A liquid metal type ceramic high-voltage variable resistance device

A technology of liquid metal and ceramic resistors, applied in the direction of liquid resistors, etc., can solve the problems of complex commutation circuits, increased costs, and superconductors are difficult to meet the requirements of industrial applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

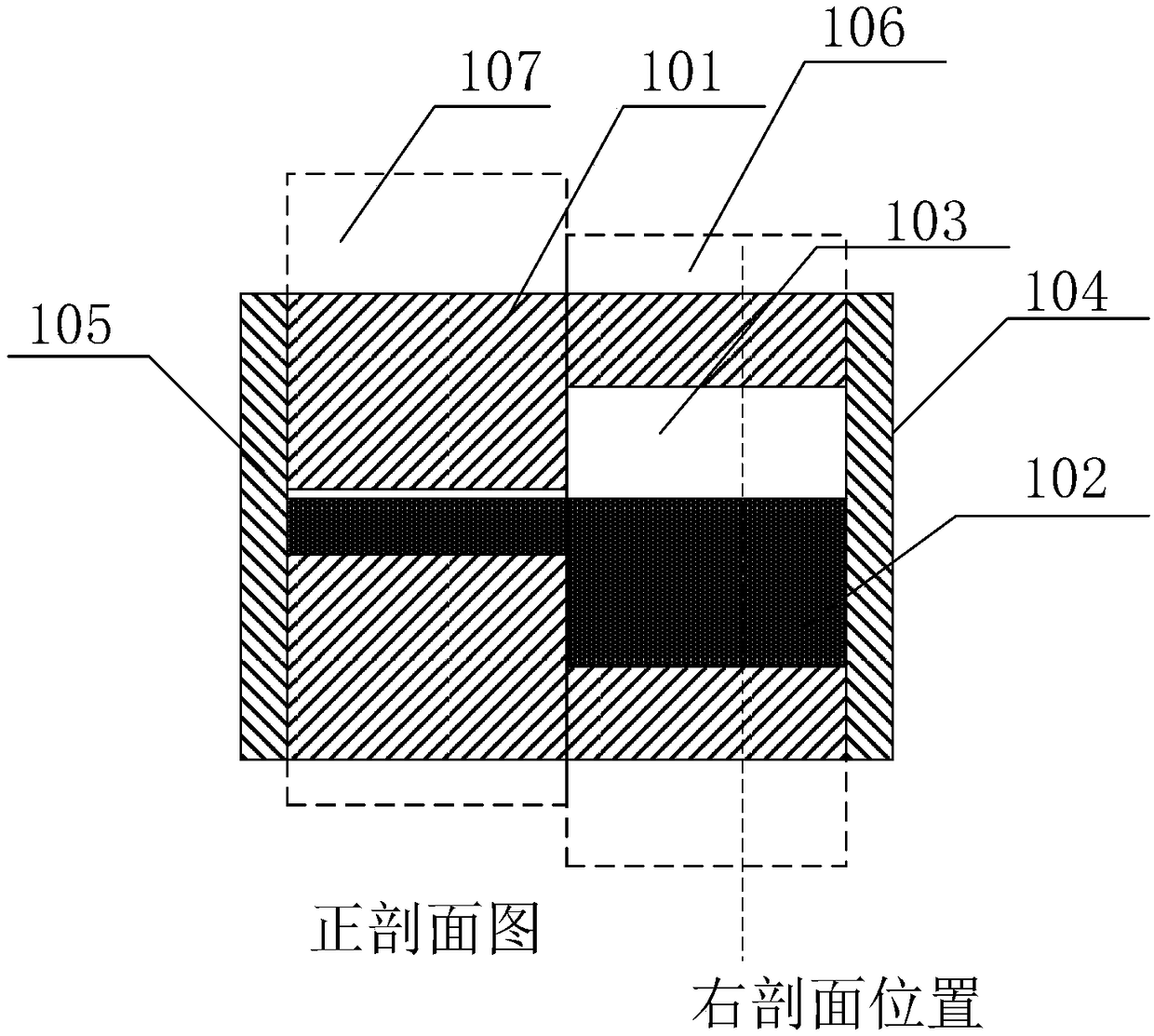

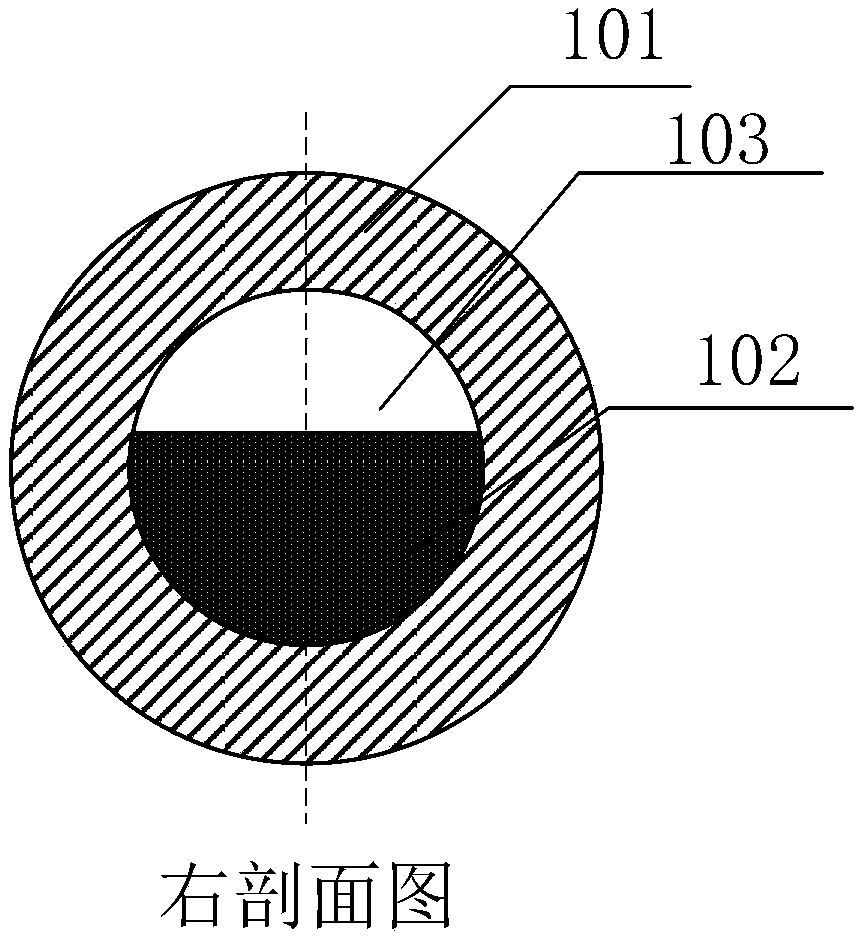

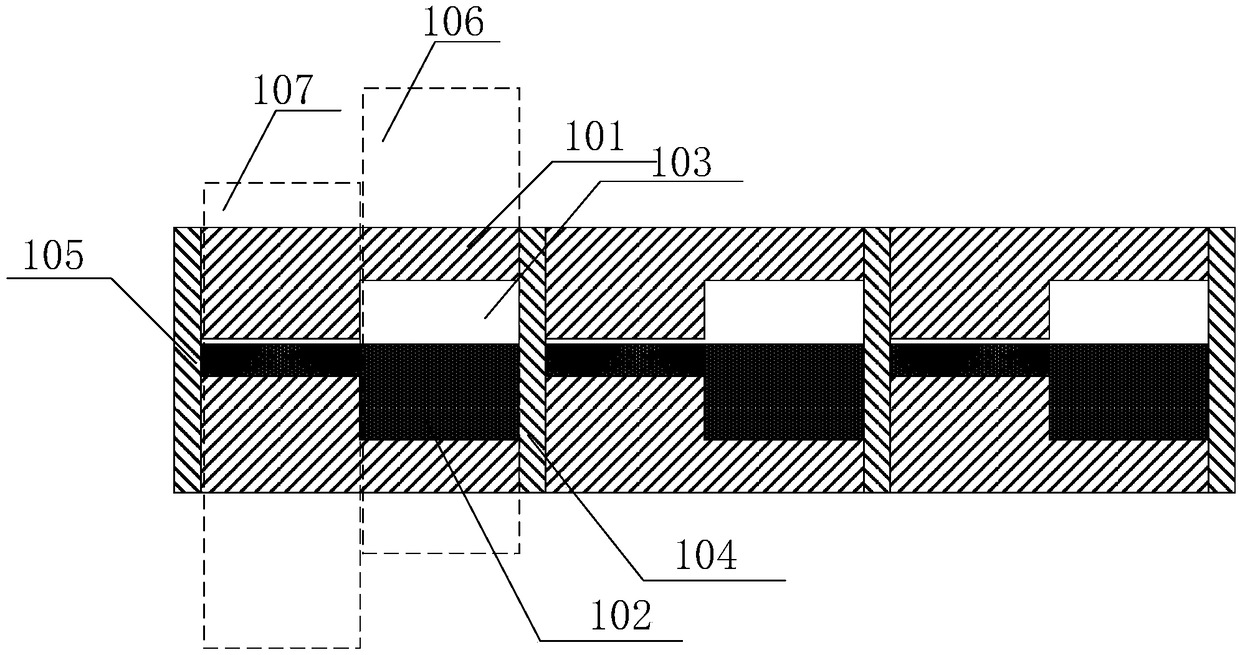

[0023] Example: such as image 3 A liquid metal type ceramic high-voltage variable resistance device shown includes a ceramic resistance chamber 101 , liquid metal 102 , gas medium 103 , right electrode 104 , and left electrode 105 .

[0024] The left electrode 105 and the right terminal 104 are fixed on the left and right ends of the ceramic resistance cavity 101 to form a sealed cavity.

[0025] The ceramic resistance cavity 101 is composed of a thick cavity 106 with a larger diameter and a fine cavity 107 with a smaller diameter that communicate with each other;

[0026] The liquid metal 102 is filled in the ceramic resistance cavity 101, and the liquid metal 102 needs to be able to enter the fine cavity 107 when placed horizontally, and conduct the left electrode 105 and the right electrode 104, so The liquid metal 102 cannot fill the ceramic resistor chamber 101.

[0027] The gas medium fills the rest of the ceramic resistance cavity 101 and must have good insulation pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com