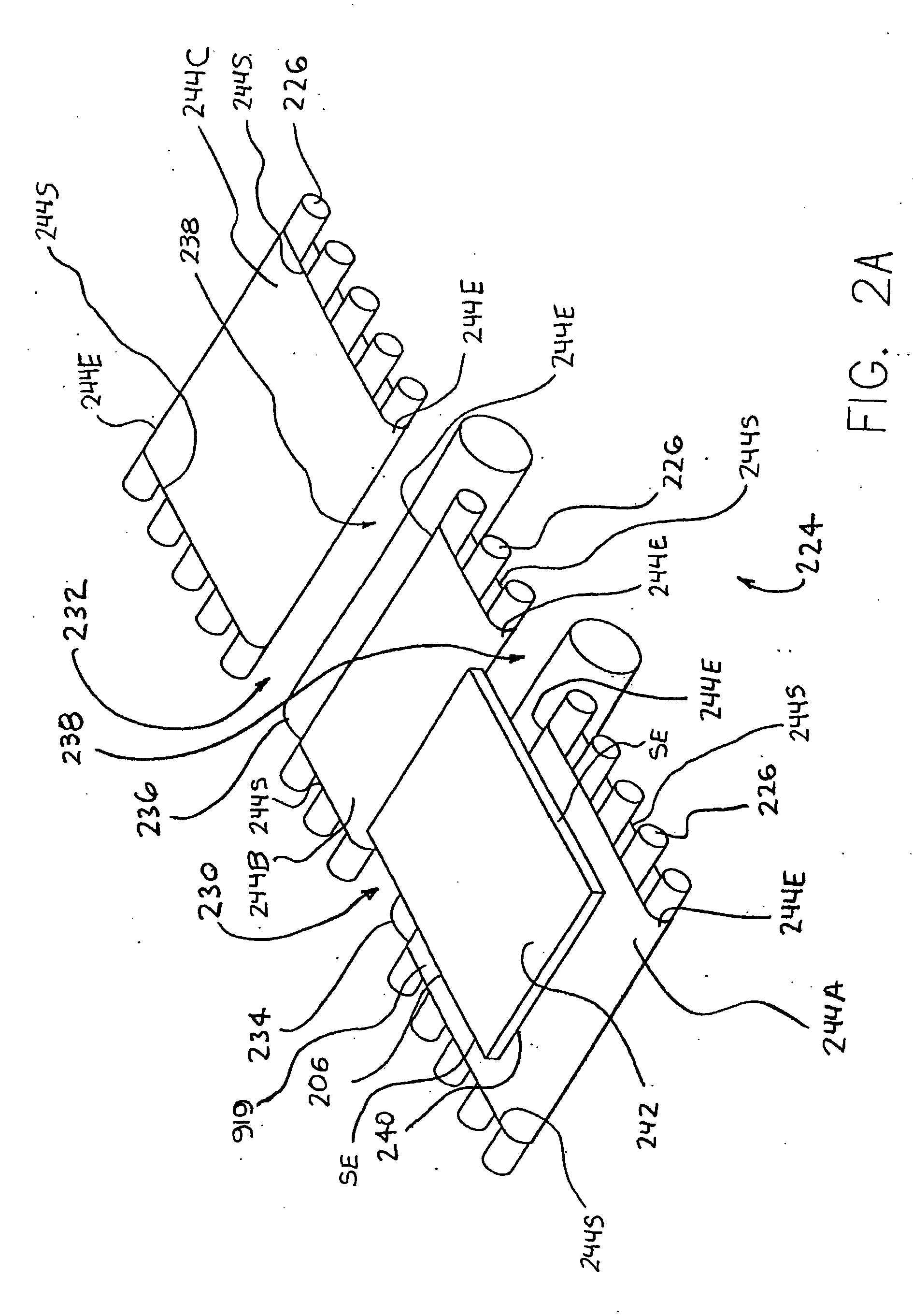

Method and system for multi-channel ink-jet printing

A printing apparatus having an array of printheads arranged along a single printhead axis, and capable of printing images and a coating layer on the substrate during a single printing operation. The coating layer can comprise a specialized printing fluid such as a layer of substantially white ink. The apparatus can perform a pre-coat printing operation, in which the coating layer is deposited first on the substrate, and the image is then printed over the coating layer. The apparatus can also perform a post-coat printing operation, in which the image is first printed onto the substrate, and the coating layer is then deposited over the image. The printhead array includes at least one printhead for printing inks to form the images, and at least one printhead for printing a specialized fluid to form the coating layer. Depending on the printing mode, a controller allocates certain nozzles of the array for printing inks and certain nozzles for printing the specialized fluid. As each section of a substrate advances under the array, it first receives a coating layer, and then an image layer; or it first receives an image layer and then a coating layer. The invention is particularly advantageous for printing on non-white and transparent substrates, as well as for printing backlit signs.

Owner:ELECTRONICS FOR IMAGING INC

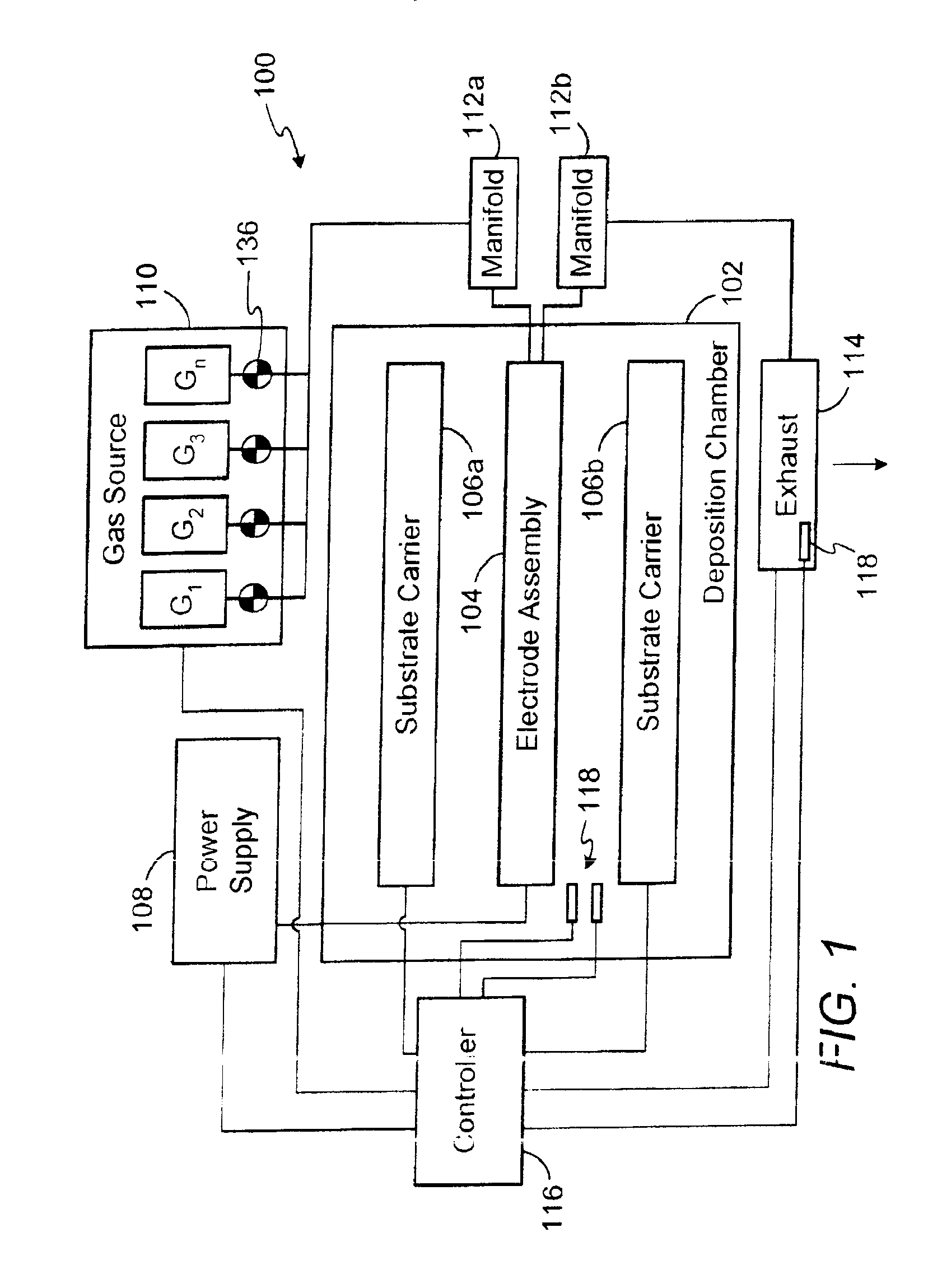

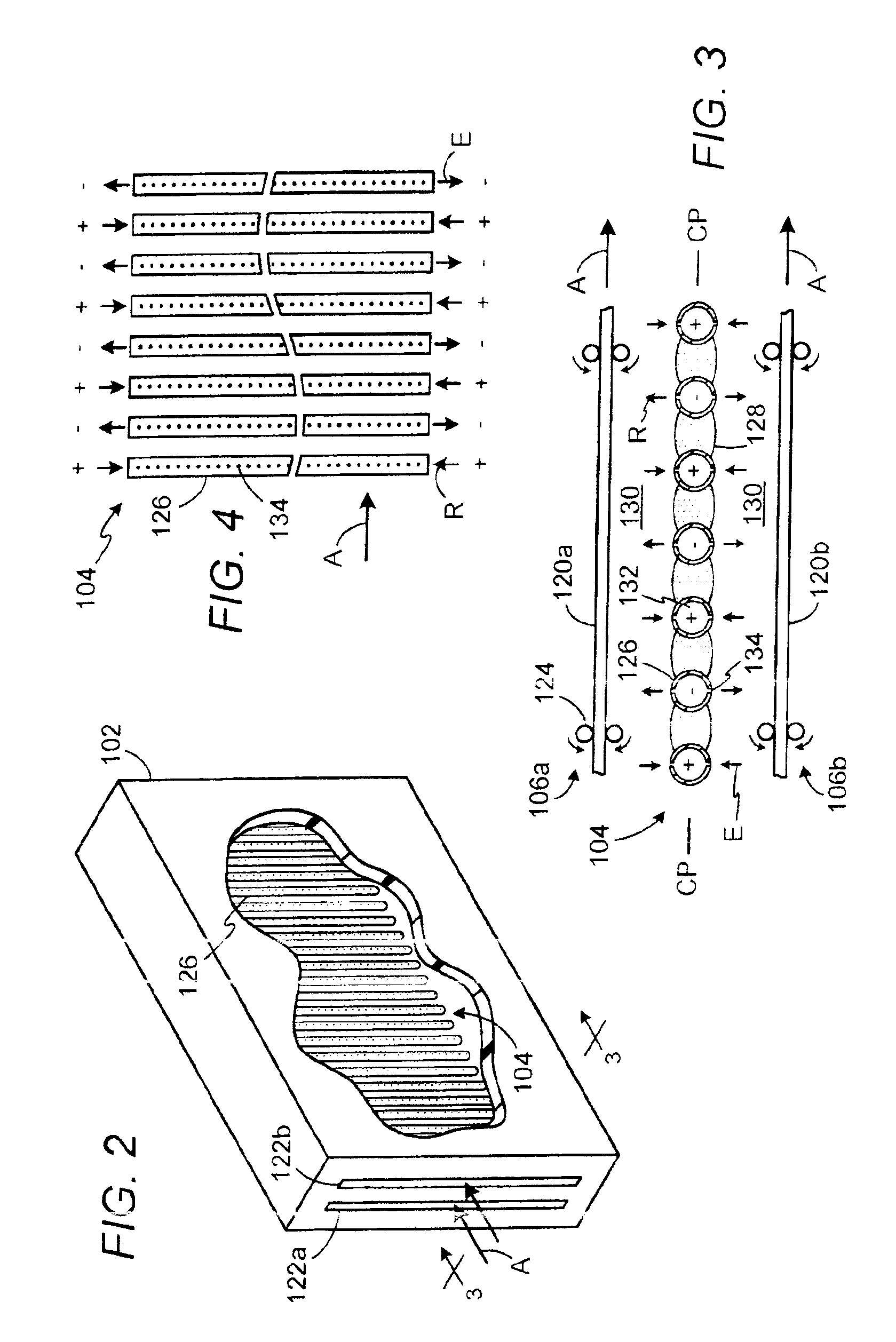

Barrier coating deposition for thin film devices using plasma enhanced chemical vapor deposition process

InactiveUS20080139003A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingSilicon oxideSolar cell

A method to produce barrier coatings (such as nitrides, oxides, carbides) for large area thin film devices such as solar panels or the like using a high frequency plasma enhanced chemical vapor deposition (PECVD) process is presented. The proposed process provides a uniform deposition of barrier coating(s) such as silicon nitride, silicon oxide, silicon carbide (SiNx, SiO2, SiC) at a high deposition rate on thin film devices such as silicon based thin film devices at low temperature. The proposed process deposits uniform barrier coatings (nitrides, oxides, carbides) on large area substrates (about 1 m×0.5 m and larger) at a high frequency (27-81 MHz). Stable plasma maintained over a large area substrate at high frequencies allows high ionization density resulting in high reaction rates at lower temperature.

Owner:NOVASOLAR HLDG

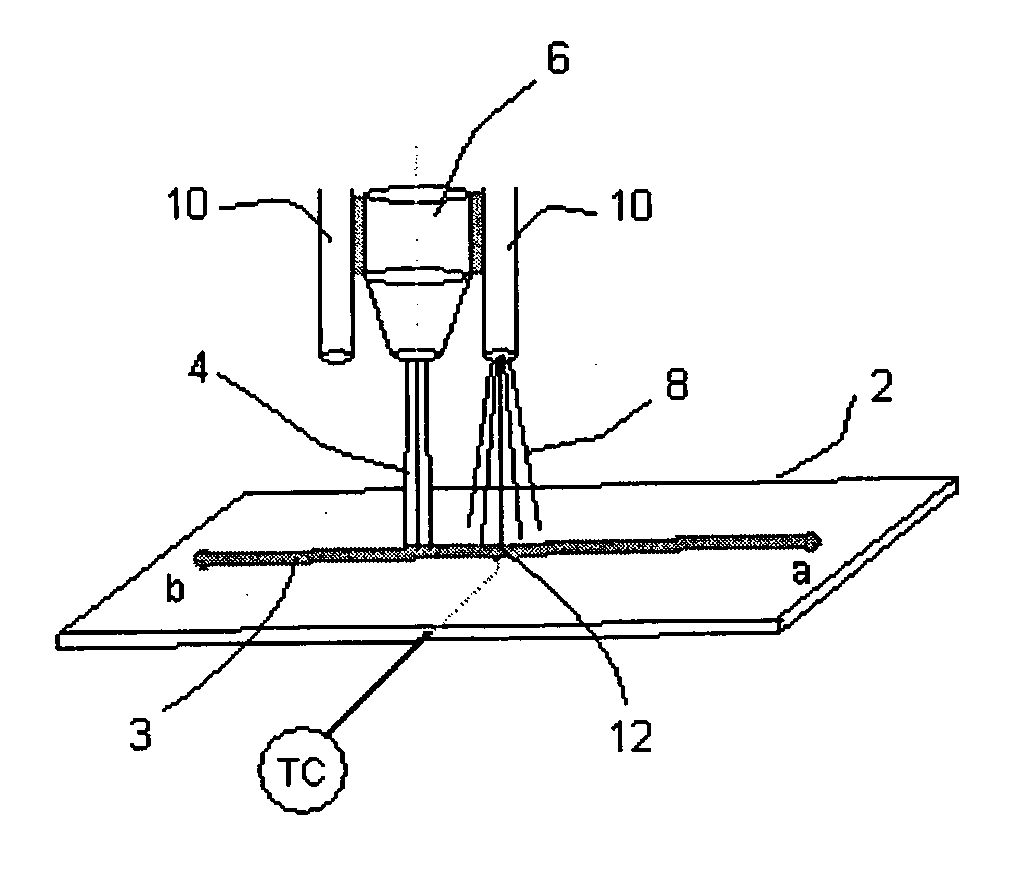

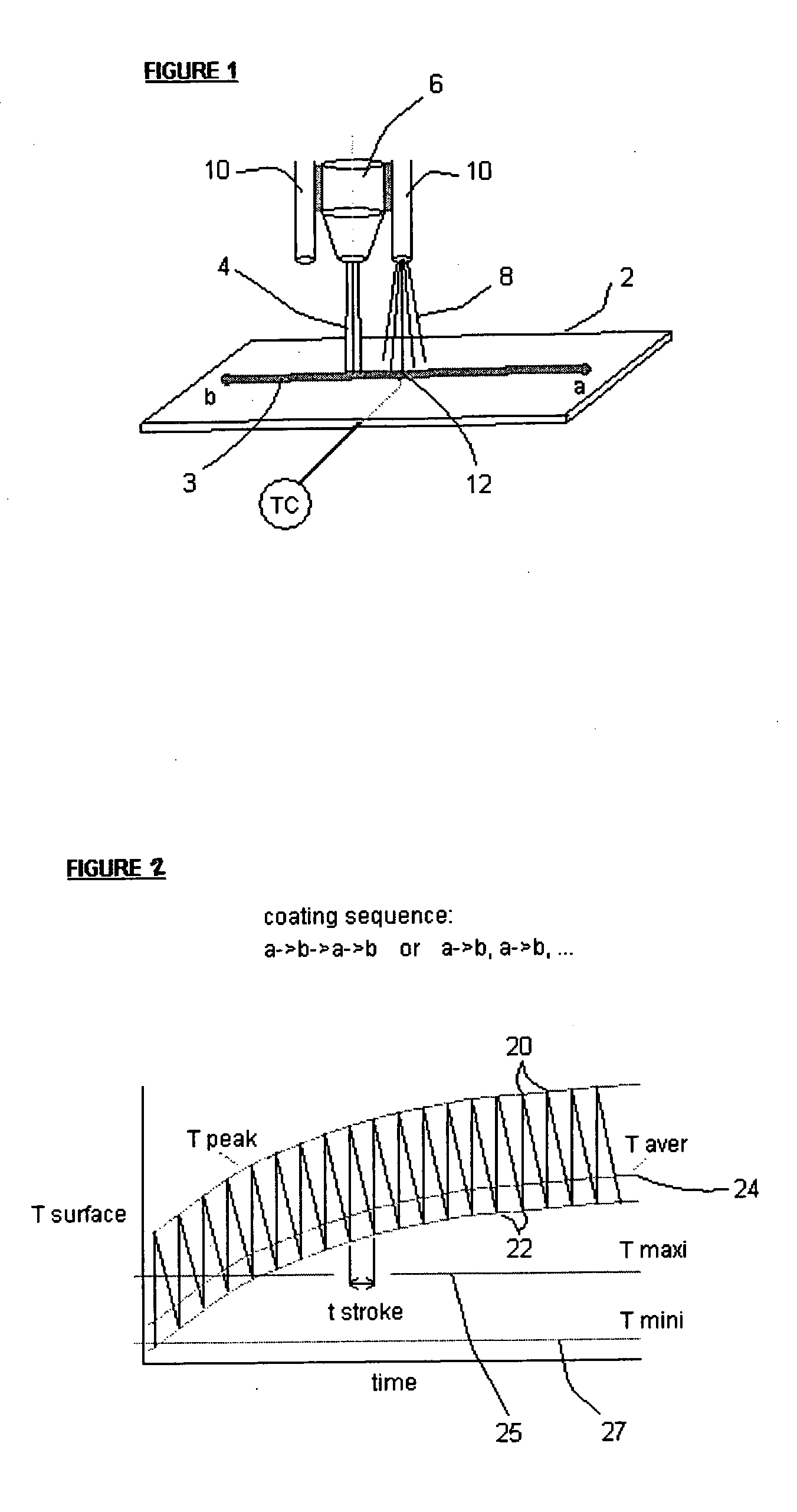

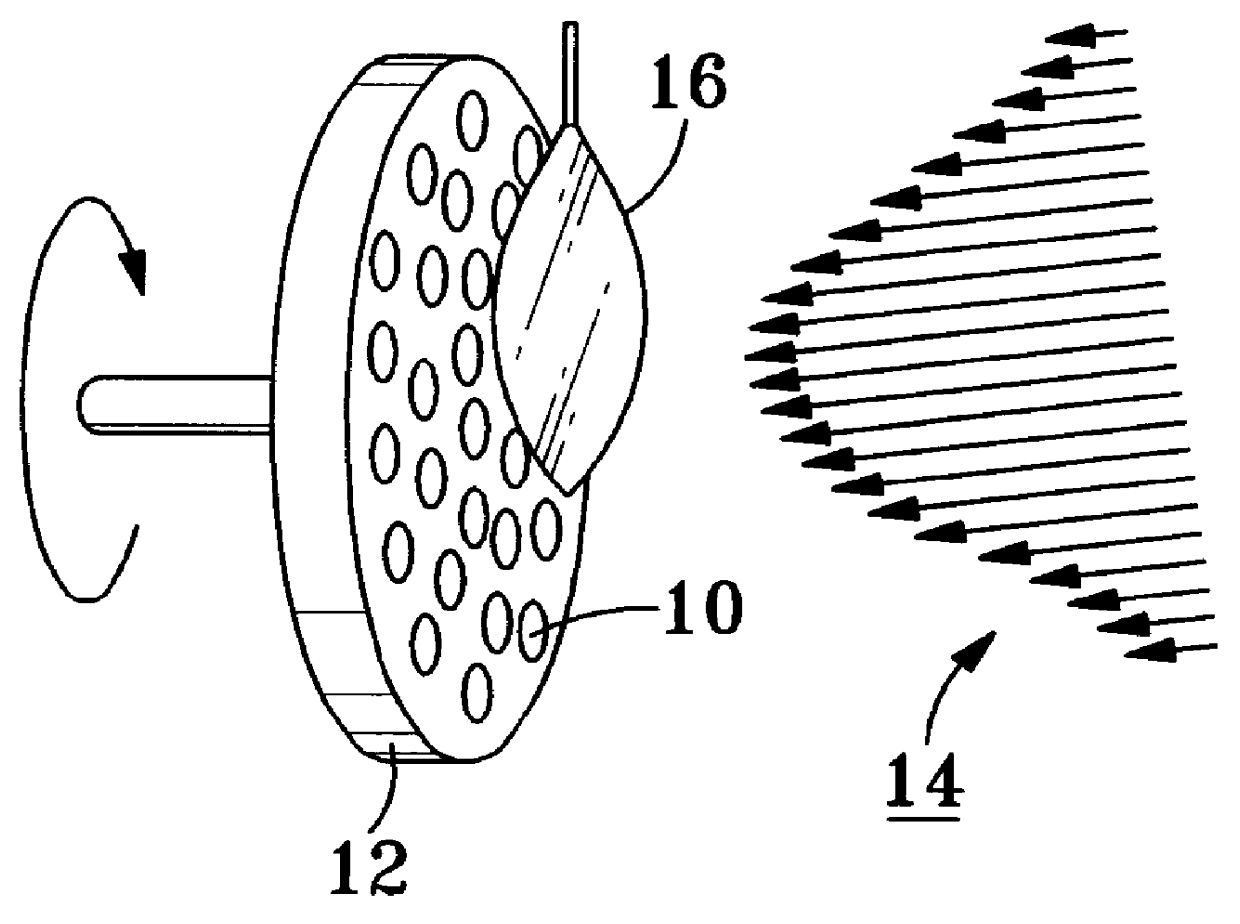

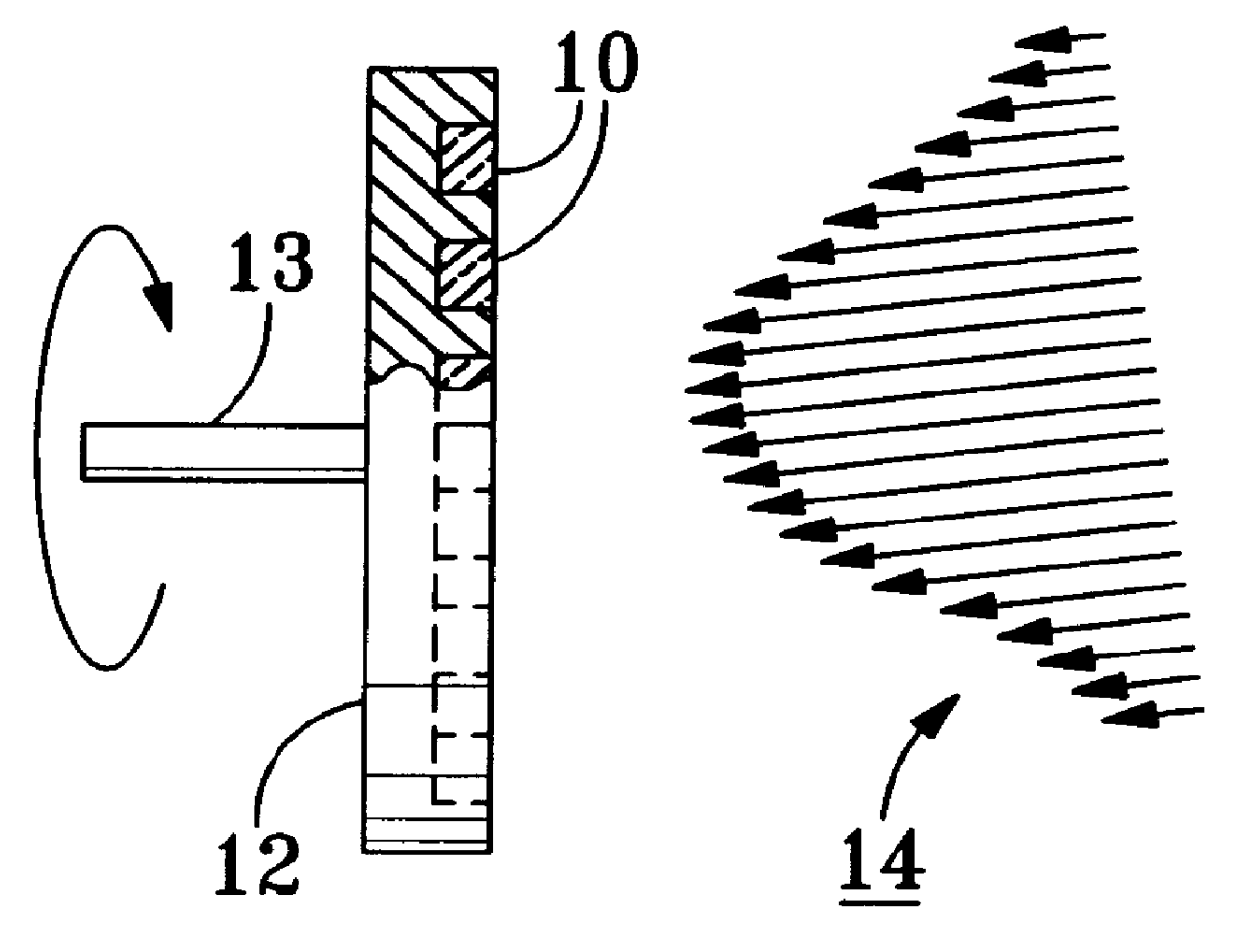

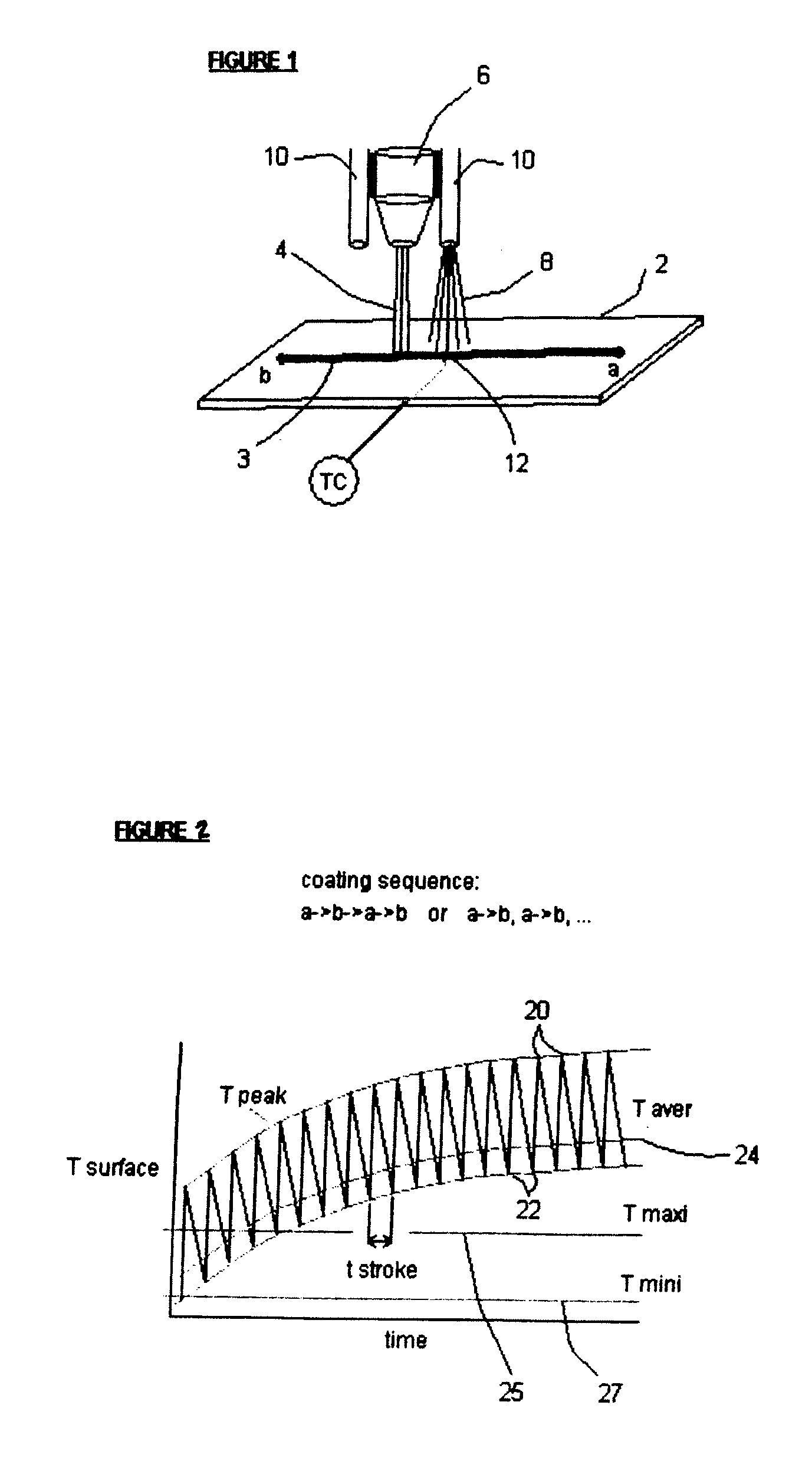

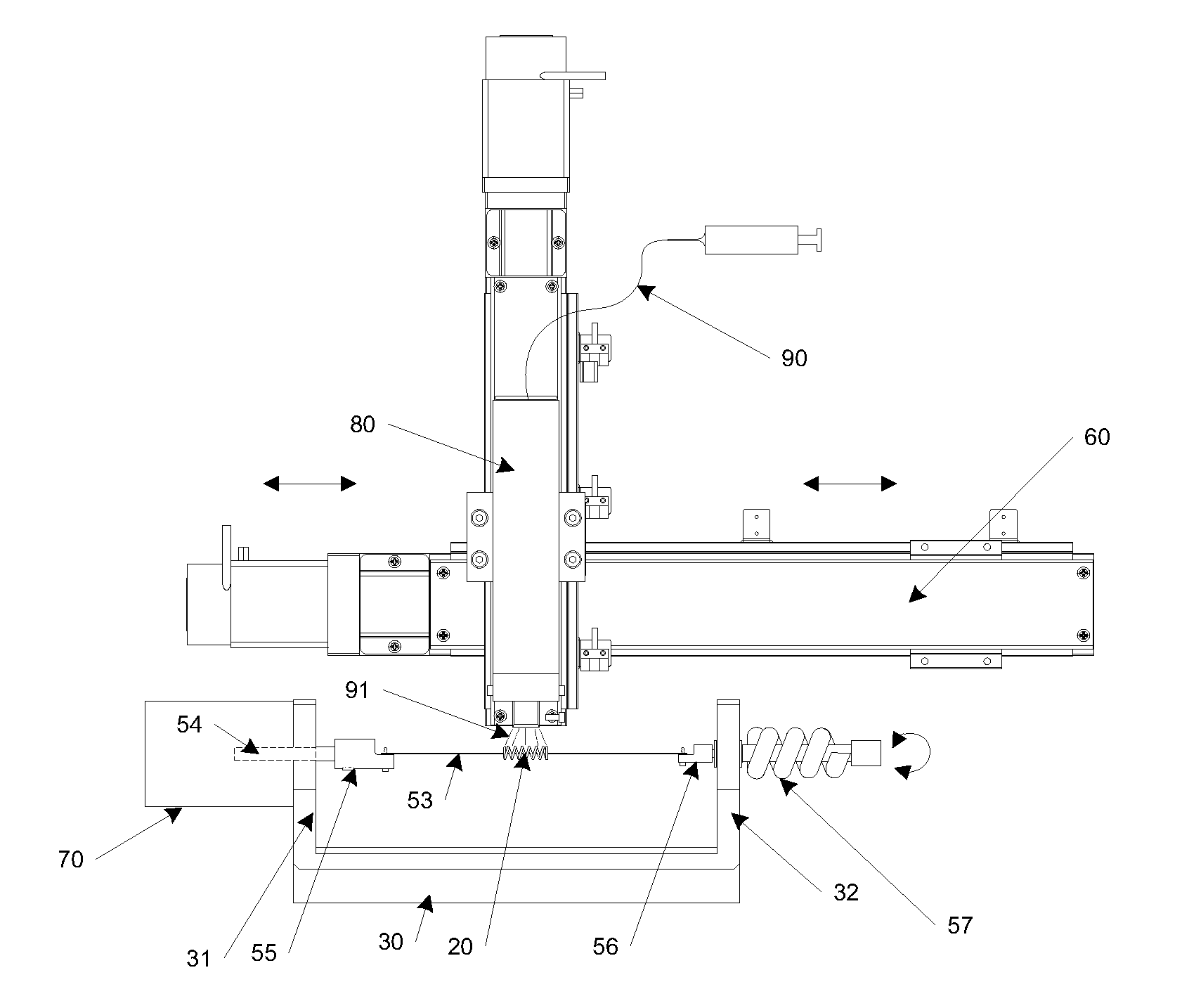

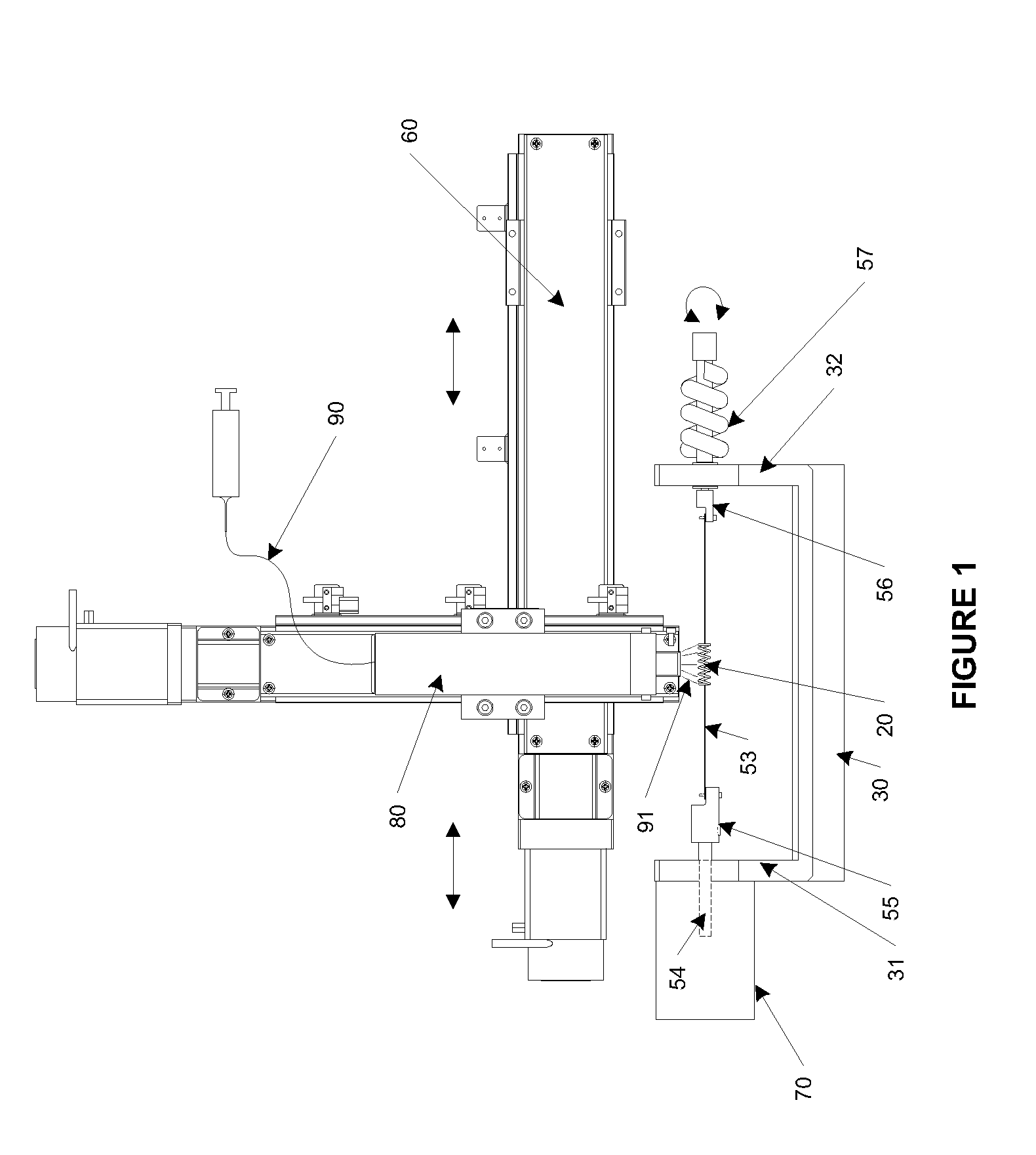

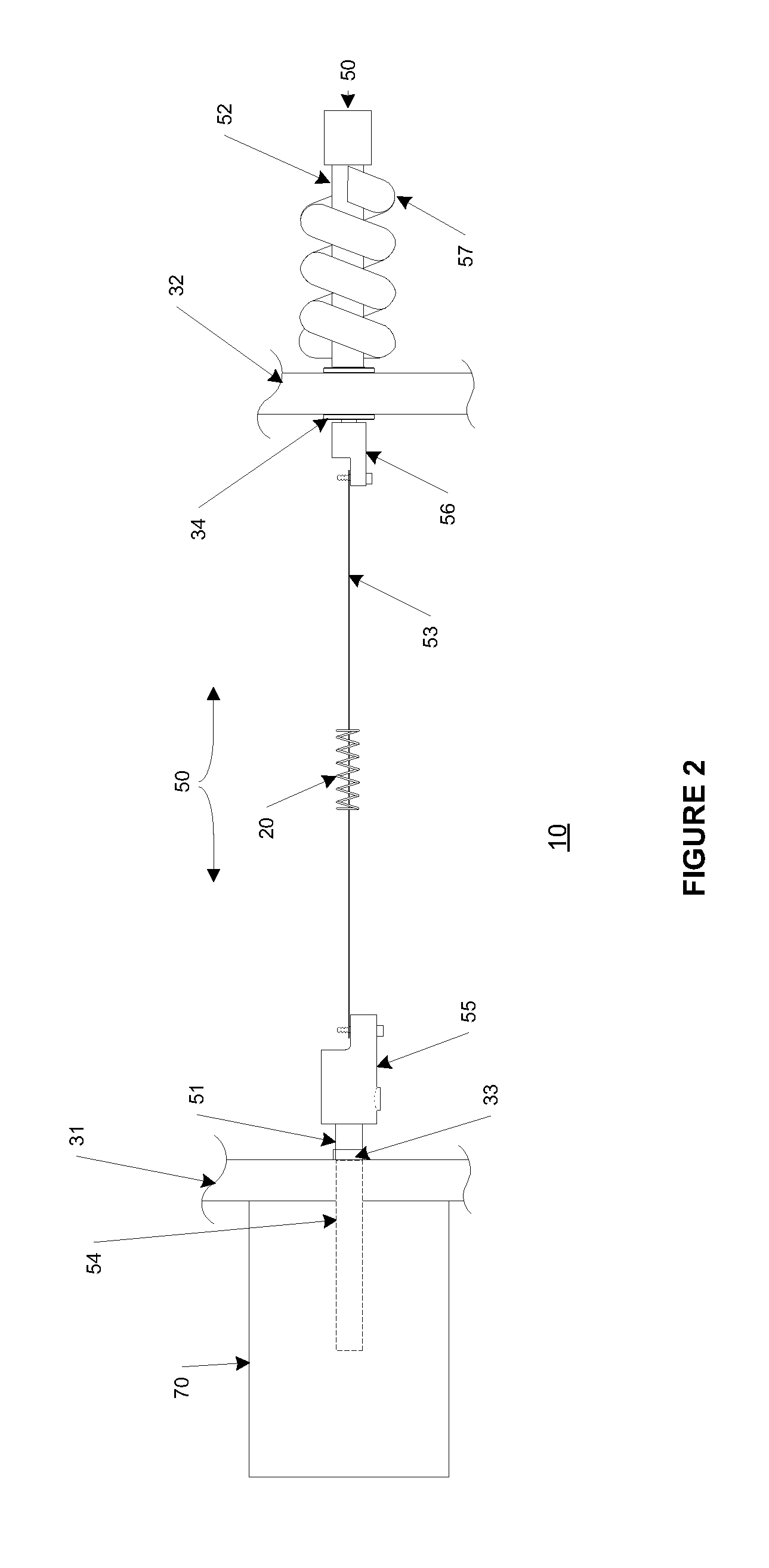

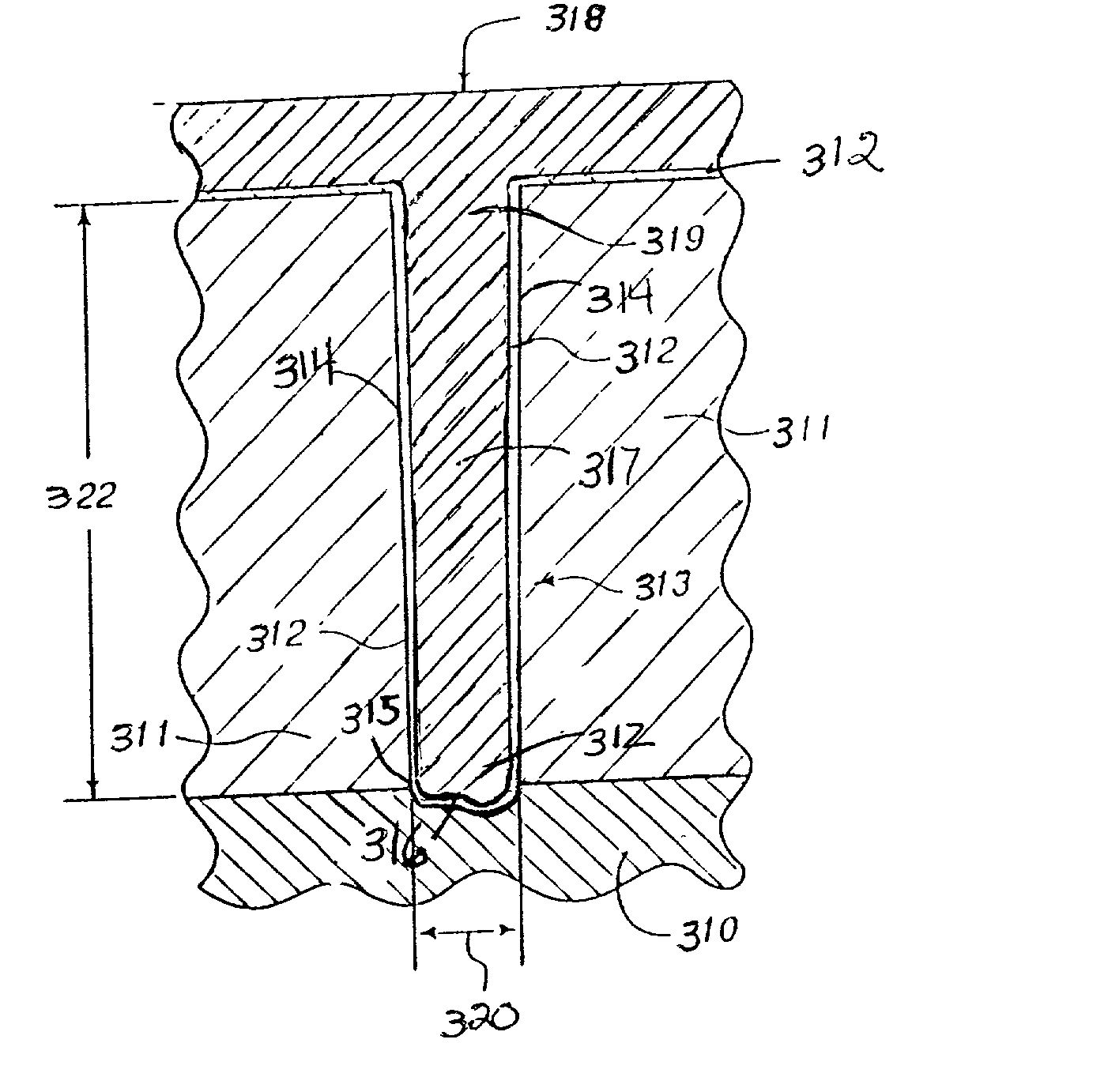

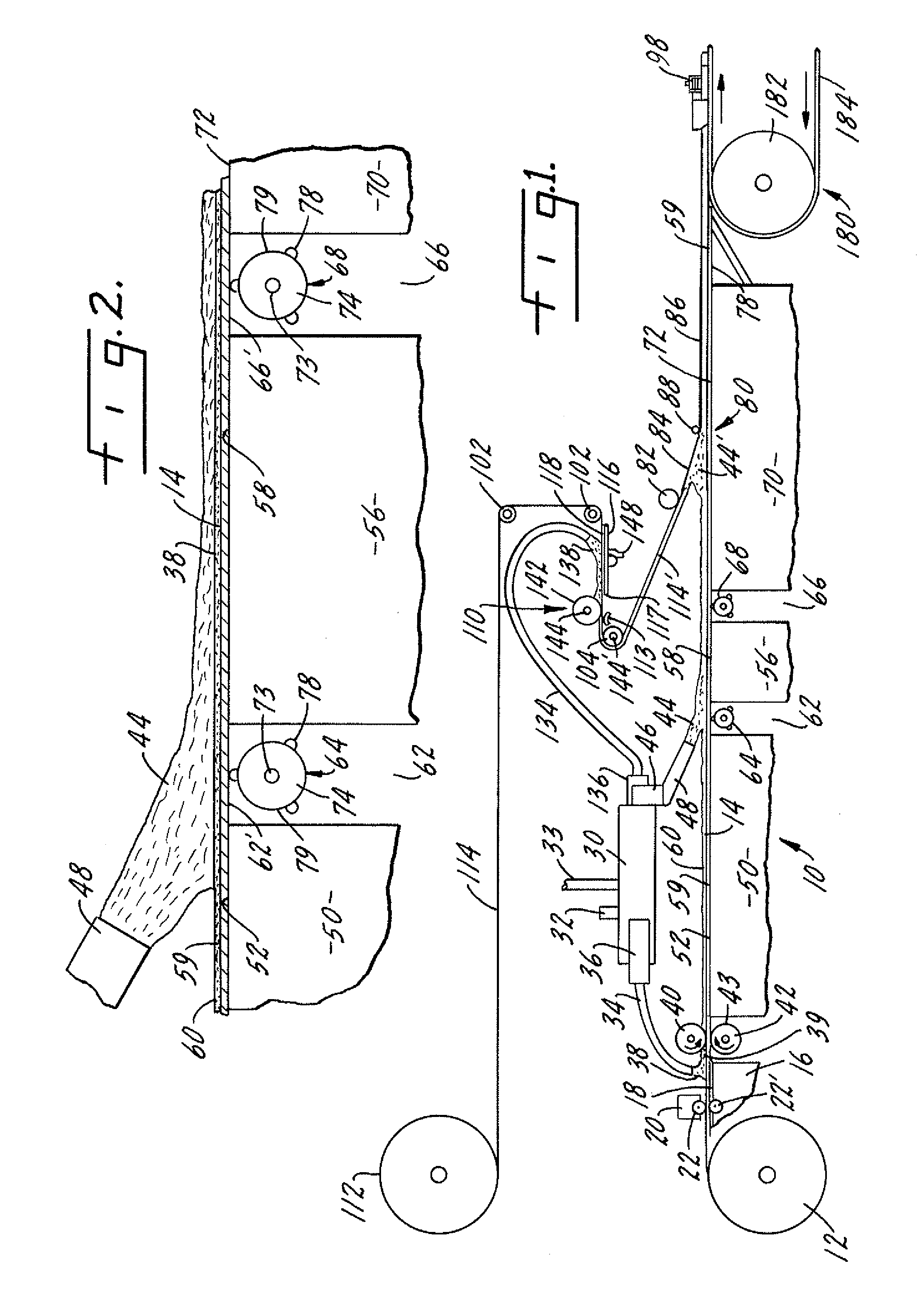

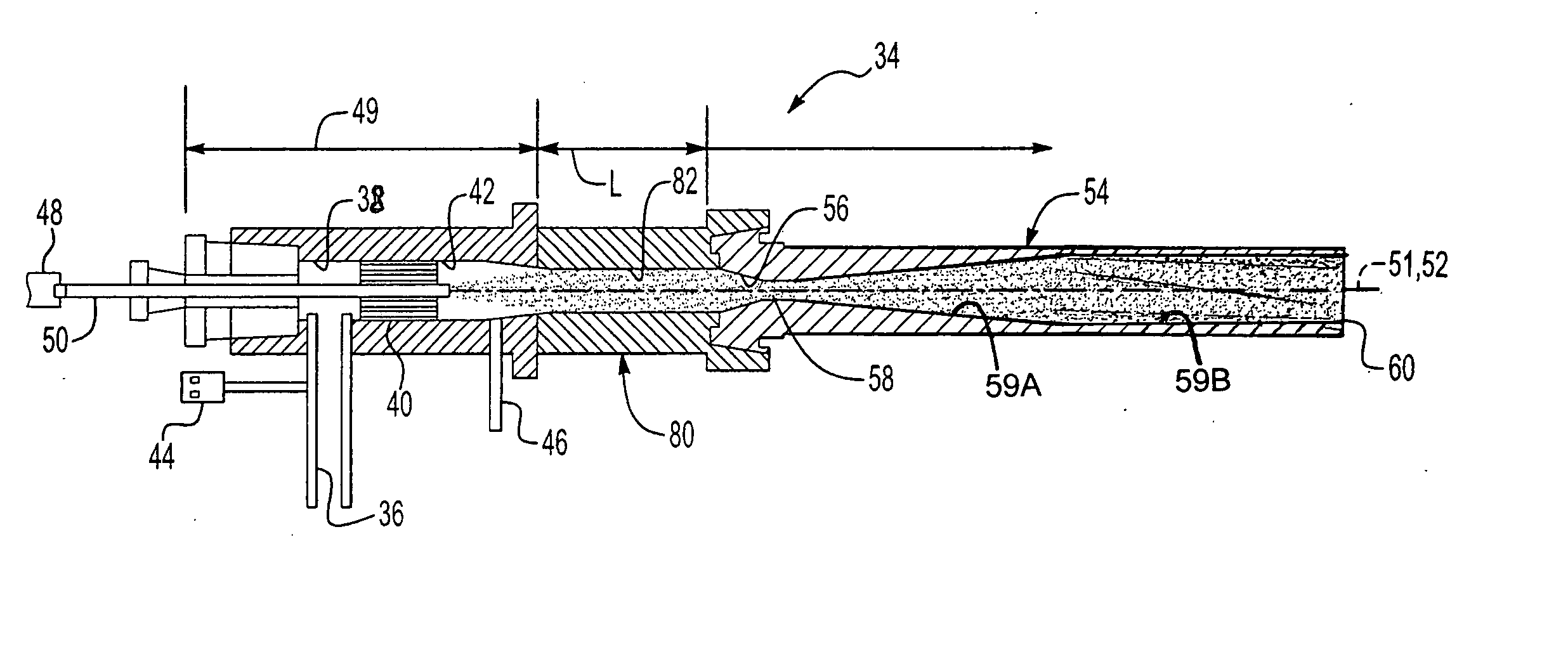

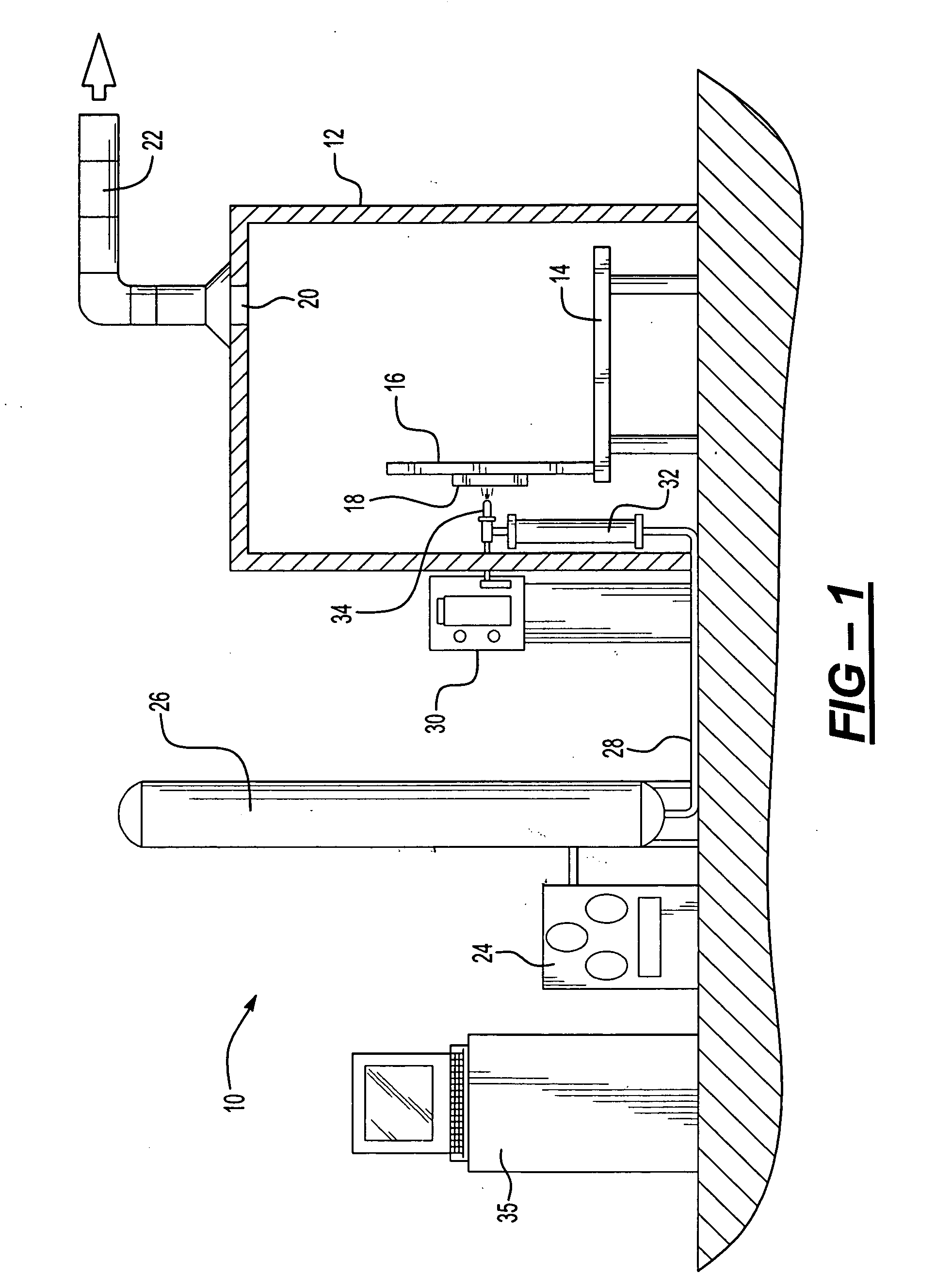

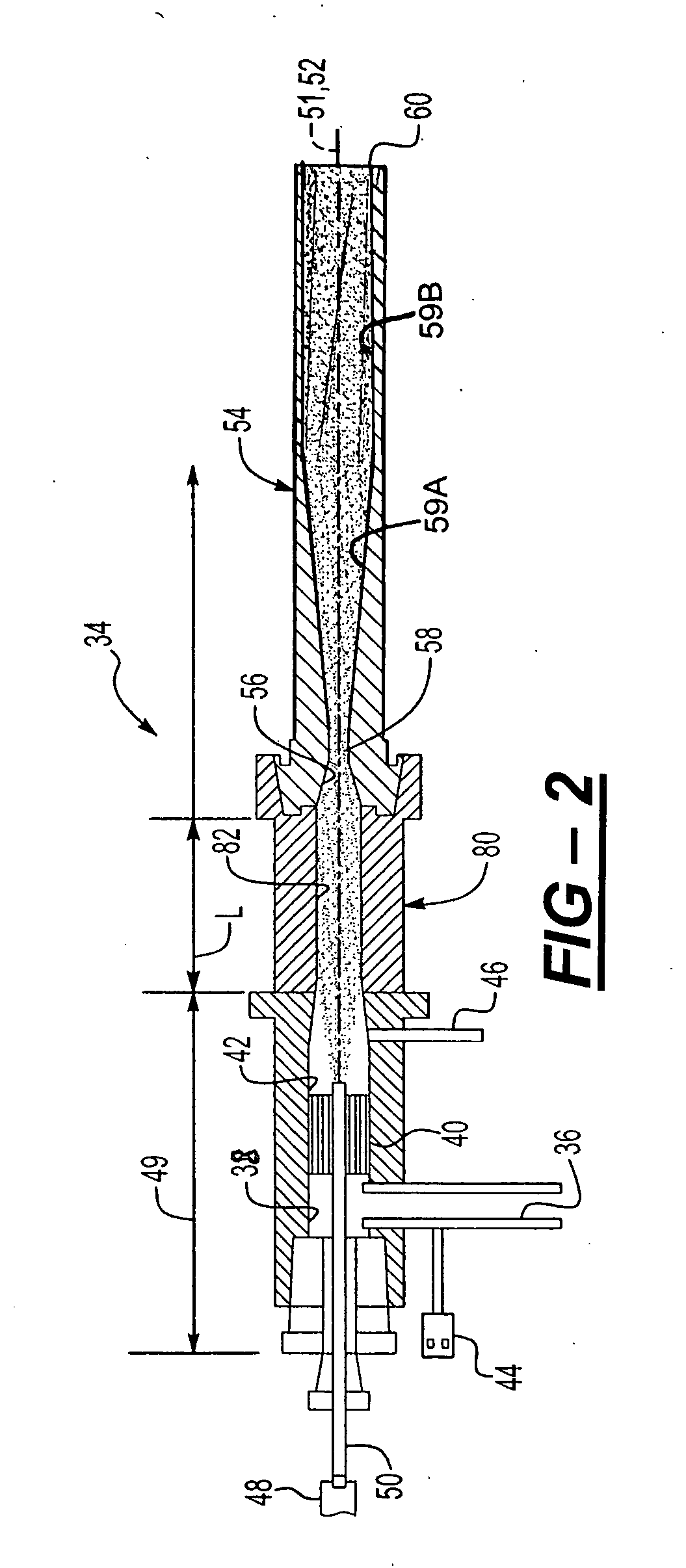

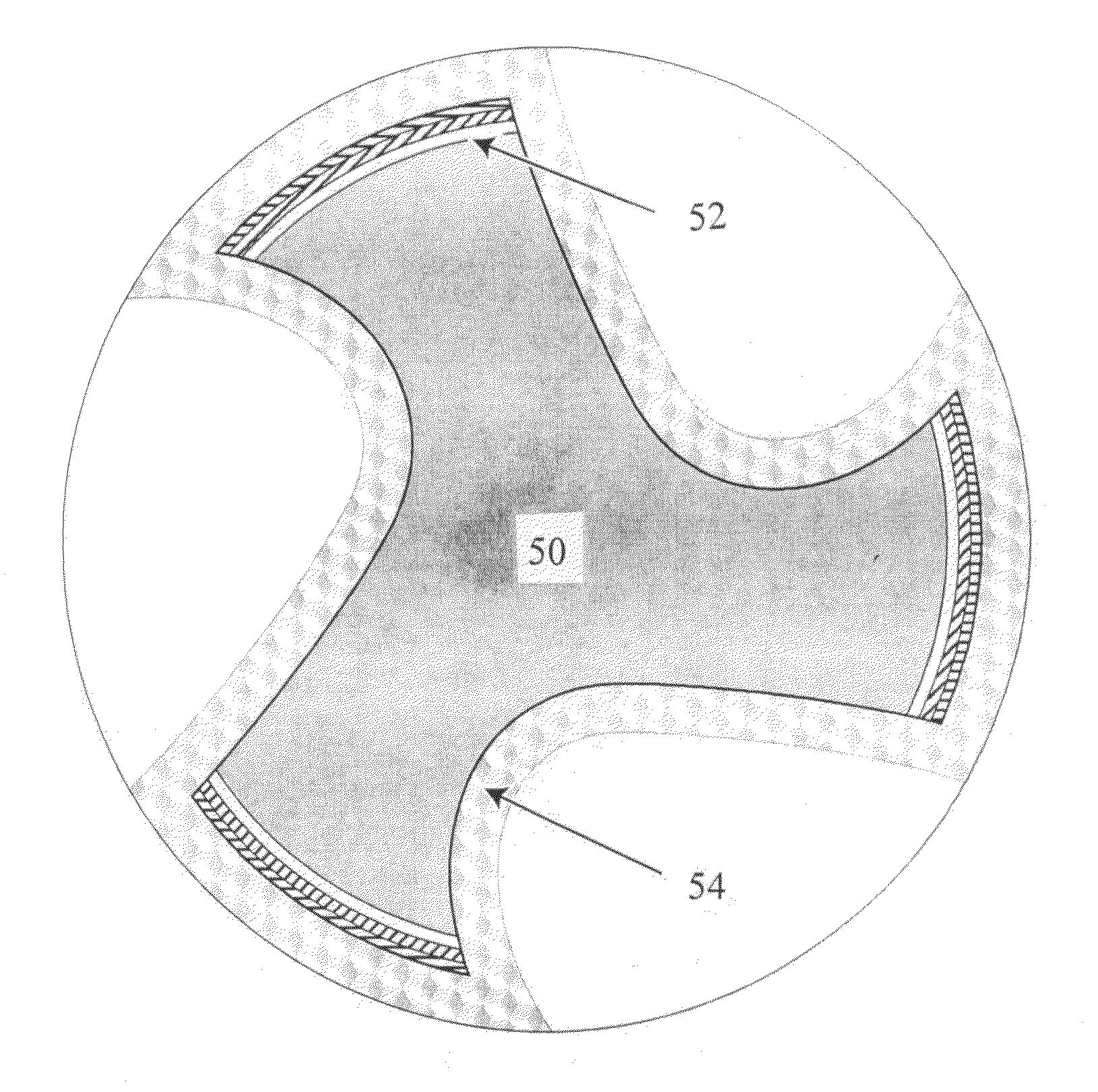

Thermal deposition coating method

ActiveUS20060228465A1Excellent coating production rateDamaging internal stressLiquid surface applicatorsMolten spray coatingThermal depositionRelative motion

A process for the thermal deposition coating of a workpiece, said process comprising the steps of: (c) thermally depositing a coating on a metallic surface of a workpiece from a deposition head wherein at least one condition selected from the group of: coating deposition rate onto said surface, relative motion between the surface and said deposition head, and cryogenic coolant application rate onto said workpiece is controllable; (d) substantially simultaneously measuring temperatures at a plurality of locations over the metallic surface of the workpiece; (c) determining an average temperature of the temperatures measured in step (b); (d) comparing the average temperature to a preselected minimum temperature and a preselected maximum temperature for the workpiece; and (e) adjusting at least one of the controllable conditions if said average temperature is not between the preselected minimum temperature and the preselected maximum temperature for the workpiece. Standard deviations of all temperature readings and controlling the relative motion speed between the thermal coating deposition head and the workpiece provide another improvement for obtaining temperature uniformity over the workpiece surface.

Owner:AIR PROD & CHEM INC

Ultrasonic assisted deposition of anti-stick films on metal oxides

InactiveUS20020130441A1Inhibit entry and adhesionLiquid surface applicatorsOptical articlesUltrasonic assistedCasting mold

A method and apparatus for ultrasonic assisted deposition of a release agent onto a workpiece is disclosed. The release agent can be any fluorinated or non-fluorinated phosphorous-containing organic acid. The workpiece can be any workpiece desired to be coated with the release agent, such as a surface needing an anti-stick coating required in a plastic casting or injection mold. Metal oxide workpiece surfaces strongly bond to fluorinated phosphorus-containing organic acids. In particular, the present invention can deposit anti-stick coatings onto smooth or porous surfaces, such as anodized aluminum and its alloys, using ultrasonic assisted deposition

Owner:KORRY ELECTRONICS

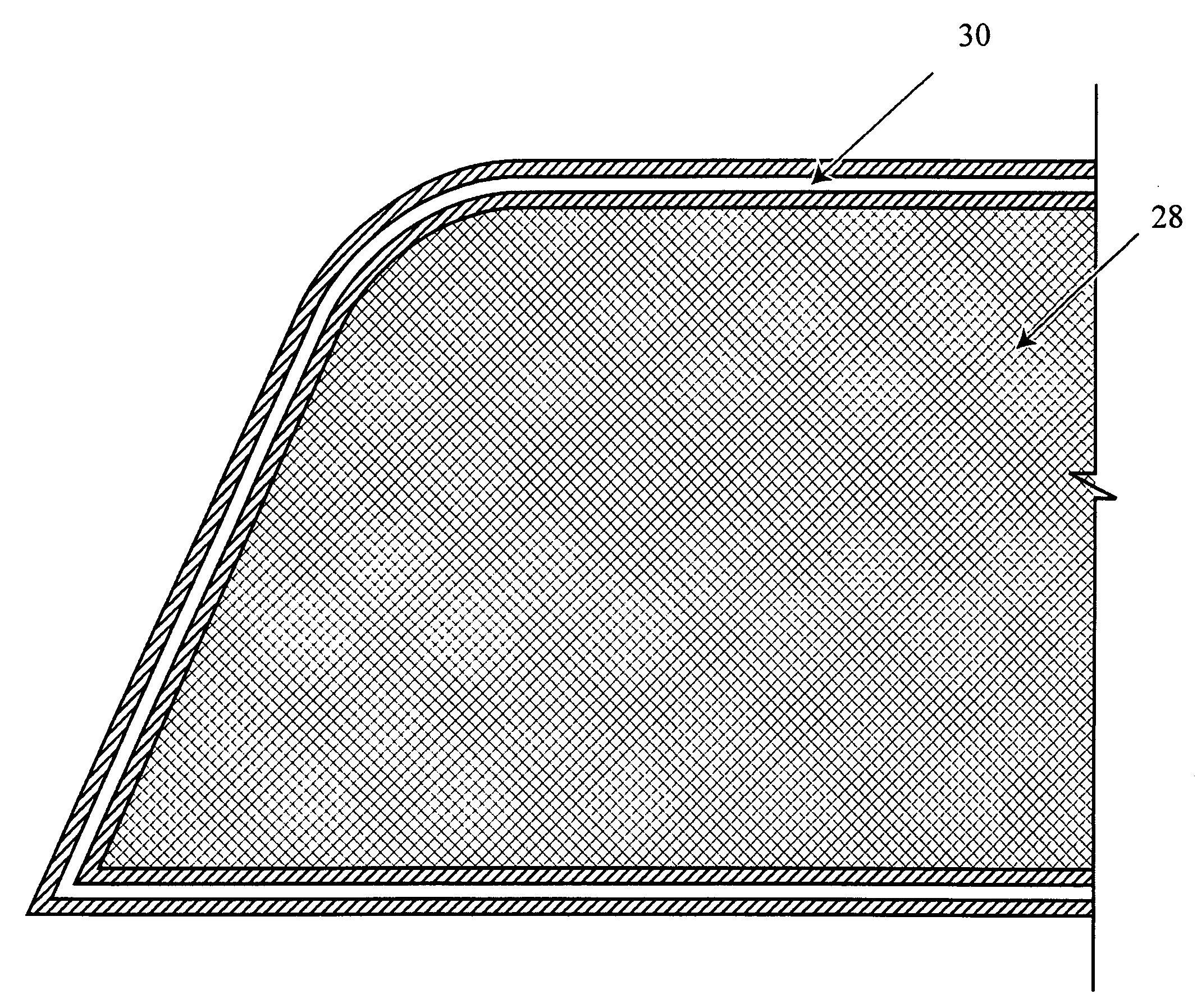

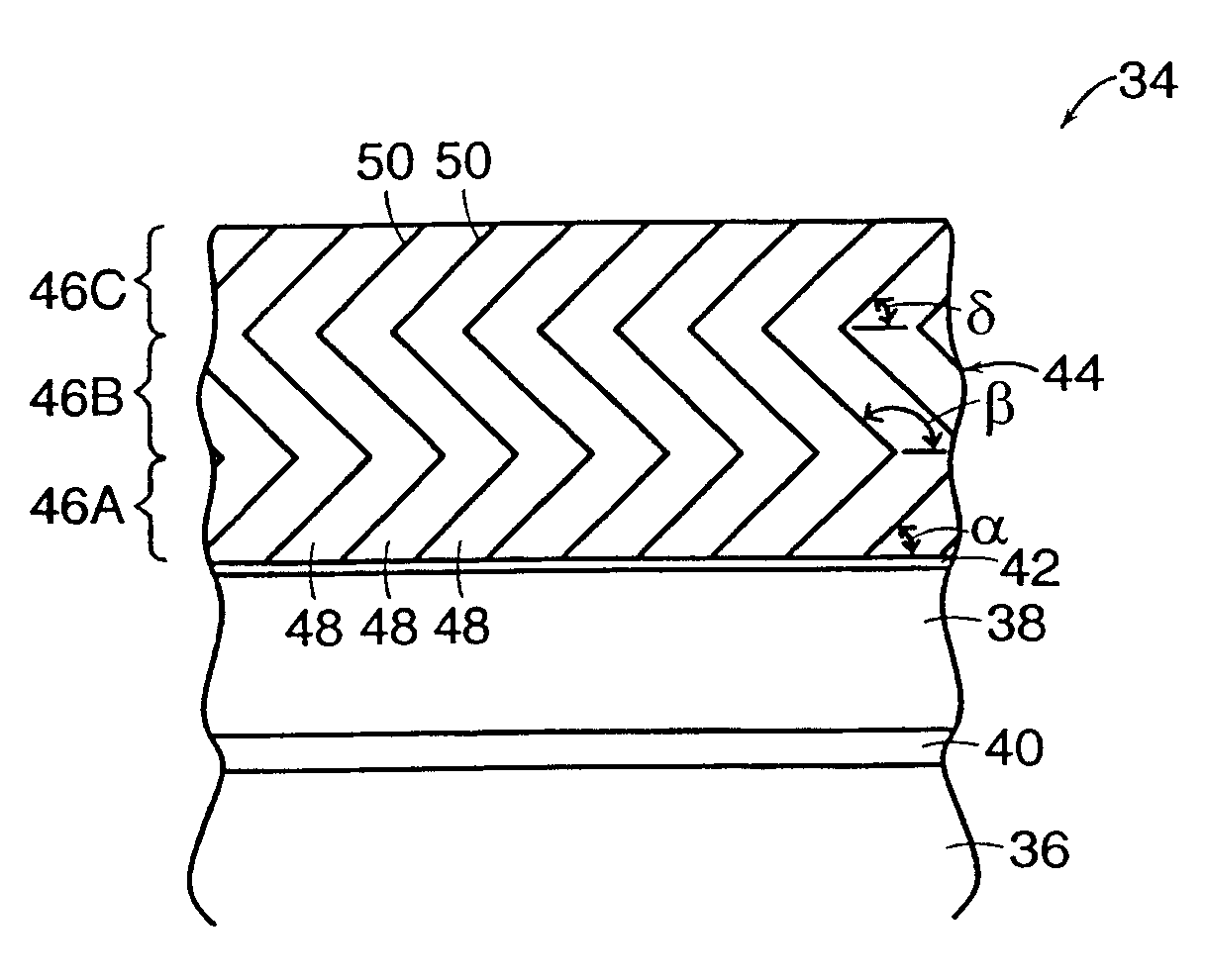

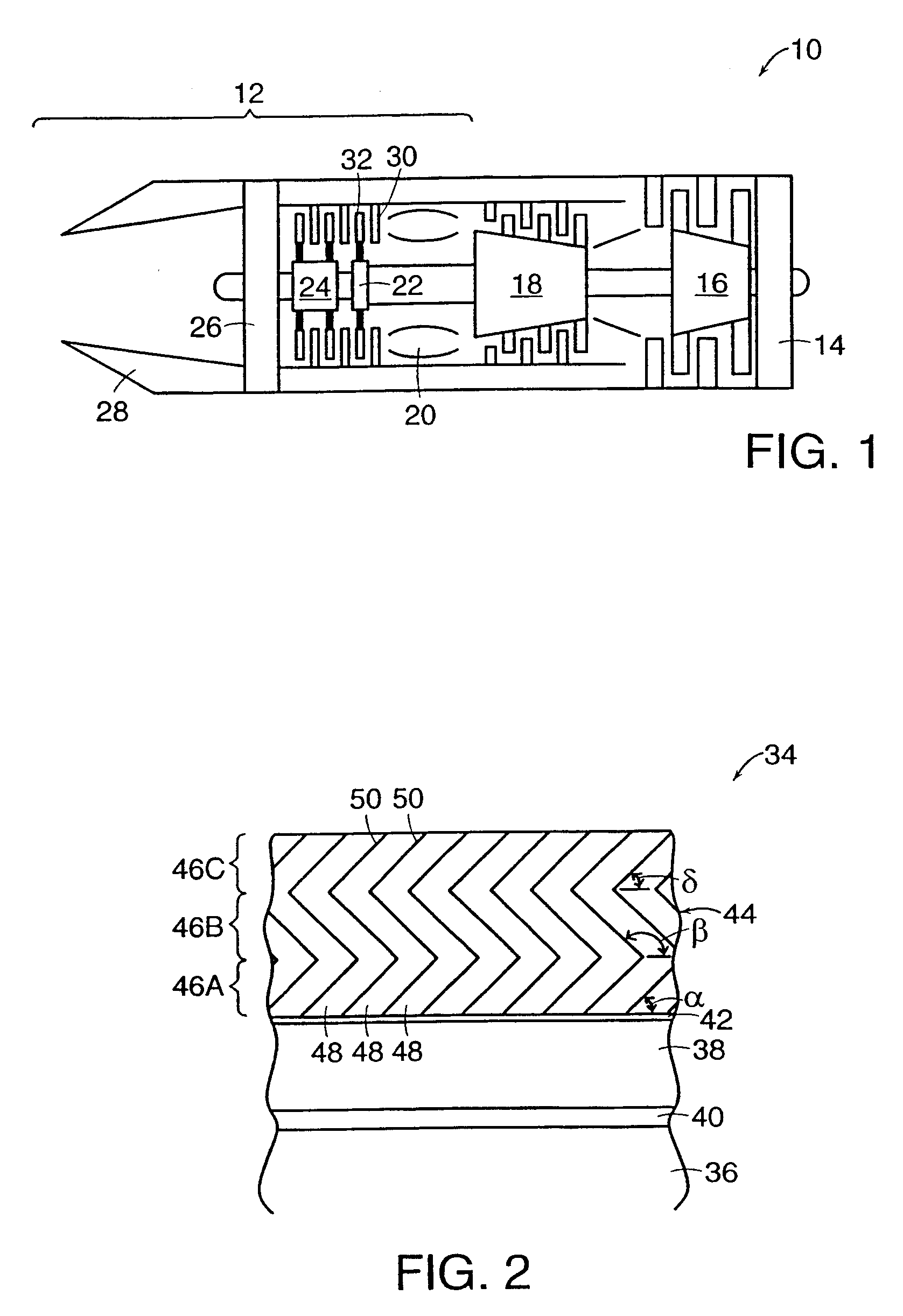

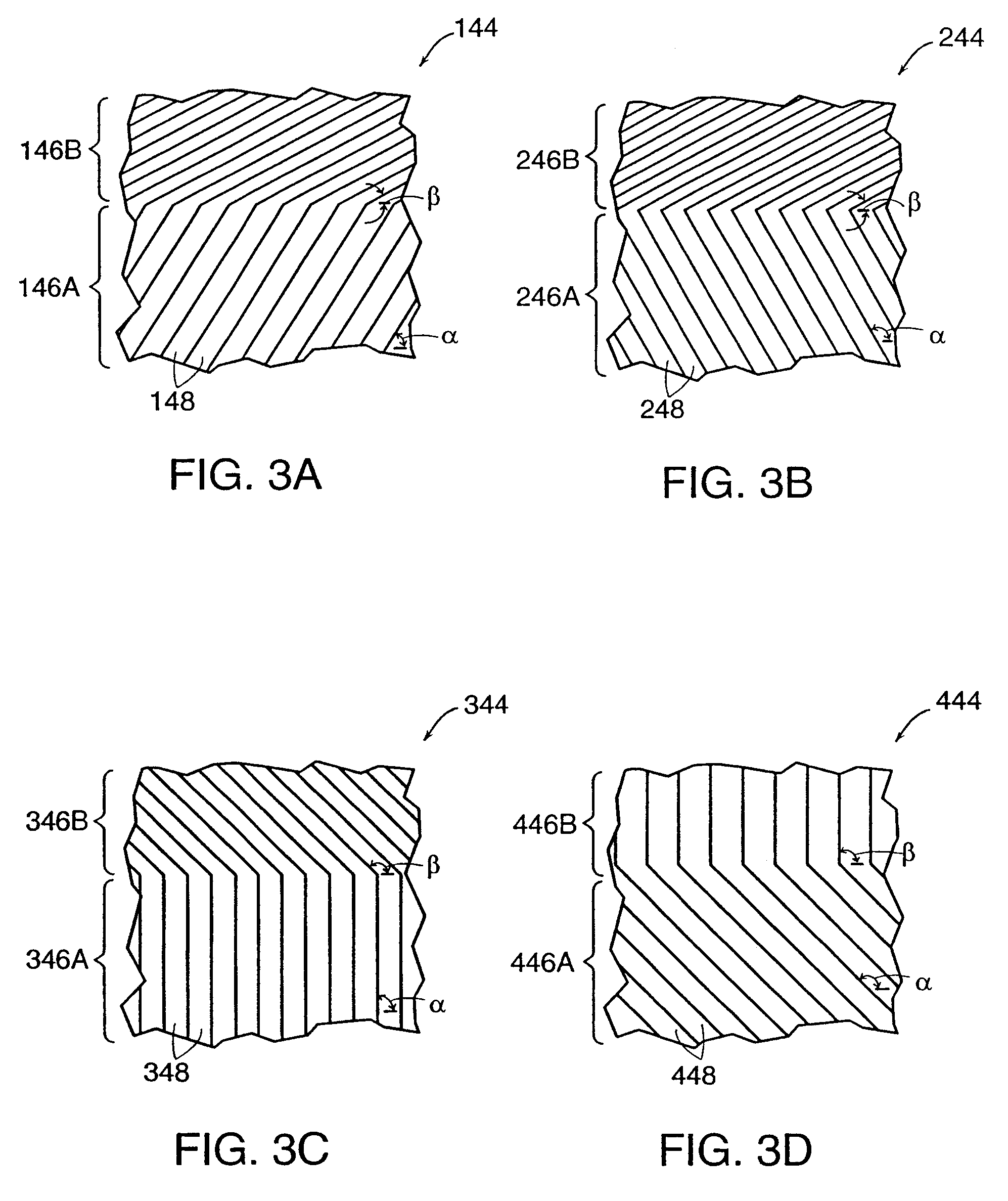

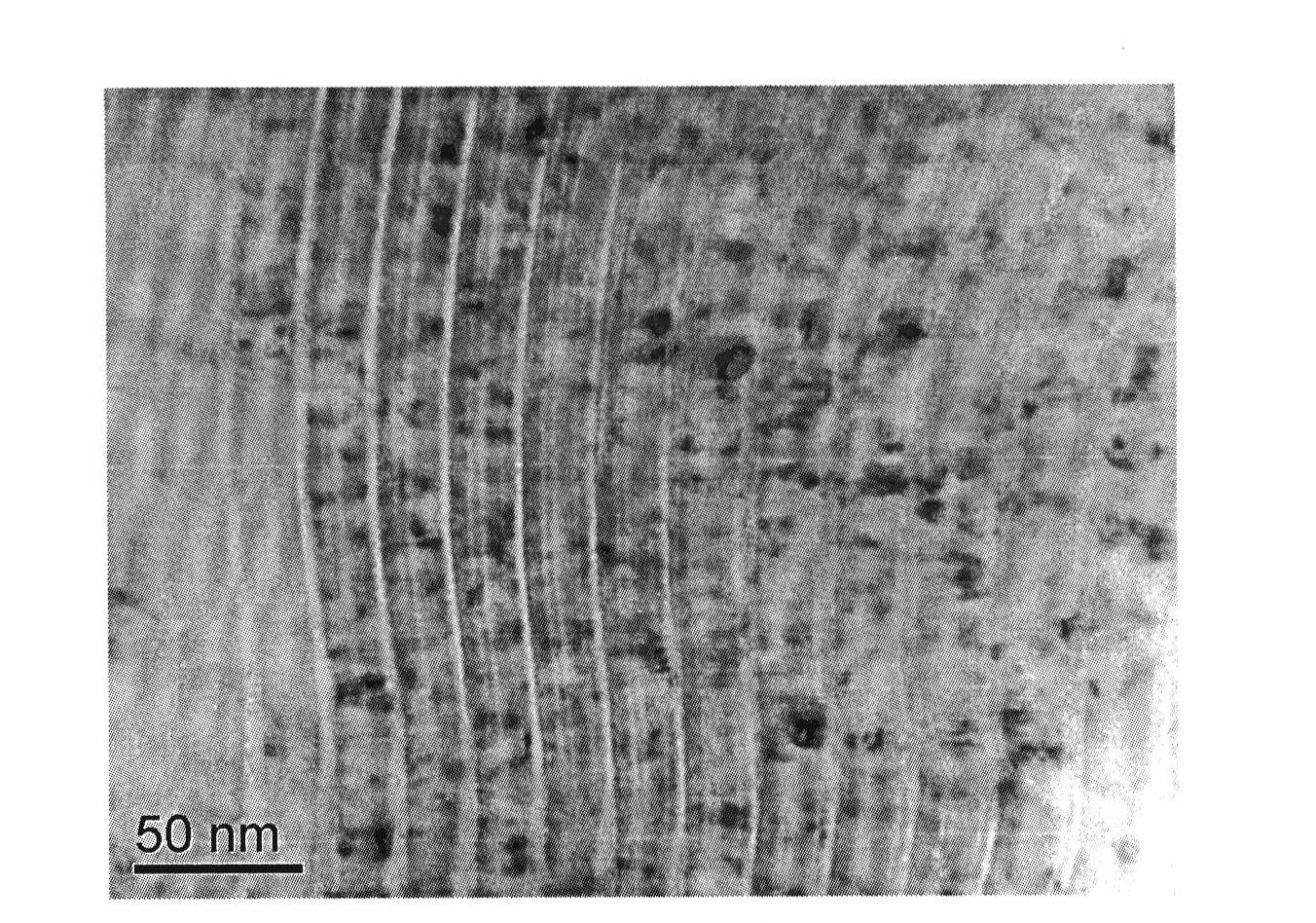

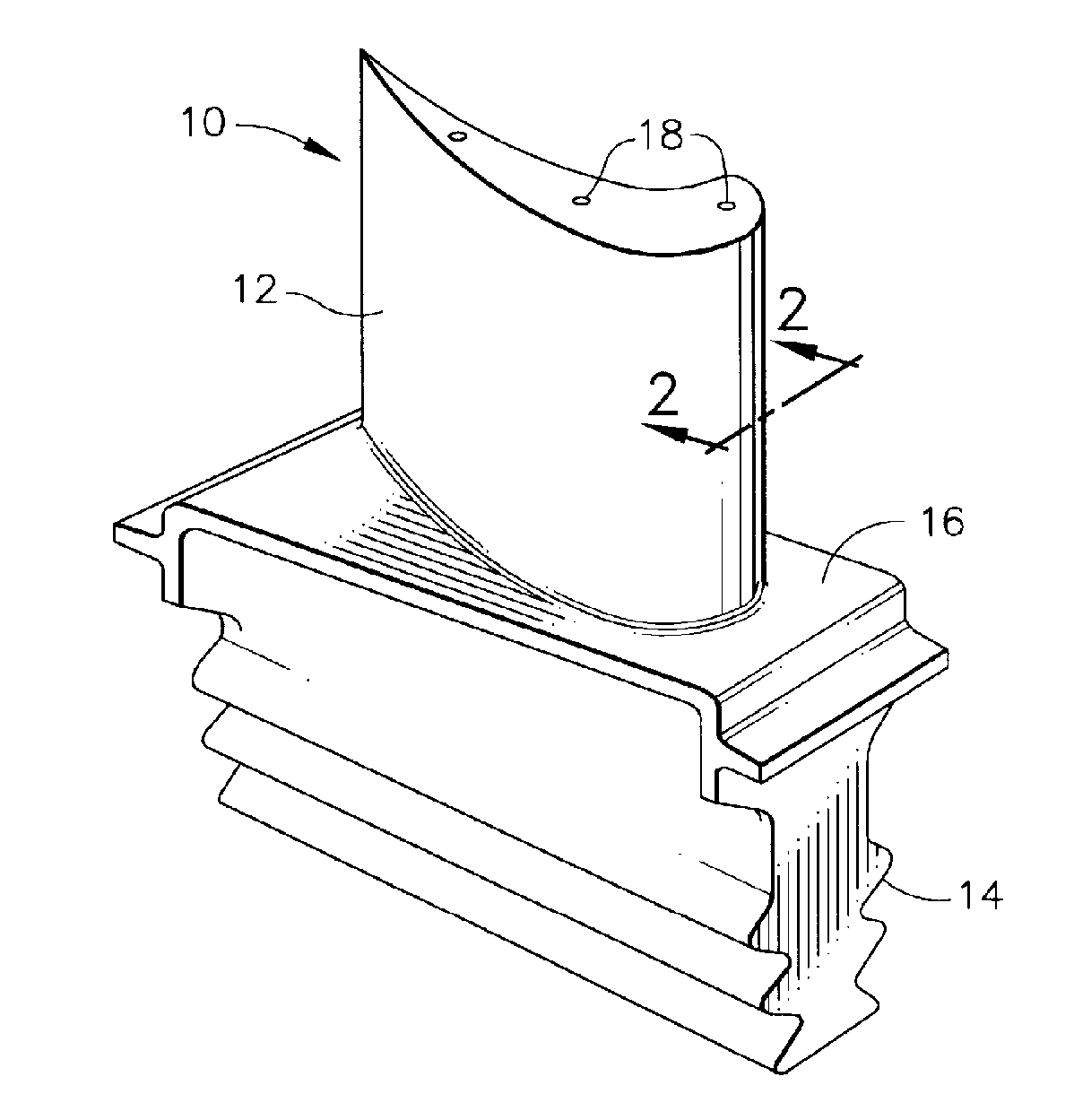

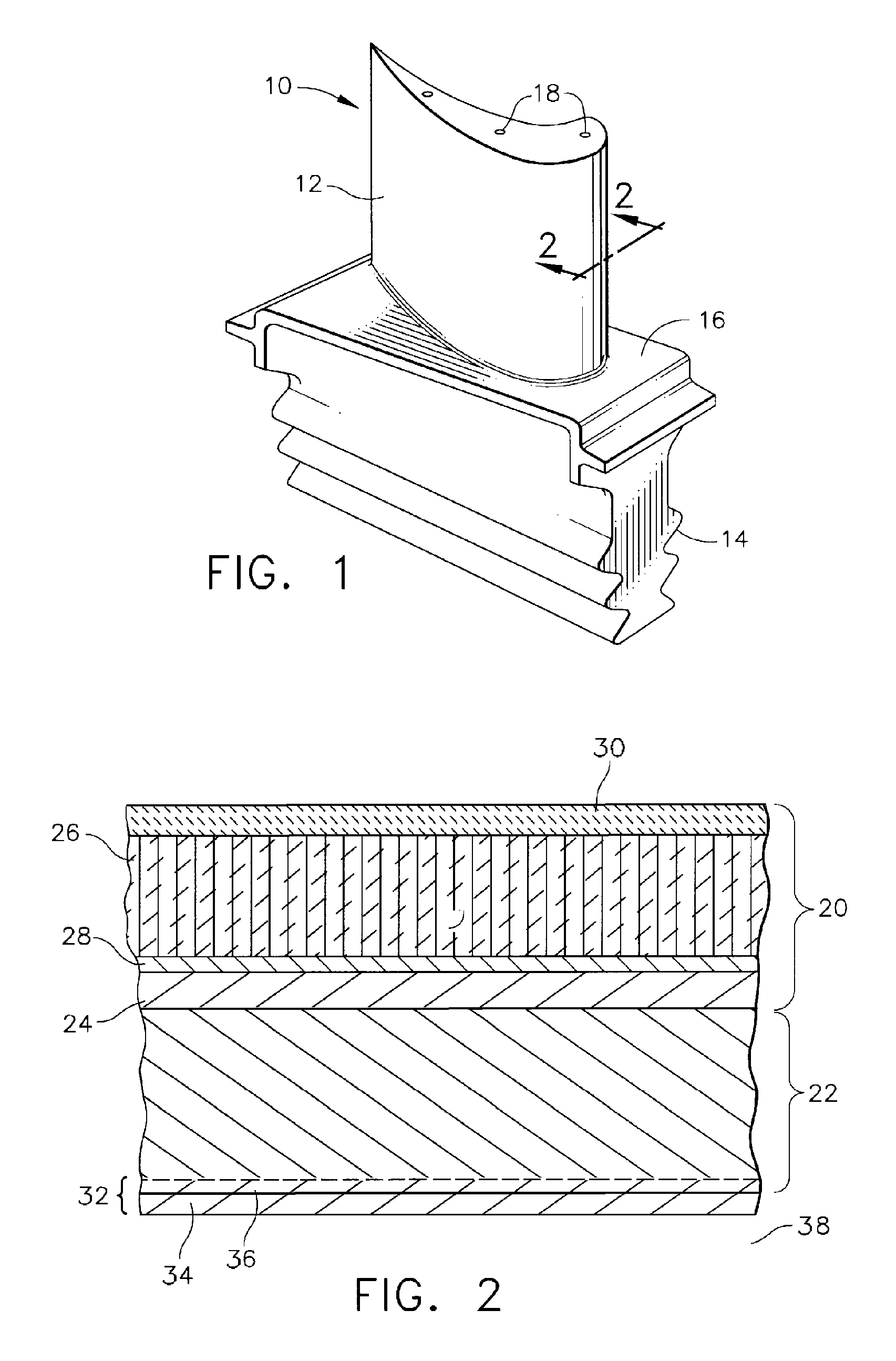

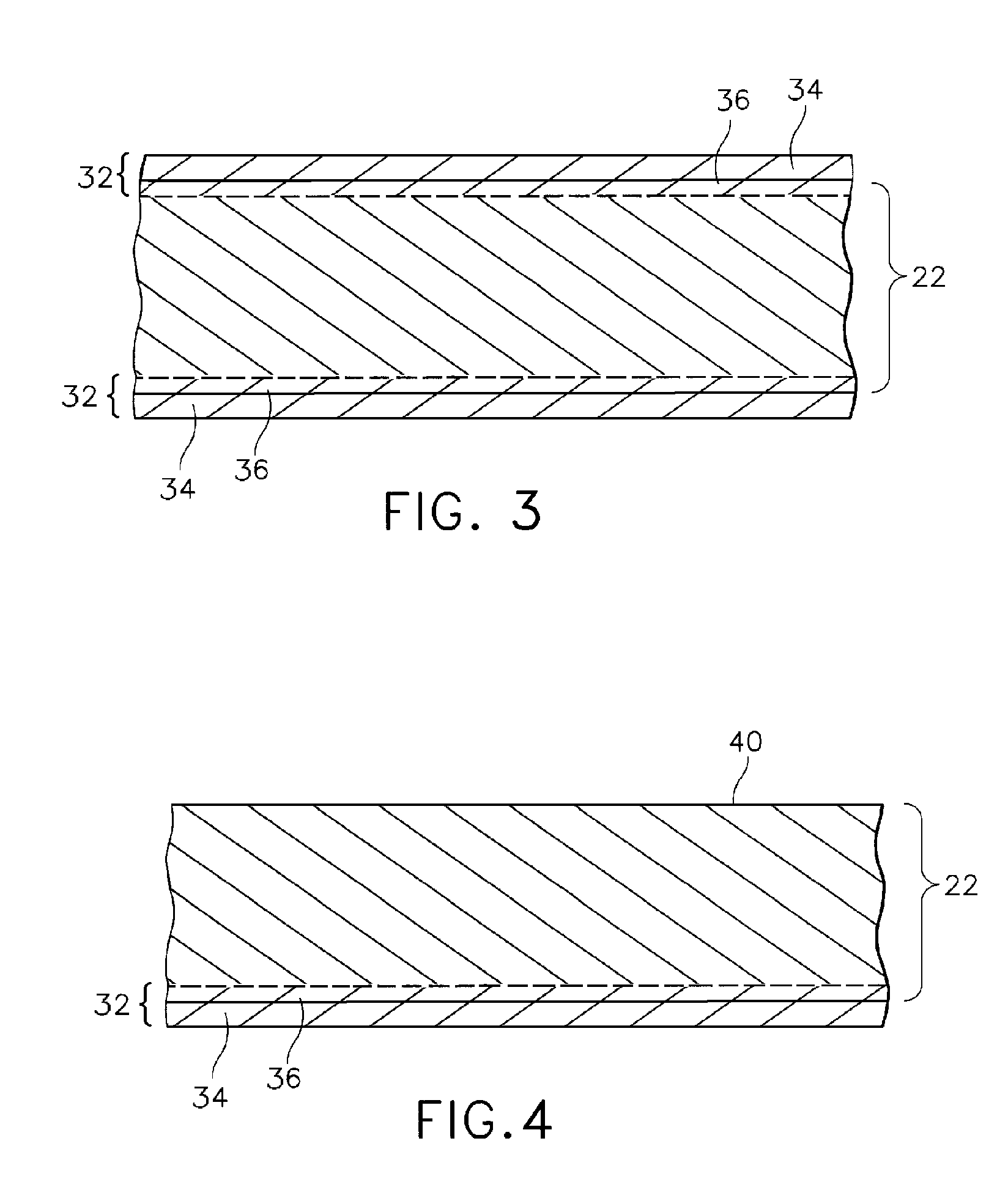

Thermal barrier coating ceramic structure

InactiveUS6455173B1PropellersSurface reaction electrolytic coatingElectron beam physical vapor depositionVapor cloud

A multilayered ceramic topcoat of a thermal barrier coating system is useful for high temperature corrosive applications such as hot section components in gas turbine engines. The ceramic topcoat includes at least two layers, each having generally columnar grain microstructures with different grain orientation directions. A preferred method of producing the multilayered ceramic topcoat includes positioning a superalloy substrate at a first angled orientation relative to a ceramic vapor cloud in an electron beam physical vapor deposition apparatus for a time sufficient to grow a first ceramic layer. The substrate is then reoriented to a second, different angled orientation for a time sufficient to grow a second ceramic layer. The ceramic layers exhibit columnar microstructures having respective grain orientation directions which are related to the first and second substrate orientations. For uniformly coating a complex contoured surface such as a turbine blade airfoil, the blade can be rotated during coating deposition at each angled orientation. Alternatively, the article may be continuously reoriented according to a predetermined speed cycle to produce generally arcuate, sinusoidal, helical, or other columnar grain microstructures.

Owner:MARIJNISSEN GILLION HERMAN +4

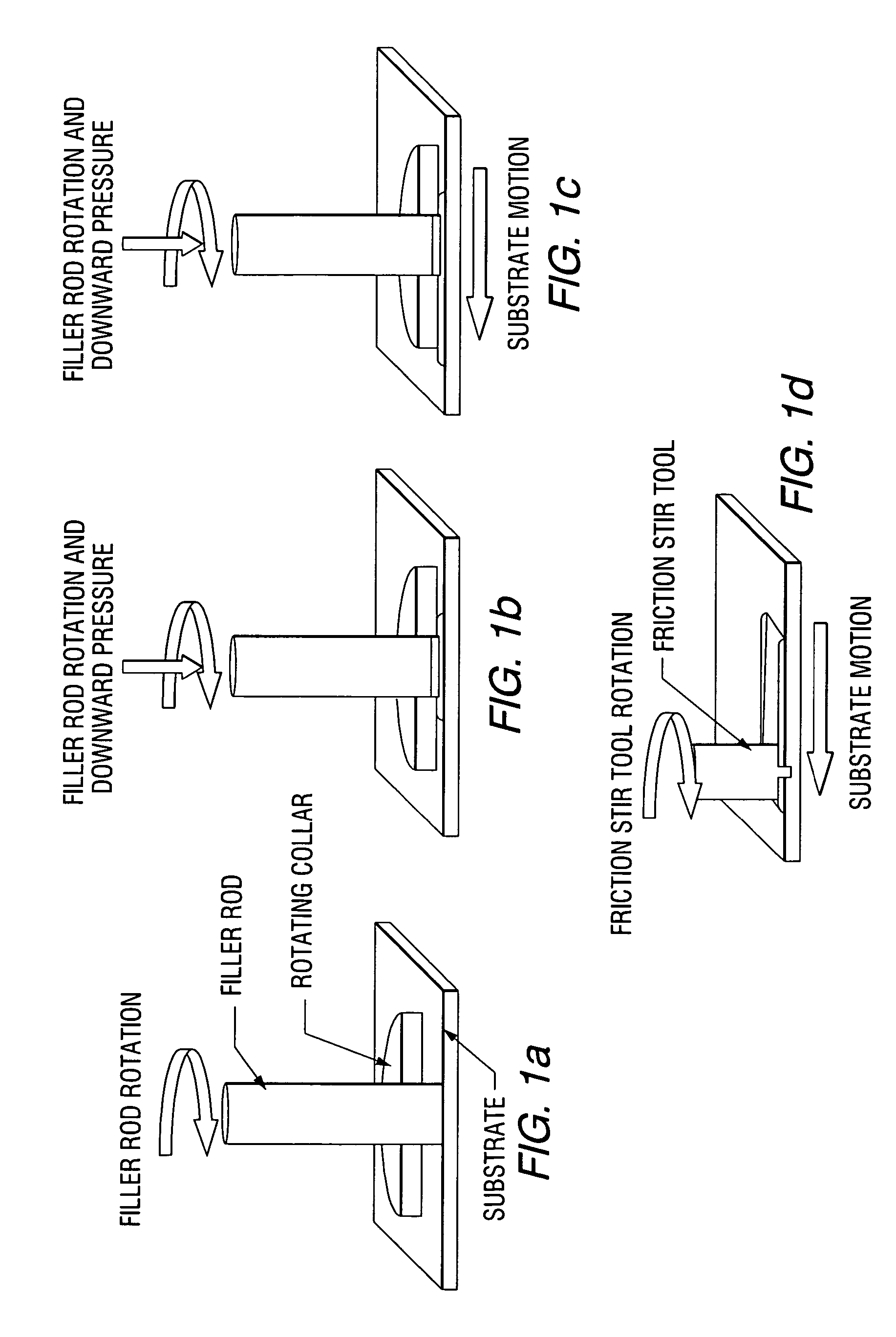

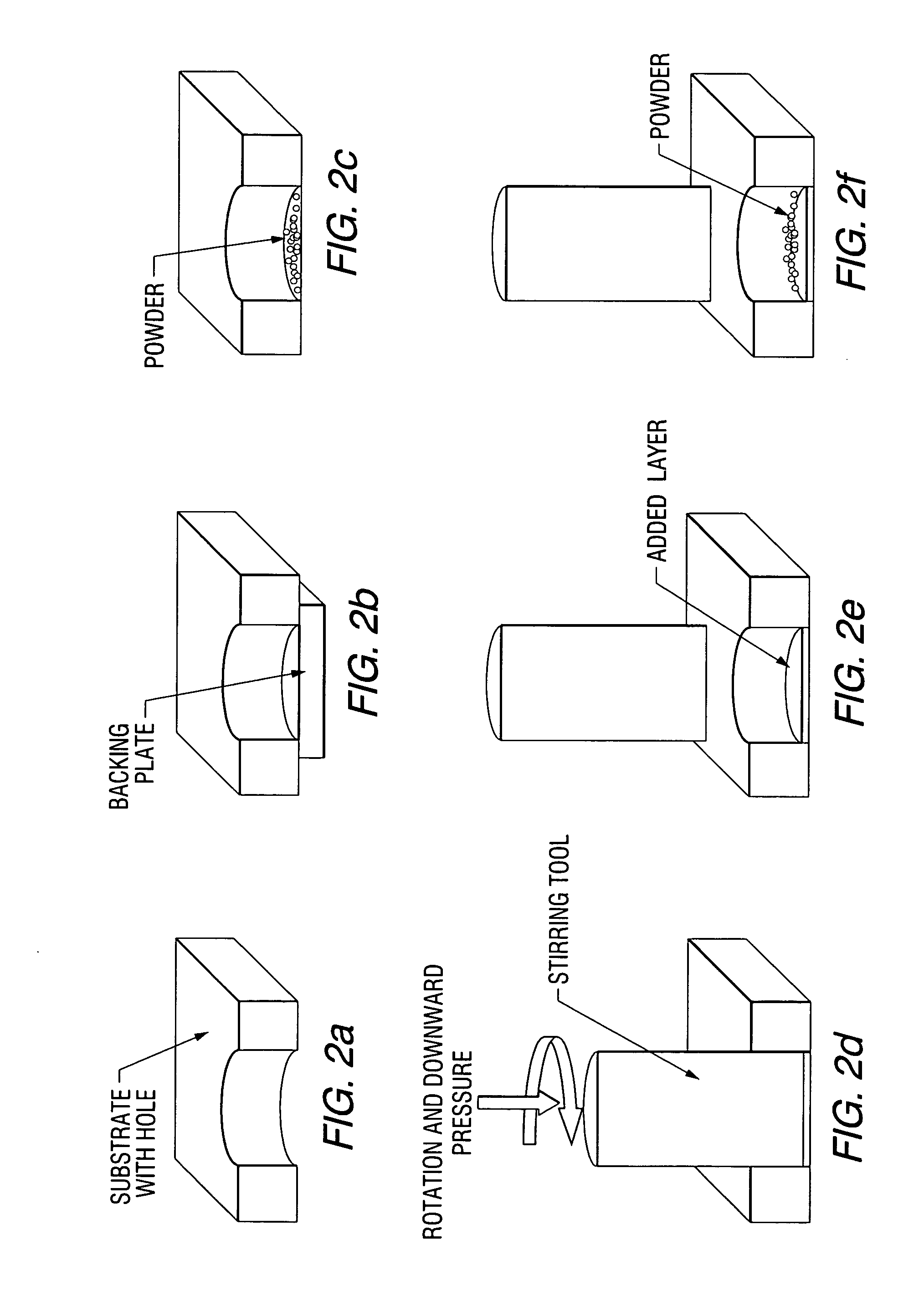

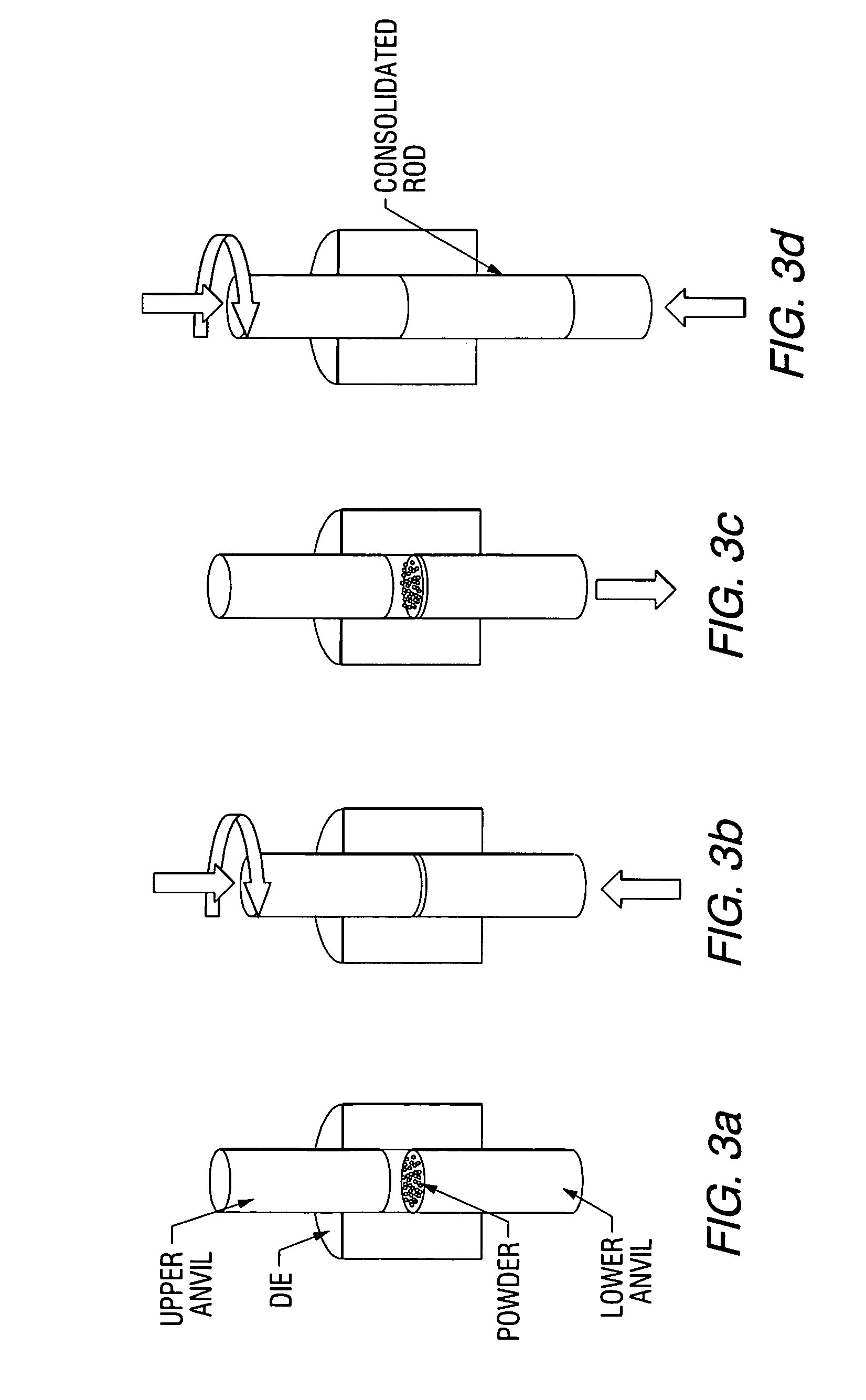

Friction stir fabrication

InactiveUS20080041921A1High bonding strengthHigh densityCooking-vessel materialsPressure inorganic powder coatingMetal matrix compositeFriction stir processing

A low-temperature friction-based coating method termed friction stir fabrication (FSF) is disclosed, in which material is deposited onto a substrate and subsequently stirred into the substrate using friction stir processing to homogenize and refine the microstructure. This solid-state process is capable of depositing coatings, including nanocrystalline aluminum and / or metal matrix composites and the like, onto substrates such as aluminum at relatively low temperatures. A method of making rod stock for use in the FSF process is also disclosed.

Owner:MELD MFG CORP

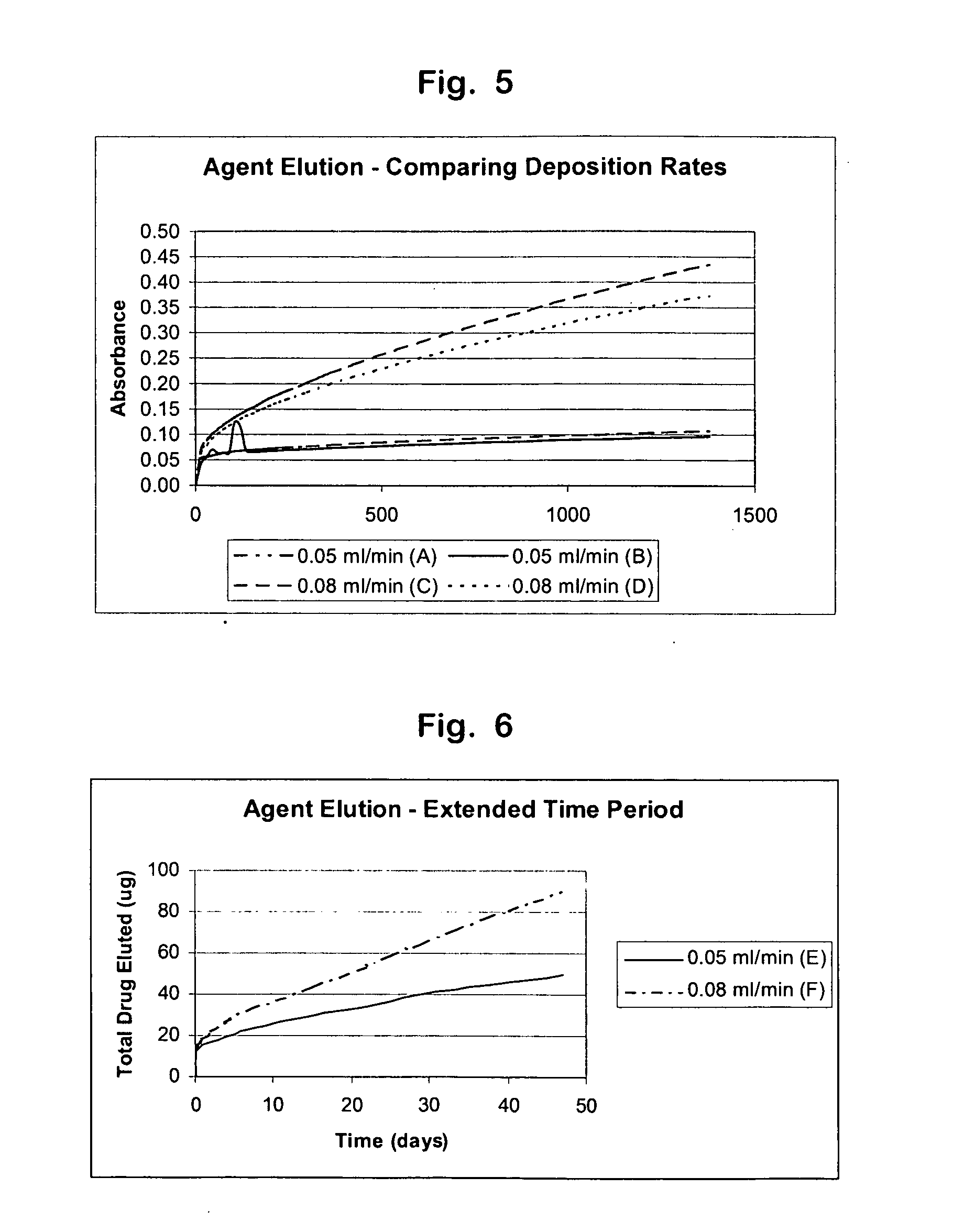

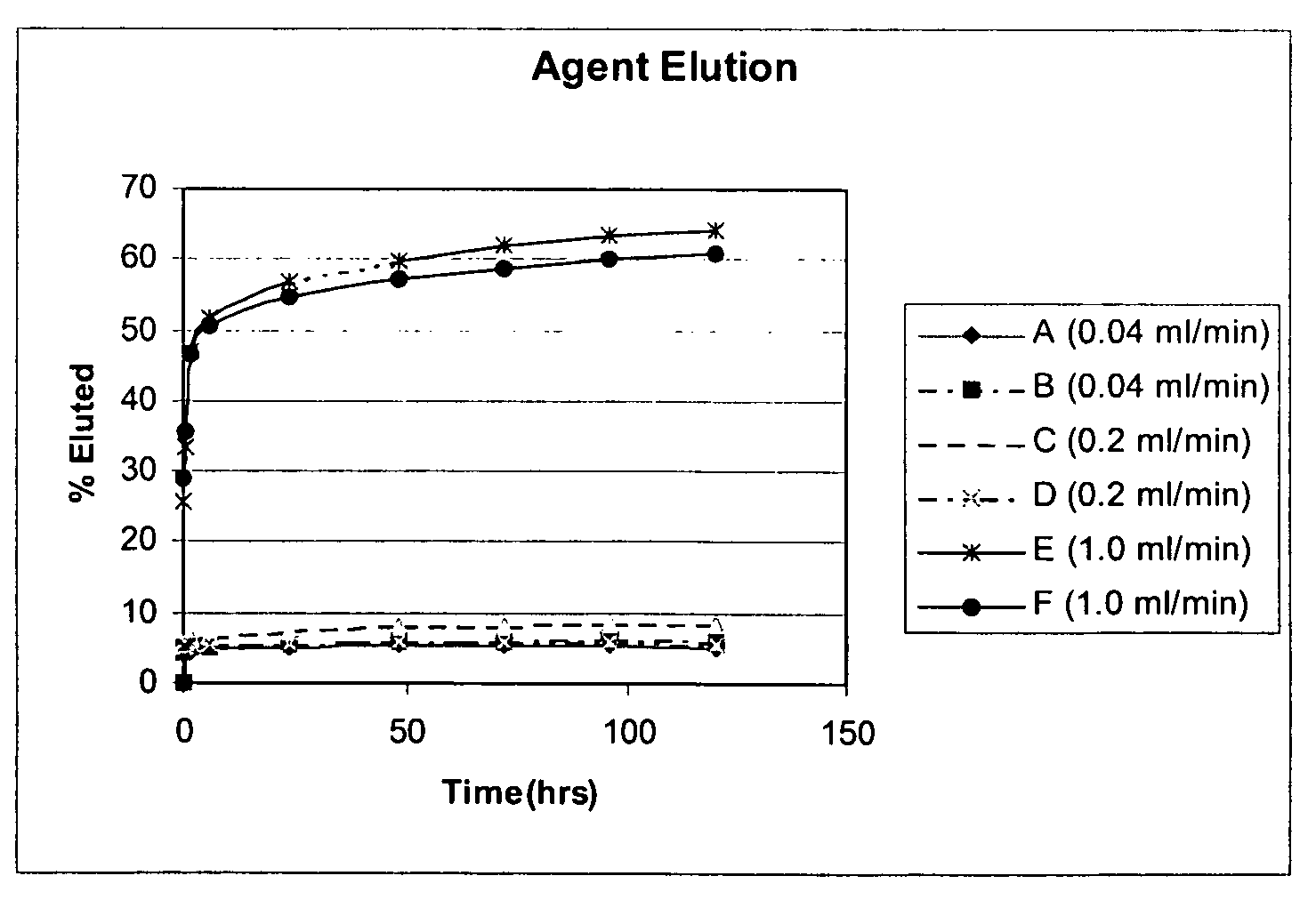

Methods, devices, and coatings for controlled active agent release

The present invention relates to methods, devices, and coatings, wherein active agent release is determined by deposition rate of a coating or material. In an embodiment, the invention includes a method for coating a medical device, including identifying active agent elution rates for a coating composition applied to substrates at a plurality of coating deposition rates, selecting one of the coating deposition rates, and applying the coating composition to the medical device at the selected deposition rate. In an embodiment, the invention includes a combination including a medical device and a composition for coating the surface of a medical device with an active agent in a manner that permits the coated surface to release the active agent over time when implanted in vivo.

Owner:SURMODICS INC

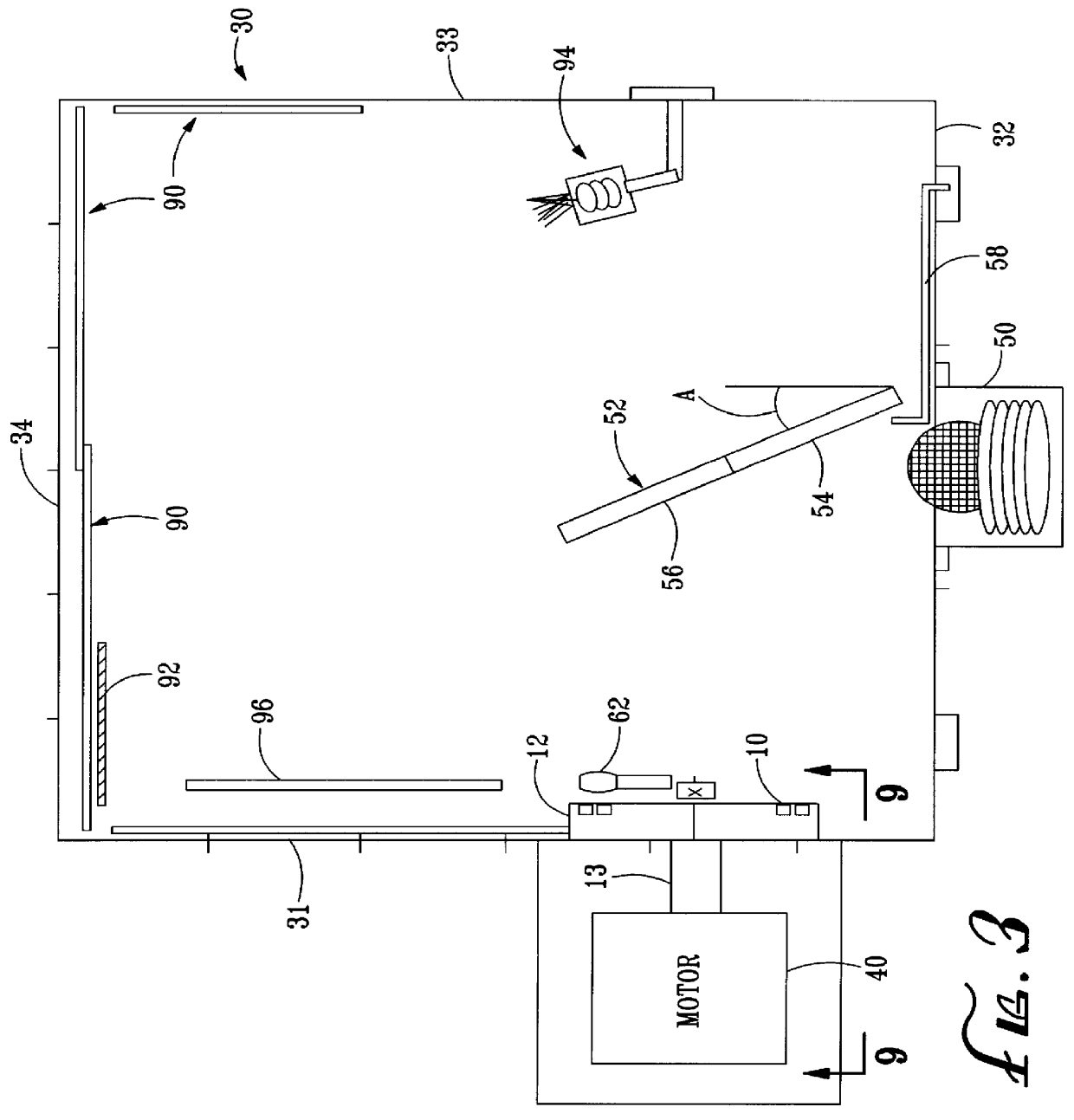

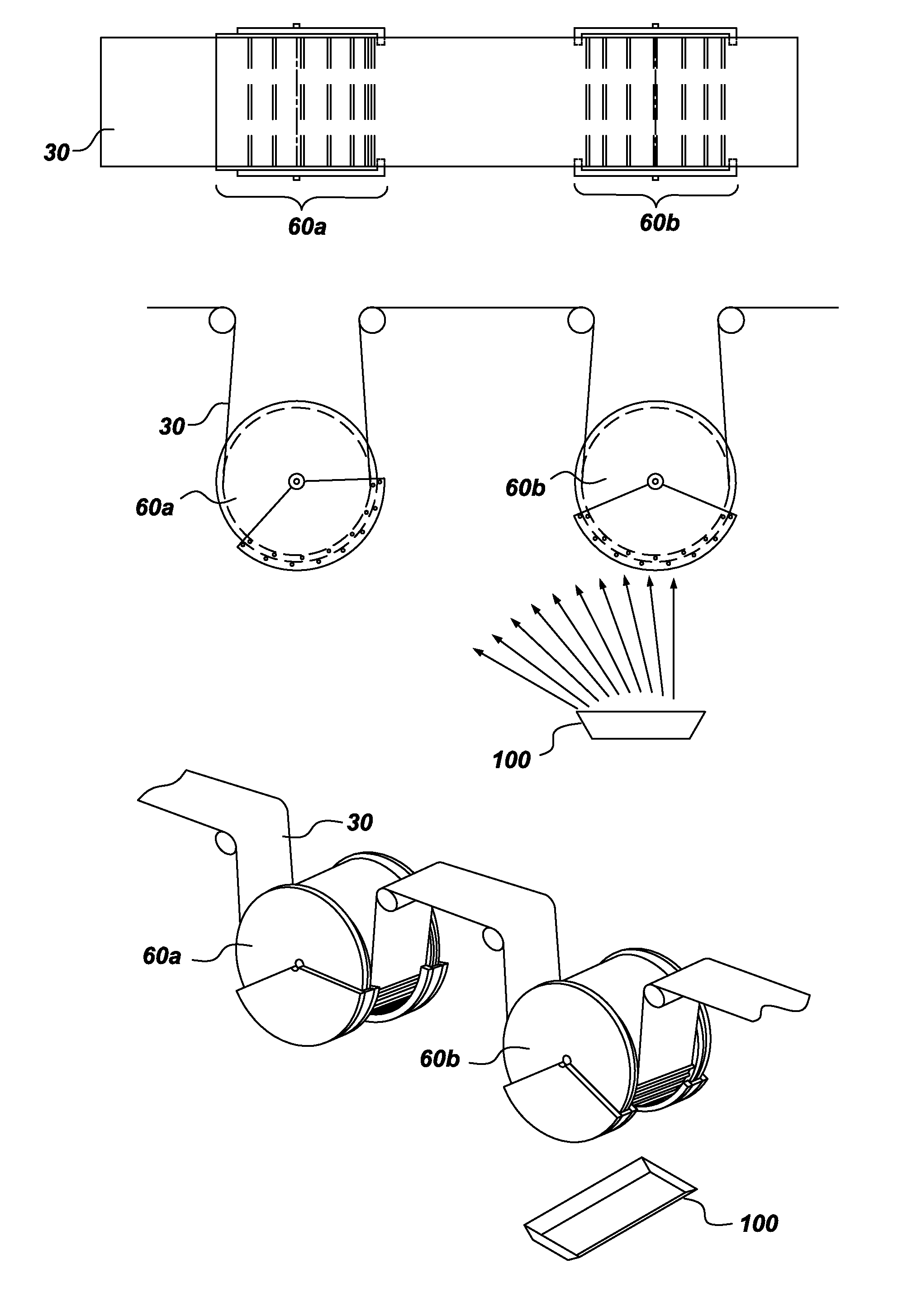

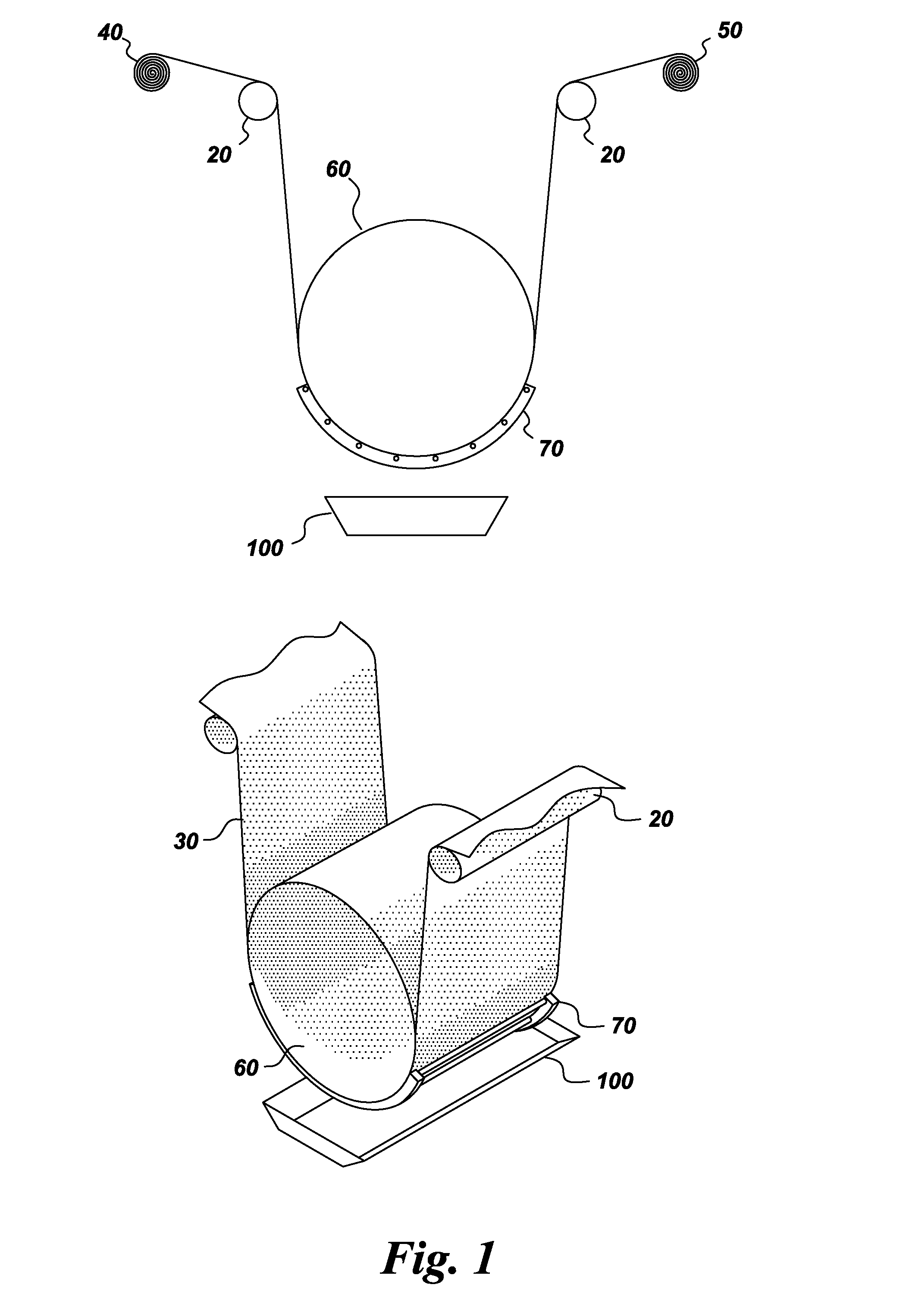

Use of multiple masks to control uniformity in coating deposition

The uniformity of individual layers of multiple coating materials deposited on a substrate in a vacuum deposition process (such as for manufacturing mirrors for use in ring laser gyroscopes) is improved by an apparatus and method that include changing the masks placed in front of the substrate upon which the coating materials are to be deposited. Separate masks are tuned for each particular coating material to compensate for the unique plume shape of the material, and provide a uniform deposition of that particular coating material. Each mask is positioned in front of the substrate when the material for which the mask has been tuned is being deposited. The masks are changed when the coating material is changed, without venting the chamber.

Owner:NORTHROP GRUMMAN SYST CORP

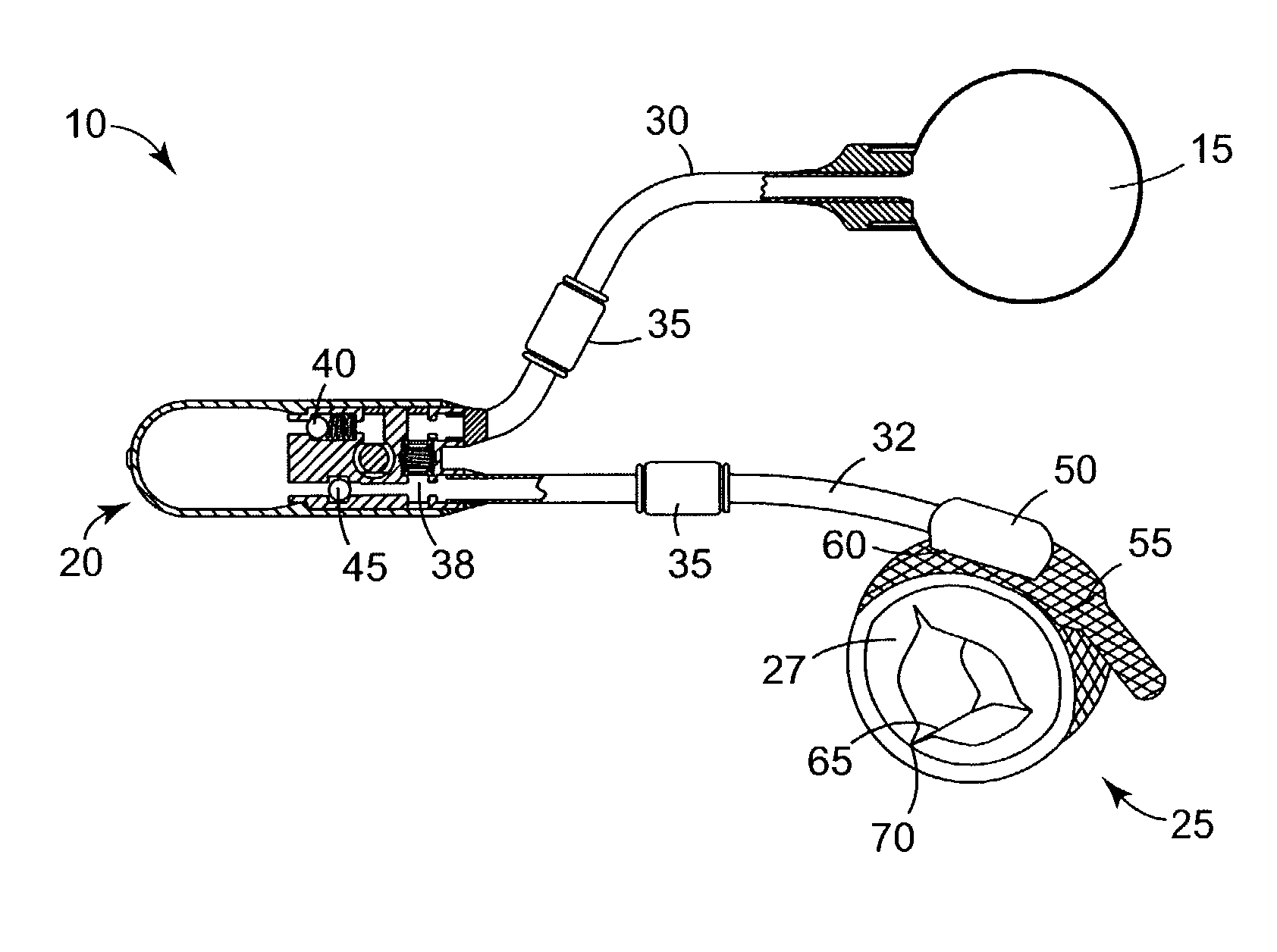

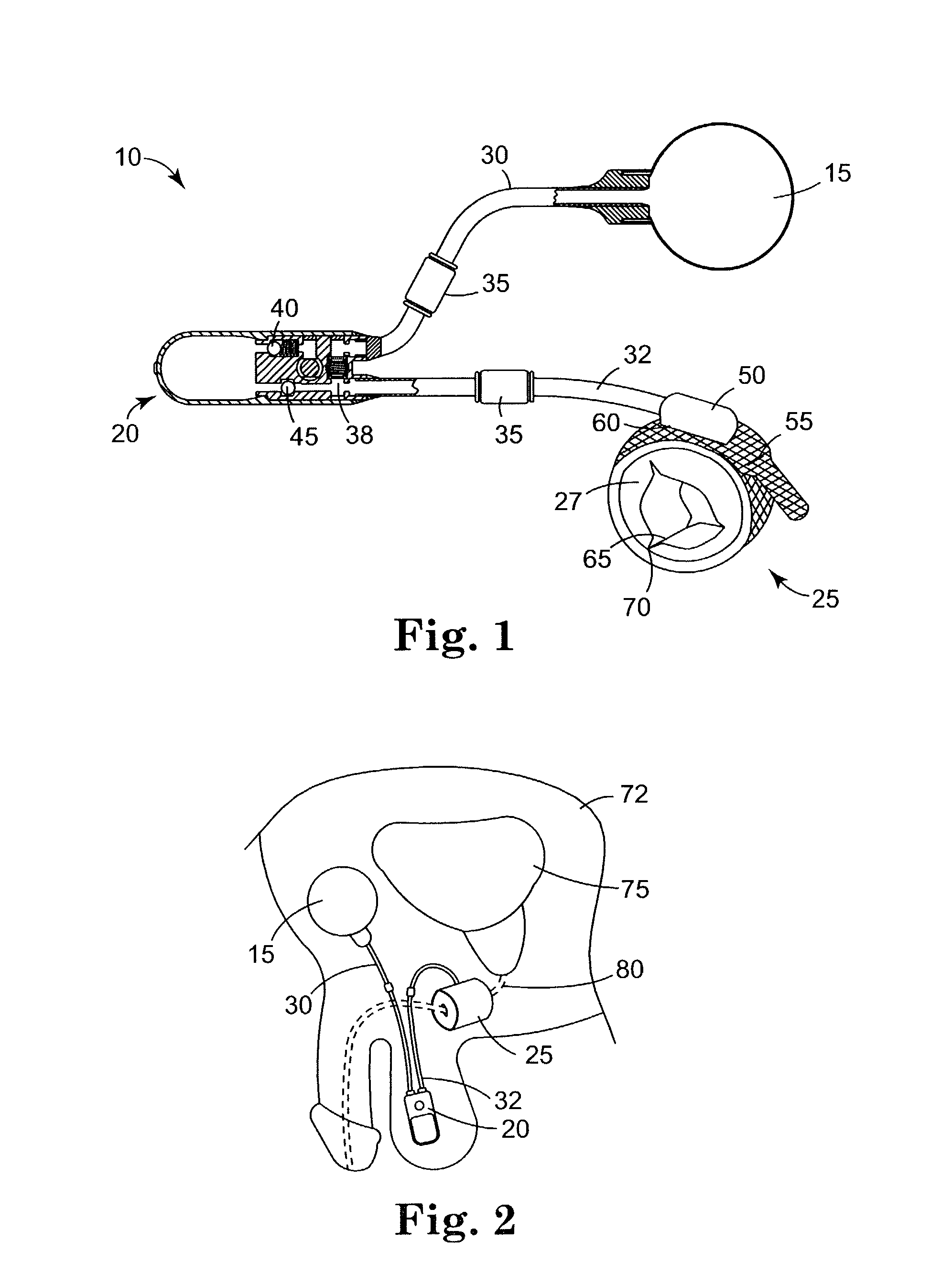

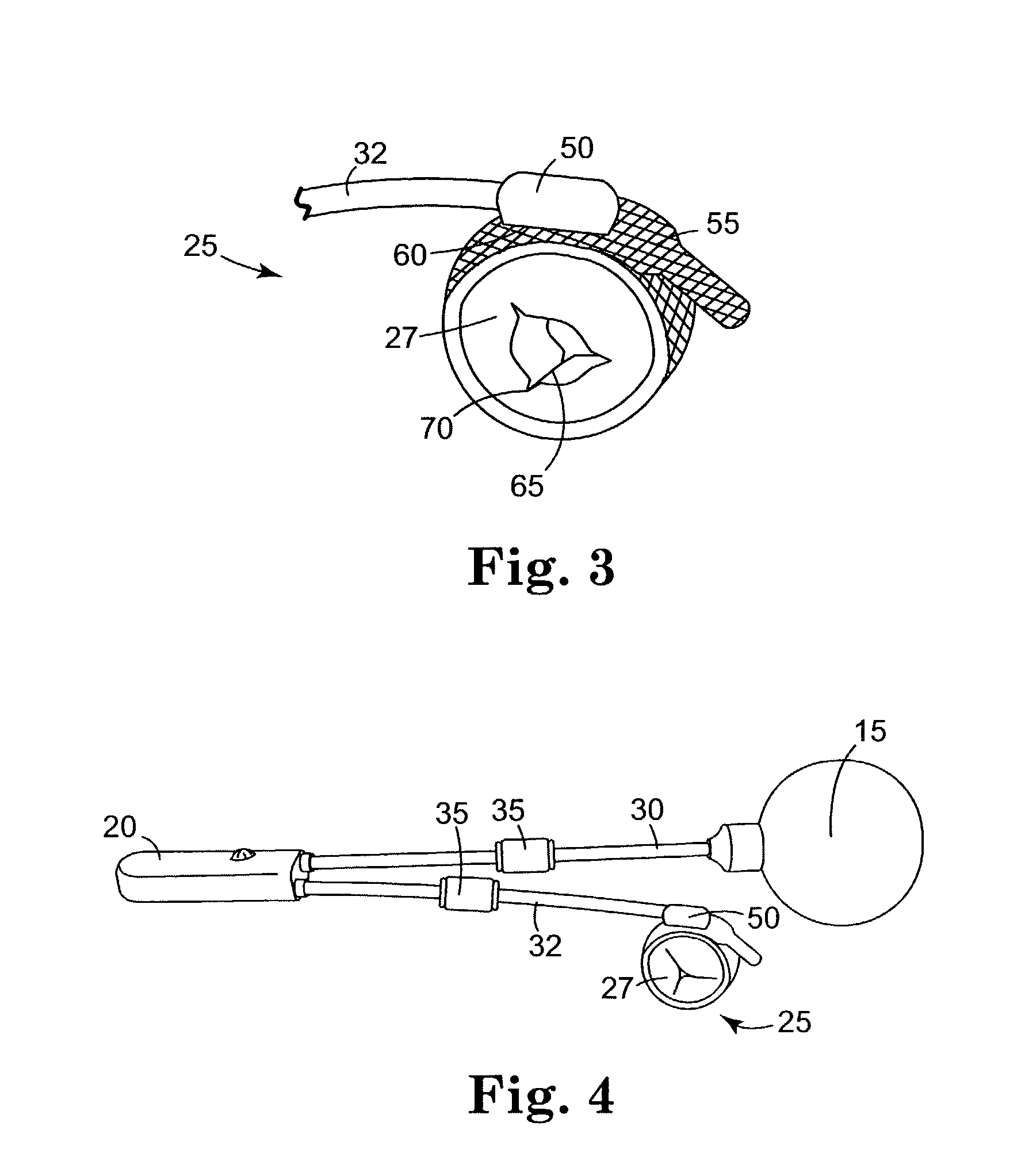

Parylene coated components for artificial sphincters

InactiveUS7011622B2Prevent and inhibit wearPrevent and inhibit and abrasionAnti-incontinence devicesSurgeryParylene coatingVacuum chamber

This invention provides an artificial sphincter including a component coated on at least one contacting surface with a polymeric material, the polymeric coating adapted to expand and return to an original configuration and to prevent or inhibit wear or abrasion of the contacting surface. The polymeric material is parylene in some embodiments. The component adapted for inflation and deflation may be a cuff formed from silicon and adapted to surround a urethra or a rectum. Also provided by the present invention is a method of depositing a coating to a surface of an inflatable component by providing a vacuum chamber system having an inner chamber positioned within an outer chamber. At least one coating material is introduced into at least one of the inner and outer chambers to deposit a coating onto an exposed surface of the component. This invention also provides methods of masking portions of surfaces of an inflatable component to prevent a coating from being deposited on the masked portion.

Owner:BOSTON SCI SCIMED INC

Flash evaporation-plasma coating deposition method

The present invention provides a method for the formation of an organic coating on a substrate. The method includes: providing a substrate in a vacuum; providing at least one vaporized organic material comprising at least one component from at least one source, wherein the vaporized organic material is capable of condensing in a vacuum of less than about 130 Pa; providing a plasma from at least one source other than the source of the vaporized organic material; directing the vaporized organic material and the plasma toward the substrate; and causing the vaporized organic material to condense and polymerize on the substrate in the presence of the plasma to form an organic coating.

Owner:3M INNOVATIVE PROPERTIES CO

Methods, devices, and coatings for controlled active agent release

The present invention relates to methods, devices, and coatings, wherein active agent release is determined by deposition rate of a coating or material. In an embodiment, the invention includes a method for coating a medical device, including identifying active agent elution rates for a coating composition applied to substrates at a plurality of coating deposition rates, selecting one of the coating deposition rates, and applying the coating composition to the medical device at the selected deposition rate. In an embodiment, the invention includes a combination including a medical device and a composition for coating the surface of a medical device with an active agent in a manner that permits the coated surface to release the active agent over time when implanted in vivo.

Owner:SURMODICS INC

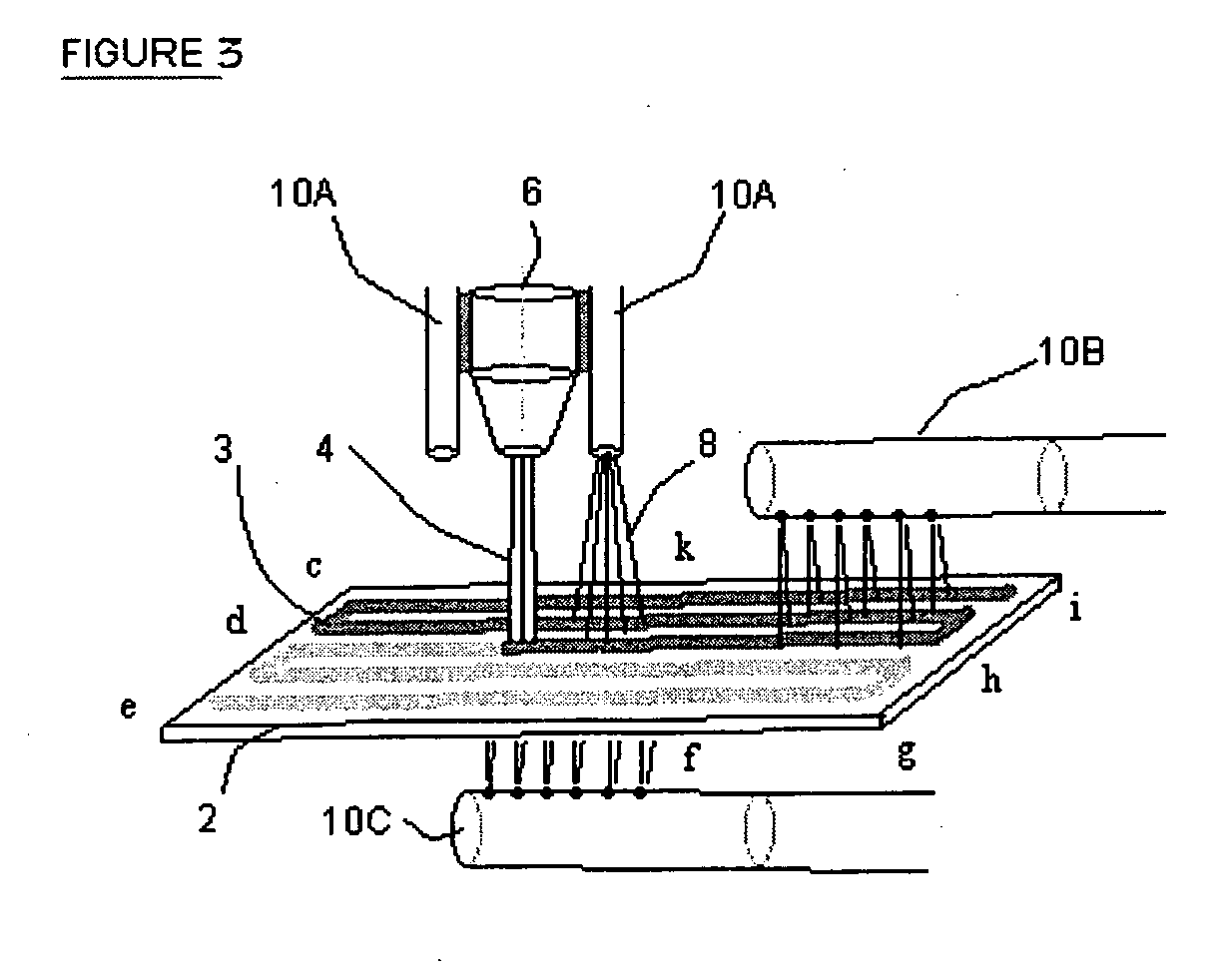

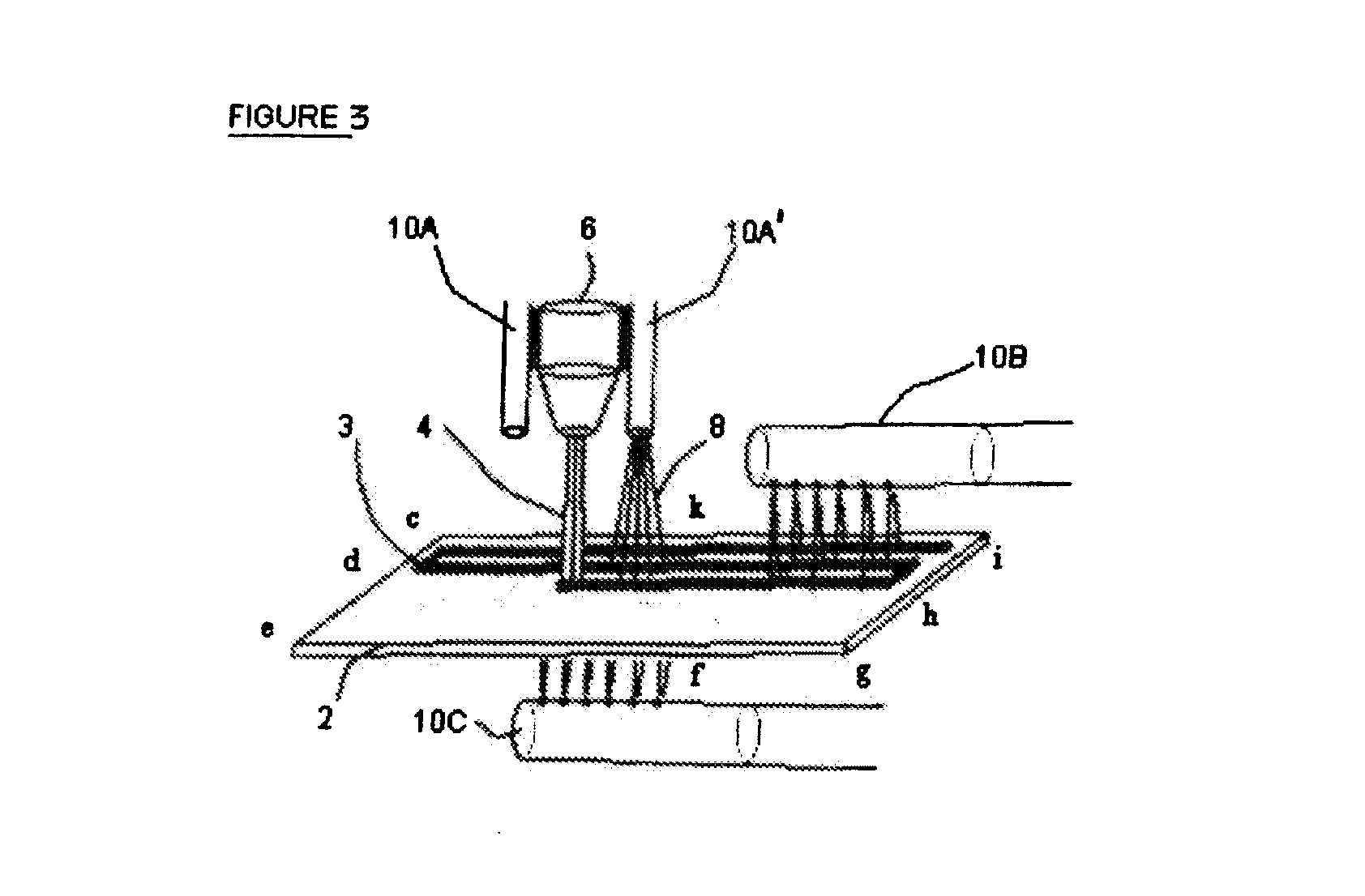

Thermal Deposition Surface Treatment Method, System and Product

ActiveUS20080087359A1Increase ratingsDamaging internal stressLiquid surface applicatorsMolten spray coatingThermal depositionCoolant flow

A process for treating a workpiece, said process comprising the steps of: (c) altering the temperature of a workpiece surface wherein at least one condition selected from the group of: thermal treatment rate, relative motion between the surface and said thermal treatment rate, coolant flow rate onto said surface, heating flow rate onto said surface and the relative speed between the heating means or the cooling means and the surface is controllable; (d) simultaneously measuring temperatures at a plurality of locations over the surface of the workpiece; (c) determining an average temperature of the temperatures measured in step (b); (d) comparing the average temperature to a preselected minimum temperature and a preselected maximum temperature for the workpiece; and (e) automatically adjusting at least one of the controllable conditions if said average temperature is not between the preselected minimum temperature and the preselected maximum temperature for the workpiece. A system for performing a thermal treatment process and the resulting product are also provided. Standard deviations of all temperature readings and controlling the relative motion speed between the thermal coating deposition head and the workpiece provide another improvement for obtaining temperature uniformity over the workpiece surface.

Owner:AIR PROD & CHEM INC

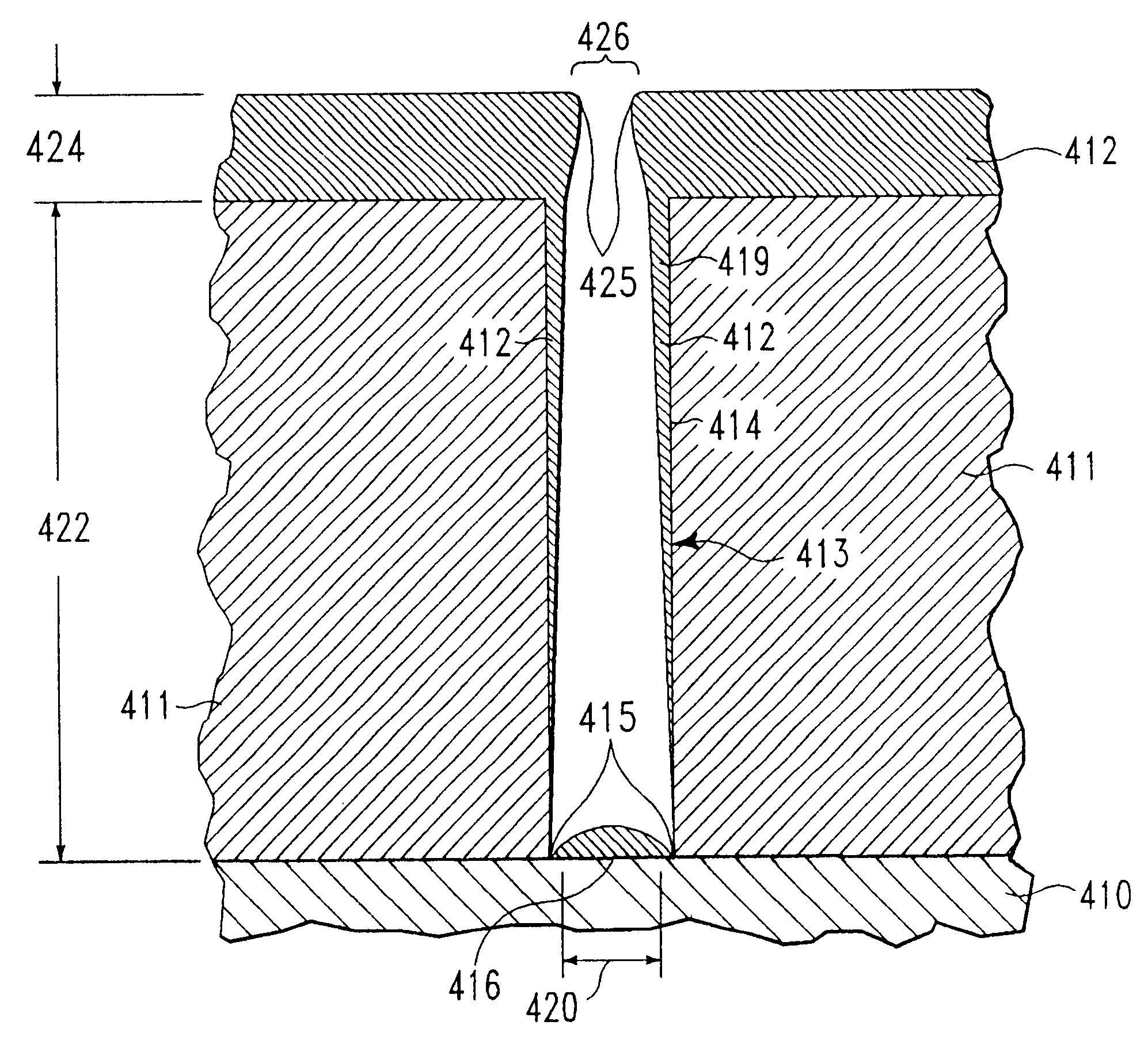

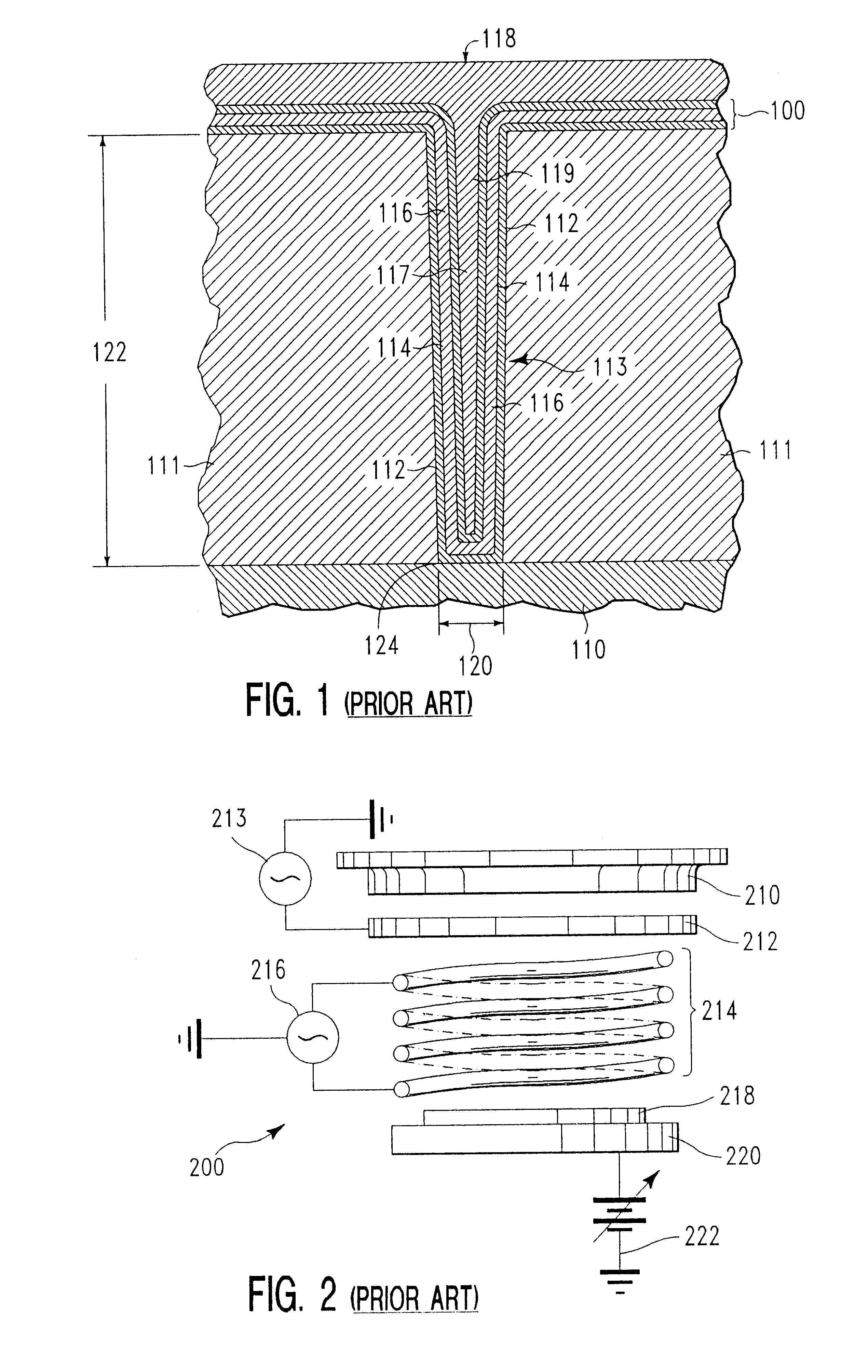

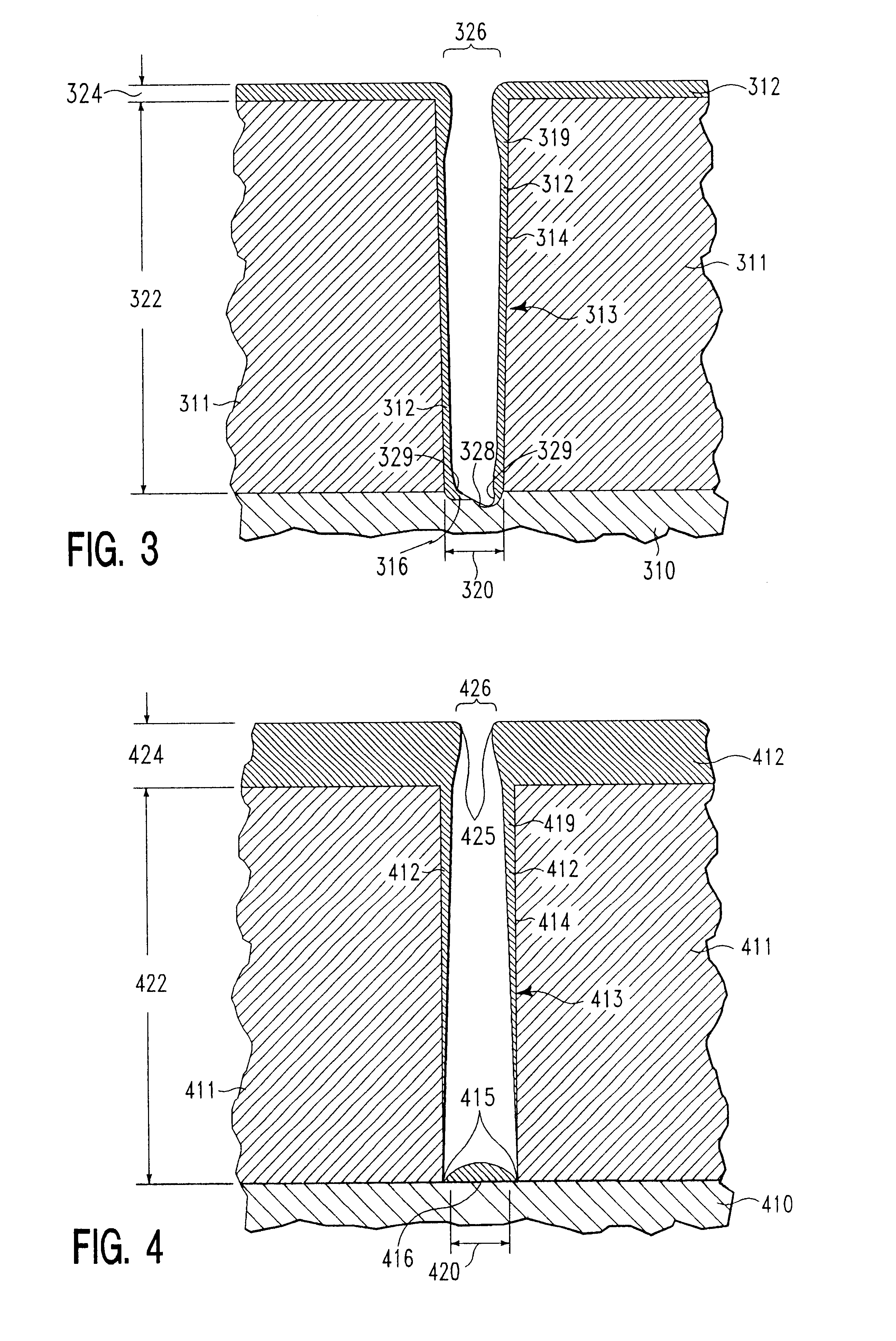

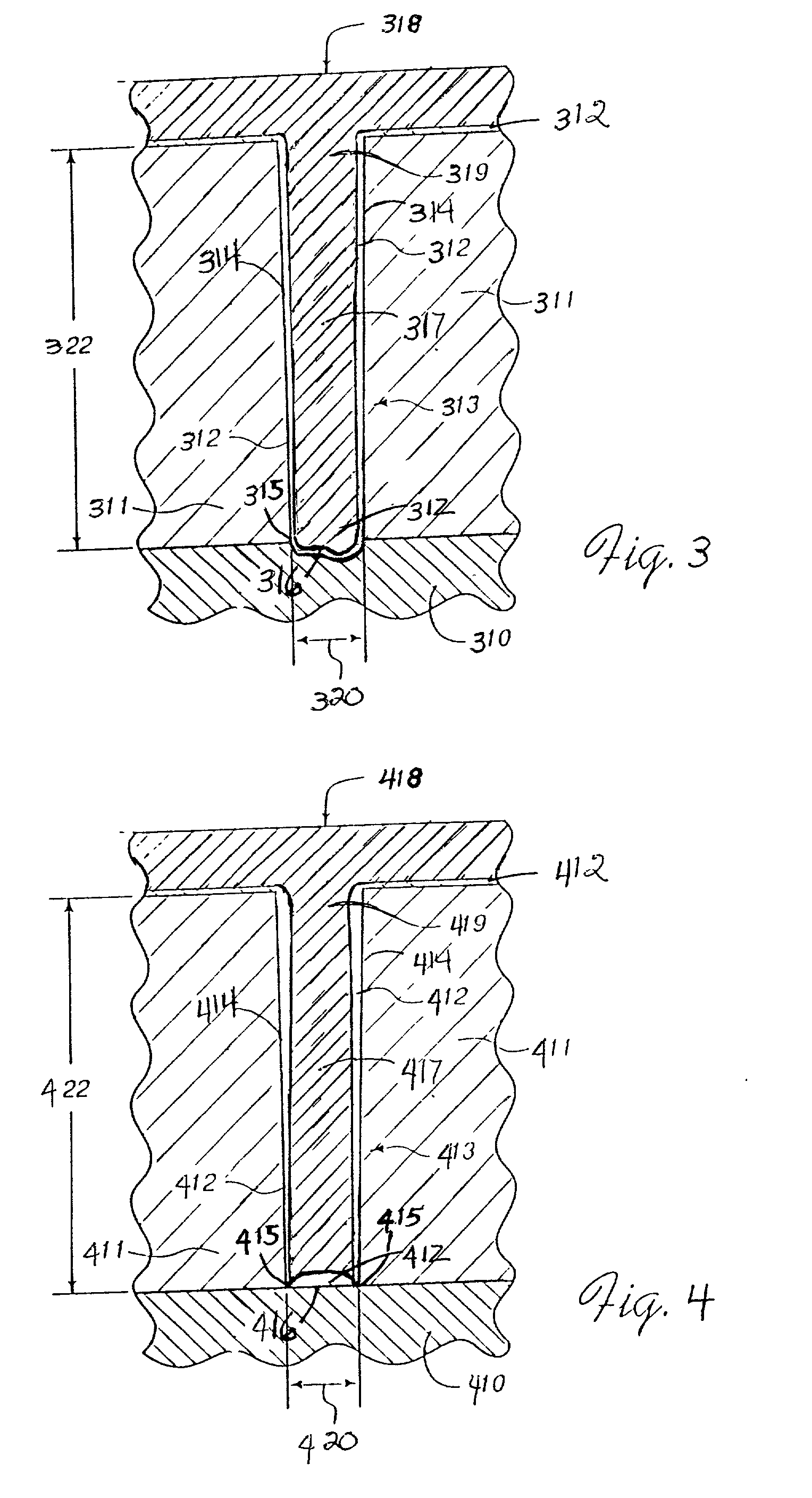

Damage-free sculptured coating deposition

We disclose a method of applying a sculptured layer of material on a semiconductor feature surface using ion deposition sputtering, wherein a surface onto which the sculptured layer is applied is protected to resist erosion and contamination by impacting ions of a depositing layer. A first protective layer of material is deposited on a substrate surface using traditional sputtering or ion deposition sputtering, in combination with sufficiently low substrate bias that a surface onto which the layer is applied is not eroded away or contaminated during deposition of the protective layer. Subsequently, a sculptured second layer of material is applied using ion deposition sputtering at an increased substrate bias, to sculpture a shape from a portion of the first protective layer of material and the second layer of depositing material. The method is particularly applicable to the sculpturing of barrier layers, wetting layers, and conductive layers upon semiconductor feature surfaces.

Owner:APPLIED MATERIALS INC

Chromium nitride aluminum-titanium composite coating, cutter deposited with same, and preparation method

InactiveCN102166849AHigh hardnessStrong adhesionVacuum evaporation coatingSputtering coatingOxidation resistantHigh surface

The invention discloses a chromium nitride aluminum-titanium composite coating, a cutter deposited with the same, and a preparation method. A Cr bonding layer, a CrN supporting layer and a main wear-resistant layer are sequentially deposited on a cutter substrate, wherein the main wear-resistant layer is a multi-layer composite coating composed of a TiAlN layer in a nanocrystalline structure and a CrTiAlN layer in a superlattice structure in an alternate mode, thereby obtaining the cutter with the chromium nitride aluminum-titanium composite coating. The chromium nitride aluminum-titanium composite coating provided by the invention combines the advantages of high hardness, low friction coefficient, strong adhesive force and high oxidation resistance temperature of the superlattice structure and nanocrystalline structure. The obtained cutter has high surface hardness, relatively strong film-base adhesive force, good wear resistance and good high temperature resistance.

Owner:YICHANG HOUHUANG VACUUM TECH

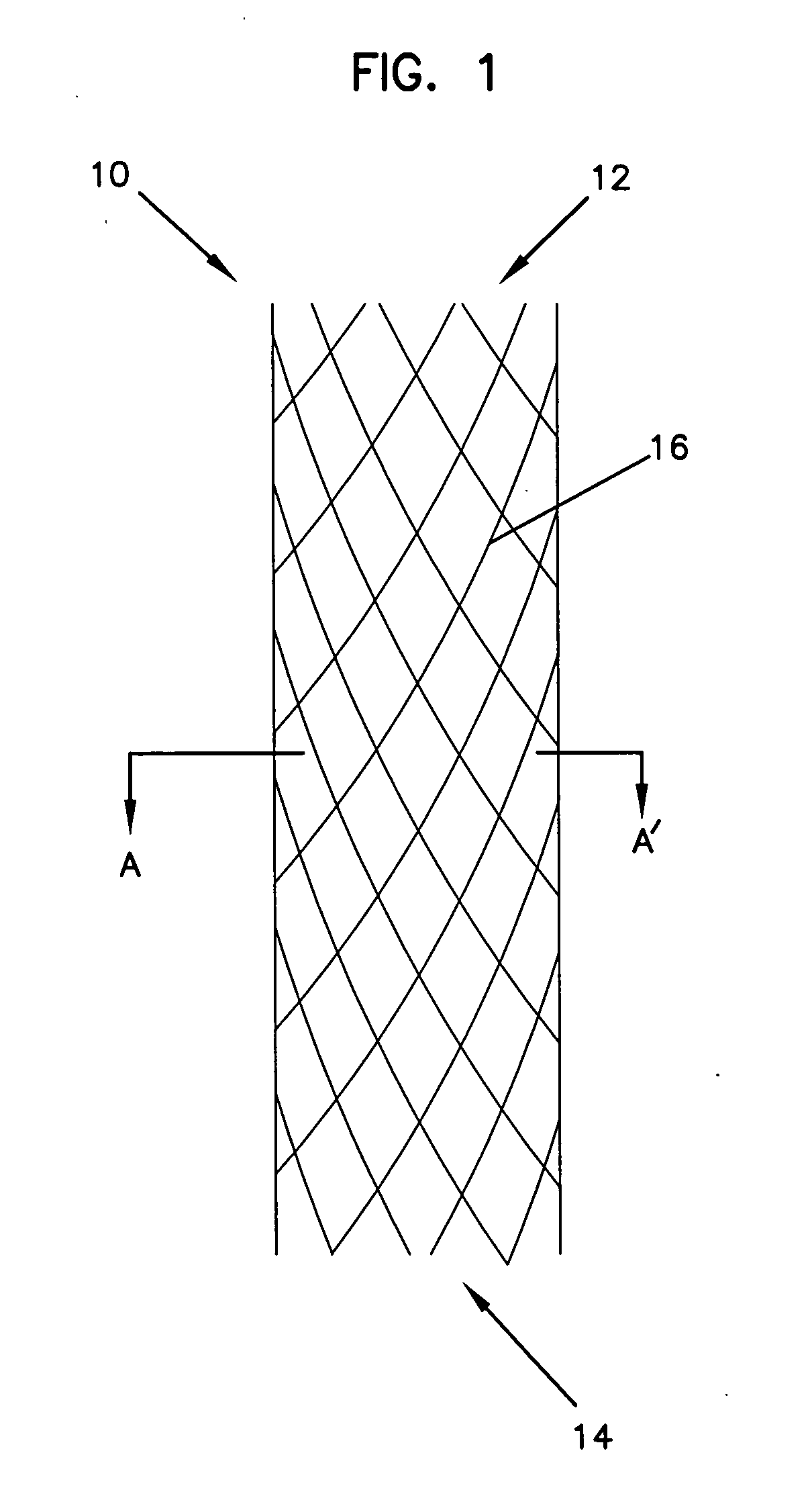

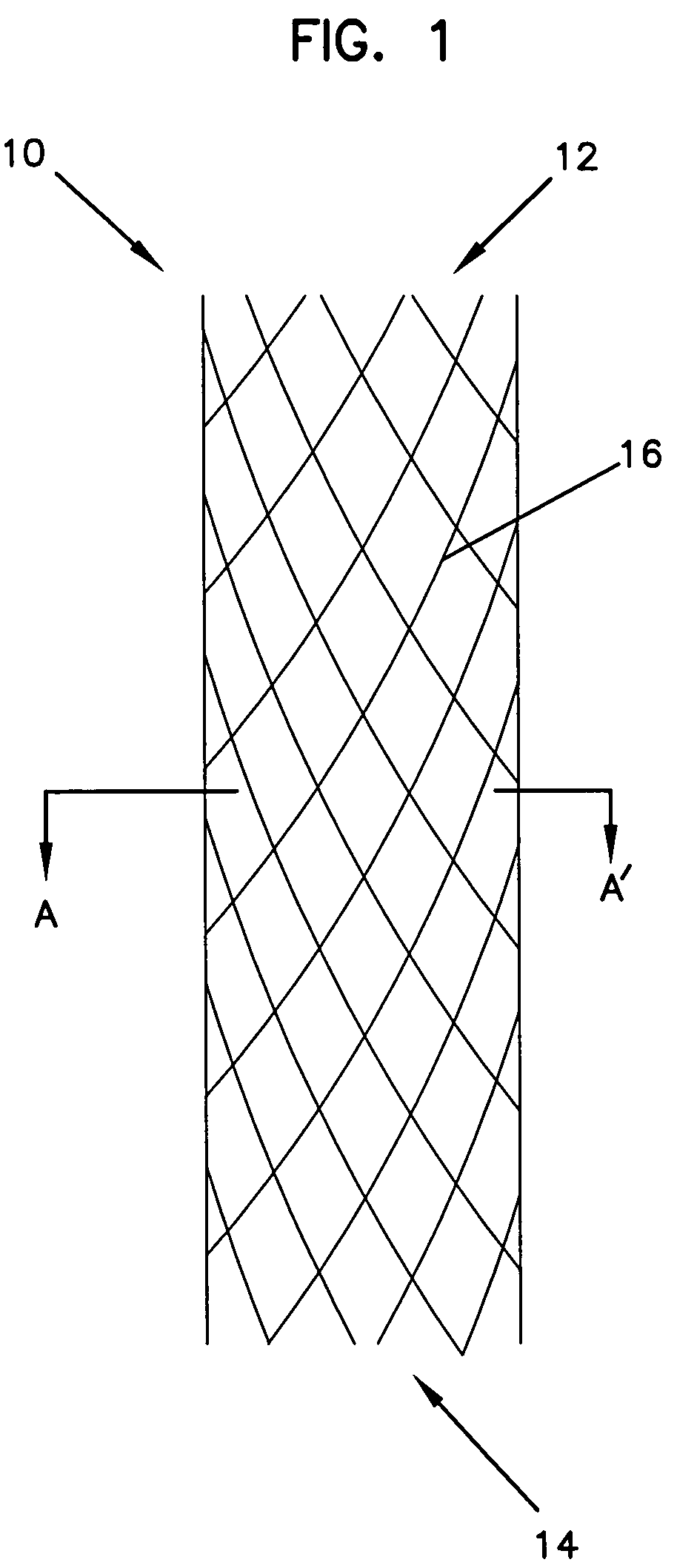

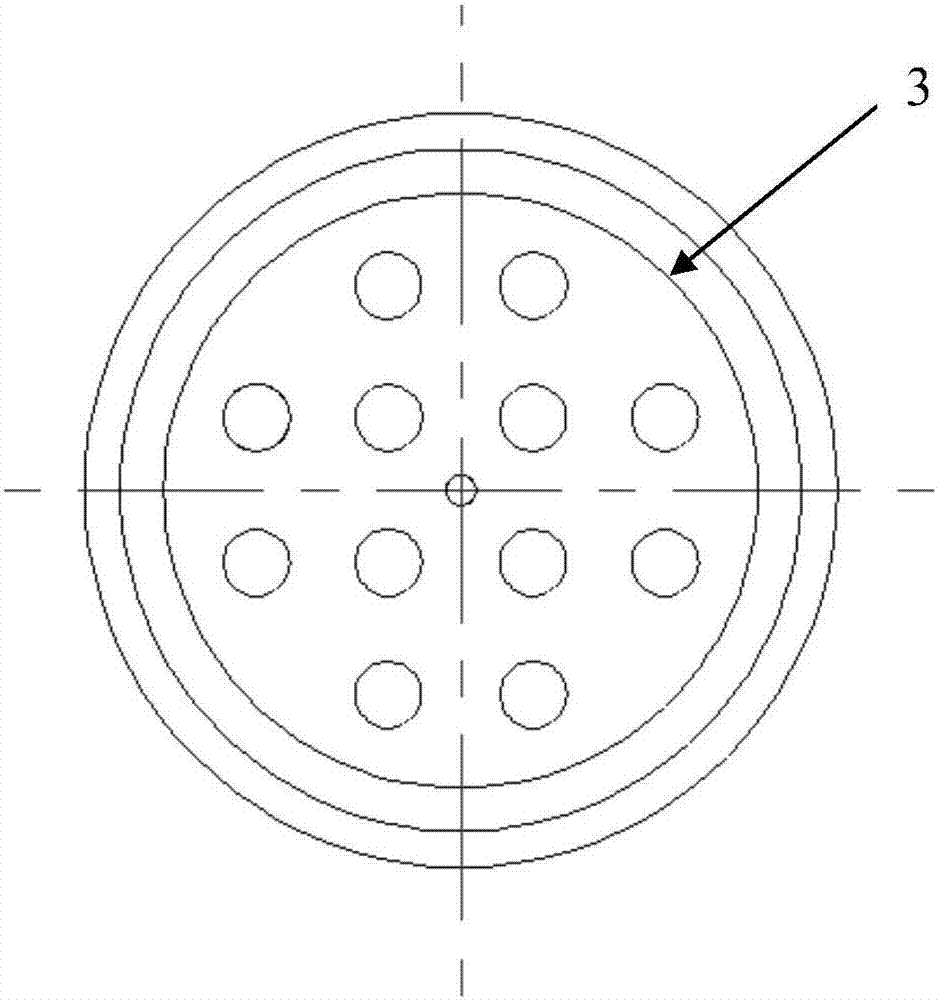

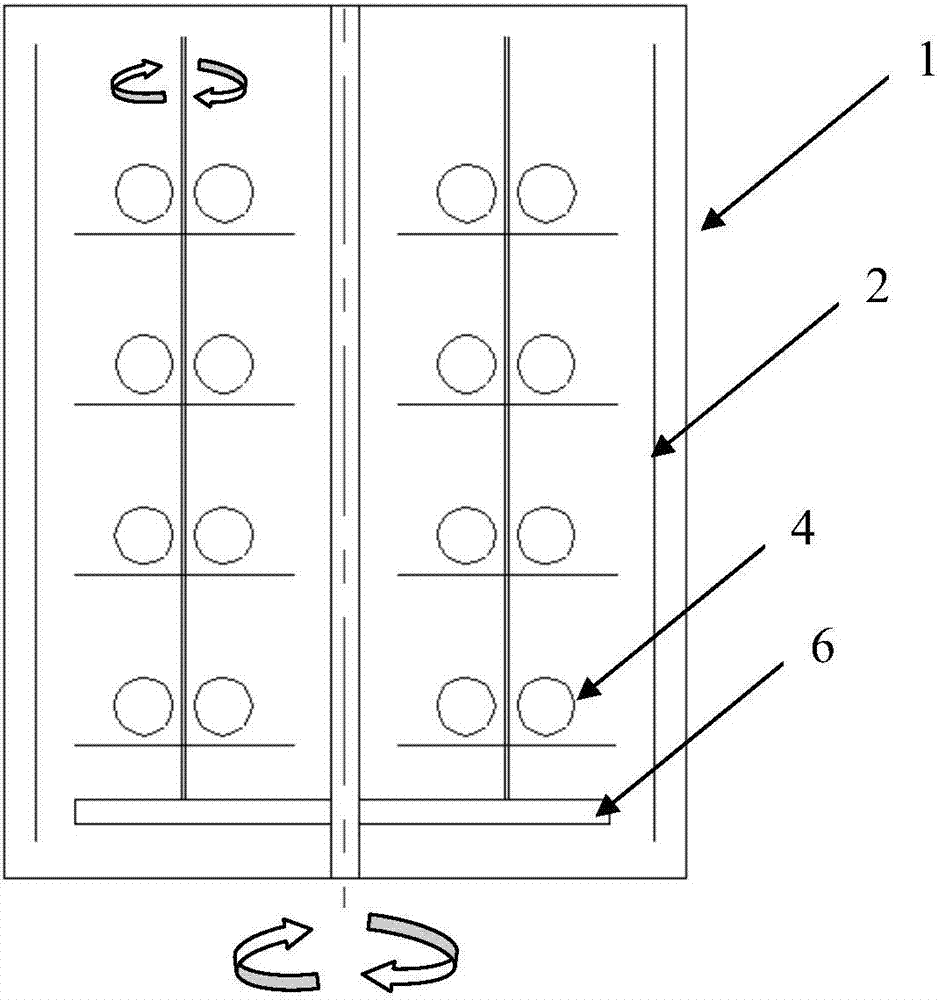

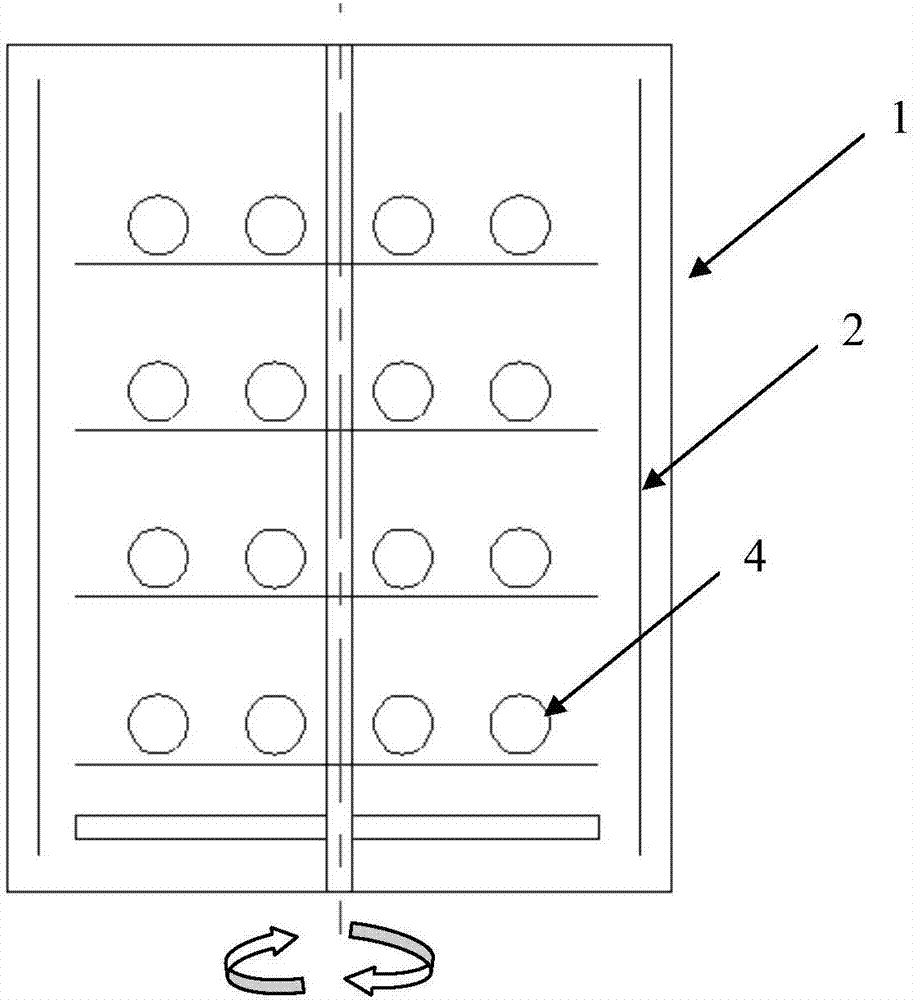

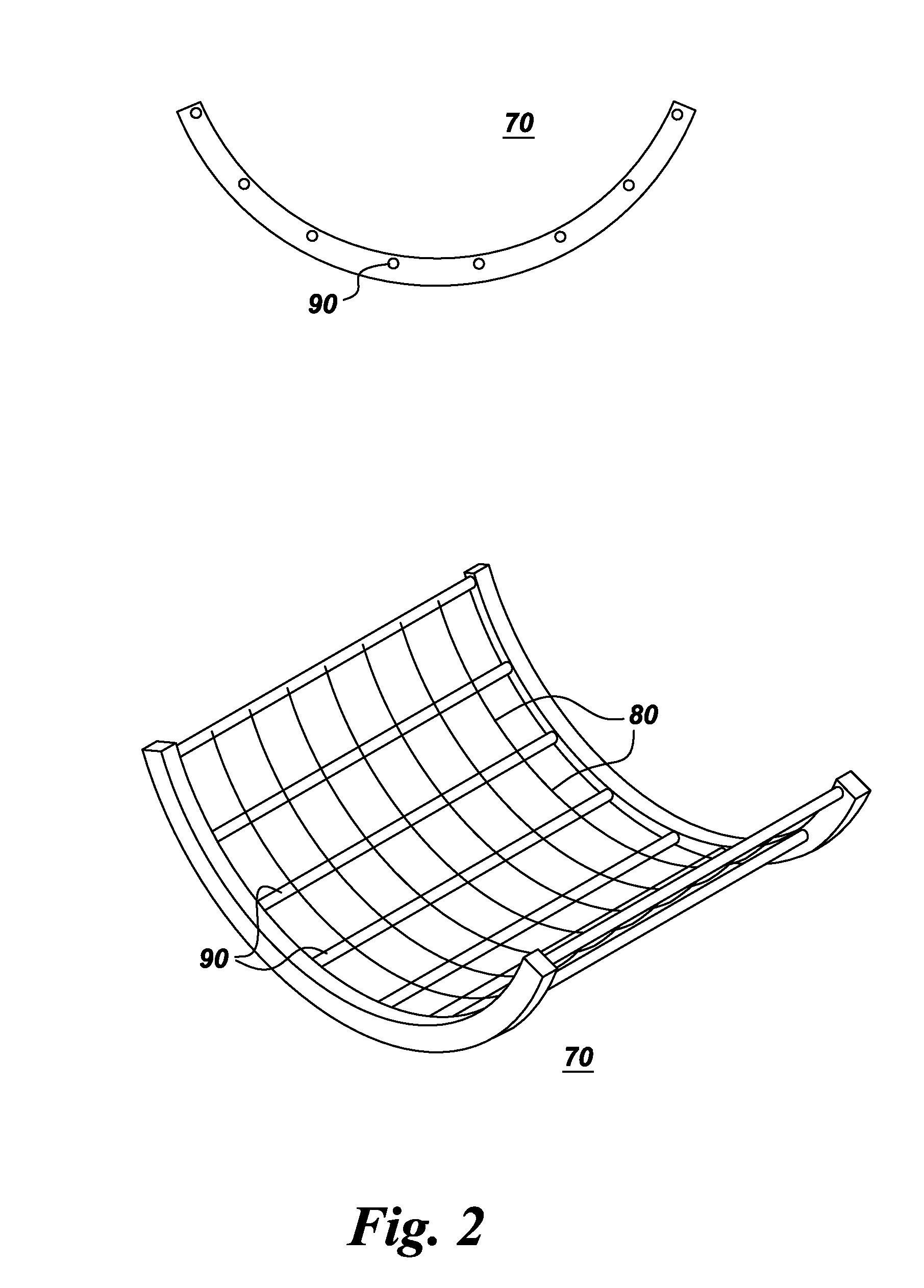

Method for Holding a Medical Device During Coating

InactiveUS20090093870A1Remove shadowsSolve the lack of tensionStentsBalloon catheterMedical deviceBiomedical engineering

The present invention is directed towards the holding of medical devices during manufacture to enable the application of therapeutic and / or protective coatings. More specifically, the present invention provides medical device holders that securely retain stents and other medical devices during the application of a coating while minimizing compressive and tensile forces applied to the stents. The invention avoids disruptions to coating quality due to holder blockage during coating deposition. The invention discloses an improved device containing a mandrel and frame that may improve coating uniformity by eliminating shadowing from the frame of the medical device holder when applying coatings to stents and other medical devices.

Owner:BACOUSTICS LLC

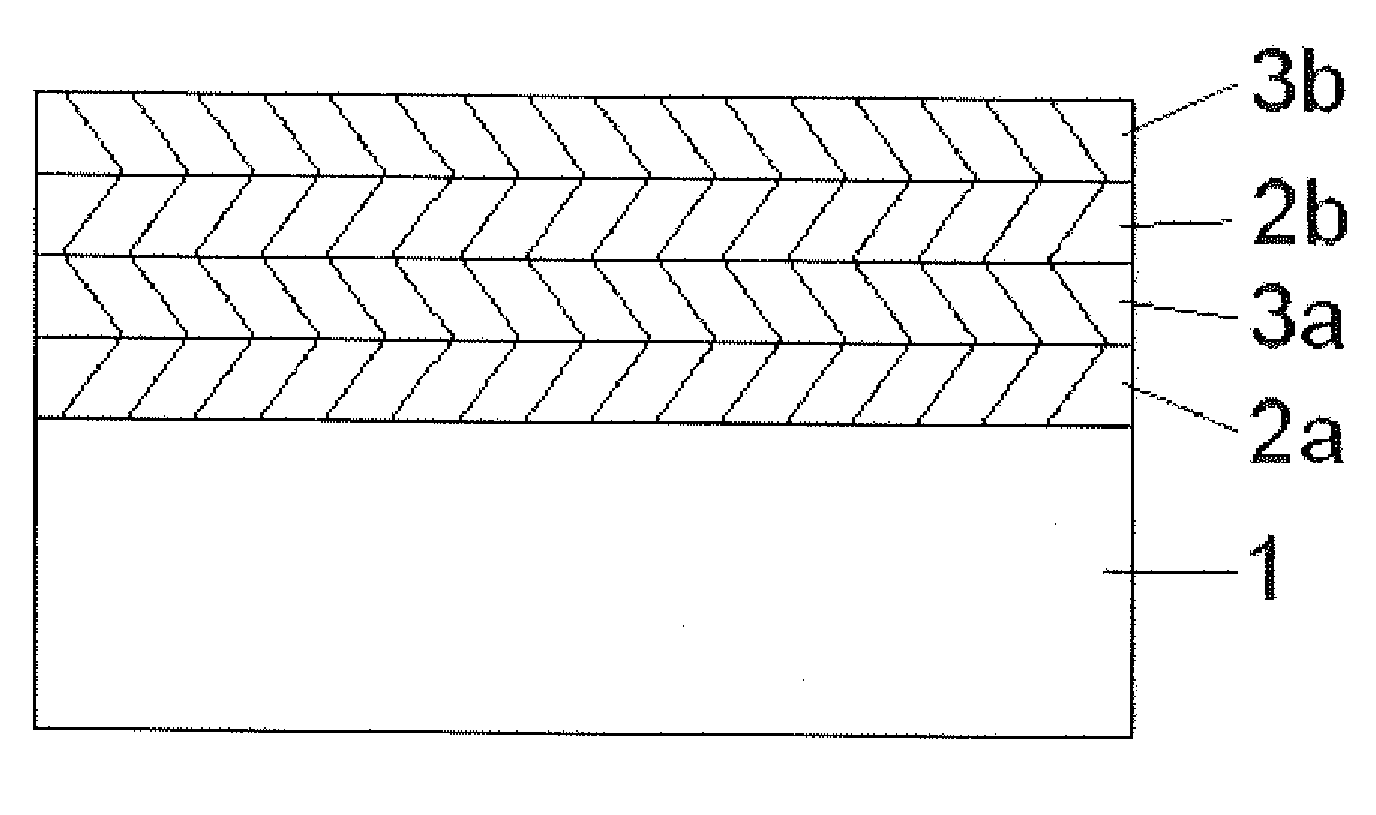

CrTiAlSiN nano composite coating, cutter deposited with same and preparation method thereof

InactiveCN101879794AHigh bonding strengthHigh surface hardnessLayered productsVacuum evaporation coatingAdhesiveHardness

The invention relates to a CrTiAlSiN nano composite coating, a cutter deposited with the same and a preparation method thereof. The composite coating comprises a bonding layer, a supporting layer and a main wear layer, wherein the bonding layer consists of Cr, the supporting layer consists of CrN, and the main wear layer is a CrSiN / TiAlSiN nano multilayered composite coating formed by alternating CrSiN layers and TiAlSiN layers or an nc-CrTiAlN / a-Si3N4 nanocrystalline composite coating formed by embedding nanocrystalline CrTiAlN into amorphous Si3N4. The bonding layer is deposited on a cutter matrix, and then the supporting layer and the main wear layer are deposited to obtain the cutter deposited with the coating. The obtained CrTiAlSiN nano composite coating has the advantages of high hardness, low friction coefficient and strong adhesive force; and the cutter deposited with the coating has higher surface hardness, stronger film-matrix adhesive force and good wear-resisting property and high temperature resistance.

Owner:湖北三环成套工业有限公司

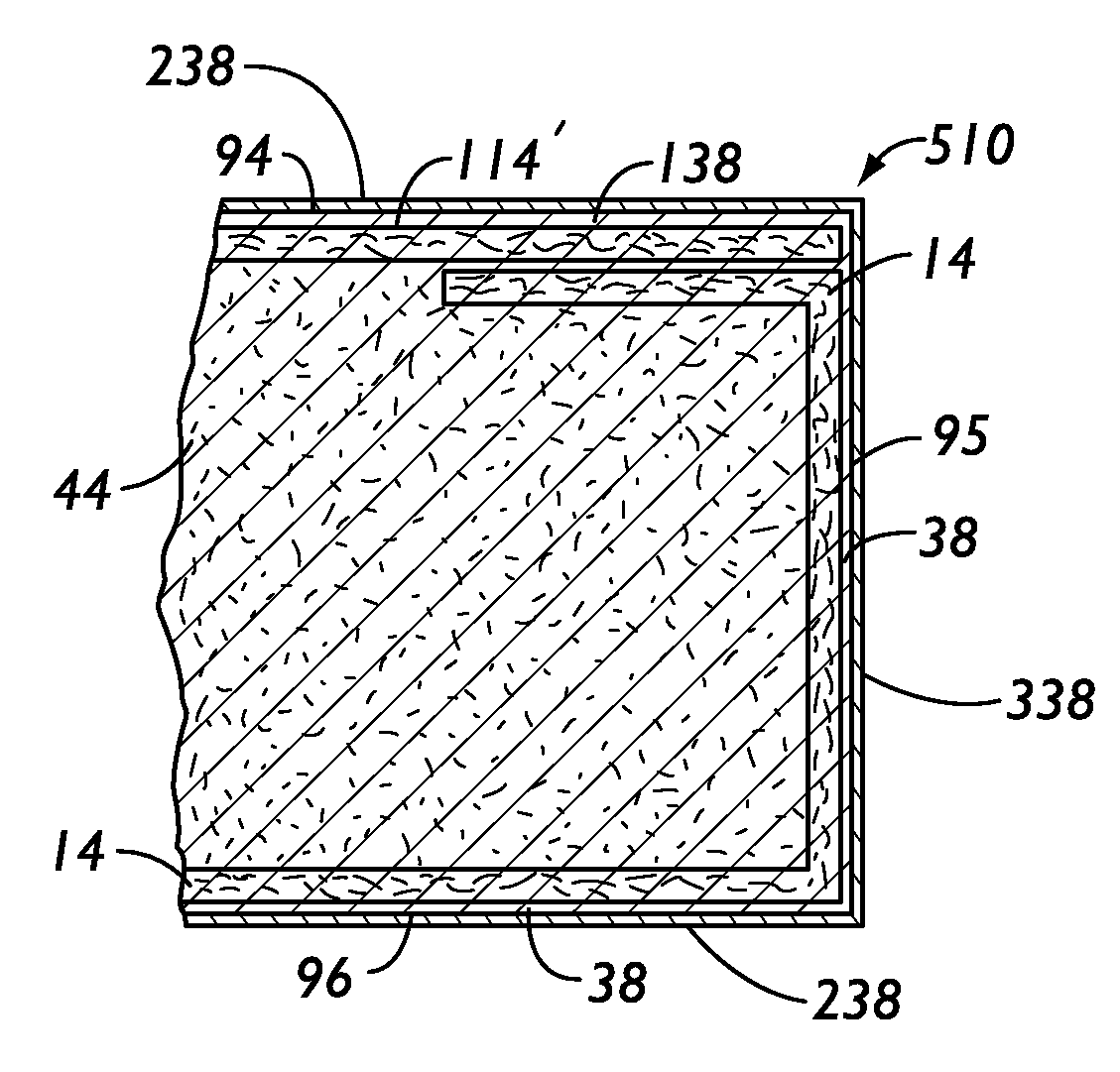

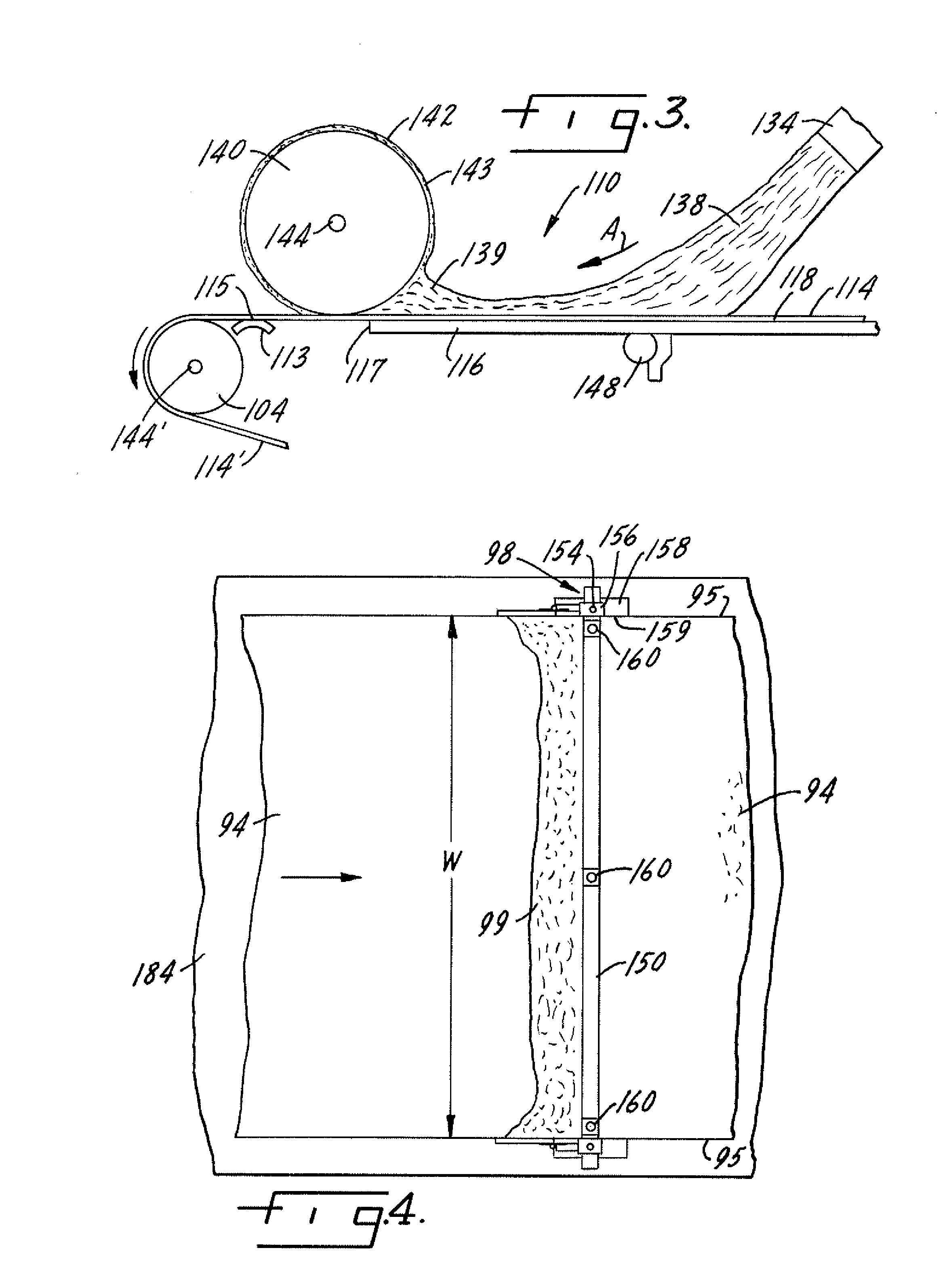

Coater having interrupted conveyor system

Methods and coaters for applying films onto a substrate (e.g., a large-area glass substrate) are disclosed. Certain embodiments involve a coater for applying thin films onto a sheet-like substrate. The coater in some embodiments has a transport system adapted for conveying the substrate along a path of substrate travel extending through the coater. The substrate transport system in certain embodiments includes an upward coating deposition gap. The coater preferably has a source of coating material adapted for delivering coating material upwardly through such gap and onto a bottom major surface of the substrate as the substrate is conveyed along a desired portion of the path of substrate travel, which portion of the path of substrate travel extends over the upward coating deposition gap.

Owner:CARDINAL CG

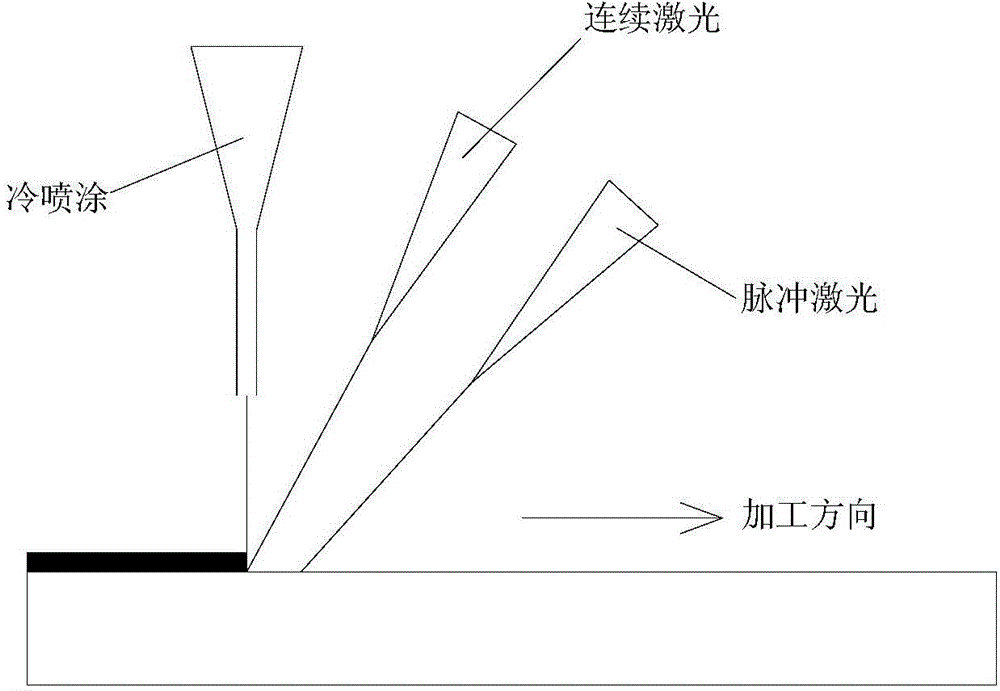

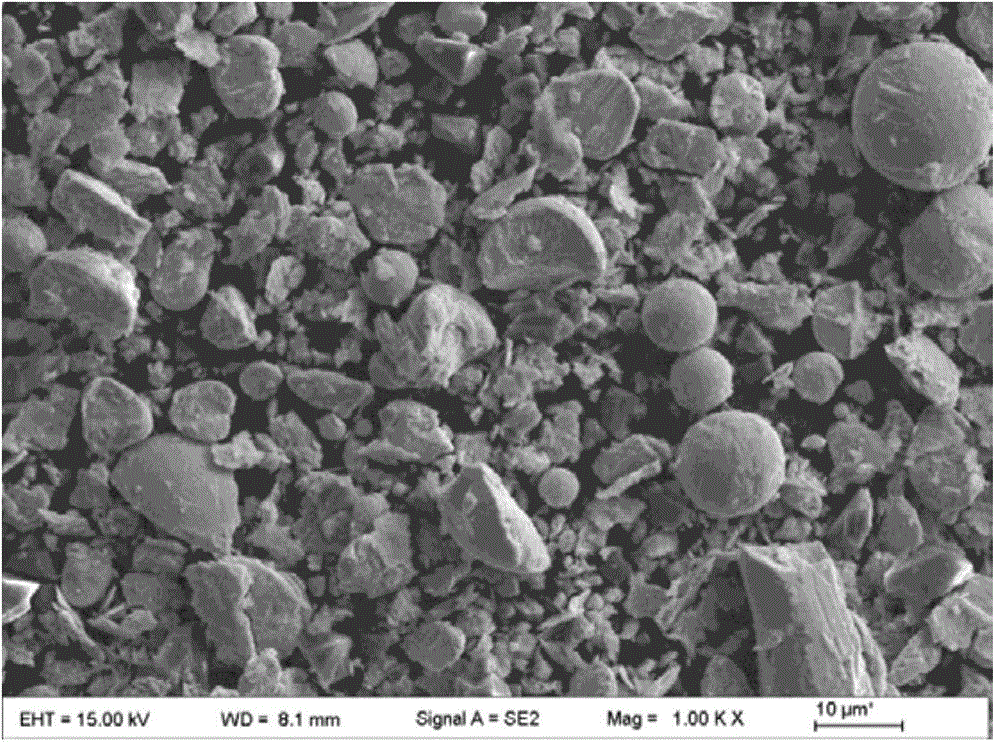

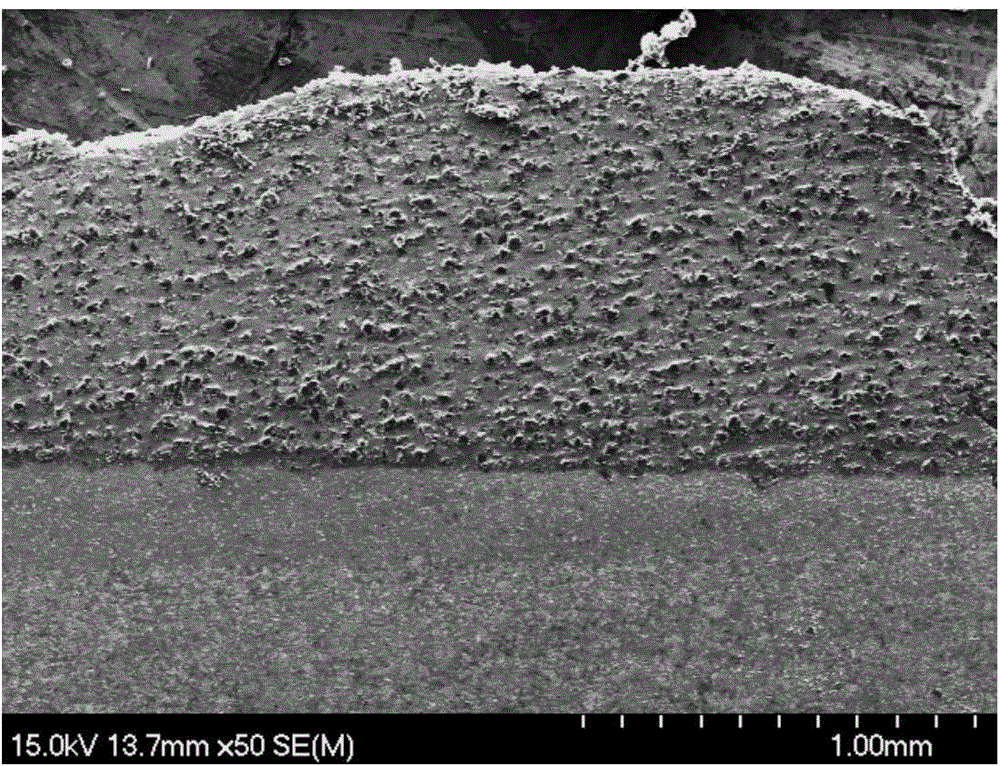

Metal-based/diamond laser composite coating and preparation method thereof

ActiveCN104018156AAvoid easy decompositionInhibition of dissolutionMovable spraying apparatusLaser beam welding apparatusCompound aHardness

The invention discloses a metal-based diamond laser composite coating and a preparation method thereof. The preparation method comprises the following steps: firstly selecting high-hardness metal powder and diamond powder with proper grain size and shape, uniformly mixing the high-hardness metal powder and the diamond powder by using a ball-milling method, and finally preparing the composite coating on a matrix by using a method of synchronously compounding a laser texturing technology, a laser heat treatment technology and a cold spraying technology. The thickness of the composite coating is over 1mm, and the diamond volume content in the coating is more than 45%. The preparation of the composite coating by using the high-hardness metal powder as the diamond binding phase is realized, and the binding strength of the composite coating and the matrix is improved through the pulse texturing treatment, and finally the stable and high-quality high-hardness metal-based / diamond composite high wear-resisting coating is prepared, and the integration, the automation and the efficiency of the matrix surface treatment and the coating deposition treatment are realized.

Owner:ZHEJIANG UNIV OF TECH +1

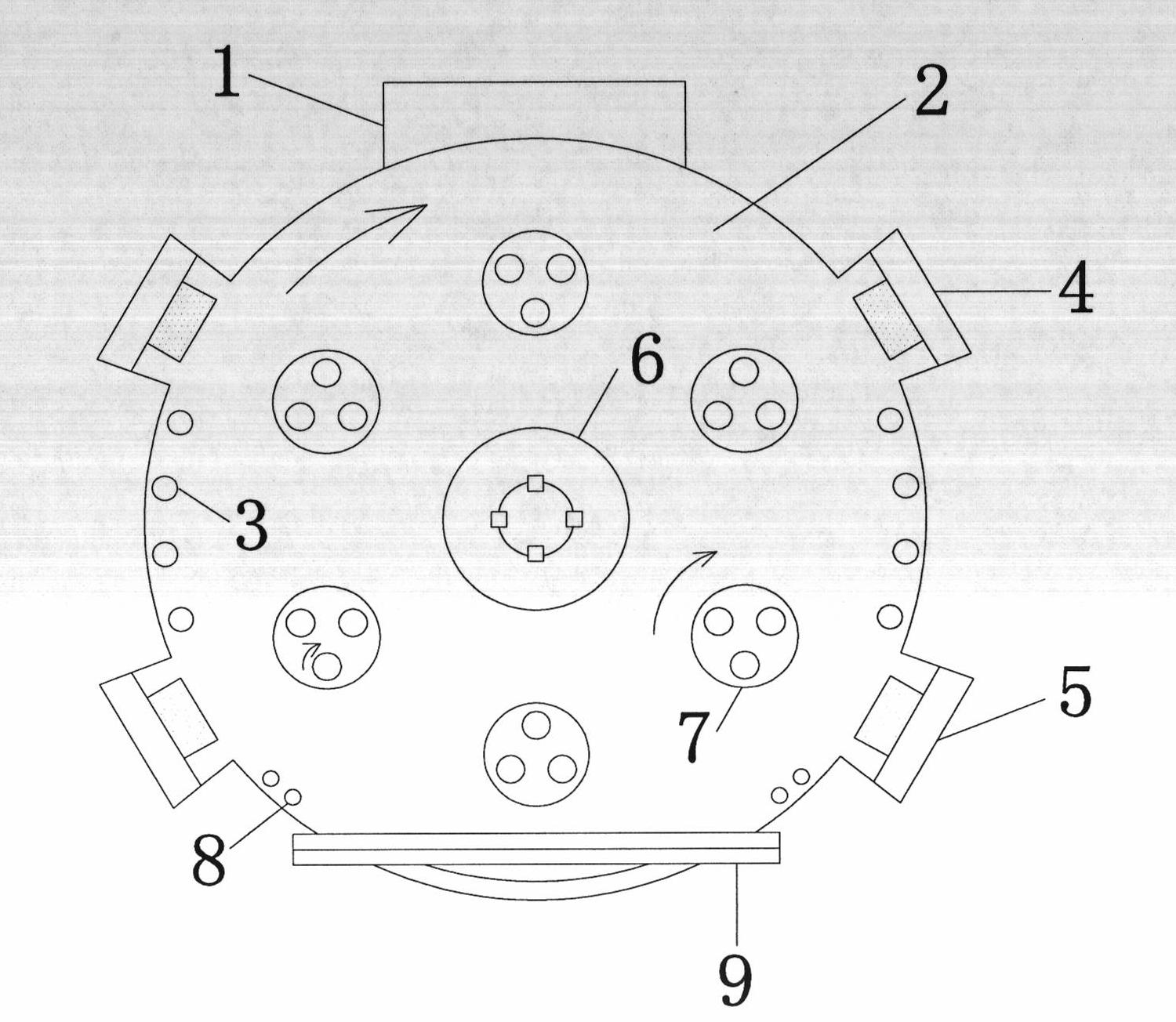

Base material motion type device and method for preparing nano coating through plasma discharge

PendingCN106958012APlay an active roleSolve uneven thicknessElectric discharge tubesNanotechnologySolventDeposition process

The invention discloses a base material motion type device and method for preparing a nano coating through plasma discharge, and belongs to the technical field of plasmas. The device comprises electrodes, a vacuum exhaust device, a gas pipeline and a base material fixing device; and the method comprises the following steps that the base material fixing device can do motions in the space formed by the electrodes under the driving of a moving mechanism, and monomer steam is introduced into a reaction chamber to carry out plasma chemical vapor deposition, wherein the deposition process comprises a pretreatment stage and a coating stage, the plasma discharge mode in the pretreatment stage is high-power continuous discharge and the plasma discharge mode in the coating stage is small-power continuous discharge. In the preparation process of the coating, the movement characteristic of the base material and the plasma discharge energy are combined and linked; the base material does motions while the plasma discharge occurs, so that the coating deposition efficiency is improved, and the uniformity and compactness of the thickness of the coating are improved; and the coating prepared by the method has the characteristics of being waterproof, moisture-proof, and anti-fungus, and has acid solvent resistance, alkaline solvent resistance, acid salt mist resistance, alkaline salt mist resistance and the like.

Owner:JIANGSU FAVORED NANOTECHNOLOGY CO LTD

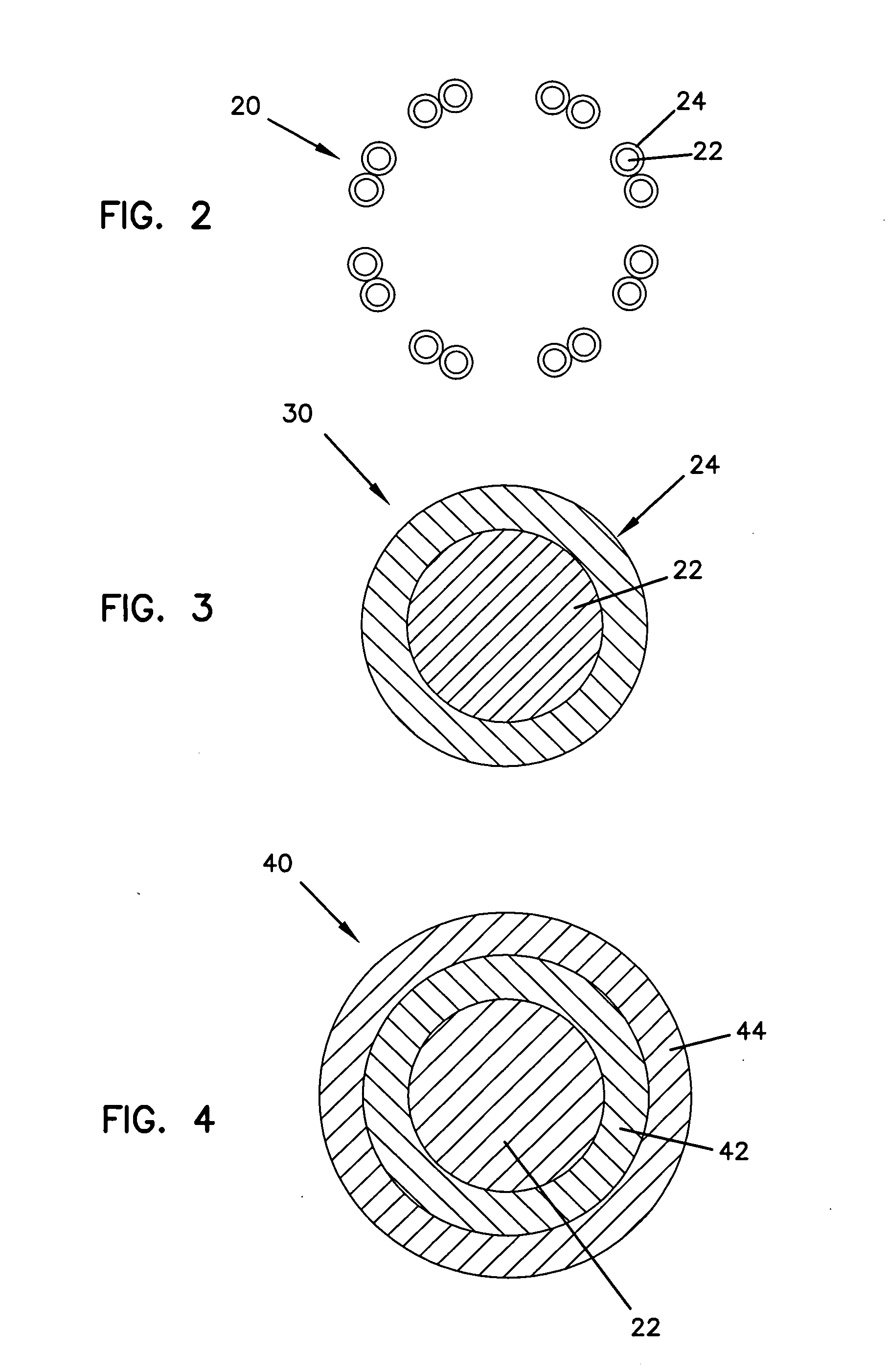

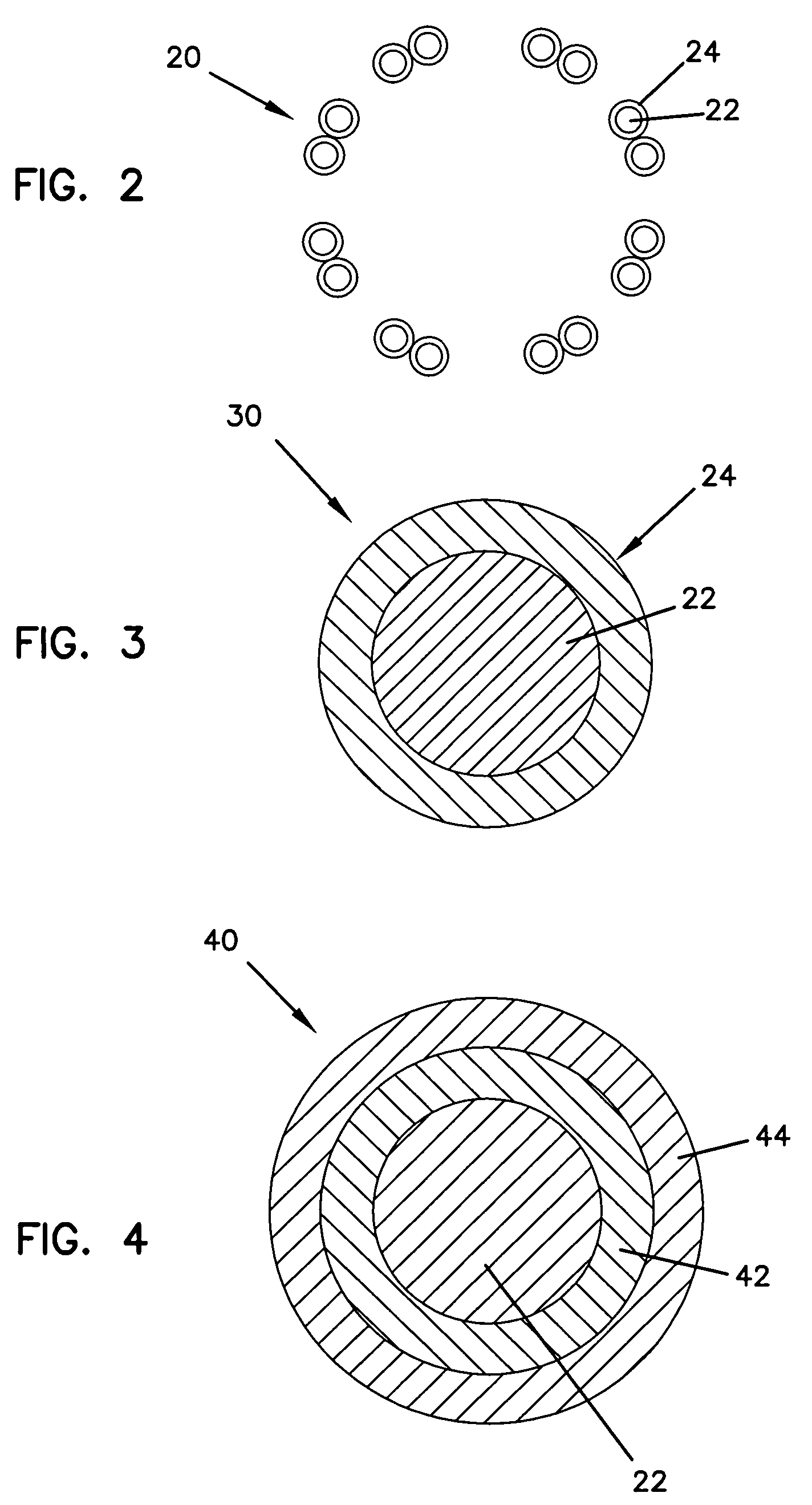

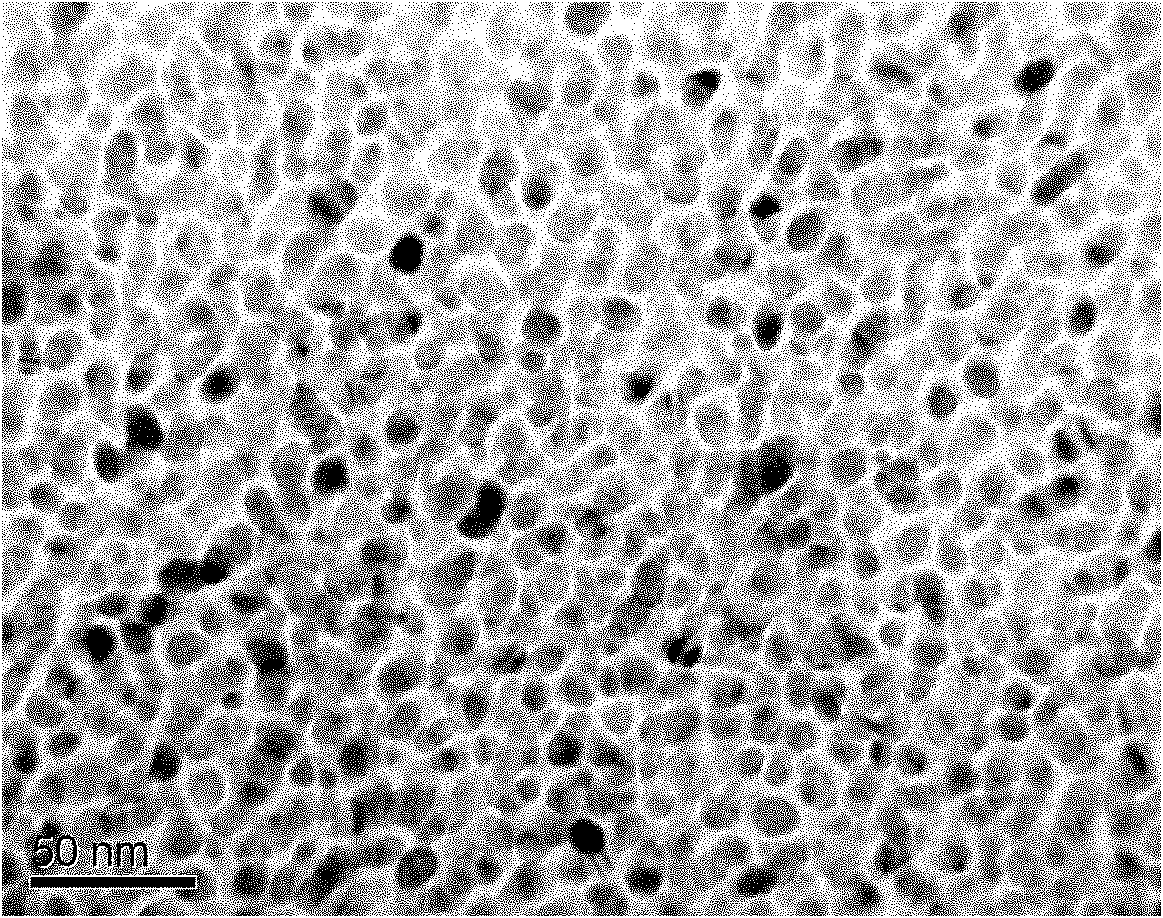

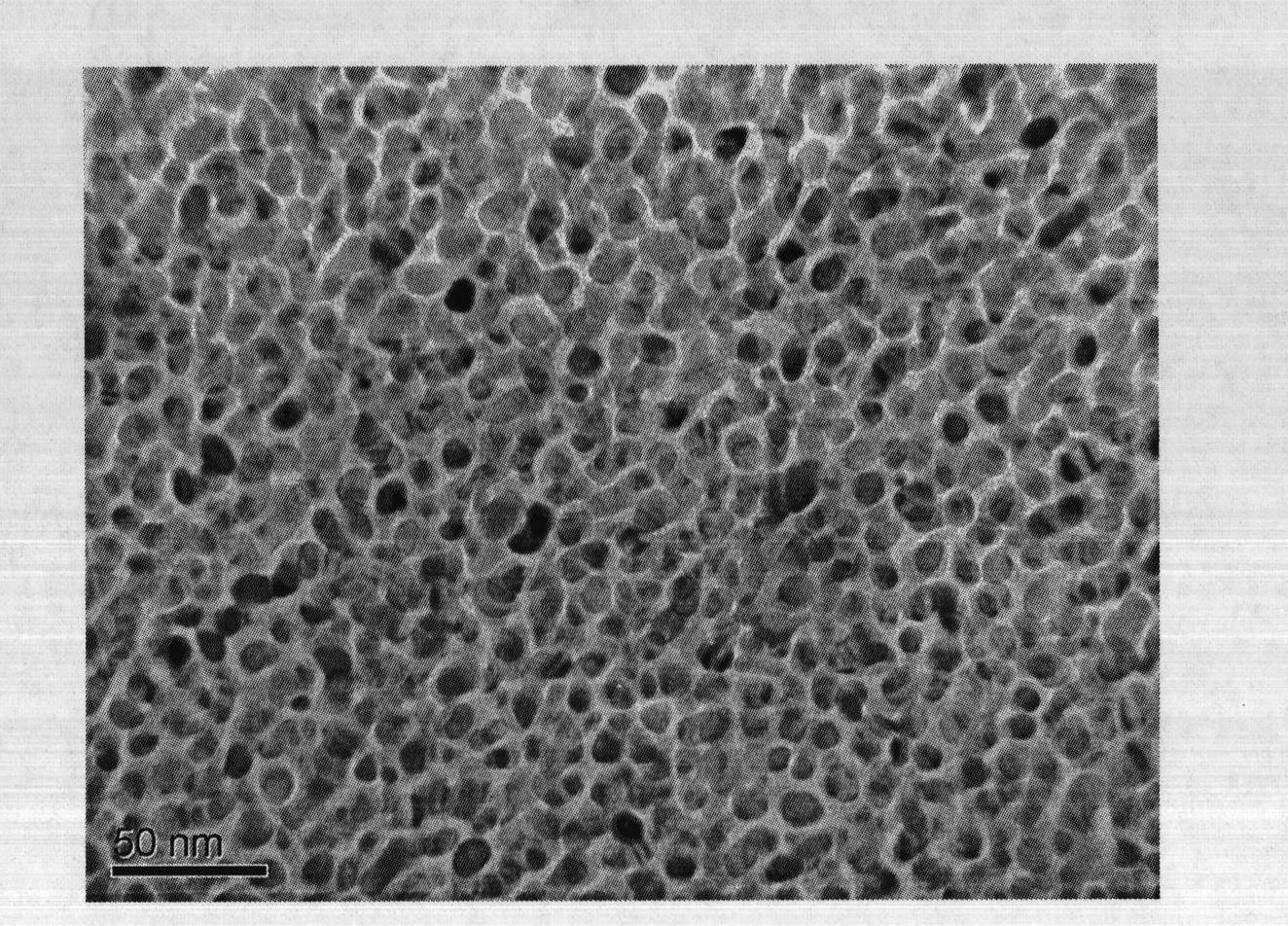

Atomic plasma deposited coatings for drug release

InactiveUS20090186068A1Prevent elutionReduced elutionStentsCoatingsControlled drugsPlasma deposition

Nanophase single or multiple layer time release coatings over drugs attached to metal surfaces are described. The coatings are deposited over a drug attached to a porous metal substrate using an atomic plasma deposition procedure. Porosity of the substrate and the number of APD deposited layers controls drug release when the attached drug is exposed to an aqueous medium.

Owner:NANOSURFACE TECH

Damage-free sculptured coating deposition

We disclose a method of applying a sculptured layer of material on a semiconductor feature surface using ion deposition sputtering, wherein a surface onto which the sculptured layer is applied is protected to resist erosion and contamination by impacting ions of a depositing layer, said method comprising the steps of: a) applying a first portion of a sculptured layer with sufficiently low substrate bias that a surface onto which said sculptured layer is applied is not eroded away or contaminated in an amount which is harmful to said semiconductor device performance or longevity; and b) applying a subsequent portion of said sculptured layer with sufficiently high substrate bias to sculpture a shape from said the first portion, while depositing additional layer material. The method is particularly applicable to the sculpturing of barrier layers, wetting layers, and conductive layers upon semiconductor feature surfaces and is especially helpful when the conductive layer is copper. In the application of a barrier layer, a first portion of barrier layer material is deposited on the substrate surface using standard sputtering techniques or using an ion deposition plasma, but in combination with sufficiently low substrate bias voltage (including at no applied substrate voltage) that the surfaces impacted by ions are not sputtered in an amount which is harmful to device performance or longevity. Subsequently, a second portion of barrier material is applied using ion deposition sputtering at increased substrate bias voltage which causes resputtering (sculpturing) of the first portion of barrier layer material, while enabling a more anisotropic deposition of newly depositing material. A conductive material, and particularly a copper seed layer applied to the feature may be accomplished using the same sculpturing technique as that described above with reference to the barrier layer.

Owner:APPLIED MATERIALS INC

Coatings for glass reinforced faced gypsum board

InactiveUS20090087616A1Increase surface tensionLayered productsDecorative surface effectsGypsumPolymer chemistry

A coating method for gypsum board having a surface gypsum layer in which a polymer additive has been entrained including forming a gypsum board including the polymer additive entrained in a surface layer, application of a preferably acrylic primary coating, curing and drying the gypsum board, passing the gypsum board through a first roll coater wherein a second fluid coating is deposited over the primary layer of the dried, coated gypsum board in which the polymer additive has been entrained, the coating then being dried and cured, wherein the coating material of the primary coating forms a chemical bond with the polymer additive entrained in the surface layer of the gypsum board and the polymer of the primary coating forms a chemical bond with the second fluid coating. A coating material which can form copolymer bonds with the second coating is then deposited on the second coating and then dried and cured, resulting in coated gypsum board having a low surface tension surface that is essentially impermeable to water and vapor or moisture penetration.

Owner:BPB LTD

Process for inhibiting SRZ formation and coating system therefor

InactiveUS20050118334A1Reduce morbidityIncrease contentLiquid surface applicatorsBlade accessoriesCoating systemReaction zone

A process for reducing the incidence of a secondary reaction zone (SRZ) in alloys prone to SRZ formation, particularly superalloys that have a high refractory element content. The process finds use with articles having a wall region that defines external and internal surfaces on the exterior and within the article, respectively. Diffusion coatings are formed on the internal and external surfaces of the article, with at least the diffusion coating on the external surface comprising an additive layer and a diffusion zone that is beneath the additive layer and extends into the wall region. The additive layer and at least a portion of the diffusion zone of the external diffusion coating is then removed to define an exposed surface region on the exterior of the article. An overlay coating is then deposited on the exposed surface region.

Owner:GENERAL ELECTRIC CO

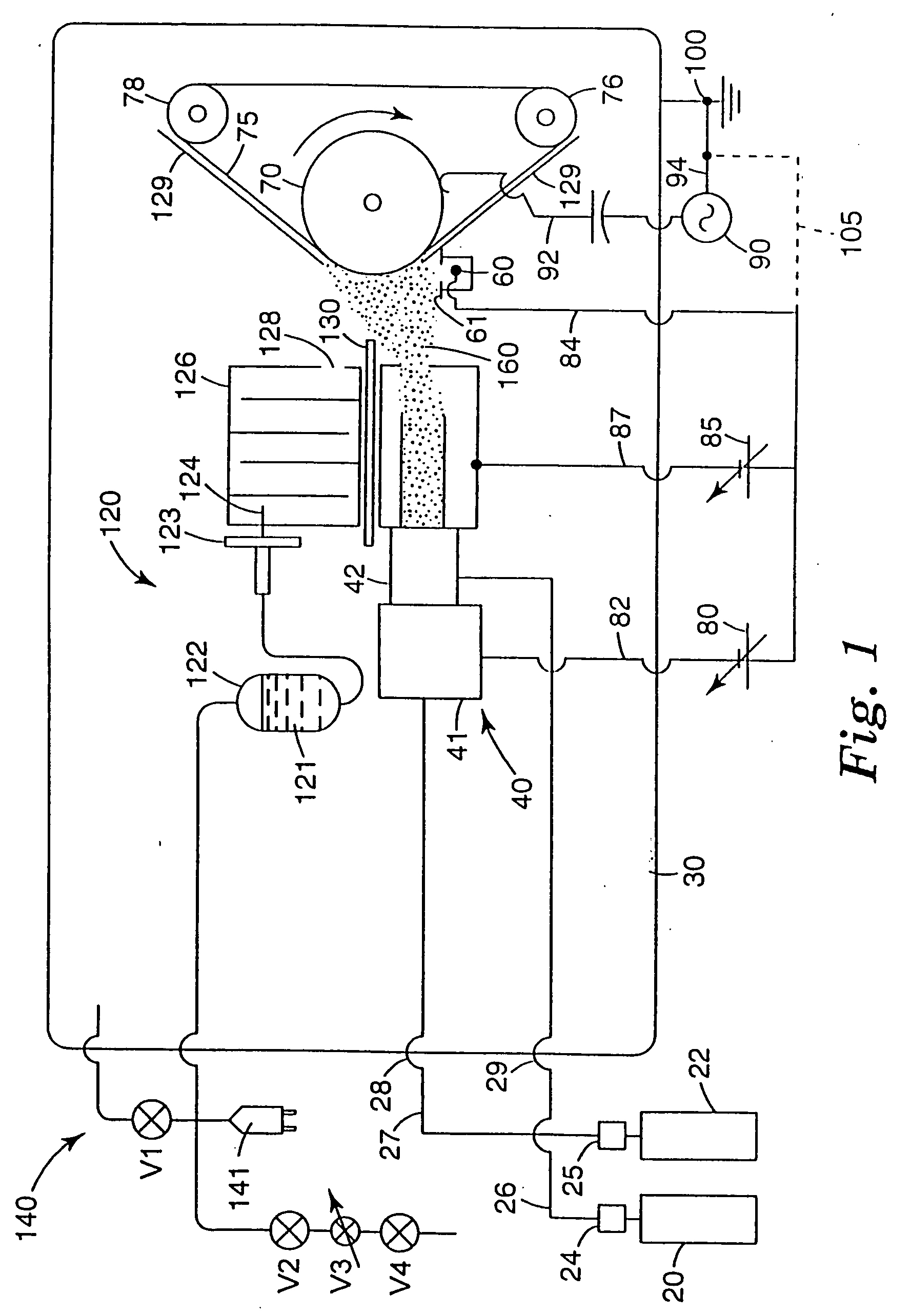

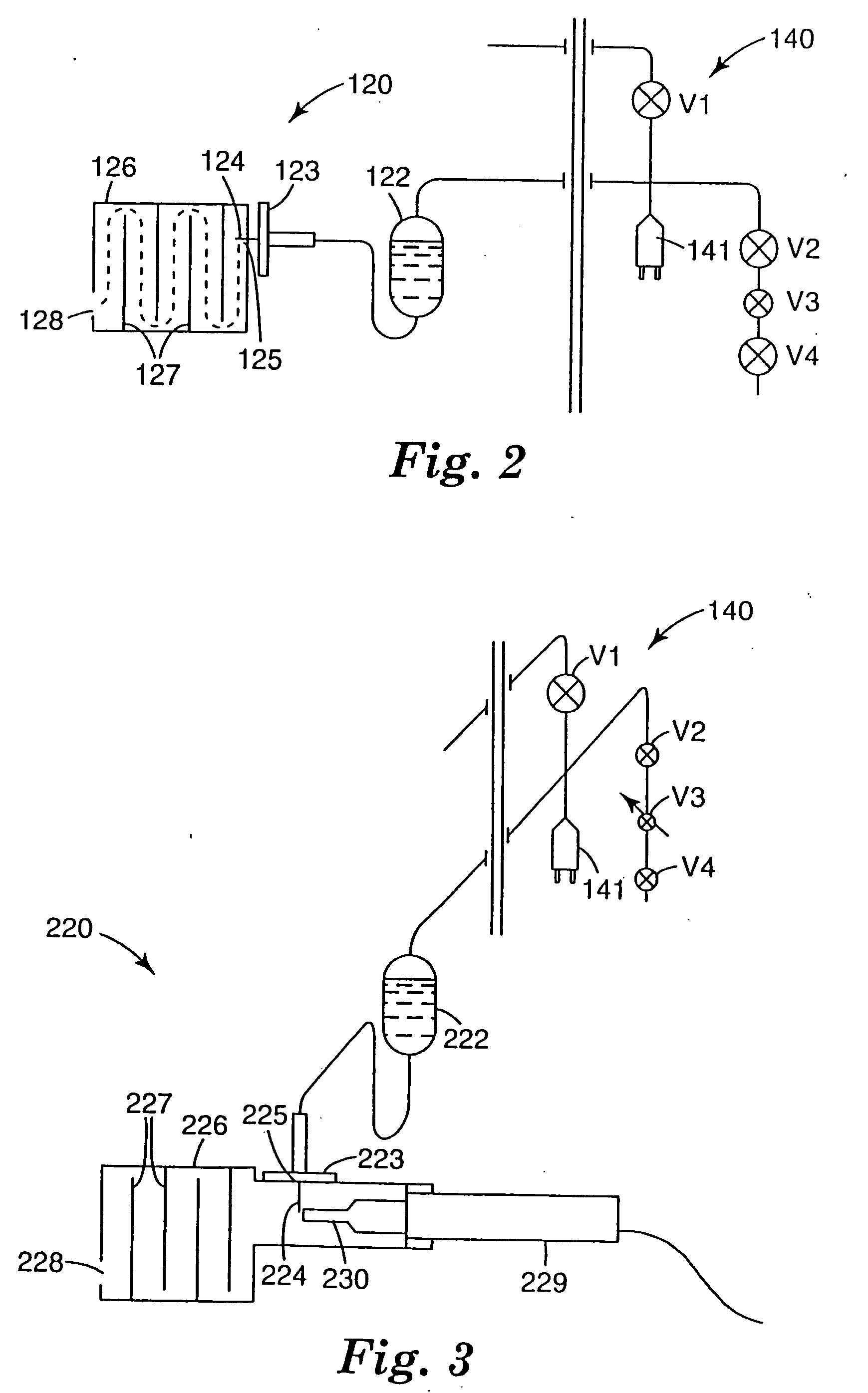

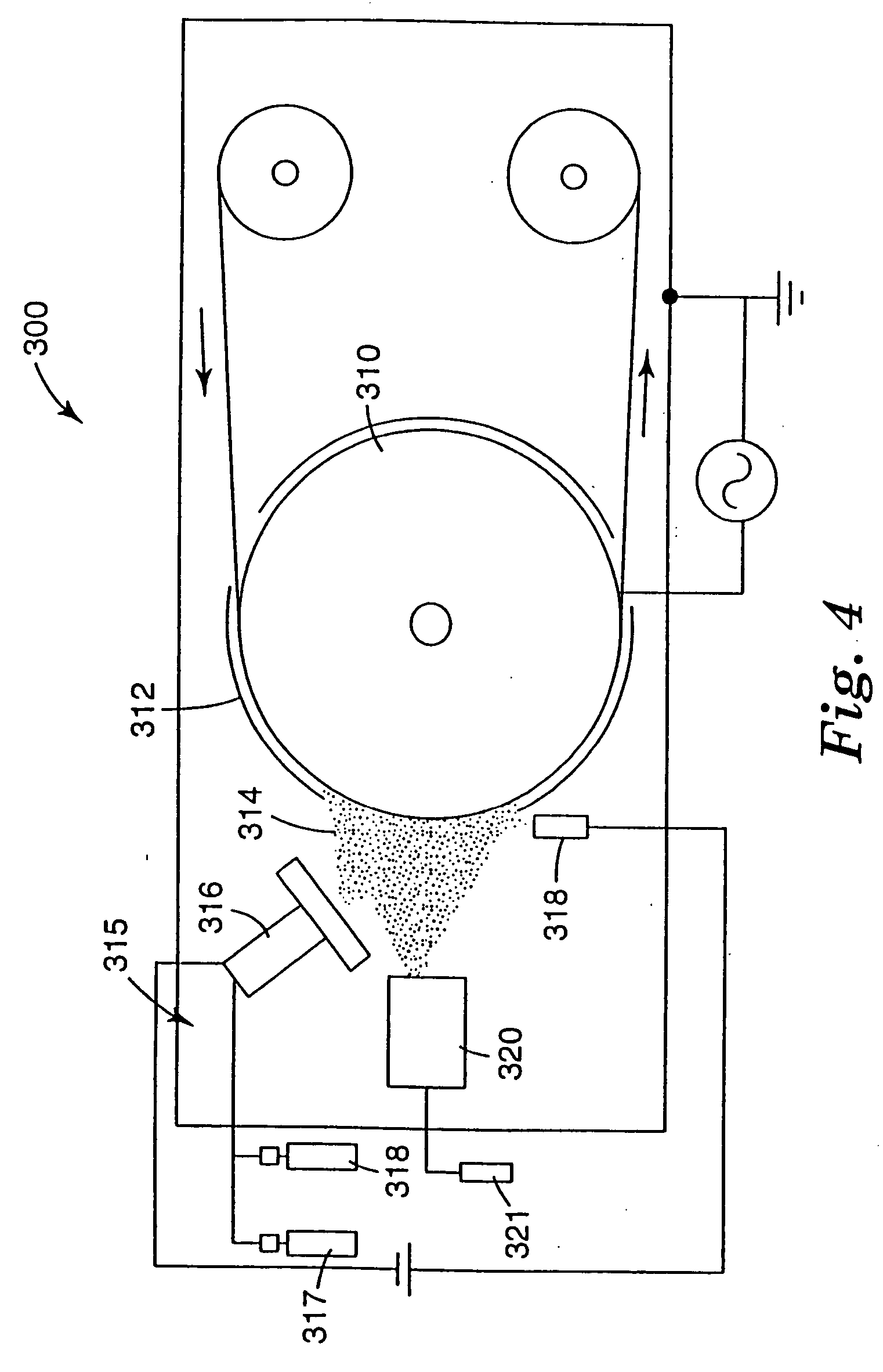

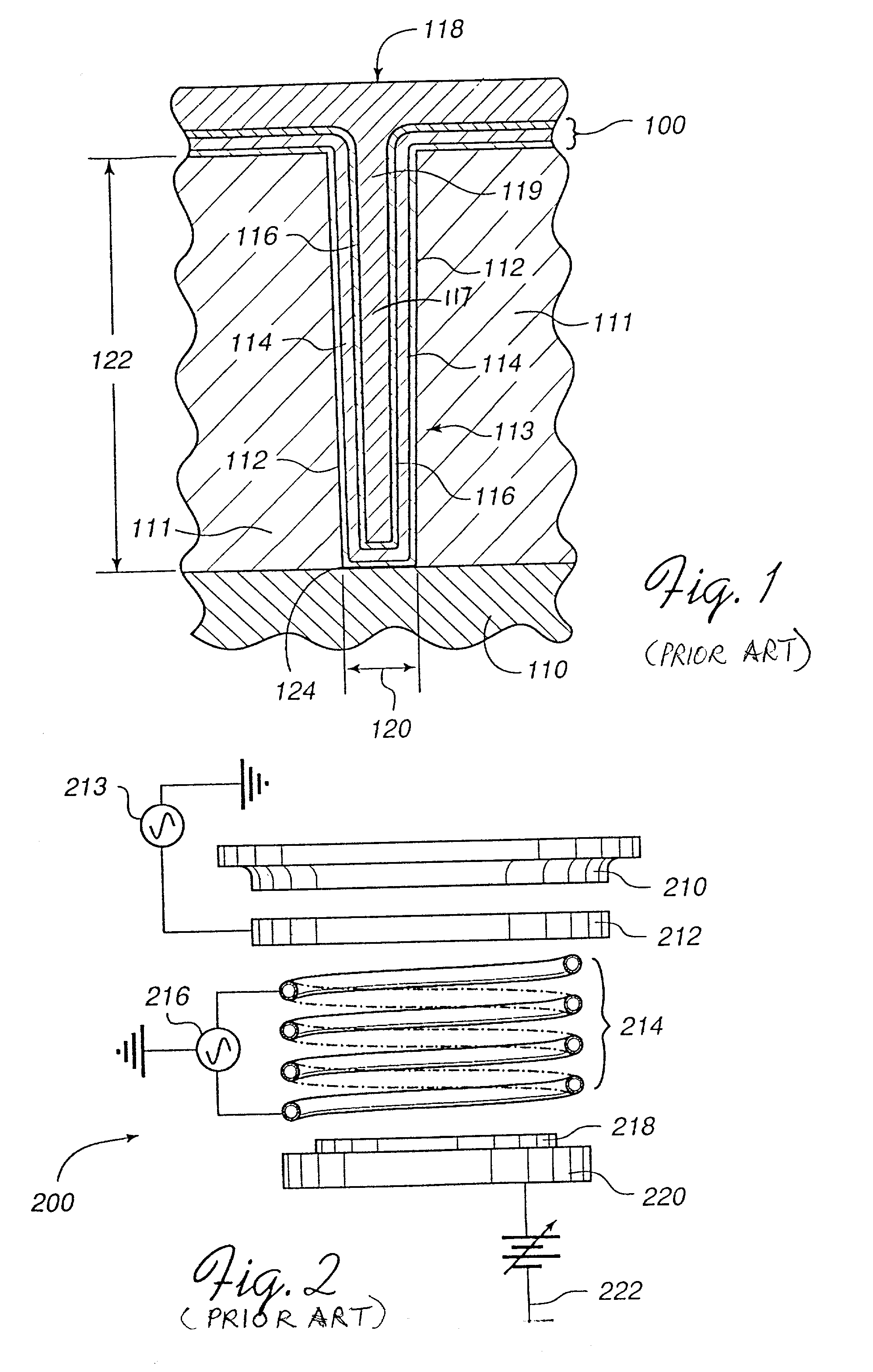

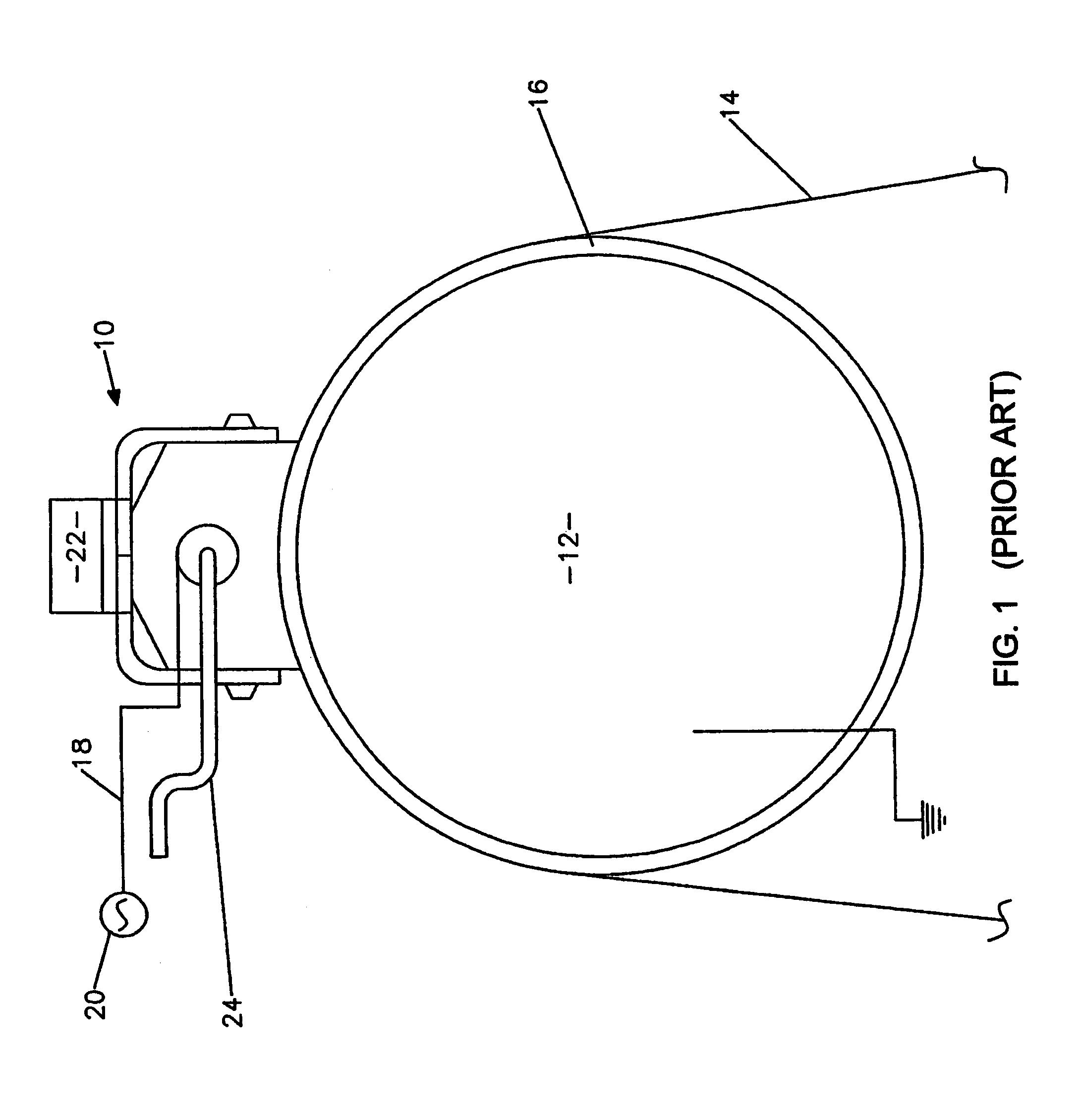

Atmospheric glow discharge with concurrent coating deposition

InactiveUS7067405B2Improve adhesionImprove curingElectric discharge tubesSemiconductor/solid-state device manufacturingMetallic electrodeGas phase

A plasma is produced in a treatment space by diffusing a plasma gas at atmospheric pressure and subjecting it to an electric field created by two metallic electrodes separated by a dielectric material, a precursor material is mixed with the plasma, and a substrate film or web is coated by vapor deposition of the vaporized substance at atmospheric pressure in the plasma field. The deposited precursor is cured by electron-beam, infrared-light, visible-light, or ultraviolet-light radiation, as most appropriate for the particular material being-deposited. Plasma pre-treatment and post-treatment steps are used to enhance the properties of the resulting coated products. Similar results are obtained by atomizing and spraying the liquid precursor in the plasma field.

Owner:SIGMA LAB OF ARIZONA

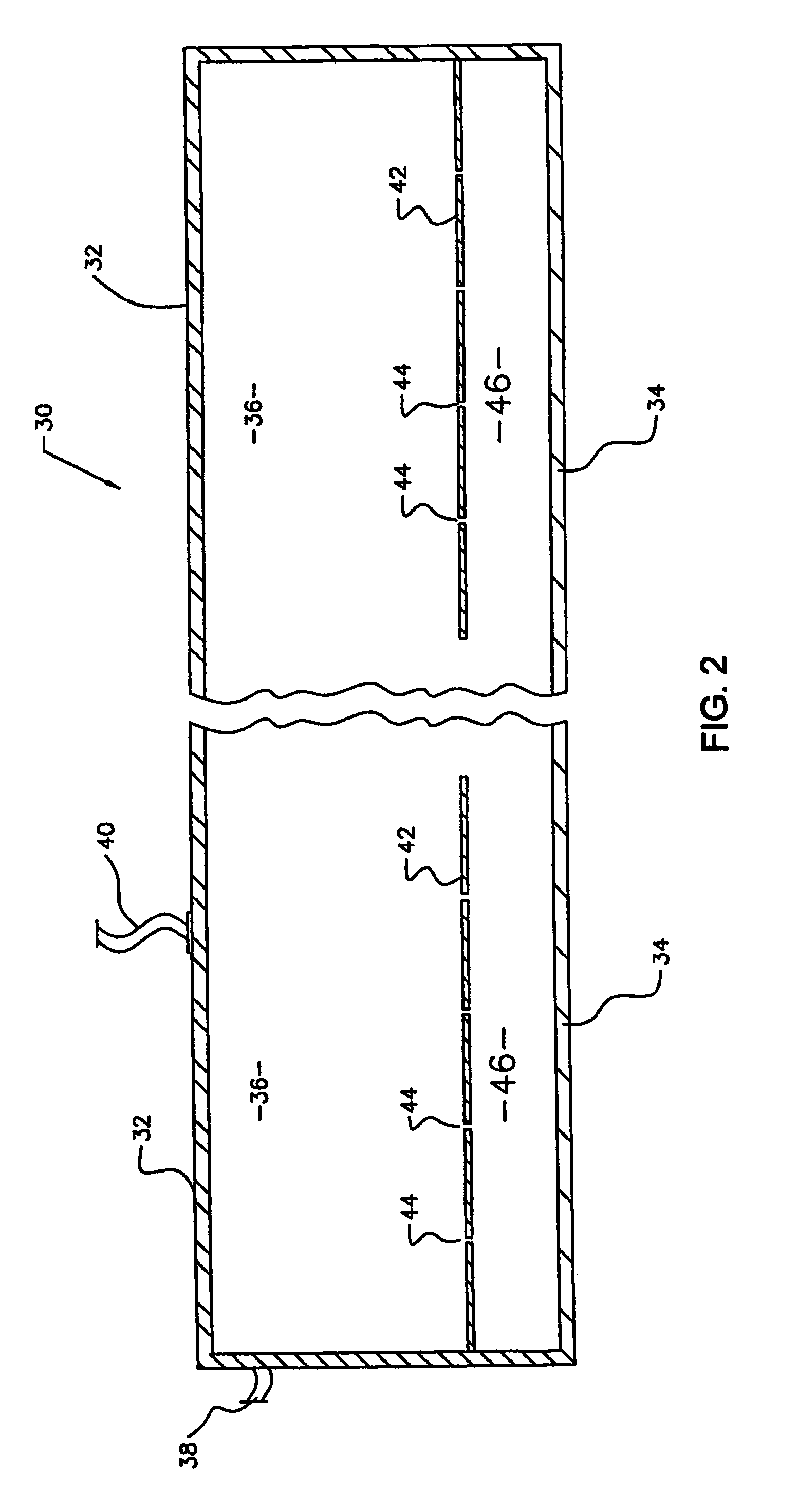

Apparatus and methods to form a patterned coating on an OLED substrate

InactiveUS20110065282A1Avoid depositionCellsVacuum evaporation coatingDeposition processMaterials science

An apparatus for applying a patterned coating to an OLED substrate in a continuous roll-to-roll vapor based deposition process is provided comprising a vapor deposition source, a processing drum, a drive roller, and a shadow mask wherein the shadow mask comprises a mask line feature that selectively prevents deposition of the coating onto the substrate. Also presented is a method for applying the coating.

Owner:GENERAL ELECTRIC CO

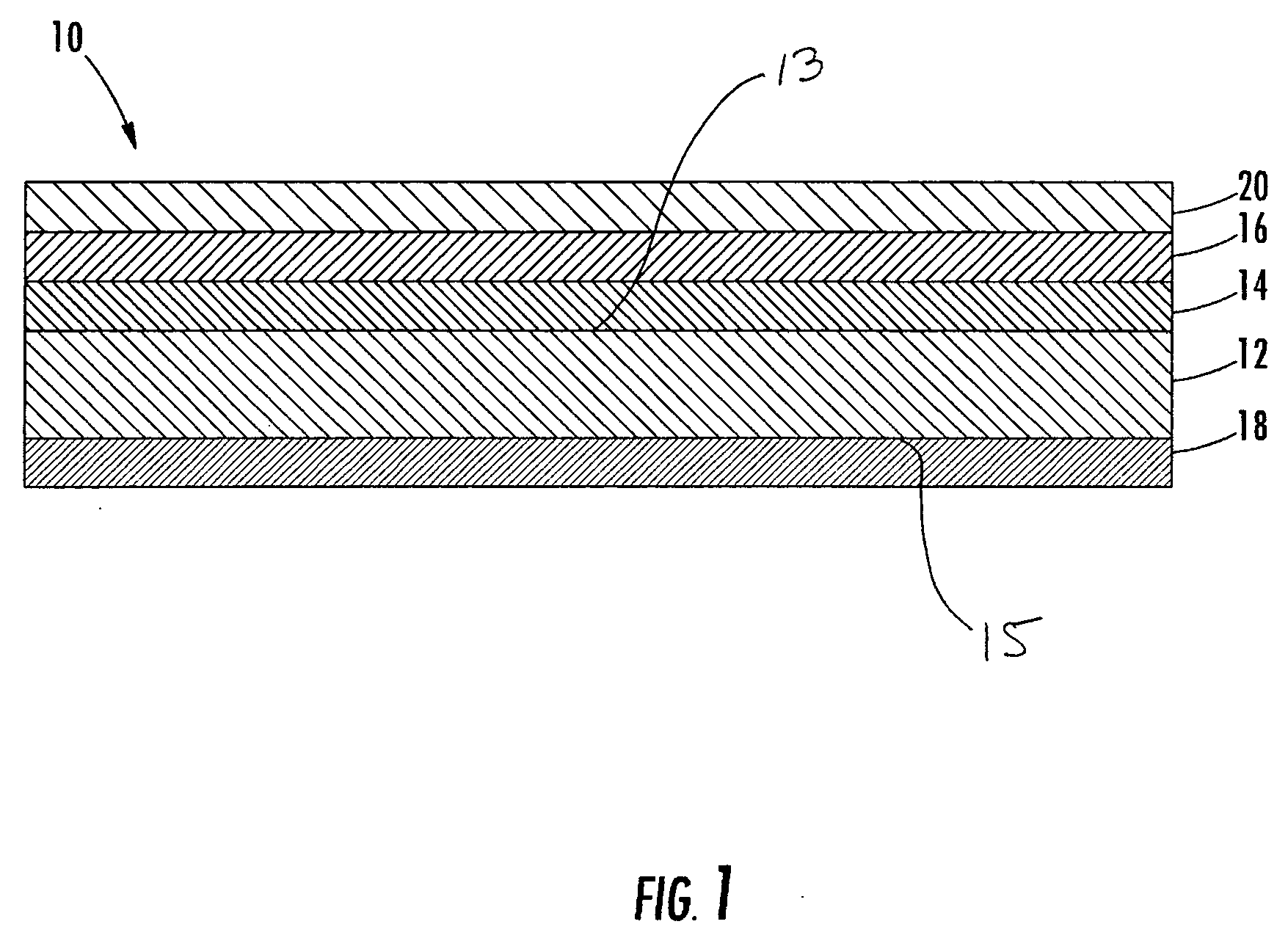

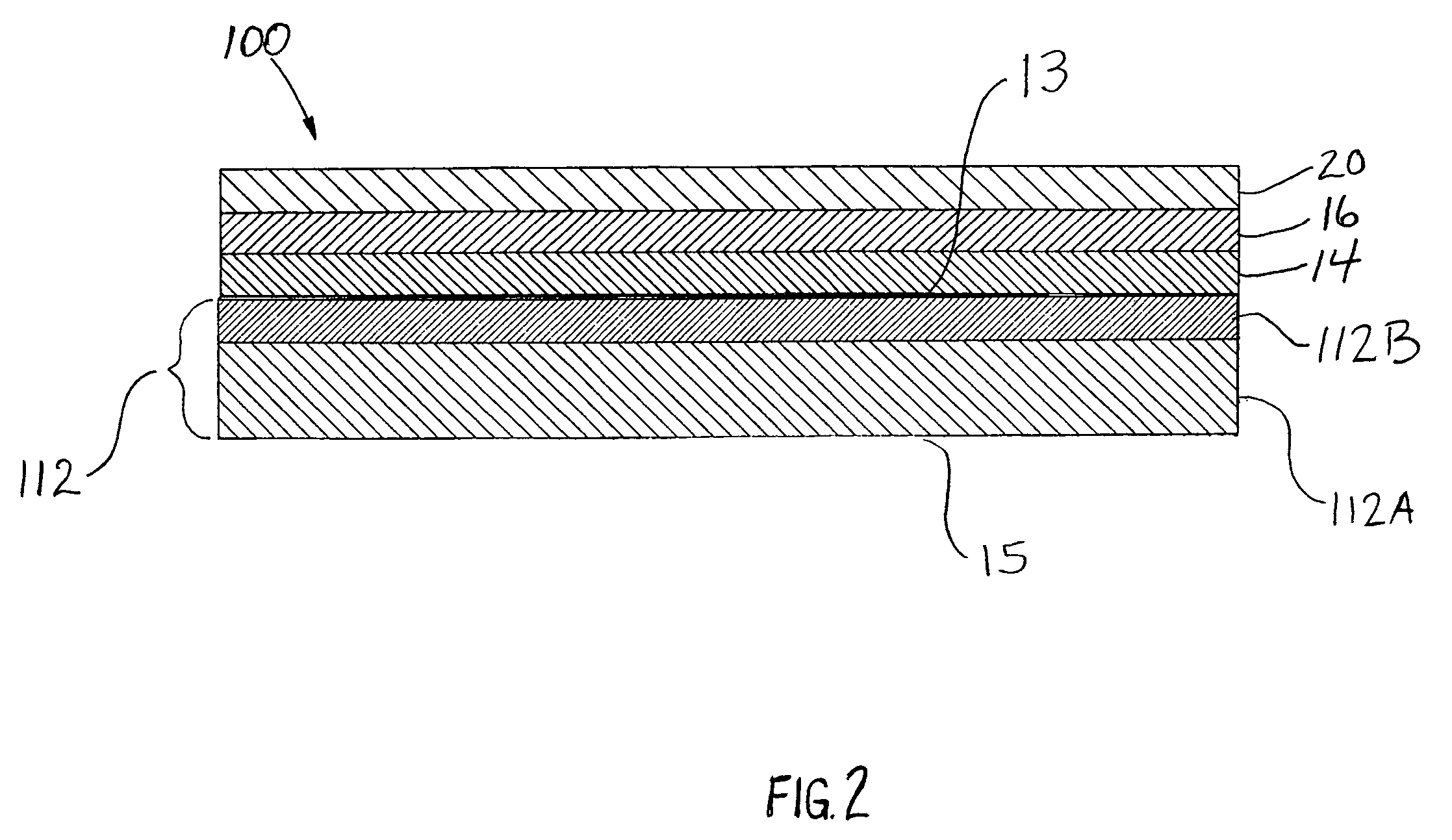

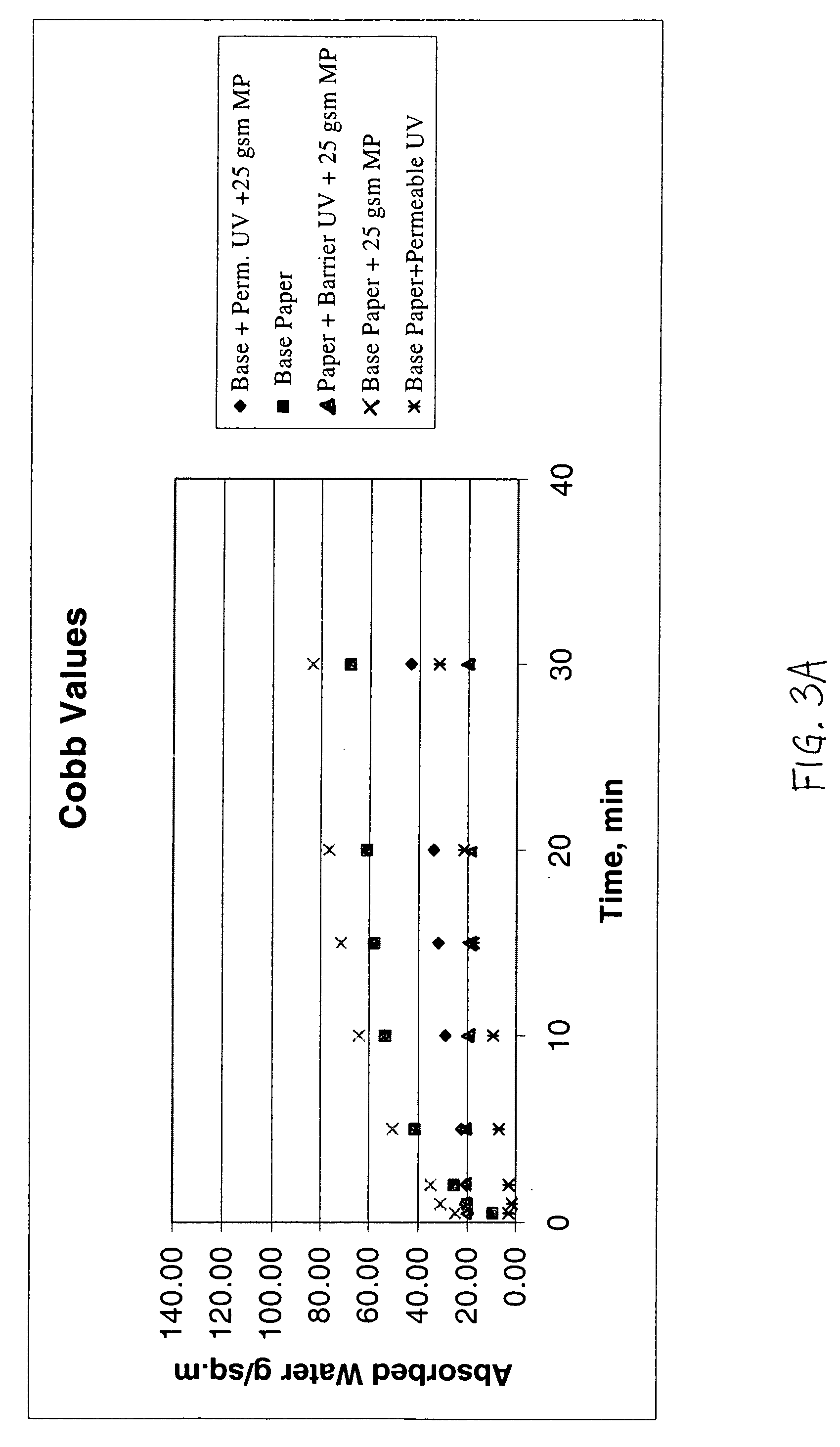

Ink-jet media having an ink-vehicle permeable coating and a microporous coating

An ink-jet media having an absorbent substrate with a front surface and a back surface. The front surface of the substrate is coated with an ink-vehicle permeable, preferably radiation-cured coating. A microporous ink-receptive coating is deposited on top of the ink-vehicle permeable coating. An optional protective layer may be deposited on top of the microporous ink-receptive layer. The back surface of the substrate may also be optionally coated with a polymer curl-controlling coating.

Owner:ARKWRIGHT ADVANCED COATING

Continuous in-line manufacturing process for high speed coating deposition via a kinetic spray process

InactiveUS20060040048A1Constant cross-sectional areaMolten spray coatingPretreated surfacesSpray coatingEngineering

An improved kinetic spray system and a method for using the same in a high speed manufacturing environment are disclosed. The improved kinetic spray nozzle system comprises: a gas / powder exchange chamber connected to a first end of a powder / gas conditioning chamber having a length along a longitudinal axis of equal to or greater than 20 millimeters; a converging diverging supersonic nozzle, the supersonic nozzle having a converging section separated from a diverging section by a throat, the diverging section comprising a first portion and a second portion, with the first portion having a cross-sectional area that increases along a length of the first portion and with the second portion having a substantially constant cross-sectional area along a length of the second portion; and the converging section connected to a second end of the powder / gas conditioning chamber opposite the first end. The method includes: use of the disclosed nozzle system with the addition of hard particles that permit maximum enhancement of particle temperature while not permitting clogging of the nozzle; use of controlled particle feed rates to match the desired very high traverse speeds; and use of pre-heating of the substrate to clean it an to enhance particle bonding. With the disclosed nozzle system coupled with the disclosed methods one can apply kinetic spray coatings at traverse speeds of over 200 centimeters per second with a deposition efficiency of over 80 percent.

Owner:F W GARTNER THERMAL SPRAYING

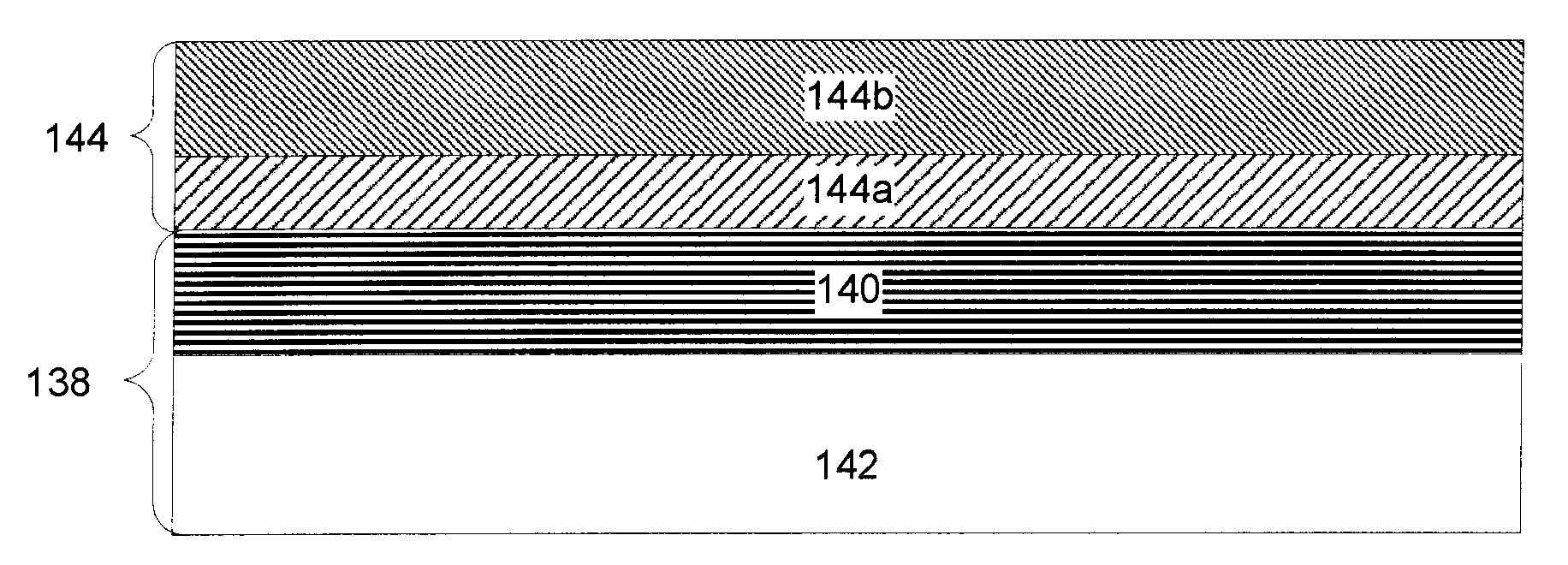

Wear resistant vapor deposited coating, method of coating deposition and applications therefor

ActiveUS7939172B2Stable cutting edgeReduce frictionPigmenting treatmentSurgeryWear resistantShape-memory alloy

A low friction top coat over a multilayer metal / ceramic bondcoat provides a conductive substrate, such as a rotary tool, with wear resistance and corrosion resistance. The top coat further provides low friction and anti-stickiness as well as high compressive stress. The high compressive stress provided by the top coat protects against degradation of the tool due to abrasion and torsional and cyclic fatigue. Substrate temperature is strictly controlled during the coating process to preserve the bulk properties of the substrate and the coating. The described coating process is particularly useful when applied to shape memory alloys.

Owner:G&H TECH LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com