Method of producing smooth titanium nitride films having low resistivity

a technology of titanium nitride and resistivity, which is applied in the direction of vacuum evaporation coating, semiconductor/solid-state device details, coatings, etc., can solve the problems of affecting the overall conductivity of the layered conductive structure, affecting the effect of the overall conductivity of the conductive structure, and affecting the effect of the subsequent photolithographic indexing process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example two

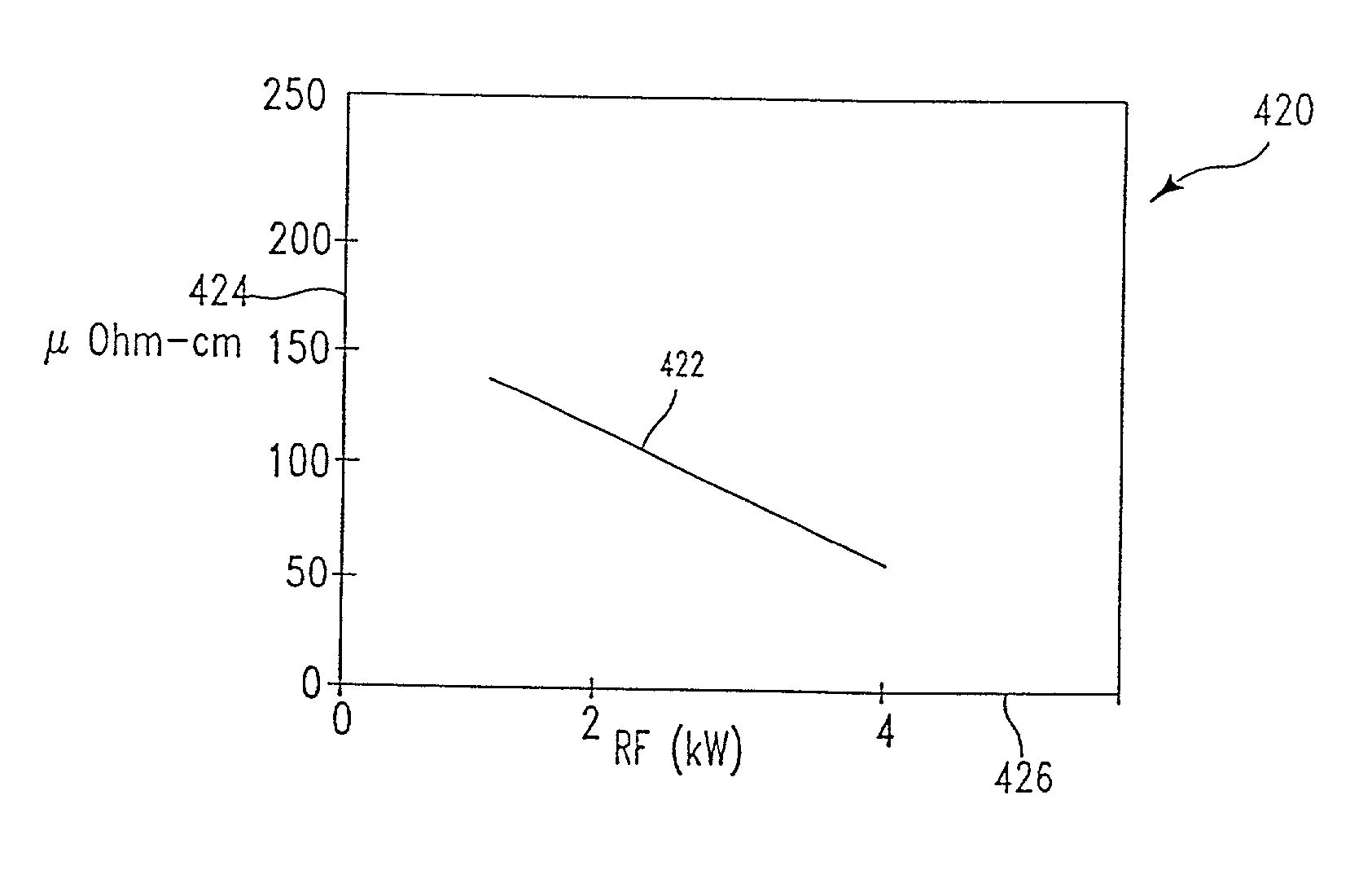

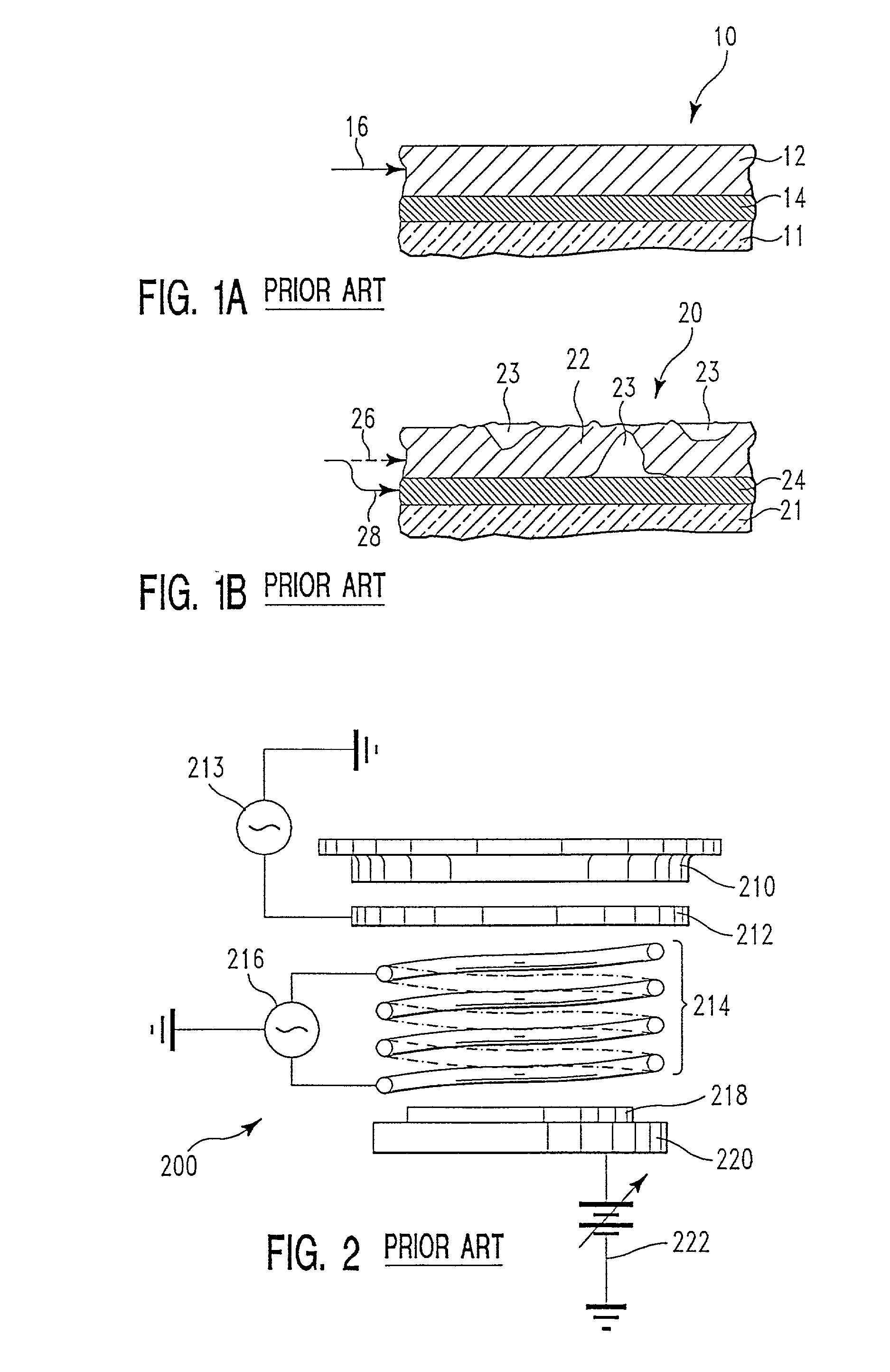

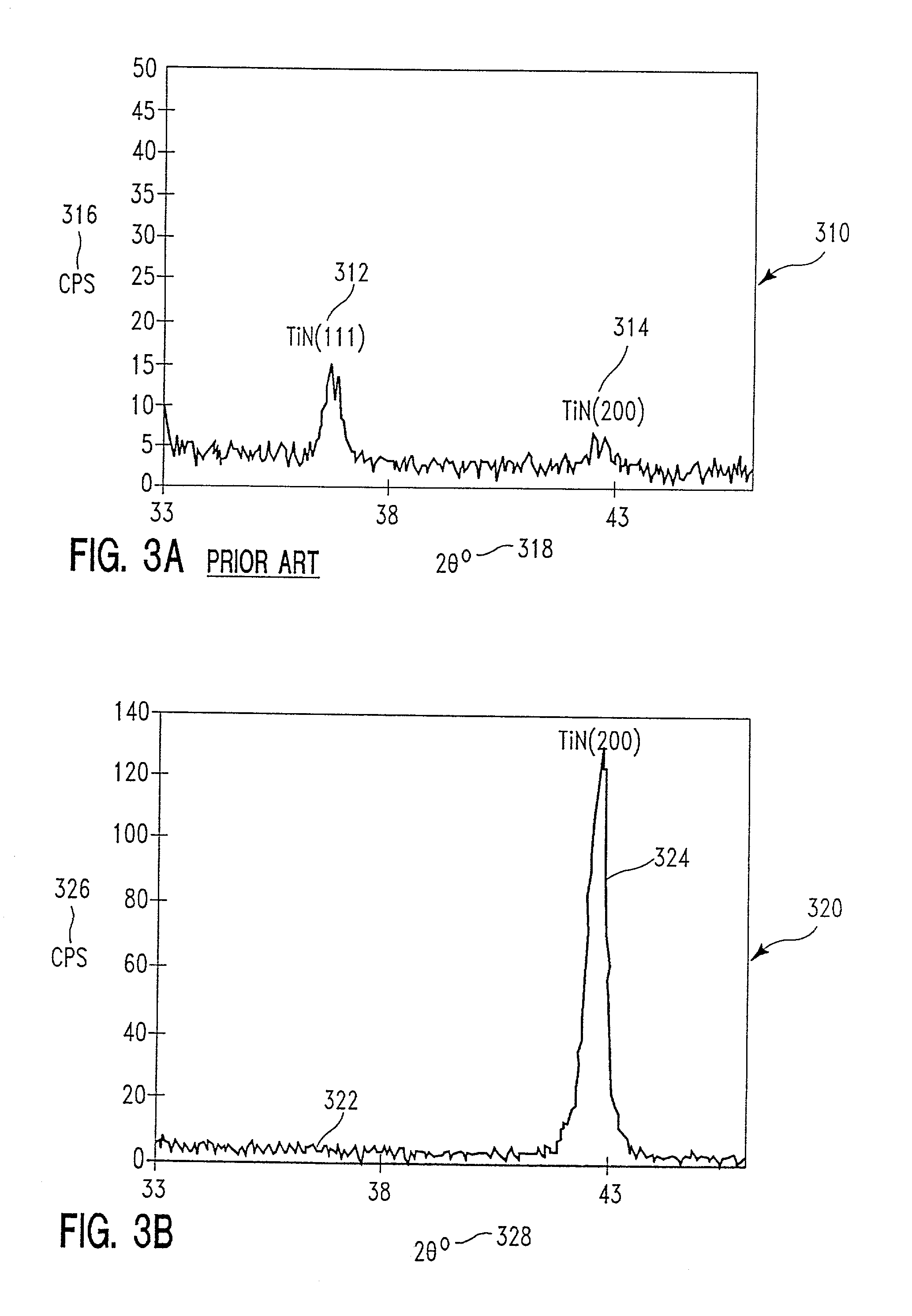

[0058] Using the equipment described above, with the DC power to sputtering target cathode 212 set at 6 kW; the coil 214 RF power set at 2 MHz and 4 kW; an argon gas flow rate of 10 sccm and a nitrogen gas flow rate of 60 sccm; with the process chamber pressure set at 25 mT; and, the substrate surface at about 300.degree. C., a 600 .ANG. thick titanium nitride film having a stoichiometric titanium nitride content, a {200} crystal orientation of about 100% and a resistivity of about 52 .mu..OMEGA.-cm was obtained.

[0059] The lower resistivity is attributed to the high {200} crystal orientation of the titanium nitride-comprising film. These physical characteristics are attributed to control of the gas phase deposition mixture composition and the quantity of the deposition mixture contacting the substrate surface over a given time period. The gas phase deposition mixture composition is believed to depend to a large extent on the DC power to the target and the RF power to the ionization ...

example three

[0070] Is Using the equipment described above, with the DC power to sputtering target cathode 212 set at 6 kW; the coil 214 RF power set at 2 MHz and 4 kW; an argon gas flow rate of 10 sccm and a nitrogen gas flow rate of 60 sccm; with the process chamber pressure set at 25 mT; and, the substrate surface at about 300.degree. C., a 600 .ANG. thick titanium nitride film having a stoichiometric titanium and nitrogen content, a {200} crystal orientation of about 100%, a resistivity of about 52 .mu..OMEGA.-cm, and a surface roughness of 0.57 nanometers (5.7 .ANG.) was obtained. Prior to the present invention, a typical surface roughness for reactive ion deposition sputtered titanium nitride films had been in the range of about 11 .ANG.. A titanium nitride film having a smoother film surface reduces any topography on the film surface which might be carried through on overlying layers, thereby improving photolithographic indexing during subsequent process steps.

[0071] To obtain a titanium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperatures | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com