Preparation method of refractory carbide particle reinforced copper infiltrated tungsten composite

A technology of carbide particles and composite materials, used in metal processing equipment, transportation and packaging, etc., can solve the problems of difficult to prepare transition metal carboborides, transition metal carbides and low solid solubility of borides, and achieve spherical shape. The effect of improving the mechanical properties and reducing the particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

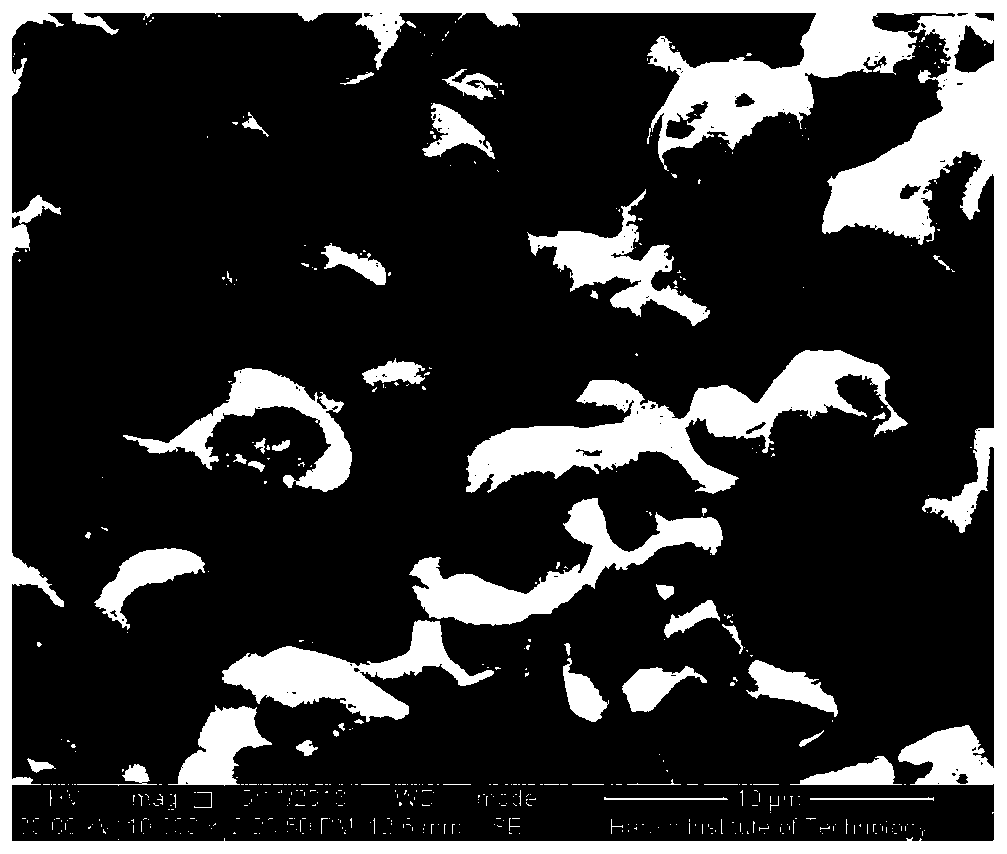

[0025] (1) With 200mL deionized water as the dispersion medium, first add 1mL of polyvinyl alcohol resin dispersant and 1mL of polyvinyl alcohol binder, until the dispersant and binder are completely dissolved in the dispersion medium, then add 100g of powder, of which The powder is composed of zirconium carbide and tungsten powder, the mass ratio of zirconium carbide and tungsten powder in the powder is 5:95, the purity of zirconium carbide and tungsten powder is >99%, and the particle size of zirconium carbide and tungsten powder is 1μm~2μm , after ultrasonic treatment for 30 min, a slurry was obtained.

[0026] (2) Use a sand mill to grind the slurry prepared in step 1 at a speed of 2000rpm for 10 hours, so that the slurry is more uniform and stable and the particle size of carbide and tungsten powder is refined; then the spray drying granulator will mix the slurry The material is sprayed and granulated to obtain zirconium carbide / tungsten composite powder particles with a ...

specific Embodiment approach 2

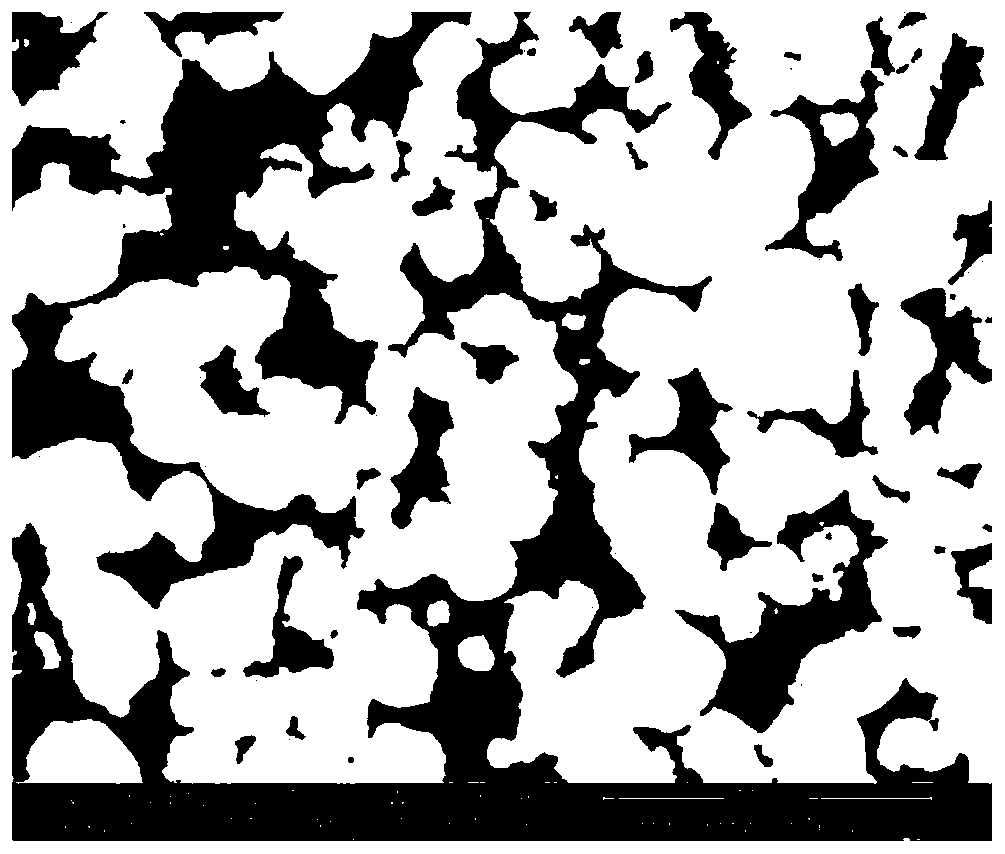

[0032] (1) With 200mL deionized water as the dispersion medium, first add 1mL of polyvinyl alcohol resin dispersant and 1mL of polyvinyl alcohol binder, until the dispersant and binder are completely dissolved in the dispersion medium, then add 100g of powder, of which The powder is composed of zirconium carbide and tungsten powder, the mass ratio of zirconium carbide and tungsten powder in the powder is 10:90, the purity of zirconium carbide and tungsten powder is >99%, and the particle size of zirconium carbide and tungsten powder is 1μm~2μm , after ultrasonic treatment for 30 min, a slurry was obtained.

[0033] (2) Use a sand mill to grind the slurry prepared in step 1 at a speed of 2000rpm for 10 hours to make the slurry more uniform and stable and to refine the particle size of carbide and tungsten powder. Use a laser particle size analyzer to measure the slurry after mixing The particle size D90 of the medium powder particles is 132nm; then use a spray drying granulator...

specific Embodiment approach 3

[0039] (1) With 200mL deionized water as the dispersion medium, first add 1mL of polyvinyl alcohol resin dispersant and 1mL of polyvinyl alcohol binder, until the dispersant and binder are completely dissolved in the dispersion medium, then add 100g of powder, of which The powder is composed of zirconium carbide and tungsten powder, the mass ratio of zirconium carbide and tungsten powder in the powder is 15:85, the purity of zirconium carbide and tungsten powder is >99%, and the particle size of zirconium carbide and tungsten powder is 1μm~2μm , after ultrasonic treatment for 30 min, a slurry was obtained.

[0040] (2) Use a sand mill to grind the slurry prepared in step 1 at a speed of 2000rpm for 10 hours to make the slurry more uniform and stable and to refine the particle size of carbide and tungsten powder. Use a laser particle size analyzer to measure the slurry after mixing The particle size D90 of medium powder particles is 107nm; then use a spray drying granulator to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com