Radiofrequency plasma synthetic method for extracting alumina from aluminum residues

A synthesis method and alumina technology, which is applied in the field of simultaneously processing aluminum slag and producing alumina, can solve the problems that no effective technology has been found for aluminum slag treatment, and it cannot meet the needs of users.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

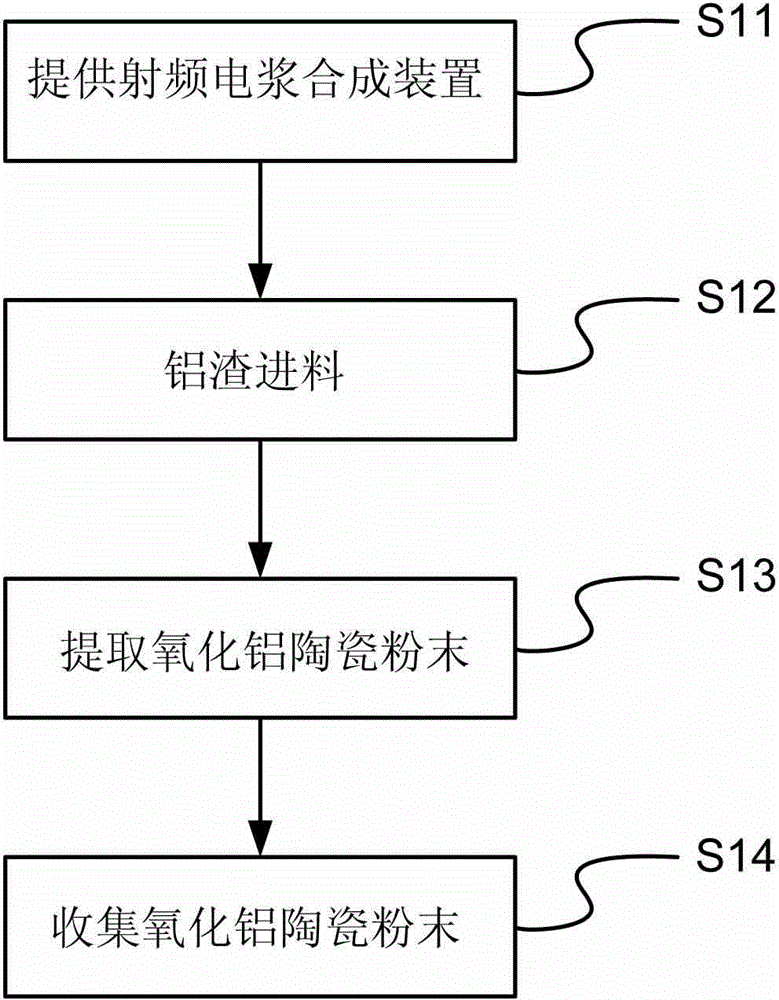

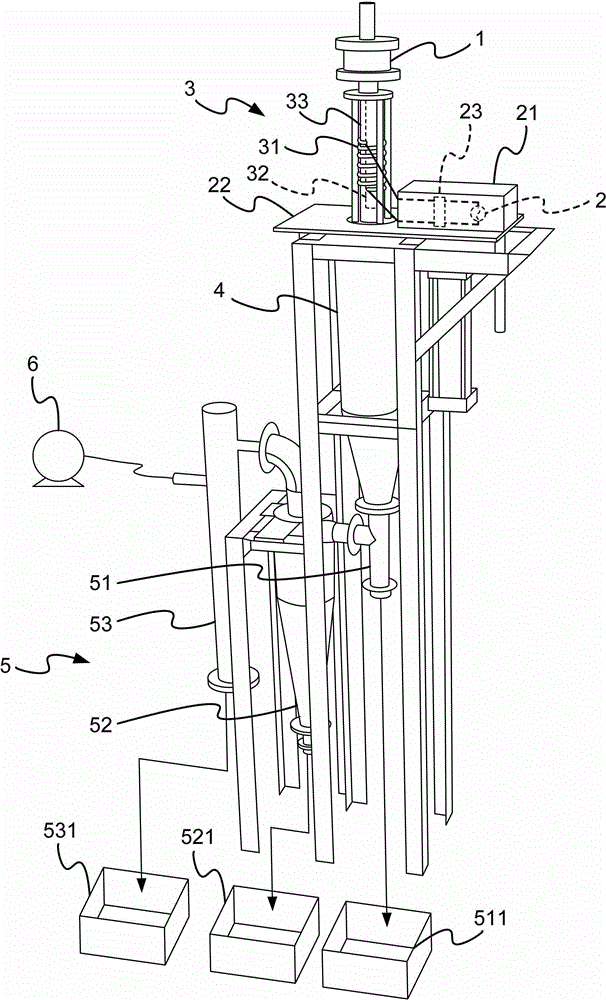

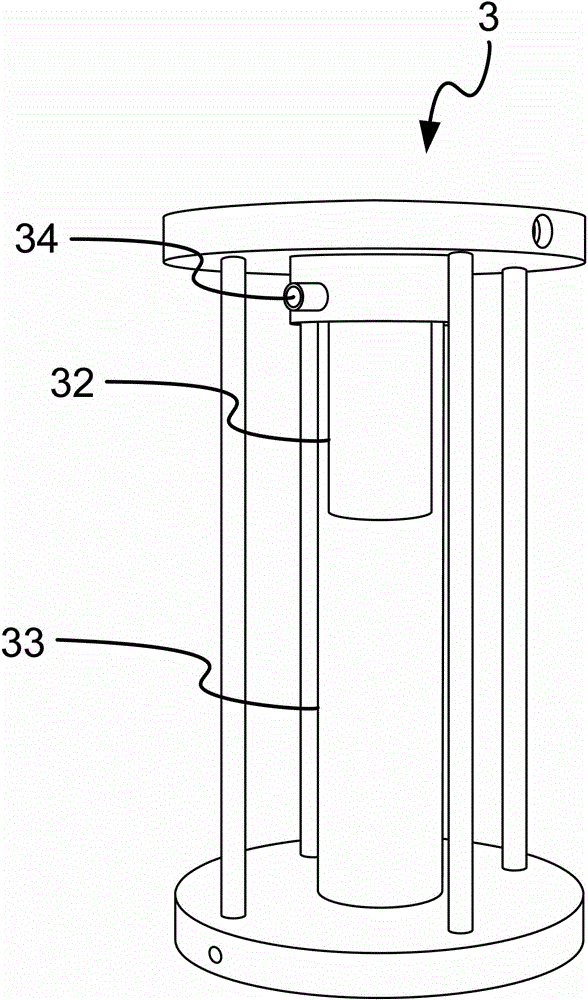

[0050] see Figure 1 ~ Figure 3 Shown are the schematic flow chart of the synthesis of alumina ceramic powder of the present invention, the schematic diagram of the radio frequency plasma synthesis device of the present invention, and the schematic diagram of the reactor-thermoplasma source of the present invention. As shown in the figure: the present invention is a radio frequency plasma synthesis method, which extracts aluminum oxide (Al 2 o 3 ), which at least includes the following steps:

[0051] (A) Provide radio frequency plasma synthesis device S11: provide a radio frequency plasma synthesis device, which includes a powder feeder 1; a radio frequency generator 2, located in a matching box 21 and installed on a base 22, Coupled to an induction coil 31 via a matching circuit 23; a thermal plasma source 3, one end of which is connected to the powder feeder 1, and the other end is passed through the base 22, and has an induction coil with 2 to 6 turns 31; a reaction cha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com