Method for preparing spherical molybdenum-based powder

A spherical, molybdenum-based technology, applied in the field of preparation of ultra-fine spherical molybdenum-based powder, can solve the problems of irregularly shaped powder, etc., and achieve the effects of small particle size, simple process and high sphericity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

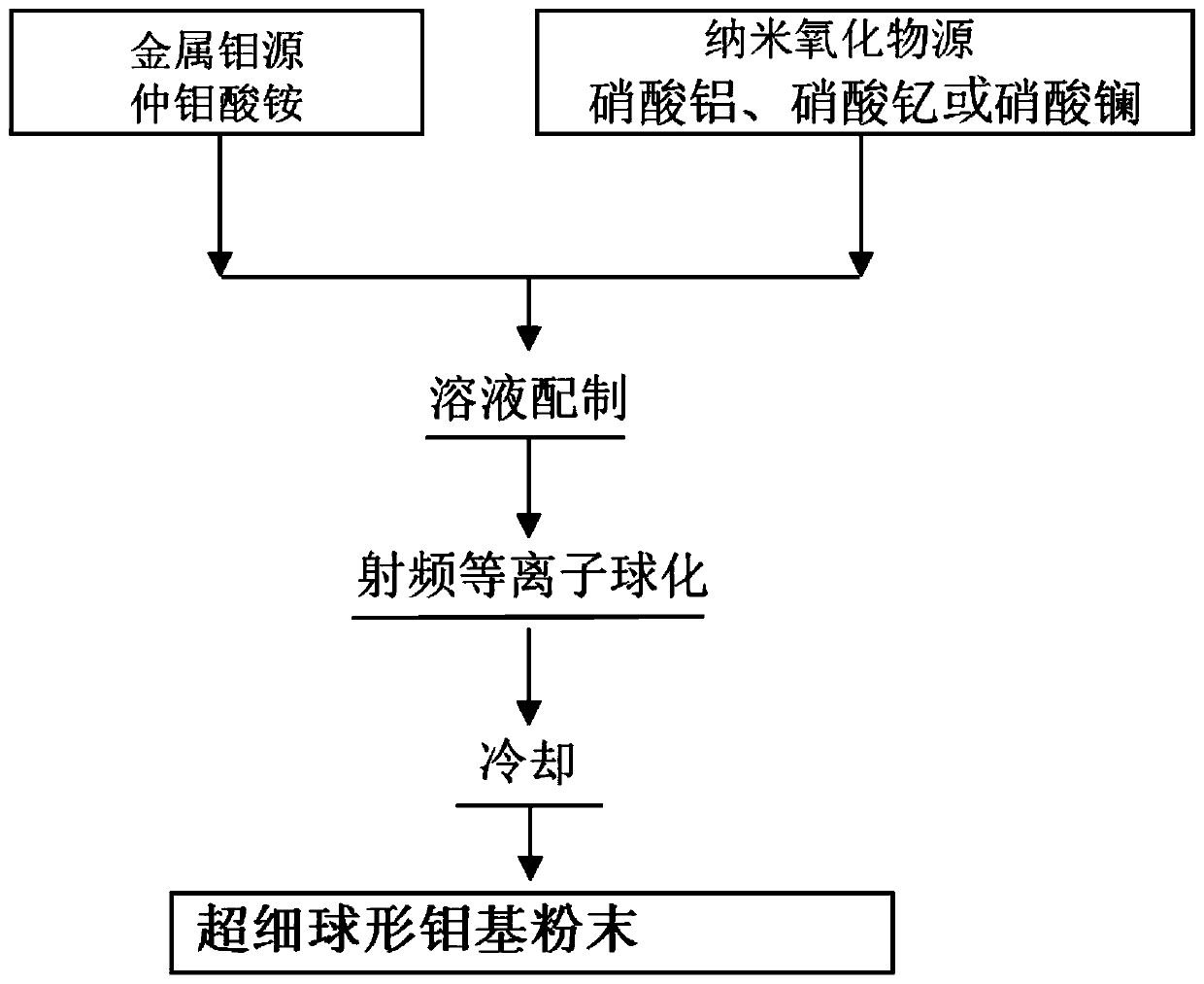

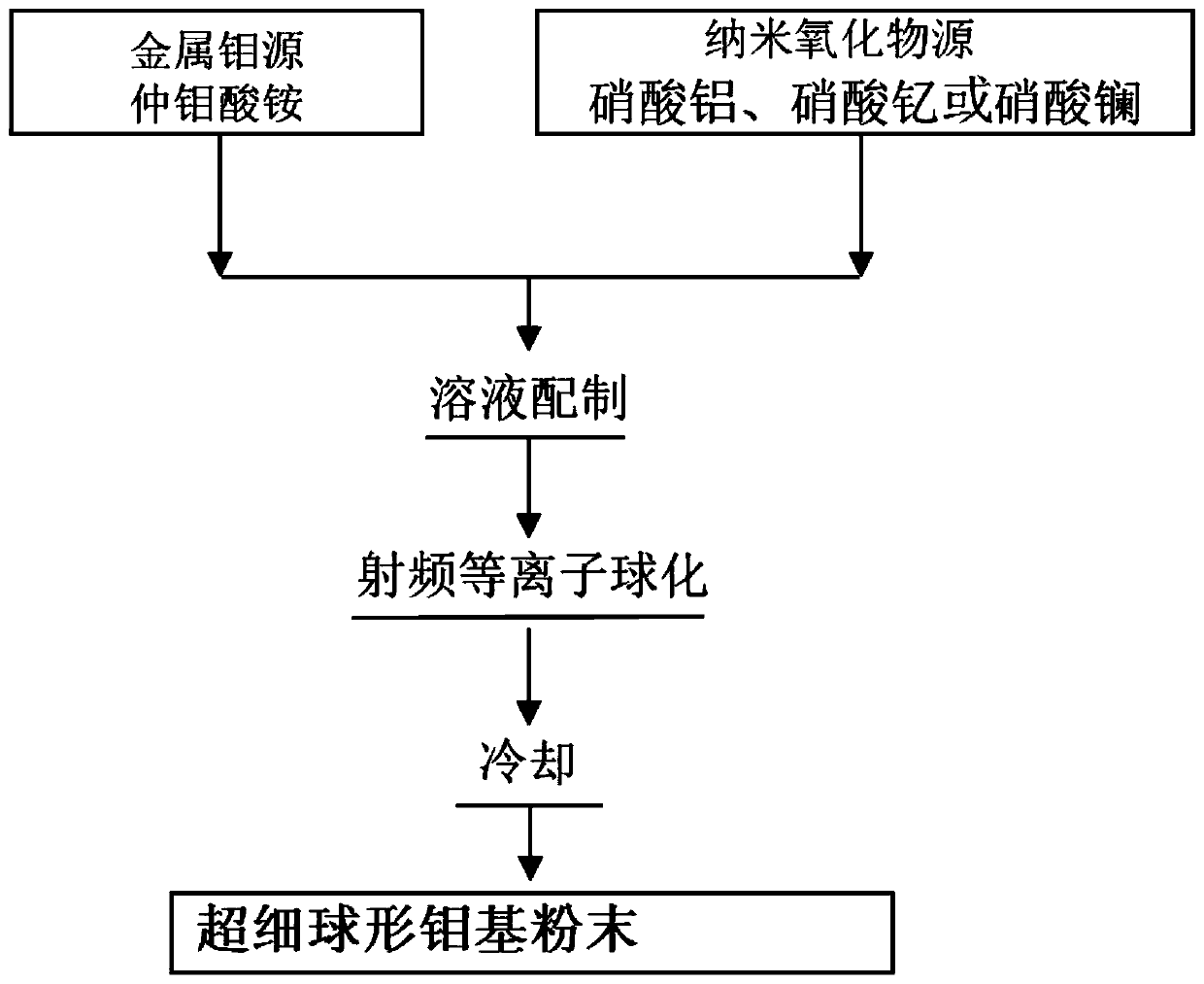

[0025] Such as figure 1 Shown, a kind of preparation method of ultrafine spherical molybdenum base powder of the present invention, described method comprises the following steps,

[0026] Configuration of S1 precursor solution: the metal molybdenum source is ammonium paramolybdate, mixed with nano oxides, dissolved in the solvent, and after continuous stirring, a transparent precursor solution is obtained;

[0027] Preparation of S2 ultra-fine spherical molybdenum-based powder: The transparent precursor solution obtained in S1 is prepared by radio frequency plasma spheroidization technology to obtain ultra-fine spherical molybdenum-based powder, and the average particle size of the oxide dispersed phase in the ultra-fine spherical molybdenum-based powder is Diameter ≤ 15nm.

[0028] According to an embodiment of the present disclosure, the solvent in S1 is deionized water.

[0029] According to an embodiment of the present disclosure, the nano-oxide in S1 is Al(NO 3 ) 3 9...

Embodiment 1

[0035]Embodiment 1: Mo-1wt%Al 2 o 3 Preparation of Ultrafine Spherical Molybdenum-Based Powder

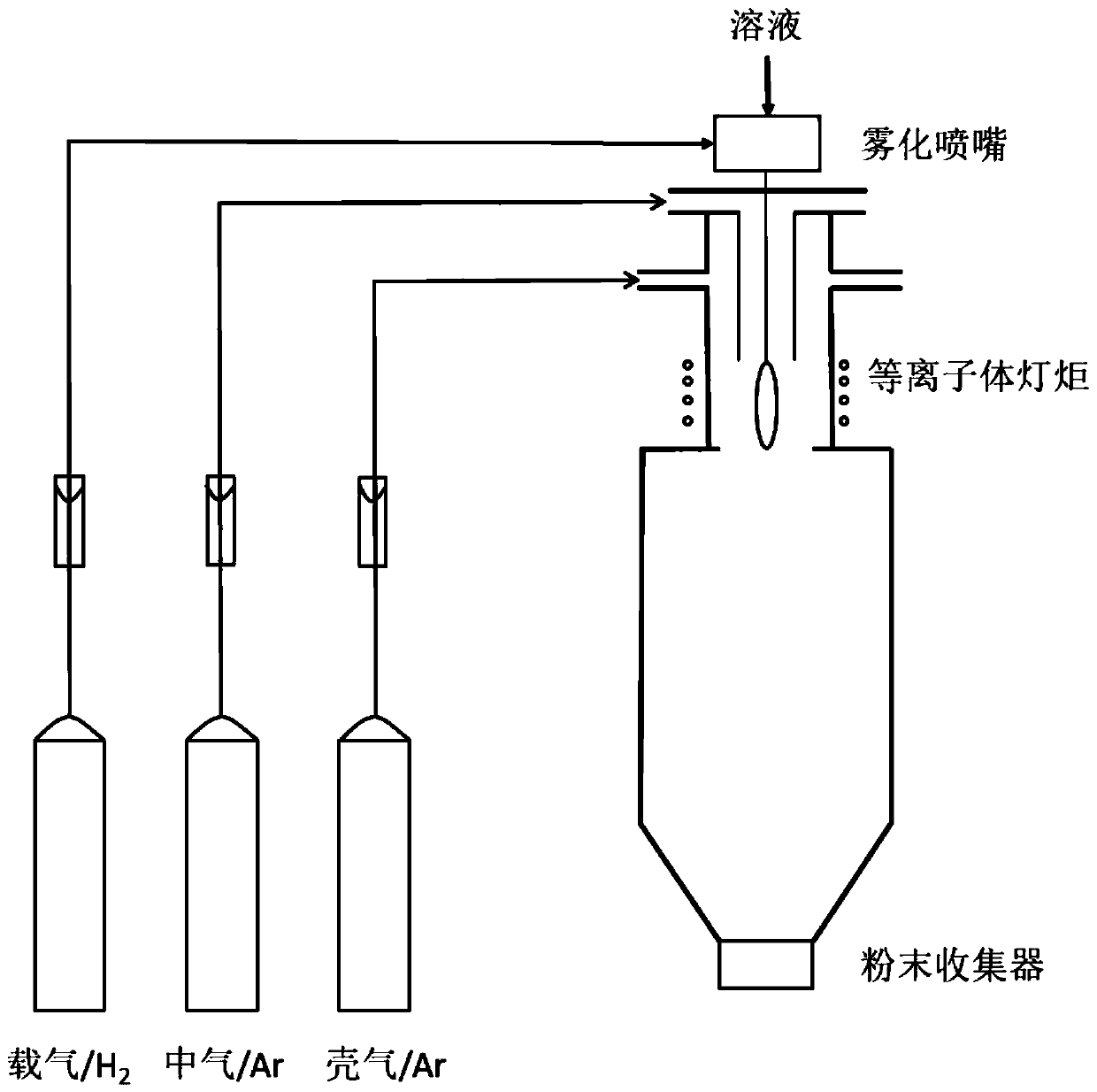

[0036] Ammonium paramolybdate ((NH 4 ) 6 Mo 7 o 24 4H 2 O) and aluminum nitrate (Al(NO 3 ) 3 9H 2 O) Dissolve in deionized water at a molar ratio of 7.514:1, and stir evenly in a container to obtain a precursor mixed solution. During the radio frequency plasma spheroidization process, the negative pressure is 6500Pa; the middle gas is argon, and the flow rate of the middle gas is 30L / min; the shell gas is argon, and the flow rate of the shell gas is 70L / min; the hydrogen gas with a flow rate of 8L / min is used as the carrier gas The precursor solution is fed at a rate of 0.4L / min through the feeding system and the feeding gun, and sprayed into the plasma arc through the atomizing nozzle. The mixed solution absorbs heat and decomposes, reduces, melts and then spheroidizes in the plasma arc instantly. Finally, it enters the cooling room and condenses rapidly. Obtain Mo-1wt....

Embodiment 2

[0037] Embodiment 2: Mo-2wt%Al 2 o 3 Preparation of Ultrafine Spherical Molybdenum-Based Powder

[0038] Ammonium paramolybdate ((NH 4 ) 6 Mo 7 o 24 4H 2 O) and aluminum nitrate (Al(NO 3 ) 3 9H 2 O) Dissolve in deionized water at a molar ratio of 3.719:1, and stir evenly in a container to obtain a precursor mixed solution. During the radio frequency plasma spheroidization process, the negative pressure is 7200Pa; the middle gas is argon, and the flow rate of the middle gas is 33L / min; the shell gas is argon, and the flow rate of the shell gas is 75L / min; the hydrogen gas with a flow rate of 12L / min is used as the carrier gas The precursor solution is fed at a rate of 0.3L / min through the feeding system and the feeding gun, and sprayed into the plasma arc through the atomizing nozzle. The mixed solution absorbs heat and decomposes, reduces, melts and then spheroidizes in the plasma arc instantly. Finally, it enters the cooling room and condenses rapidly. Obtain W-2wt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com