Method for preparing titanium alloy parts by increasing and decreasing materials

A technology of adding and subtracting materials and titanium alloys, applied in the directions of additive processing, additive manufacturing, metal processing equipment, etc., can solve the problems of electrode pollution, equipment investment and high production and operation costs, and achieve high spheroidization rate and good microstructure. , Increase the effect of feedback control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings.

[0035] In the present embodiment, the method for preparing titanium alloy parts by adding and subtracting materials comprises the following steps:

[0036] Step 1. Preparation of titanium hydride particles: take commercially available titanium sponge with a particle size of 200 μm to 400 μm and place it in a reaction container, and continuously pass hydrogen gas into the container with a hydrogen flow rate of 1.5 to 3 L / s and keep the system pressure at normal pressure , slowly raise the temperature to 330-380°C, and heat for 20-40 minutes to generate loose titanium hydride; after the reaction is completed, the reaction product is crushed to obtain irregular multi-faceted granular titanium hydride.

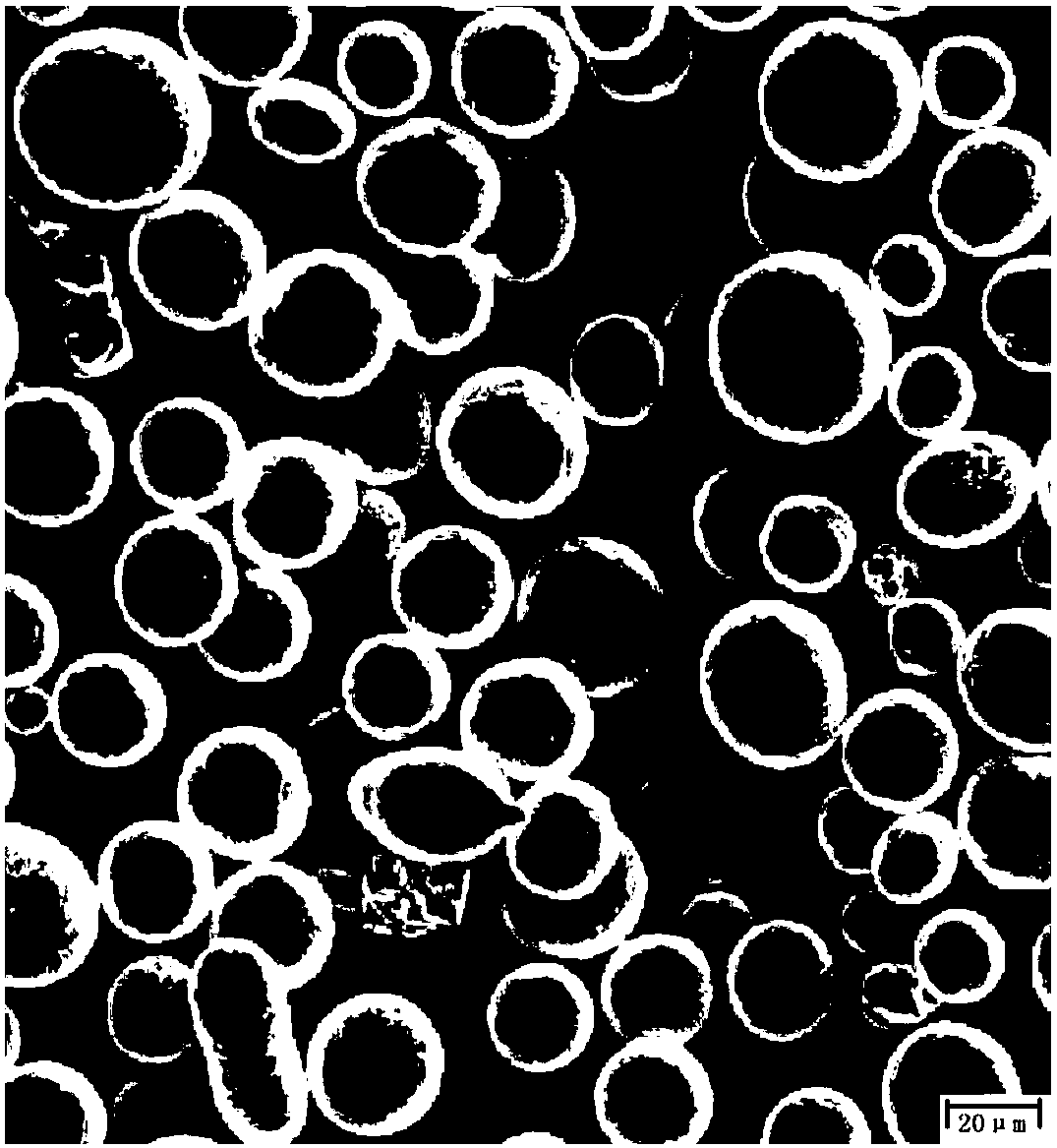

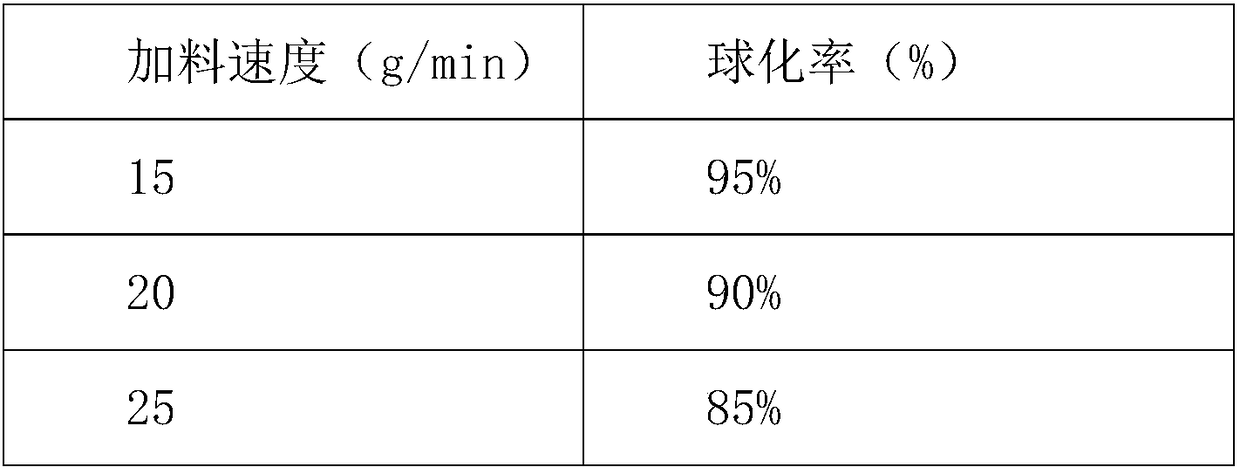

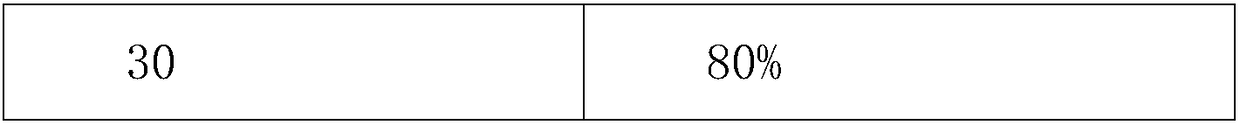

[0037] Step 2. Preparation of spheroidized titanium particles: The titanium hydride particles obtained in step 1 are subjected to radio freq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com