Radiofrequency plasma spark plug

A radio frequency plasma and spark plug technology, applied in the field of spark plugs, can solve the problems of difficult control of ignition of lean fuel mixture, and achieve the effect of reducing possibility and reducing wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

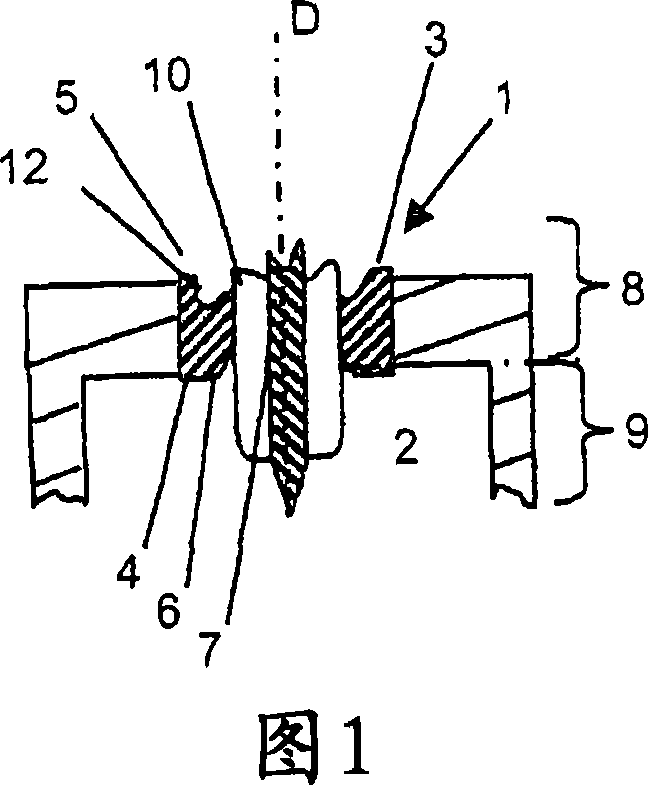

[0044] The spark plug 1 of FIG. 1 is a spark plug developed by the applicant's company as a spark plug for generating plasma. This spark plug is included in a patent application that has not yet been published on the filing date of the present application.

[0045] This spark plug comprises a cylindrical central electrode 7 with an axis of symmetry D, the part of which is called the inner part, arranged inside and at some distance from the annular housing 3 having the axis D Cylindrical tube shape.

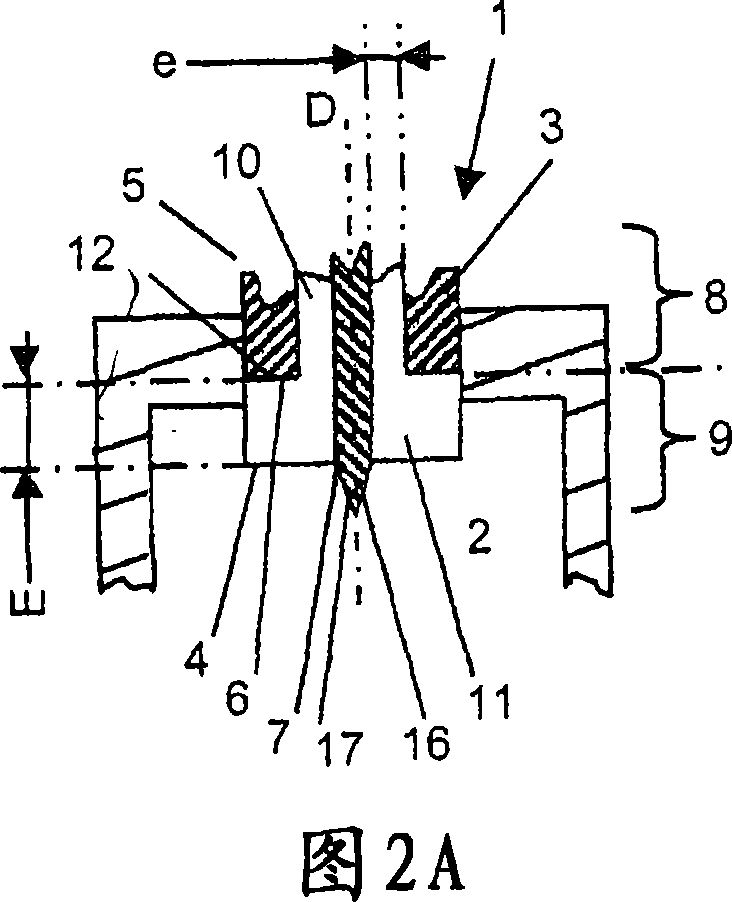

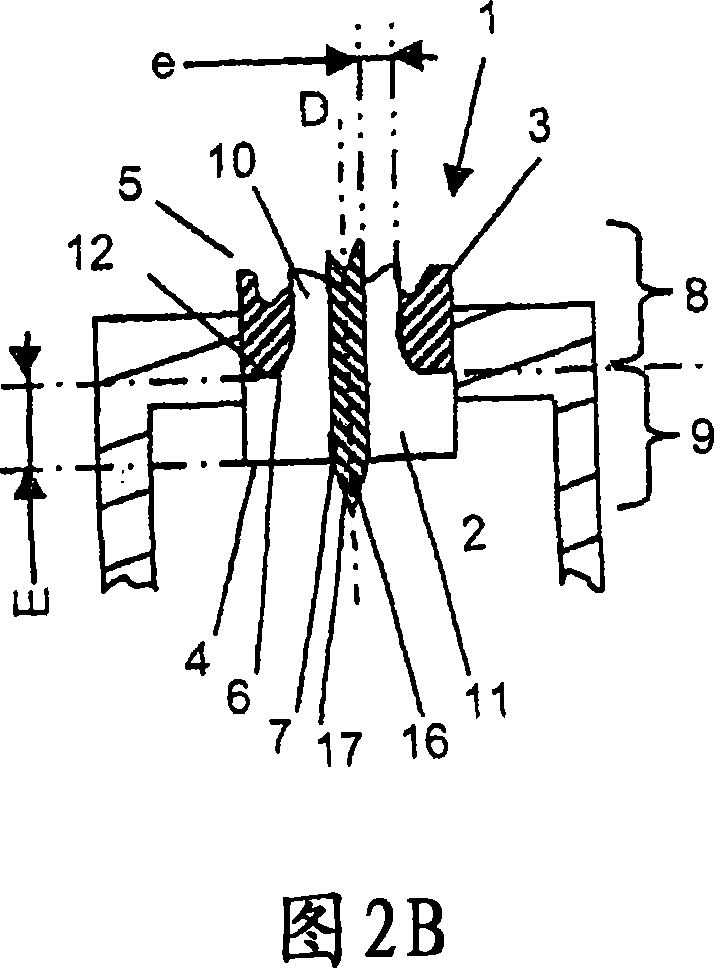

[0046] An annular insulating element is also partly arranged inside the annular casing, surrounding said central electrode, thereby separating the casing from the central electrode 7 . The insulating element, the central electrode and the housing 3 are rotationally symmetrical elements about the axis D. The center electrode 7 has an uncovered portion 16 , ie a portion not surrounded by the electrically insulating element 10 and the housing 3 , which is arranged inside the combus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com