Patents

Literature

52 results about "Radiofrequency plasma" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

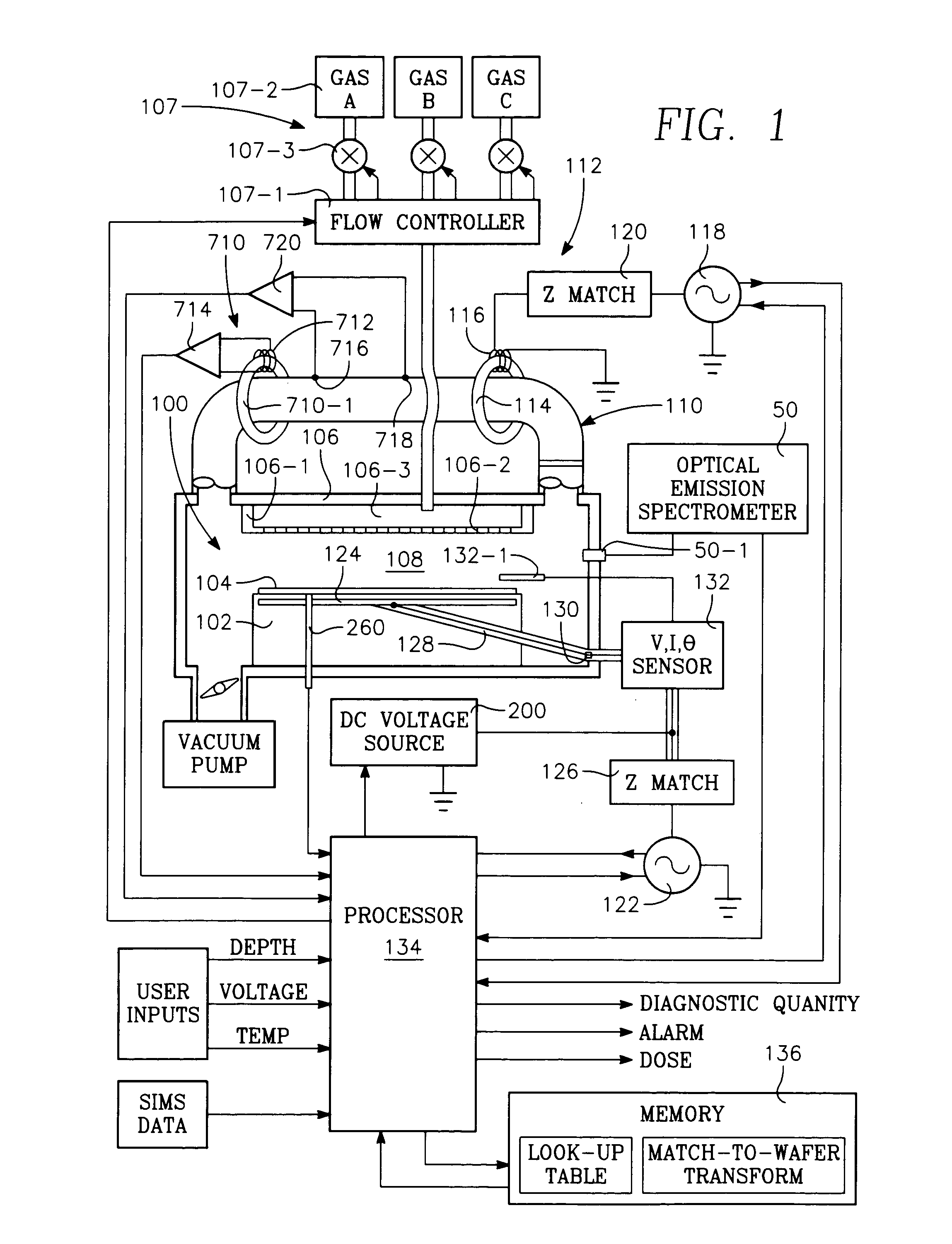

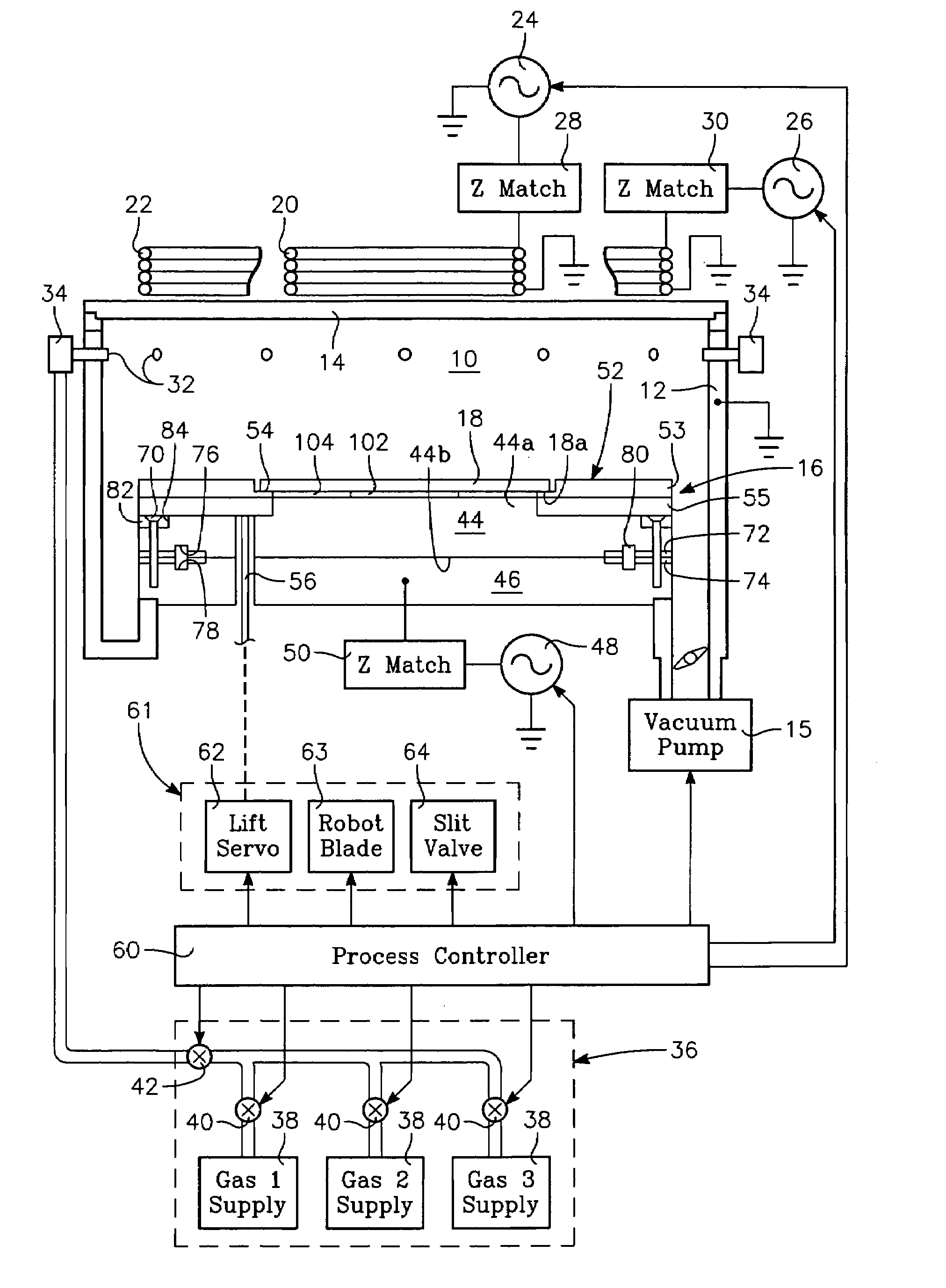

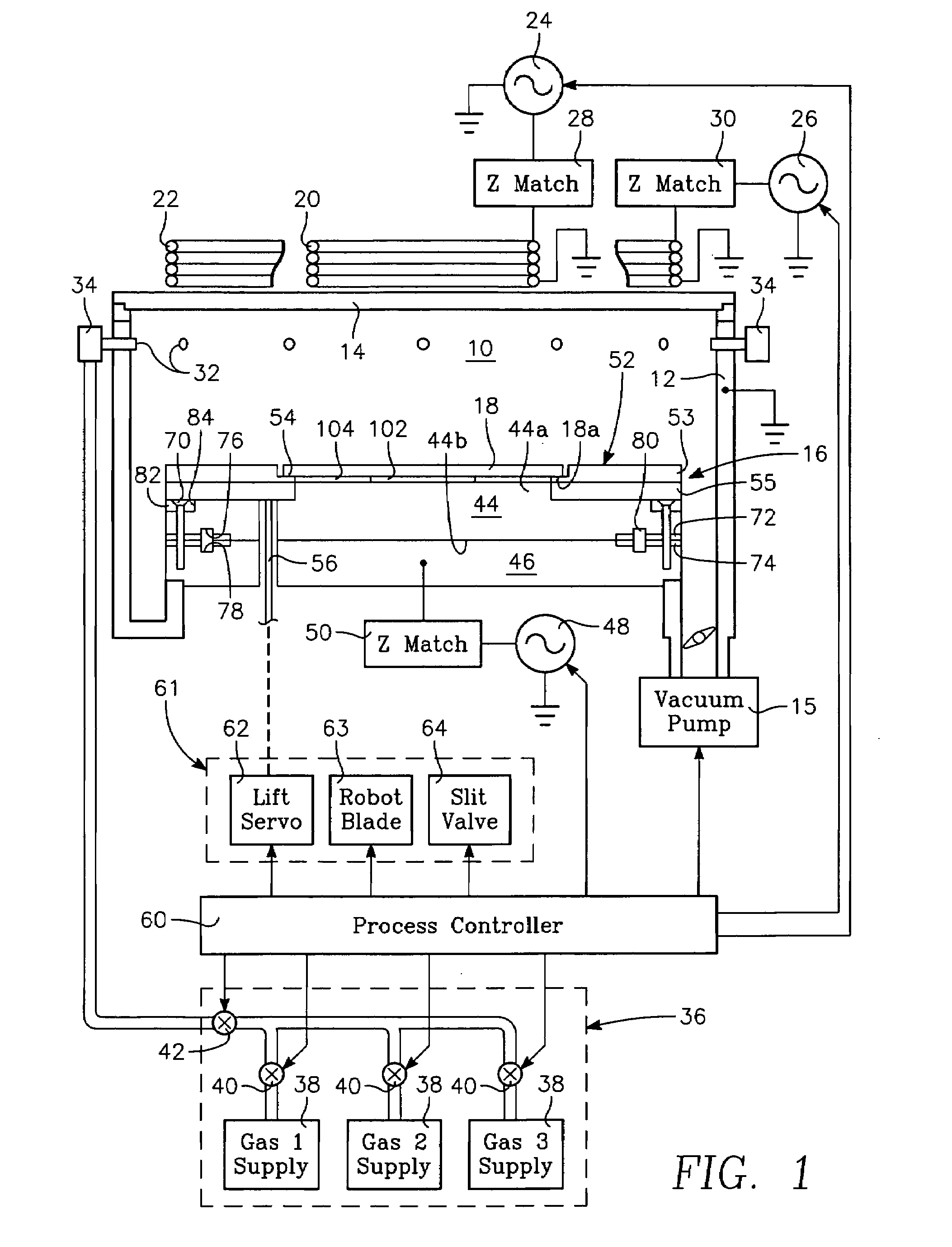

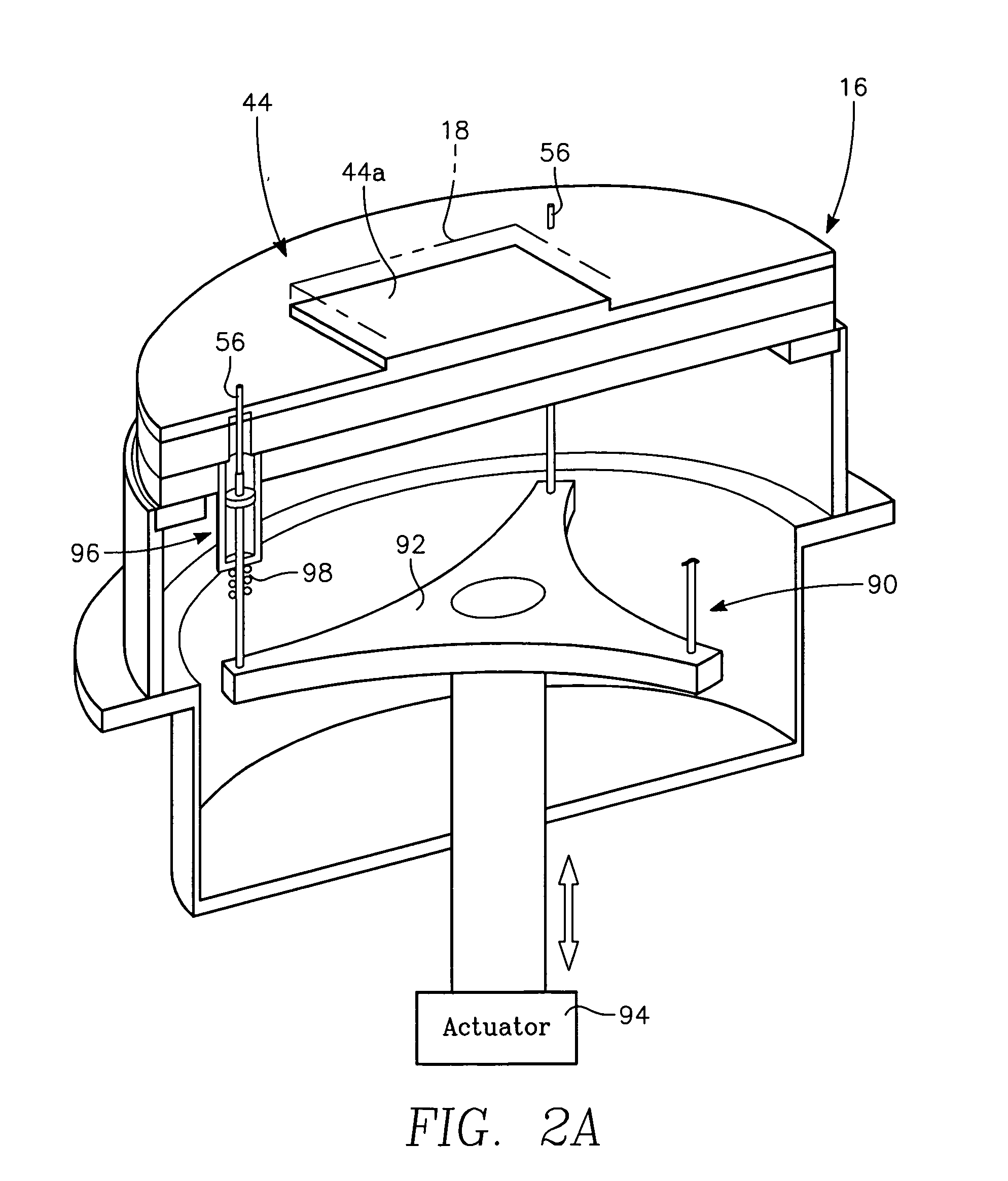

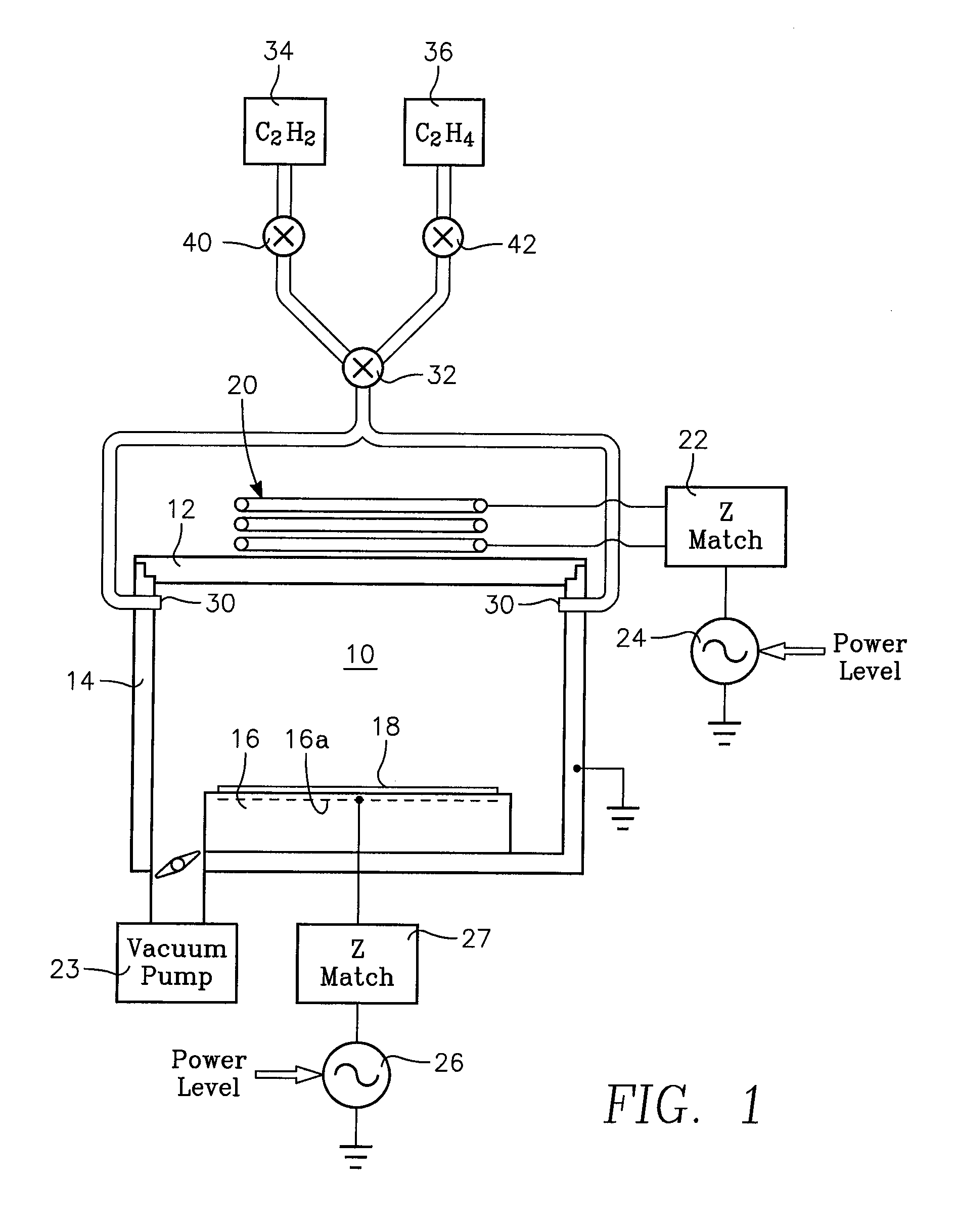

Low temperature plasma deposition process for carbon layer deposition

InactiveUS7312162B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingCarbon layerPlasma current

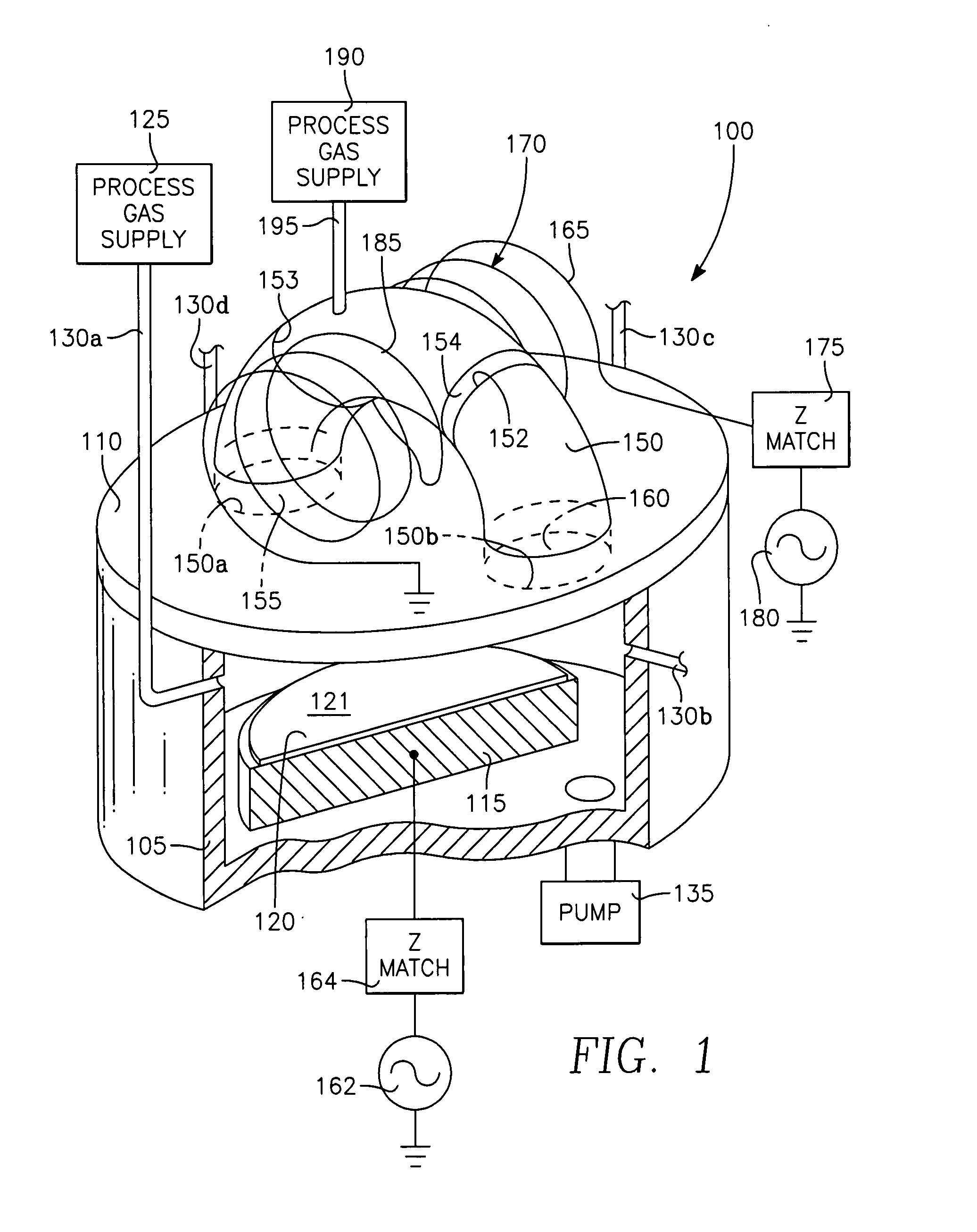

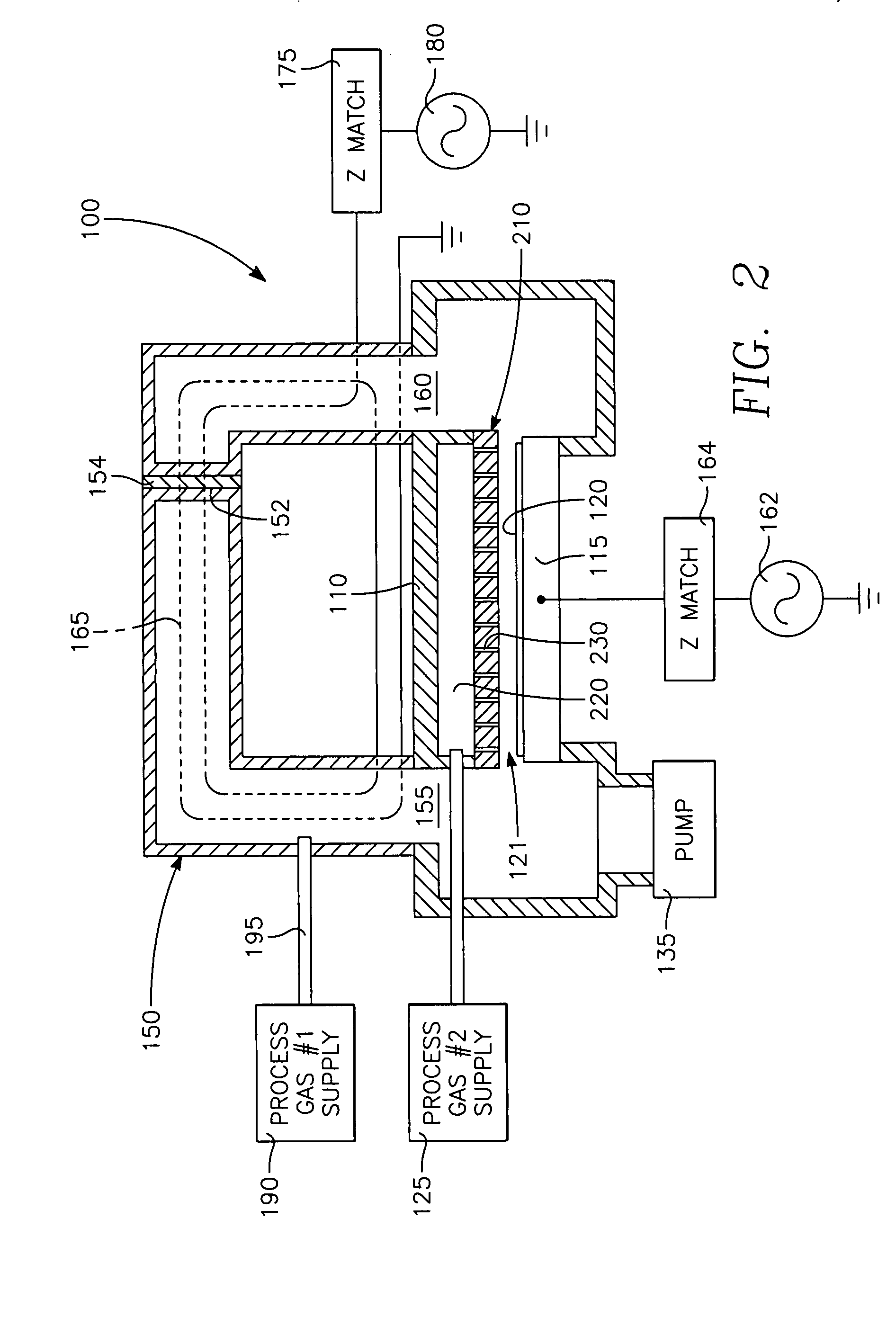

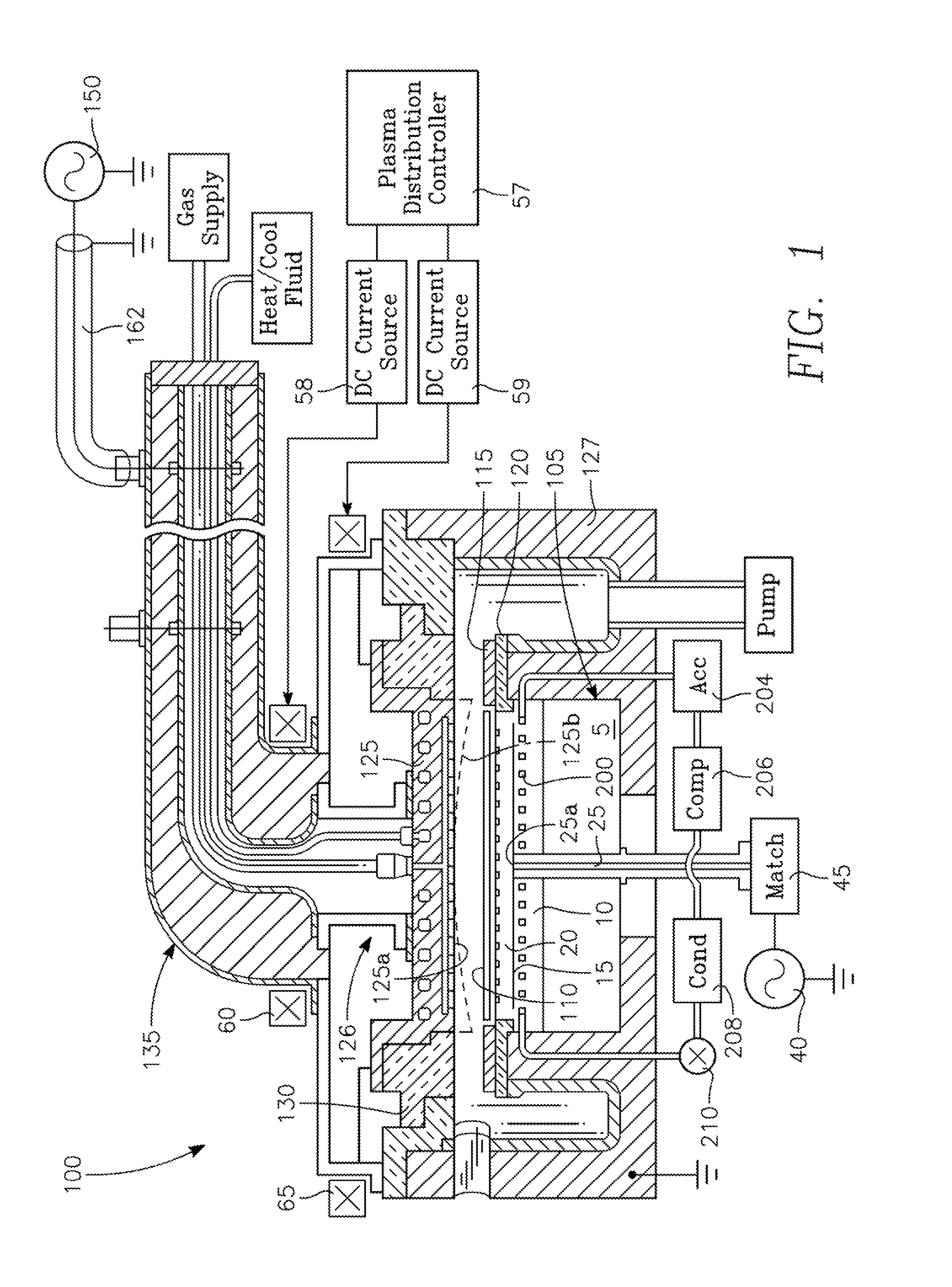

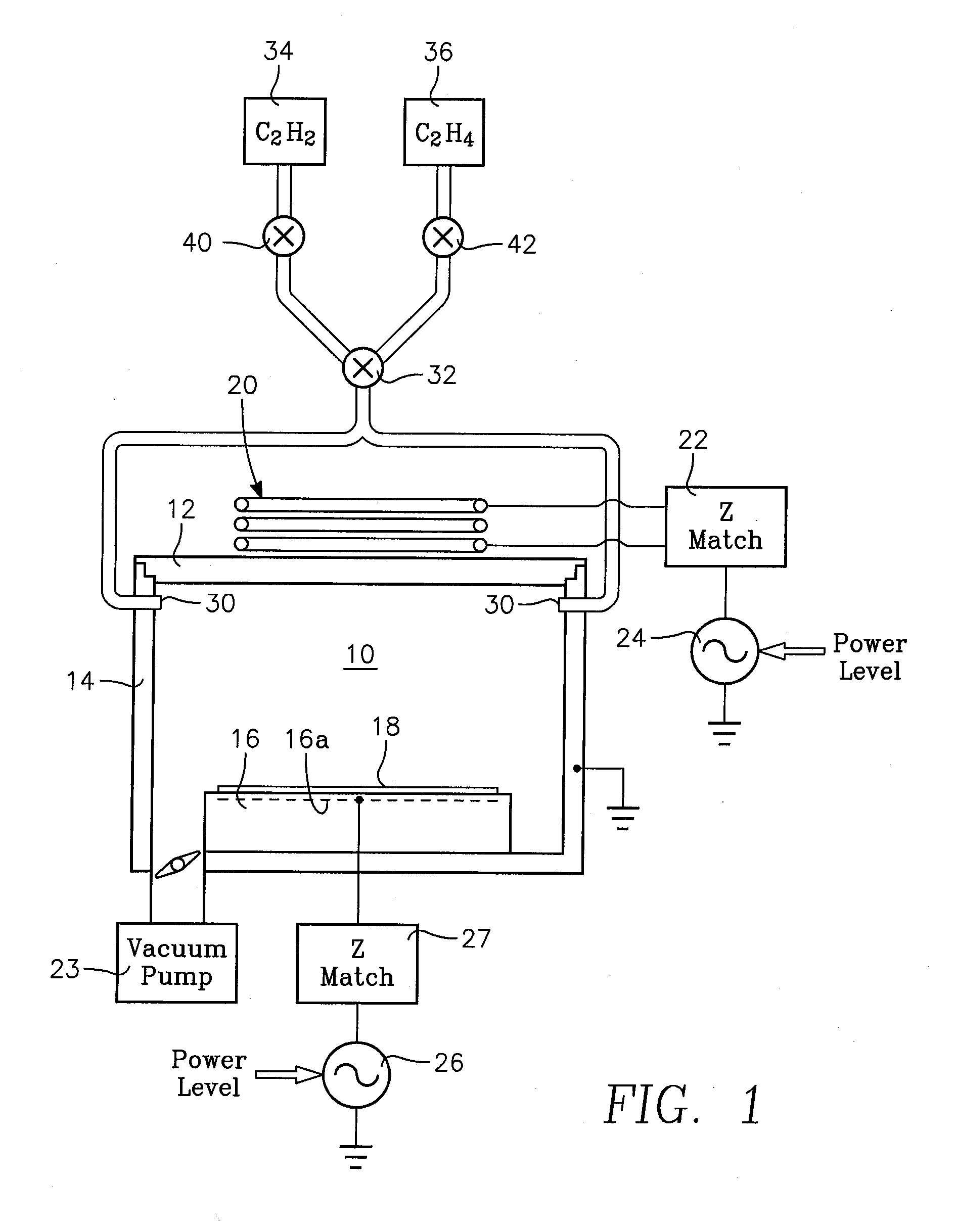

A method of depositing a carbon layer on a workpiece includes placing the workpiece in a reactor chamber, introducing a carbon-containing process gas into the chamber, generating a reentrant toroidal RF plasma current in a reentrant path that includes a process zone overlying the workpiece by coupling plasma RF source power to an external portion of the reentrant path, and coupling RF plasma bias power or bias voltage to the workpiece.

Owner:APPLIED MATERIALS INC

Low temperature CVD process with selected stress of the CVD layer on CMOS devices

Device-enhancing coatings are deposited on CMOS devices by successively masking with photoresist each one of the sets of N-channel and P-channel devices while unmasking or leaving unmasked the other set, and after each step of successively masking one of the sets of devices, carrying out low temperature CVD steps with a toroidal RF plasma current while applying an RF plasma bias voltage. The temperature of the workpiece is held below a threshold photoresist removal temperature. The RF bias voltage is held at a level at which the coating is deposited with a first stress when the unmasked set consists of the P-channel devices and with a second stress when the unmasked set consists of N-channel devices.

Owner:APPLIED MATERIALS INC

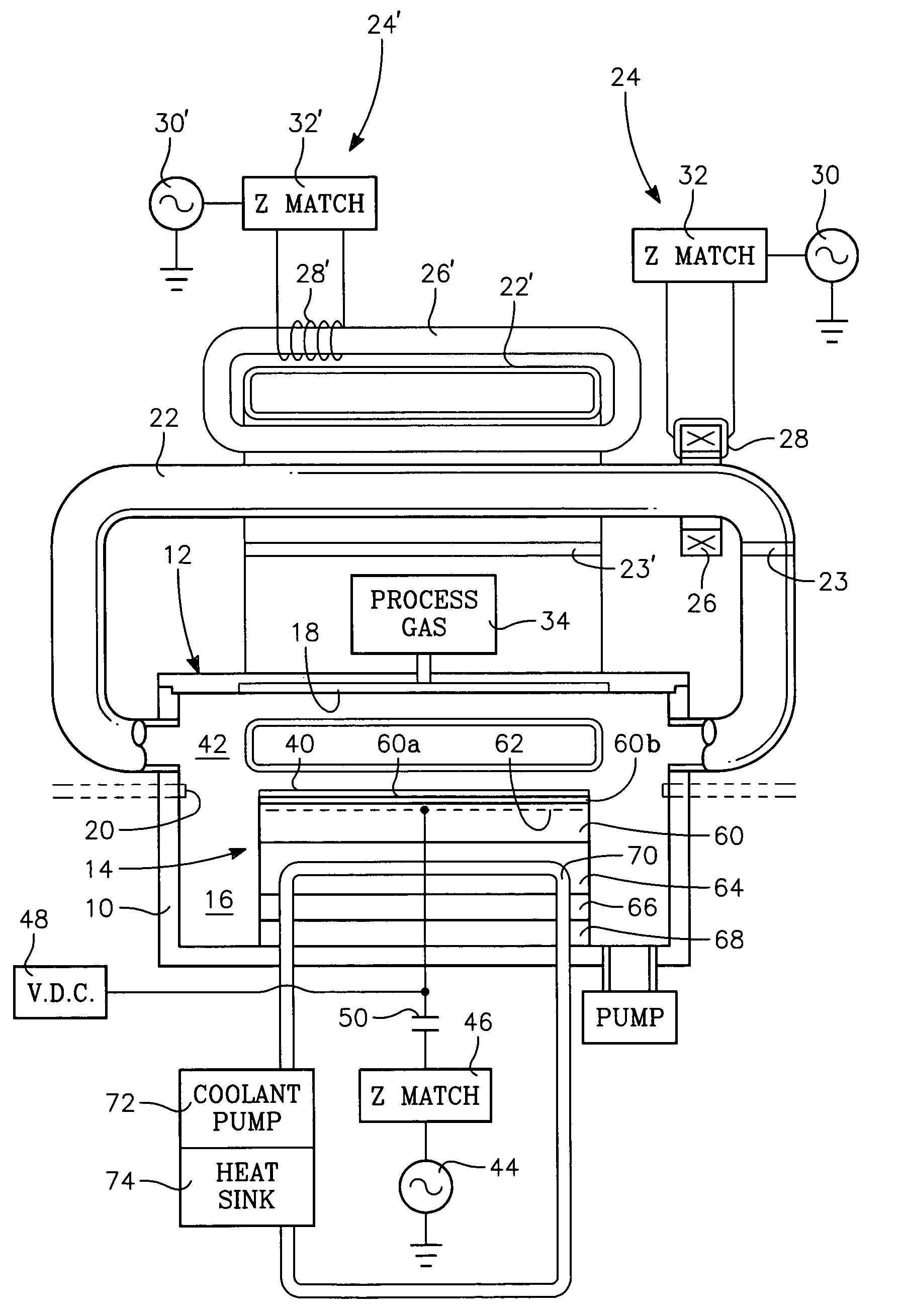

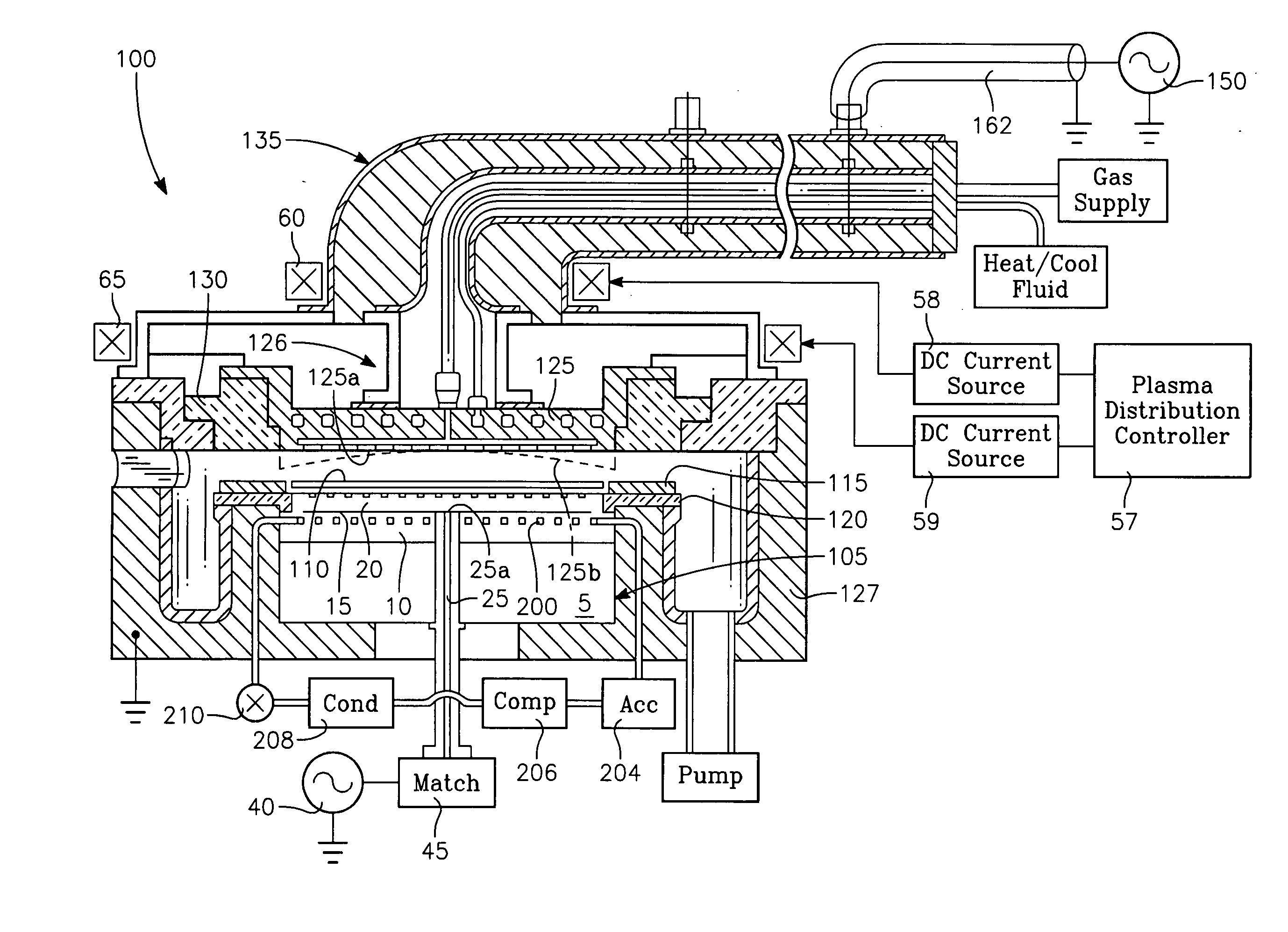

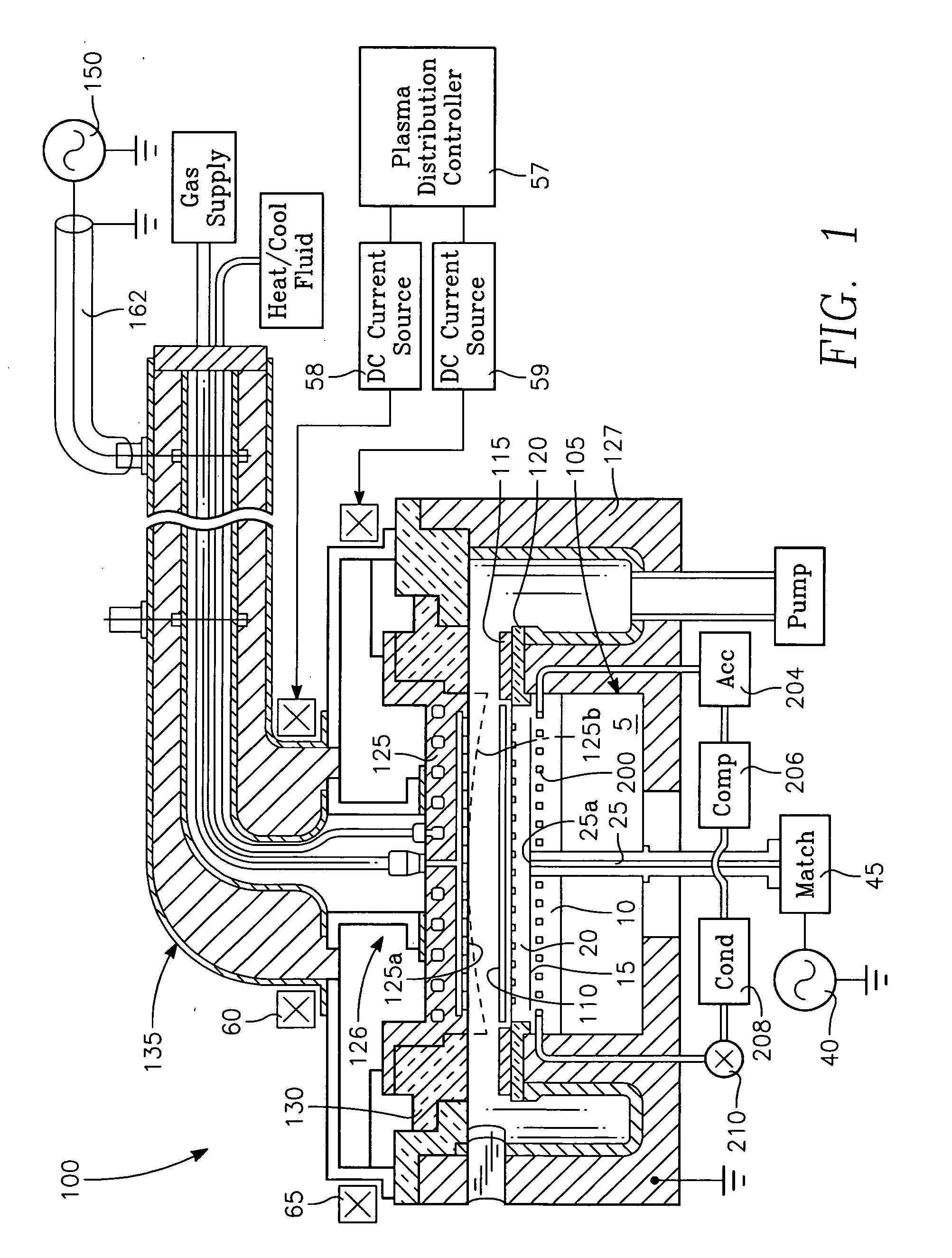

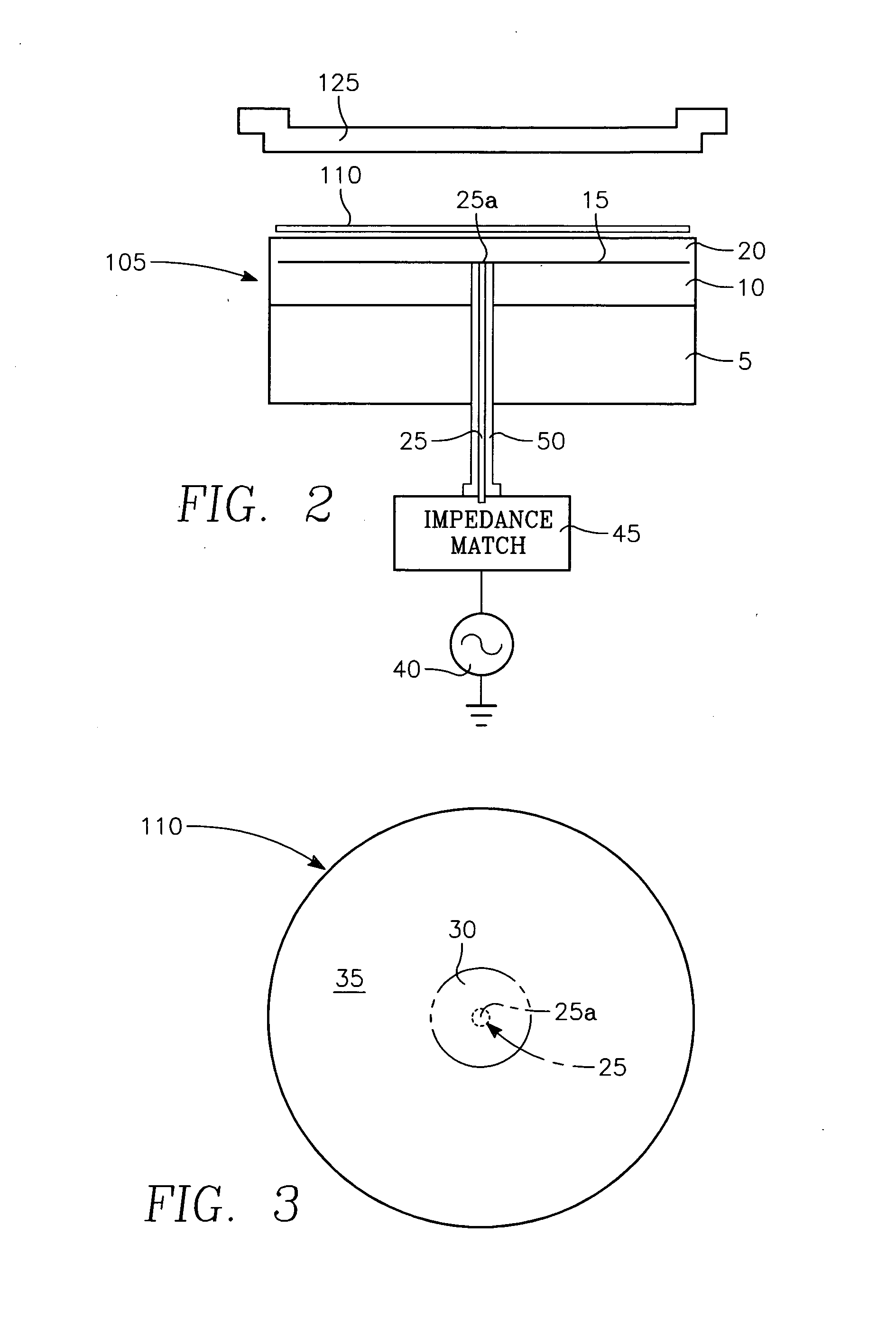

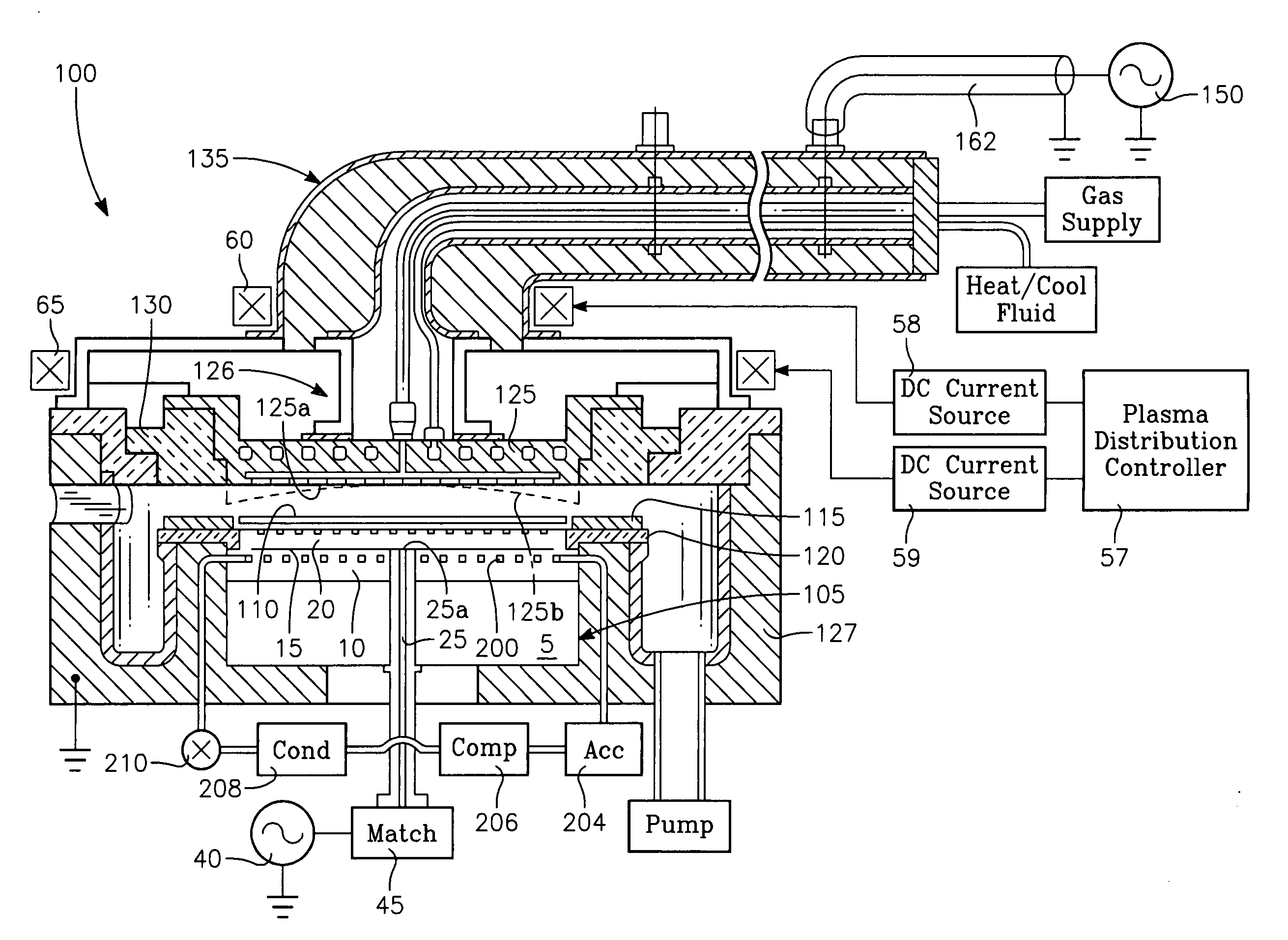

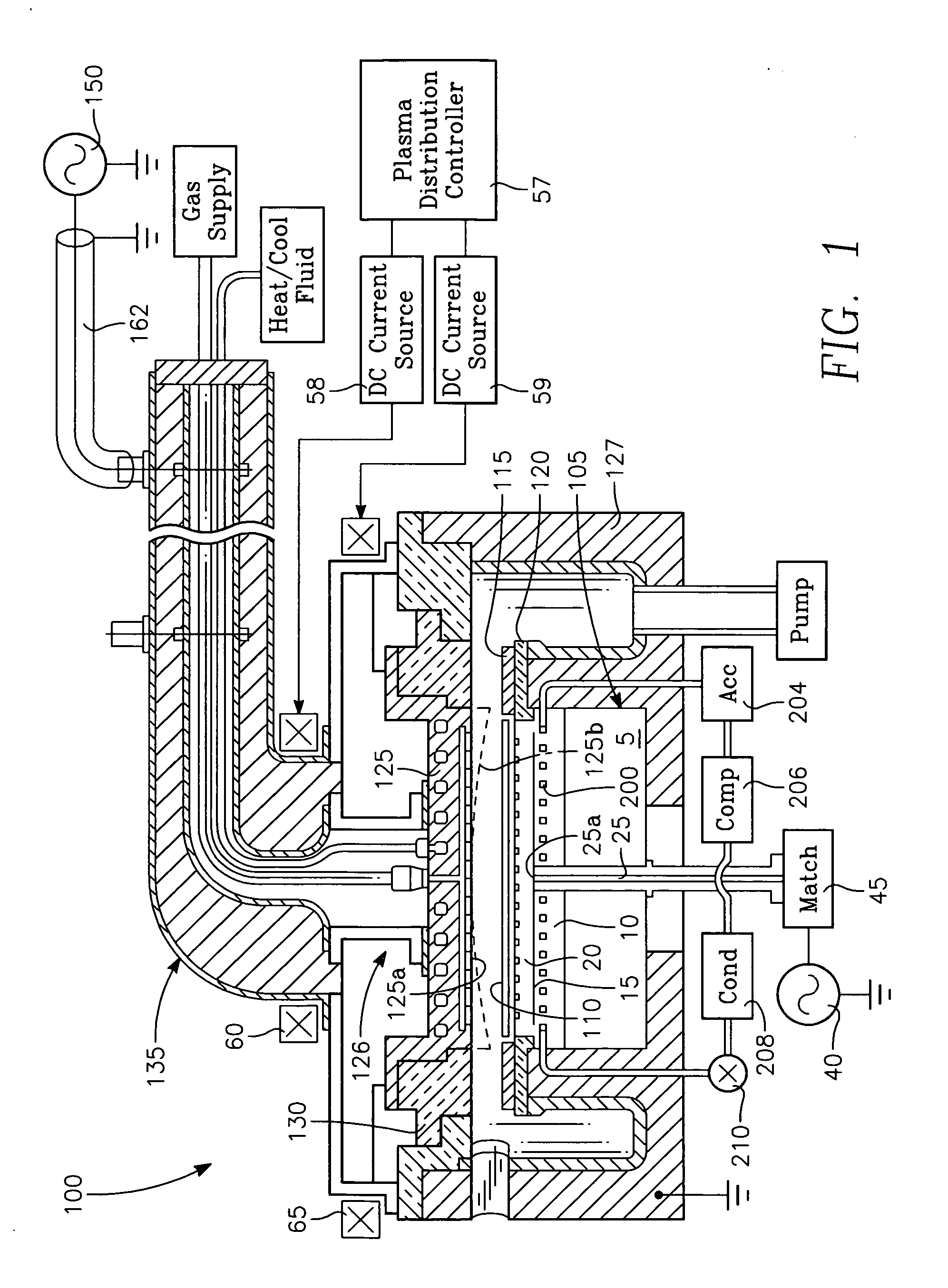

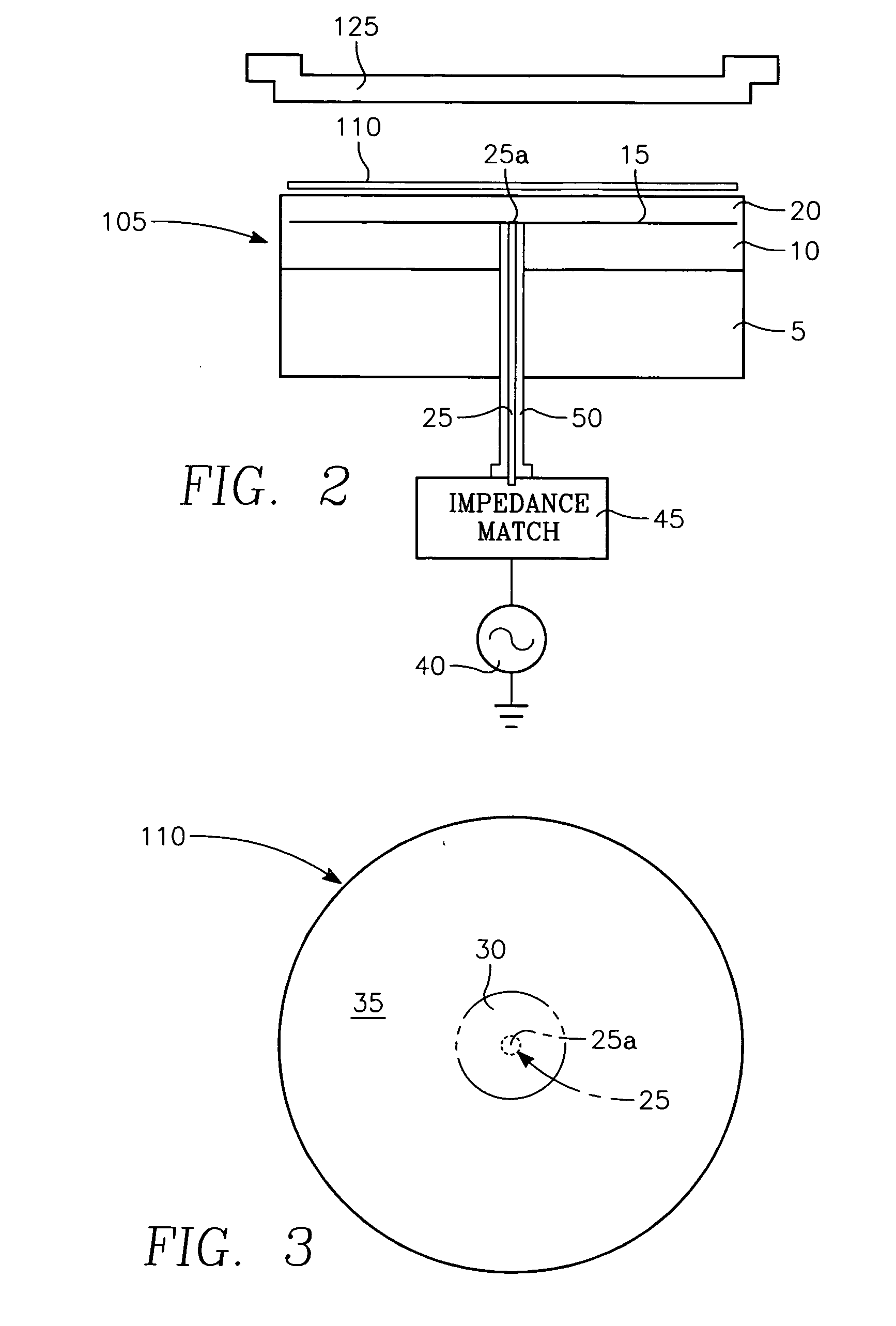

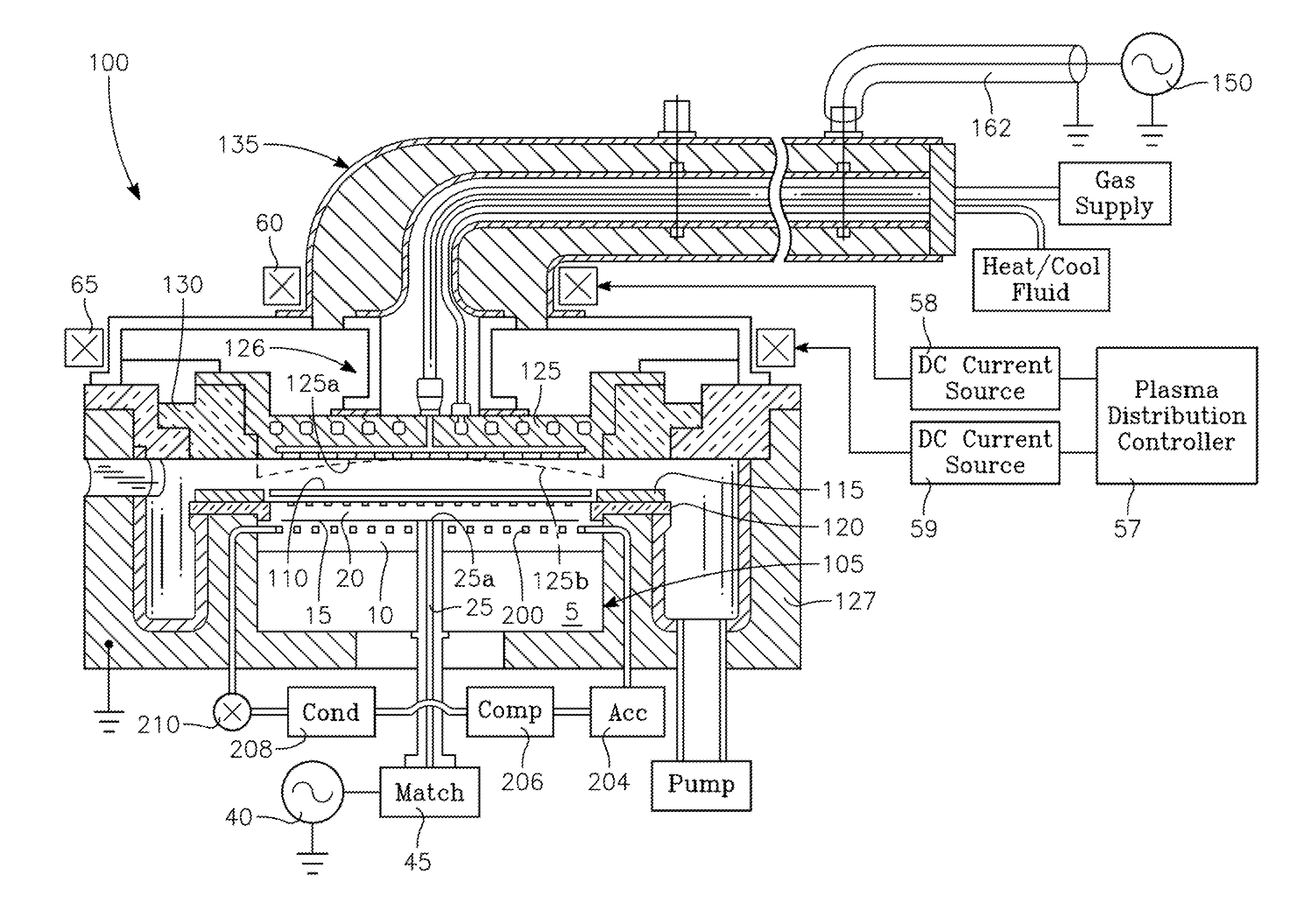

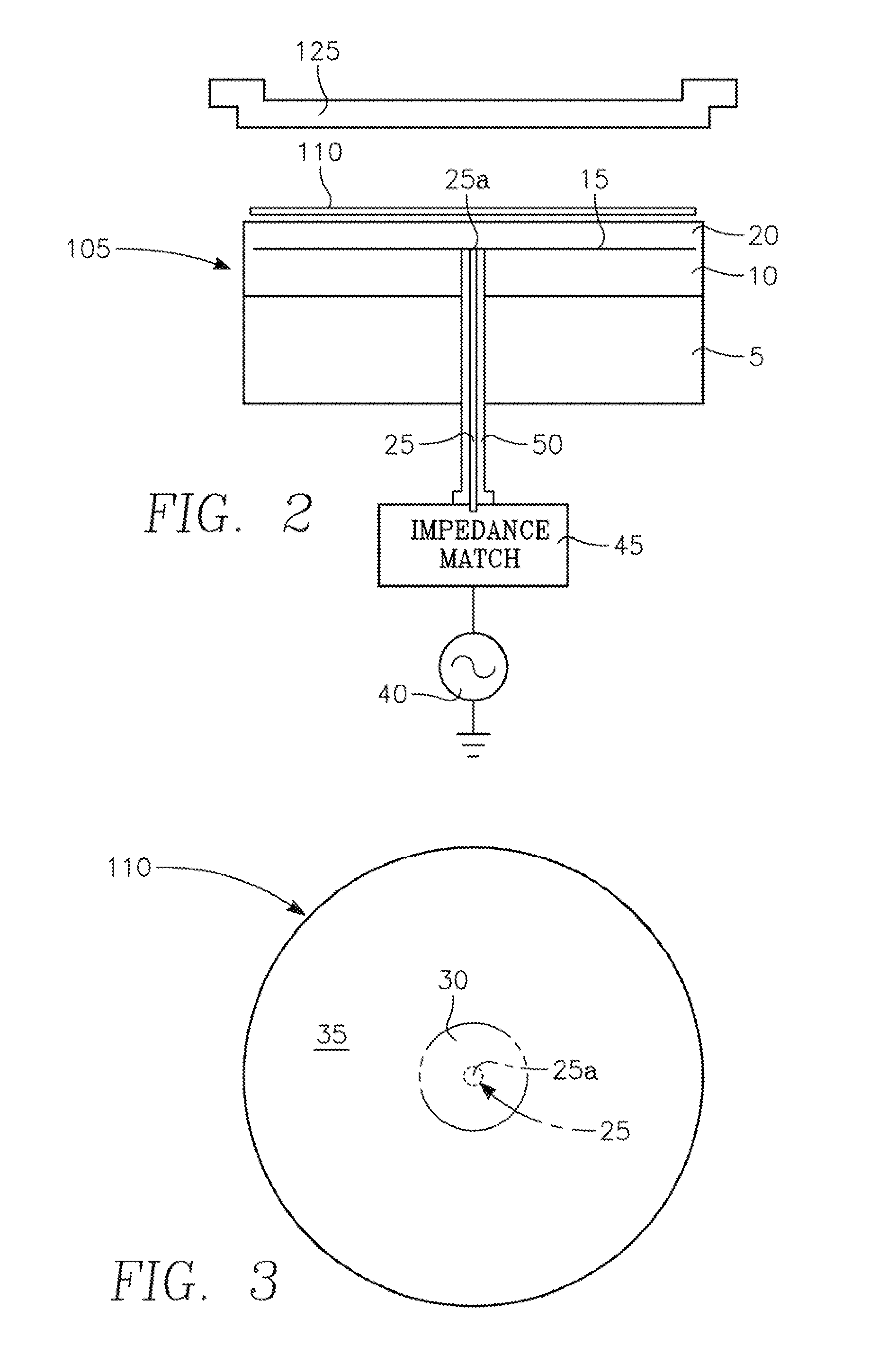

Capacitively coupled plasma reactor having a cooled/heated wafer support with uniform temperature distribution

ActiveUS20070081295A1Improve uniformityWide pressure rangeSemiconductor/solid-state device manufacturingCapacitanceGas phase

A plasma reactor for processing a workpiece includes a reactor chamber, an electrostatic chuck within the chamber for supporting a workpiece, an RF plasma bias power generator coupled to apply RF power to the electrostatic chuck and a refrigeration loop having an evaporator inside the electrostatic chuck with a refrigerant inlet and a refrigerant outlet. Preferably, the evaporator includes a meandering passageway distributed in a plane beneath a top surface of the electrostatic chuck. Preferably, refrigerant within the evaporator is apportioned between a vapor phase and a liquid phase. As a result, heat transfer between the electrostatic chuck and the refrigerant within the evaporator is a constant-temperature process. This feature improves uniformity of temperature distribution across a diameter of the electrostatic chuck.

Owner:BE AEROSPACE INCORPORATED

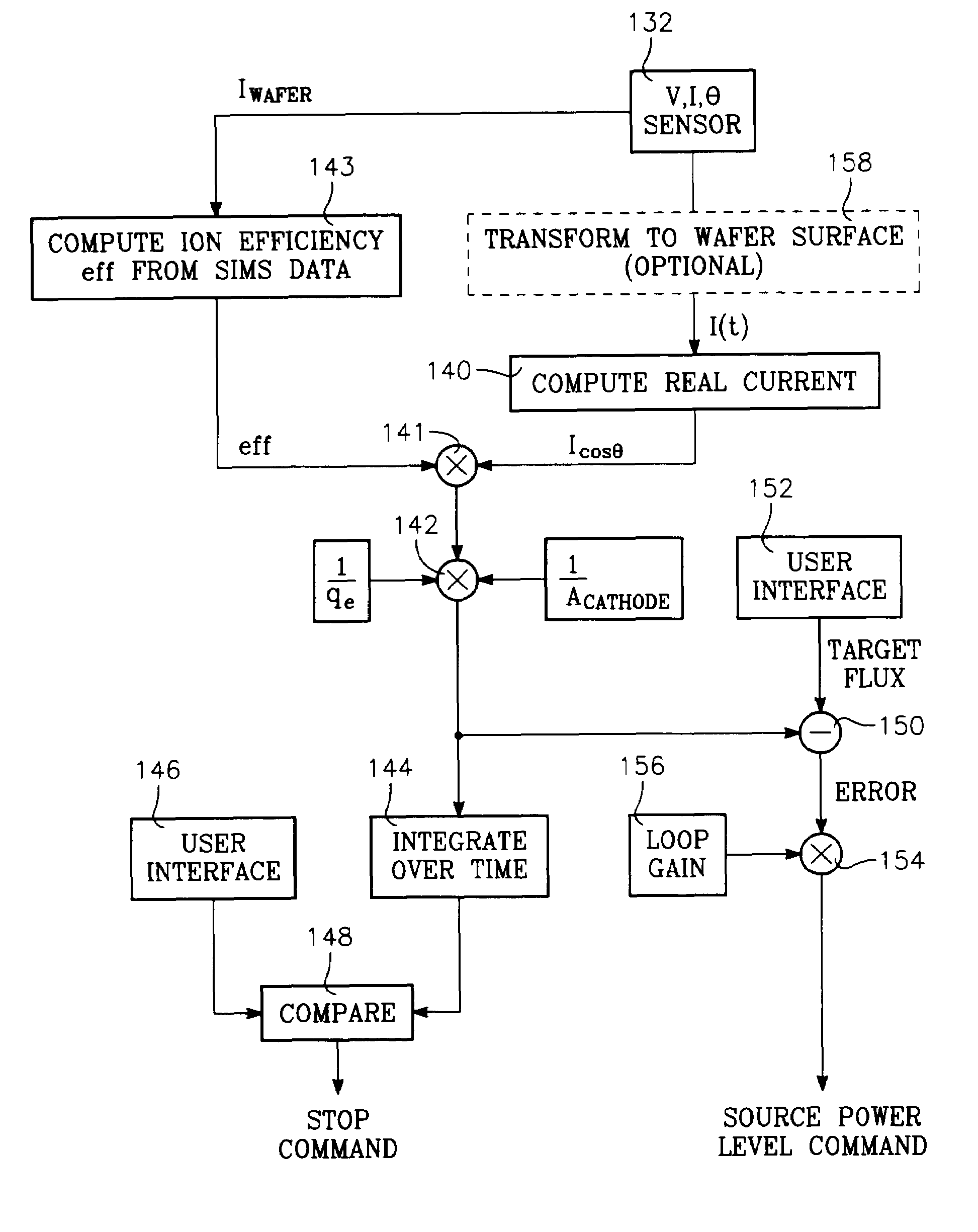

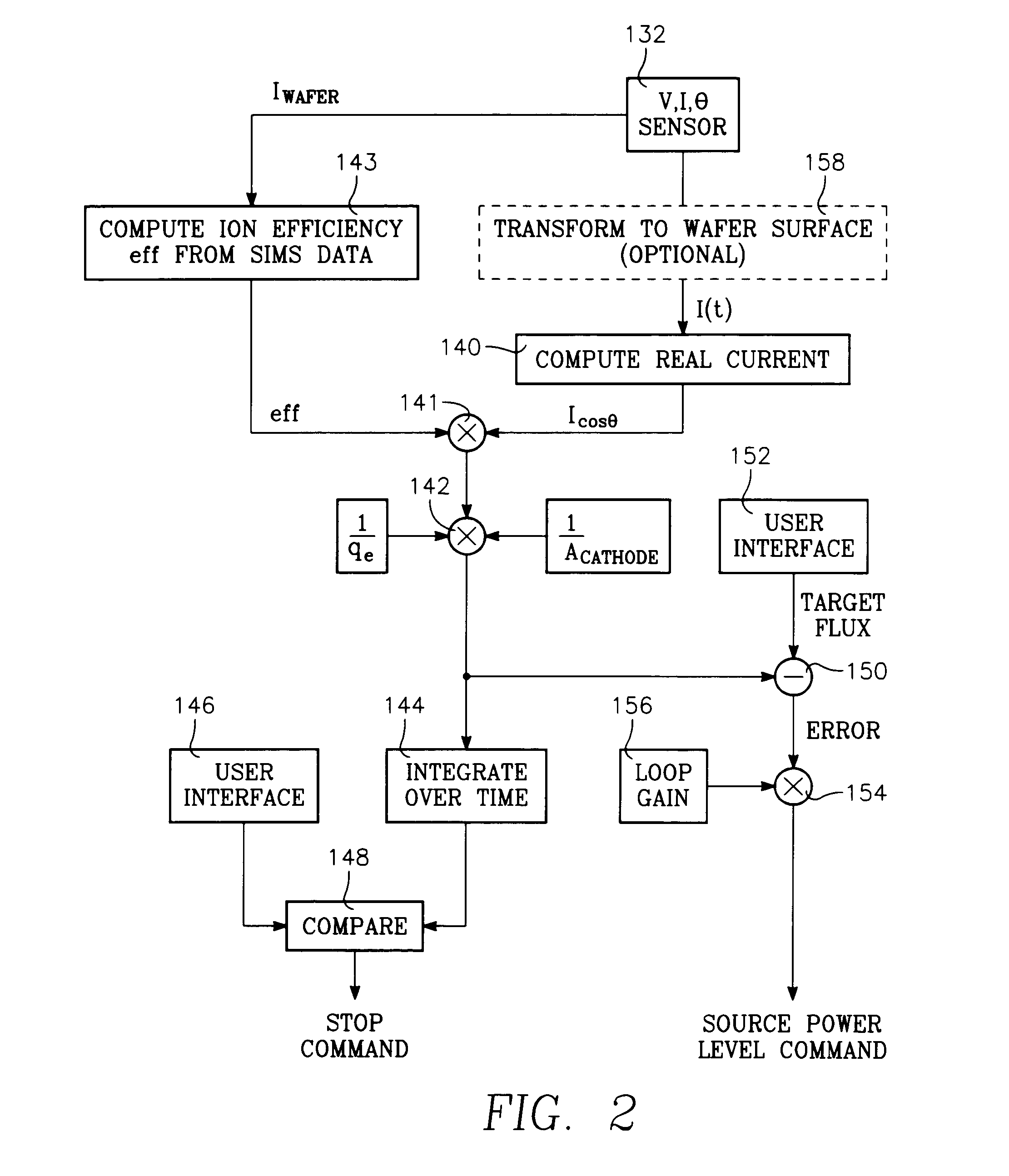

RF measurement feedback control and diagnostics for a plasma immersion ion implantation reactor

InactiveUS7666464B2Improve accuracySemiconductor/solid-state device testing/measurementElectric discharge tubesPower flowCoupling

A method of measuring ion dose in a plasma immersion ion implantation reactor during ion implantation of a selected species into a workpiece includes placing the workpiece on a pedestal in the reactor and feeding into the reactor a process gas comprising a species to be implanted into the workpiece, and then coupling RF plasma source power to a plasma in the reactor. It further includes coupling RF bias power to the workpiece by an RF bias power generator that is coupled to the workpiece through a bias feedpoint of the reactor and measuring RF current at the feedpoint to generate a current-related value, and then integrating the current-related over time to produce an ion implantation dose-related value.

Owner:APPLIED MATERIALS INC

Capacitively coupled plasma reactor having very agile wafer temperature control

ActiveUS20070081294A1Promote fillingLiquid surface applicatorsSemiconductor/solid-state device manufacturingCapacitanceProcess engineering

A plasma reactor for processing a workpiece includes a reactor chamber, an electrostatic chuck within the chamber having a top surface for supporting a workpiece and having indentations in the top surface that form enclosed gas flow channels whenever covered by a workpiece resting on the top surface. The reactor further includes thermal control apparatus thermally coupled to the electrostatic chuck, an RF plasma bias power generator coupled to apply RF power to the electrostatic chuck, a pressurized gas supply of a thermally conductive gas, a controllable gas valve coupling the pressurized gas supply to the indentations to facilitate filling the channels with the thermally conductive gas for heat transfer between a backside of a workpiece and the electrostatic chuck at a heat transfer rate that is a function of the pressure against the backside of the workpiece of the thermally conductive gas. The reactor further includes an agile workpiece temperature control loop including (a) a temperature probe in the electrostatic chuck, and (b) a backside gas pressure controller coupled to an output of the temperature probe and responsive to a specified desired temperature, the controller governing the gas valve in response to a difference between the output of the temperature probe and the desired temperature.

Owner:BE AEROSPACE INCORPORATED

Capacitivley coupled plasma reactor having a cooled/heated wafer support with uniform temperature distribution

A plasma reactor for processing a workpiece includes a reactor chamber, an electrostatic chuck within the chamber for supporting a workpiece, an RF plasma bias power generator coupled to apply RF power to the electrostatic chuck and a refrigeration loop having an evaporator inside the electrostatic chuck with a refrigerant inlet and a refrigerant outlet. Preferably, the evaporator includes a meandering passageway distributed in a plane beneath a top surface of the electrostatic chuck. Preferably, refrigerant within the evaporator is apportioned between a vapor phase and a liquid phase. As a result, heat transfer between the electrostatic chuck and the refrigerant within the evaporator is a constant-temperature process. This feature improves uniformity of temperature distribution across a diameter of the electrostatic chuck.

Owner:BE AEROSPACE INCORPORATED

Cutting fool boron nitride composite coating layer and its preparation method

InactiveCN1514039AReduce internal stressImprove bindingTurning toolsChemical vapor deposition coatingBoron nitrideCemented carbide

A coated composite boron nitride layer on the surface of cutting tool is composed of a substrate layer which is TiCxOyNz layer directly deposited on the hard alloy cutter, an intermediate binding layer which is made of Ni, Ni-contained compound, or N or B contained compound, and a boron nitride layer prepared from cubic boron nitride. Said coated layer is prepared by plasma intensified pulse laser deposition method, or hot wire added RE plasma CVD method, or their combination.

Owner:XIANGTAN UNIV

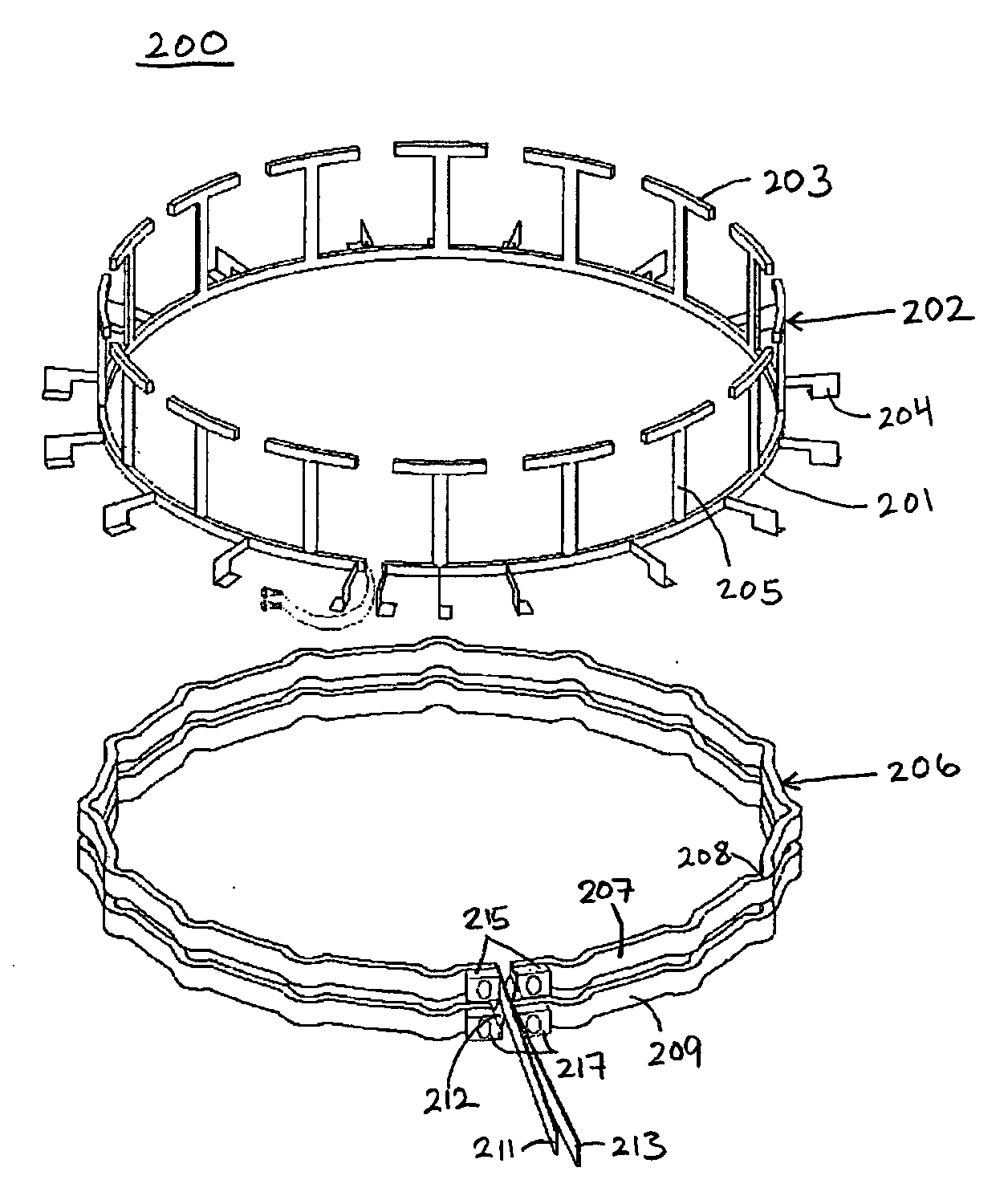

Mask etch plasma reactor with variable process gas distribution

ActiveUS20080102202A1Electric discharge tubesSemiconductor/solid-state device manufacturingNuclear engineeringEngineering

A plasma reactor for processing a workpiece such as a mask or wafer includes a vacuum chamber having a cylindrical side wall, a ceiling overlying the side wall and a ring supported on a top edge of the side wall and supporting the ceiling, the ring comprising an external surface and an interior surface. An RF plasma source power applicator and an RF source power generator coupled to the applicator furnish plasma source power. Plural passages extend in a radial direction through the ring from the external surface to the interior surface and are spaced apart along a circumference of the ring. A process gas supply furnishes process gas. An external gas flow conduit apparatus outside of the chamber extends around a circumference of the chamber and is coupled to the process gas supply. Plural external gas flow valves outside of the chamber are coupled to the external conduit at respective locations spaced apart along the conduit, each of the valves having: (a) a controlled gas output port coupled to a respective one of the plural passages at the external surface of the ring and (b) a valve control input. A gas valve configuration controller controls the valve control input of each of the valves.

Owner:APPLIED MATERIALS INC

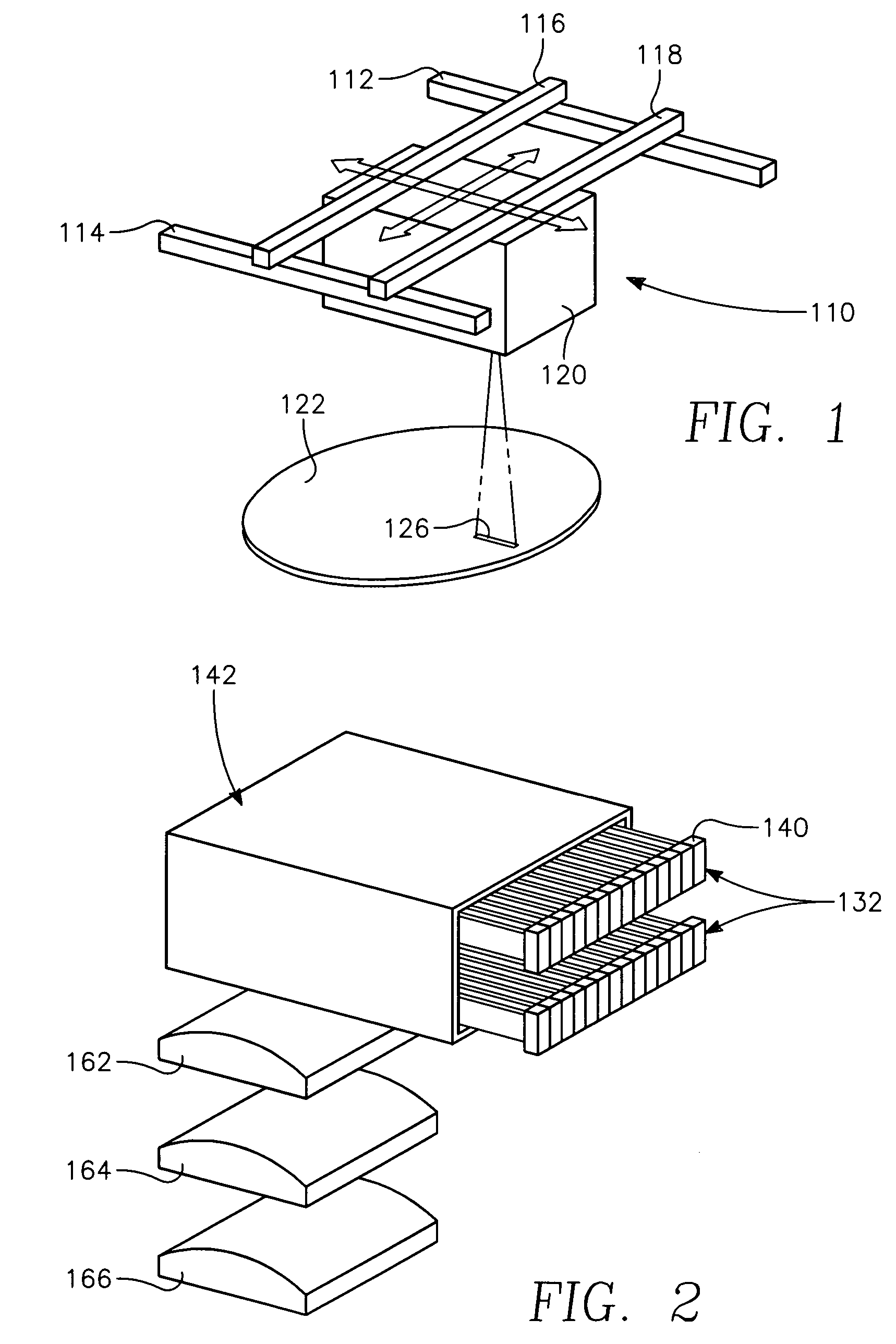

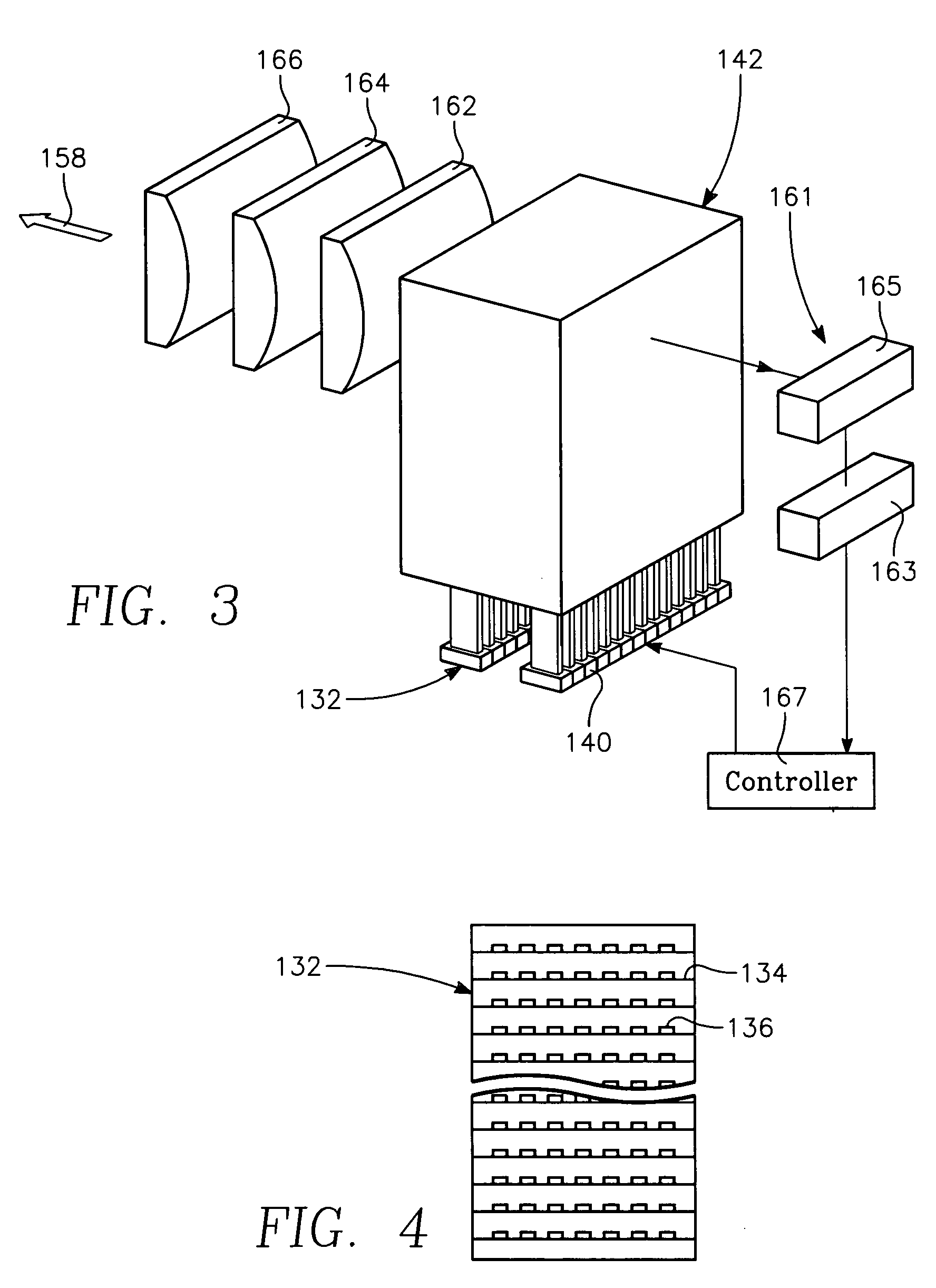

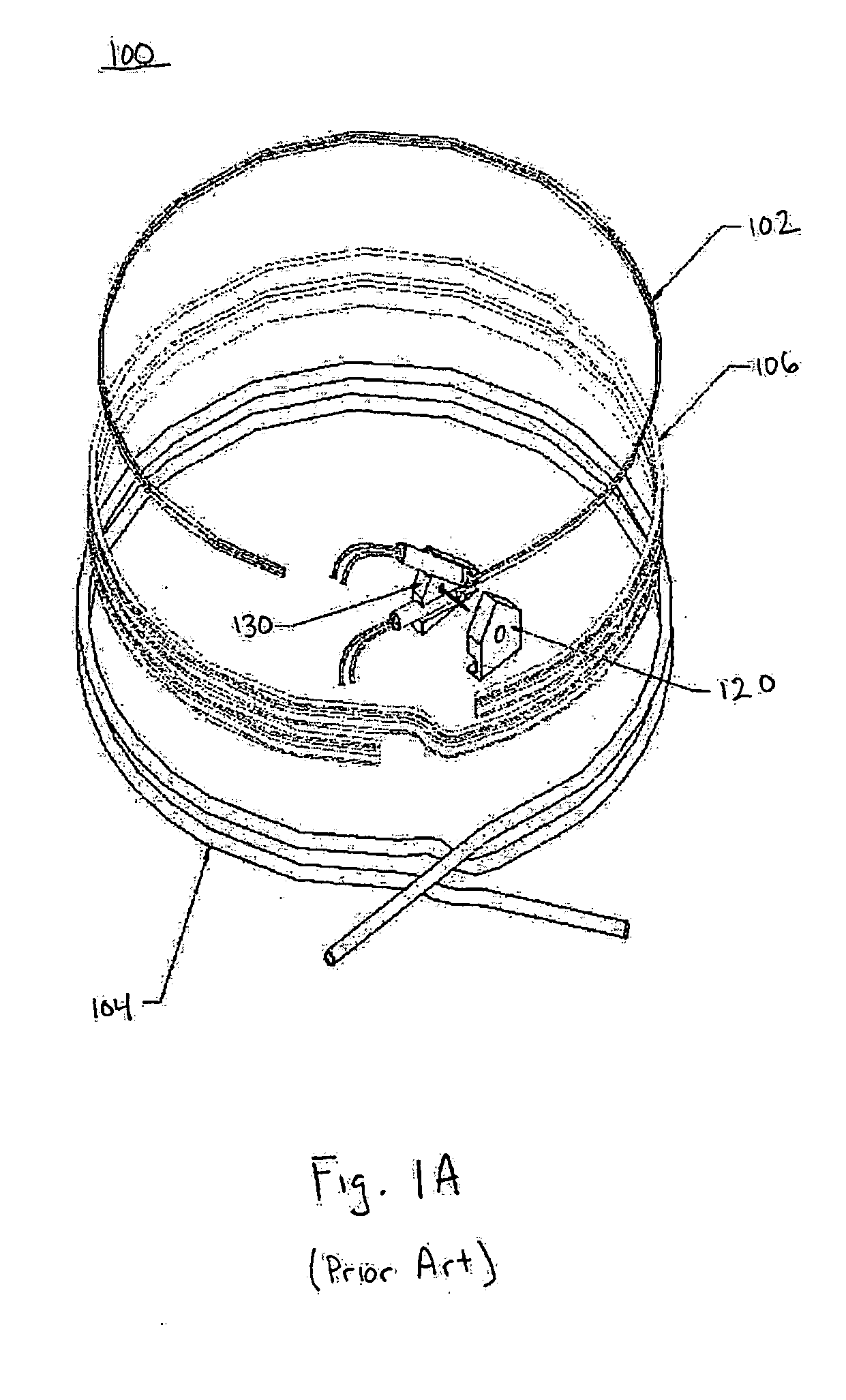

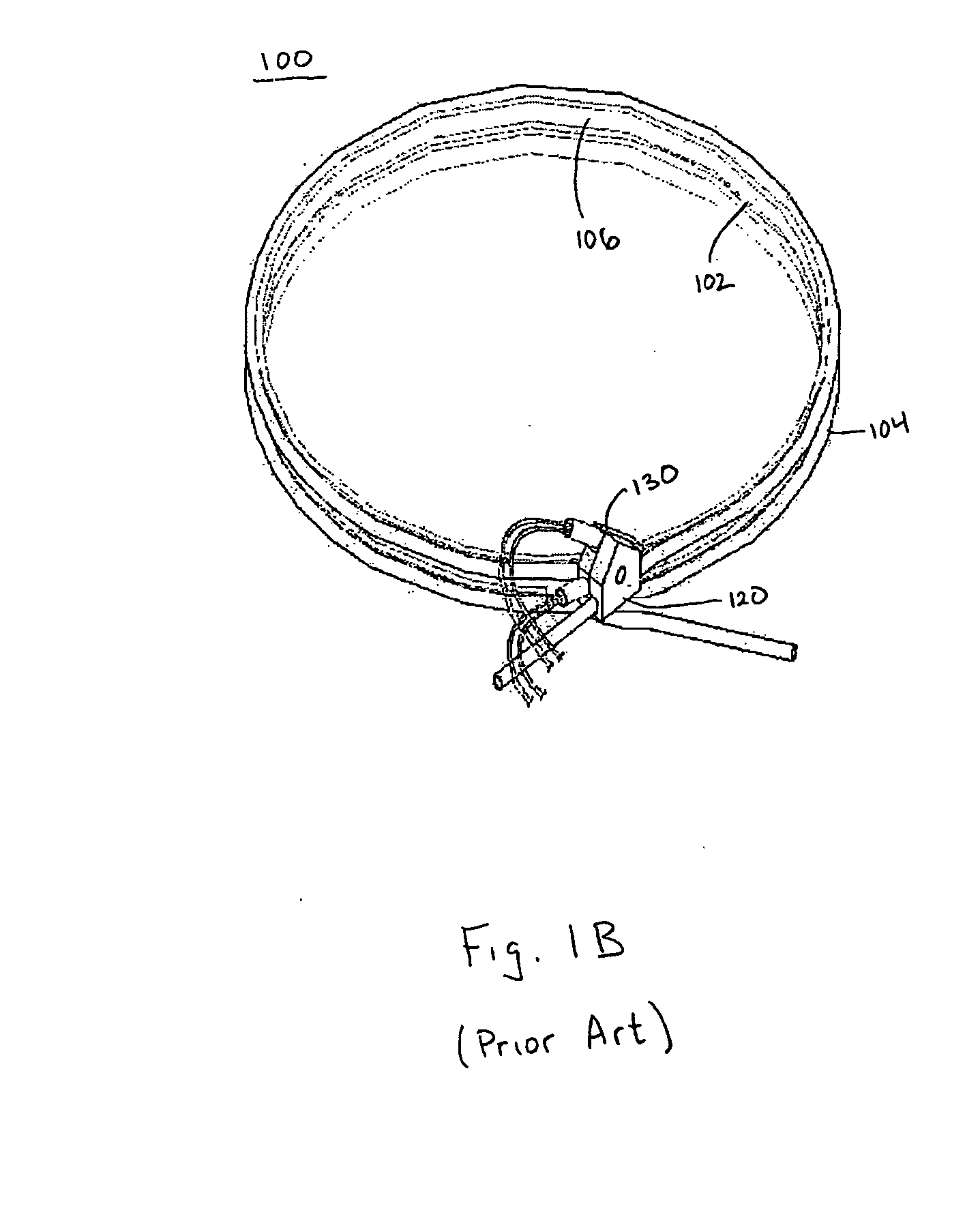

Side RF coil and side heater for plasma processing apparatus

InactiveUS20060174834A1Maximize thermal interactionElectric discharge tubesSemiconductor/solid-state device manufacturingTemperature controlControl system

A RF plasma generation and temperature control system for an inductively coupled plasma process chamber. The plasma generation system includes a heater that includes an elongated upper heating element substantially parallel to an elongated lower heating element, where the upper and lower heating elements are joined by one or more posts substantially perpendicular to the upper and lower heating elements. The system also including one or more RF coils featuring a crease at points of overlap with the posts. Also, a RF plasma generation system for an inductively coupled plasma process chamber, where the plasma generation system includes a heater thermally coupled to the chamber, and one or more RF coils coupled to the chamber, where the RF coils include a hollow tube having at least one flat side.

Owner:APPLIED MATERIALS INC

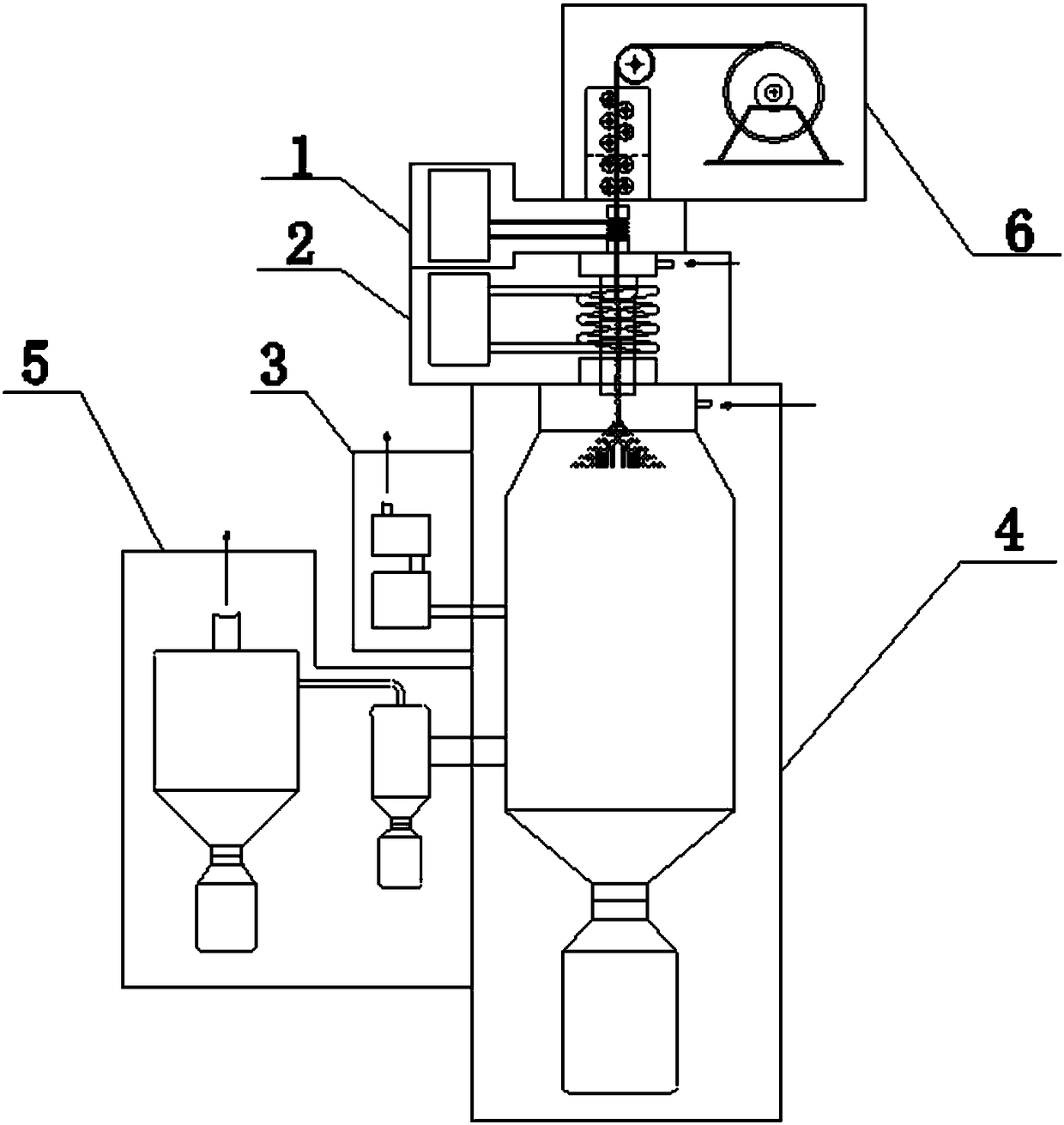

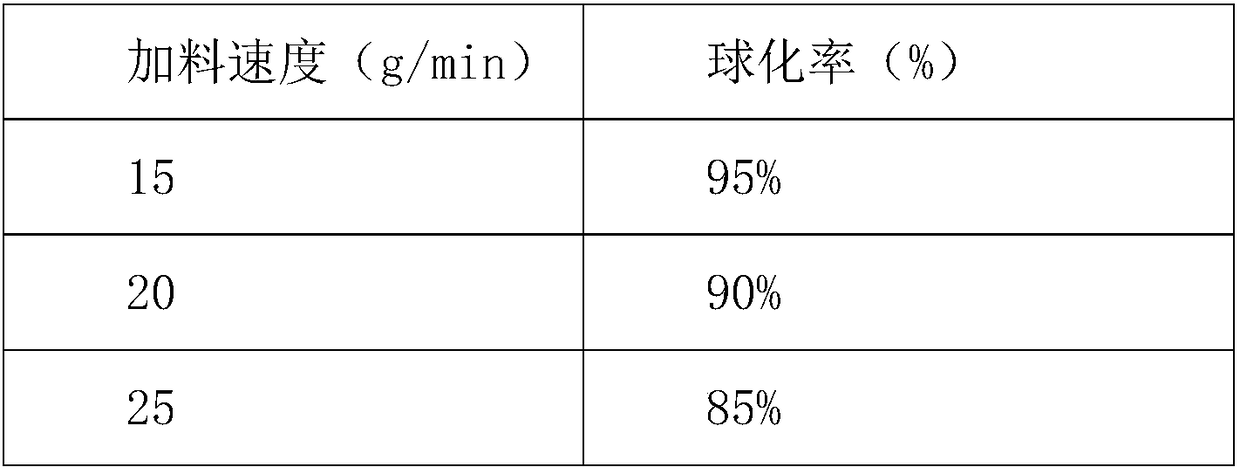

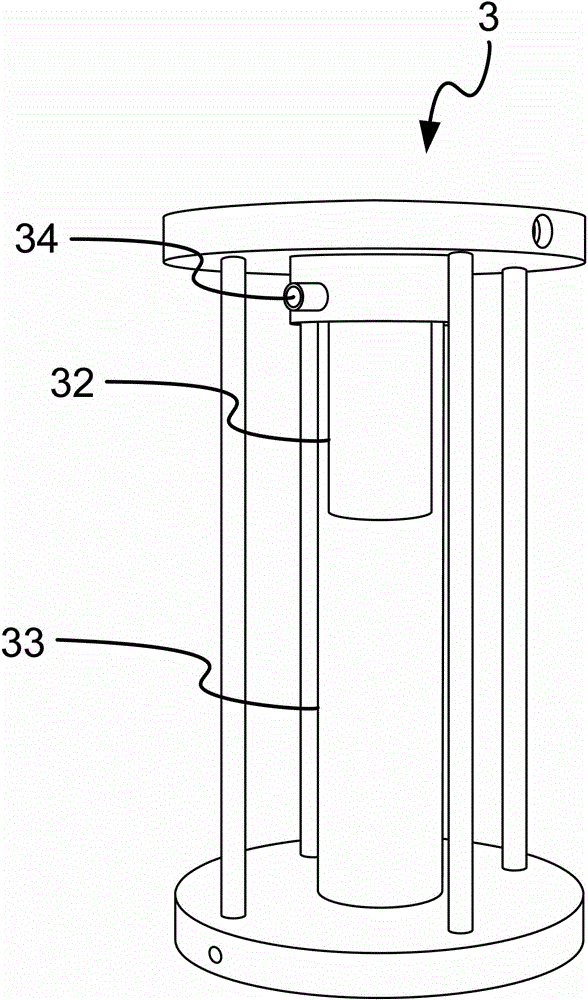

Powder preparation method for induction heating and radio frequency plasma combined atomizing powder system

ActiveCN108161019AHigh purityPrevent purityAdditive manufacturing apparatusHigh pressureRadio frequency

The invention relates to a powder preparation method for an induction heating and radio frequency plasma combined atomizing powder system. The powder preparation method comprises the following steps that (1), raw materials are prepared and processed; (2), the system is pre-vacuumed and a protective atmosphere is established; (3), wire materials are straightened and conveyed; (4), high-frequency induction preheating is carried out; (5), radio frequency plasma melting is carried out; (6), powders are prepared by atomizing; (7), separation and dust removal are carried out; and (8), the powder size is graded. The powder preparation method for the induction heating and radiofrequency plasma combined atomizing powder system uses high purity metal wire material instead of the powders as the raw materials, so that the carrying of raw materials to adsorb gas and water is reduced; a technology of the high frequency induction heating combined with the radio frequency plasma smelting and gas atomization is adopted, during the whole process of heating, melting, and the gas atomization is free of pollution and impurities in the protective atmosphere, and the degree of superheat of liquid flow ordroplets is increased during the process of radio frequency plasma smelting; and high quality spherical powders can be obtained by adopting high pressure atomizing nozzles atomizing, and the yield ofmetal powders per unit time is increased.

Owner:北京金物科技发展有限公司

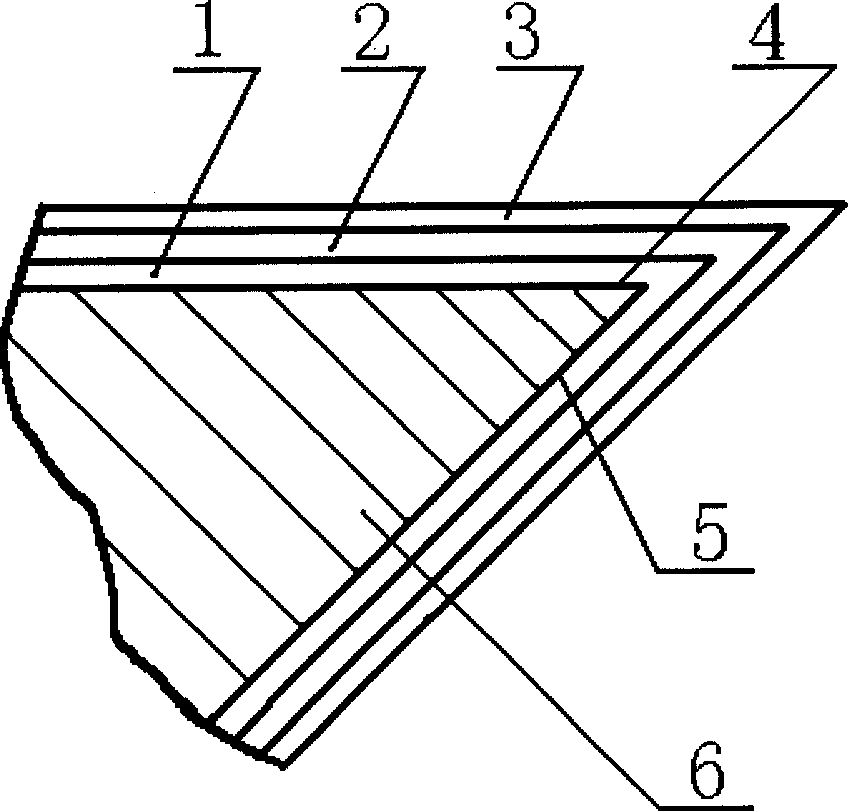

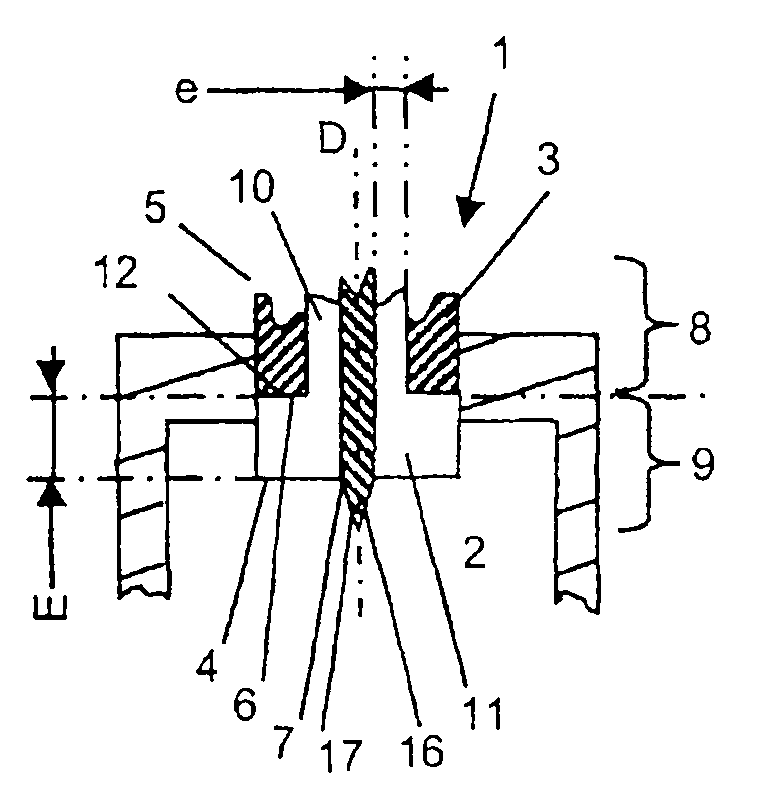

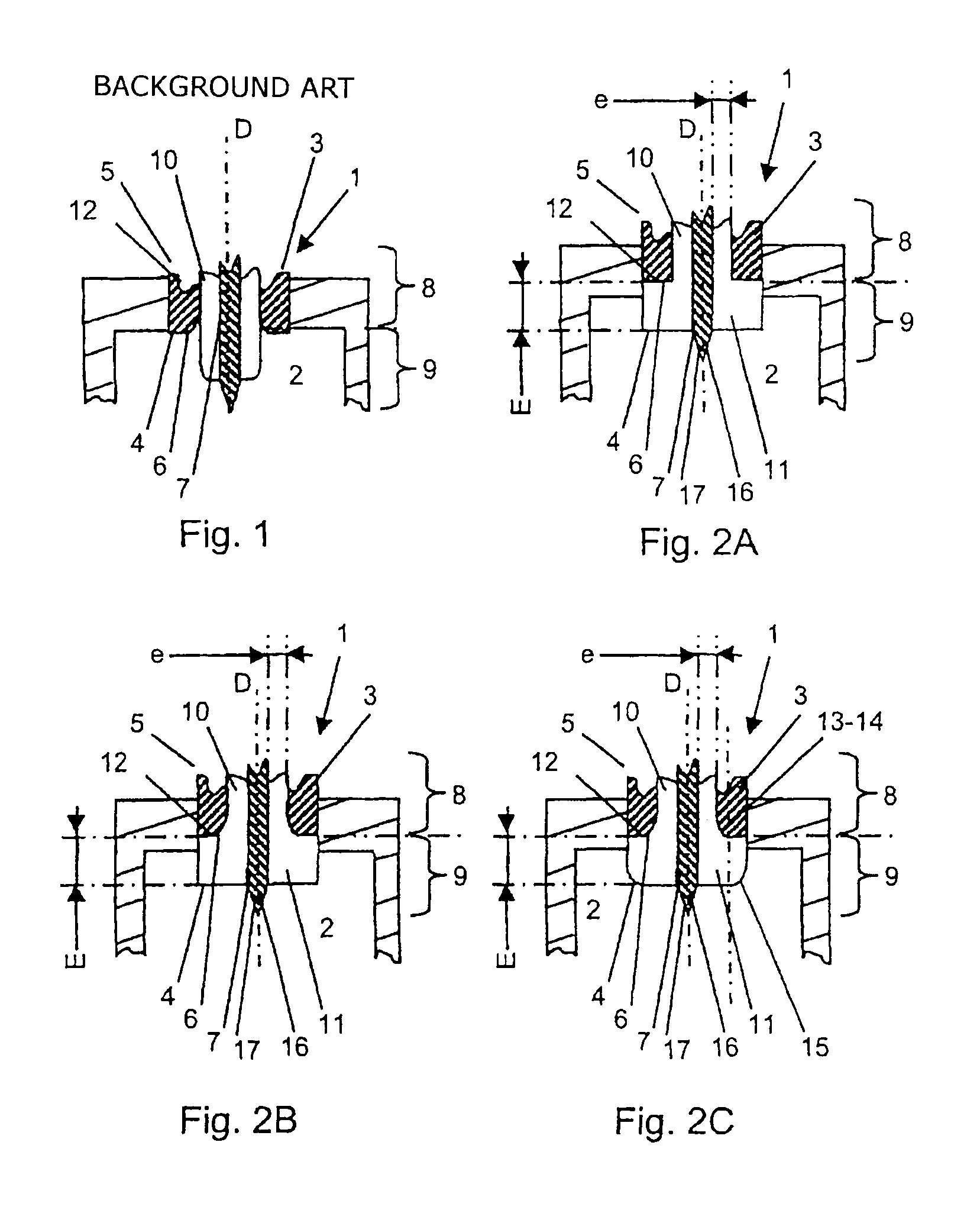

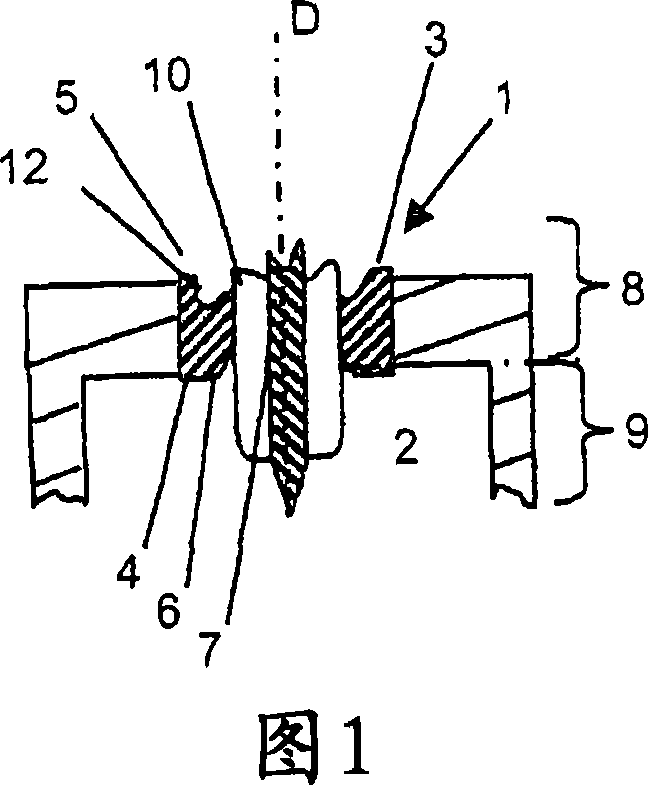

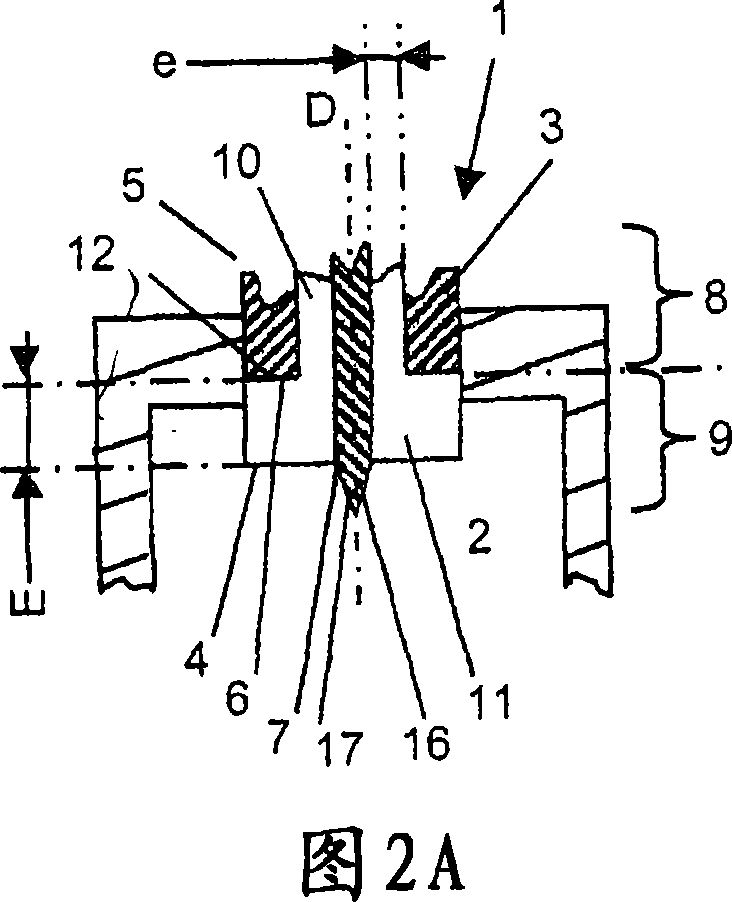

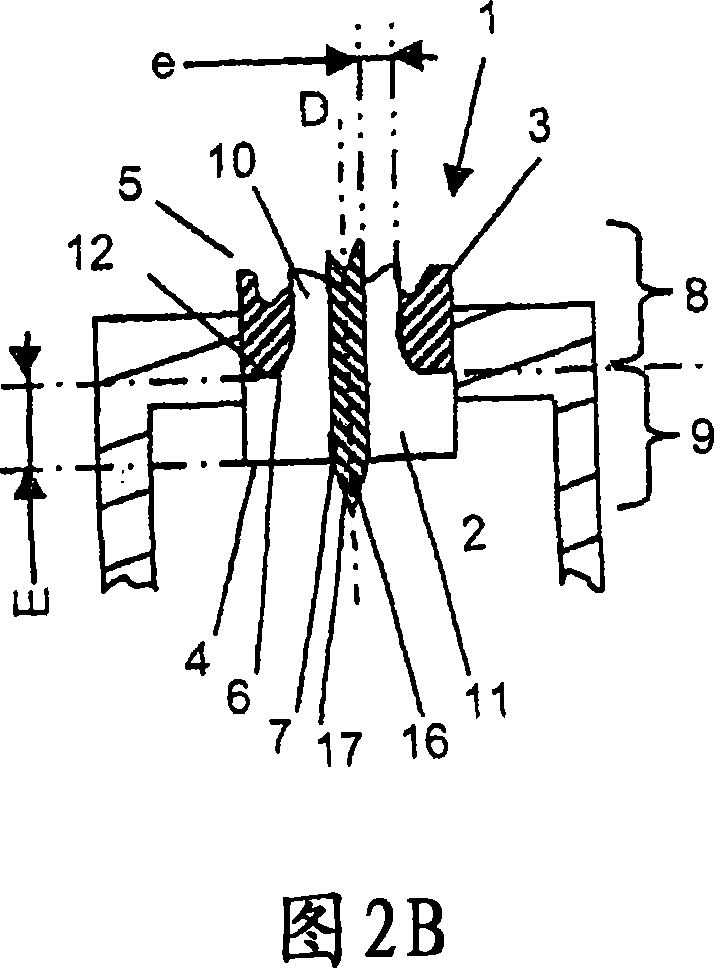

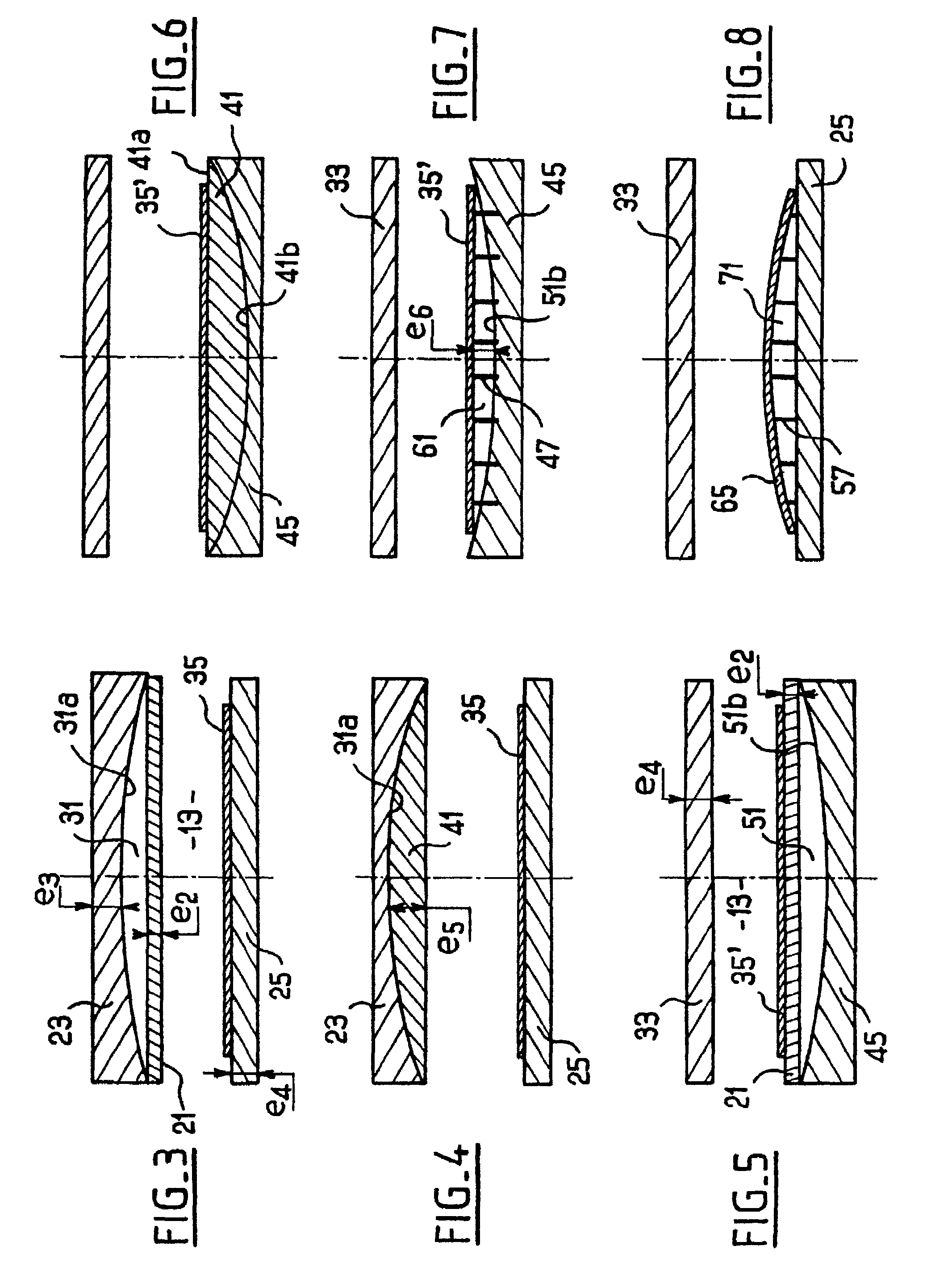

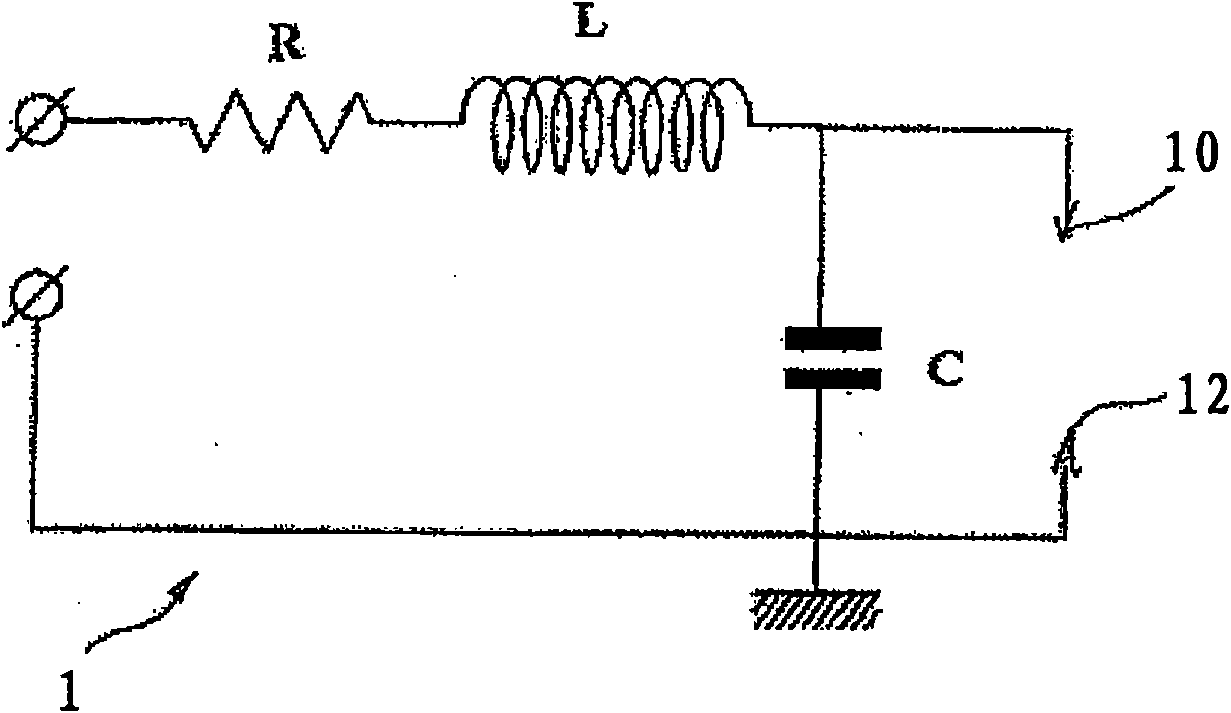

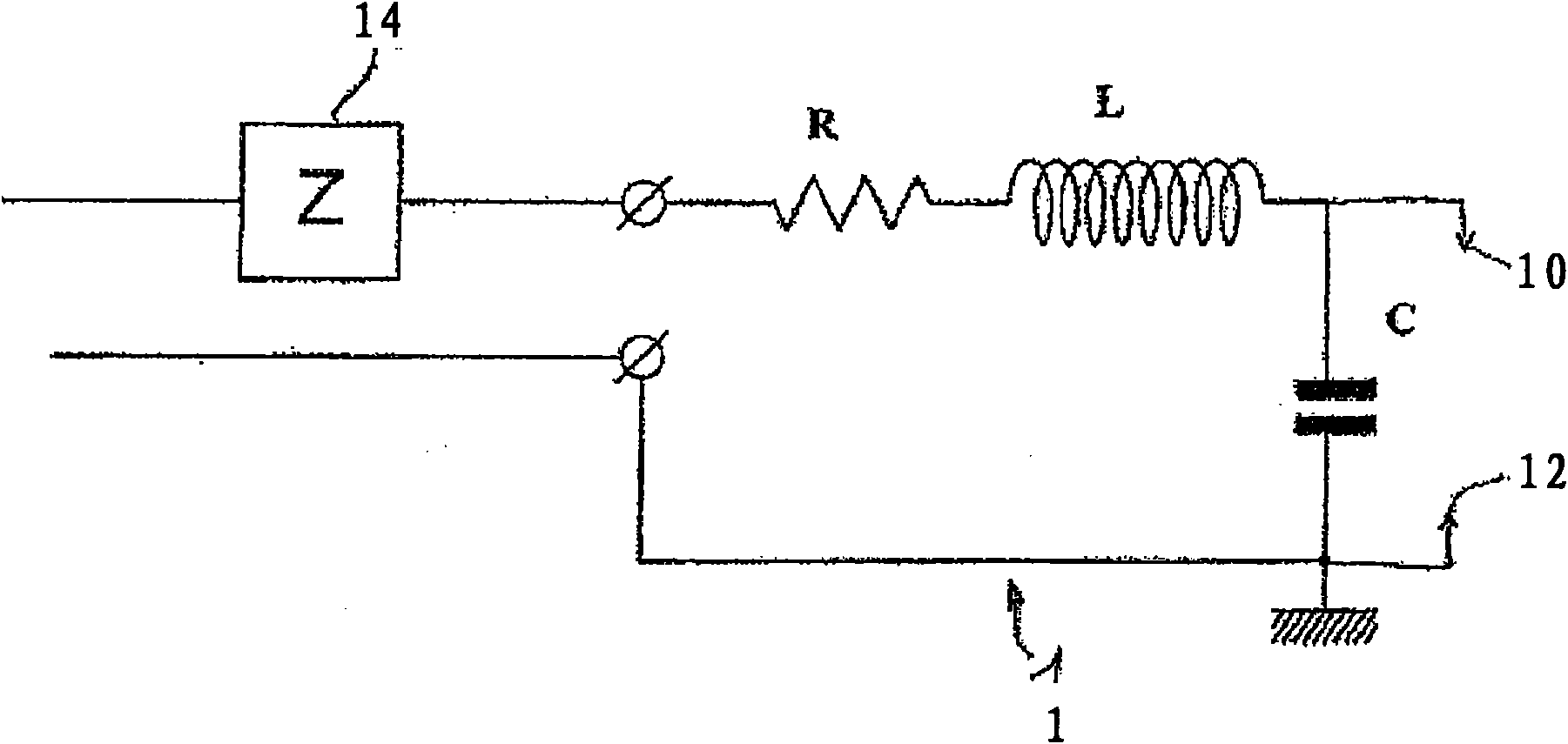

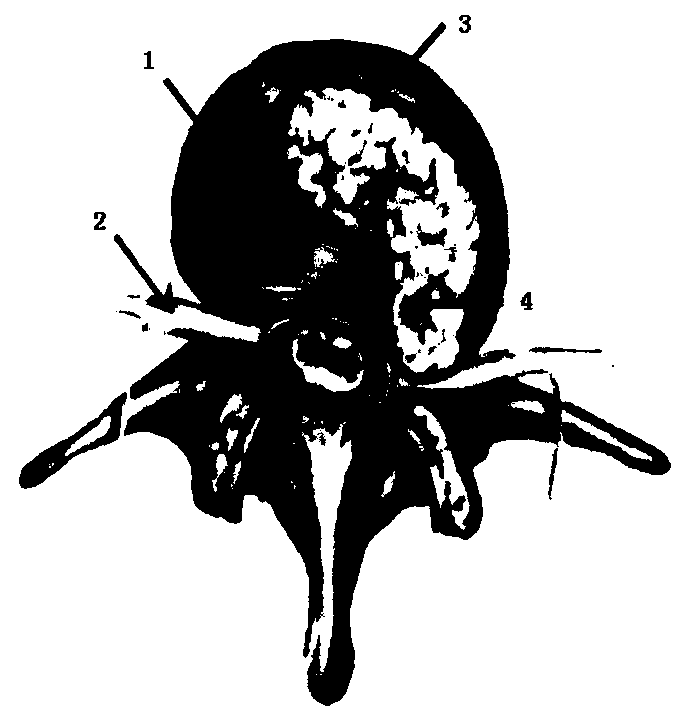

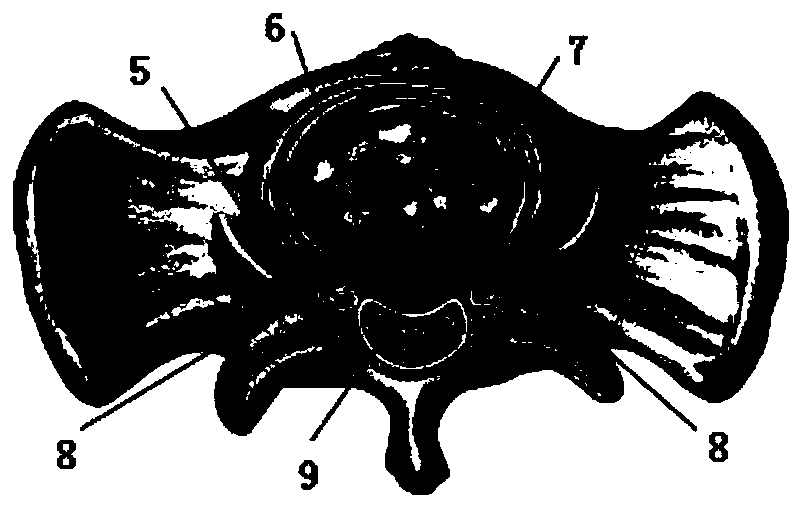

Radiofrequency plasma spark plug

A radiofrequency plasma spark plug configured to equip a combustion chamber including: an annular shell with a main axis; a central electrode made of a conductive material, extending along the main axis and including an inner portion arranged inside the annular shell and an outer portion arranged outside the annular shell; an annular electrically insulating part extending at least about the inner portion of the central electrode so as to be interposed between the shell and the electrode, the insulating part only covering part of the outer portion of the central electrode. The insulating part includes an annular flange concealing the entire circular terminal surface of the shell relative to the uncovered part of the electrode.

Owner:RENAULT SA

Radiofrequency plasma spark plug

InactiveCN101057379ANo arcingReduce or eliminate sharp cornersSparking plugsCombustion chamberConductive materials

The invention concerns a so-called radiofrequency plasma spark plug (1) designed to equip a combustion chamber (2) comprising: an annular shell (3) with a main axis D; a central electrode (7) made of a second conductive material, extending along the main axis D and including an inner portion (8) arranged inside said annular shell (3) and an outer portion (9) arranged outside said annular shell (3); an annular electrically insulating part (10) extending at least about the inner portion (8) of the central electrode (7) so as to be interposed between the shell (3) and the electrode (7), said insulating part (10) only covering part of the outer portion (9) of the central electrode (7). The insulating part (10) having an annular flange (11) concealing the entire circular terminal surface (6) of the shell relative to the uncovered part (16) of the electrode (7).

Owner:RENAULT SA

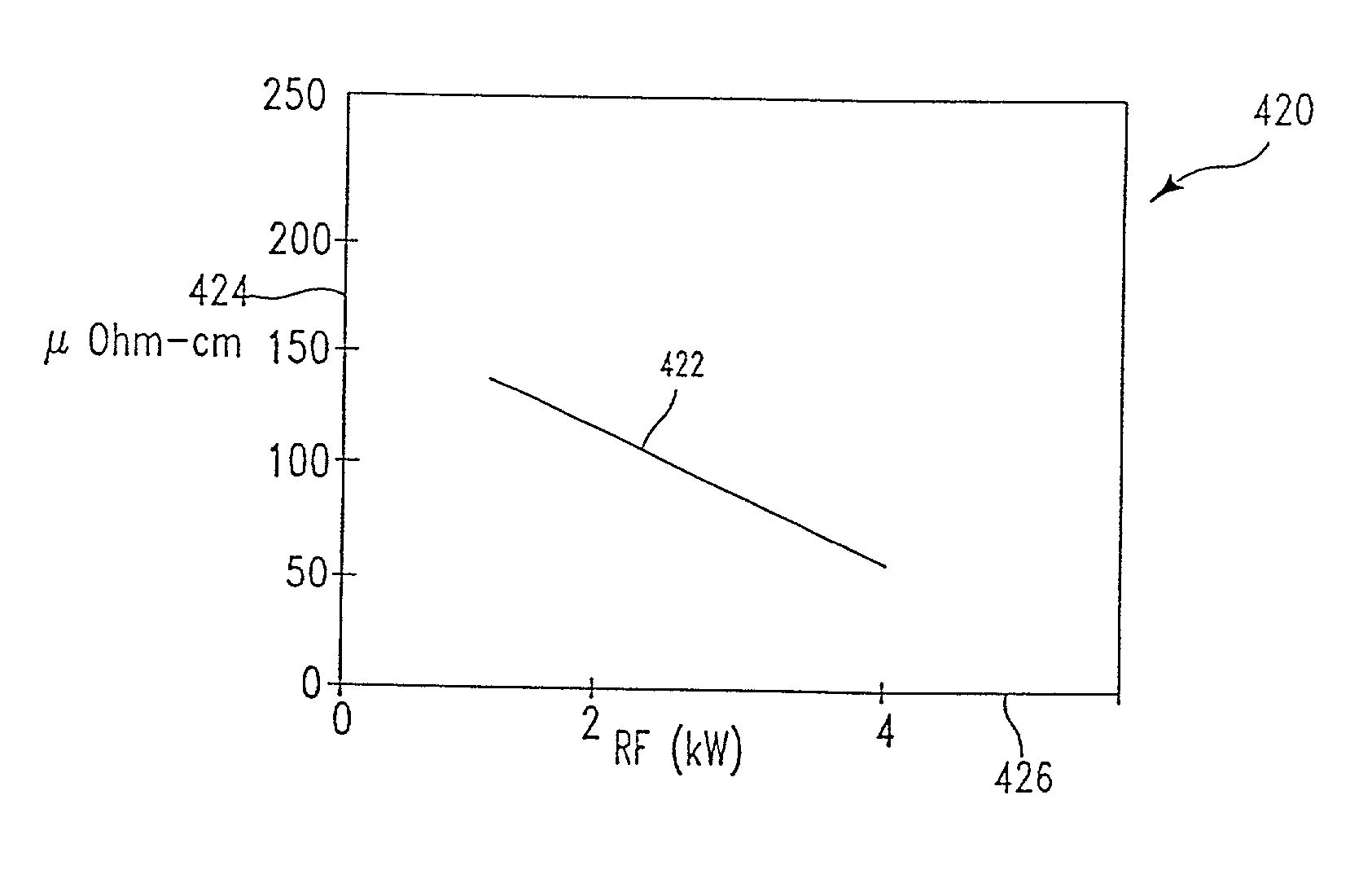

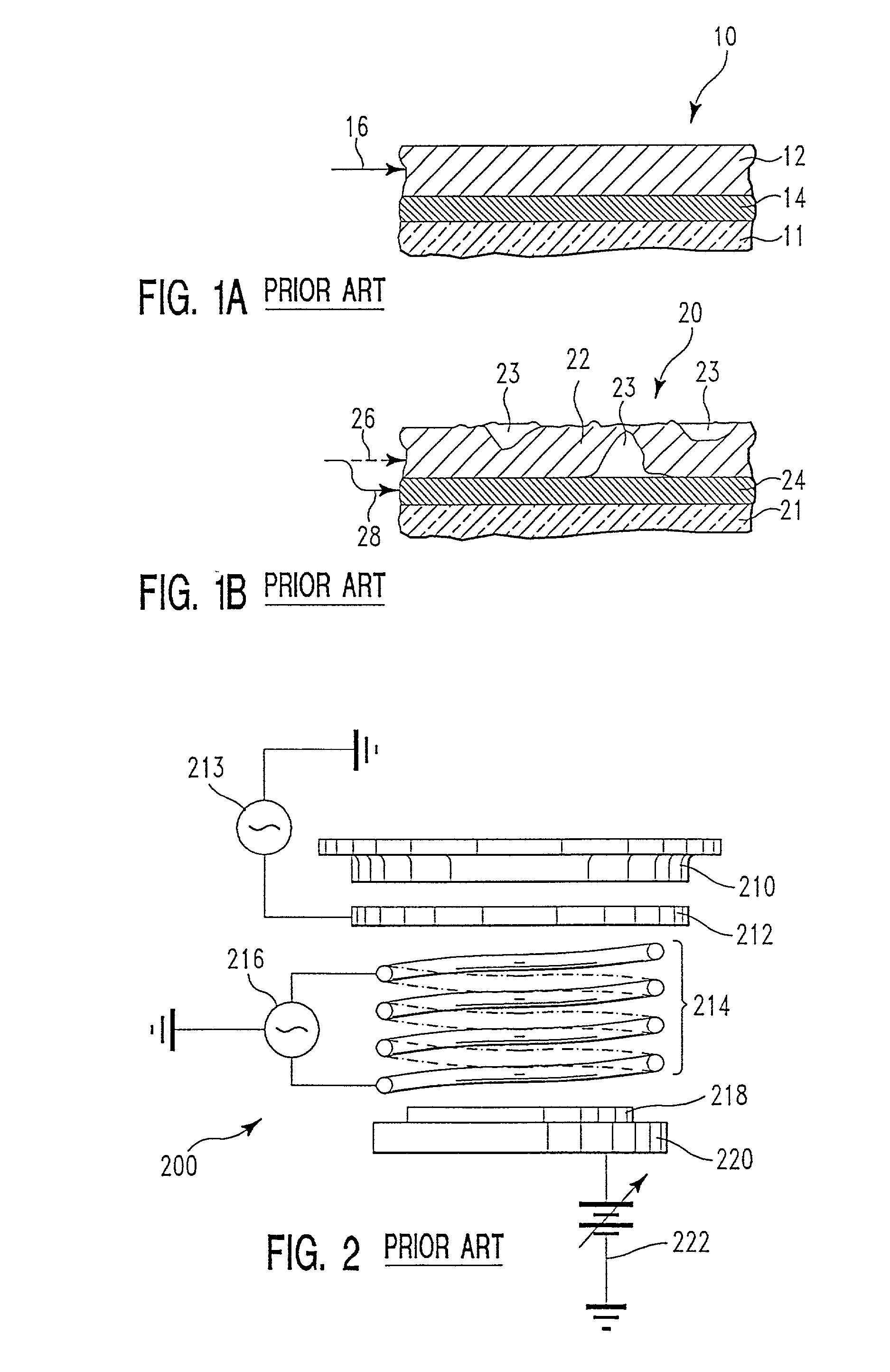

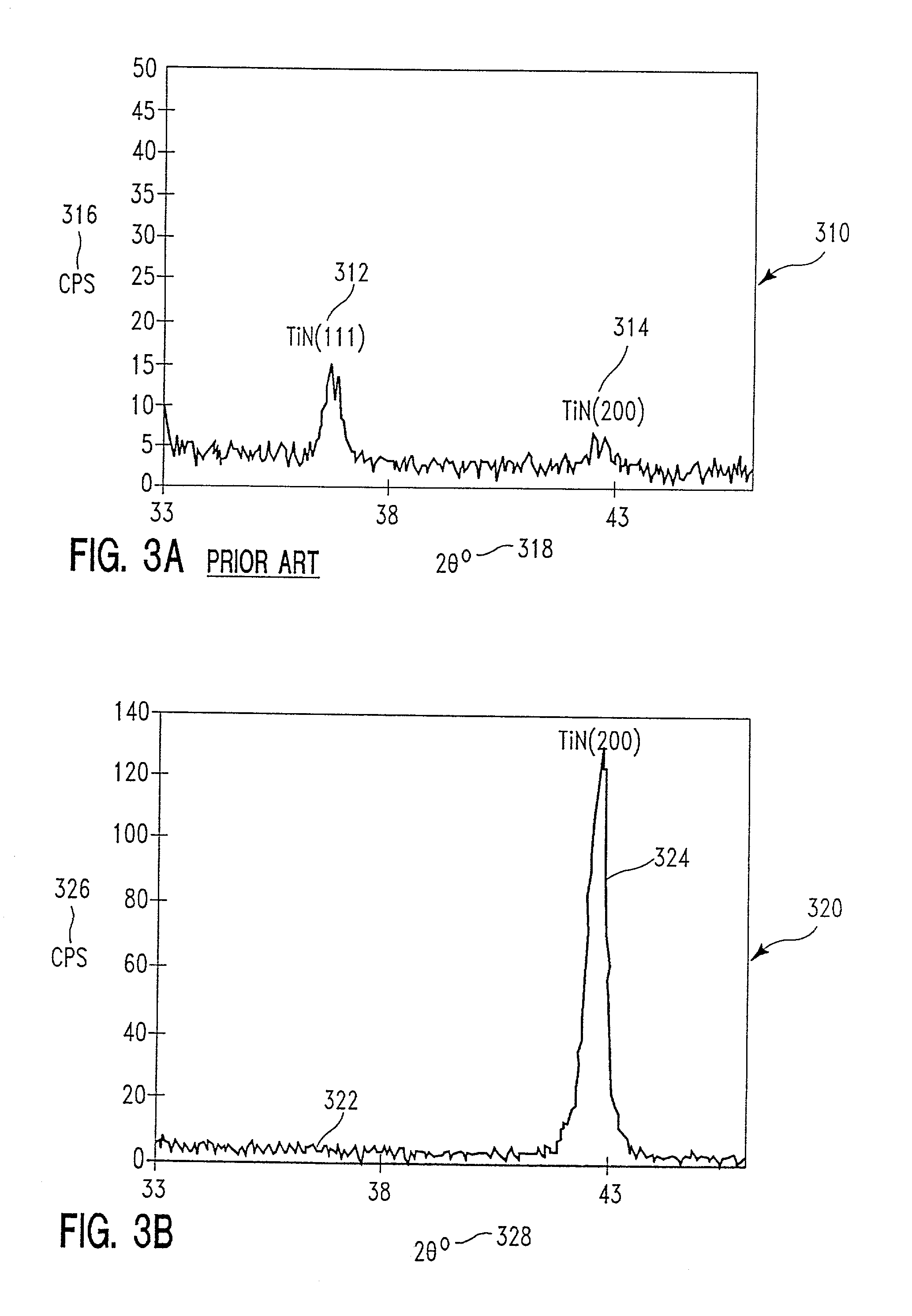

Method of producing smooth titanium nitride films having low resistivity

InactiveUS20020125123A1Layered productsSemiconductor/solid-state device detailsTitanium nitrideCrystal orientation

The resistivity of titanium nitride films is reduced, by about 40% (to less than about 60 muOhm-cm), for example; and, the film surface roughness is reduced, by about 45% (to less than 6 Å) by using a combination of particular process conditions during deposition of the film. In particular, titanium atoms produced by impact of inert gas ions upon a titanium target travel through a high density, inductively coupled rf plasma, an ion metal plasma (IMP), in which the titanium atoms are at least partially ionized. The ionized titanium ions are contacted with ionized nitrogen atoms also present in the processing chamber. The resultant gas phase composition is contacted with the surface of a semiconductor substrate on which a titanium nitride barrier layer is to be deposited. By controlling the gas phase deposition mixture composition, the quantity of the deposition mixture contacting the substrate surface over a given time period, and the pressure in the process vessel, the resistivity and surface roughness of the titanium nitride layer is adjusted. The resistivity of the titanium nitride barrier layer is principally determined by the crystal orientation of the titanium nitride. The more nearly the crystal orientation approaches 100% of the {200} orientation (the lower the percentage of {111} orientation), the lower the film resistivity. Crystal orientation is obtained by increasing the ionized content of the deposition mixture and by slowing the rate of deposition of the titanium nitride film (barrier layer). The surface roughness of the titanium nitride layer is reduced principally by reducing the pressure in the process vessel, which affects the film formation dynamics. An increase in ionized content of the deposition mixture helps reduce surface roughness until an inflection point is reached, after which surface roughness increases with increased ionized content.

Owner:NGAN KENNY KING TAI +1

Capacitively coupled plasma reactor having very agile wafer temperature control

ActiveUS20100303680A1Semiconductor/solid-state device manufacturingEnergy based chemical/physical/physico-chemical processesCapacitanceTemperature control

A plasma reactor for processing a workpiece includes a reactor chamber, an electrostatic chuck within the chamber having a top surface for supporting a workpiece and having indentations in the top surface that form enclosed gas flow channels whenever covered by a workpiece resting on the top surface. The reactor further includes thermal control apparatus thermally coupled to the electrostatic chuck, an RF plasma bias power generator coupled to apply RF power to the electrostatic chuck, a pressurized gas supply of a thermally conductive gas, a controllable gas valve coupling the pressurized gas supply to the indentations to facilitate filling the channels with the thermally conductive gas for heat transfer between a backside of a workpiece and the electrostatic chuck at a heat transfer rate that is a function of the pressure against the backside of the workpiece of the thermally conductive gas. The reactor further includes an agile workpiece temperature control loop including (a) a temperature probe in the electrostatic chuck, and (b) a backside gas pressure controller coupled to an output of the temperature probe and responsive to a specified desired temperature, the controller governing the gas valve in response to a difference between the output of the temperature probe and the desired temperature.

Owner:BE AEROSPACE INCORPORATED

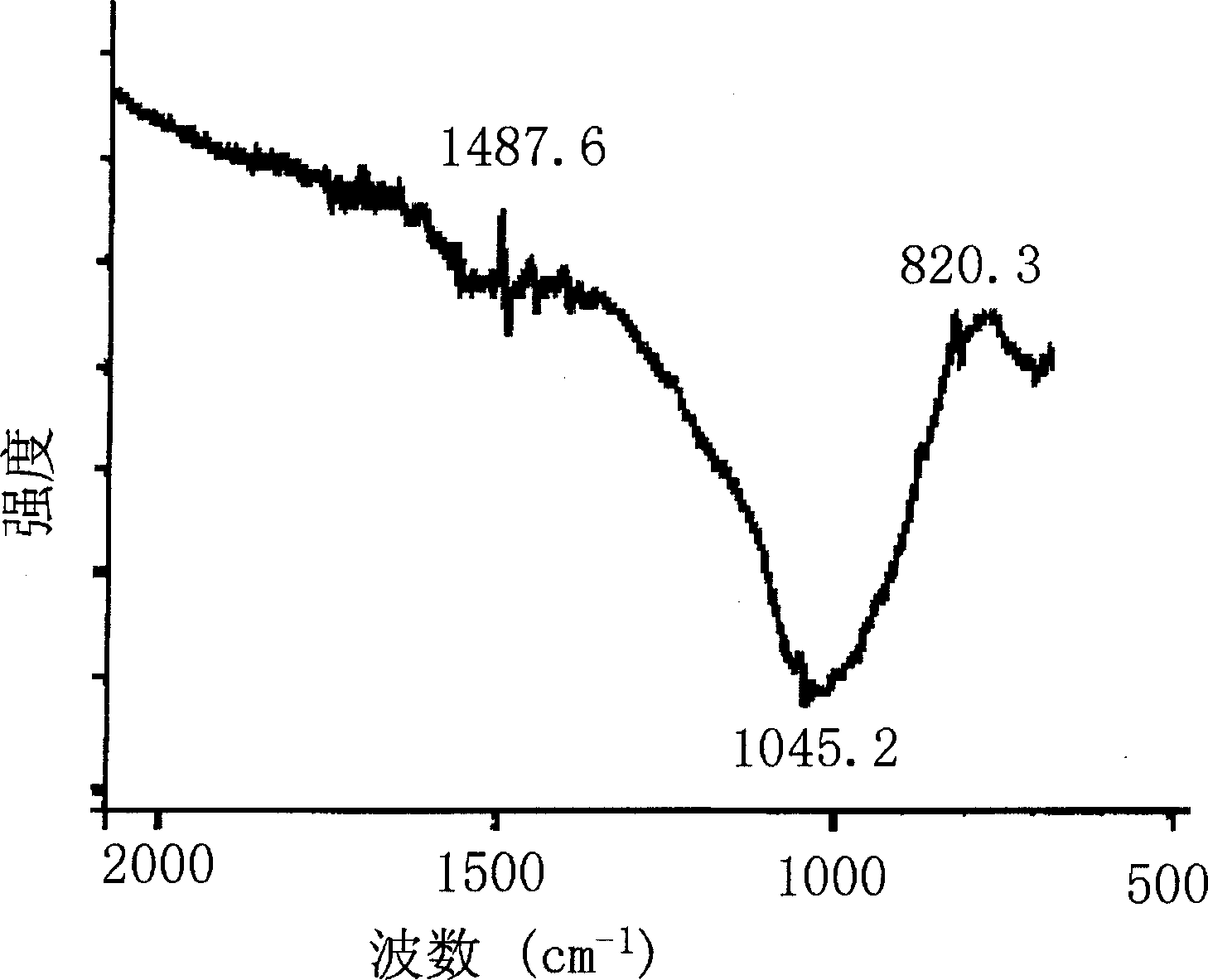

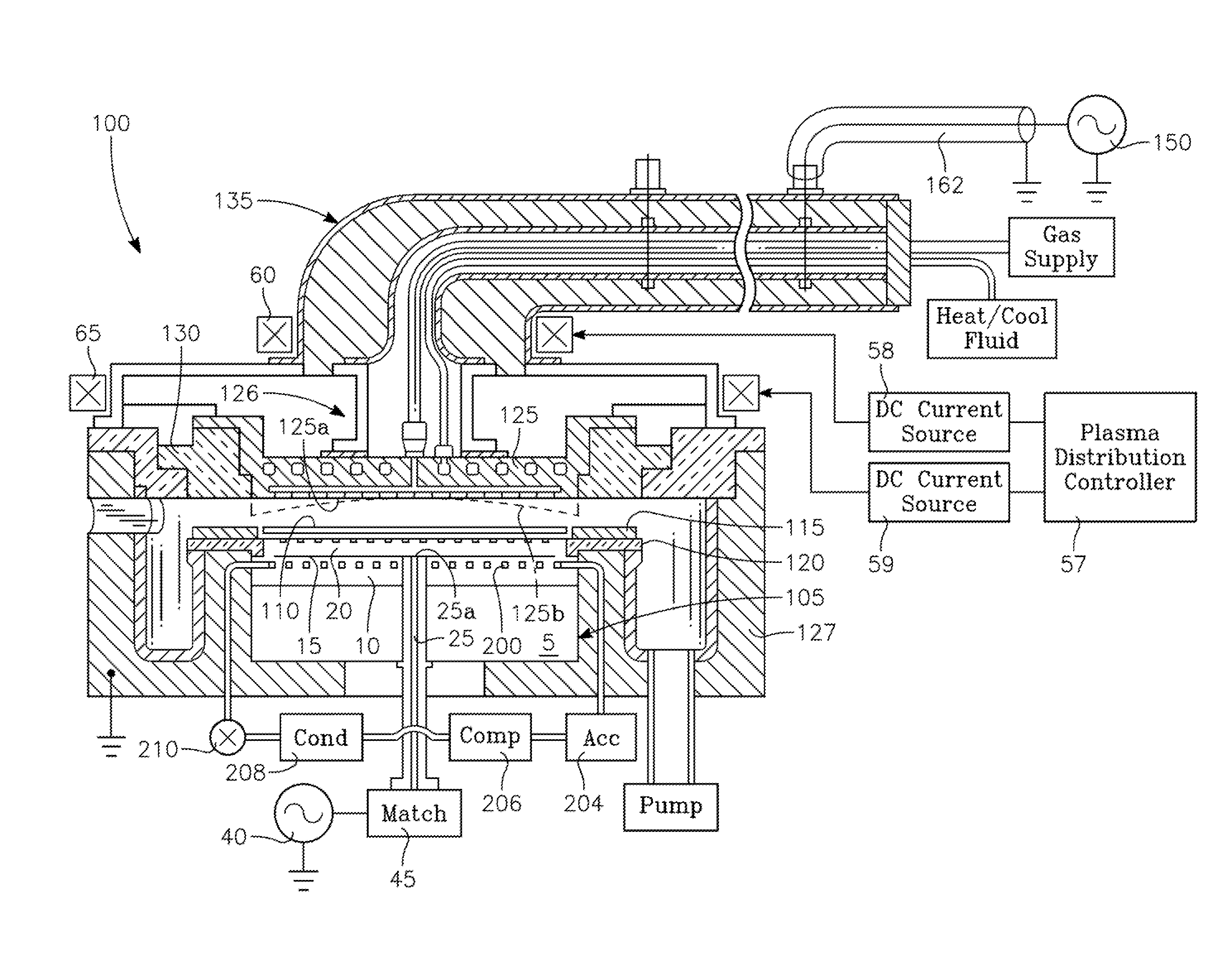

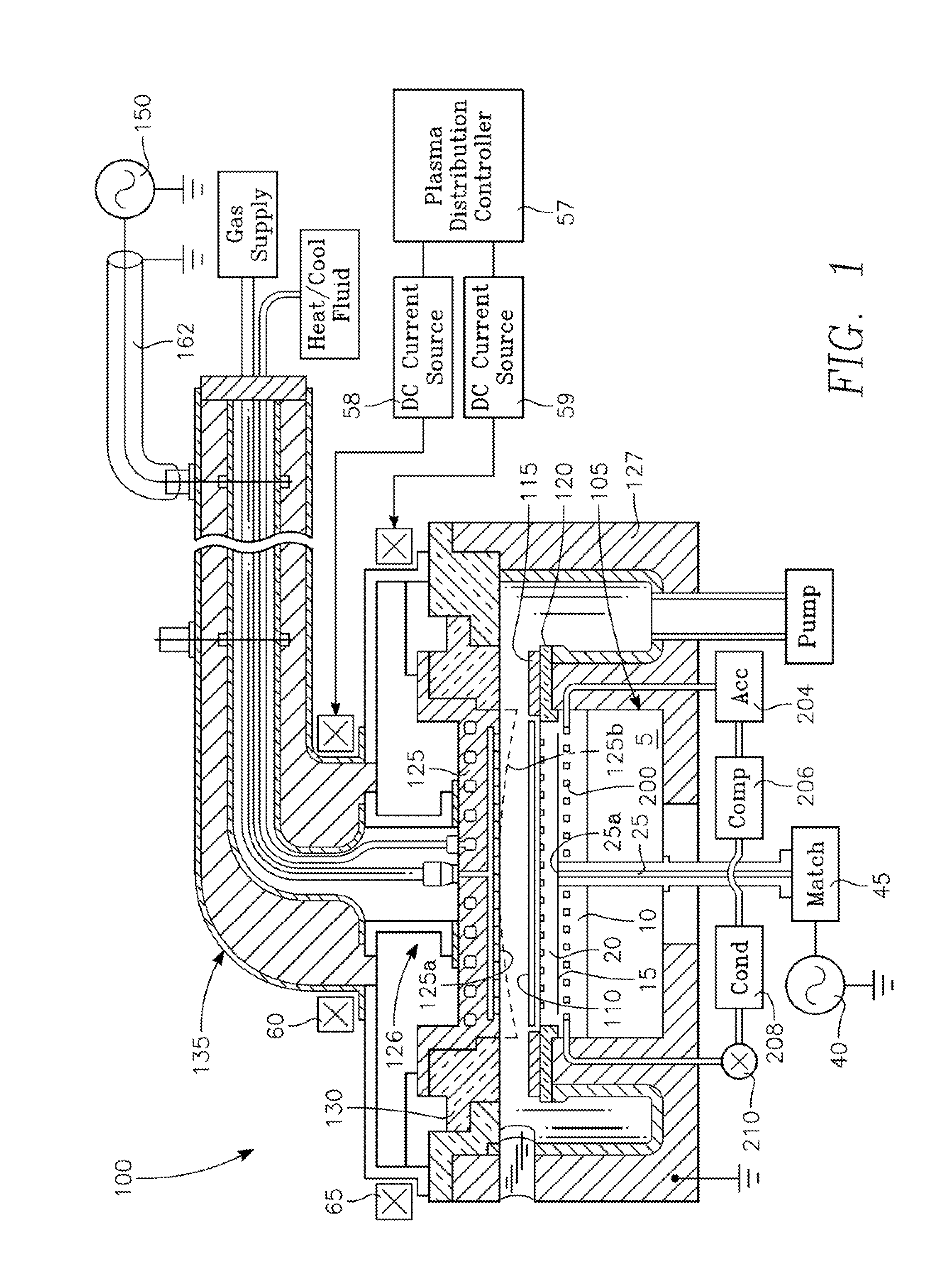

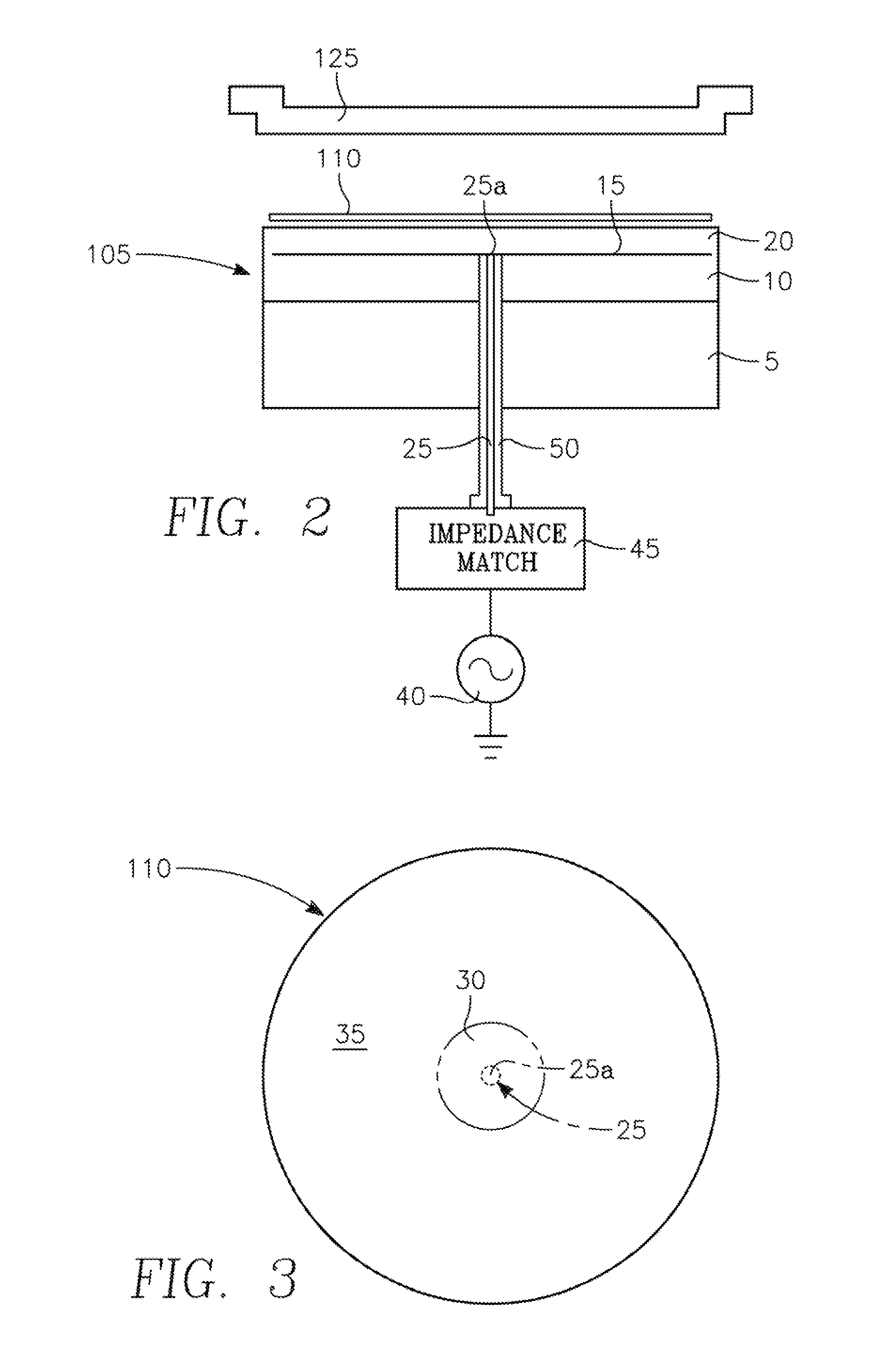

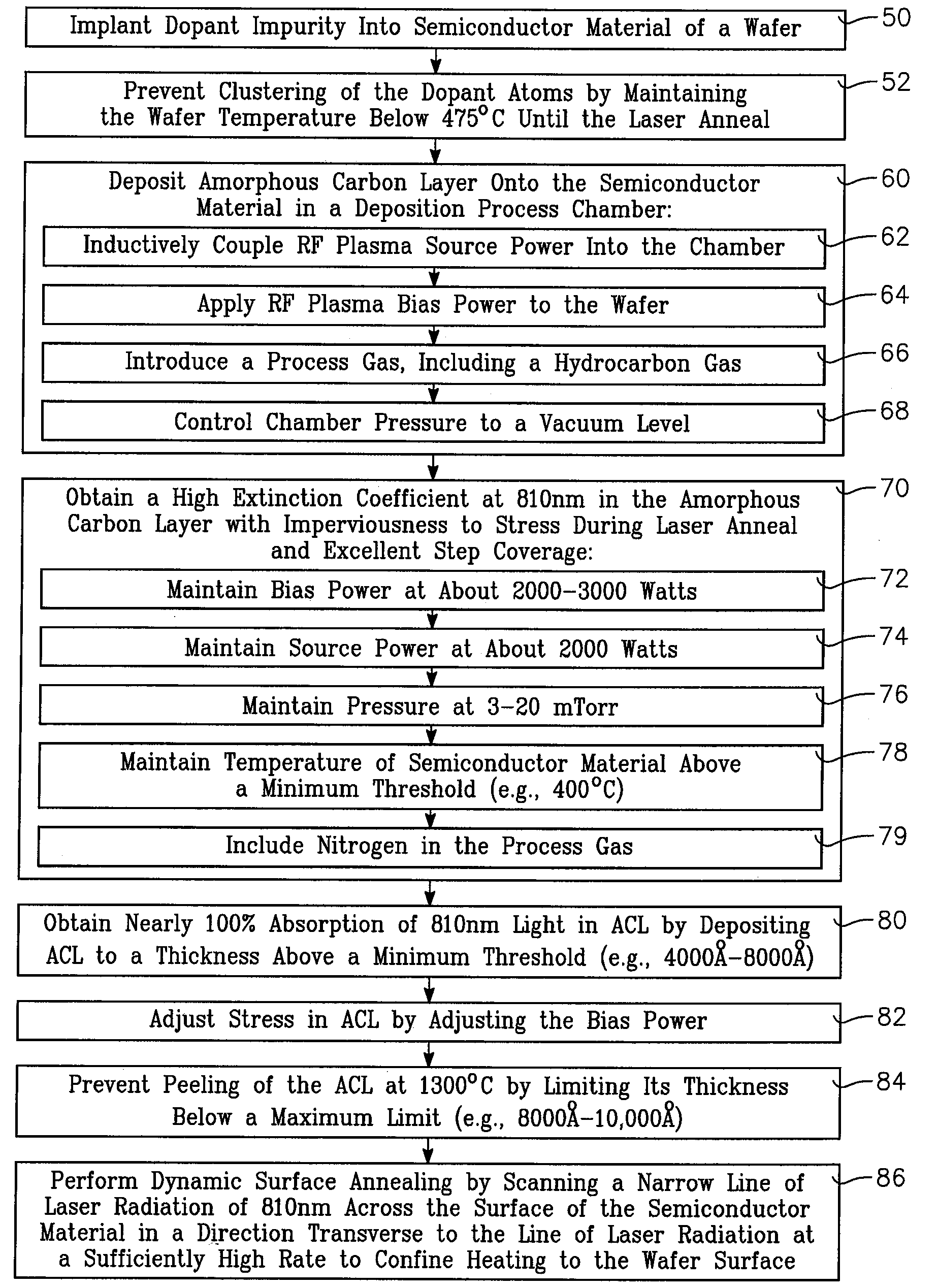

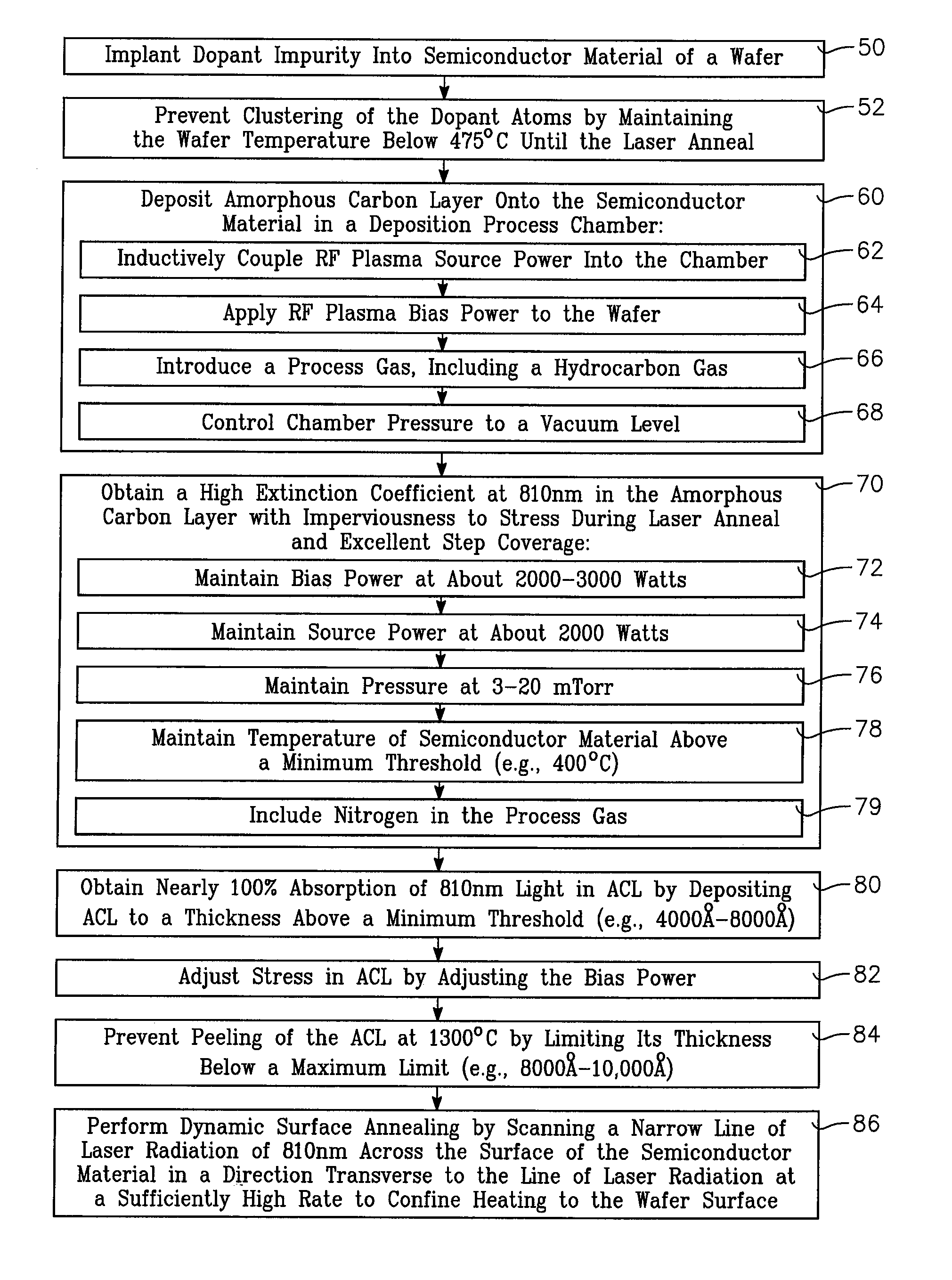

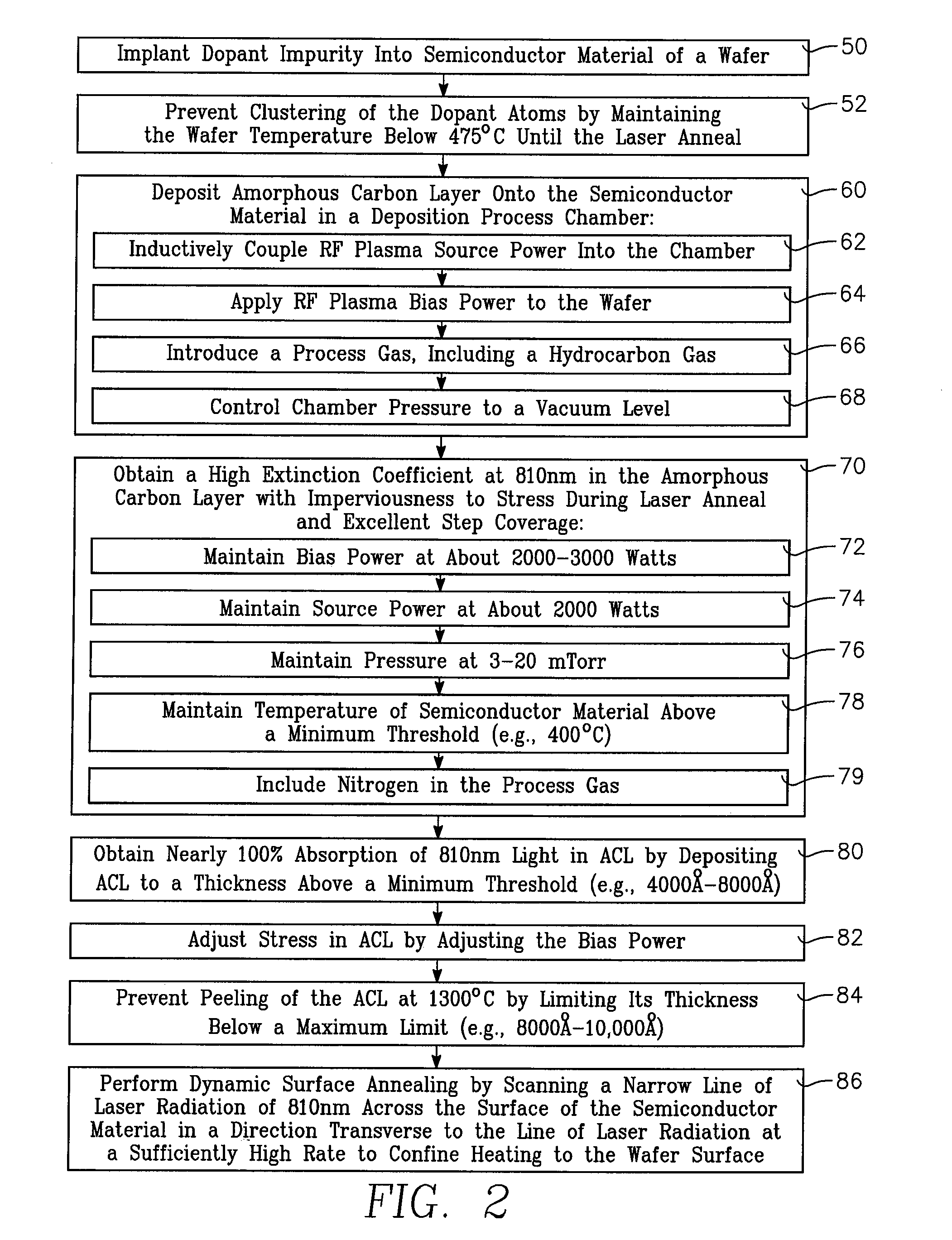

Dynamic surface annealing of implanted dopants with low temperature hdpcvd process for depositing a high extinction coefficient optical absorber layer

InactiveUS20080057681A1Improvement factorVacuum evaporation coatingSputtering coatingHigh absorptionGas phase

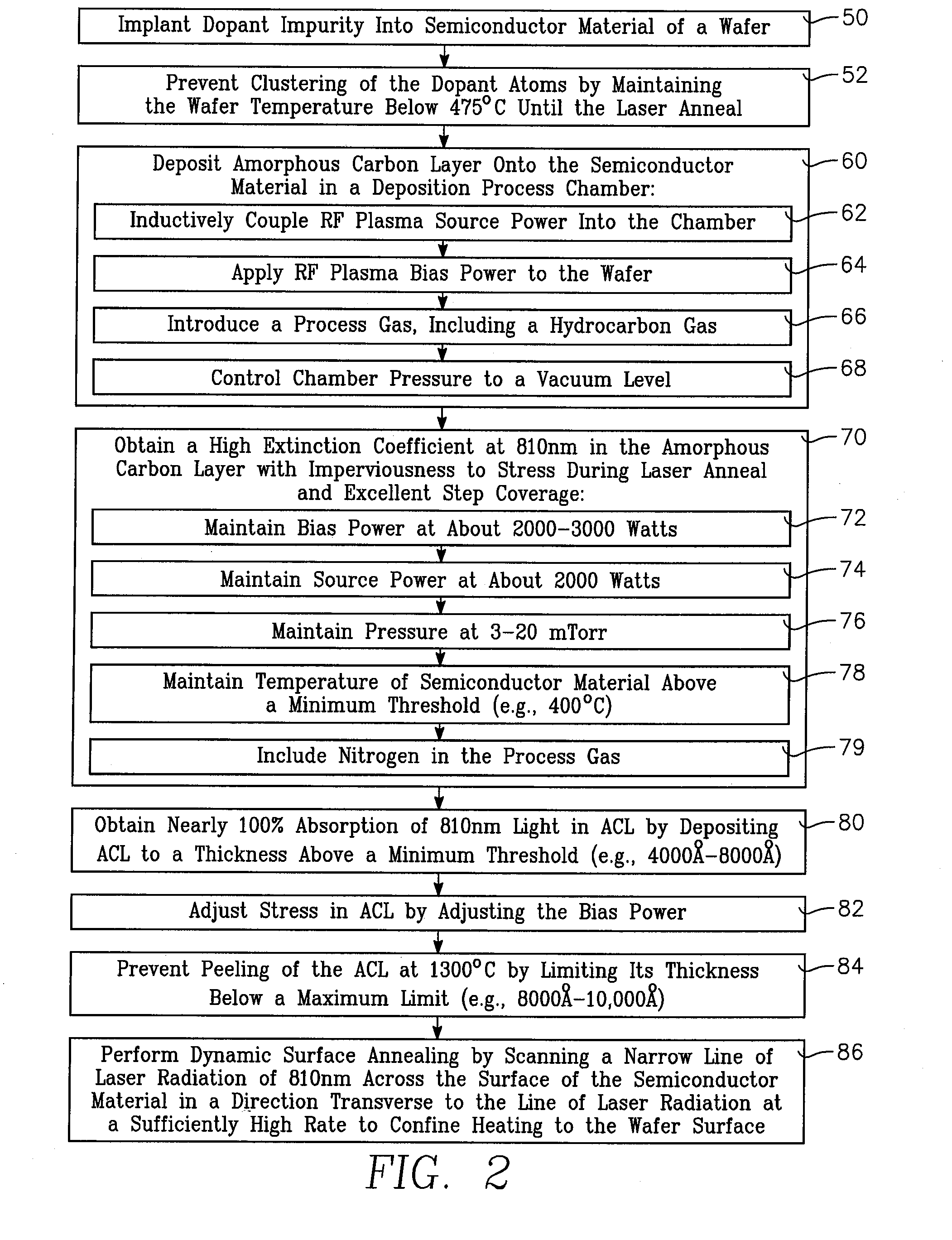

A plasma enhanced physical vapor deposition process deposits an amorphous carbon layer on an ion-implanted wafer for use in dynamic surface annealing of the wafer with an intense line beam of a laser wavelength. The deposition process is carried out at a wafer temperature below the dopant clustering threshold temperature, and includes introducing the wafer into a chamber and furnishing a hydrocarbon process gas into the chamber, preferably propylene (C3H6) or toluene (C7H8) or acetylene (C2H2) or a mixture of acetylene and methane (C2H4). The process further includes inductively coupling RF plasma source power into the chamber while and applying RF plasma bias power to the wafer. The wafer bias voltage is set to a level at which the amorphous carbon layer that is deposited has a desired stress (compressive or tensile). We have discovered that at a wafer temperature less than or equal to 475 degrees C., total RF plasma source power of 4000 Watts at about 2 MHz, RF plasma bias power of 2000-3000 Watts at about 13.56 MHz and a chamber pressure in a range of 3 mTorr to 2 Torr, the deposited amorphous carbon layer has a surprising combination of high absorption and high strength and excellent step coverage.

Owner:APPLIED MATERIALS INC

Method for preparing nano zinc oxide tube by assistance of radiofrequency plasma

InactiveCN1697132AAvoid interferenceNanostructure manufactureZinc oxides/hydroxidesSemiconductor materialsNano zinc oxide

ZnO layer with thickness of 1-8nm is developed on sapphire substrate or silicon substrate through plasma in radio frequency assistant molecular beam epitaxy device. Detection and control are carried out for gas flow by using flowmeter and leakage valve on the said molecular beam epitaxy device. When ion capture trap is opened, only, neutral particles are allowed to enter into development room; and when closed, plasma enters into the development room. Since different stabilities of polar surface and nonpolar surface of ZnO, initialized Nano rings in ZnO are formed on surface of substrate. Then, ZnO is developed along ring so as to form Nano tube. The invention develops orientated ZnO Nano tube in high quality without need of introducing catalyst or template.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

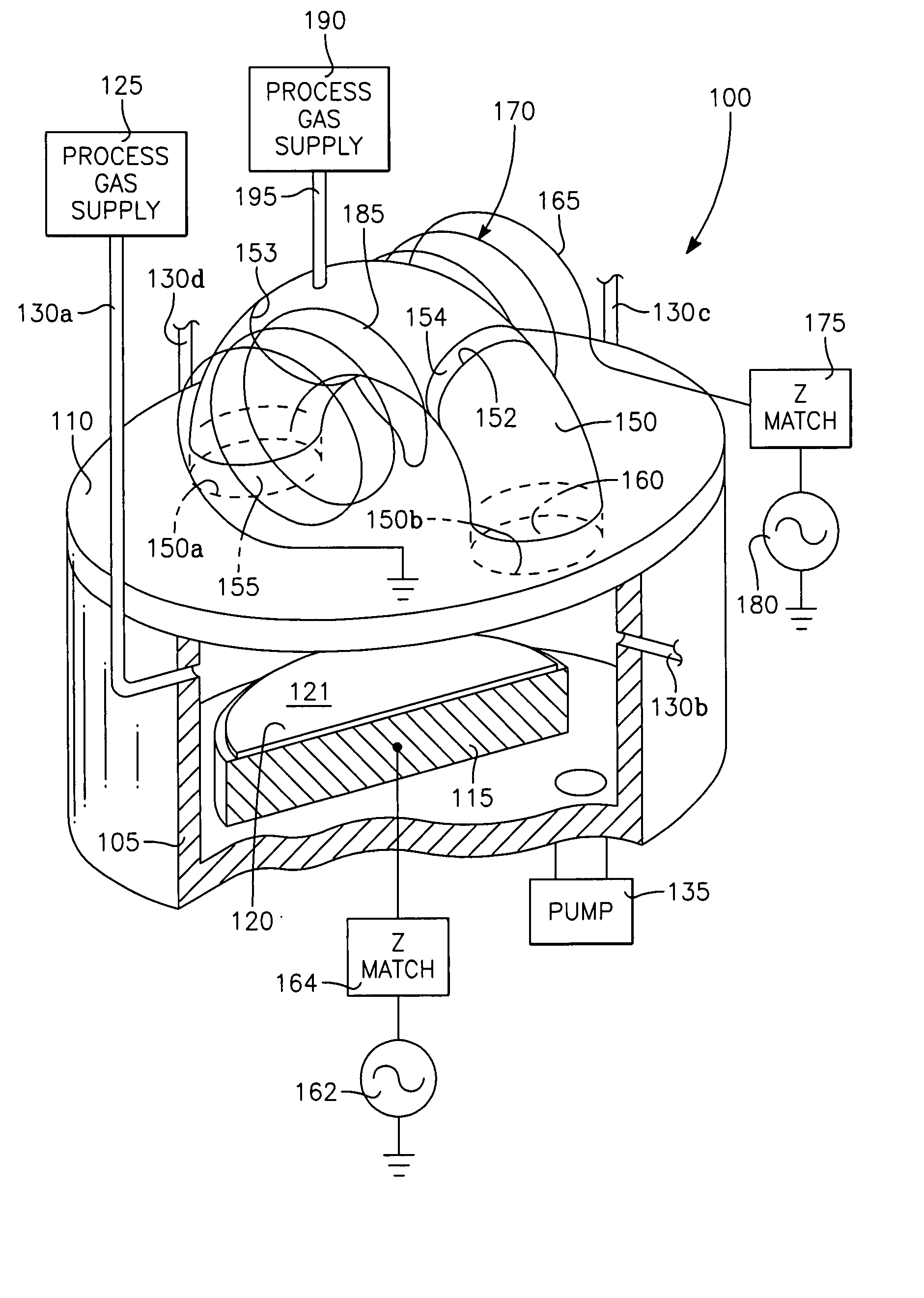

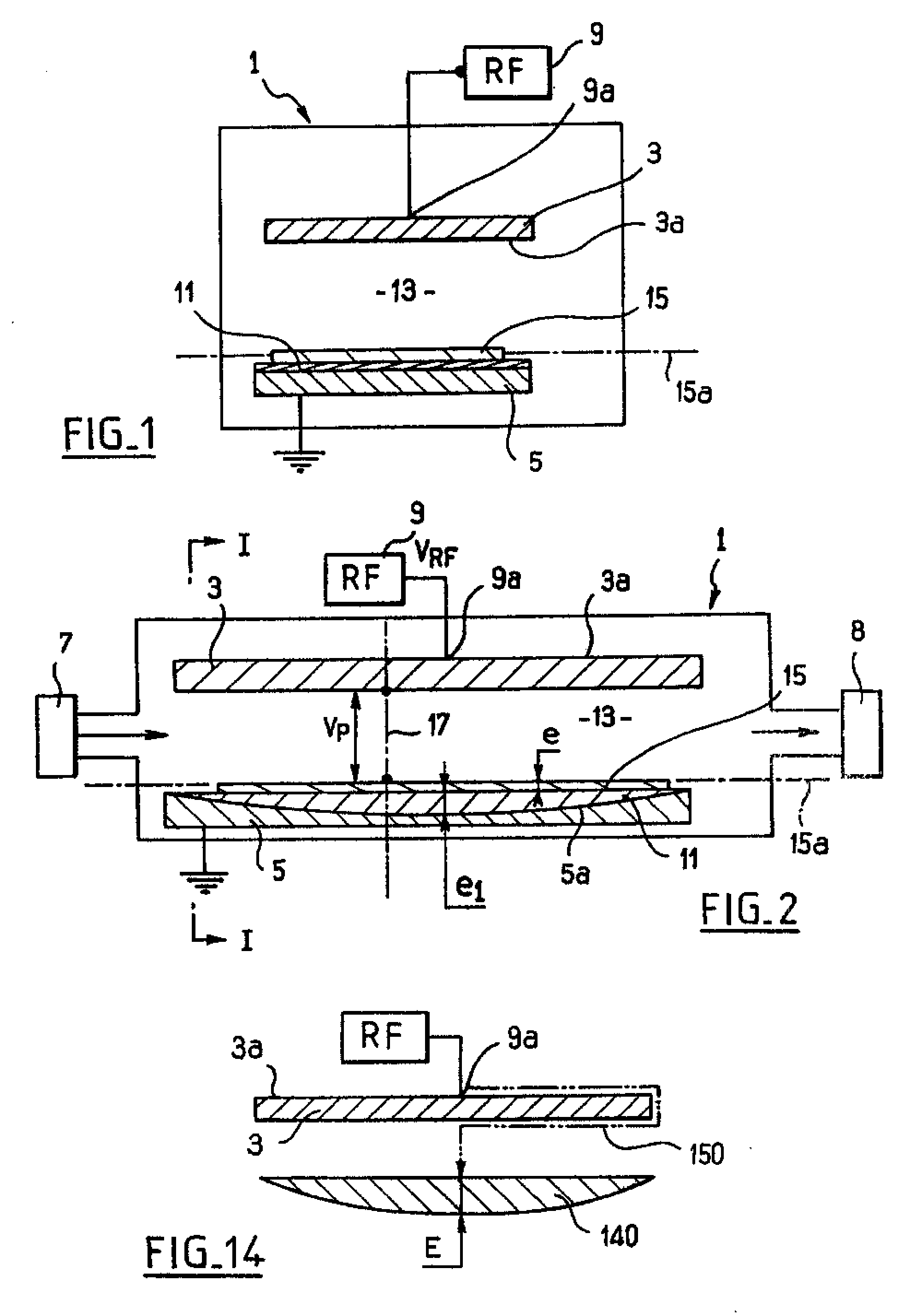

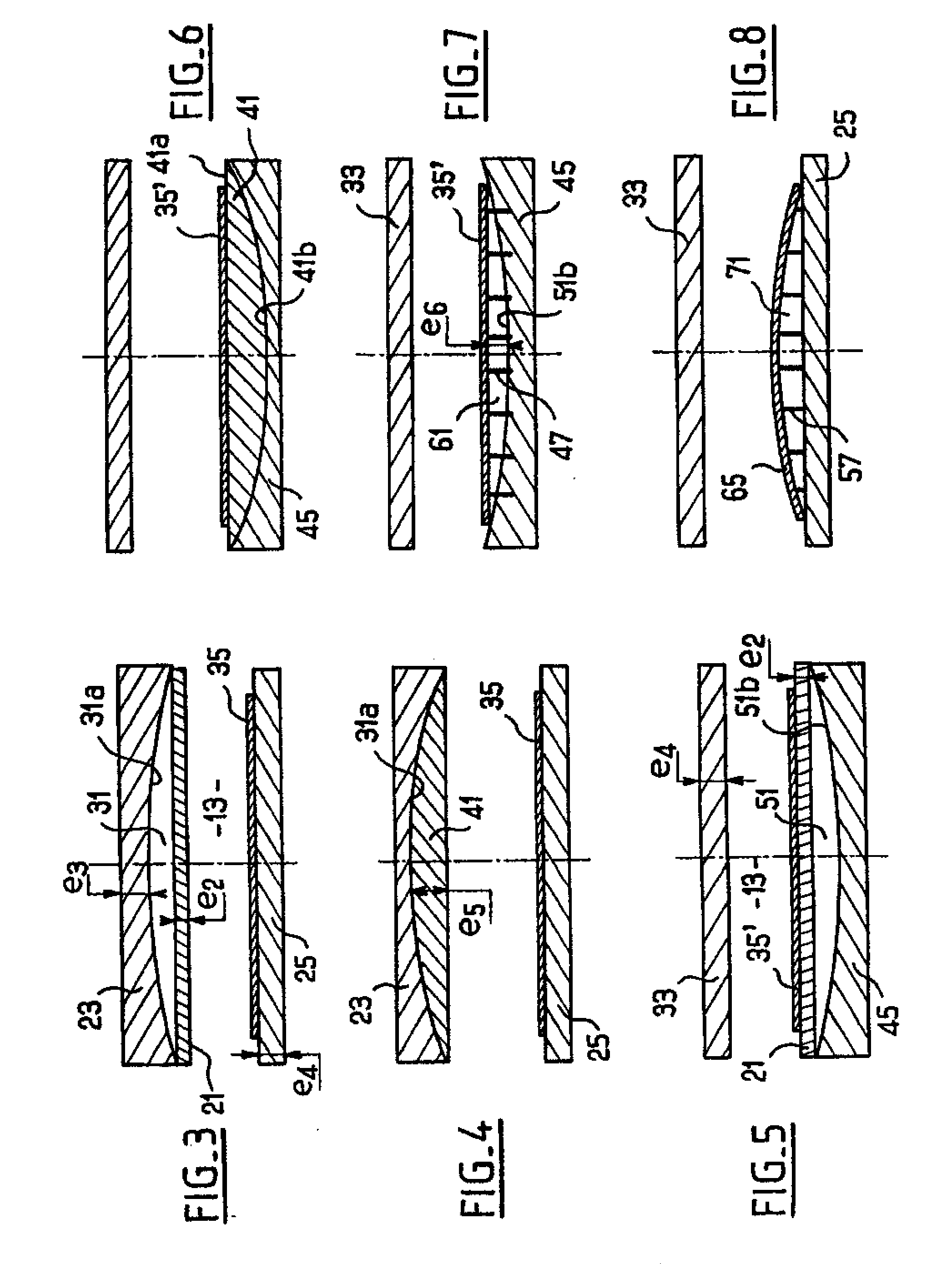

Plasma reactor for the treatment of large size substrates

InactiveUS7661388B2Electric discharge tubesSemiconductor/solid-state device manufacturingEngineeringLarge size

Owner:EVATEC

Method for preparing titanium alloy parts by increasing and decreasing materials

InactiveCN108526488ALow costHigh purityAdditive manufacturing apparatusTransportation and packagingManufacturing technologyOriginal data

The invention discloses a method for preparing titanium alloy parts by increasing and decreasing materials. The method specifically comprises the steps that titanium hydride particles are prepared, specifically, titanium sponge is adopted as a raw material, the titanium sponge reacts with hydrogen to produce titanium hydride, and after the reaction is completed, the produced titanium hydride is crushed; spheroidized titanium particles are prepared, specifically, the crushed titanium hydride particles are subjected to radiofrequency plasma spheroidizing treatment; material increasing and decreasing processing is conducted, specifically, a three-dimensional CAD model is generated according to the parts and imported into a software program of a material increasing and decreasing mixed processing system; software generates a plurality of deposition layers and deposition modules, and the deposition path and deposition parameter of each deposition module are set; and detecting is conducted in real time, the material is subjected to material decreasing processing repair according to original data and real-time detected data. According to the method, high-precision spheroidized titanium alloy particle materials are combined with a material increasing and decreasing manufacturing technology, and the method can be widely applied in industry.

Owner:GUANGDONG UNIV OF TECH

Method of increasing photoelectricity convesion efficiency of TiO2 photecell

InactiveCN1564329AEasy to separateImprove photoelectric conversion efficiencyFinal product manufacturePhotovoltaic energy generationEngineeringRadio frequency

The invented method carries processing for nano TiO2 in radiofrequency plasma generating device by using gas to raise photoelectric conversion efficiency of TiO2 photocell. The method is as following: placing nano TiO2 in radiofrequency plasma generating device, after vacuumizing, at least one of following gas Ar, He, N2, N2+H2 is added to radiofrequency plasma generating device; adjusting following parameters: gas flow rate 0.01-0.90 liter / minute, power of radio frequency 50-1000W, temperature 100-550deg.C and processing time 0.5-10 hour. The product is obtained after processing. The processed product possesses better performance of photovoltaic conversion, and conversion efficiency is raised to 30%-80%.

Owner:WUHAN UNIV

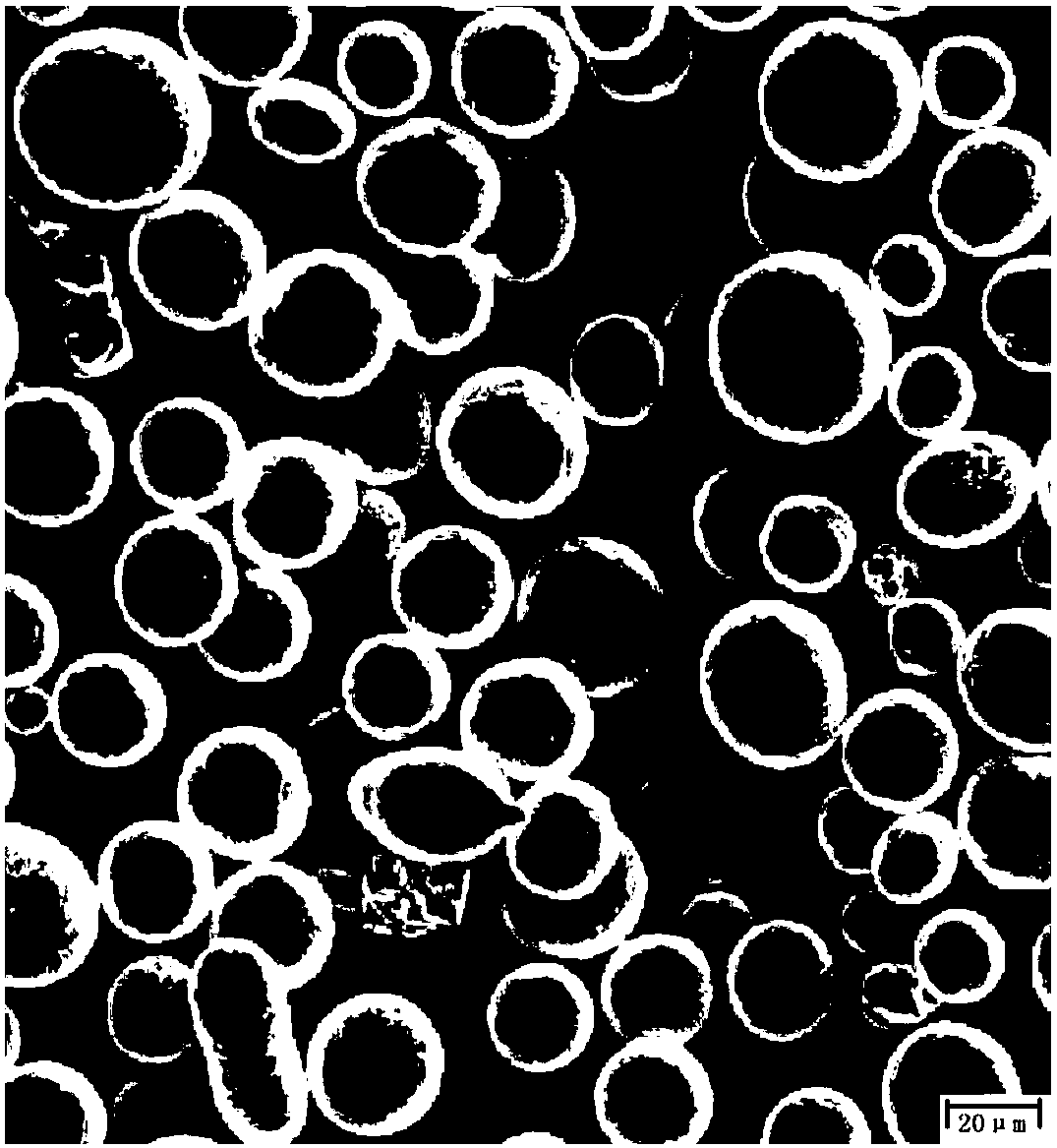

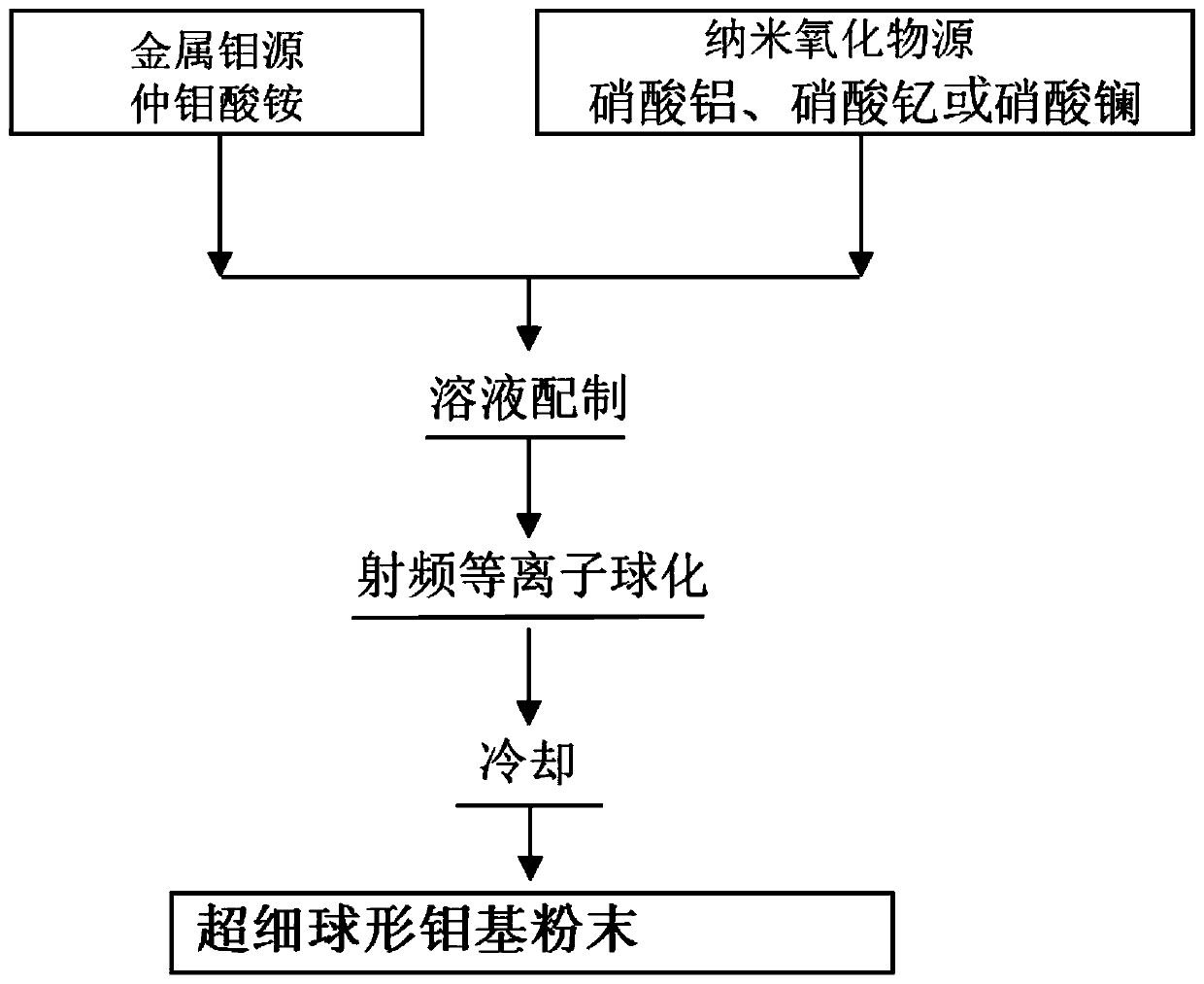

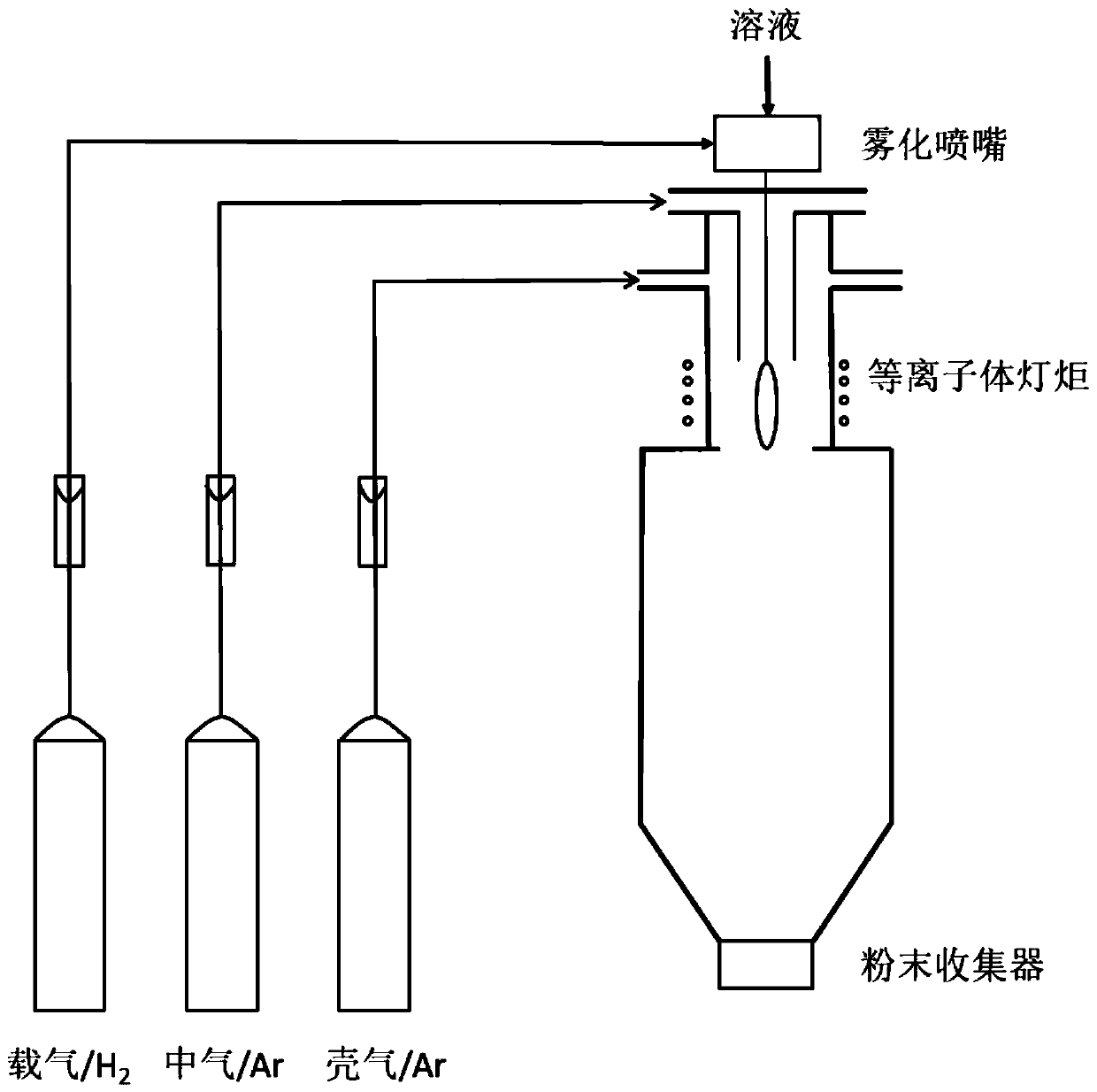

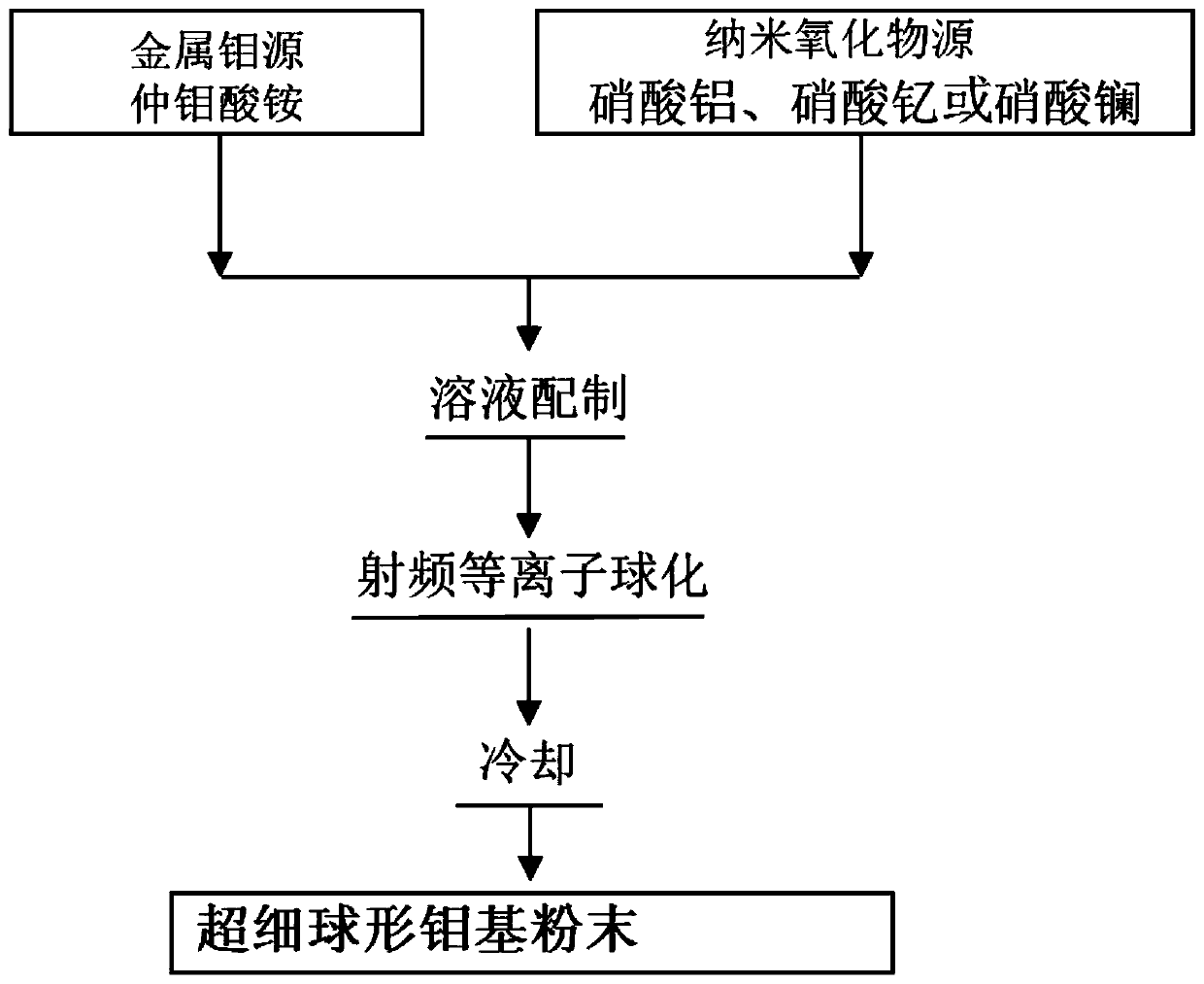

Method for preparing spherical molybdenum-based powder

ActiveCN110014162AHigh sphericitySmall particle sizeAdditive manufacturing apparatusTransportation and packagingSolventPlasma heating

The invention belongs to the field of preparation and research for a spherical metal-based powder, and provides a method for preparing a superfine spherical molybdenum-based powder. The method comprises the following steps: S1, preparation for a precursor solution: a metal molybdenum source and a nanometer oxide in raw materials are dissolved in an appropriate amount of solvent and then stirred toobtain the transparent precursor solution; and S2, preparation for a superfine spherical powder product: radiofrequency plasma spheroidization is carried out on the obtained precursor solution, the precursor solution is conveyed to an atomizing nozzle by carrier gas and atomized, and then arrives at a high-temperature area for radiofrequency plasma heating, a solute in the precursor solution is decomposed to obtain the nano-composite powder of WO3 and the corresponding oxide, then the nano-composite powder reacts with H2 to obtain oxide-dispersion-strengthened molybdenum powder, then the composite powder is melted and becomes spherical under the effect of surface tension, and is cooled to obtain the product. The method provides a new thought for preparing the superfine spherical oxide-dispersion-strengthened molybdenum powder, and has the advantages of being short in production period, low in cost, convenient to operate, and the like.

Owner:UNIV OF SCI & TECH BEIJING +1

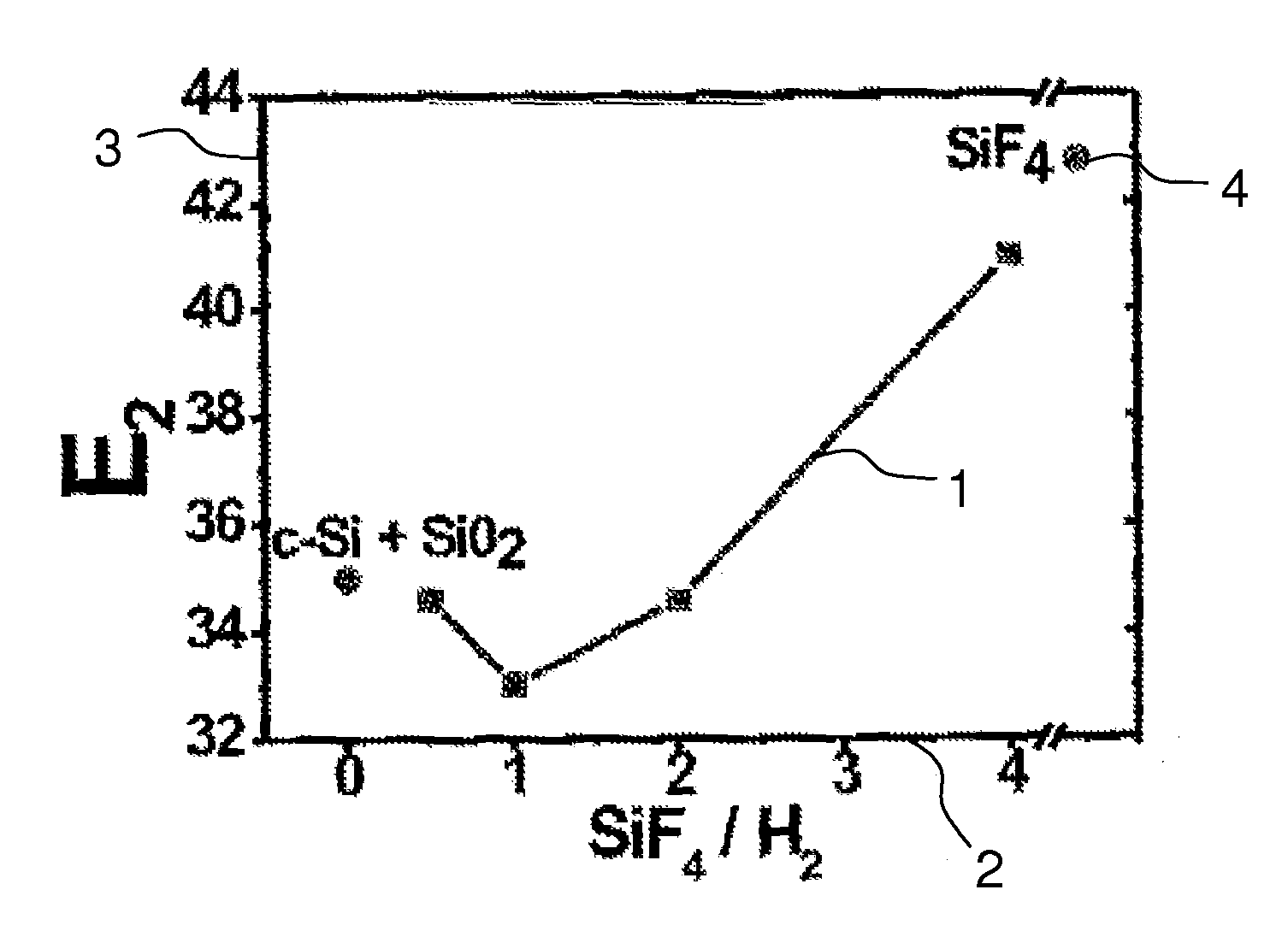

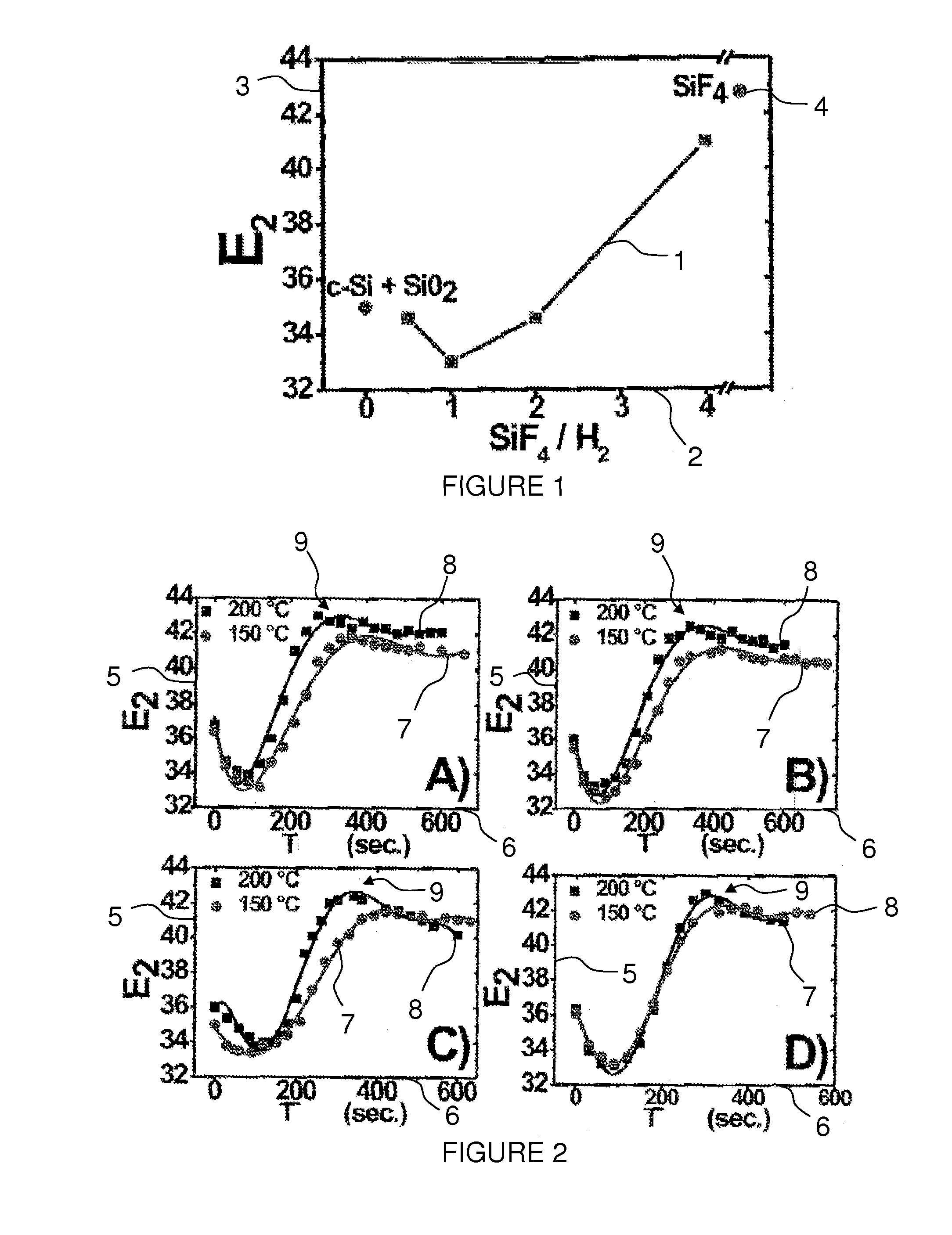

Method for cleaning the surface of a silicon substrate

ActiveUS8404052B2Reduce manufacturing costReduce usageLighting and heating apparatusFinal product manufacturePhysical chemistrySilicon oxide

A method for cleaning the surface of a silicon substrate, covered by a layer of silicon oxide includes: a) exposing the surface for 60 to 900 seconds to a radiofrequency plasma, generated from a fluorinated gas, to strip the silicon oxide layer and induce the adsorption of fluorinated elements on the substrate surface, the power density generated using the plasma being 10 mW / cm2 to 350 mW / cm2, the fluorinated gas pressure being 10 mTorrs to 200 mTorrs, and the substrate temperature being lower than or equal to 300° C.; and b) exposing the surface including the fluorinated elements for 5 to 120 seconds to a hydrogen radiofrequency plasma, to remove the fluorinated elements from the substrate surface, the power density generated using the plasma being 10 mW / cm2 to 350 mW / cm2, the hydrogen pressure being 10 mTorrs to 1 Torr, and the substrate temperature being lower than or equal to 300° C.

Owner:TOTAL PUTEAUX FR

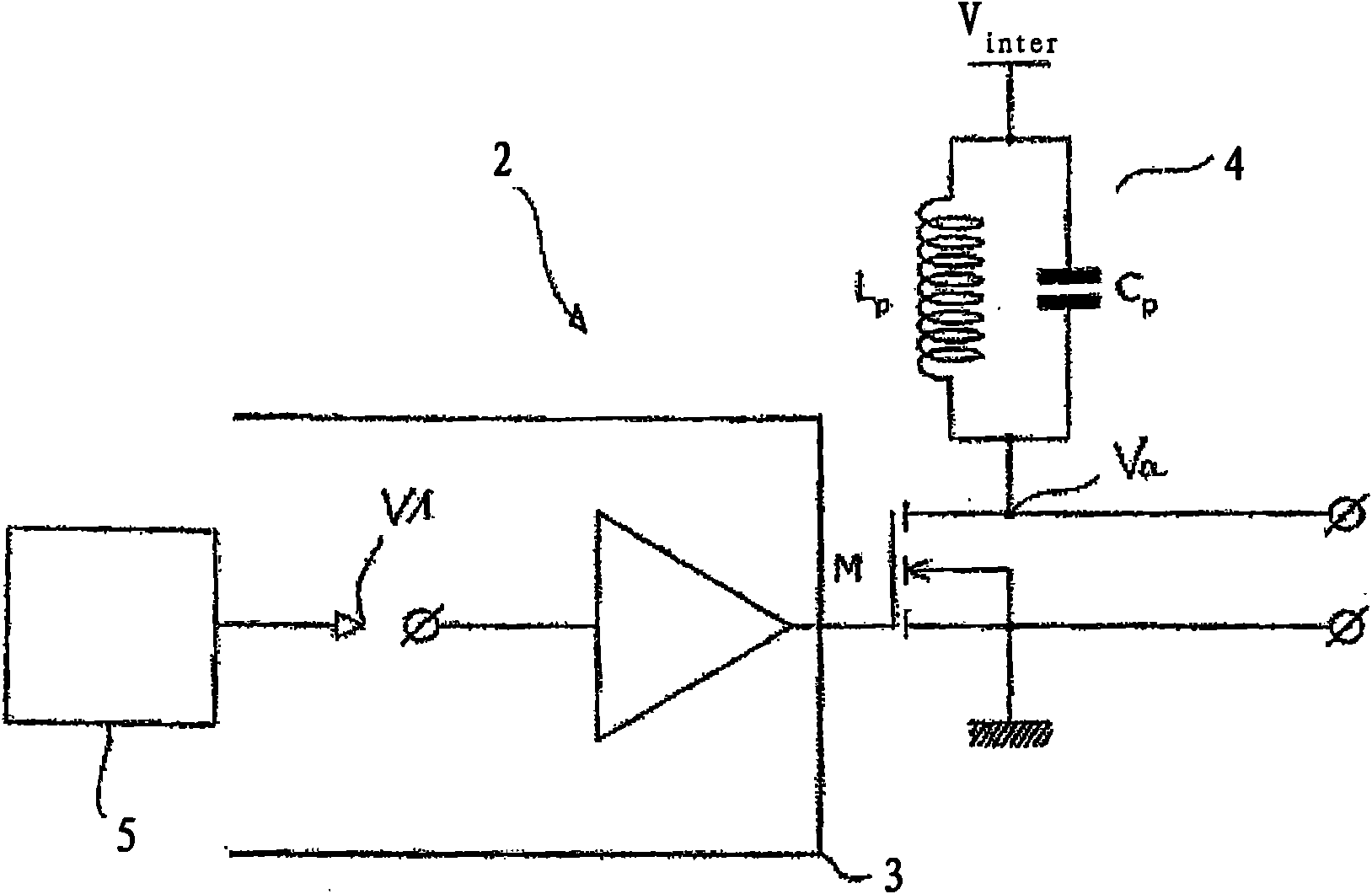

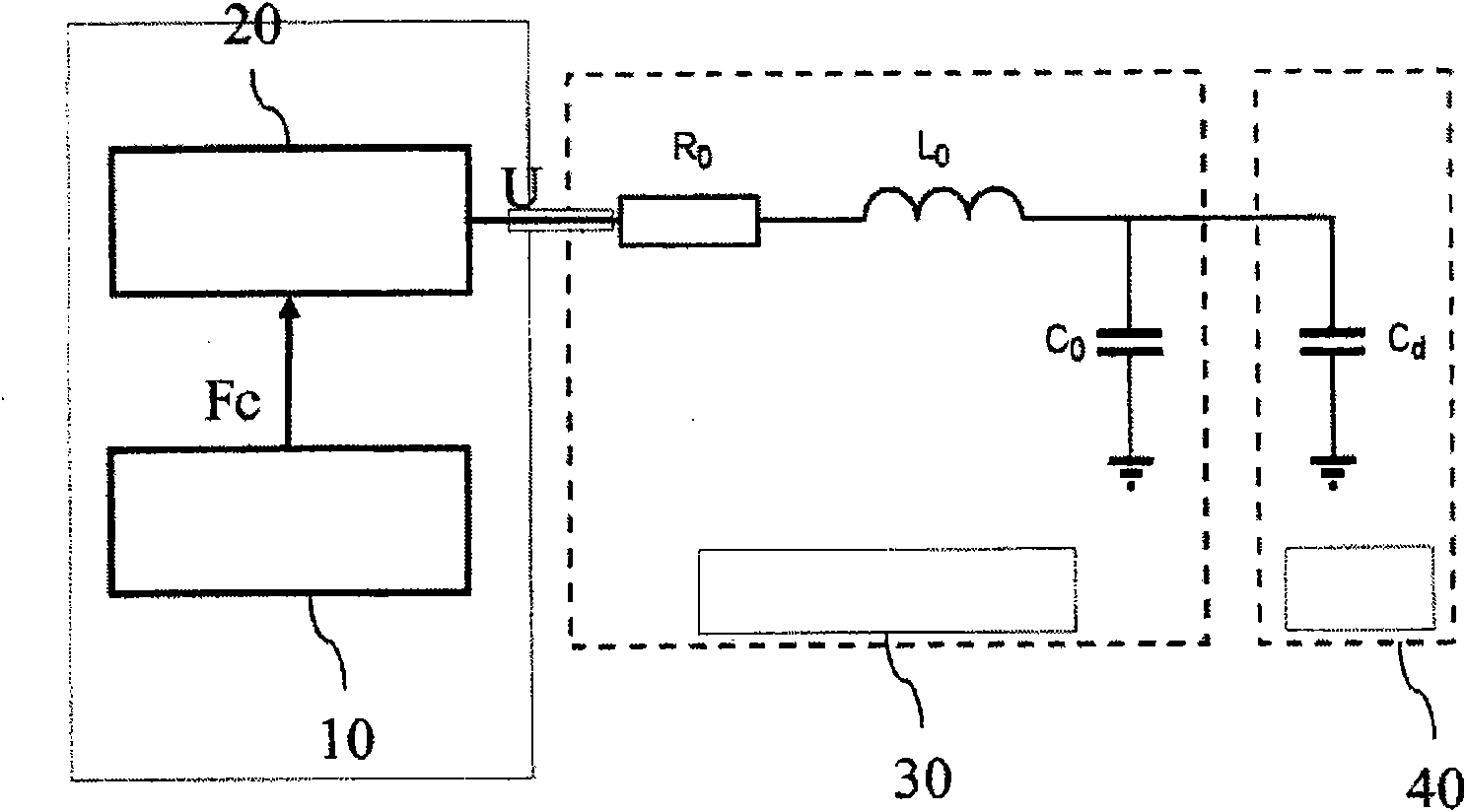

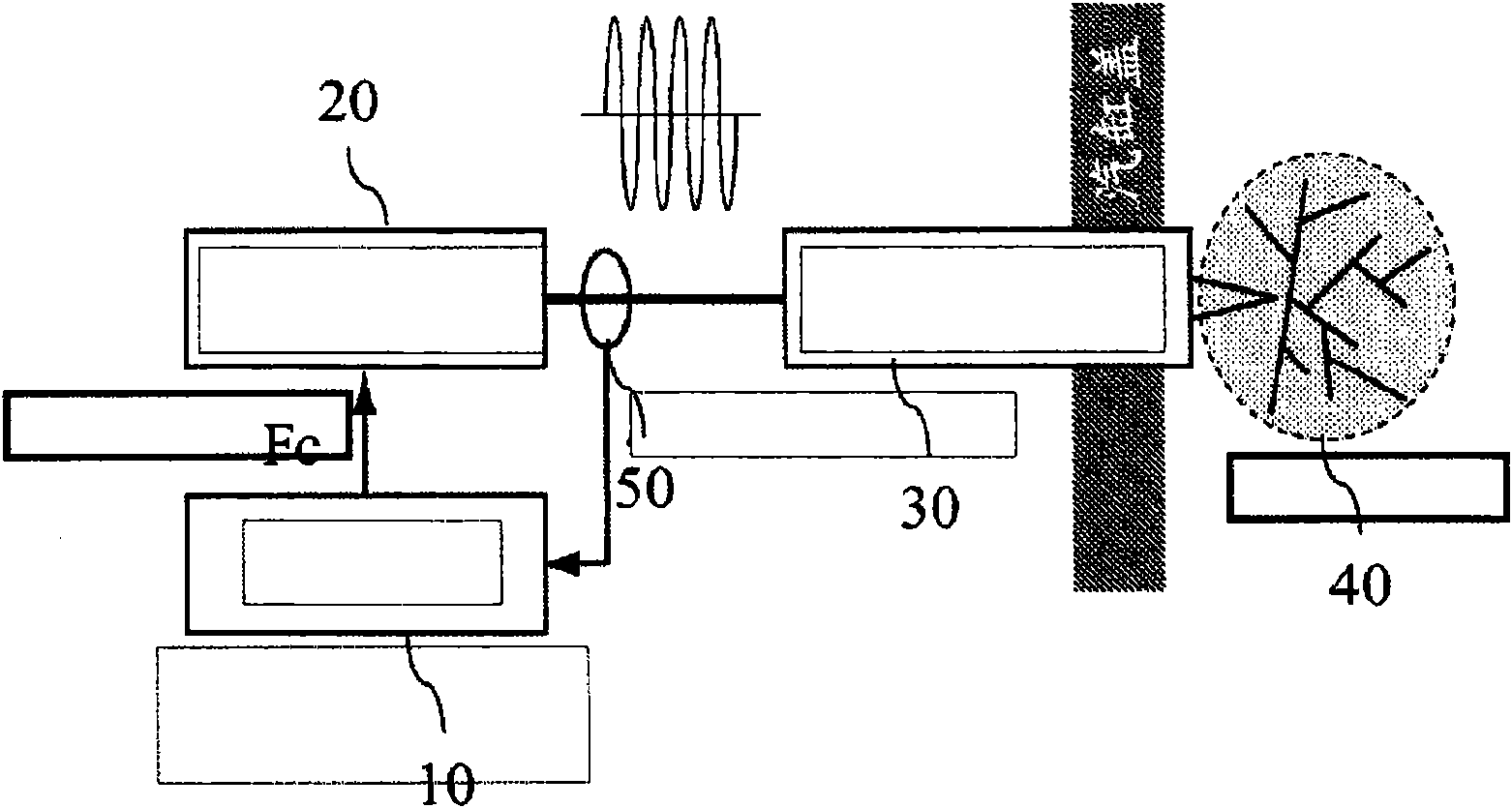

Control of a plurality of plug coils via a single power stage

The invention relates to a radiofrequency plasma generating device that comprises: a supply circuit (2) including a switch (M) controlled by a control signal (V1) for applying a voltage (Vinter) on an output of the control circuit at a control frequency; at least two plasma-generating circuits (BB1, BB2, BB3, BB4) connected in parallel at the output of the supply circuit, each circuit having its own resonance frequency and being capable of generating plasma when a high voltage level is applied to the output of the supply circuit at a frequency substantially equal to the resonance frequency of the plasma generation circuit; and a supply control device (5) for determining the control frequency from the resonance frequencies (F1, F2, F3, F4) of the plasma generation circuits in order to selectively control each circuit according to the control frequency used.

Owner:RENAULT SA

Preparation method of refractory carbide particle reinforced copper infiltrated tungsten composite

ActiveCN110791674ALow densityImprove mechanical propertiesTransportation and packagingMetal-working apparatusBorideTransition metal carbides

The invention relates to a preparation method of a refractory carbide particle reinforced copper infiltrated tungsten composite, and belongs to the technical field of copper infiltrated tungsten composites. The problem that transition metal carbon borides are difficult to prepare due to low solid solution between existing transition metal carbides and borides is solved. According to the preparation method of the refractory carbide particle reinforced copper infiltrated tungsten composite, tungsten powder and transition metal carbide powder are configured into slurry, and composite powder is obtained after grinding, spray drying and radiofrequency plasma spheroidization are carried out. A porous blank body is obtained by the composite powder through modes of mold pressing and isostatic coolpressing, a porous preformed body is obtained after degumming and high temperature sintering, and the refractory carbide particle reinforced copper infiltrated tungsten composite is prepared by infiltrating metal copper at 1100 DEG C-1400 DEG C. The density and thermal conductivity of the composite is further reduced without reducing the ablation resistance of a copper infiltrated tungsten material, and meanwhile, the mechanical properties are greatly improved.

Owner:HARBIN INST OF TECH

Radiofrequency plasma synthetic method for extracting alumina from aluminum residues

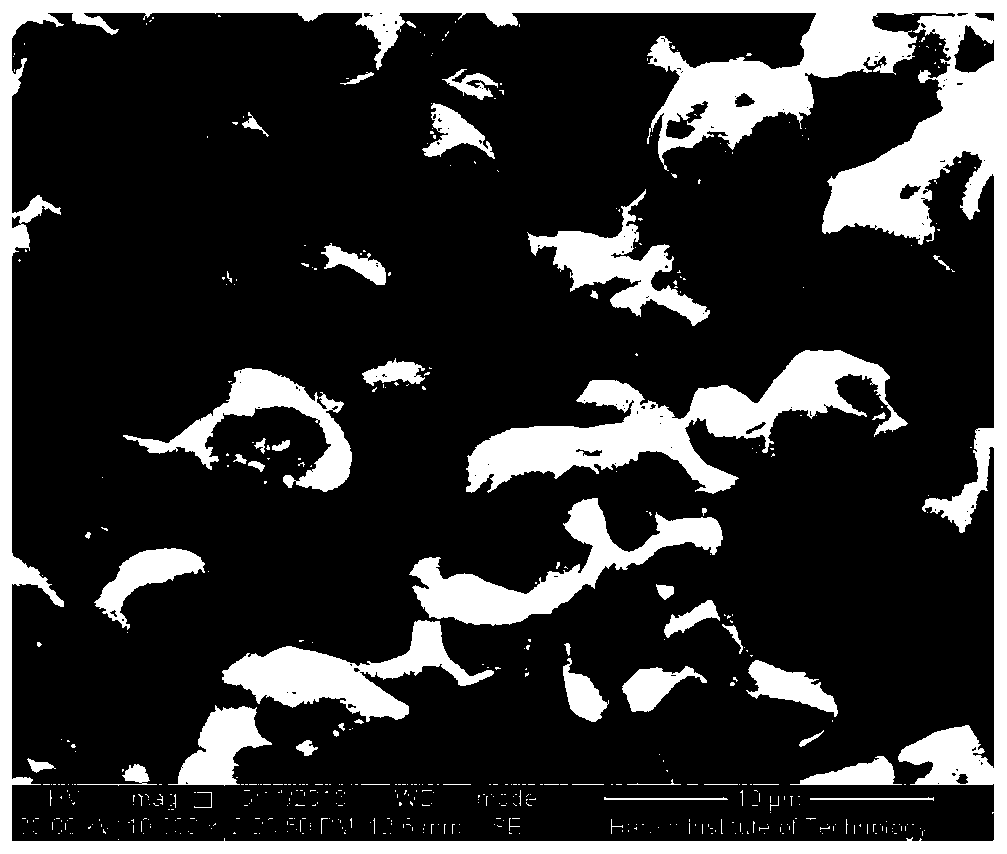

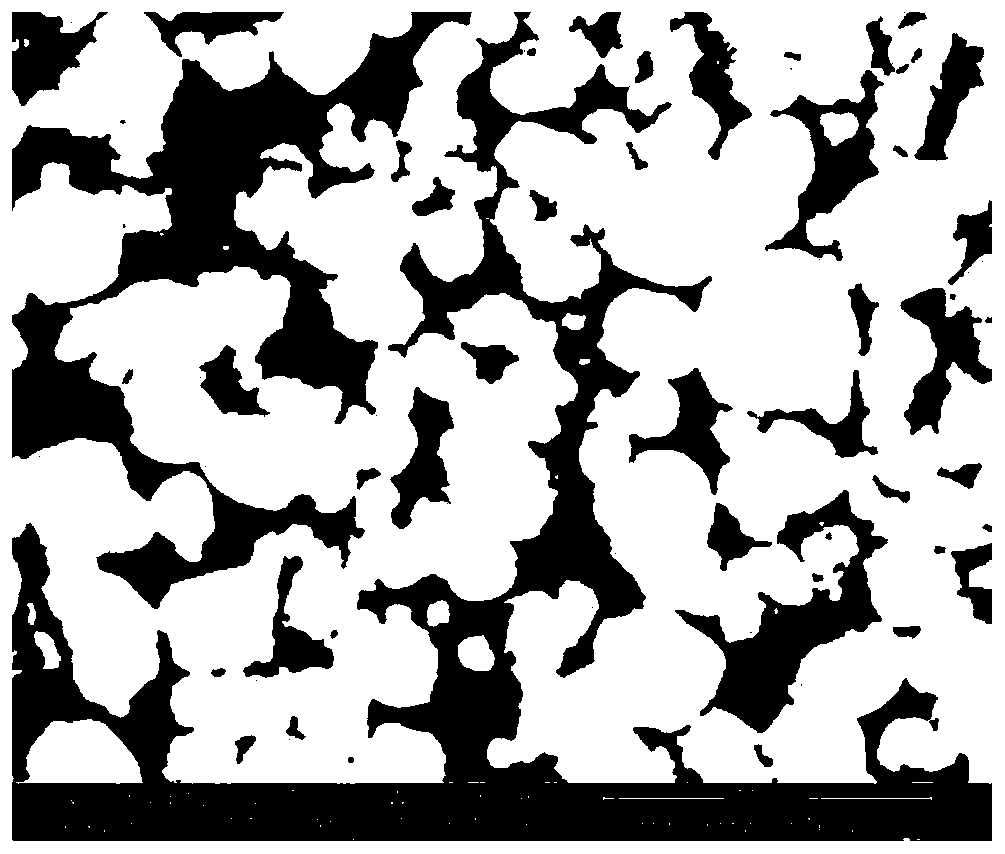

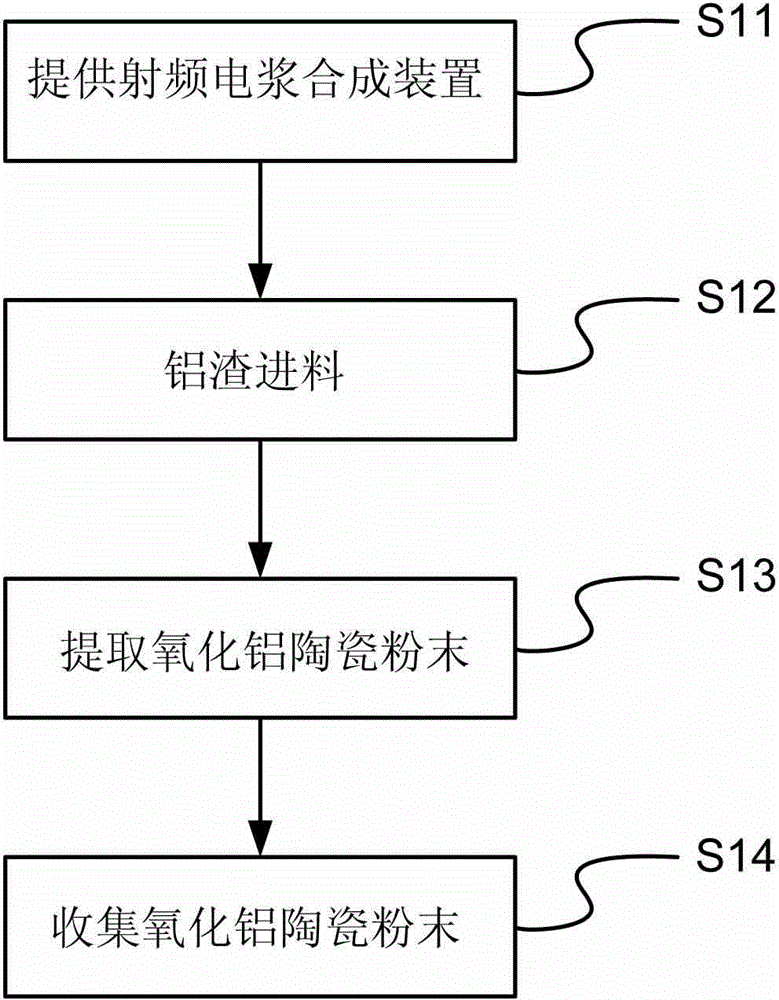

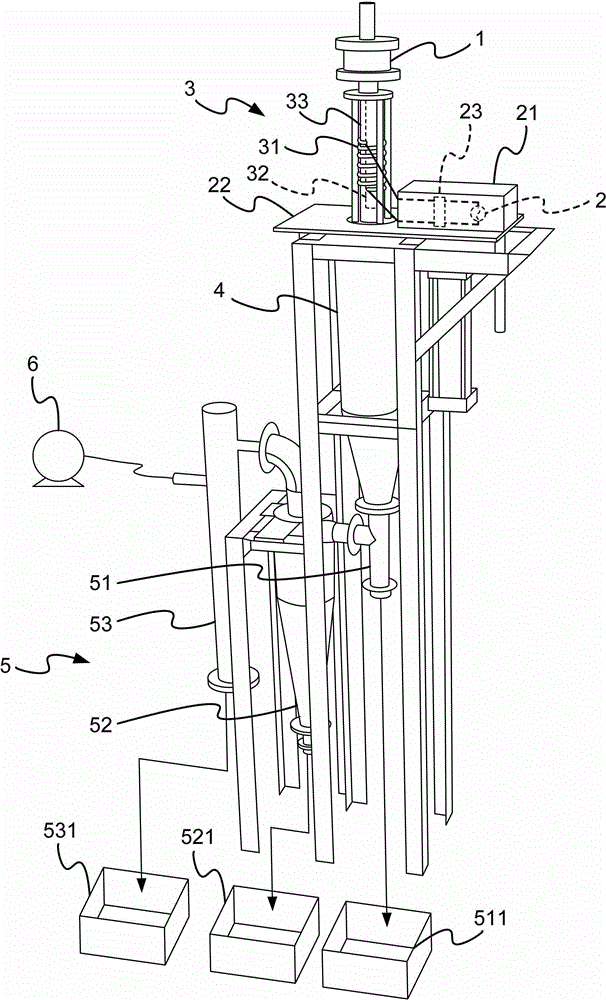

InactiveCN105819475AExtend the life cycleAvoid exploitationSolid waste disposalAluminium oxides/hydroxidesPlasma technologyRadio frequency

The invention relates to a radiofrequency plasma synthetic method for extracting alumina from aluminum residues. The method is characterized in that a thermal plasma technology is used for constructing a radiofrequency plasma synthesis apparatus as a high-temperature heat source, through processing of the thermal plasma and high temperature purifying of the aluminum residues, thereby the alumina is extracted from the aluminum residues to obtain the alumina ceramic powder, at the same time, the aluminum residues can be processed, alumina is produced, and the aluminum residues can be transited to merchantable products. The radiofrequency plasma synthesis apparatus comprises a powder feeder, a radio frequency generator, a thermal plasma source, a reaction chamber, a powder collection unit and a vacuum pump.

Owner:蒋世杰 +1

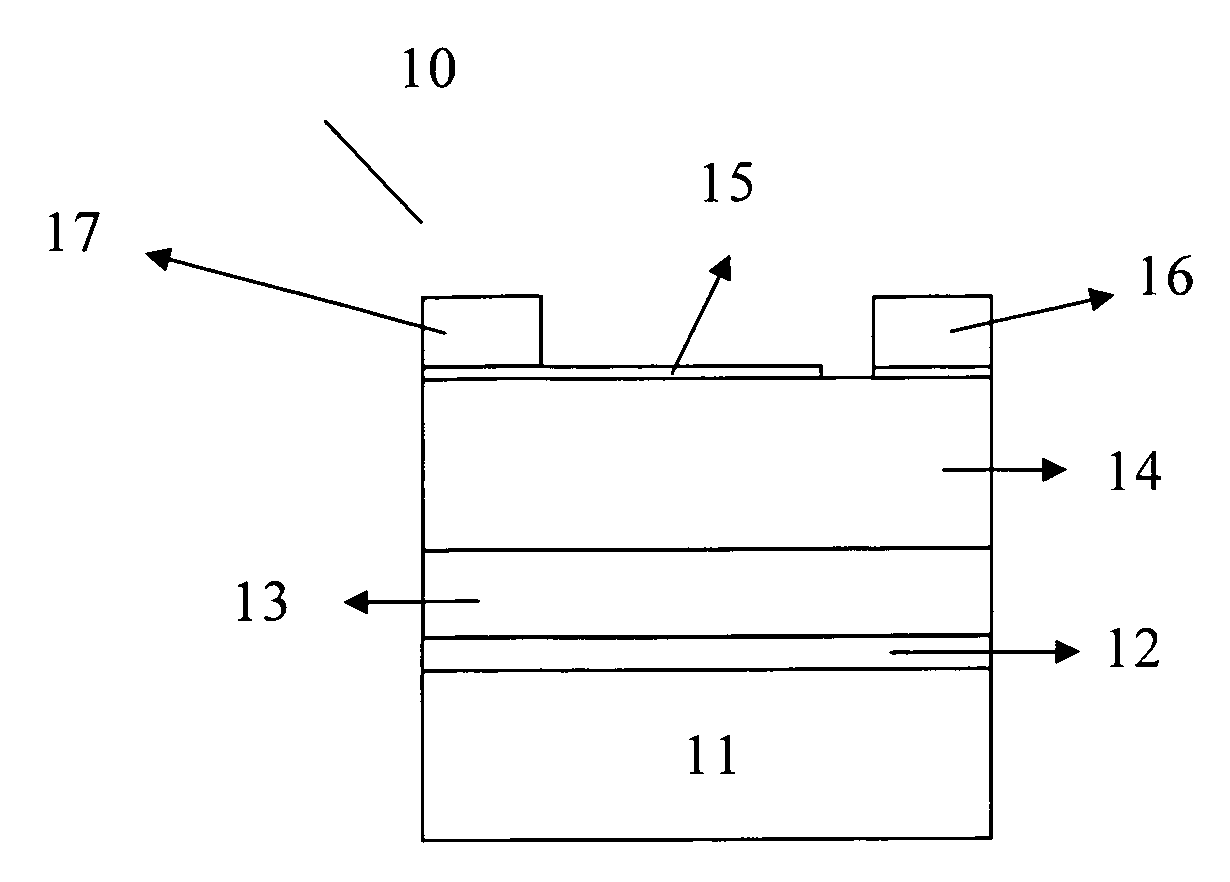

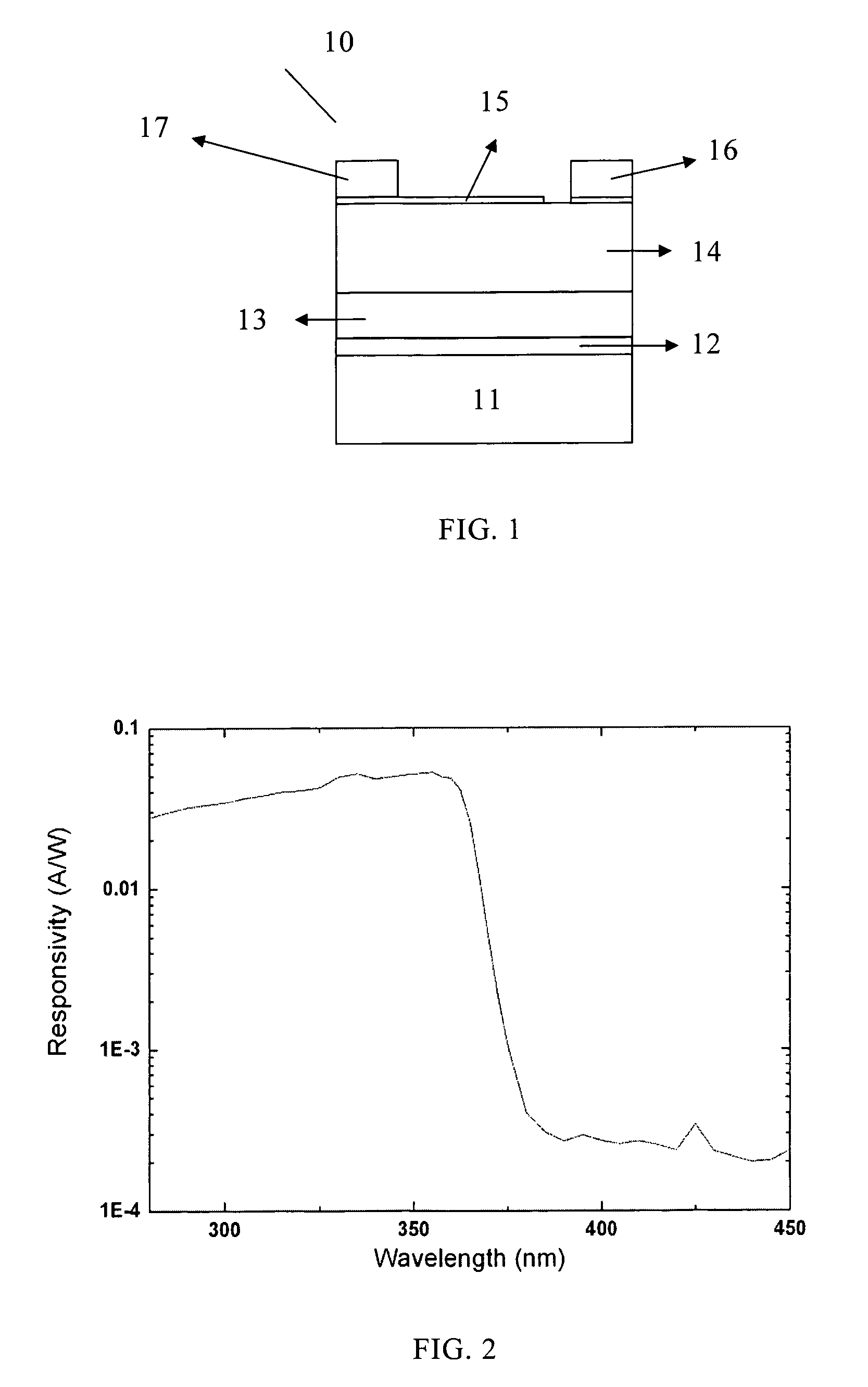

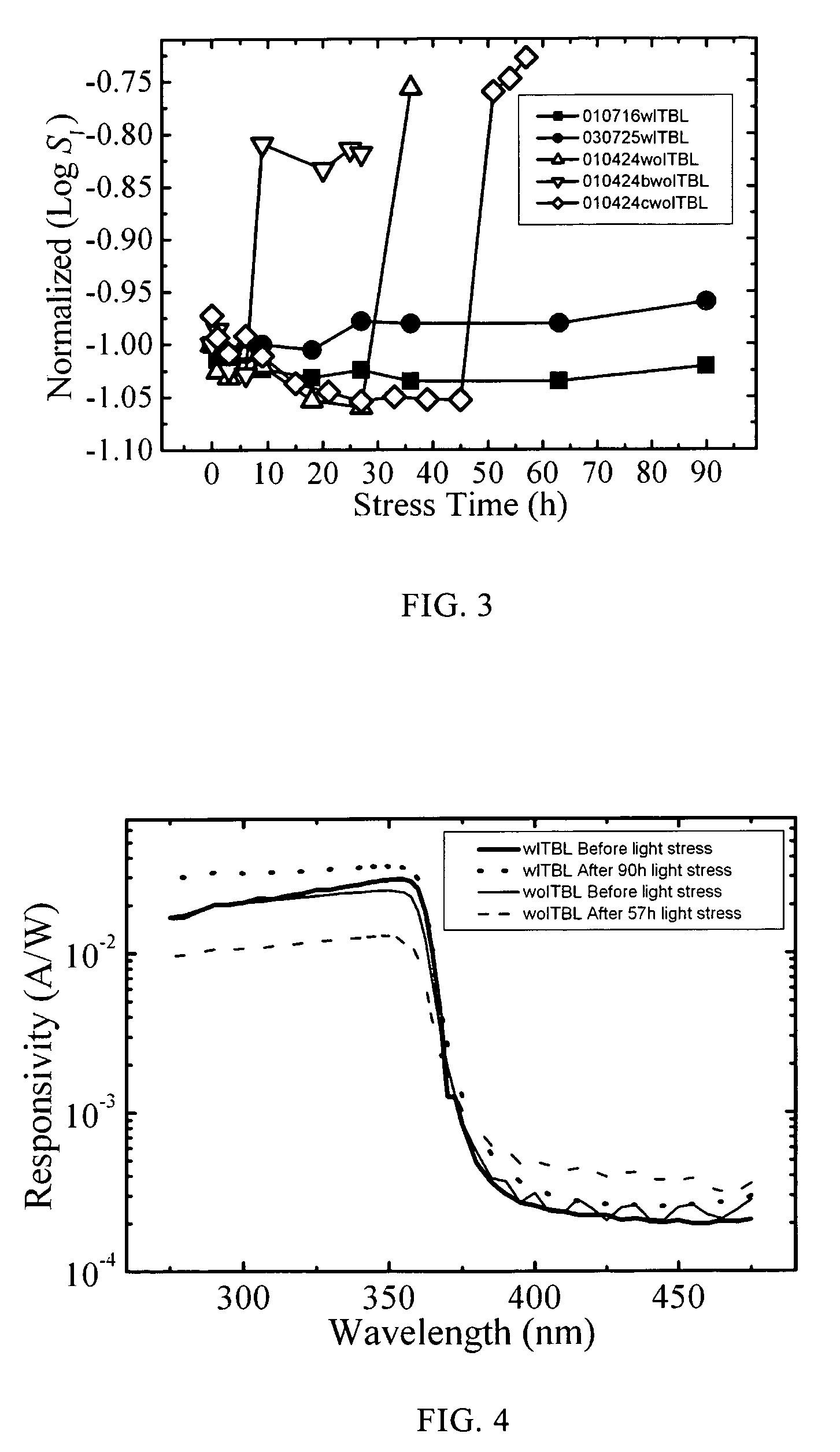

Ultraviolet detector

ActiveUS7470940B2Improved reliability and UV radiation hardnessRapid responseTransistorSolid-state devicesUltraviolet detectorsOhmic contact

An UV detector, comprising: a sapphire substrate; a high temperature AlN buffer layer grown on the sapphire substrate; an intermediate temperature GaN buffer layer grown on the high temperature AlN buffer layer; a GaN epitaxial layer deposited on the intermediate temperature GaN buffer layer; a Schottky junction formed on top of the GaN epitaxial layer; and a plurality of ohmic contacts also formed on top of the GaN epitaxial layer, wherein, the high temperature AlN buffer layer and the intermediate temperature GaN buffer layer together form a double buffer layer structure so as to improve the reliability and radiation hardness of the UV detector; and wherein the high temperature AlN buffer layer and the intermediate temperature GaN buffer layer are formed by RF-plasma enhanced MBE growth technology.

Owner:THE HONG KONG POLYTECHNIC UNIV

Dynamic surface annealing of implanted dopants with low temperature HDPCVD process for depositing a high extinction coefficient optical absorber layer

A plasma enhanced physical vapor deposition process deposits an amorphous carbon layer on an ion-implanted wafer for use in dynamic surface annealing of the wafer with an intense line beam of a laser wavelength. The deposition process is carried out at a wafer temperature below the dopant clustering threshold temperature, and includes introducing the wafer into a chamber and furnishing a hydrocarbon process gas into the chamber, preferably propylene (C3H6) or toluene (C7H8) or acetylene (C2H2) or a mixture of acetylene and methane (C2H4). The process further includes inductively coupling RF plasma source power into the chamber while and applying RF plasma bias power to the wafer. The wafer bias voltage is set to a level at which the amorphous carbon layer that is deposited has a desired stress (compressive or tensile). We have discovered that at a wafer temperature less than or equal to 475 degrees C., total RF plasma source power of 4000 Watts at about 2 MHz, RF plasma bias power of 2000-3000 Watts at about 13.56 MHz and a chamber pressure in a range of 3 mTorr to 2 Torr, the deposited amorphous carbon layer has a surprising combination of high absorption and high strength and excellent step coverage.

Owner:APPLIED MATERIALS INC

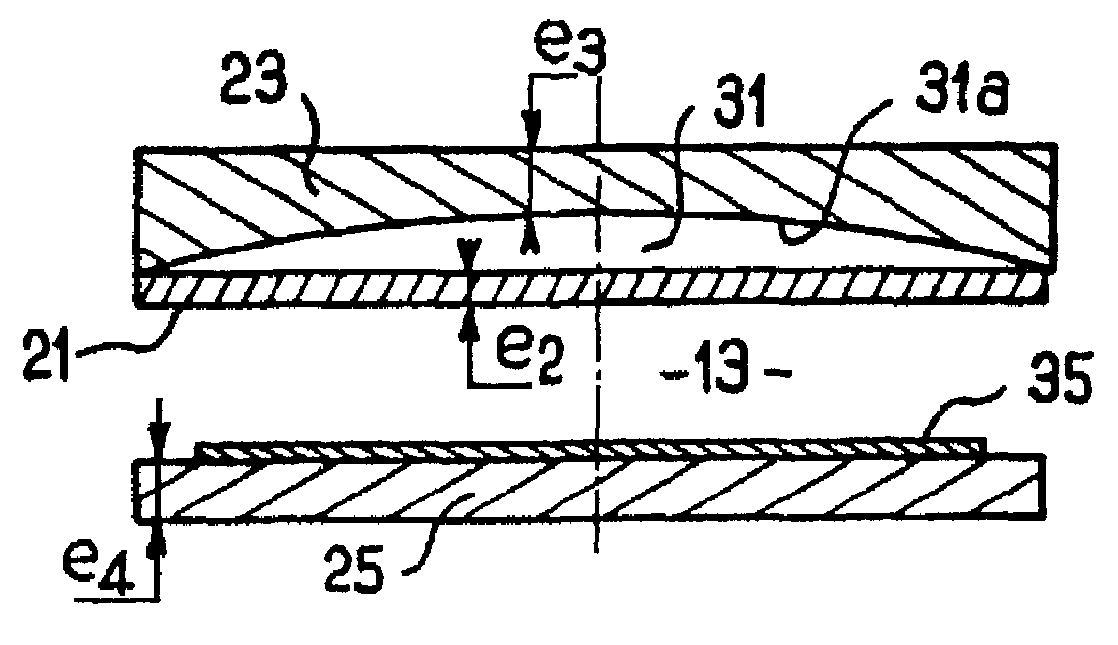

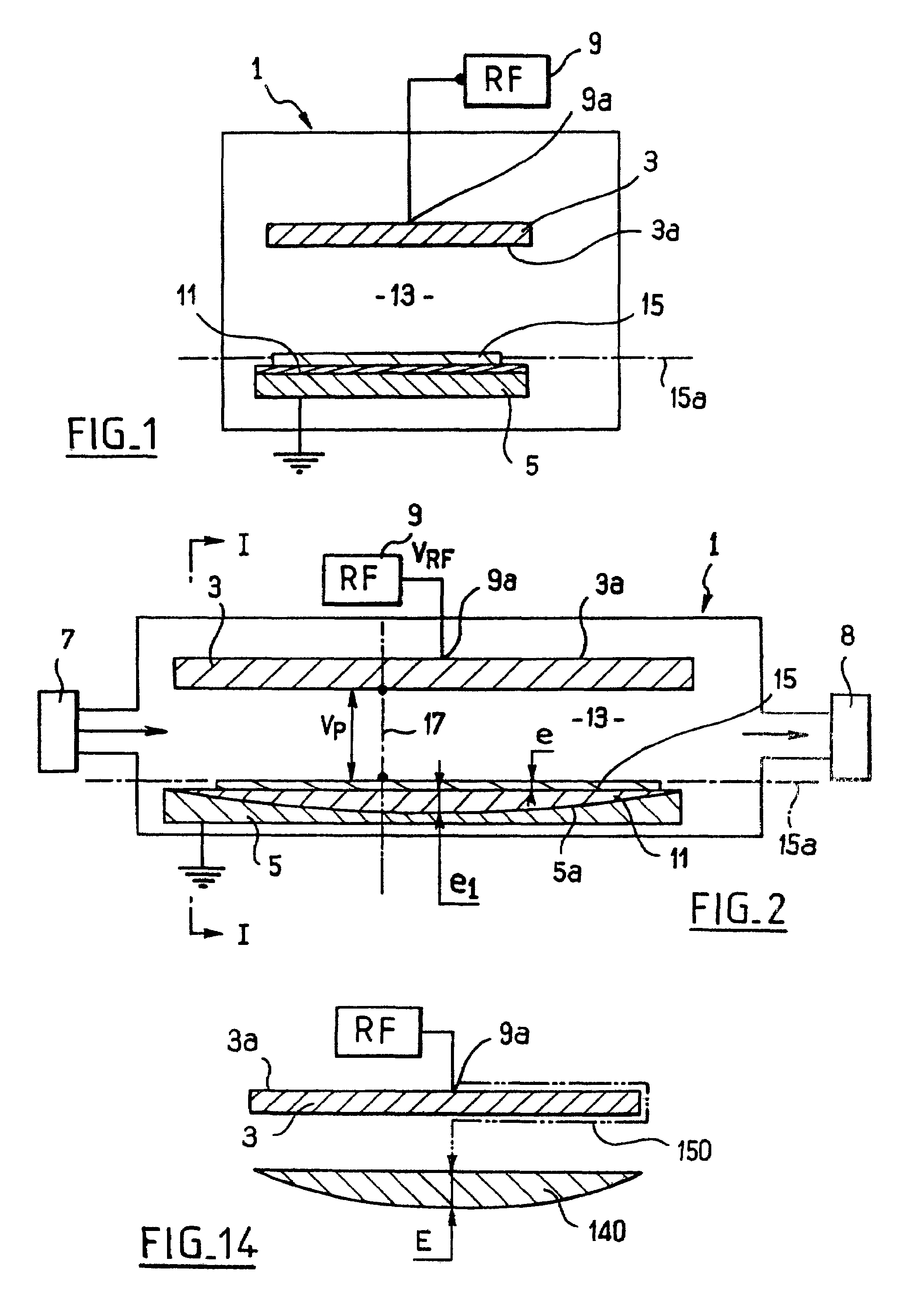

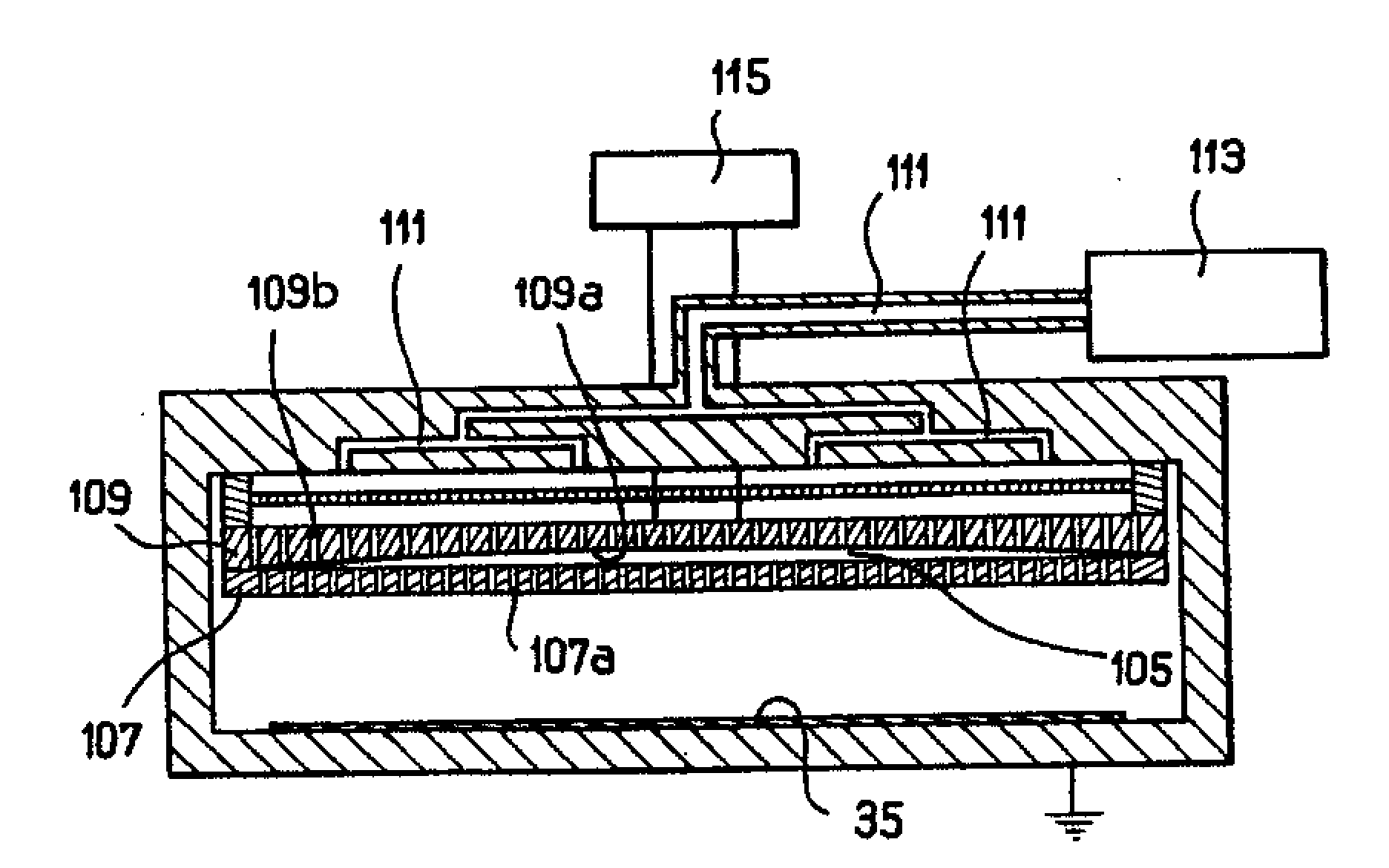

Plasma reactor for the treatment of large size substrates

InactiveUS20080184934A1Electric discharge tubesSemiconductor/solid-state device manufacturingCapacitanceProcess region

A radiofrequency plasma reactor with first and second spaced electrodes has a concave surface facing a substrate supporting surface. A process area between the electrodes has a gas inlet for a process gas. A radiofrequency generator for frequencies greater than 13.56 MHz is connected to an electrode for generating a plasma discharge in and a gas outlet evacuates process gas. A dielectric layer has a convex surface engaging the concave electrode surface and an opposite planar surface. The substrate supporting surface receives a substrate of at least 0.7 m and defines a boundary of the process area to be exposed to the plasma. The dielectric layer is electrically in series with the substrate and plasma discharge and has capacitance per unit surface values which are not uniform for a distribution profile to compensate process non-uniformity along the working surface.

Owner:EVATEC

A bendable radiofrequency plasma surgical electrode for treating discogenic low back pain

InactiveCN109199580AWith bending functionReduced toleranceSurgical instruments for heatingOuter CannulaRadiofrequency plasma

The invention discloses a bendable plasma surgical electrode for treating intervertebral disc protrusion, which relates to the technical field of medical instruments, comprising a sub-needle, an insulating head, a loop tube, a relay cannula, a four-lumen tube, an outer cannula, a cannula fixing frame, a handle mechanism, a housing and a cable, wherein the sub-needle is embedded in the insulating head, the insulating head is embedded in the loop tube, and the sub-needle and the loop tube form a positive and negative electrode loop on the head through an electrically conductive liquid and are isolated by the insulating head. The invention relates to a flexible plasma surgical electrode for treating intervertebral disc protrusion, which has multiple therapeutic functions, has small postoperative trauma, simple operation and high safety, can precisely perform ablation and decompression, solves the shortcomings of the existing therapeutic methods, and meets the treatment needs of a patientgroup.

Owner:上海方润医疗科技股份有限公司

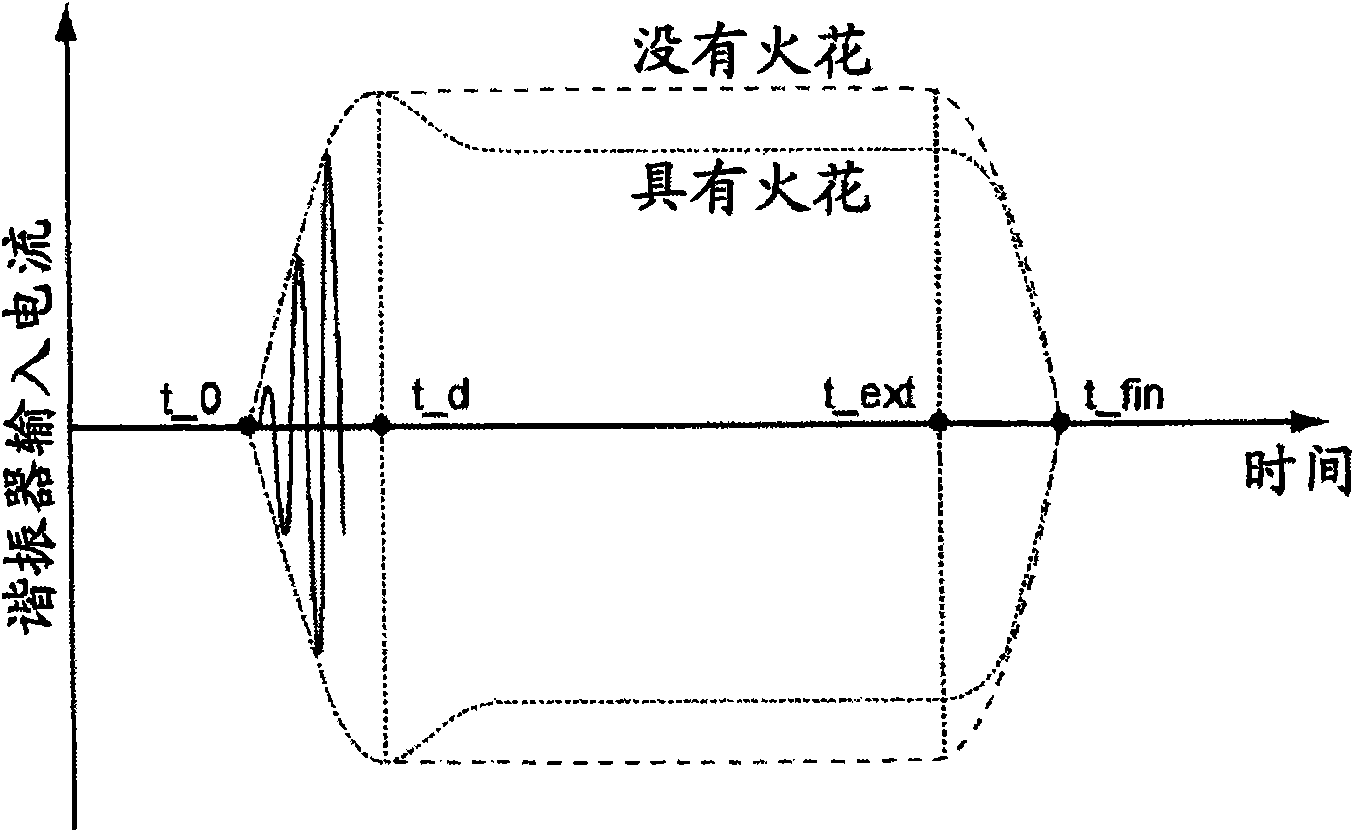

Optimisation of the excitation frequency of a radiofrequency plug

The invention relates to a device for generating a radiofrequency plasma, which comprises a supply module (20) applying, on an output interface, an excitation signal (U) at a setpoint frequency (Fc), adapted for generating a spark (40) at the output of a plasma-generation resonator (30) connected to the output interface of the power module, and a control module (10) supplying the setpoint frequency to the power module upon a command for generating the radiofrequency plasma, wherein said device is characterised in that the control module includes a means for determining an optimal excitation frequency, capable of adapting the setpoint frequency (Fc) to the resonance conditions of the device after formation of the spark.

Owner:RENAULT SA

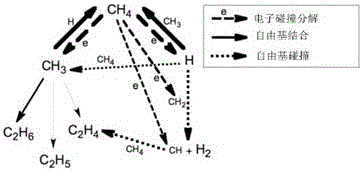

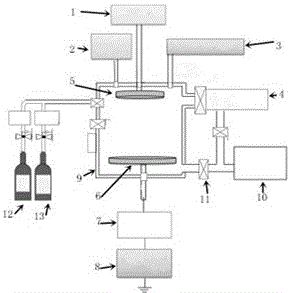

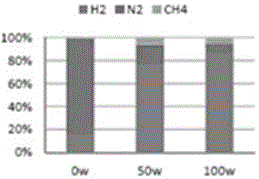

Heat treatment waste gas plasma recombination power generation method and plasma recombination reactor

ActiveCN105688618AWith low carbon emissionsBoth benefitsCombination devicesHydrogenEnergy regenerationProcess engineering

The invention provides a heat treatment waste gas plasma recombination power generation method and a plasma recombination reactor.The heat treatment waste gas plasma recombination power generation method comprises the following technical steps that 1, tail gas of heat treatment equipment is generated; 2, the tail gas of the heat treatment equipment is pretreated; 3, the pretreated tail gas is guided into the plasma recombination reactor for a recombination reaction; 4, gas prepared in the step 3 is guided into a gas turbine generator for power generation.The heat treatment waste gas plasma recombination power generation method and the plasma recombination reactor have the advantages that an existing traditional treatment technique-waste gas burning is replaced with a plasma recombination treatment technique on the basis of a target of a factory on heat treatment waste gas energy regeneration, the heat treatment waste gas can be effectively recombined into energy gas under the normal temperature condition by adopting low-energy consumption radiofrequency plasma to cooperate with a nanometal catalyst, the energy gas is connected to the gas turbine generator for power generation by cooperating with improvement of a power generator, and therefore the effects of low carbon emission and energy regeneration are simultaneously achieved.

Owner:KMC CHAIN TAICANG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com