Heat treatment waste gas plasma recombination power generation method and plasma recombination reactor

A technology of reactor and heat treatment equipment, which is applied in the field of heat treatment waste gas treatment, and can solve problems such as surface potential drop and application limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

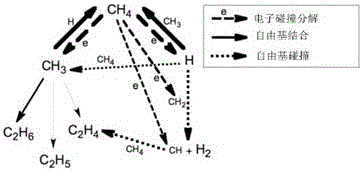

AI Technical Summary

Problems solved by technology

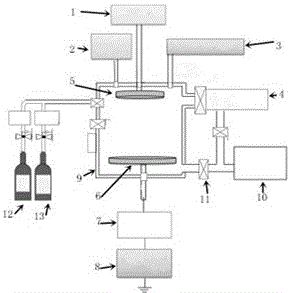

Method used

Image

Examples

Embodiment 1

[0050] The operation example 1 of the low energy consumption normal temperature plasma recombination equipment is as follows:

[0051] a. The reaction chamber will be evacuated to a vacuum state, reaching 4X10 -5 atm (1x10 -5 -5x10 -5 between atm)

[0052] b. Introduce reaction gas (propane C 3 h 8 and nitrogen N 2) And control the intake flow, and confirm that the gas flow range of the oil pump output is 20-200mL / min.

[0053] c. After the atmosphere in the reaction chamber is stable, reach 3X10 -3 Atm, turn on the RF plasma source and matcher, and control the matching conditions to achieve the best power. The power setting range is between 50W-200W.

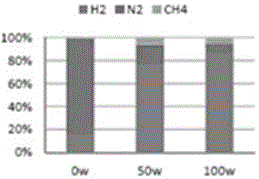

[0054] d Collect reaction gas samples, use GC to analyze and record the proportions of its various components, see image 3 .

Embodiment 2

[0056] The operation example 2 of the low energy consumption room temperature plasma recombination equipment is as follows:

[0057] a. First pump the reaction chamber to a vacuum state, reaching 3.67X10 -3 atm.

[0058] b. Introduce reaction gas (methane CH 4 and nitrogen N 2) And control the intake flow, and confirm that the gas flow range of the dry vacuum pump is 20-200mL / min.

[0059] c. The atmosphere in the reaction chamber is stable up to 6X10 -2 After atm, turn on the RF plasma source and matcher, and control the matching conditions to achieve the best power. The power setting range is between 25W-125W.

[0060] d Collect reaction gas samples, use GC to analyze the proportion of hydrogen gas under various plasma power conditions, and calculate the conversion rate of methane, see Figure 4 and Figure 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com