Patents

Literature

613 results about "Plasma deposition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Plasma Deposition. Plasma deposition processing is typically used for deposition of thin films when temperature sensitivity is an issue. In semiconductor processing, this issue often arises because of the material properties of complex devices being fabricated.

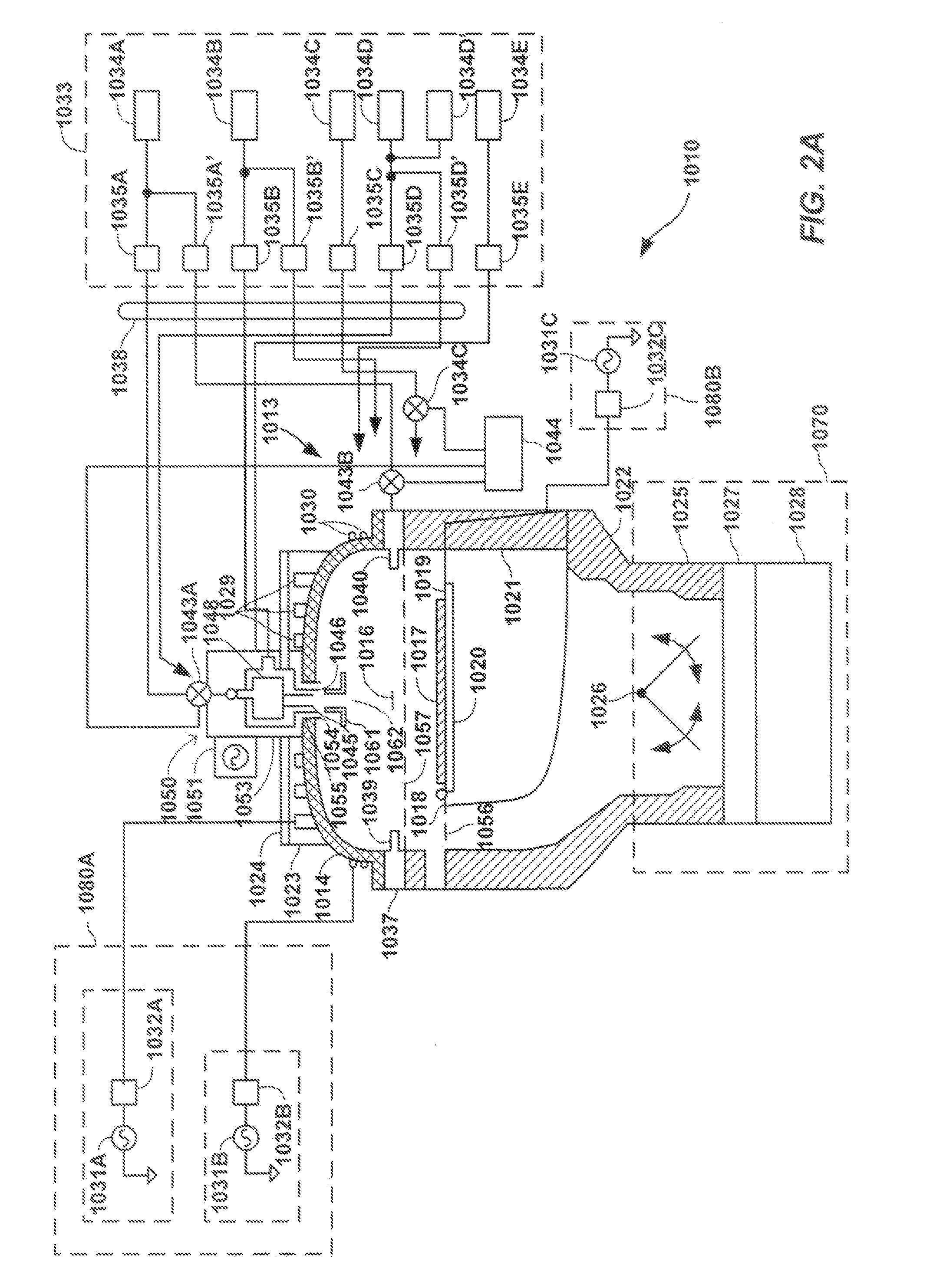

Novel method for conformal plasma immersed ion implantation assisted by atomic layer deposition

ActiveUS20110159673A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingDopantSource material

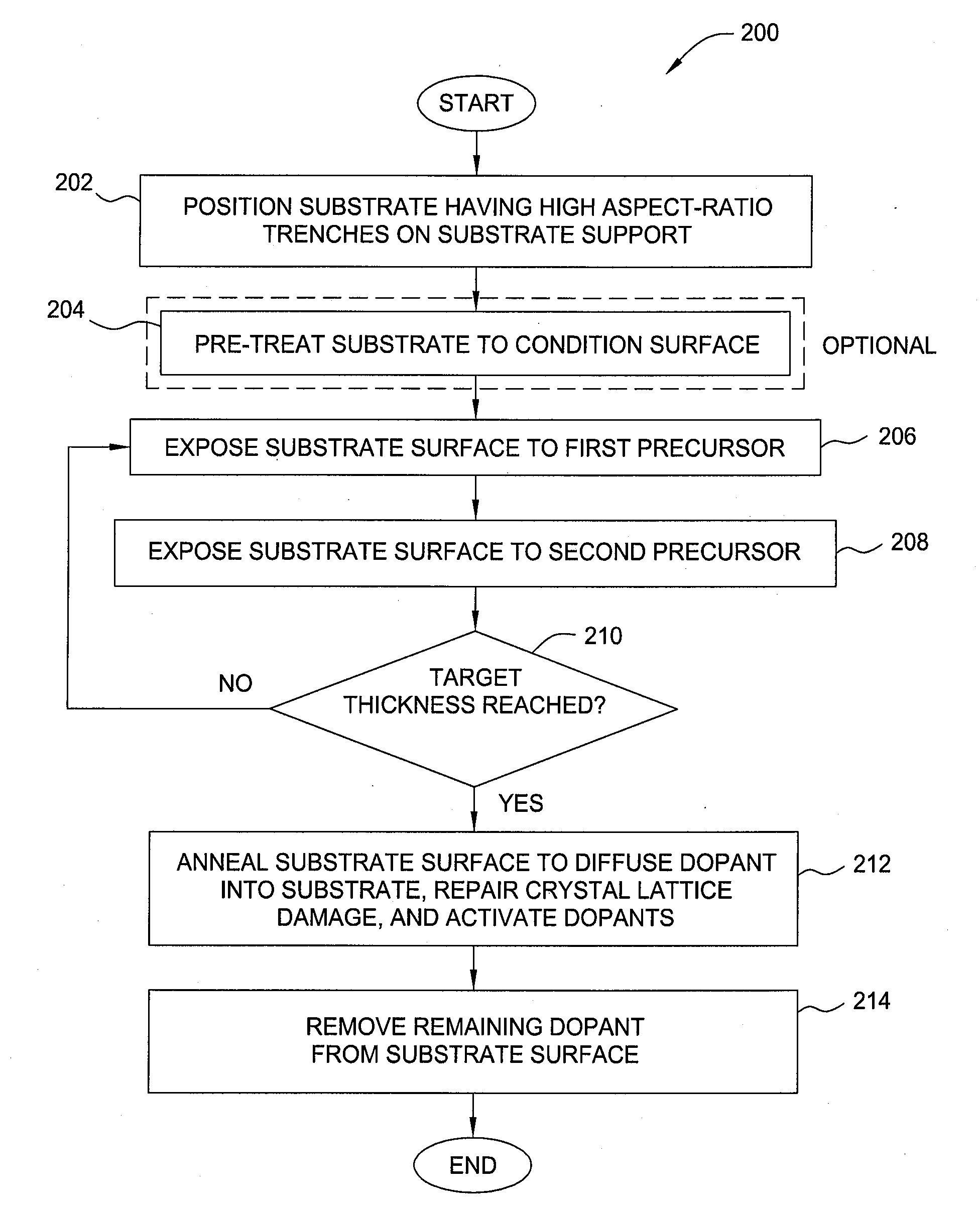

Embodiments of the invention provide a novel apparatus and methods for forming a conformal doped layer on the surface of a substrate. A substrate is provided to a process chamber, and a layer of dopant source material is deposited by plasma deposition, atomic layer deposition, or plasma-assisted atomic layer deposition. The substrate is then subjected to thermal processing to activate and diffuse dopants into the substrate surface.

Owner:APPLIED MATERIALS INC

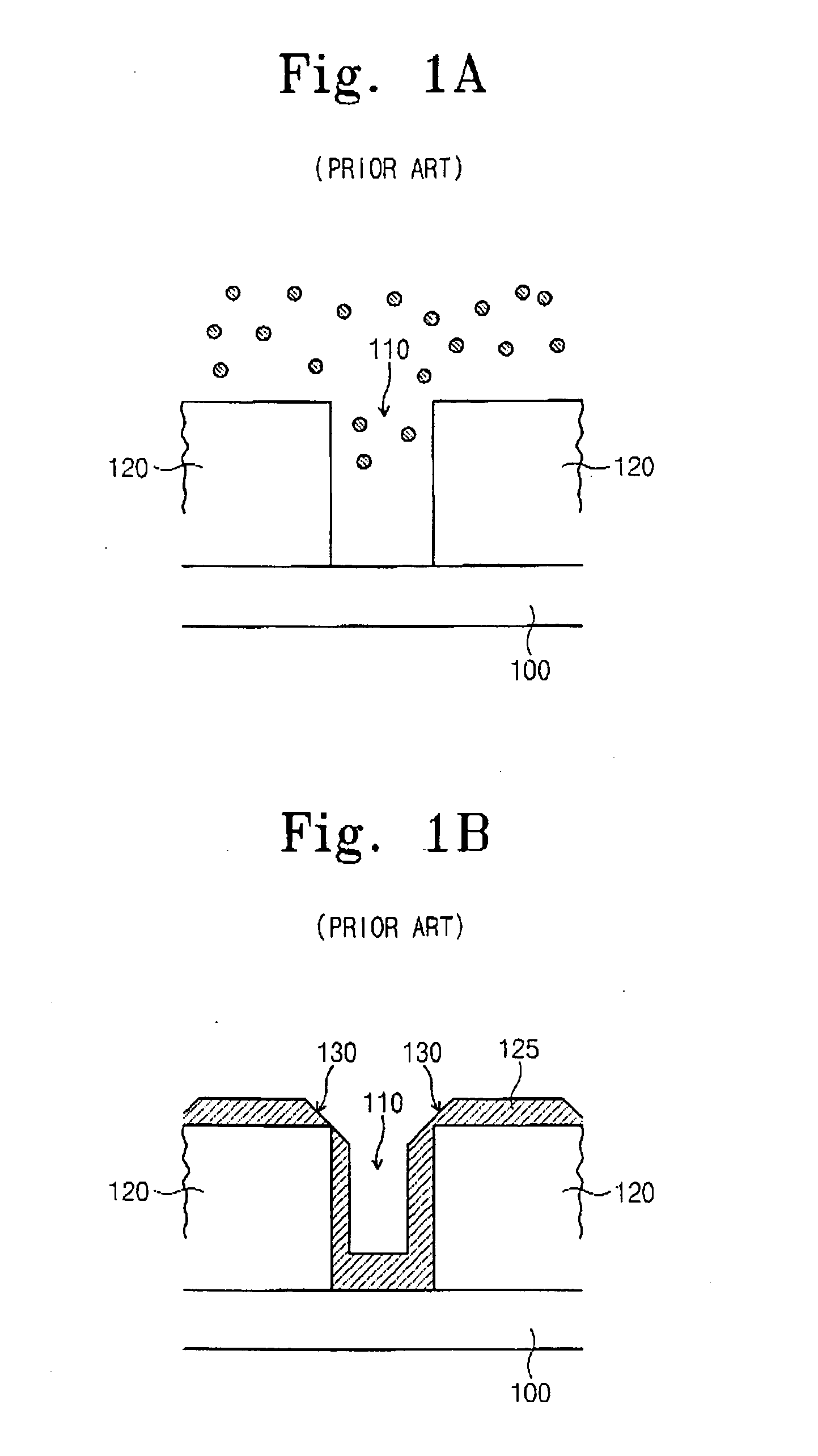

Methods of filling trenches using high-density plasma deposition (HDP)

ActiveUS20050037610A1Ultrasonic/sonic/infrasonic diagnosticsVacuum evaporation coatingHigh densityPlasma deposition

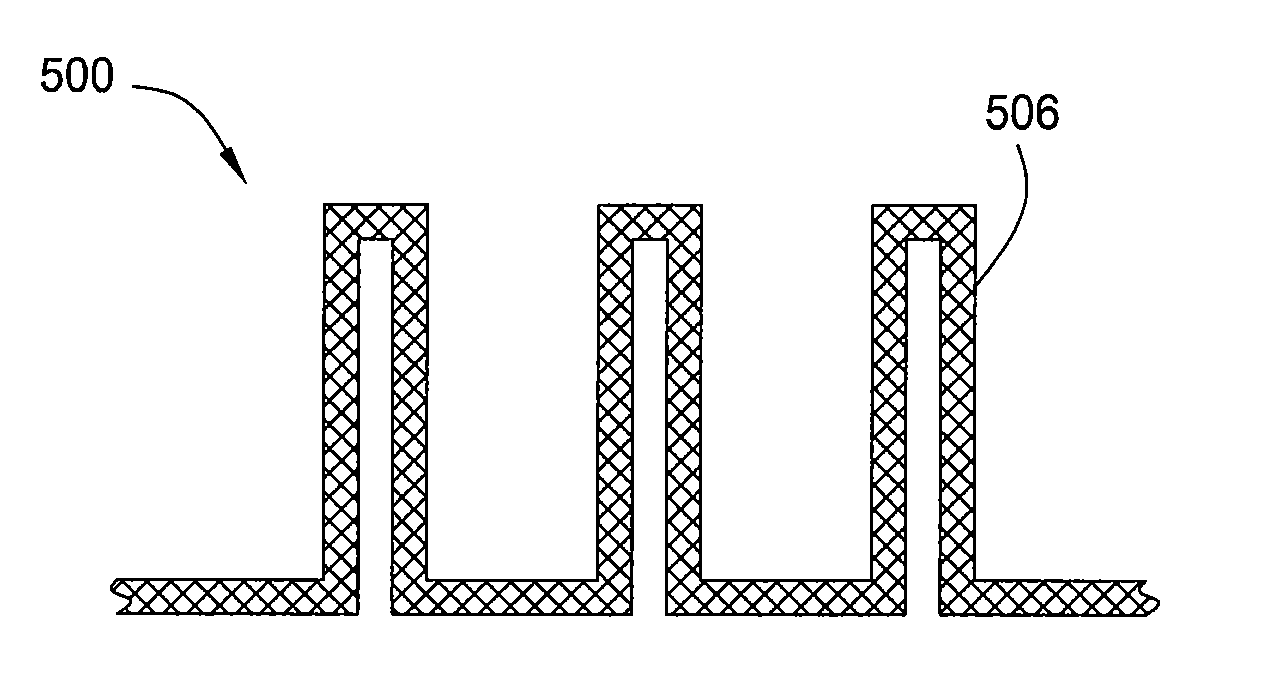

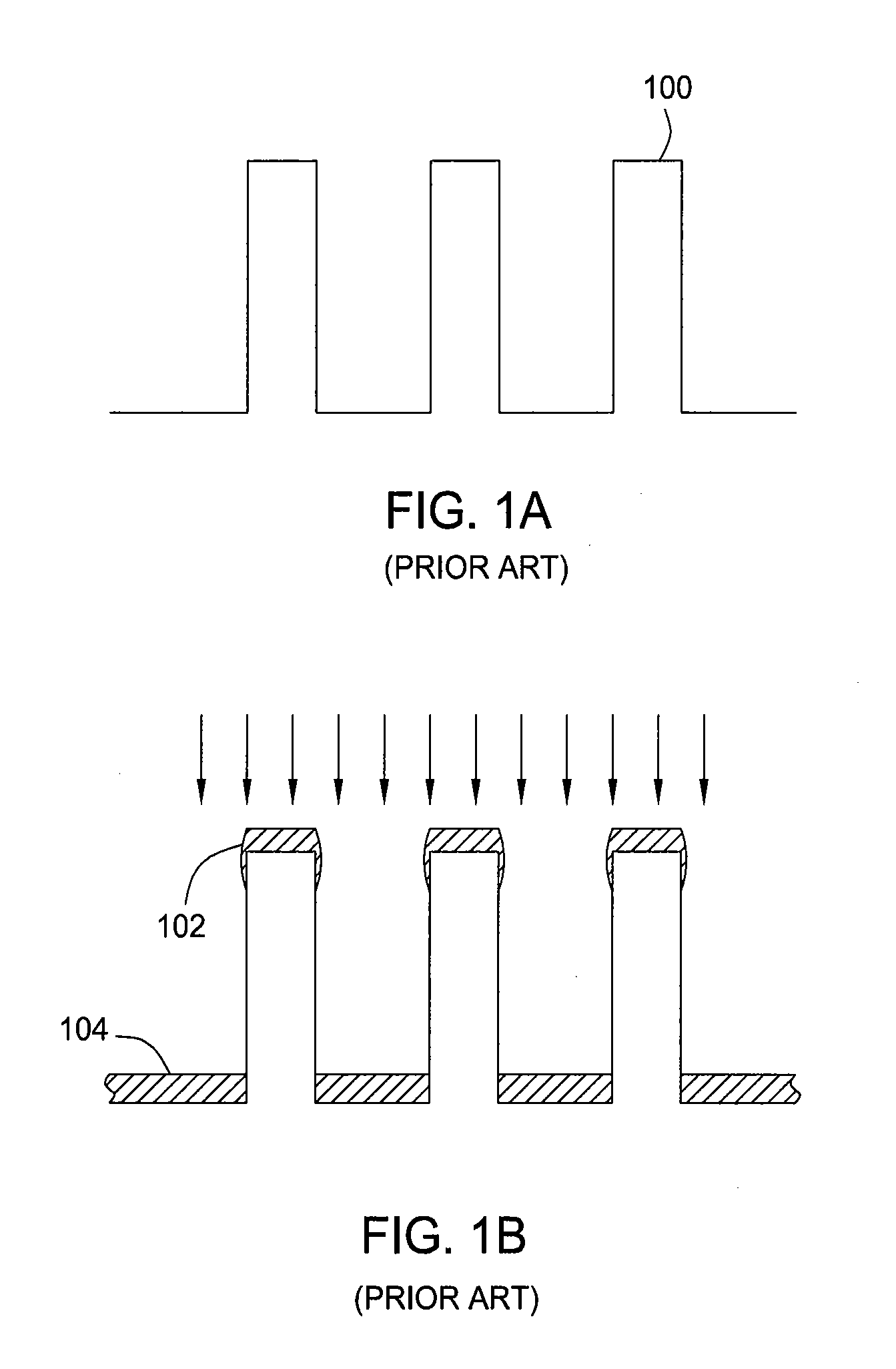

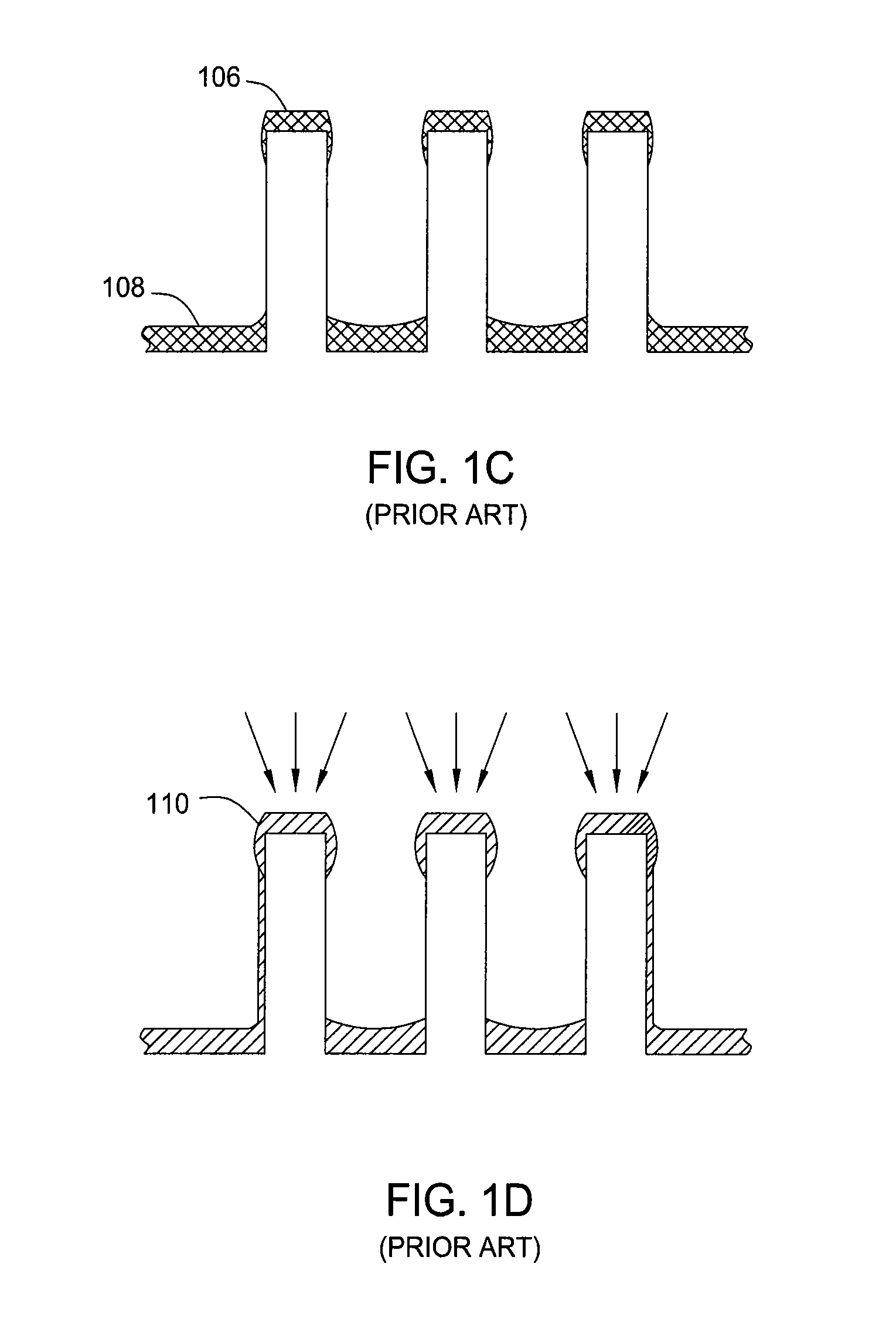

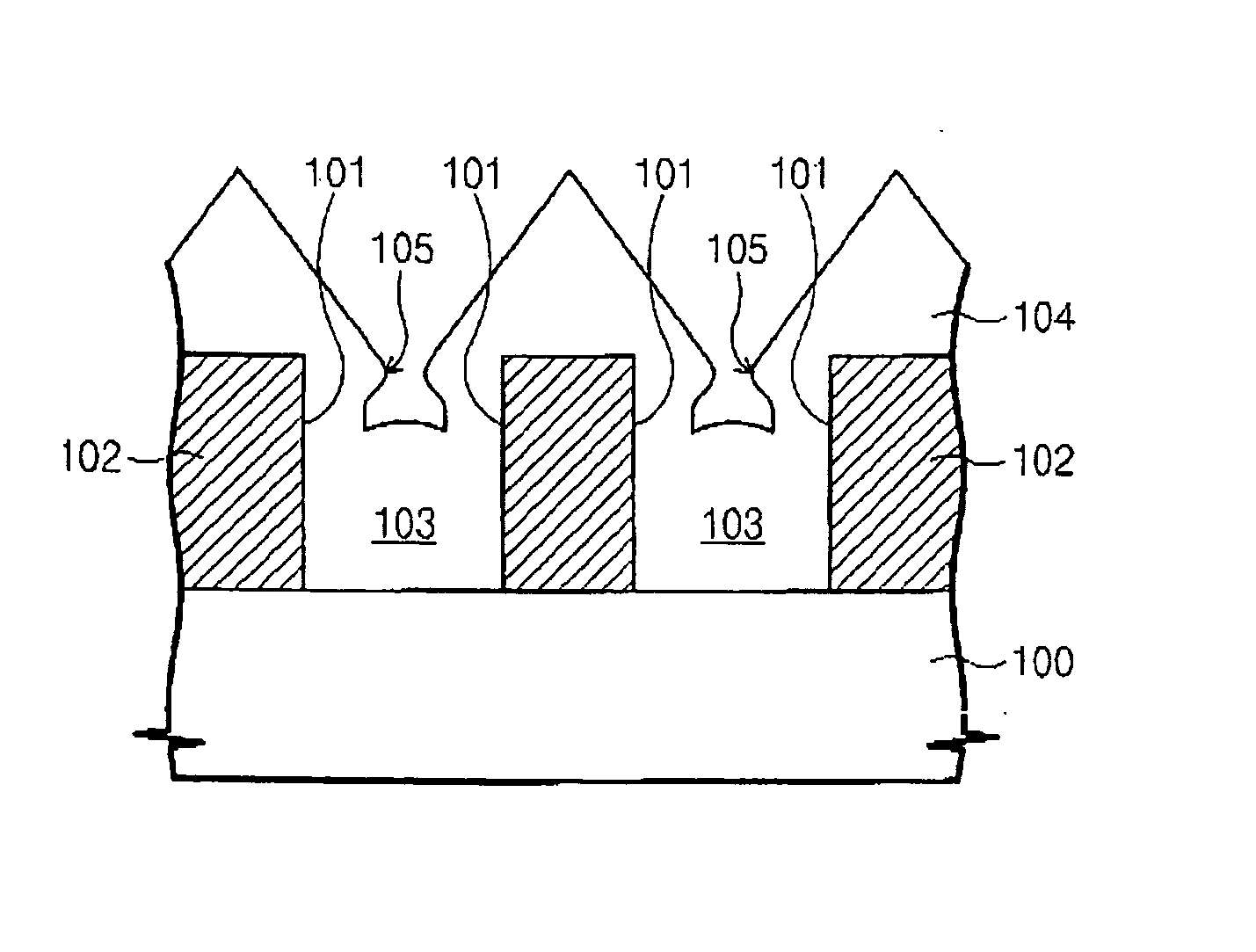

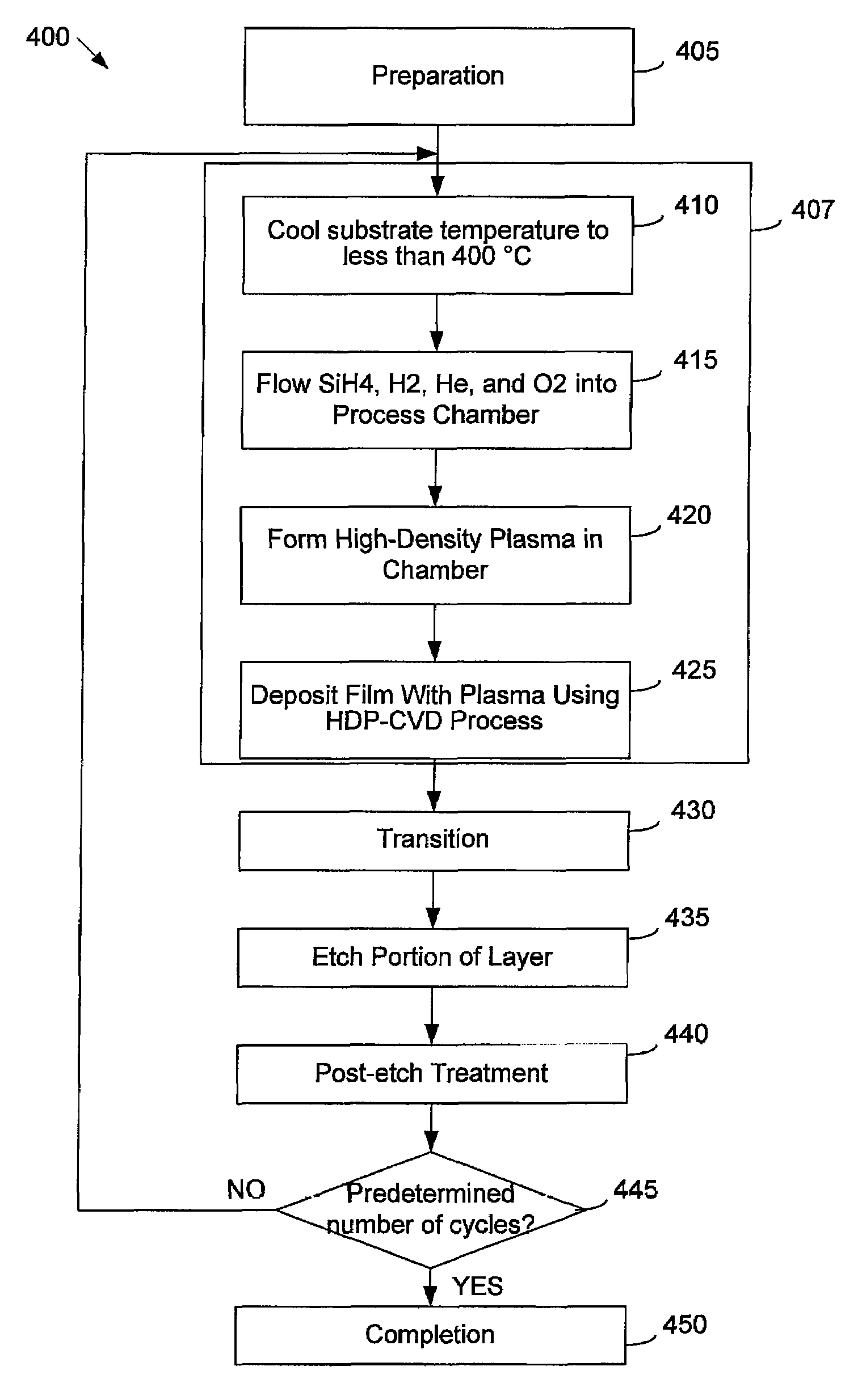

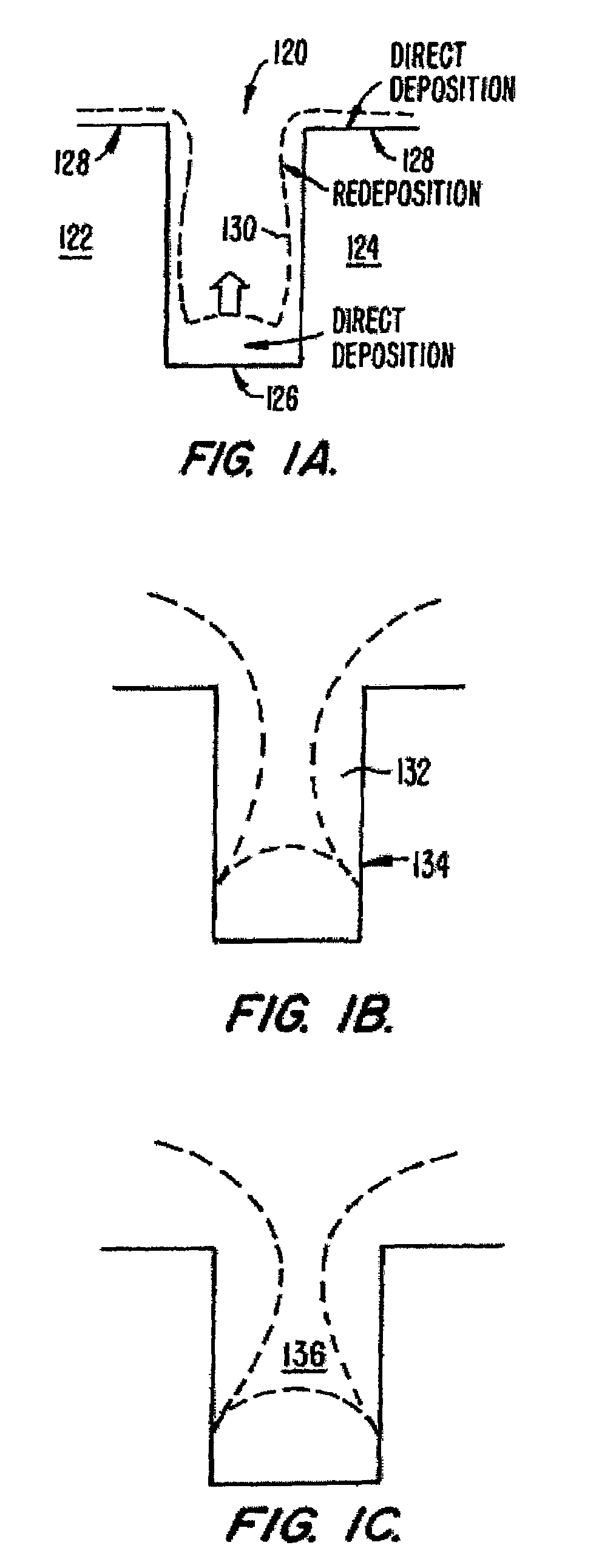

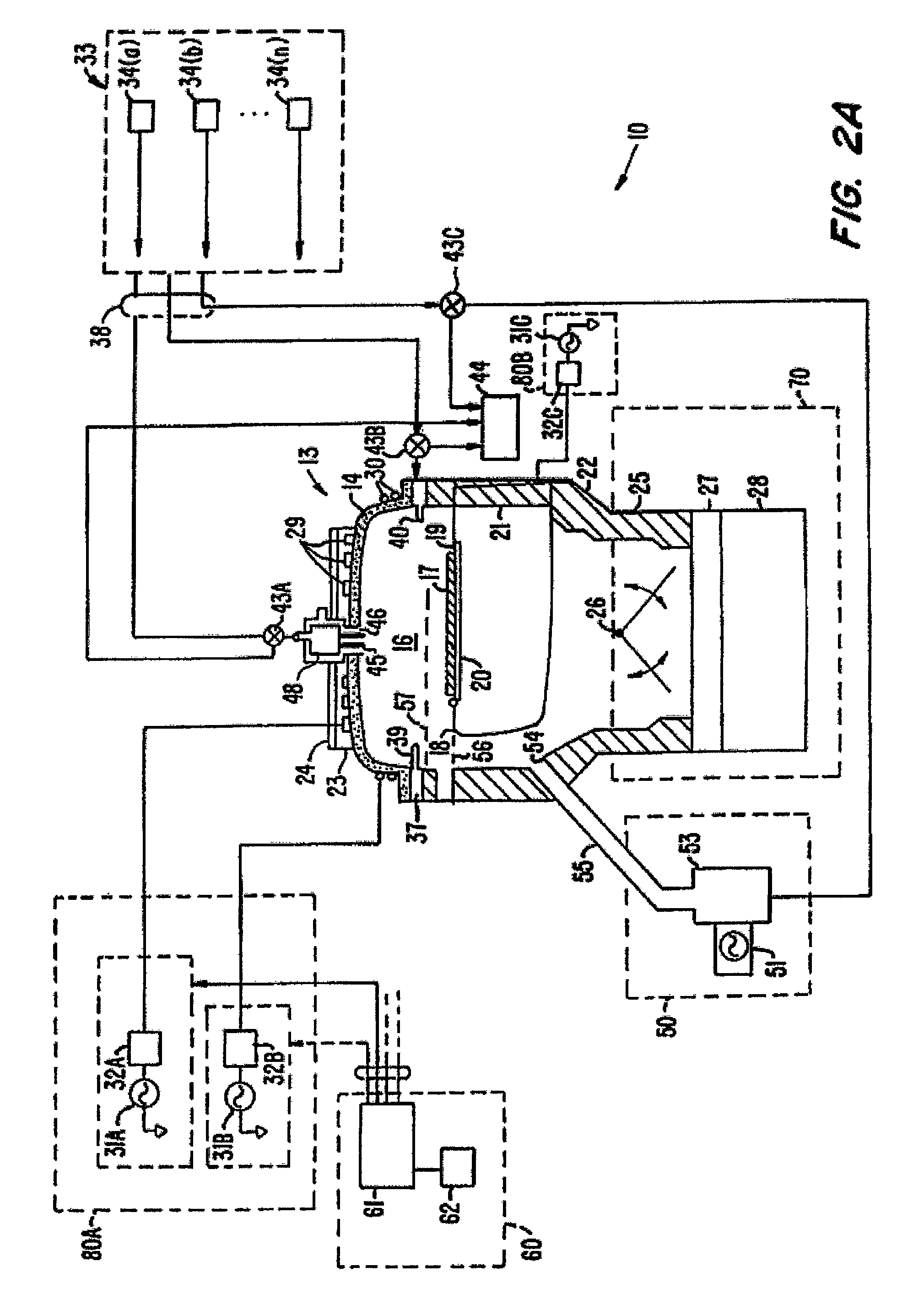

Methods of filling trenches / gaps defined by circuit elements on an integrated circuit substrate are provided. The methods include forming a first high-density plasma layer on an integrated circuit substrate including at least one trench thereon using a first reaction gas. The first high-density plasma layer is etched using an etch gas including nitrogen fluoride gas (NF3). A second high-density plasma layer is formed on the etched first high-density plasma layer using a second reaction gas including nitrogen fluoride.

Owner:SAMSUNG ELECTRONICS CO LTD

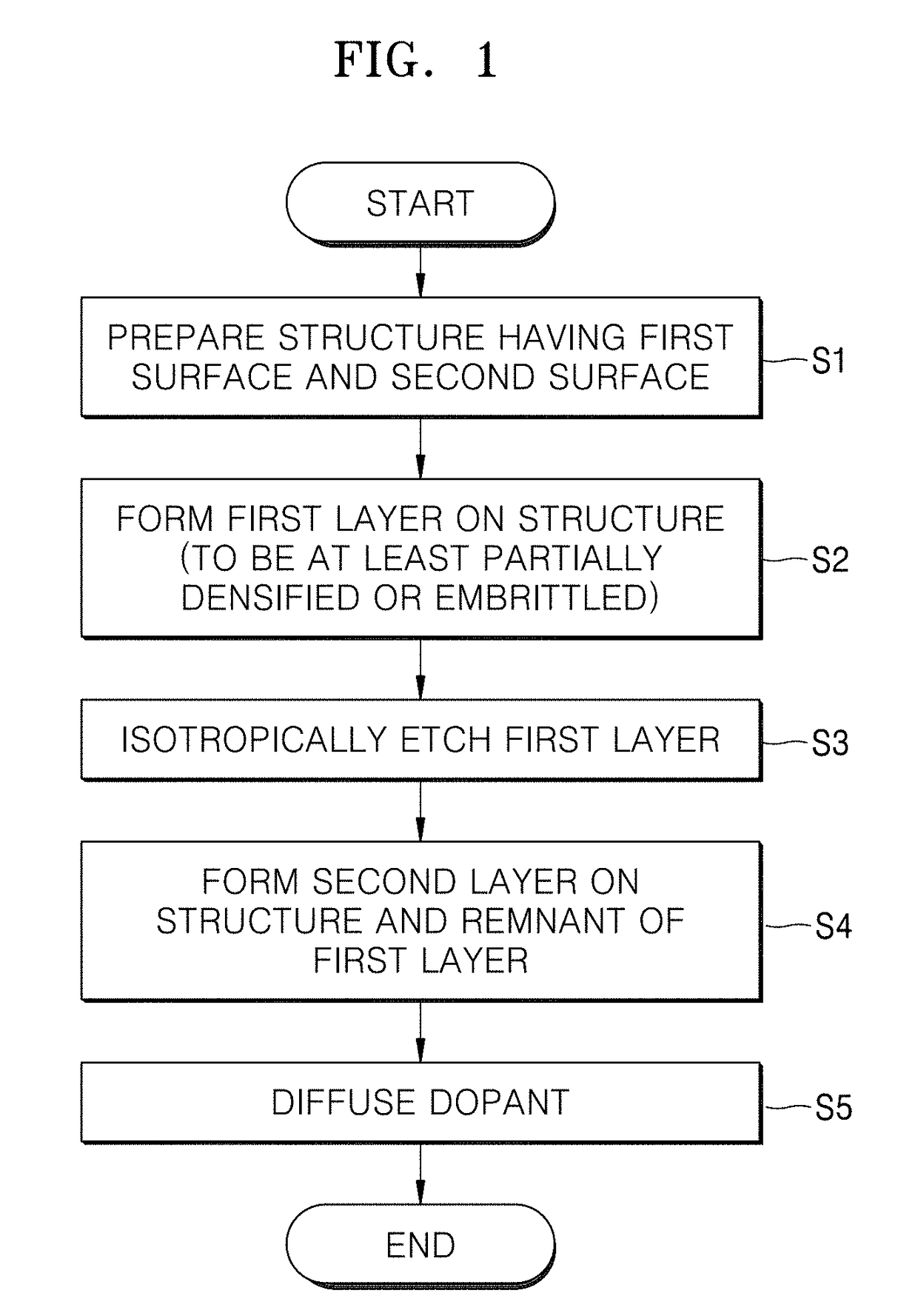

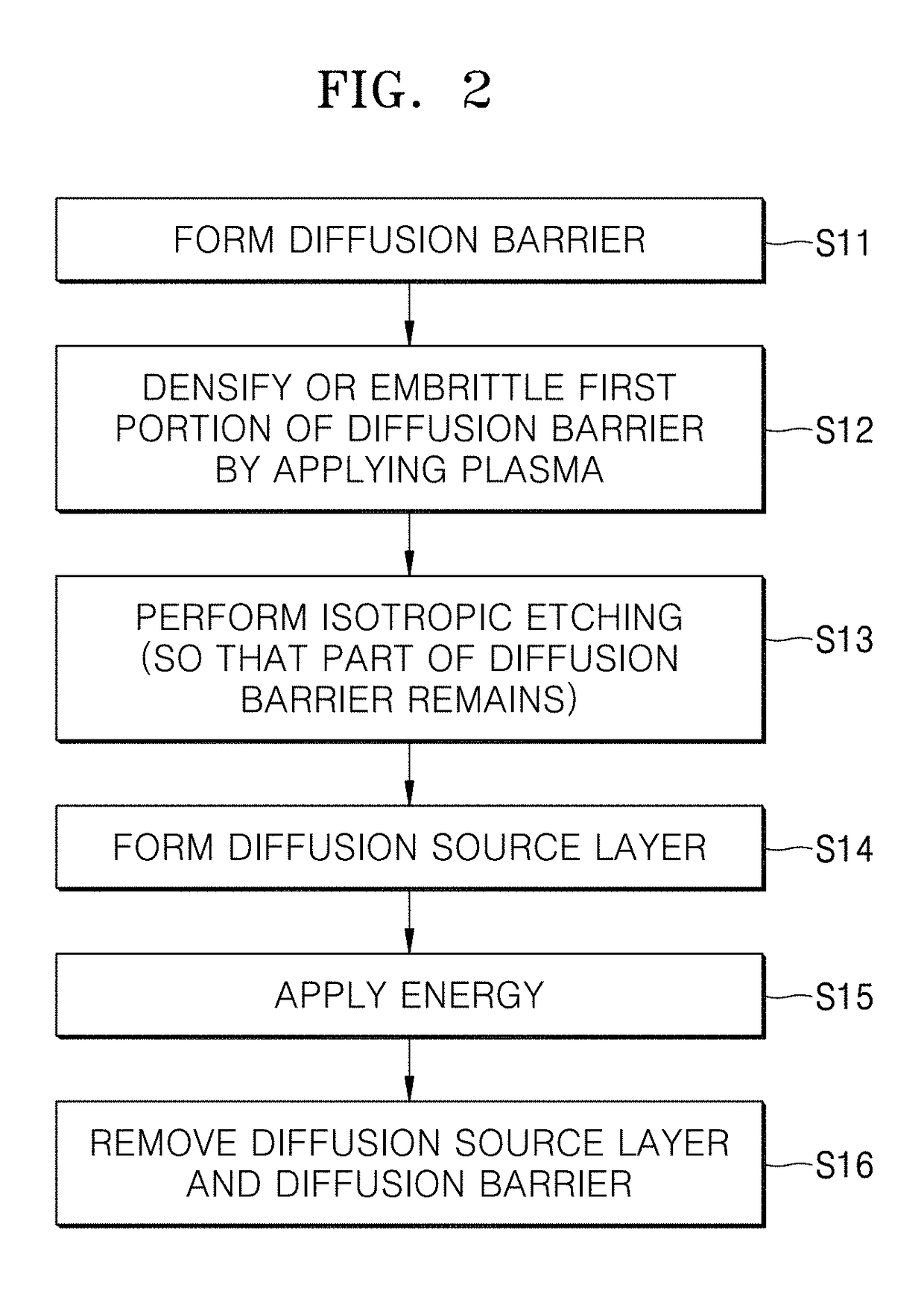

Method of processing substrate

A method of processing a substrate to enable selective doping without a photolithography process is provided. The method includes forming a diffusion barrier on the substrate having a patterned structure using plasma deposition method, removing the diffusion barrier except for part of the diffusion barrier using wet etching, forming a diffusion source layer on the patterned structure and the part of the diffusion barrier, and applying energy to the diffusion source layer.

Owner:ASM IP HLDG BV

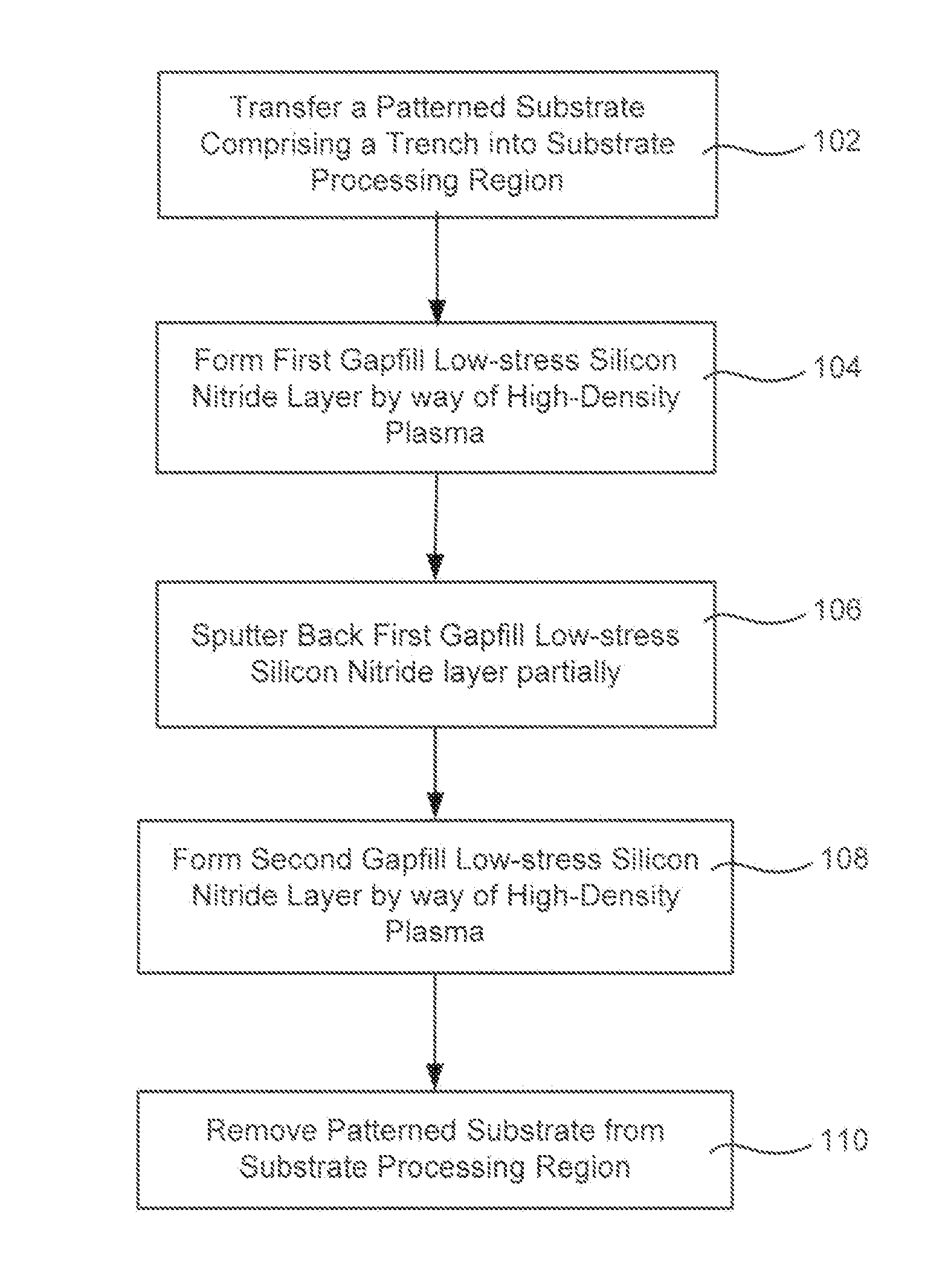

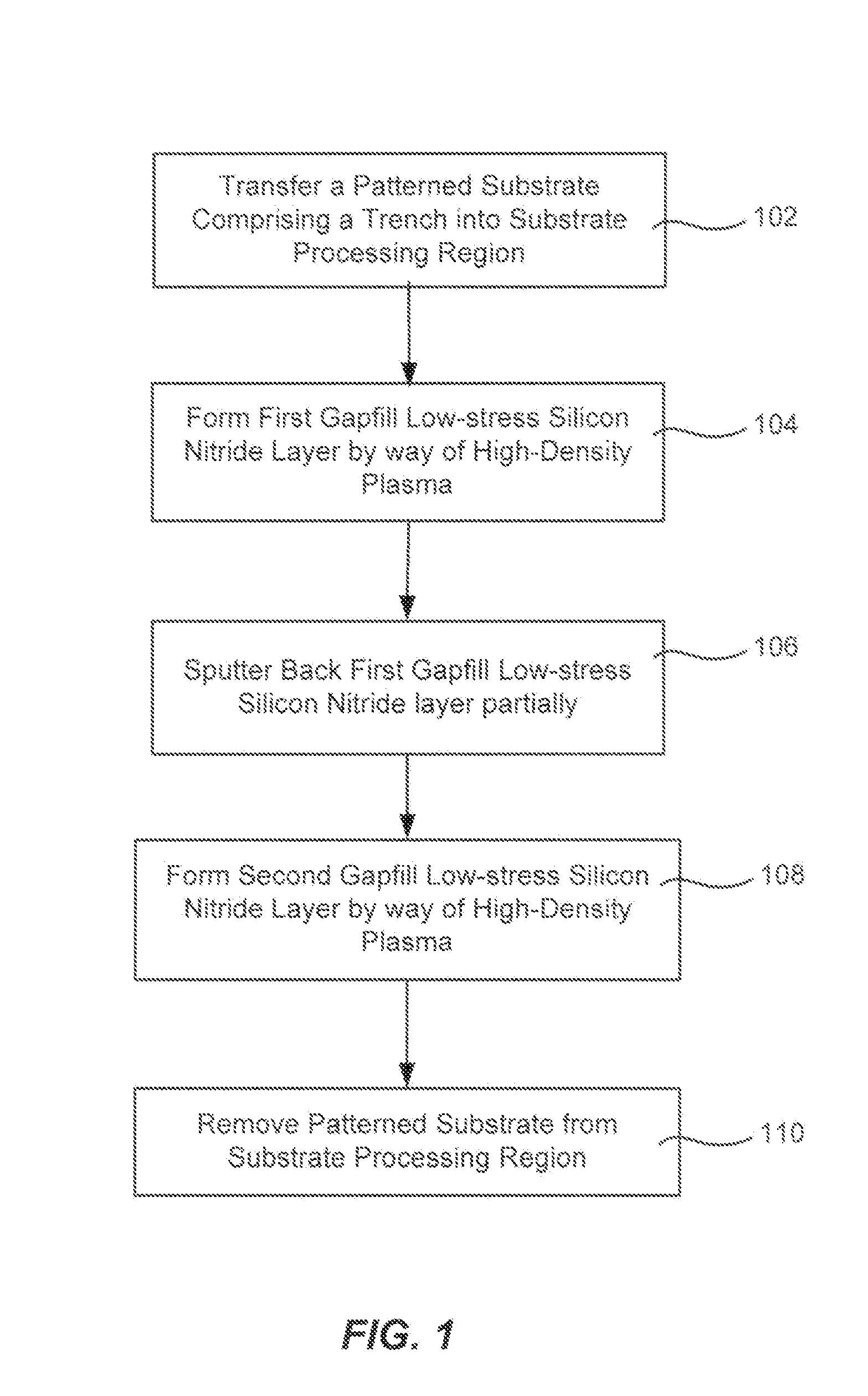

Silicon nitride gapfill implementing high density plasma

InactiveUS20140187045A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingSputteringHigh density

Methods of filling features with silicon nitride using high-density plasma chemical vapor deposition are described. Narrow trenches may be filled with gapfill silicon nitride without damaging compressive stress. A low but non-zero bias power is used during deposition of the gapfill silicon nitride. An etch step is included between each pair of silicon nitride high-density plasma deposition steps in order to supply sputtering which would normally be supplied by high bias power.

Owner:APPLIED MATERIALS INC

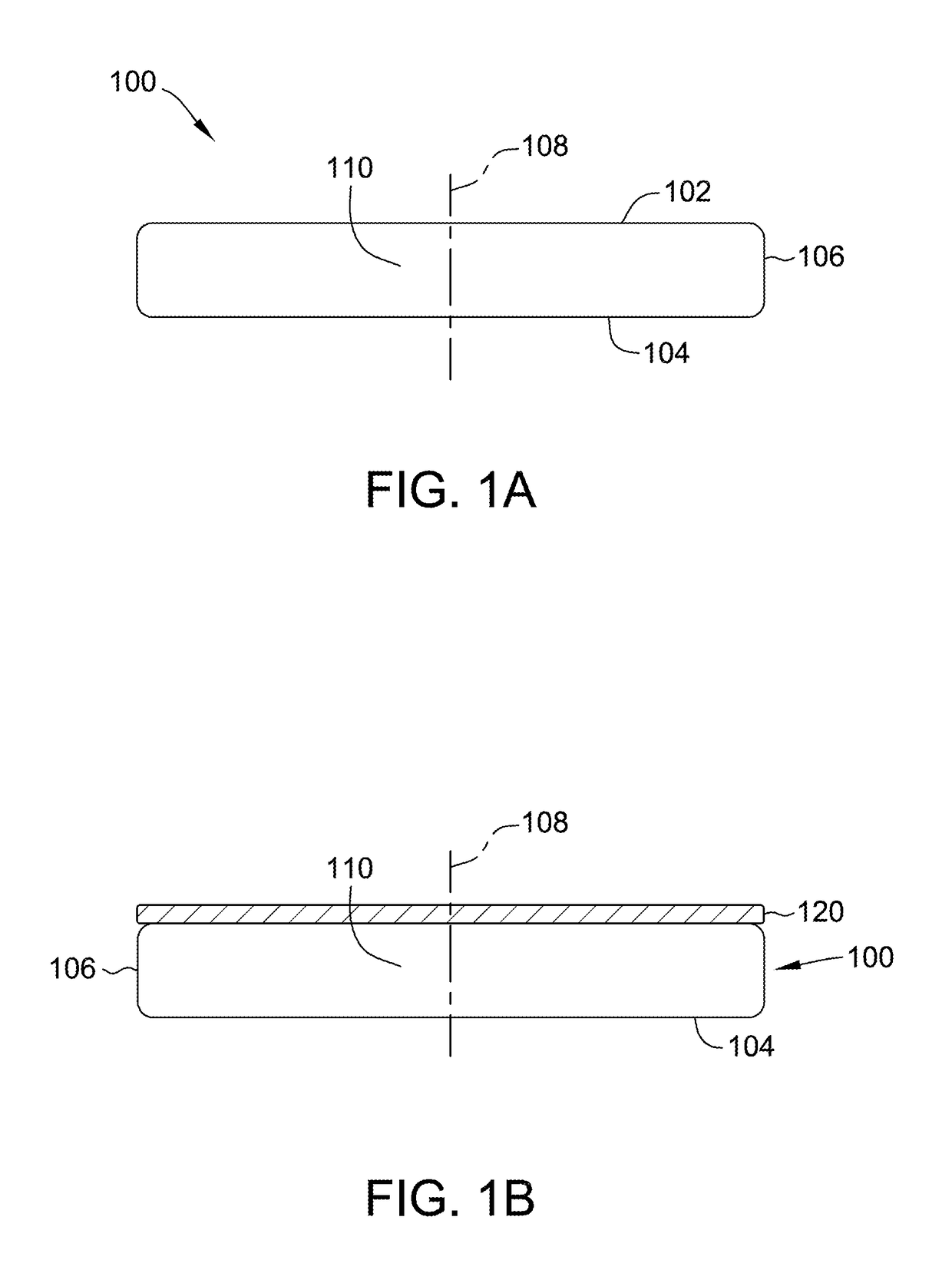

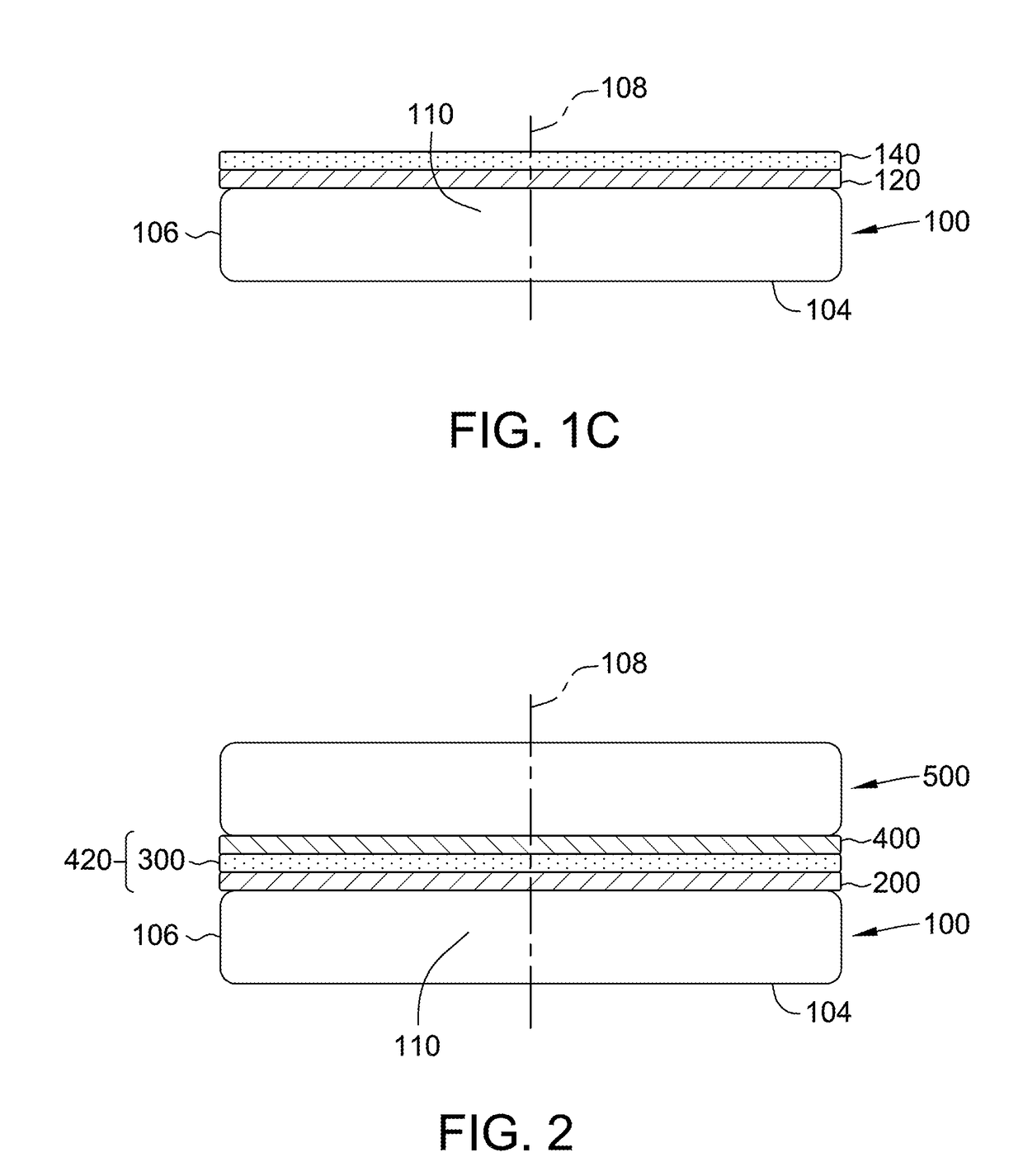

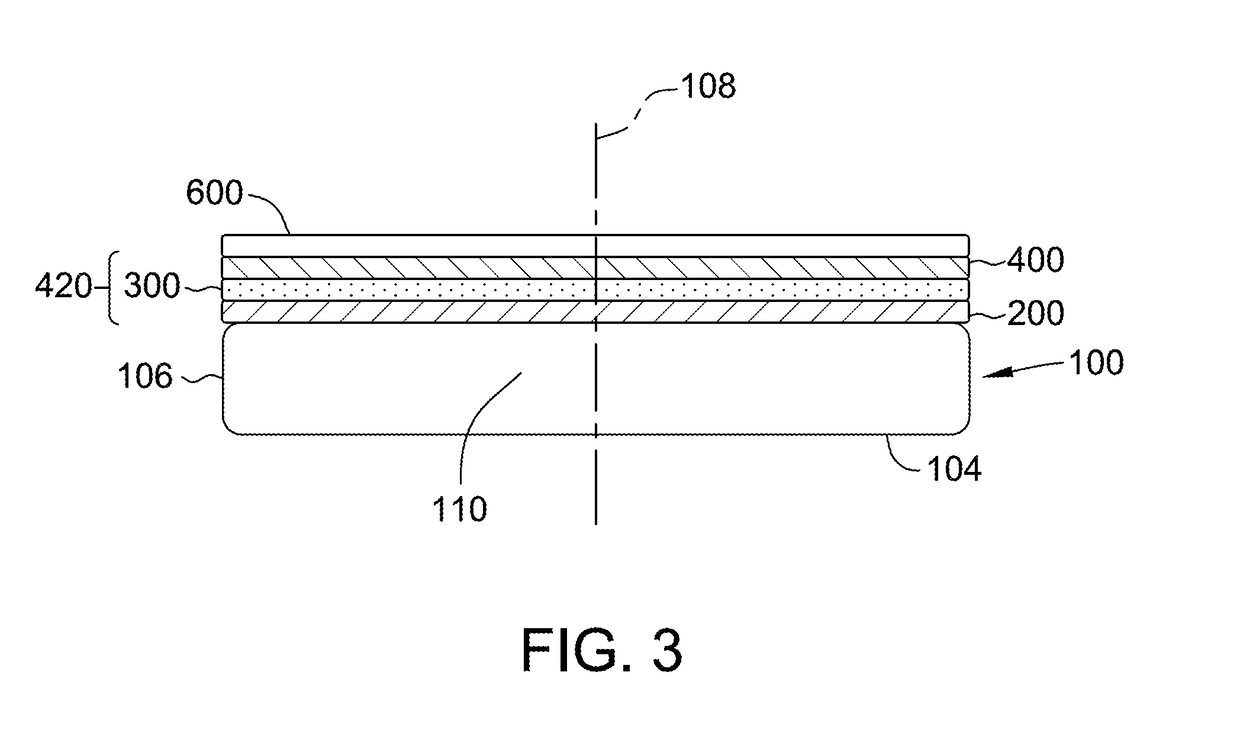

Semiconductor on insulator structure comprising a plasma nitride layer and method of manufacture thereof

ActiveUS20190067085A1Solid-state devicesSemiconductor/solid-state device manufacturingSemiconductor structurePlasma deposition

A method is provided for preparing a semiconductor-on-insulator structure comprising a silicon nitride layer deposited by plasma deposition.

Owner:GLOBALWAFERS CO LTD

Film deposition device

InactiveUS7354482B2Accurate measurementEasy to controlCellsLiquid surface applicatorsPlasma depositionEngineering

A film deposition device for depositing a film includes a depositing chamber for depositing the film with plasma. A plasma quantity monitoring device is disposed in the depositing chamber for monitoring a plasma quantity entering the depositing chamber at real time. A calculating device is electrically connected to the plasma quantity monitoring device for calculating a thickness of the film from the plasma quantity so that the thickness is monitored at real time.

Owner:SHIMADZU CORP

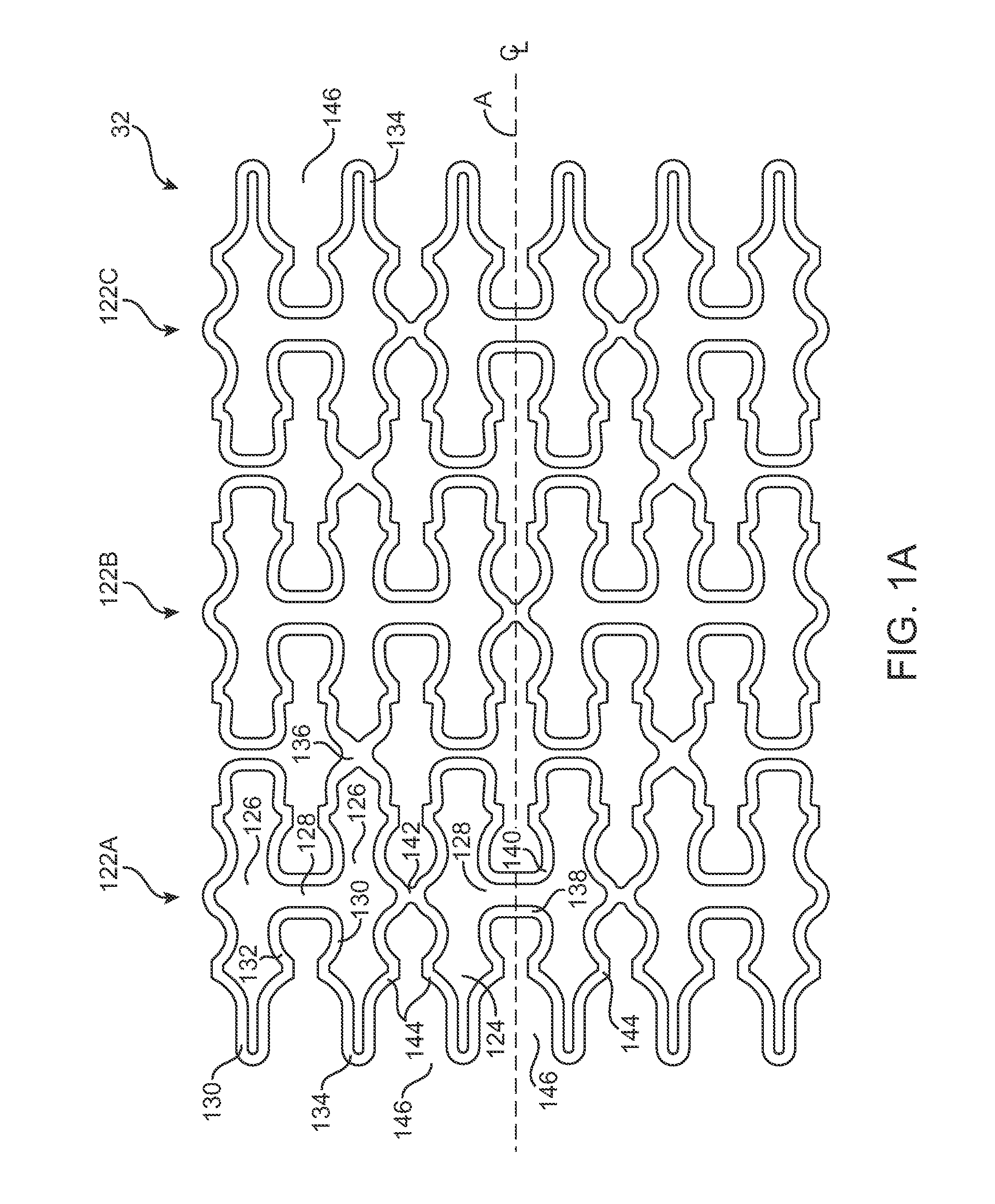

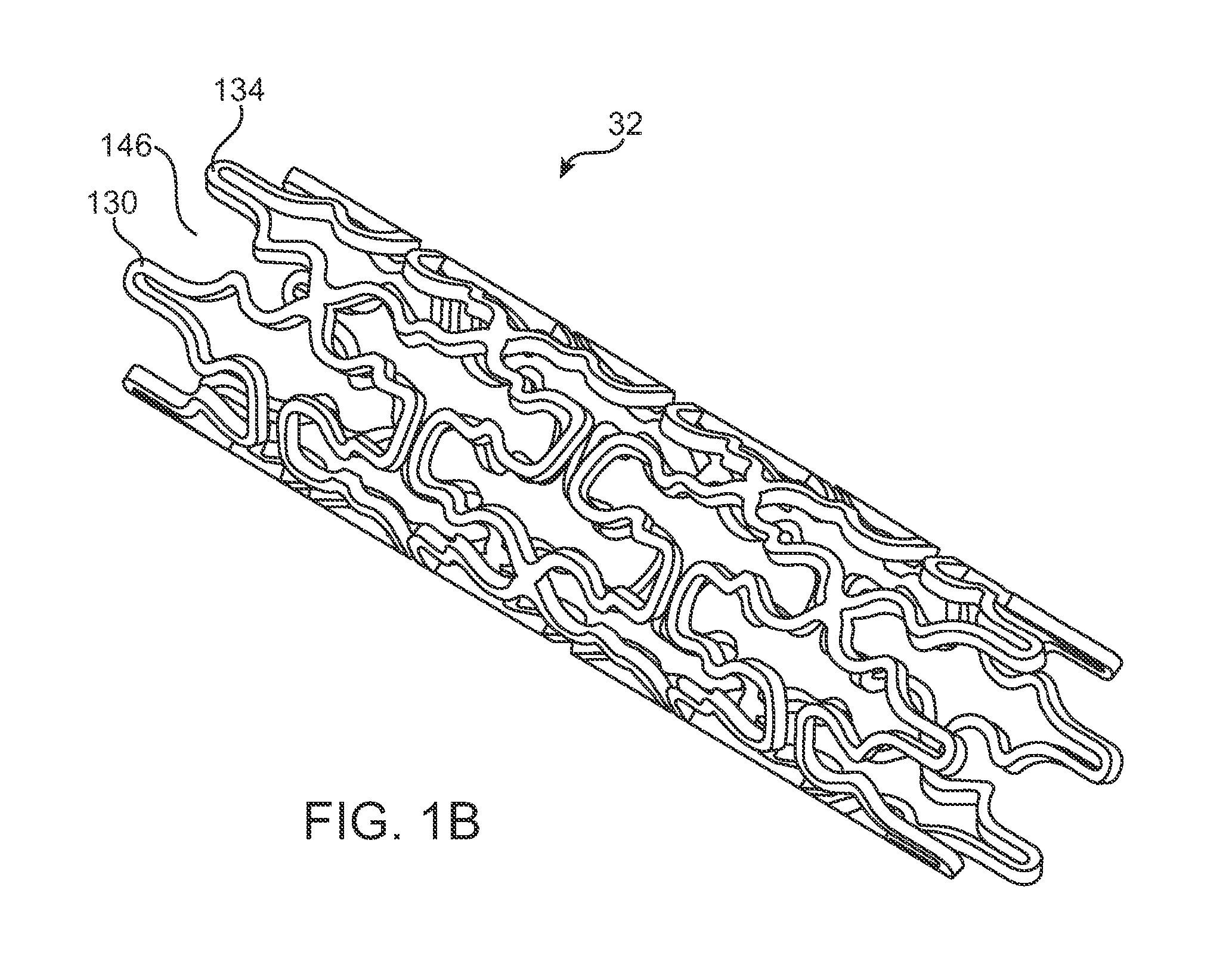

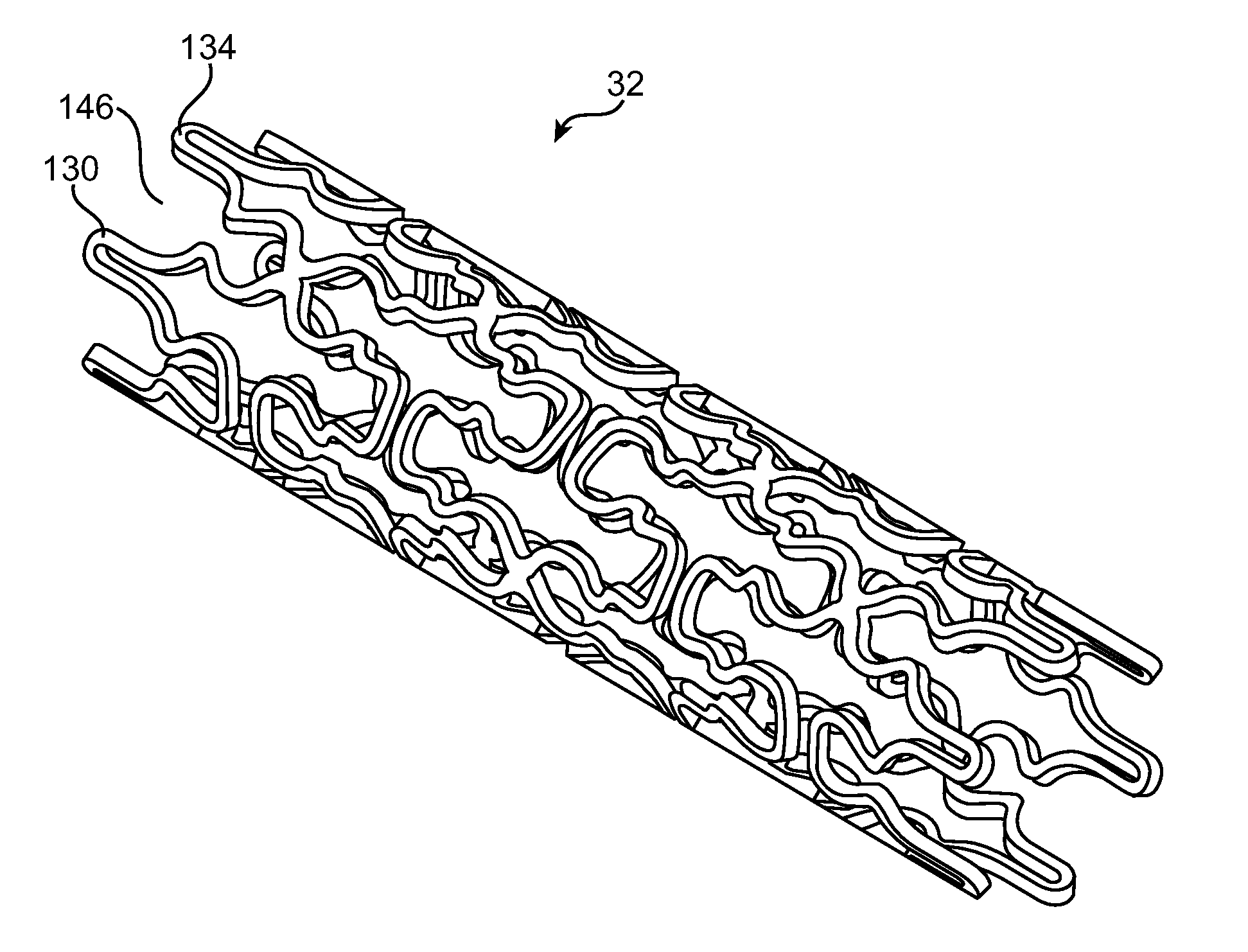

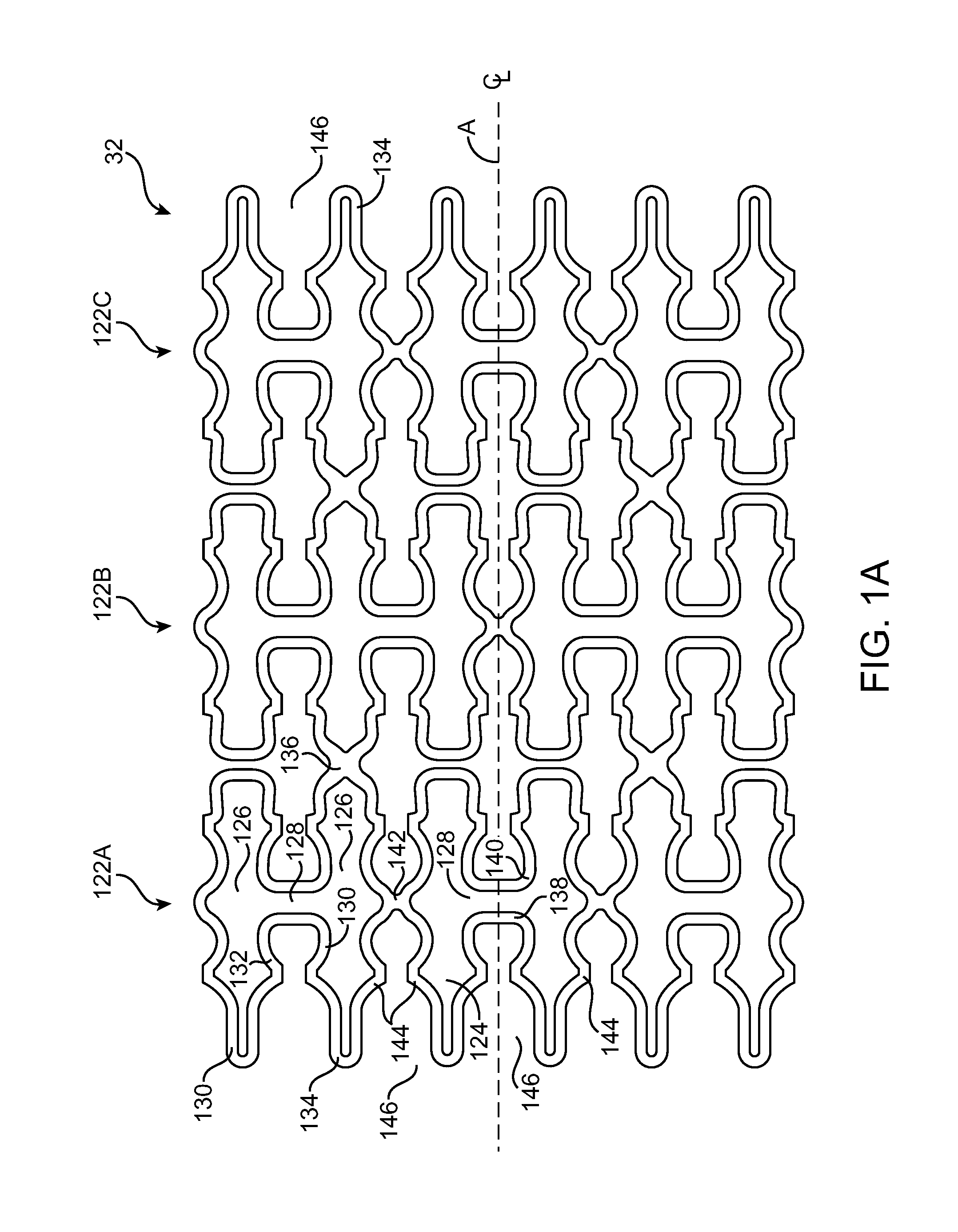

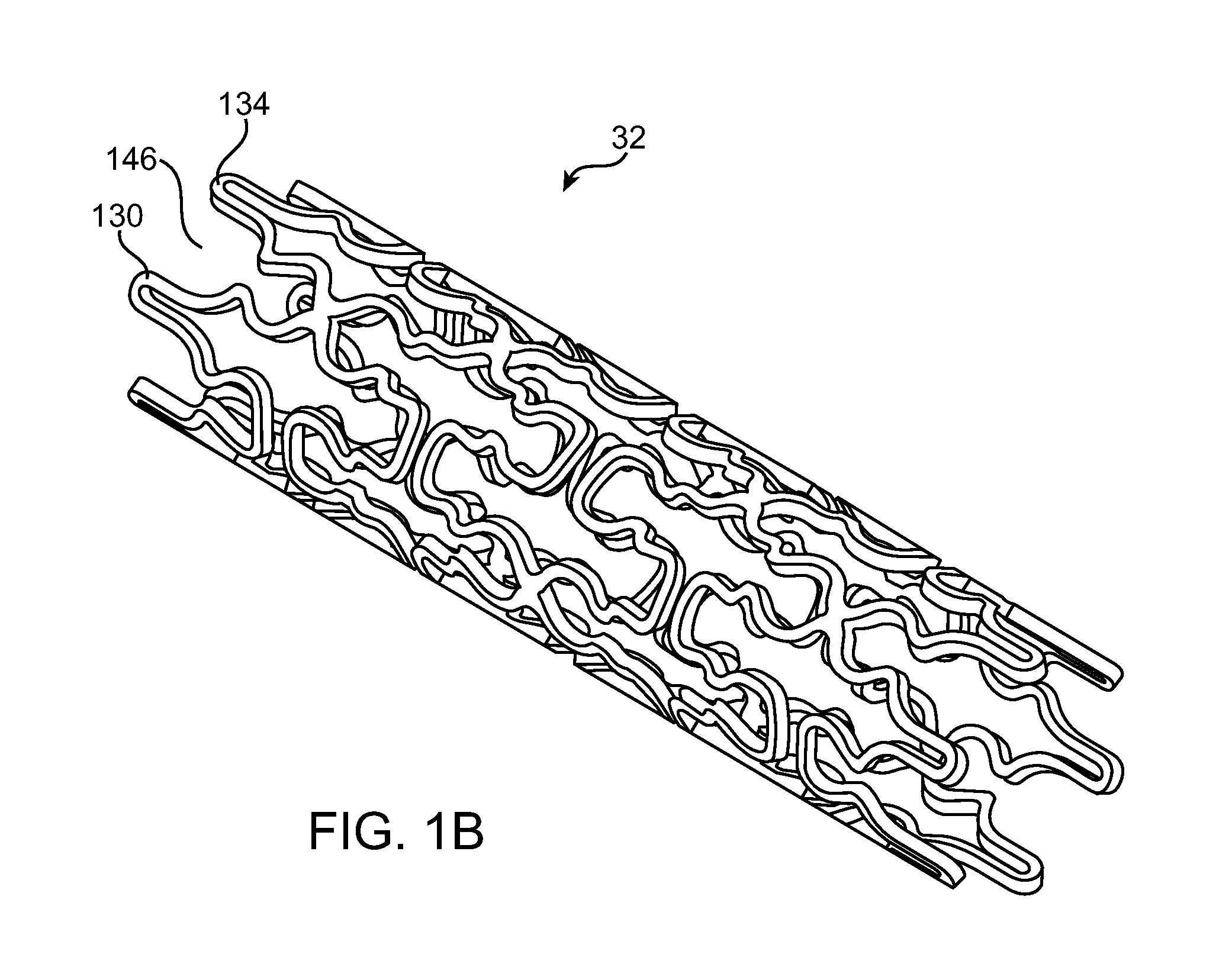

Use of plasma in formation of biodegradable stent coating

Metallic stents are treated with a gaseous species in a plasma state under conditions causing the species to polymerize and to be deposited in polymerized form on the metallic stent surface prior to the application of a drug-polymer mixture, which is done by conventional non-plasma deposition methods. The drug-polymer mixture once applied forms a coating on the stent surface that releases the drug in a time-release manner and gradually erodes, leaving only the underlying plasma-deposited polymer. In certain cases, the plasma-deposited polymer itself erodes or dissolves into the physiological medium over an extended period of time, leaving only the metallic stent. While the various polymers and drug remain on the stent, the plasma-deposited polymer enhances the adhesion of the drug-polymer anchor coating and maintains the coating intact upon exposure to the mechanical stresses encountered during stent deployment.

Owner:XTENT INC

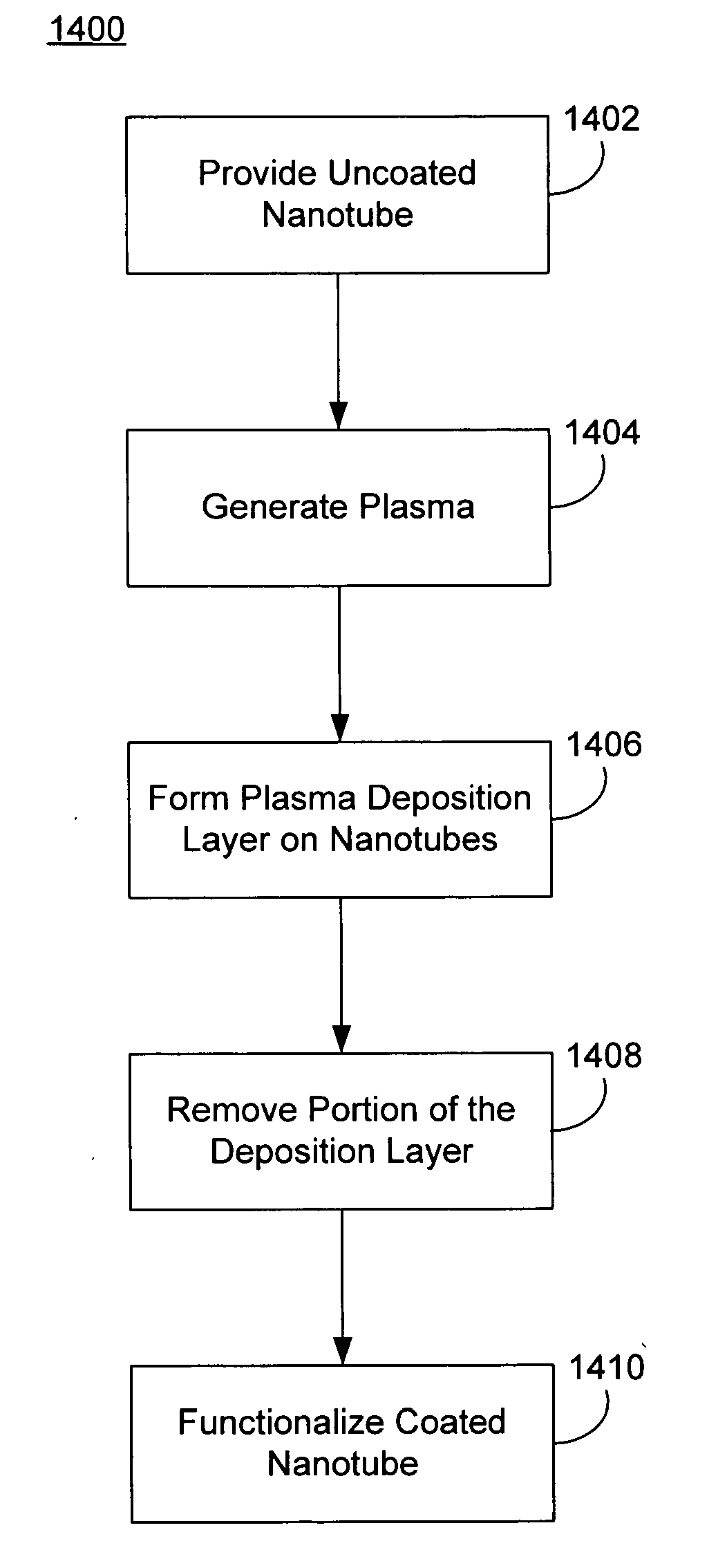

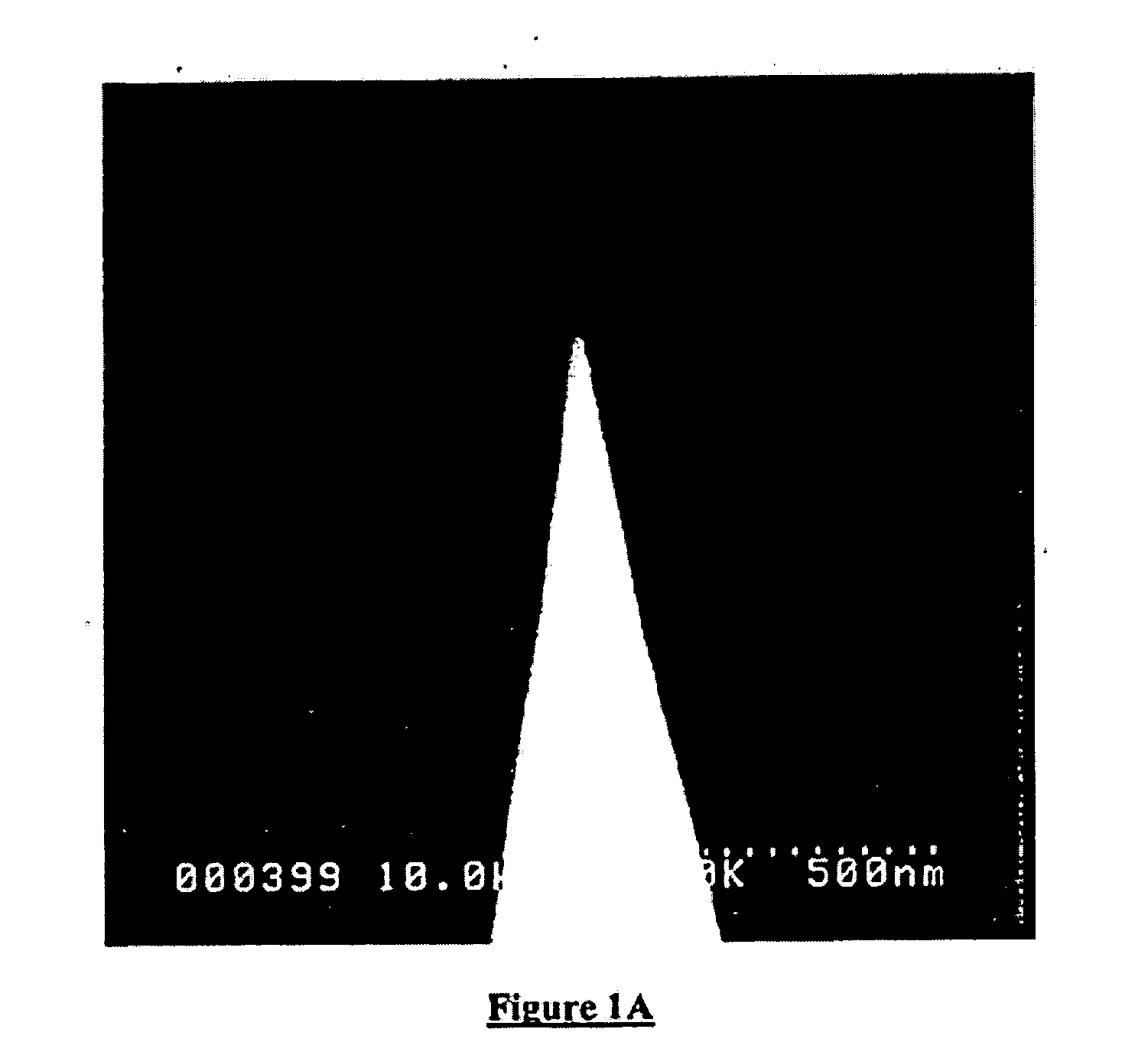

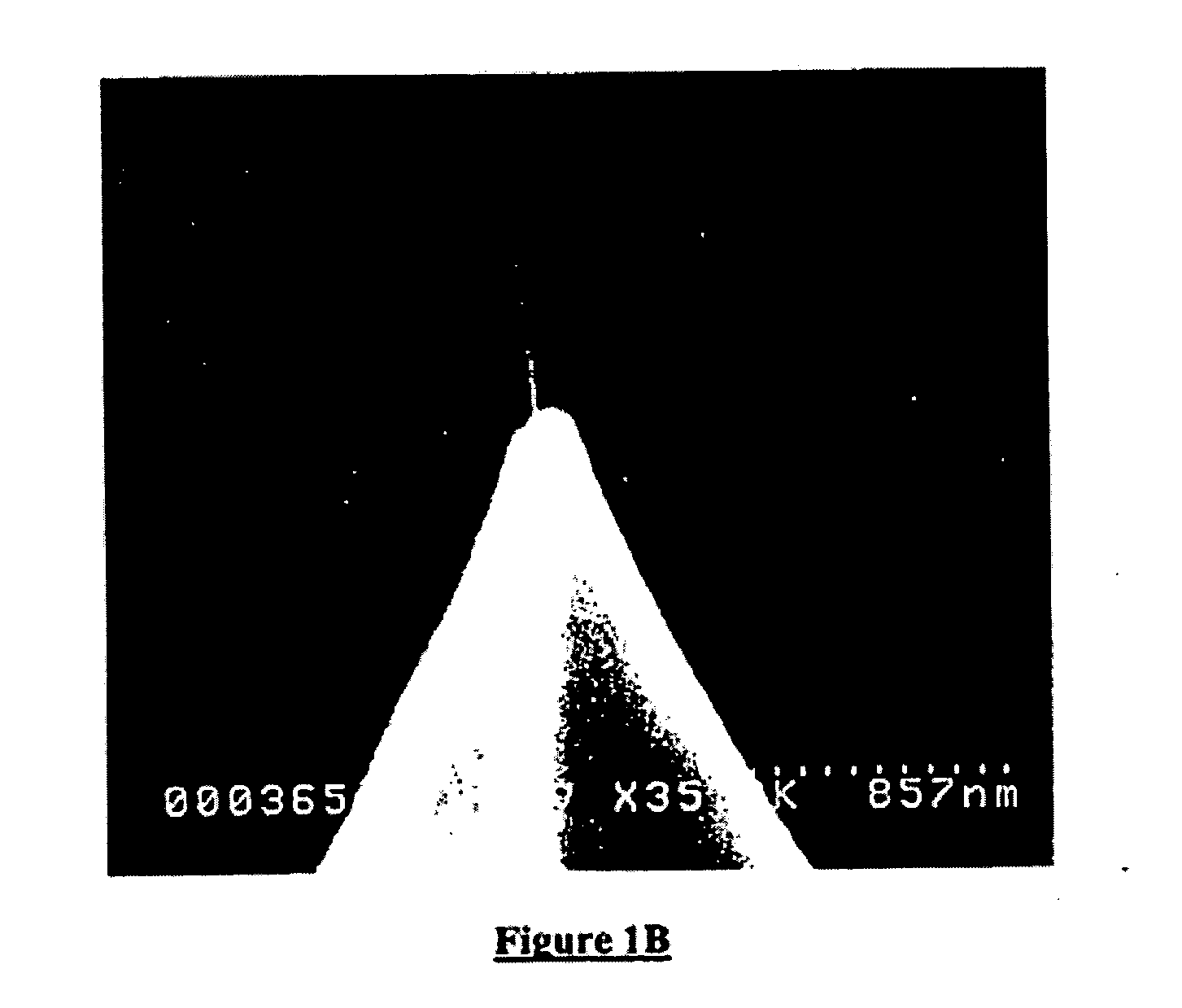

Coatings for carbon nanotubes

A coated nanotube that includes an inner nanotube having an exterior surface, and a plasma deposited layer covering at least part of the exterior surface of the inner nanotube. Also, a method of making a coated nanotube, the method where the method includes the steps of generating a plasma from a coating precursor, and exposing an inner nanotube to the plasma, where a plasma deposited layer is formed on at least a portion of the inner nanotube. Additionally, a method of making a coated nanotube that includes the steps of providing an inner nanotube, and evaporating a metal into the inner nanotube, where the metal forms a coating layer on at least a portion of the inner nanotube.

Owner:CALIFORNIA INST OF TECH

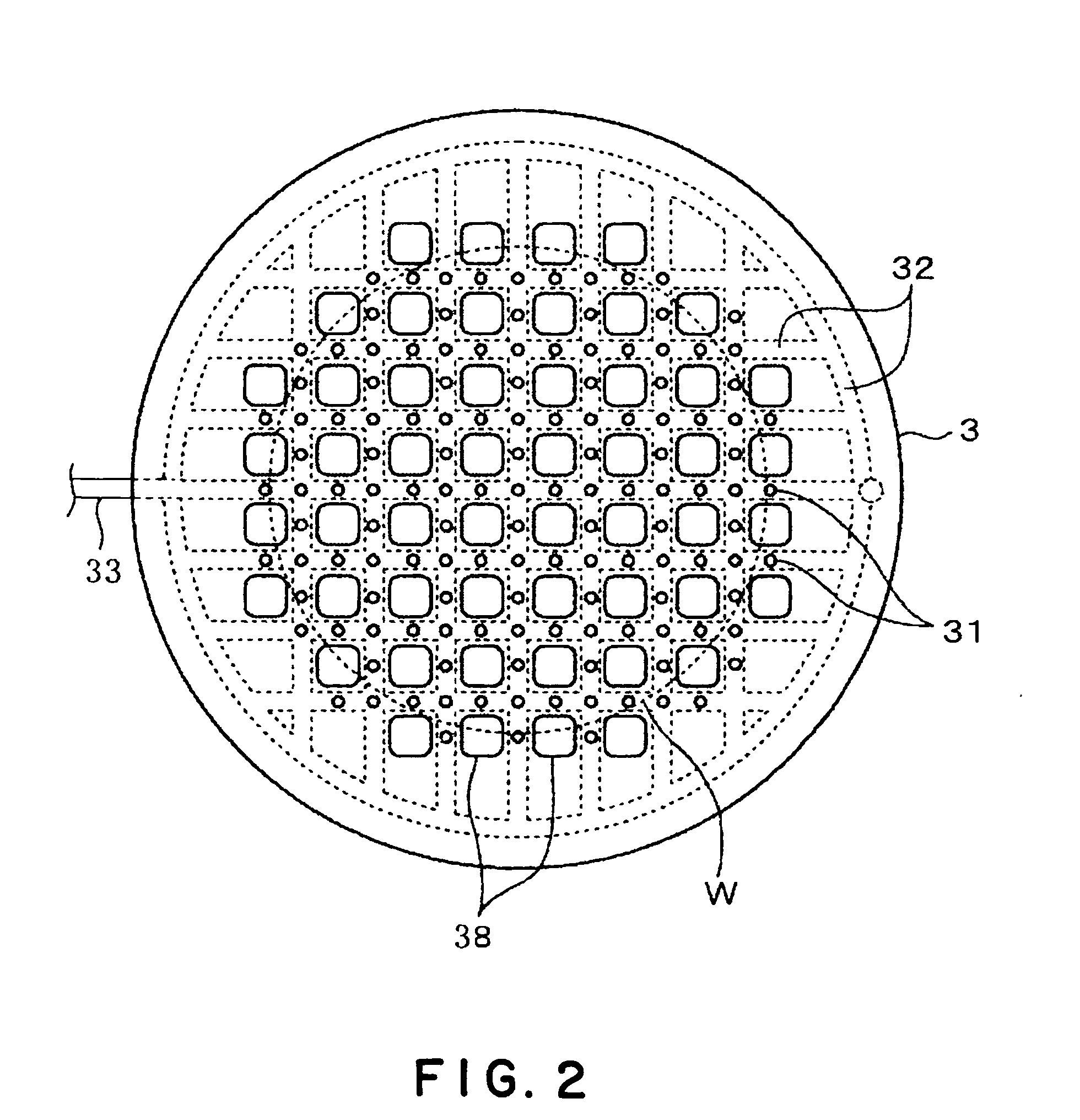

Shower plate structure for exhausting deposition inhibiting gas

ActiveUS20180171472A1Simple structureGood film uniformityLiquid surface applicatorsElectric discharge tubesPlasma depositionEngineering

A shower plate adapted to be installed in a plasma deposition apparatus including a gas inlet port, a shower head, a reaction chamber and an exhaust duct, the shower plate being adapted to be attached to the showerhead and having: a front surface adapted to face the gas inlet port; and a rear surface opposite to the front surface, wherein the shower plate has multiple apertures each extending from the front surface to the rear surface, and wherein the shower plate further has at least one aperture extending from the front surface side of the shower plate to the exhaust duct.

Owner:ASM IP HLDG BV

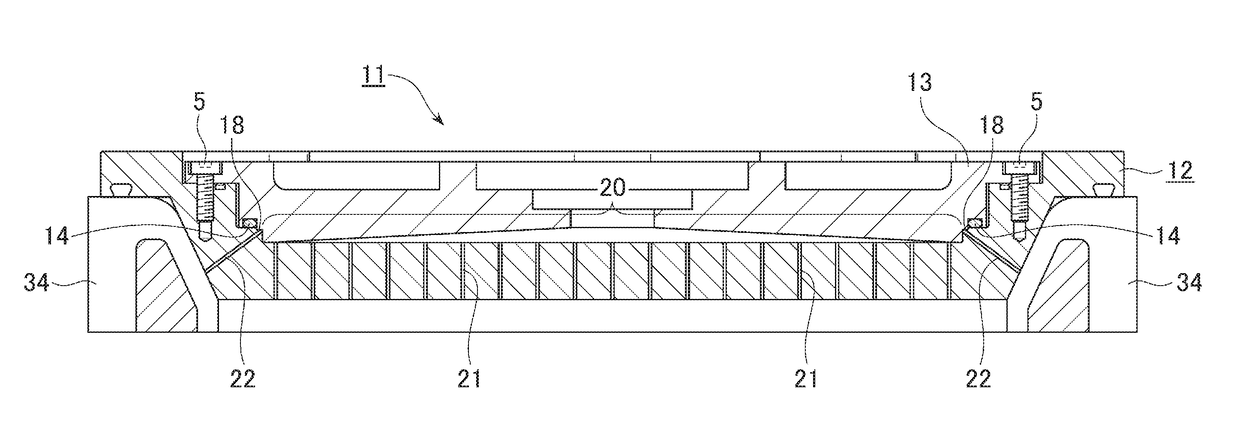

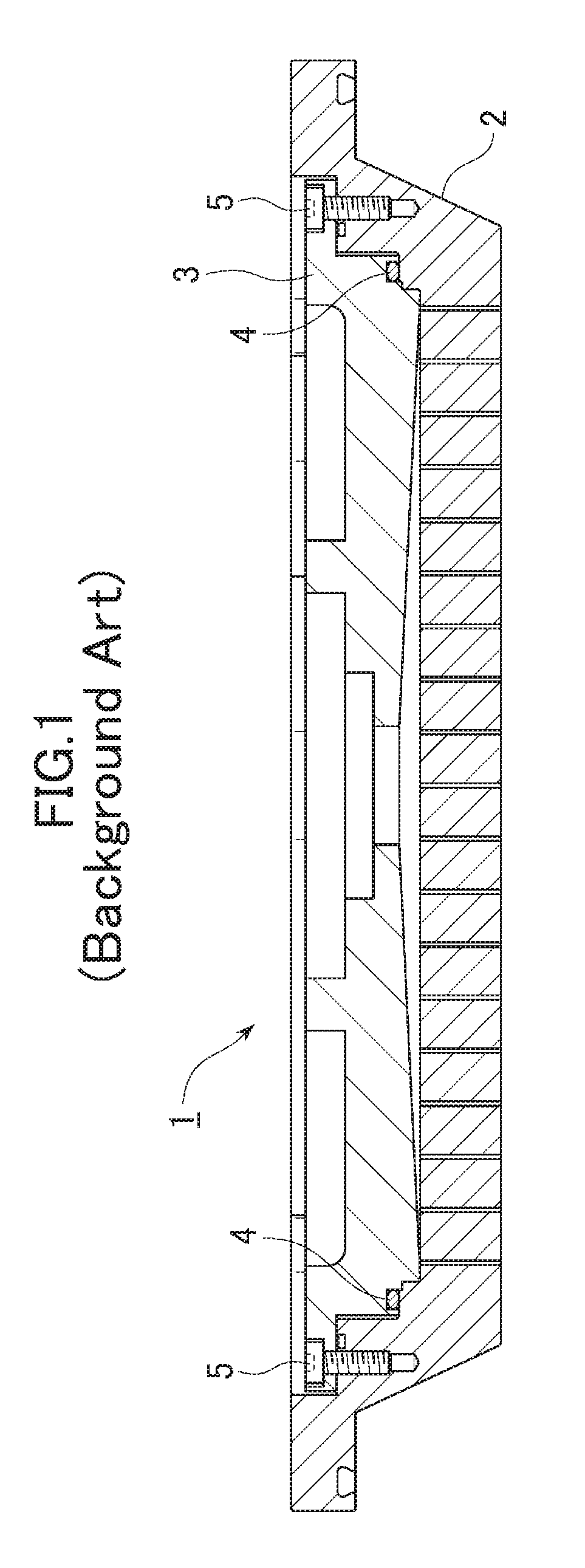

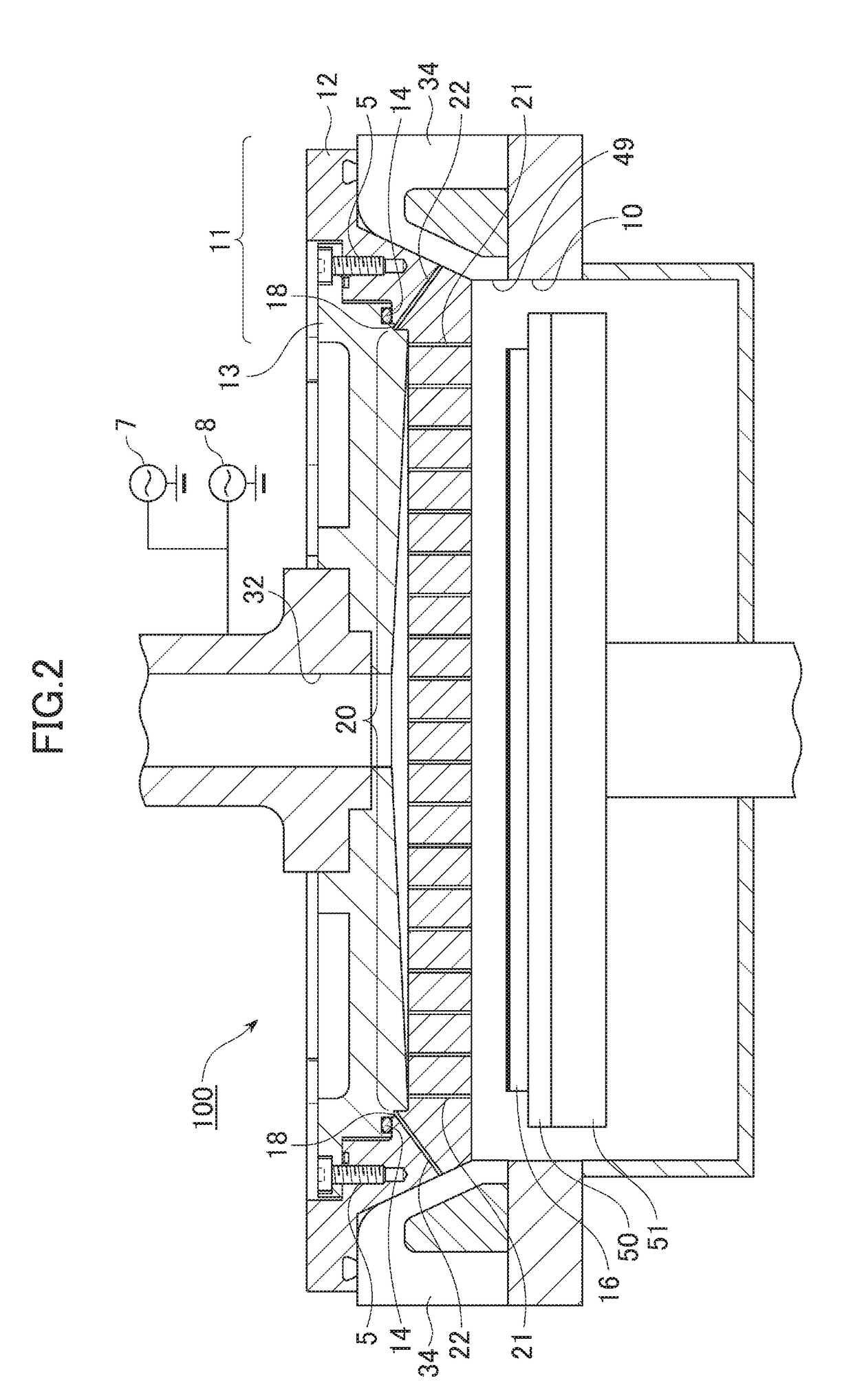

Novel method for conformal plasma immersed ion implantation assisted by atomic layer deposition

InactiveUS20090203197A1Maximize penetrationVacuum evaporation coatingSputtering coatingDopantSource material

Embodiments of the invention provide a novel apparatus and methods for forming a conformal doped layer on the surface of a substrate. A substrate is provided to a process chamber, and a layer of dopant source material is deposited by plasma deposition, atomic layer deposition, or plasma-assisted atomic layer deposition. The substrate is then subjected to thermal processing to activate and diffuse dopants into the substrate surface.

Owner:APPLIED MATERIALS INC

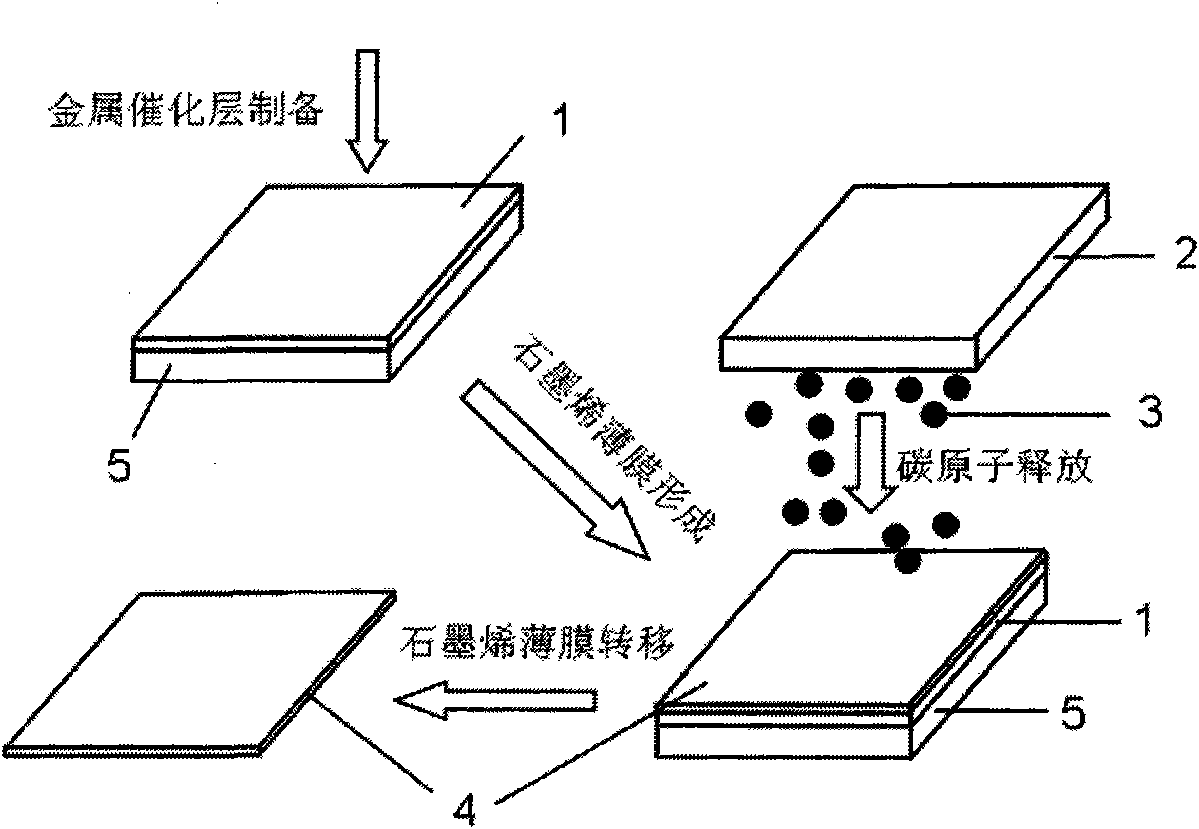

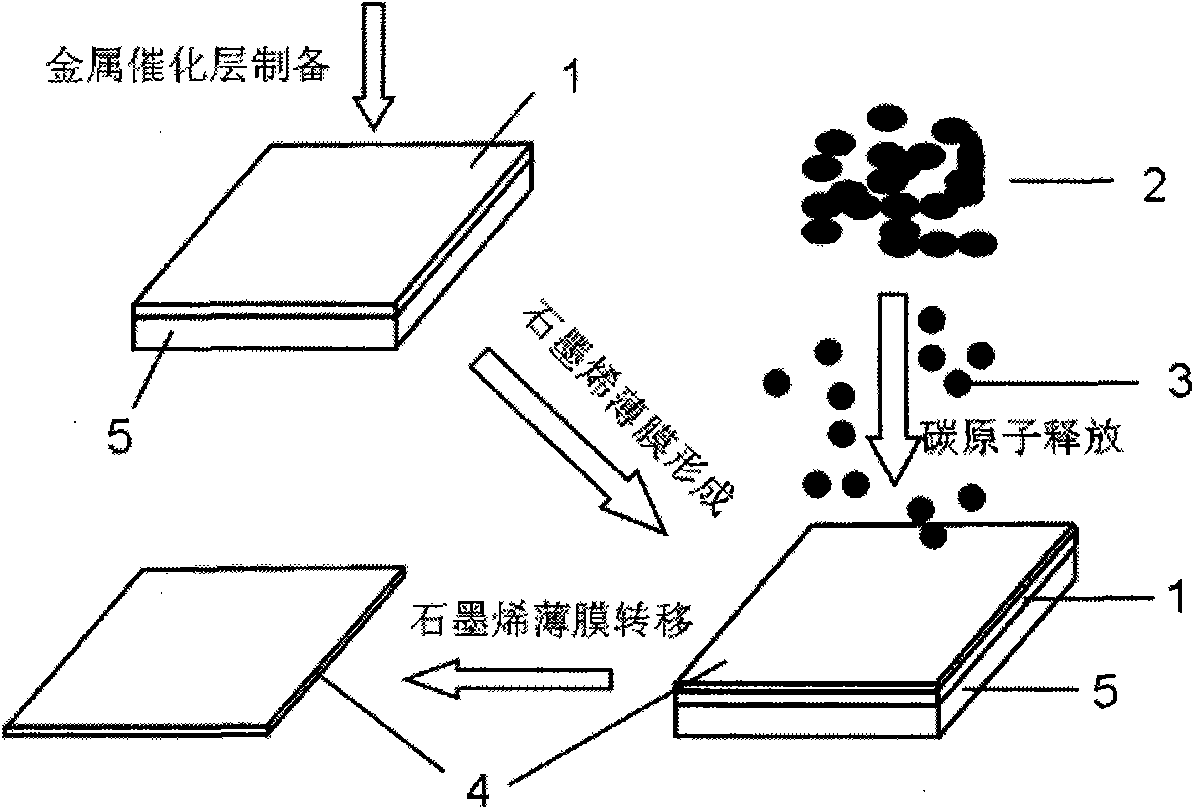

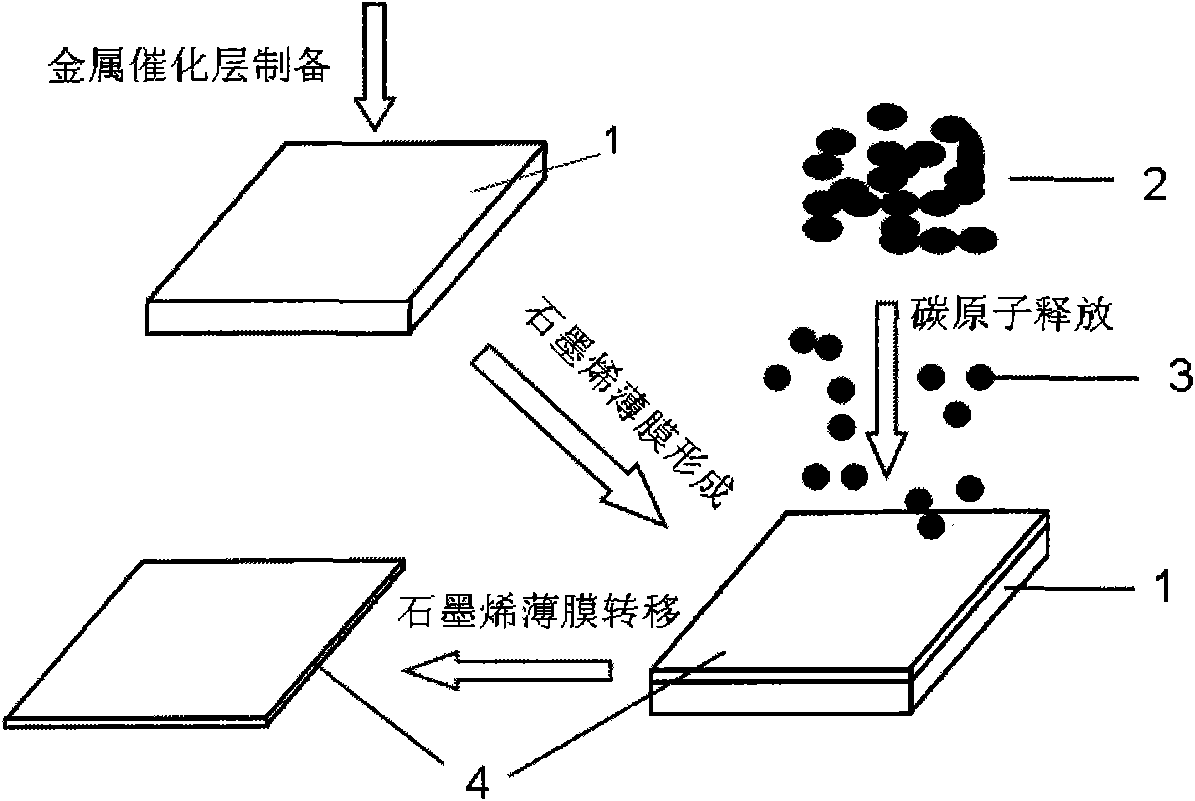

Method for preparing graphene membrane

The invention discloses a method for preparing a graphene membrane. Carbon atoms are released from a solid carbon source by a method such as heat treatment, heat evaporation, sputtering, electron beam deposition, laser deposition or plasma deposition to form the graphene membrane on a catalytic layer or a substrate, wherein the solid carbon source is graphite, amorphous carbon, diamond, fullerene or carbon nano tubes. In the method for preparing the graphene membrane, the solid carbon source is used, the method is simple; and the prepared graphene membrane is easy to control in terms of thickness, structure and size, has excellent photoelectric characteristics and is suitable for preparing high-performance photoelectronic devices on a large scale.

Owner:ZHEJIANG UNIV

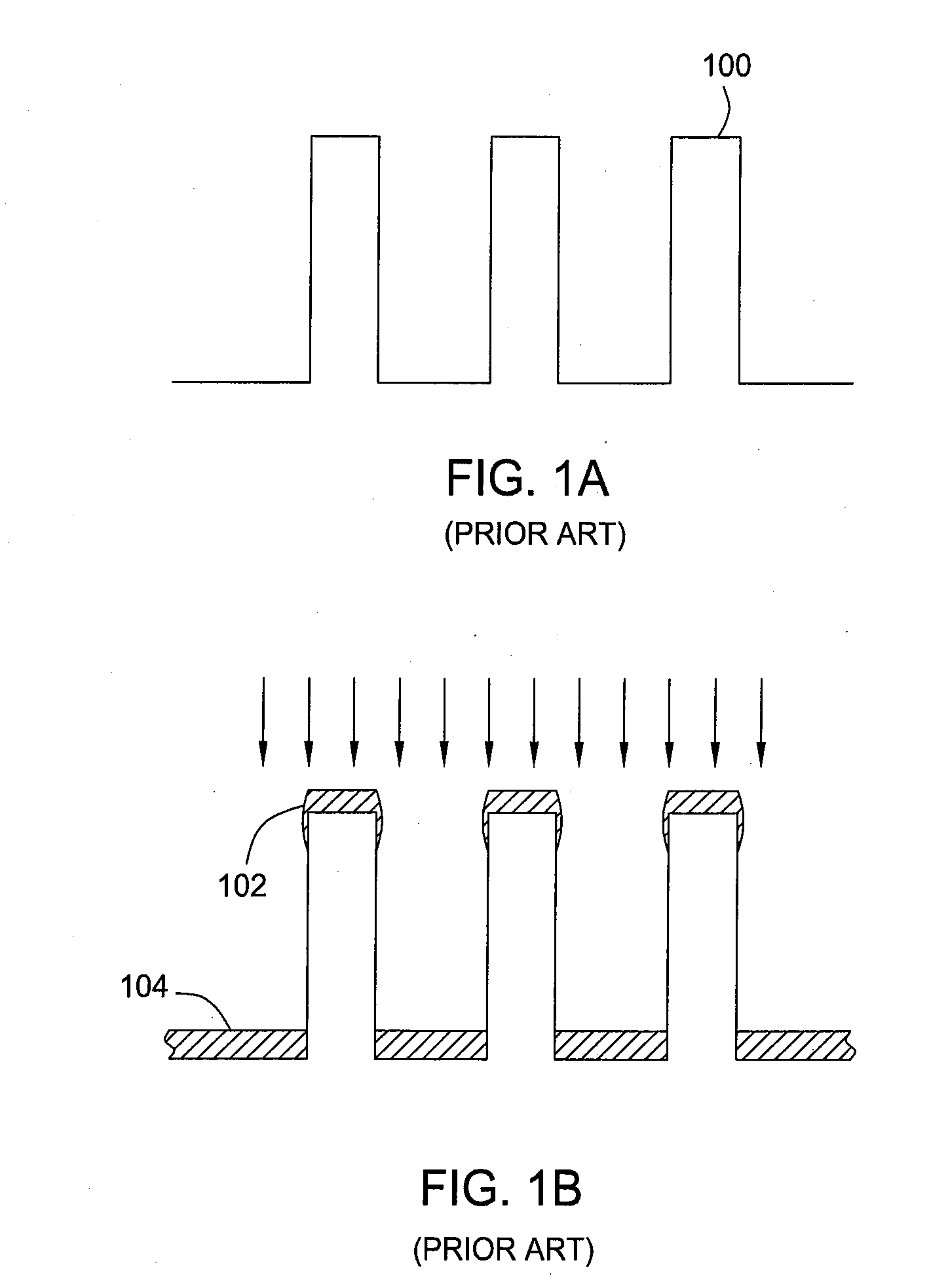

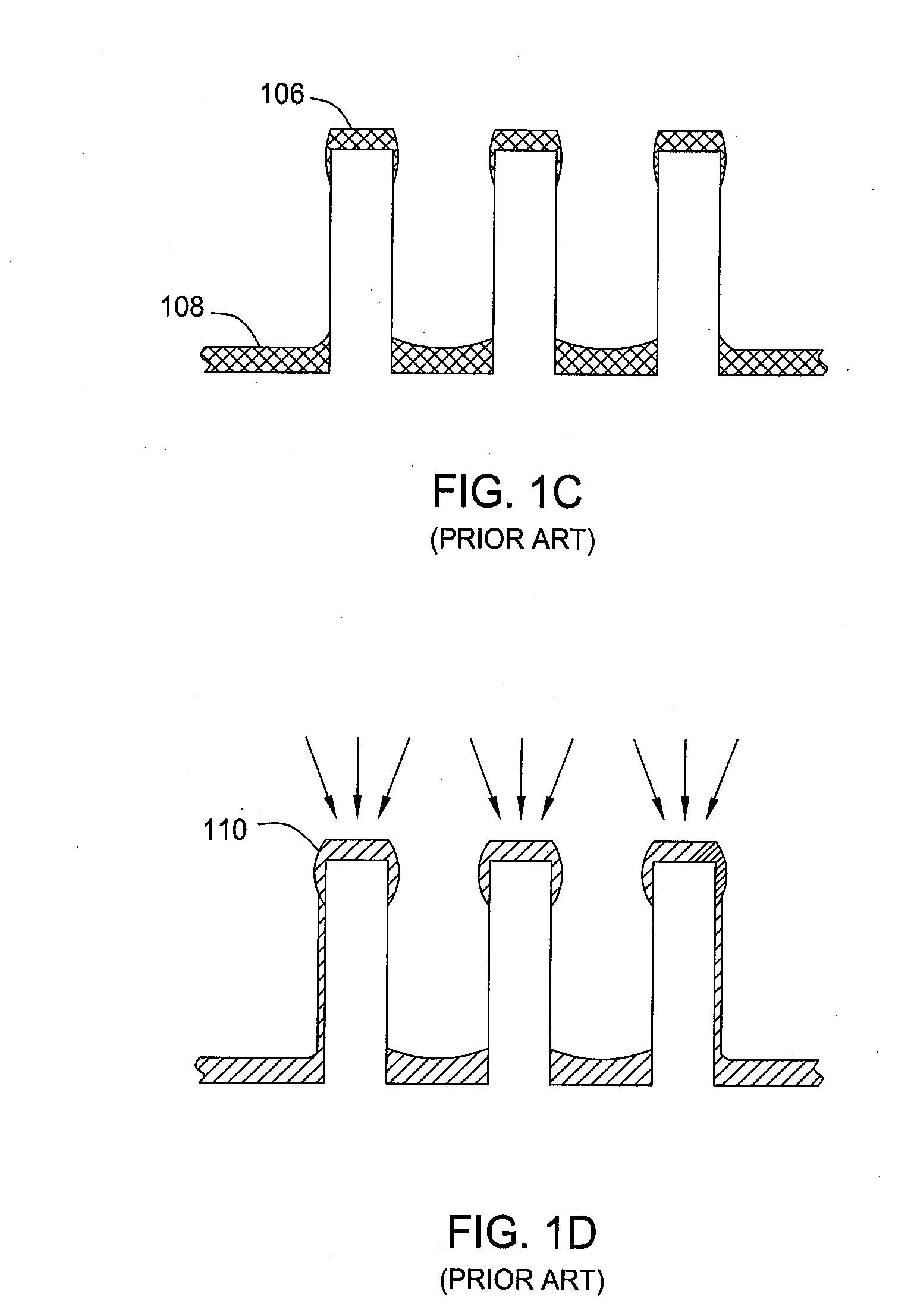

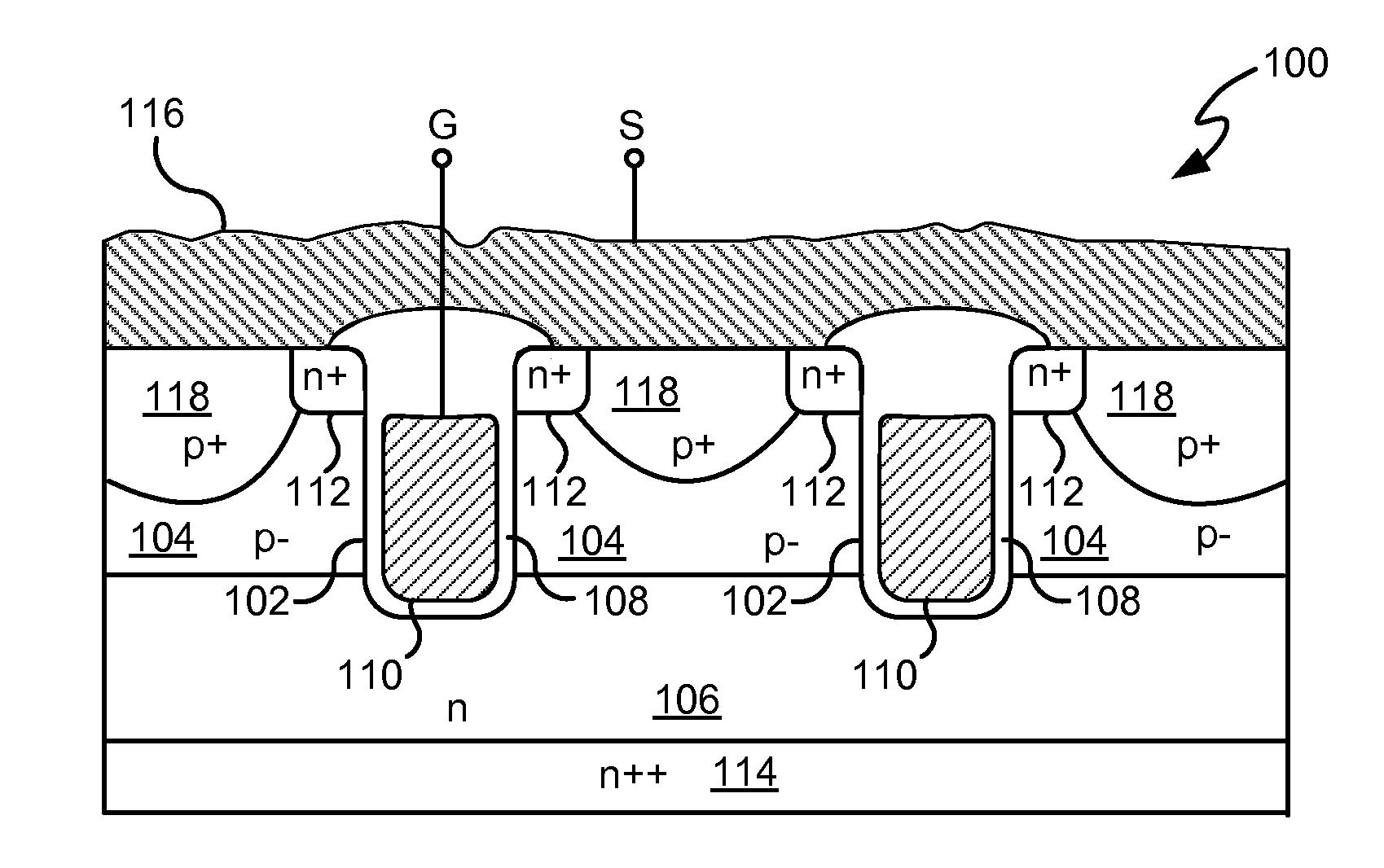

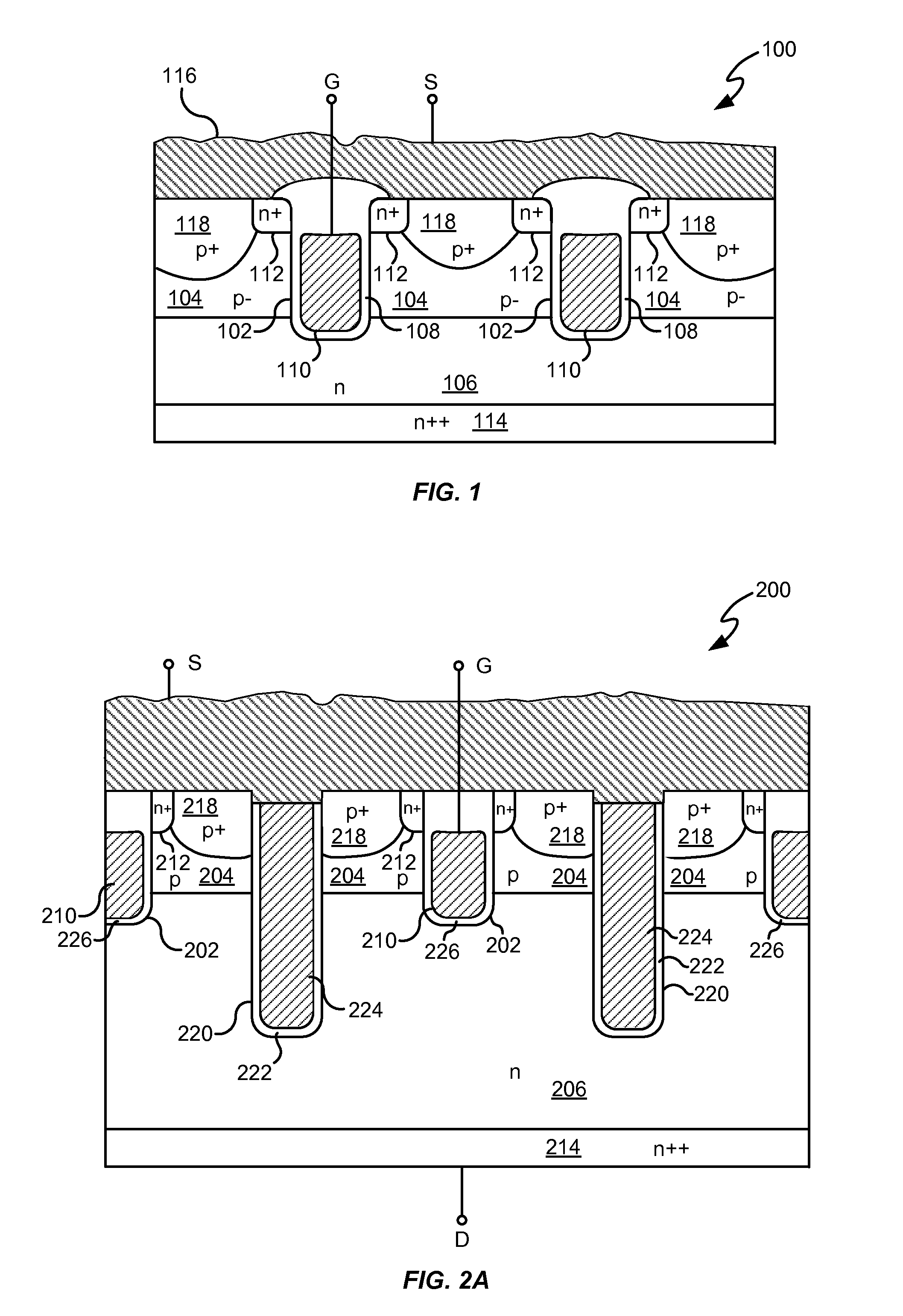

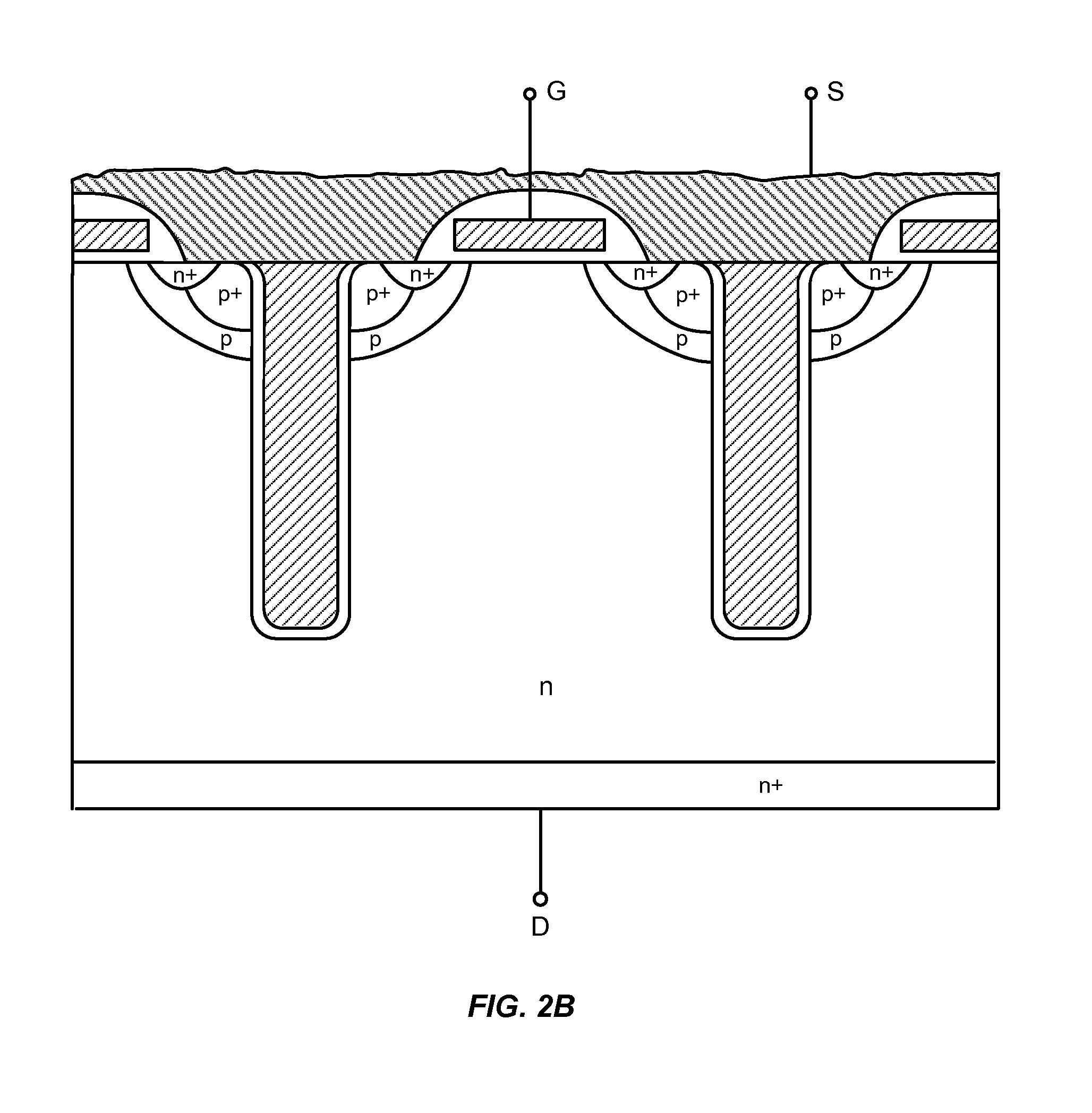

Methods of Making Power Semiconductor Devices with Thick Bottom Oxide Layer

ActiveUS20080138953A1Simple structureEasy to packTransistorEfficient power electronics conversionPower semiconductor deviceHigh density

A method for forming thick oxide at the bottom of a trench formed in a semiconductor substrate includes forming a conformal oxide film that fills the trench and covers a top surface of the substrate. and etching the oxide film off the top surface of the substrate and inside the trench to leave a substantially flat layer of oxide having a target thickness at the bottom of the trench. The oxide film can be deposited by sub-atmospheric chemical vapor deposition processes, directional Tetraethoxysilate (TEOS) processes, or high density plasma deposition processes that form a thicker oxide at the bottom of the trench than on the sidewalls of the trench.

Owner:SEMICON COMPONENTS IND LLC

Method and apparatus for cathodic arc ion plasma deposition

InactiveUS20080138529A1Easy to operateConvenient lengthMolten spray coatingVacuum evaporation coatingPlasma depositionDeposition process

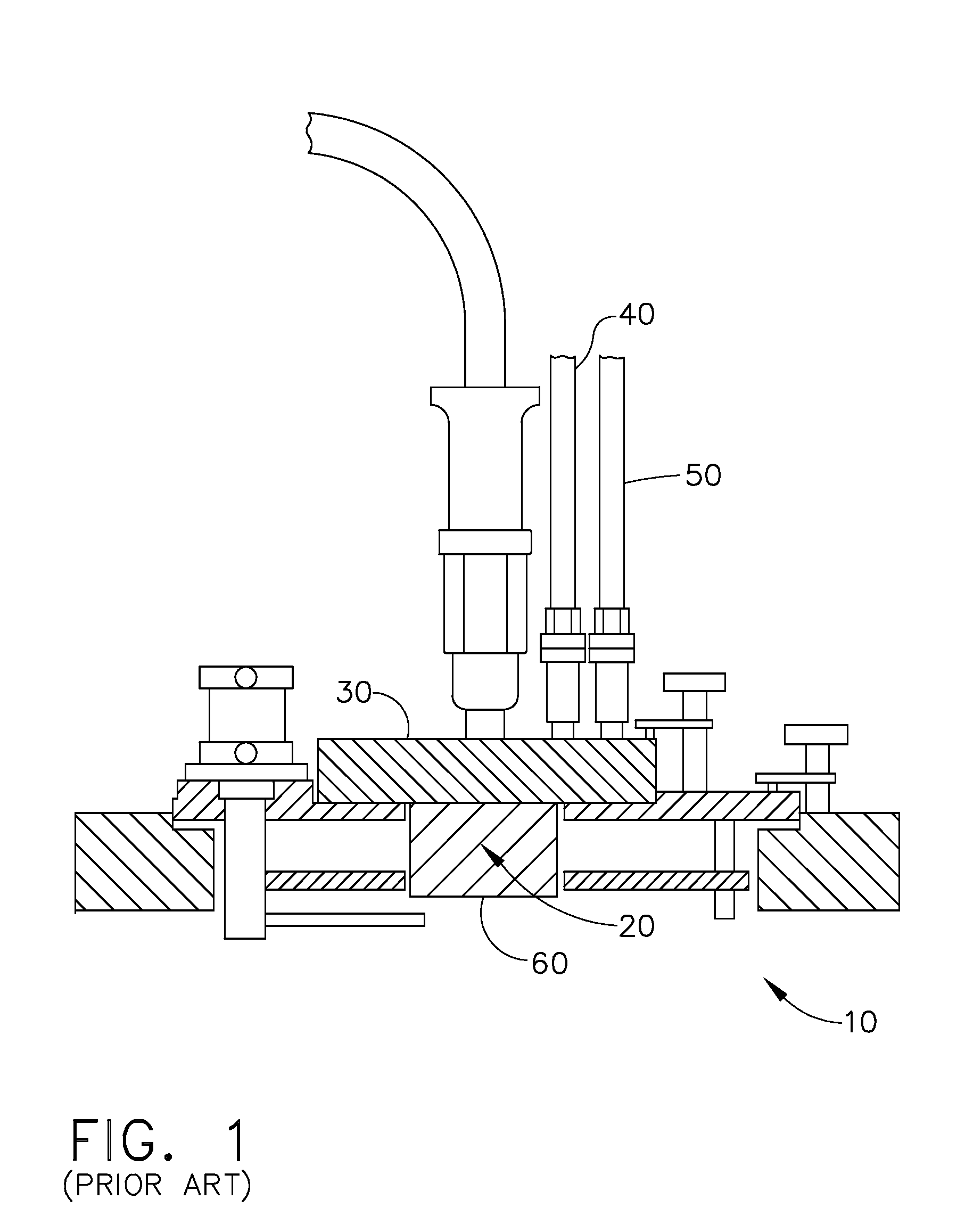

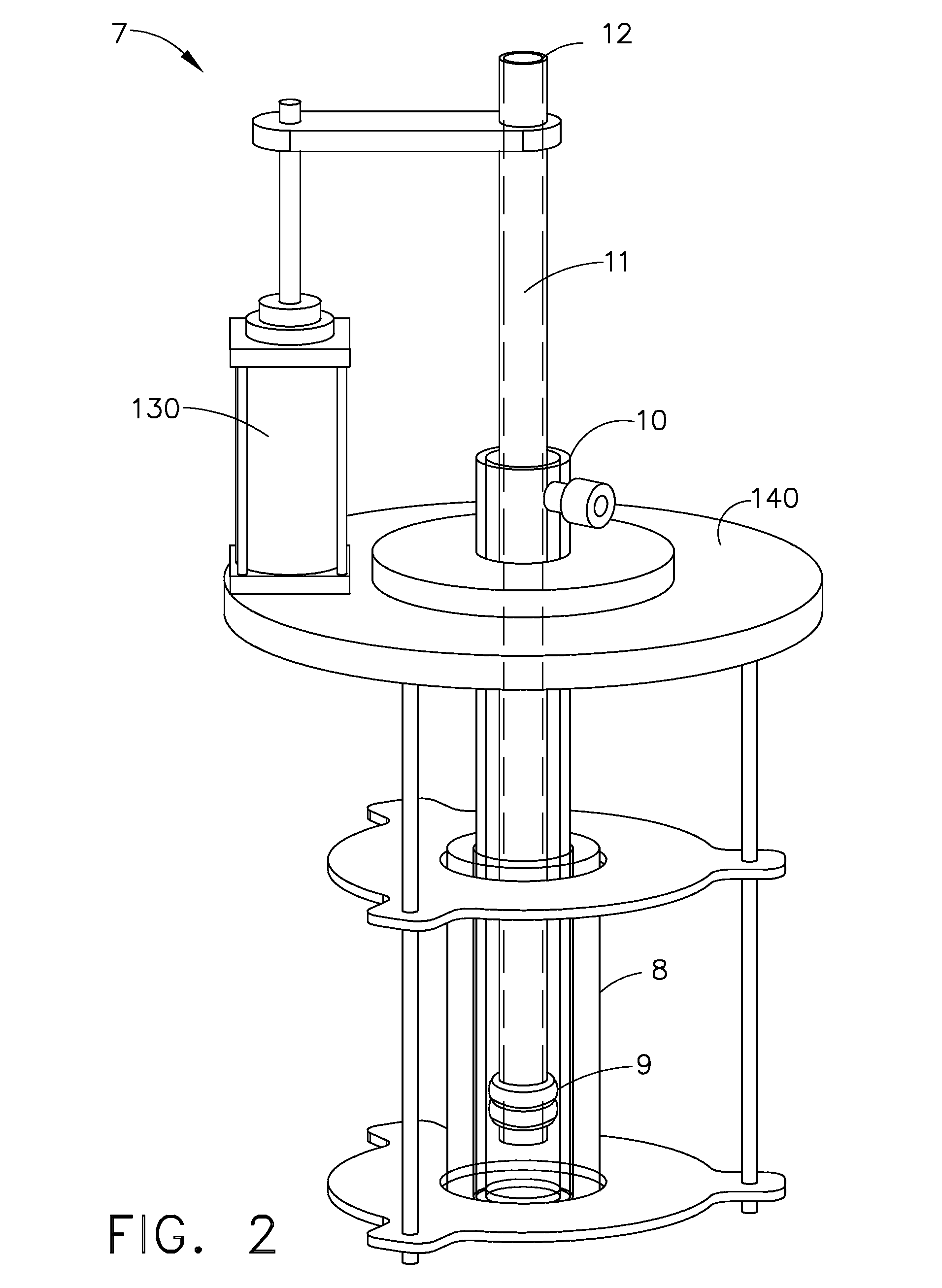

A method and apparatus for depositing a coating material on a surface of a substrate by an ion plasma deposition process using a hollow cathode is disclosed. The cathode may be a substantially cylindrical hollow cathode. A plasma arc is formed on the outer circumference of the cathode to remove coating material from the cathode, which is then deposited on a surface of a substrate. An internal arc drive magnet is contained within the hollow bore of the cathode and cooling is provided to the magnet during operation.

Owner:GENERAL ELECTRIC CO

Method of forming gate oxide having dual thickness by oxidation process

InactiveUS6124171ASemiconductor/solid-state device manufacturingSemiconductor devicesHydrogenSilanes

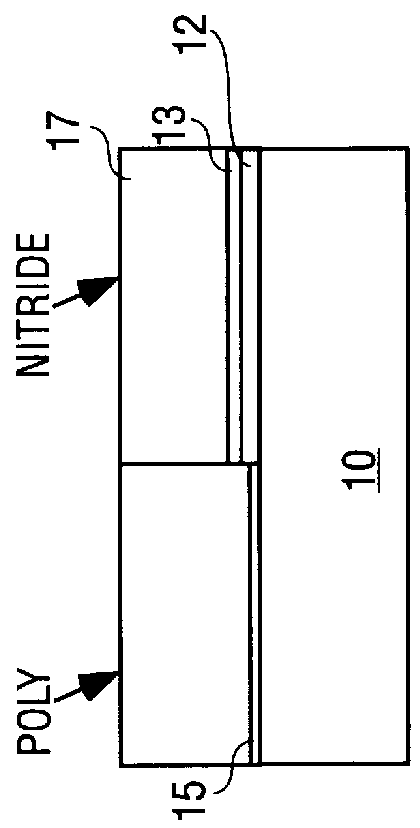

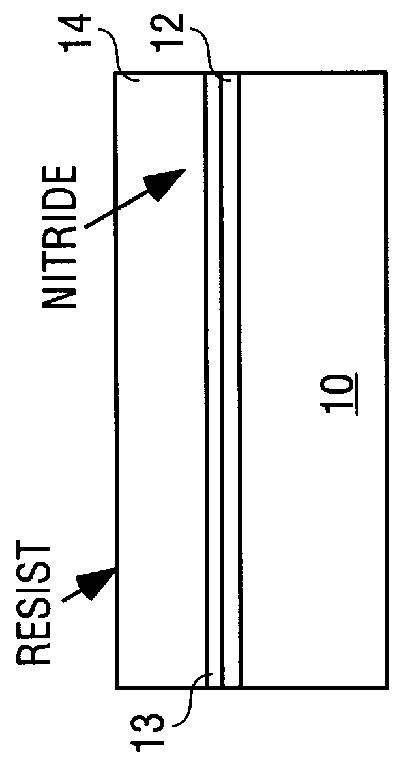

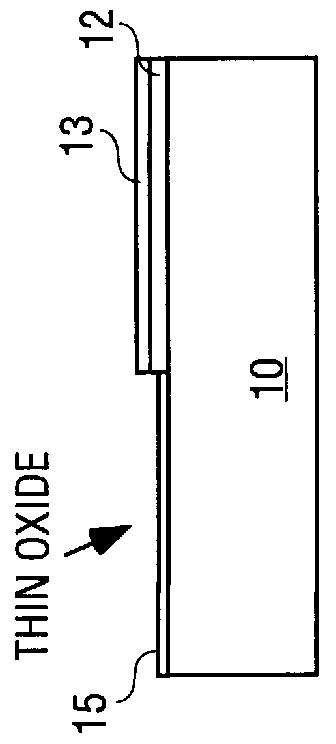

Transistors are formed on the substrate having two different thickness' of gate oxides. A silicon nitride mask is used to protect one of the gate oxides while the other is grown. A nitride mask is formed from a hydrogen balanced nitride layer formed using direct plasma deposited nitride with an ammonia and silane chemistry. In one embodiment the nitride mask remains in place in the completed transistor.

Owner:INTEL CORP

Radiopaque coatings for polymer substrates

InactiveUS20070178222A1Improve radiopacityImprove adhesionElectric discharge tubesPharmaceutical containersPolymeric surfacePolymer science

Improved radiopaque coatings particularly suitable for polymer substrates are described. A modified ion plasma deposition (IPD) method is used to provide coatings with macroparticle-dense surfaces that have excellent radiopacity. The coatings are particularly adapted to polymer surfaces because of high adherence and resistance to peeling and flaking.

Owner:NANOSURFACE TECH

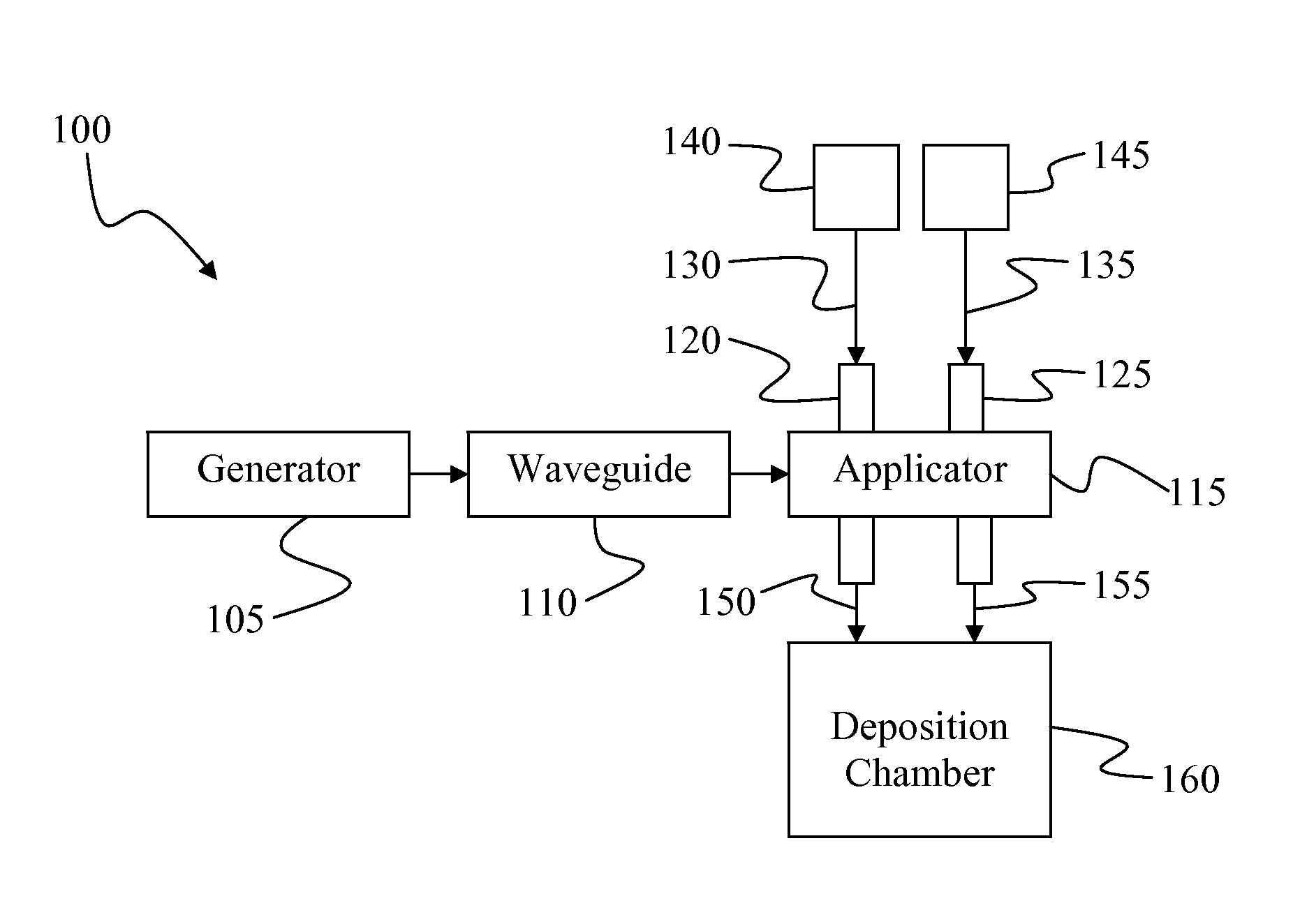

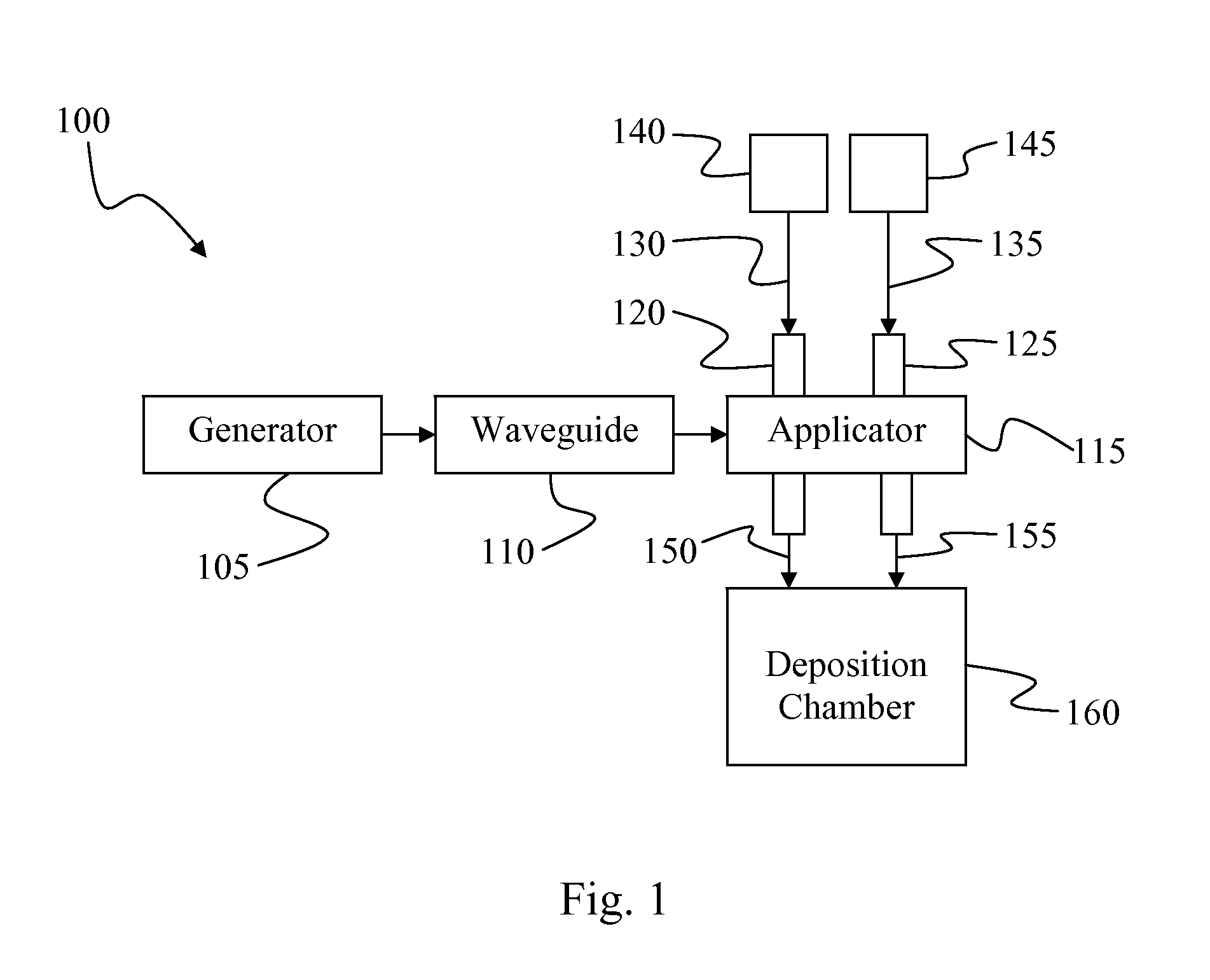

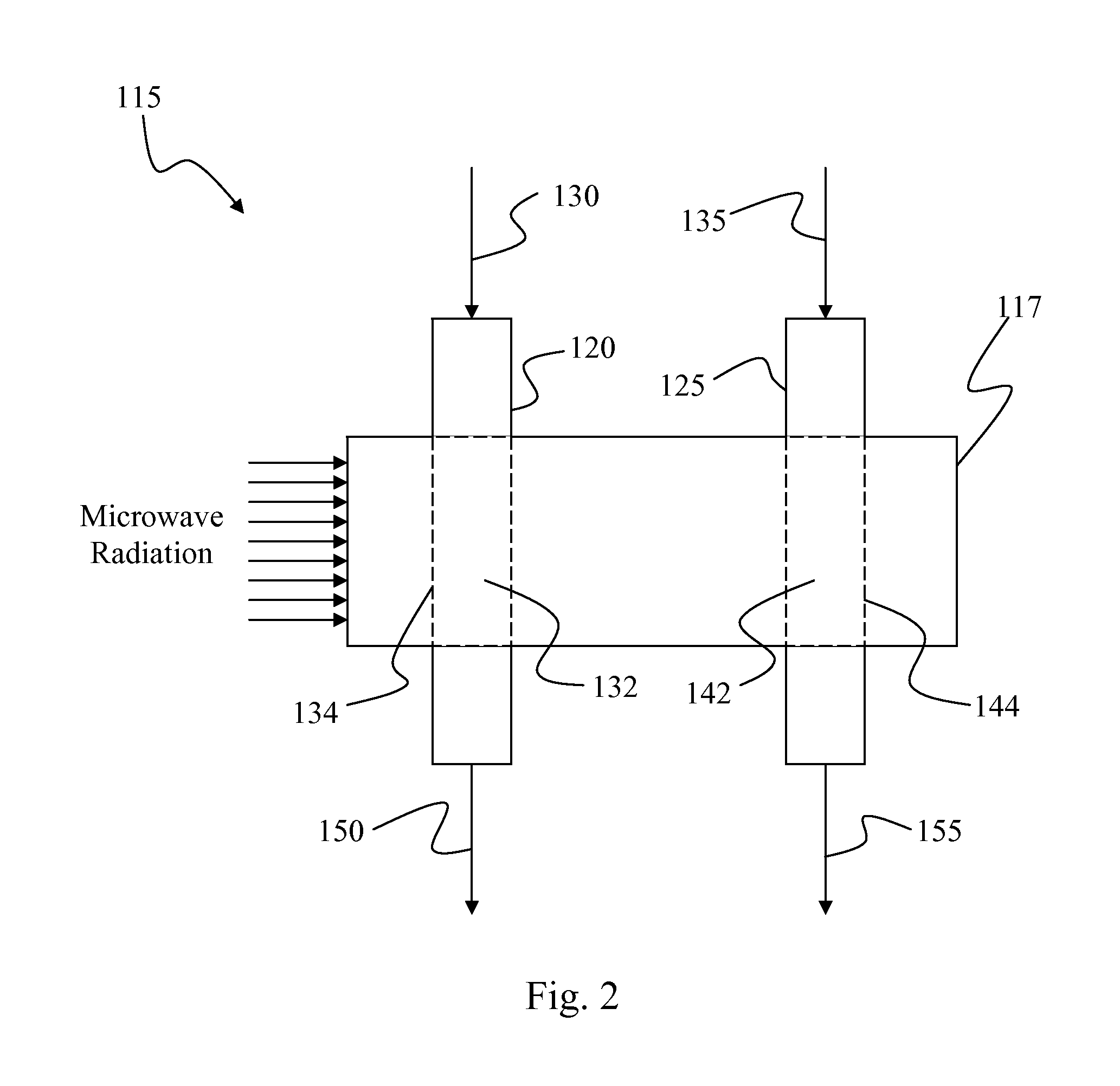

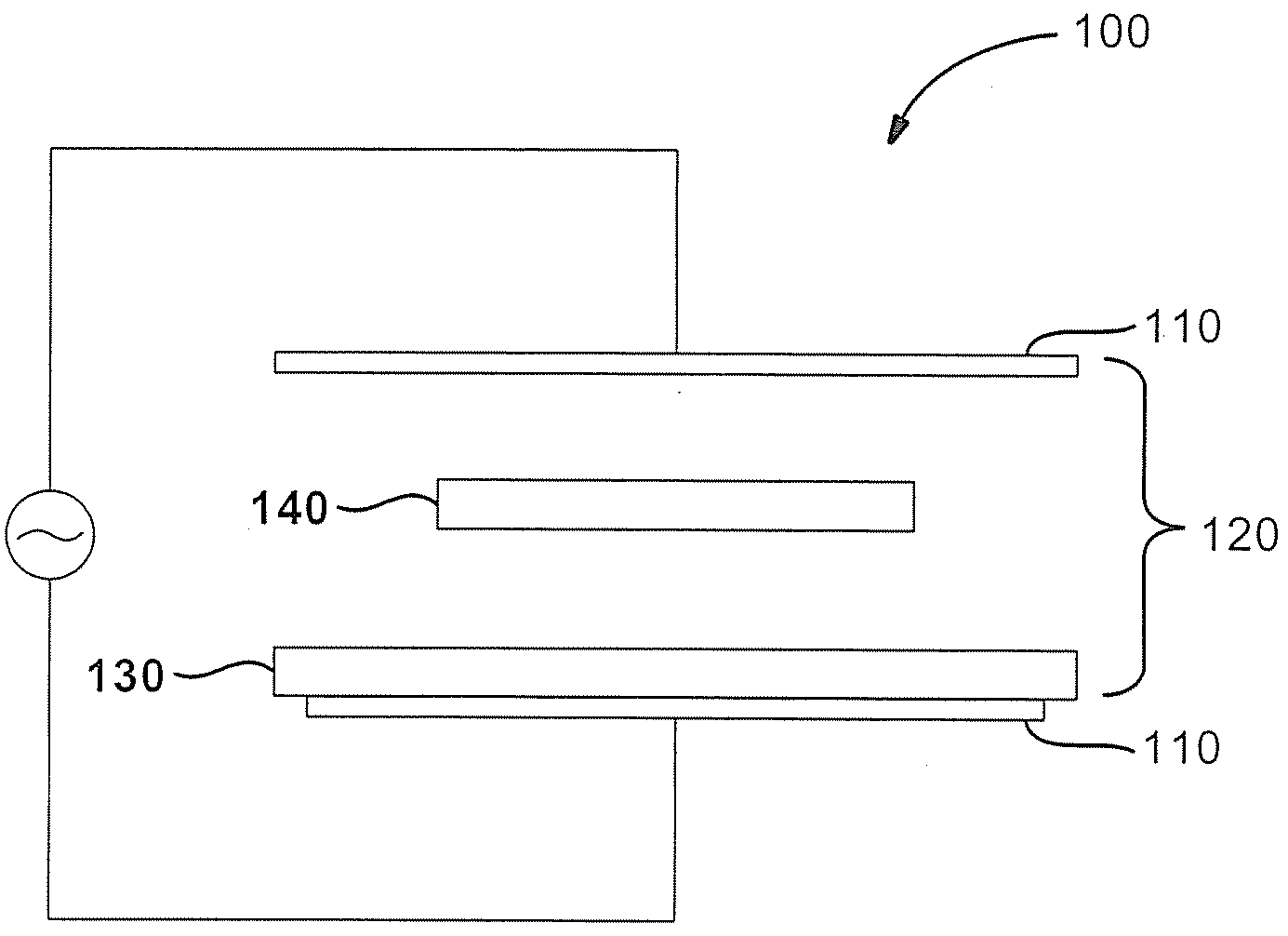

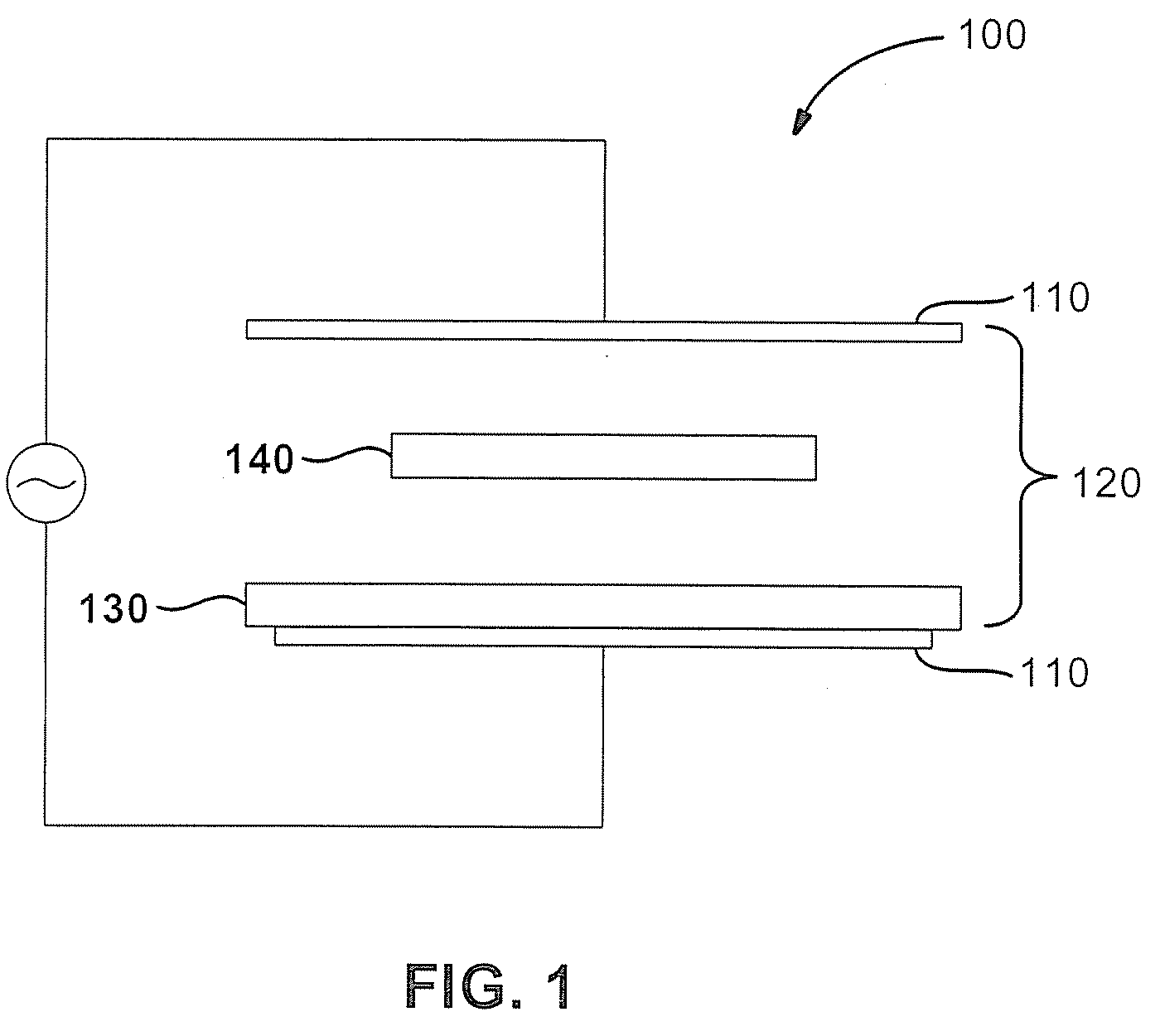

Plasma Deposition of Amorphous Semiconductors at Microwave Frequencies

InactiveUS20120040492A1Prevent and slow relaxationPrevent and slow and decayElectric discharge tubesFinal product manufacturePorosityPlasma deposition

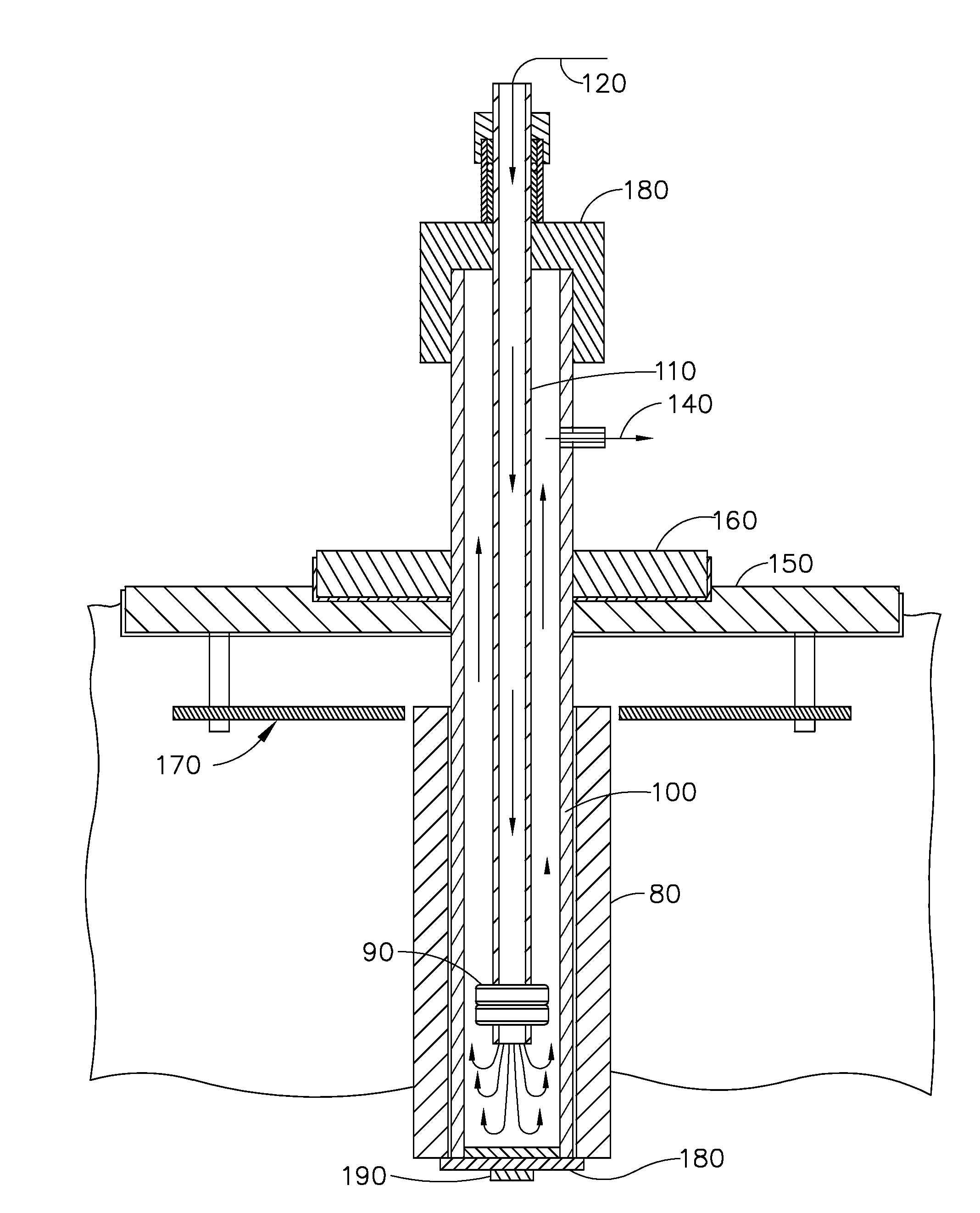

Apparatus and method for plasma deposition of thin film photovoltaic materials at microwave frequencies. The apparatus avoids unintended deposition on windows or other microwave transmission elements that couple microwave energy to deposition species. The apparatus includes a microwave applicator with conduits passing therethrough that carry deposition species. The applicator transfers microwave energy to the deposition species to activate or energize them to a reactive state conducive to formation of a thin film material. The conduits physically isolate deposition species that would react or otherwise combine to form a thin film material at the point of microwave power transfer. The deposition species are separately energized and swept away from the point of power transfer to prevent thin film deposition. Suitable deposition species include precursors that contain silicon, germanium, fluorine, and / or hydrogen. The invention allows for the ultrafast formation of silicon-containing amorphous semiconductors that exhibit high mobility, low porosity, little or no Staebler-Wronski degradation, and low defect concentration.

Owner:OVSHINSKY TECH

Biocompatible Coated Nanostructured Titanium Surfaces

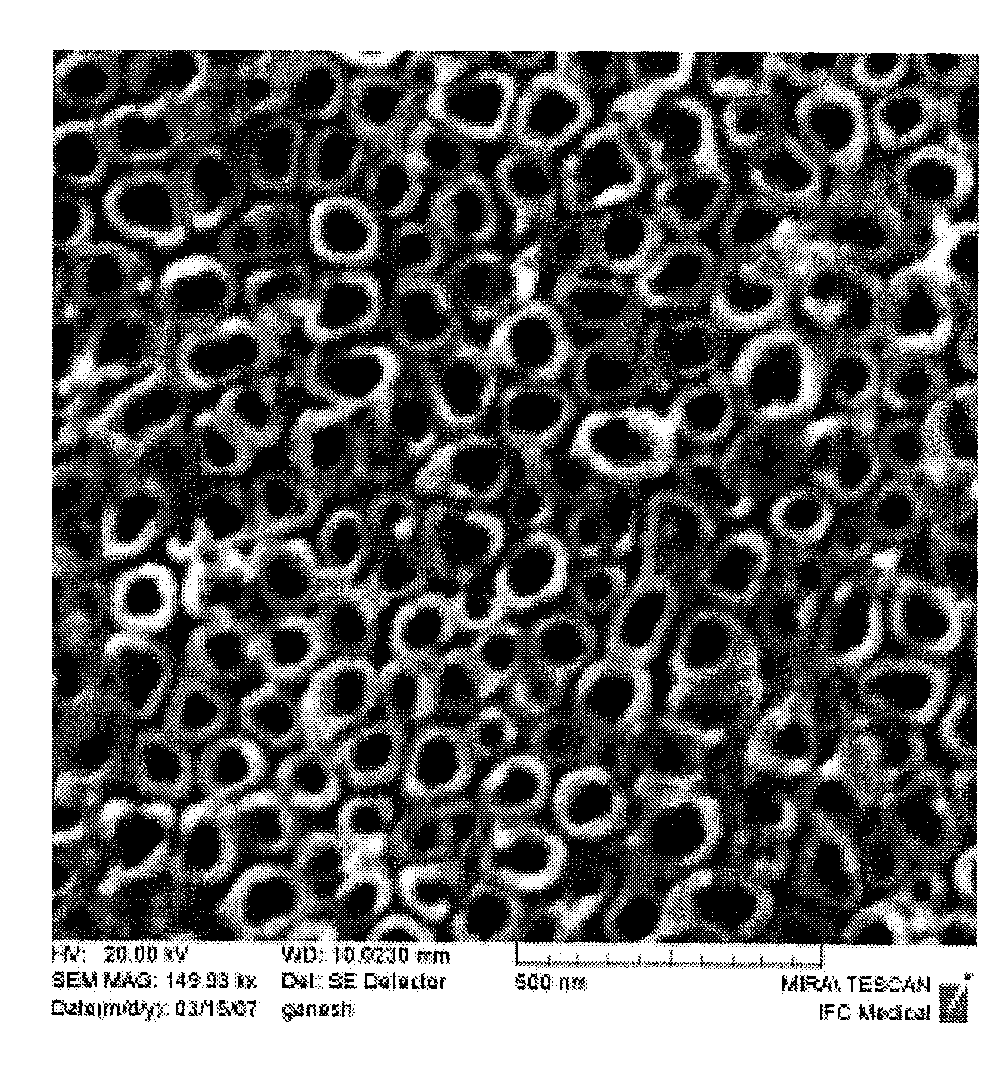

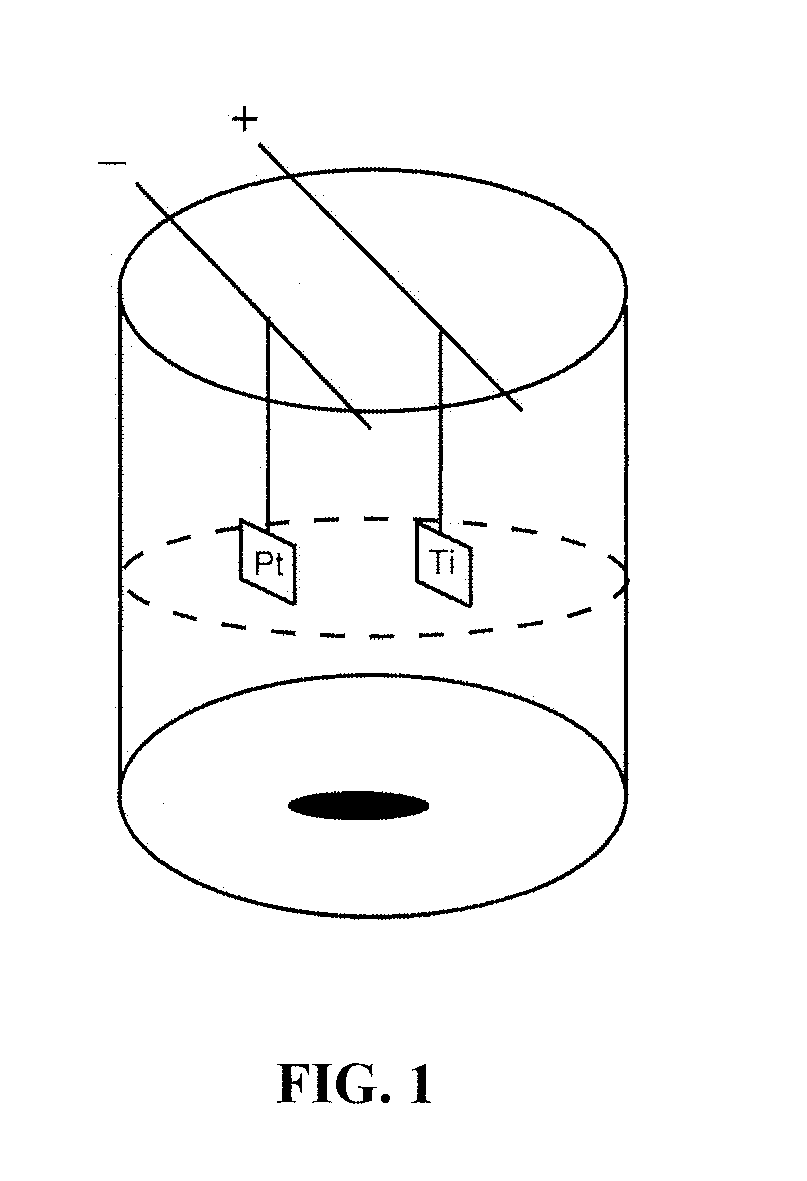

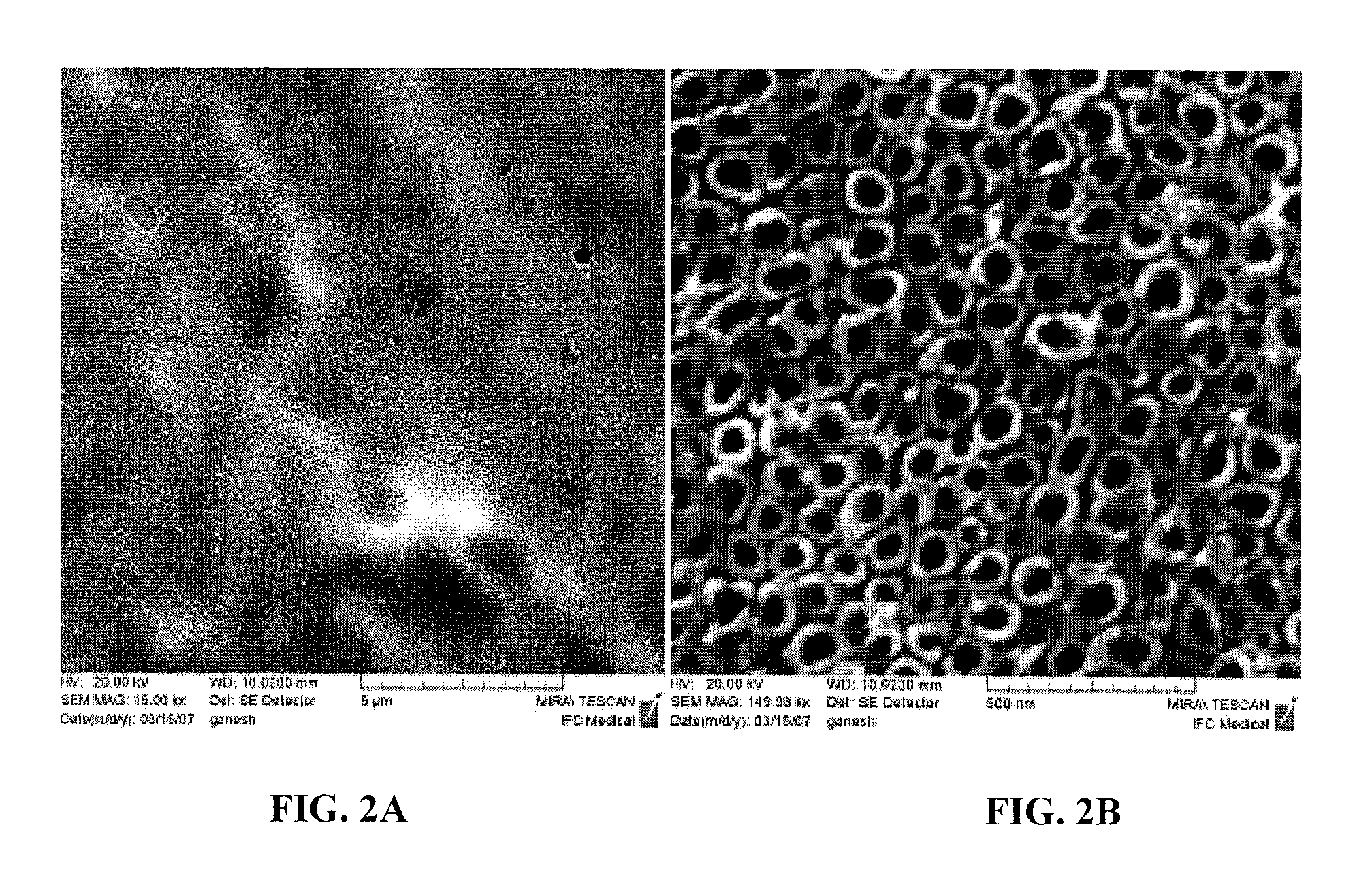

InactiveUS20100028387A1Promote bone growthStrong cell adhesionBiocideTetrapeptide ingredientsNano sizeCell adhesion

Bioactive molecules have been coated on nanotubular structured titanium substrates by molecular plasma deposition. The coatings promote cell adhesion and are particularly suited for orthopedic implants that provide improved bone cell adhesion and new tissue growth. Nanodimensional features on titanium substrates are engineered using electrochemical anodization techniques. The nanostructured surfaces provide superior support for a wide selection of polypeptide coatings.

Owner:METASCAPE

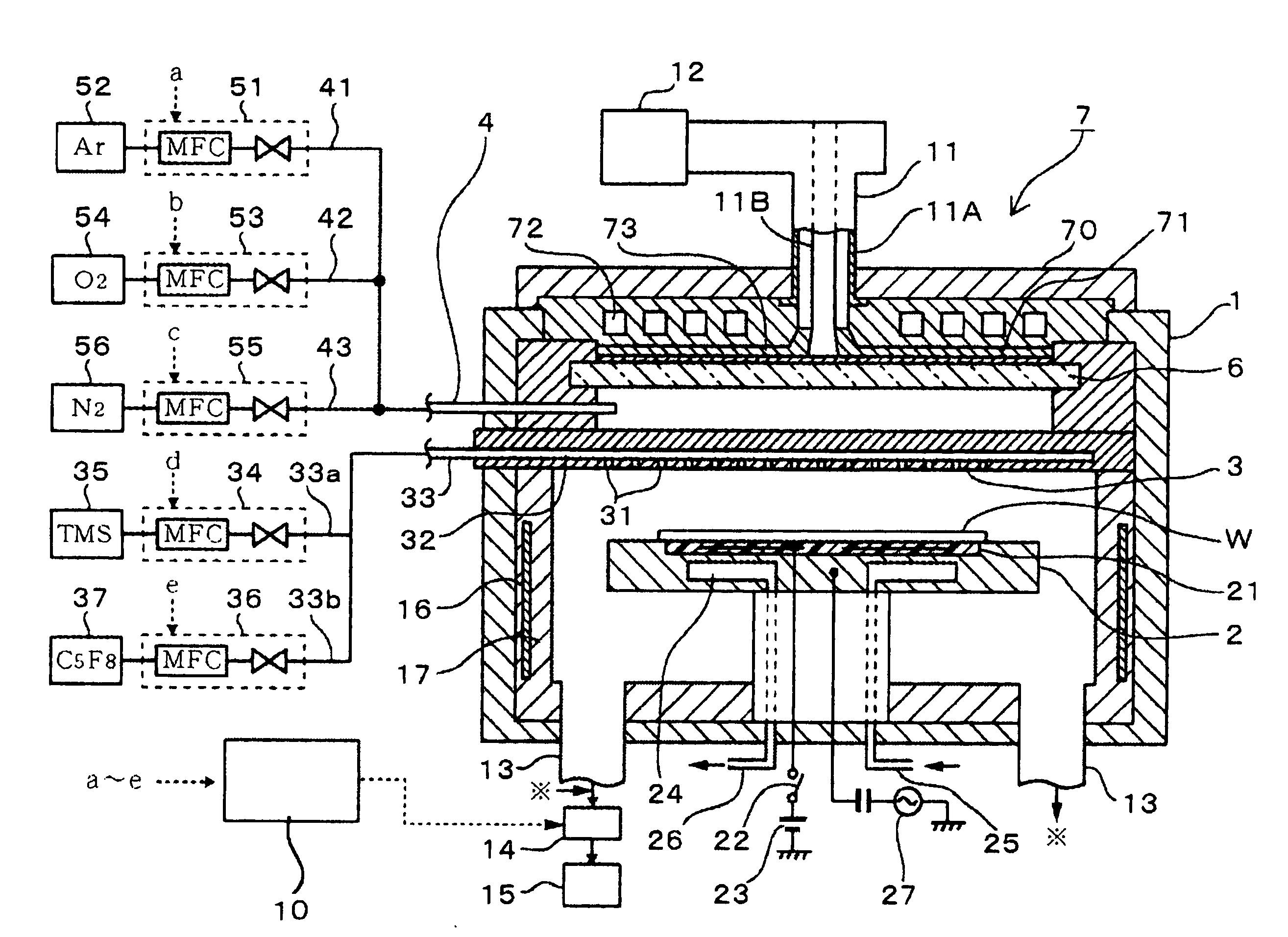

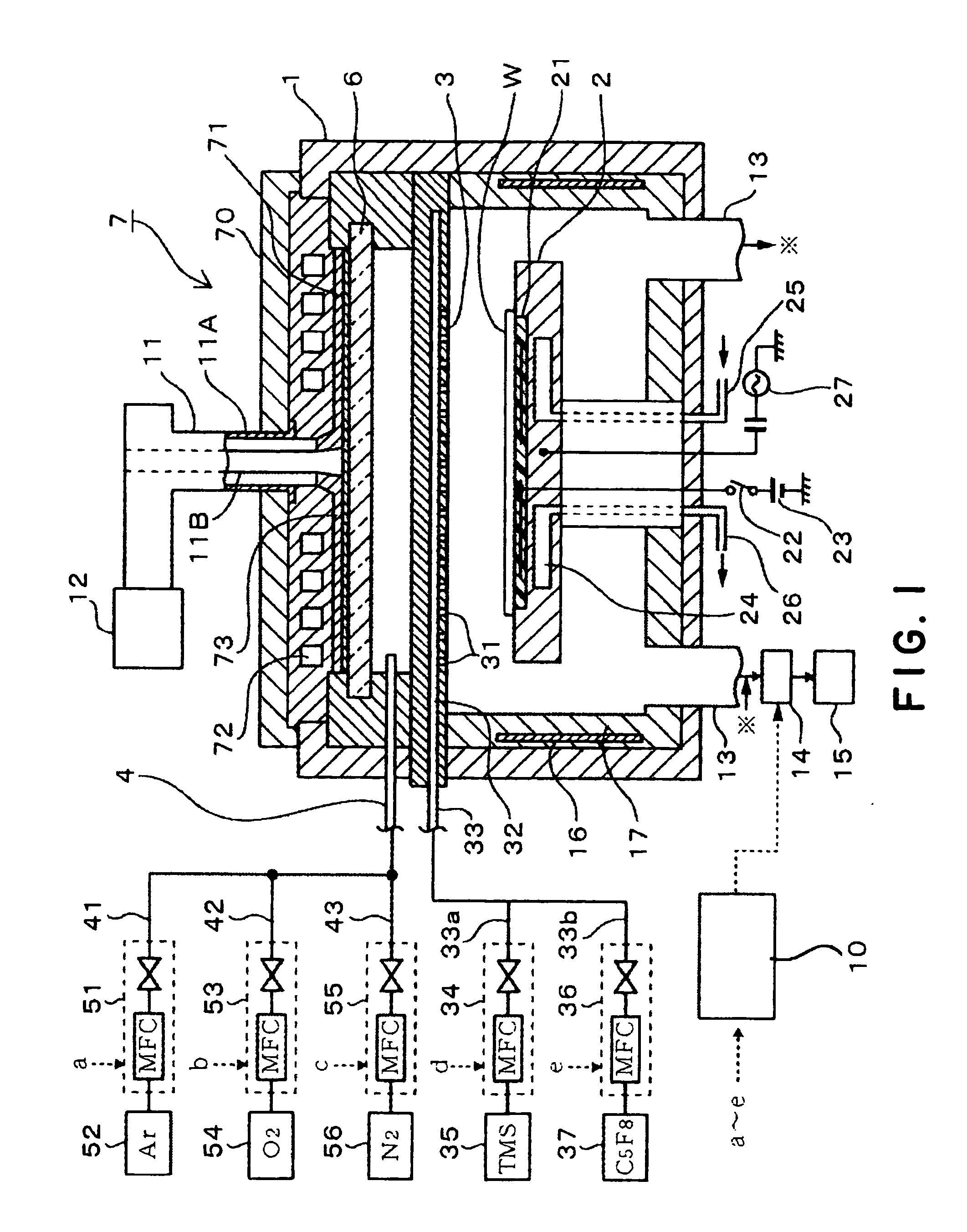

Manufacturing Method Of Semiconductor Device And Film Deposition System

InactiveUS20080254641A1Improve adhesionSemiconductor/solid-state device manufacturingChemical vapor deposition coatingDielectricNitrogen

A dielectric film (91) made of CF is deposited on a substrate. A protective layer comprising an SiCN film (93) is formed on the dielectric film (91). A film (94) serving as a hardmask made of SiCO is deposited on the protective layer by a plasma containing active species of silicon, carbon, and oxygen. When the protective layer is formed, an SiC film (92) is deposited on the dielectric film (91) by a plasma containing active species of silicon and carbon, and thereafter the SiCN film (93) is deposited on the SiC film (92) by a plasma containing active species of silicon, carbon, and nitrogen.

Owner:TOKYO ELECTRON LTD

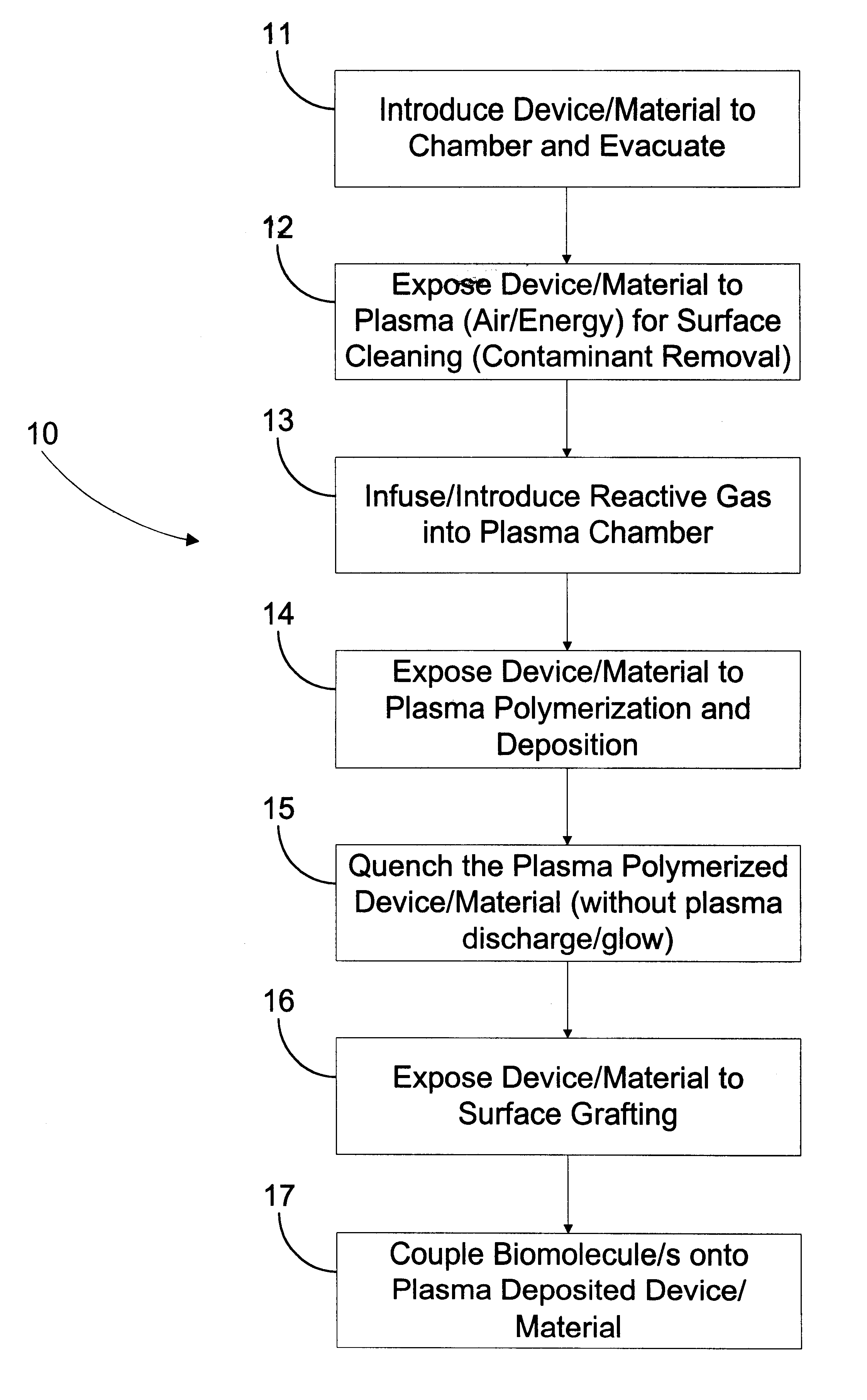

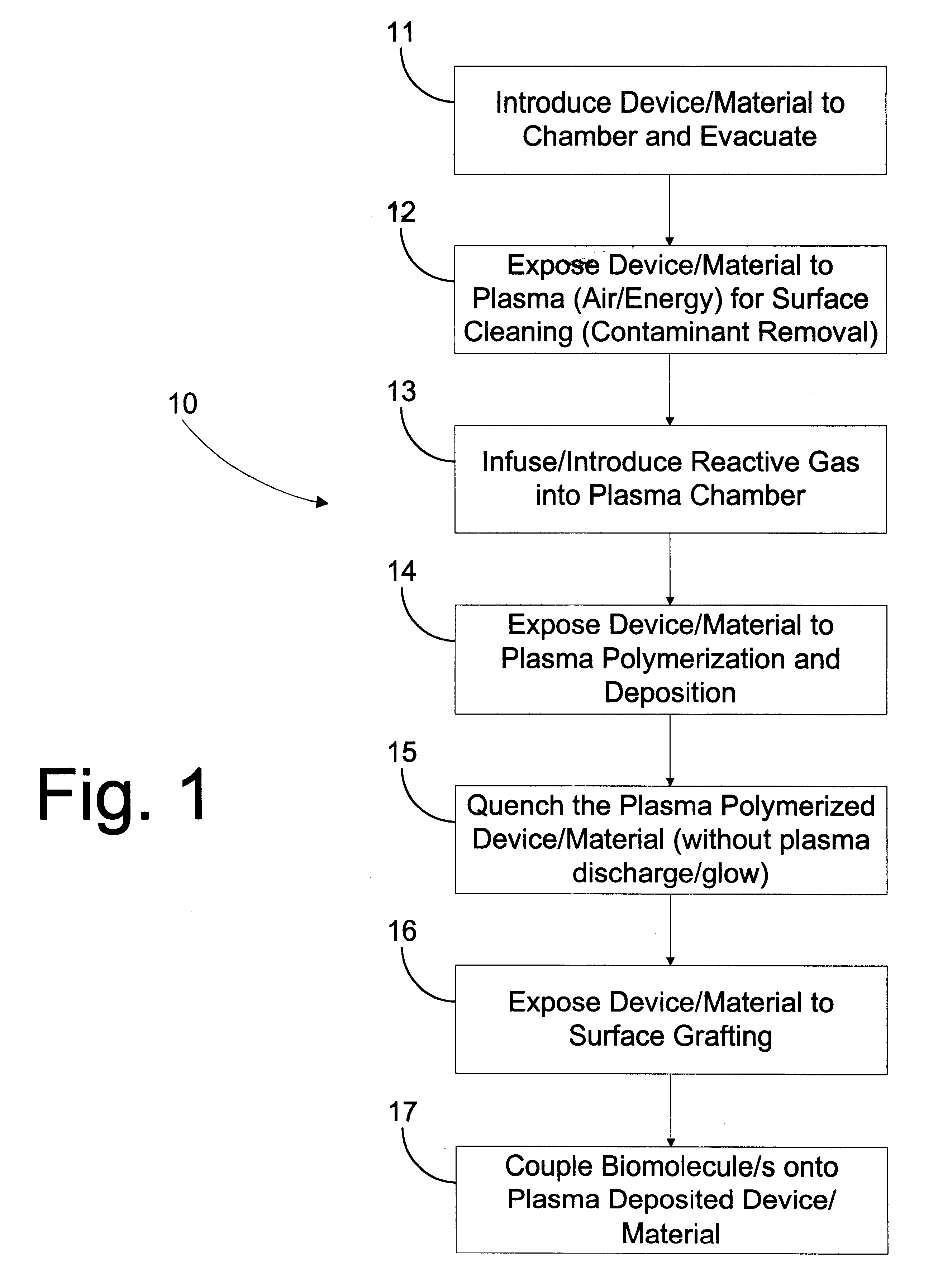

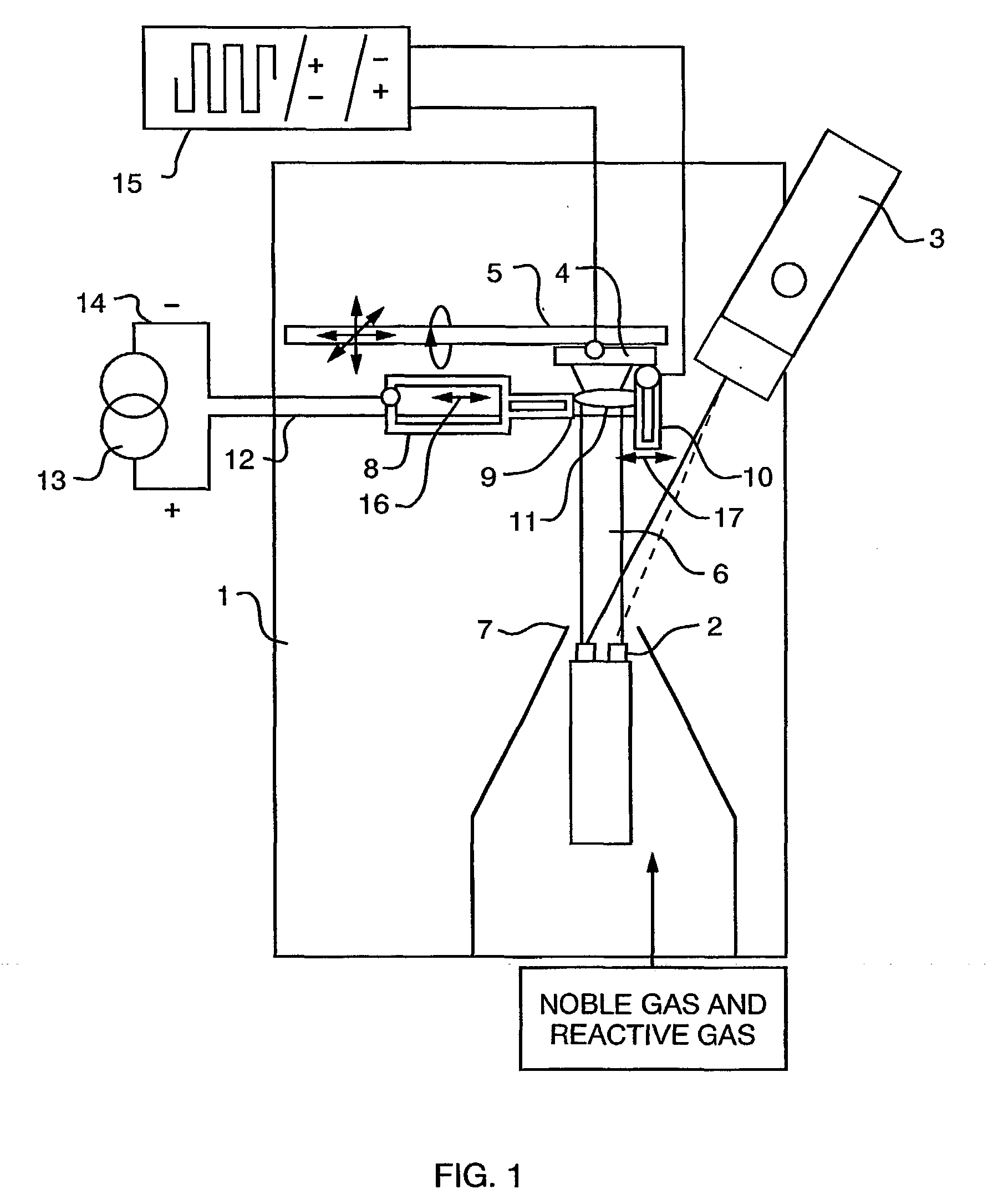

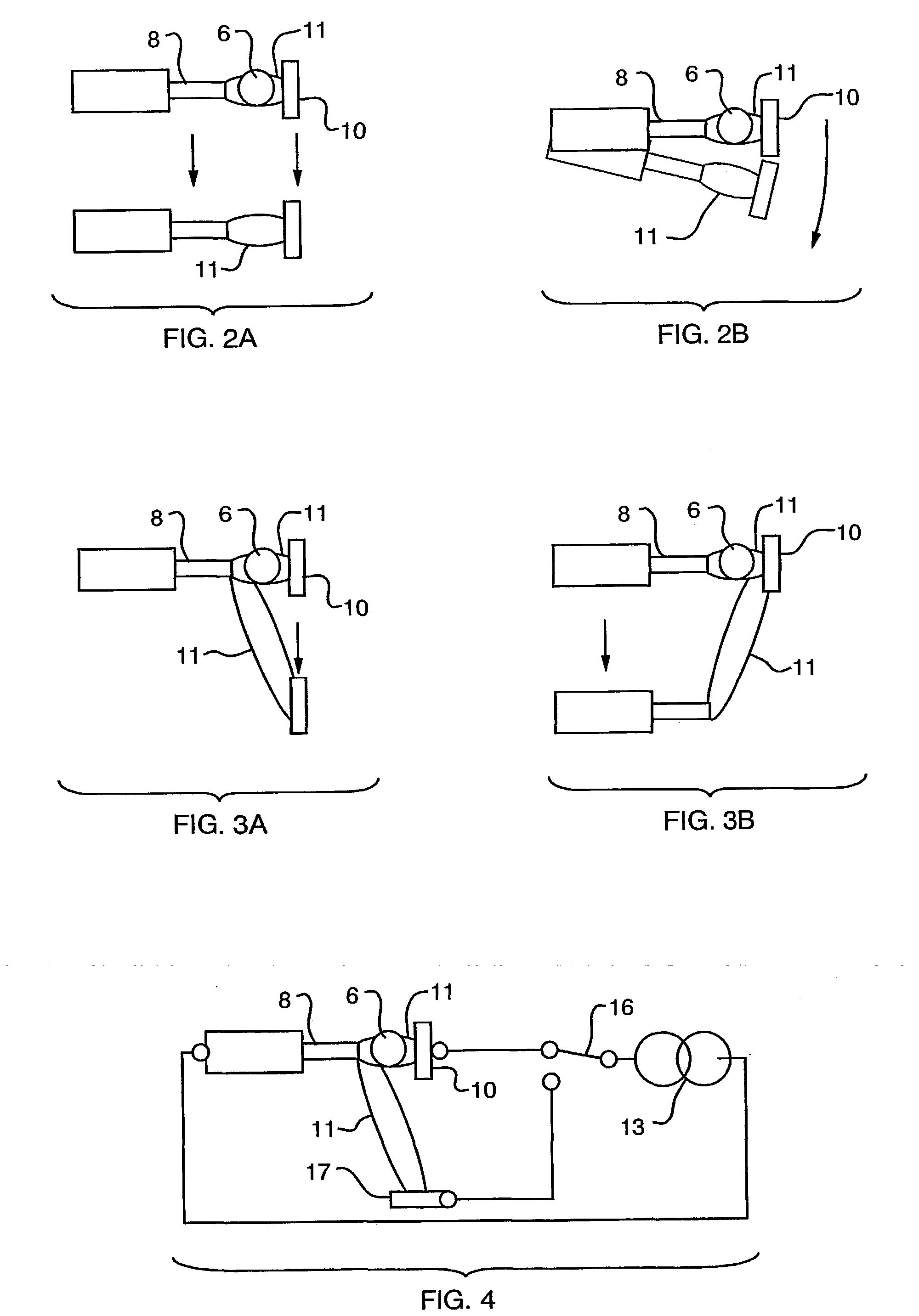

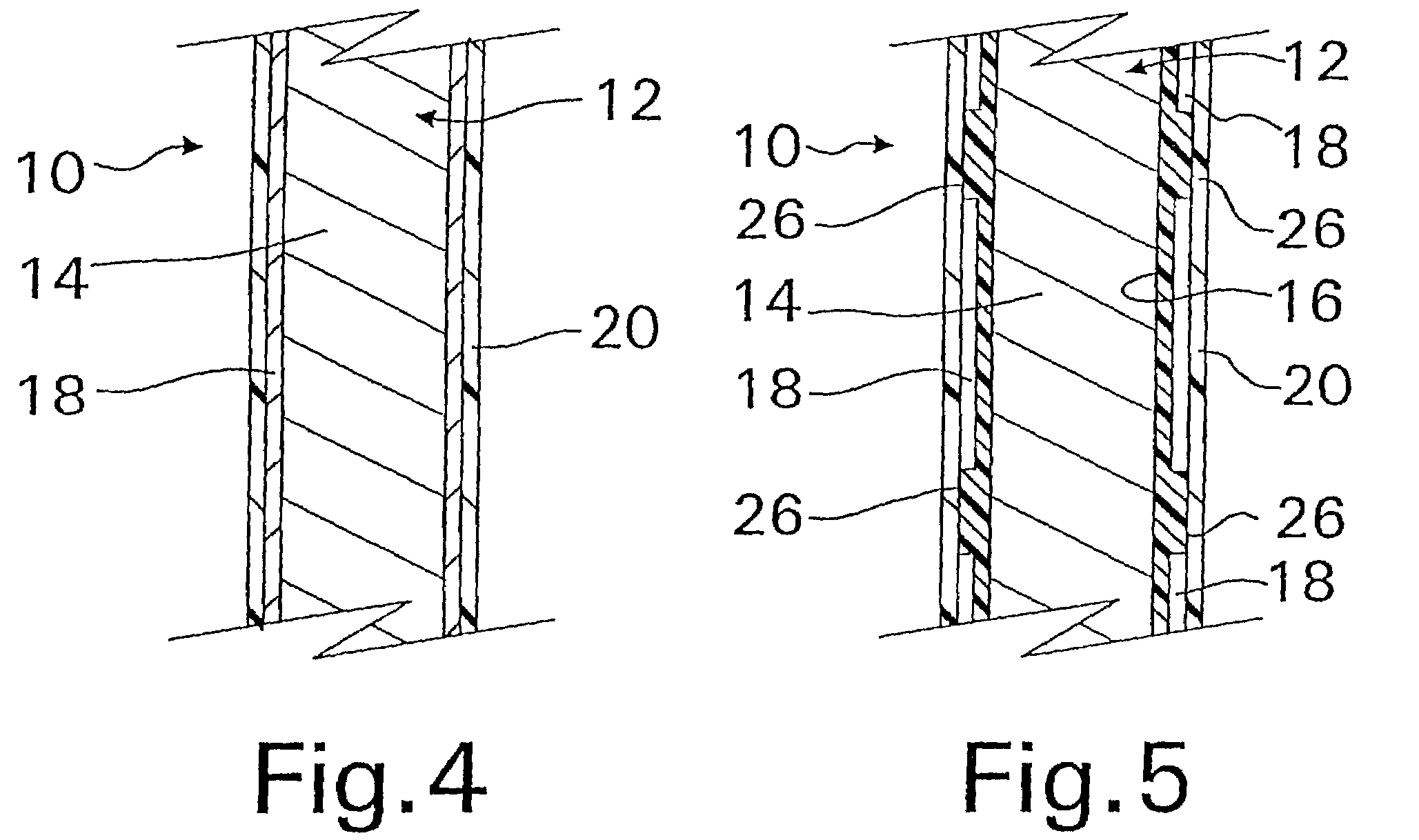

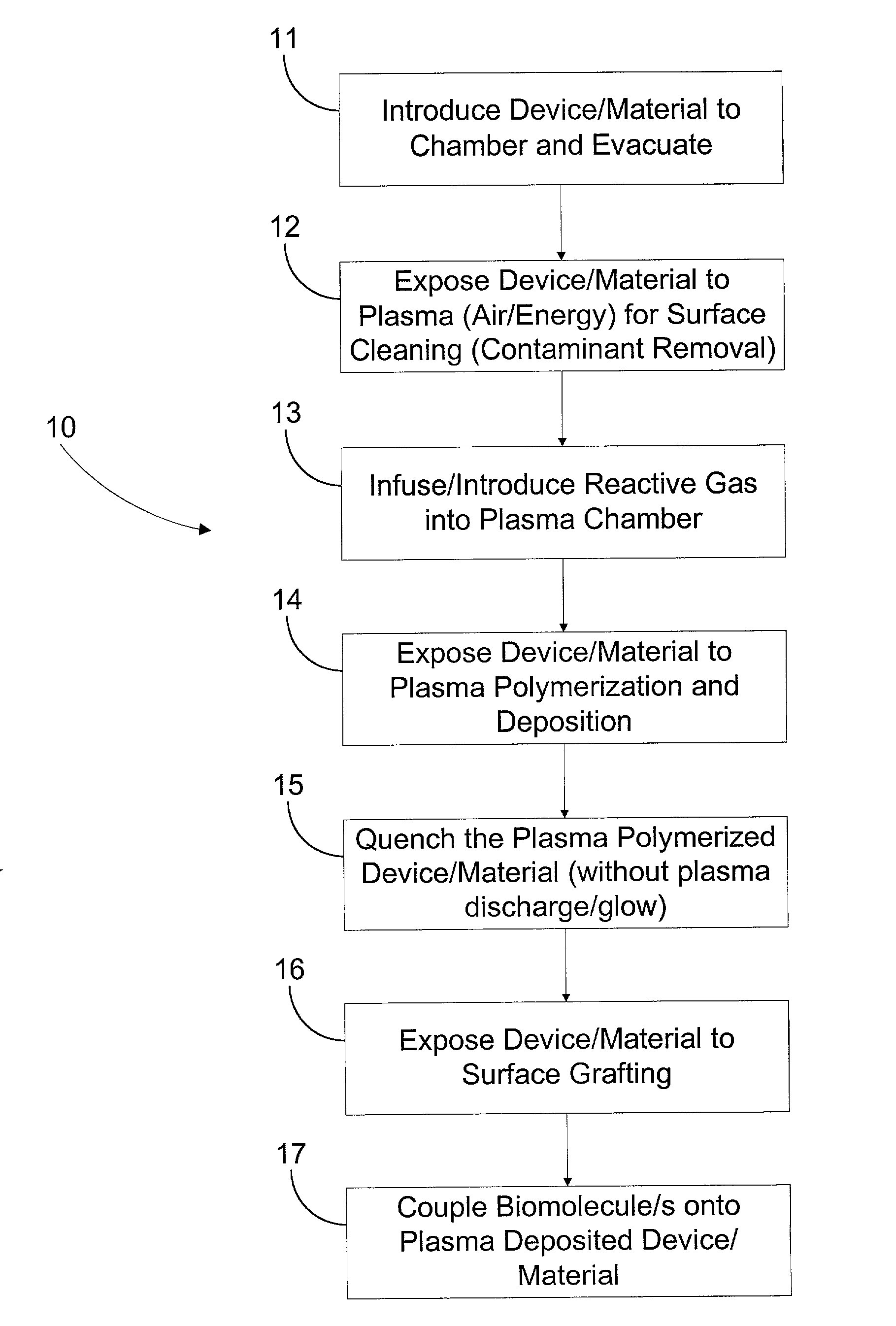

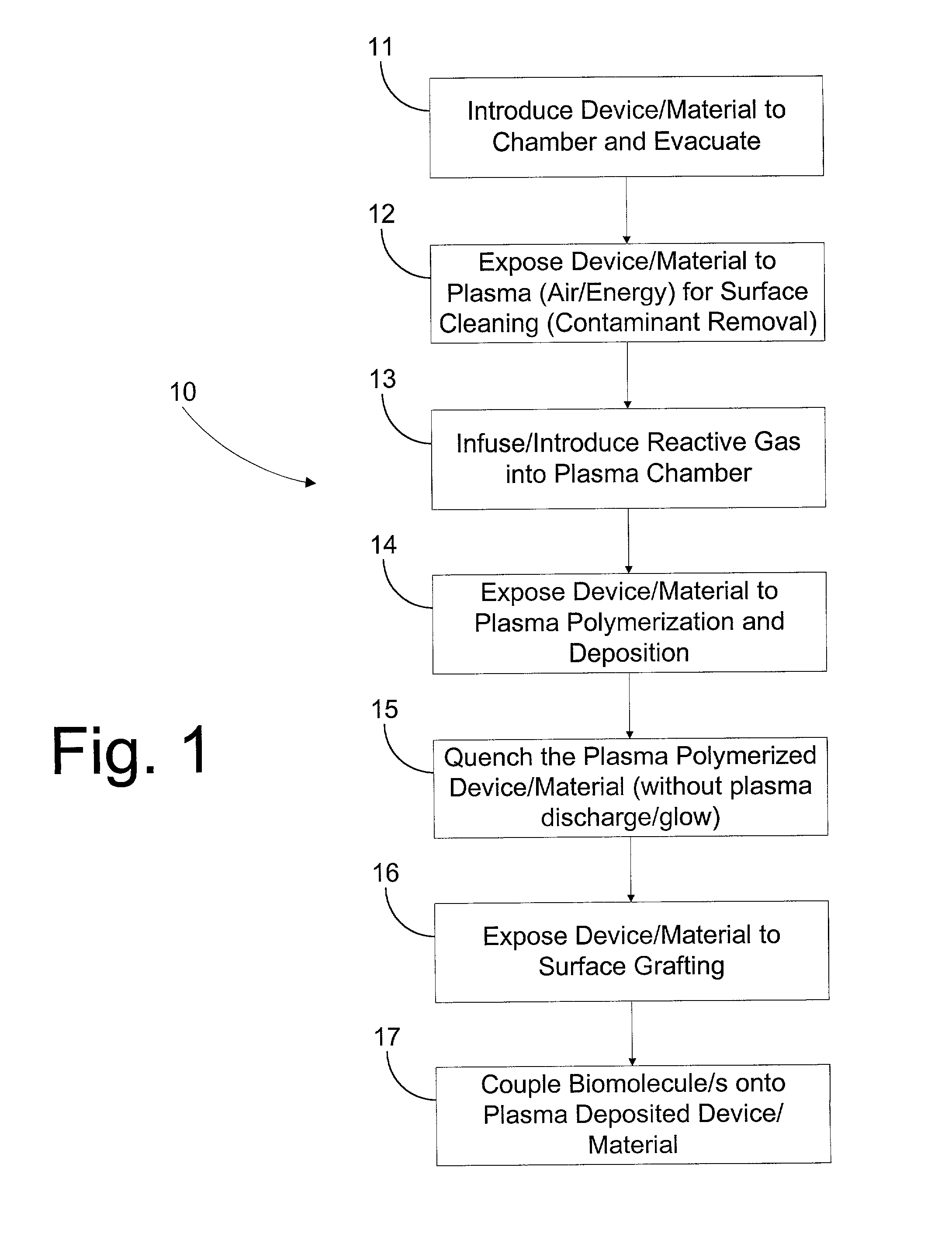

Methods for surface modification

InactiveUS6632470B2Uniform applicationAffecting its functionGlovesSurgeryReactive gasPlasma deposition

A method of modifying surfaces of a device, for example, a medical device, is disclosed. The method includes modifying a surface of a device by providing a device, exposing the device to a reactive gas and plasma energy to create a plasma deposited surface on the device, and quenching the device with the reactive gas. The device exhibits changes in its surface properties thereby making it more desirable for an intended use.< / PTEXT>

Owner:HORIZON TECH FUNDING CO LLC

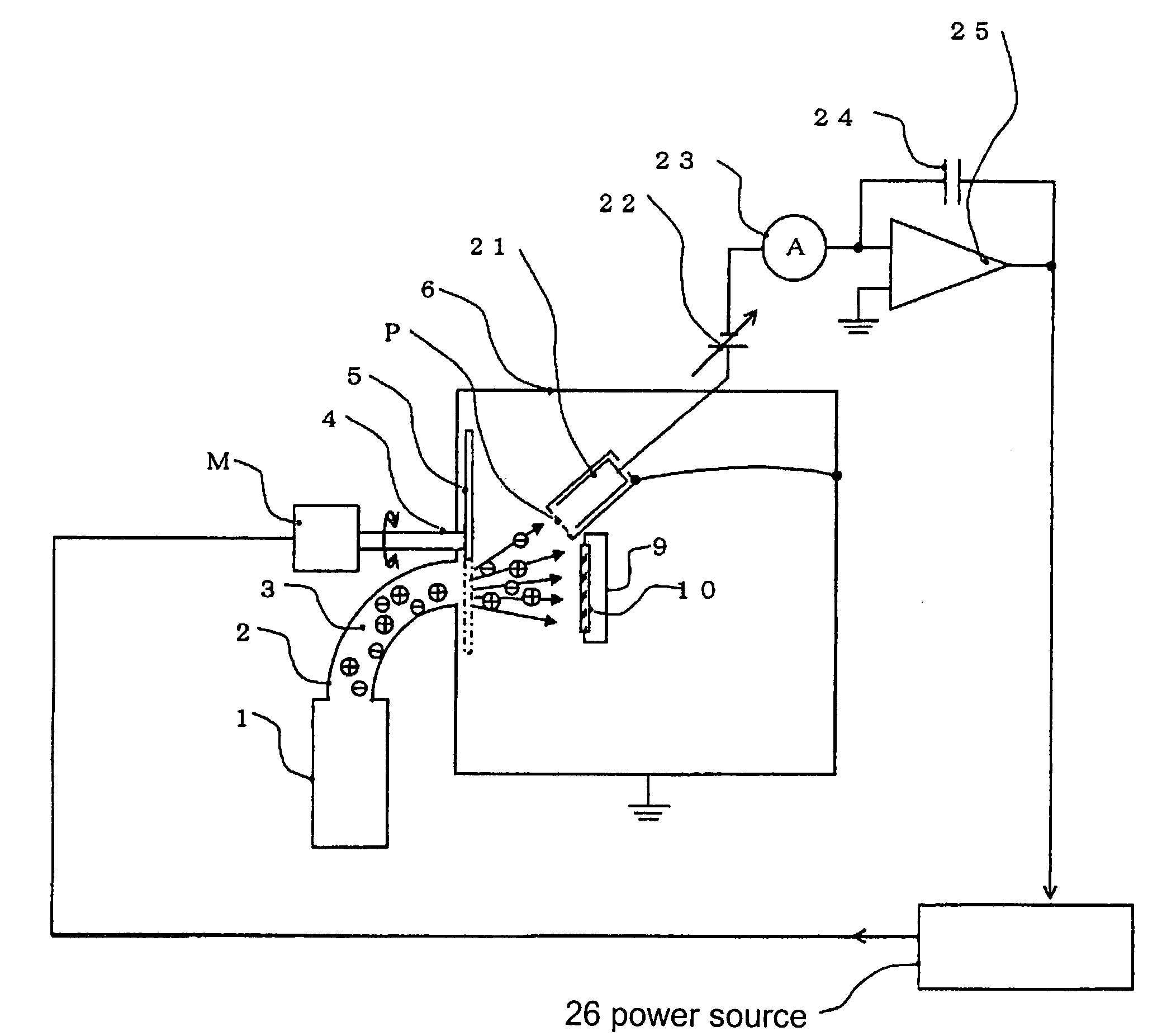

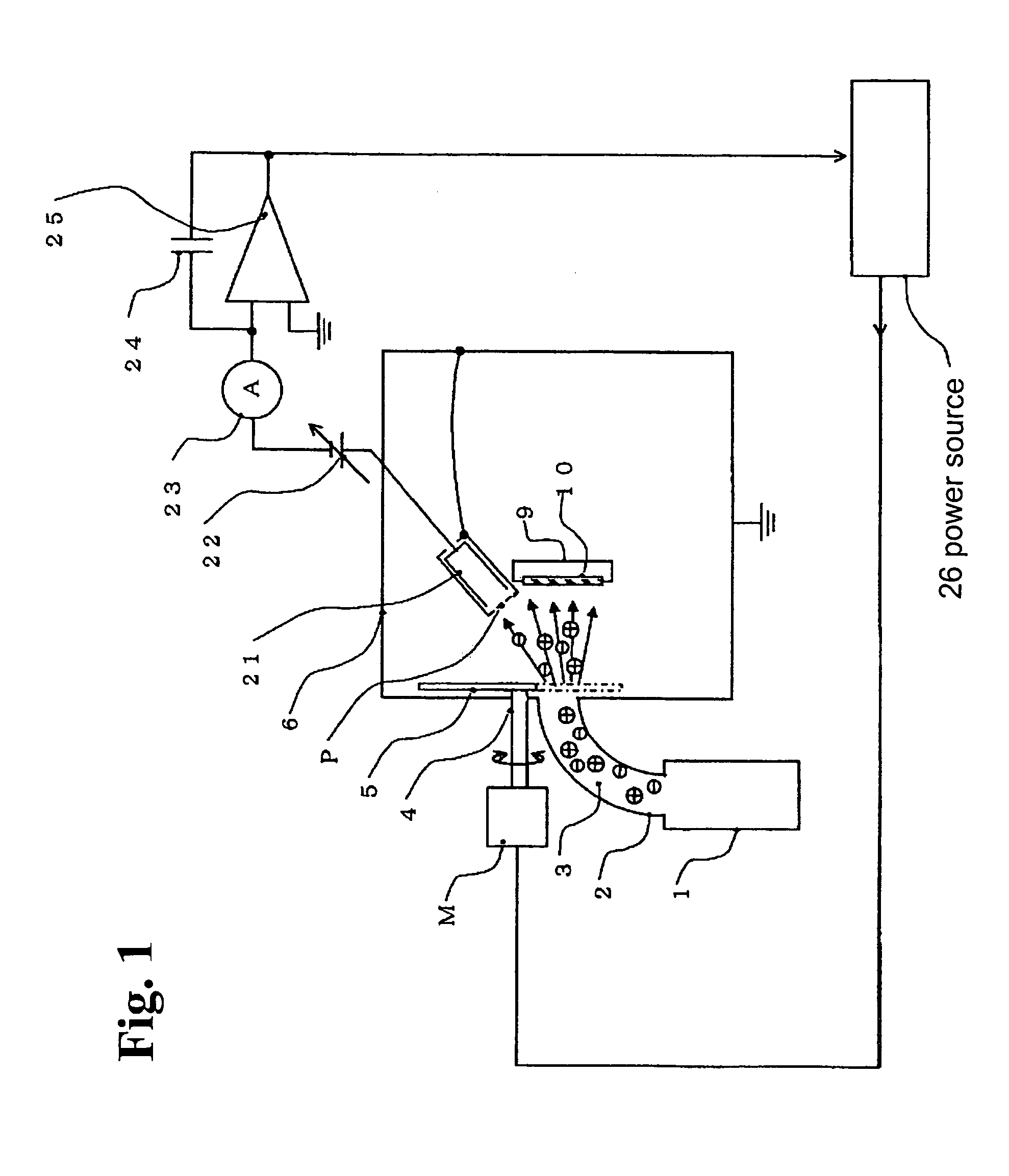

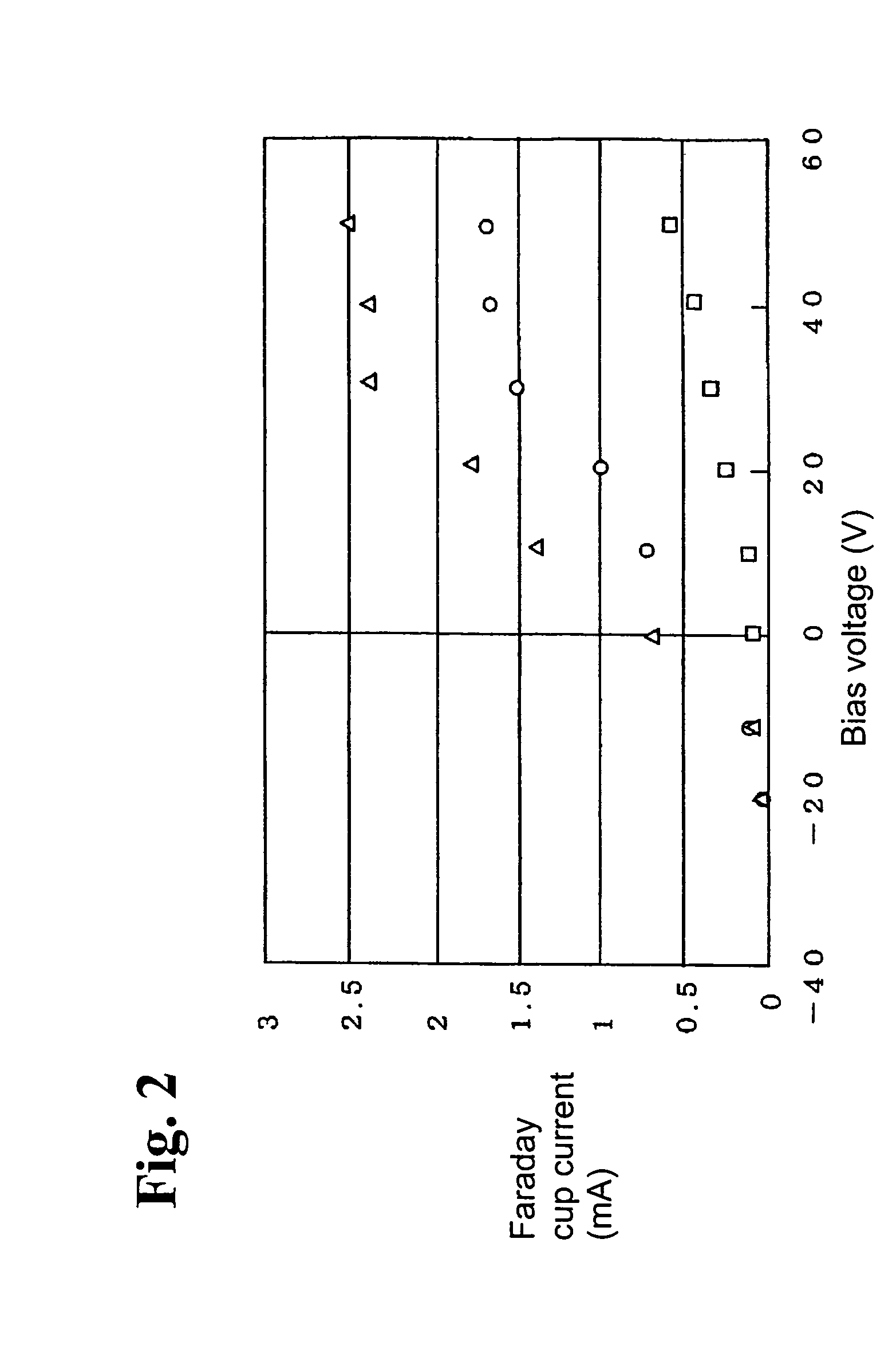

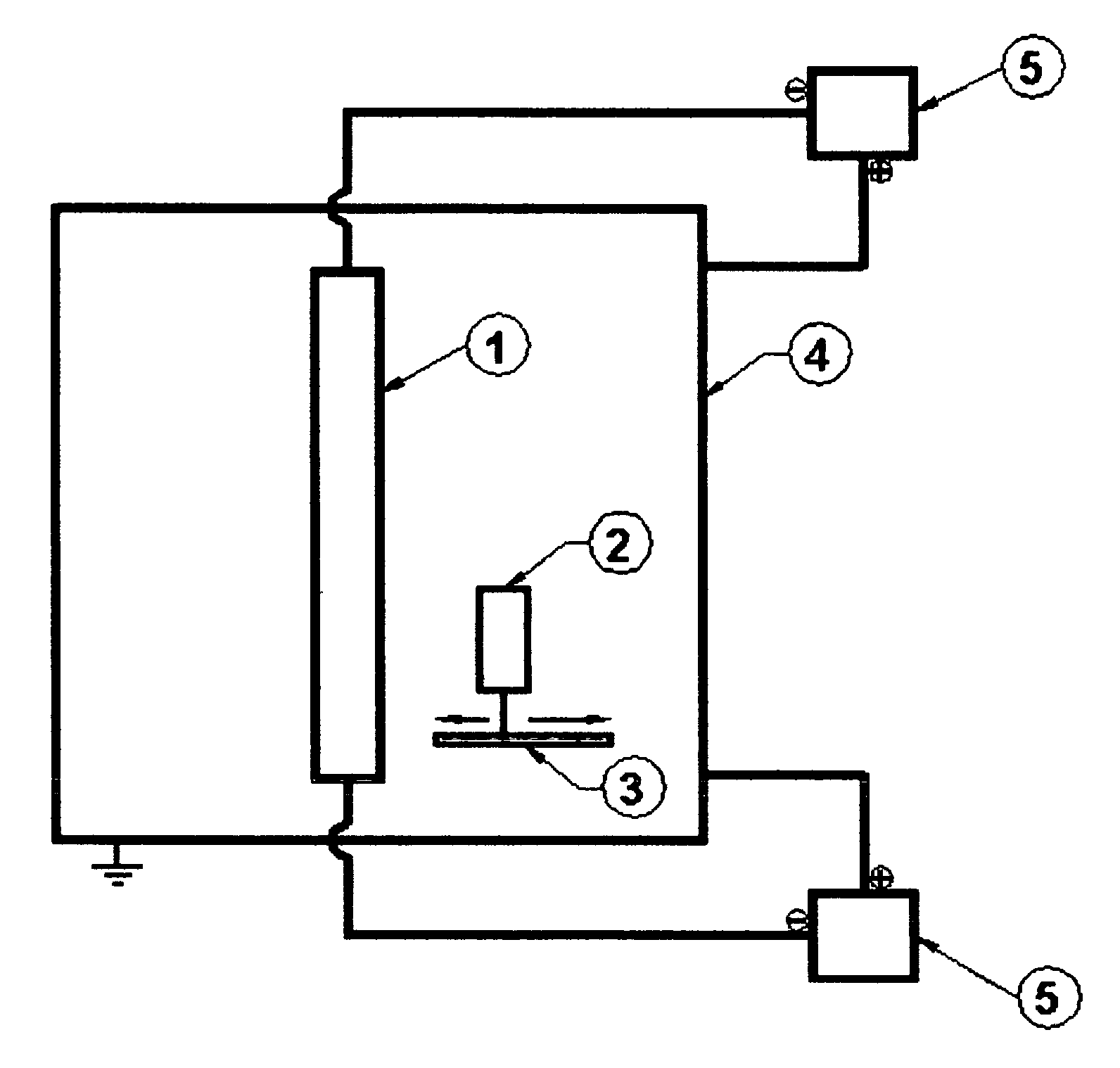

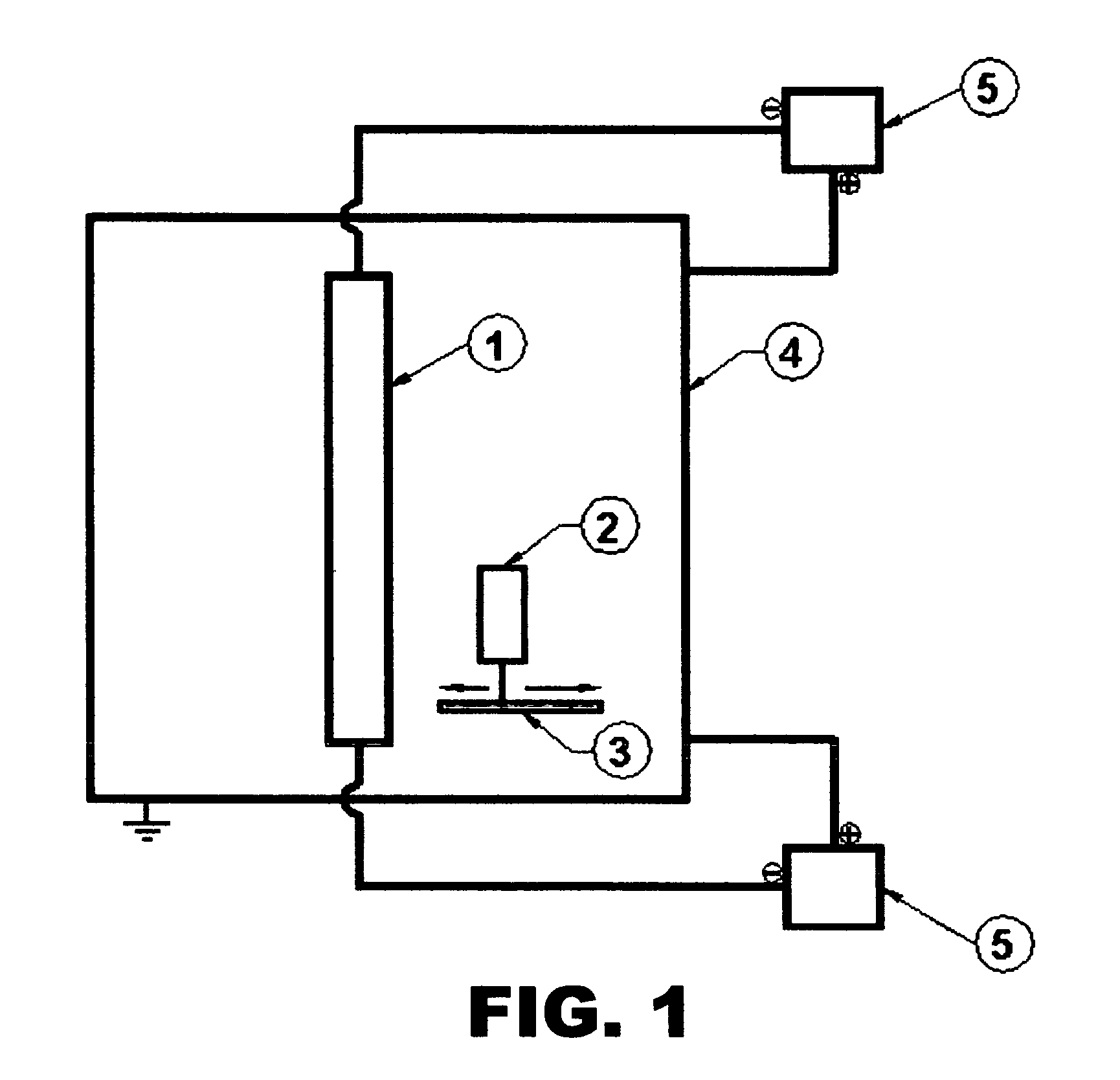

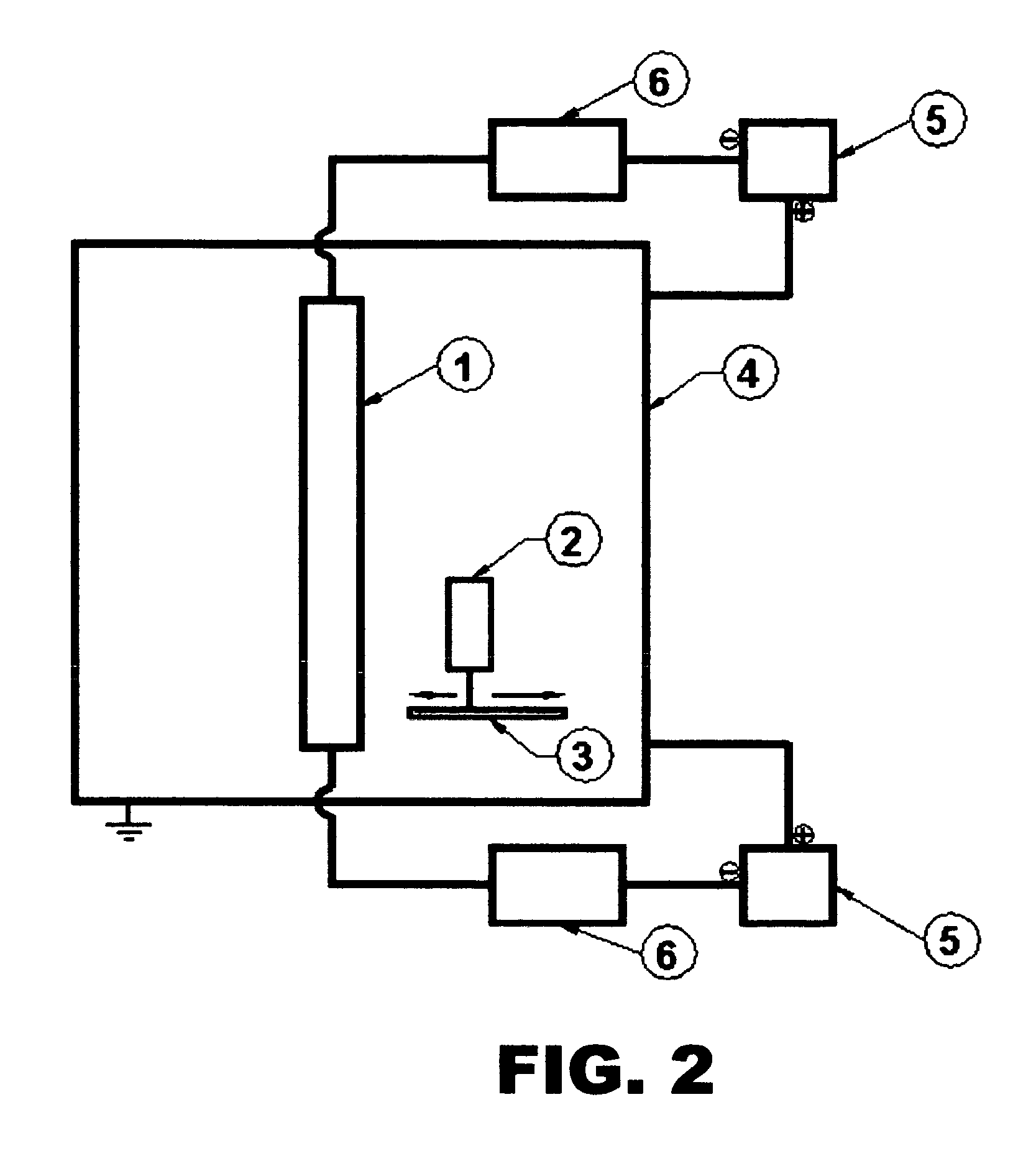

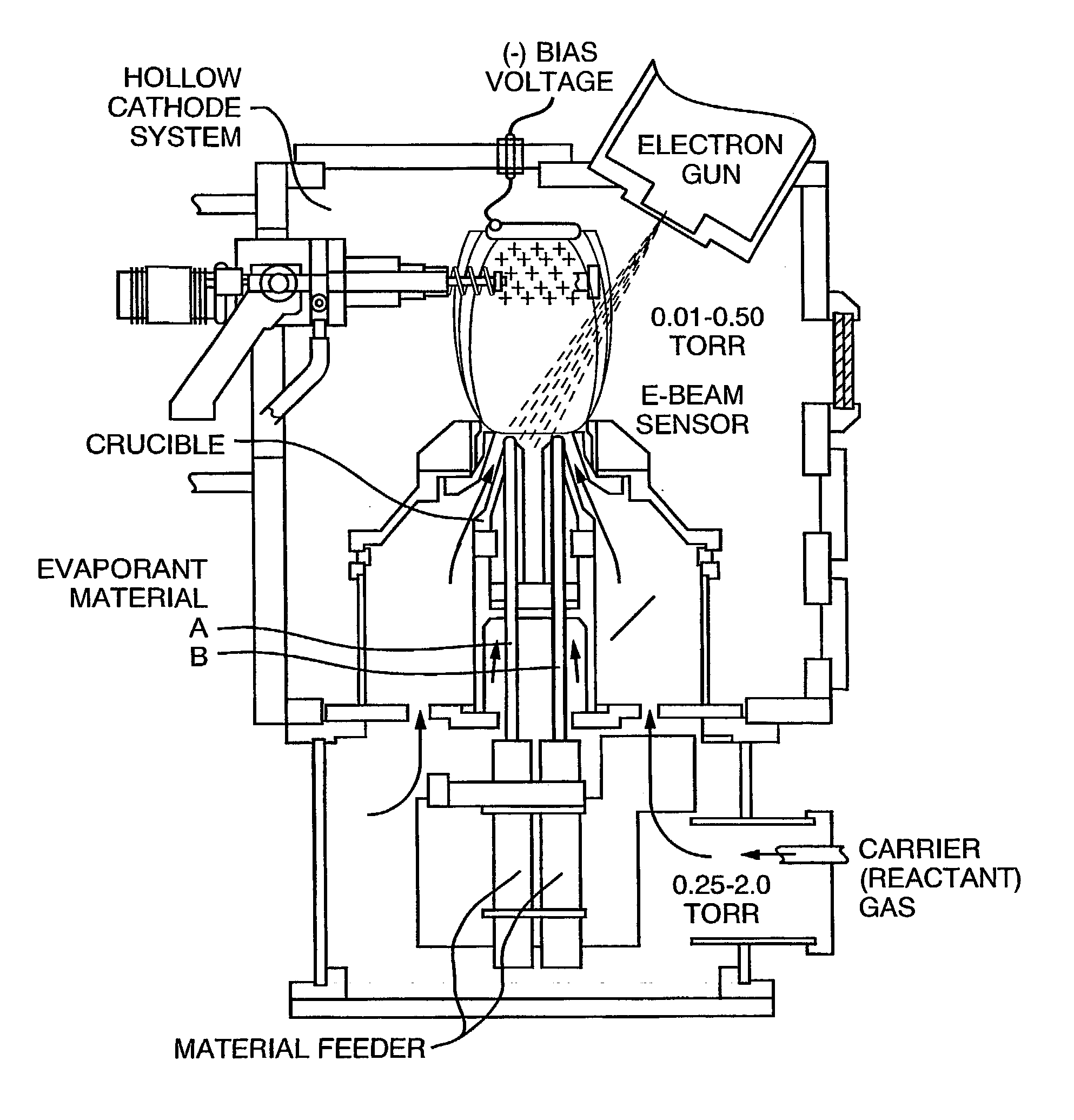

Process and apparatus for plasma activated depositions in a vacuum

InactiveUS20040118347A1Distinct propertyEffectiveness of the process and the apparatusElectric discharge tubesVacuum evaporation coatingEnergy variationNoble gas

Plasma deposition apparatus (1) and method that allows metal or nonmetal vapor (6) to be generated by electron-beam evaporation, guides that vapor using a noble gas stream (containing reactive gases in cases of reactive evaporation), ionizes the dense directed gas and vapor stream at working pressures above about 0.0001 mbar using a hollow cathode plasma arc discharge (11), and conveys the ionized vapor and / or gas stream towards the substrate (4) for impact on the surface at energies varying from thermal levels (as low as about 0.05 eV) up to about 300 eV.

Owner:UNIV OF VIRGINIA +1

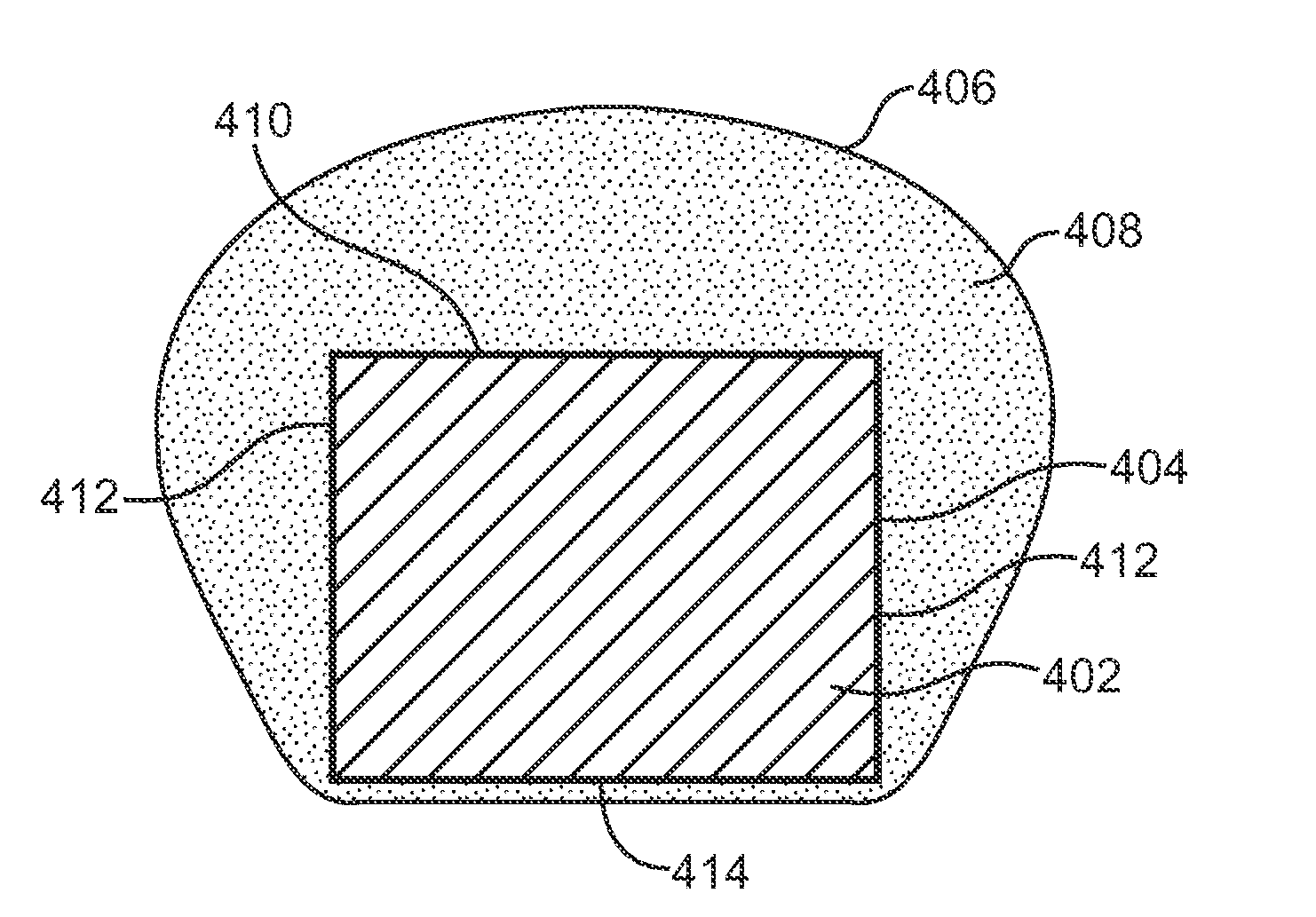

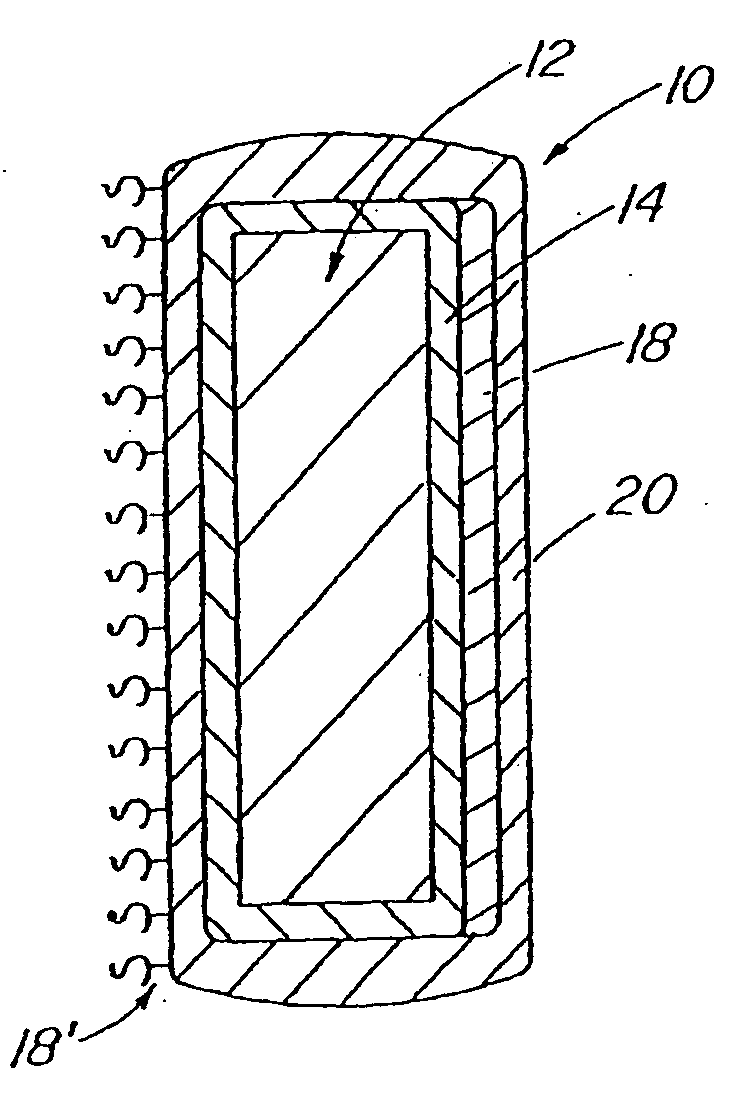

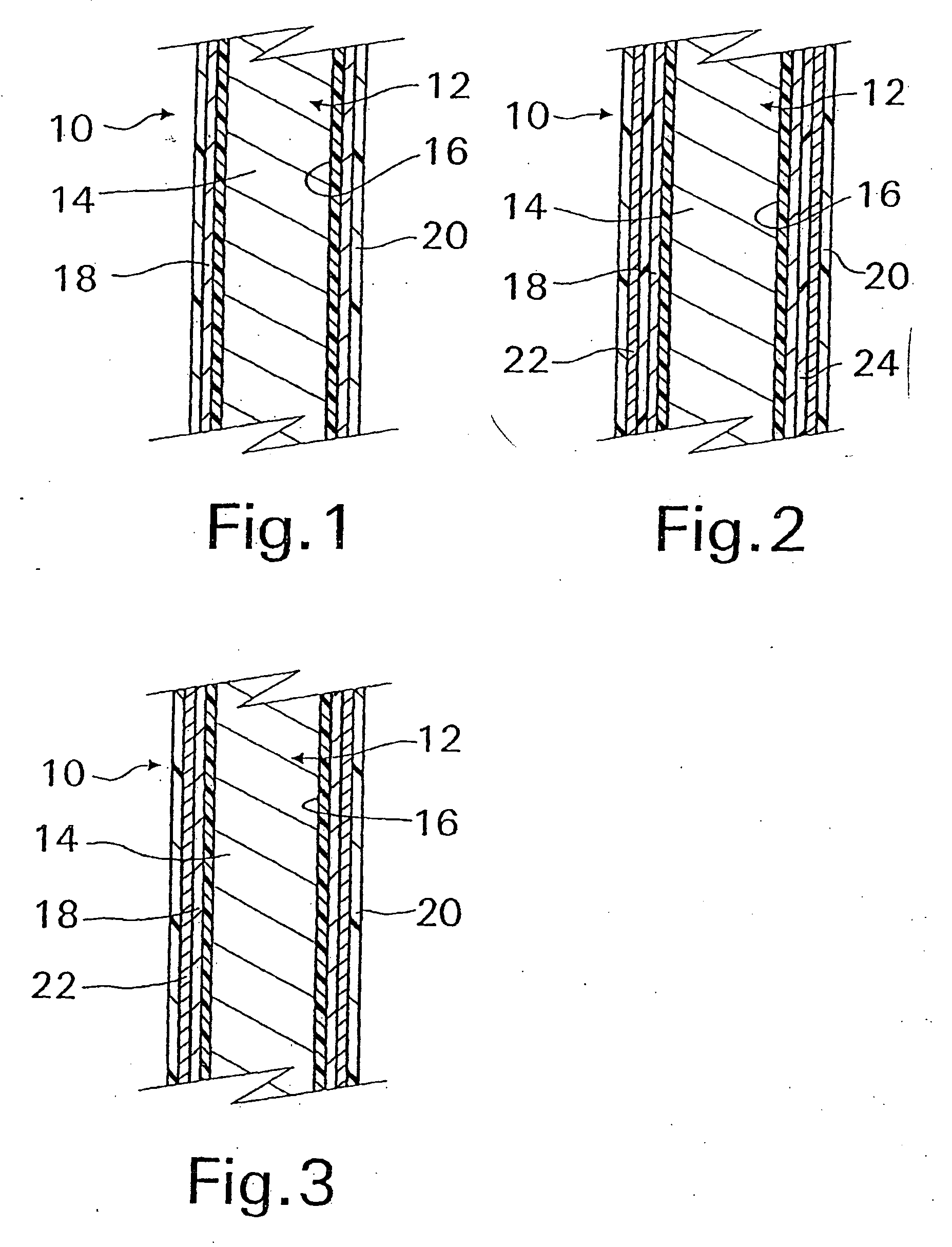

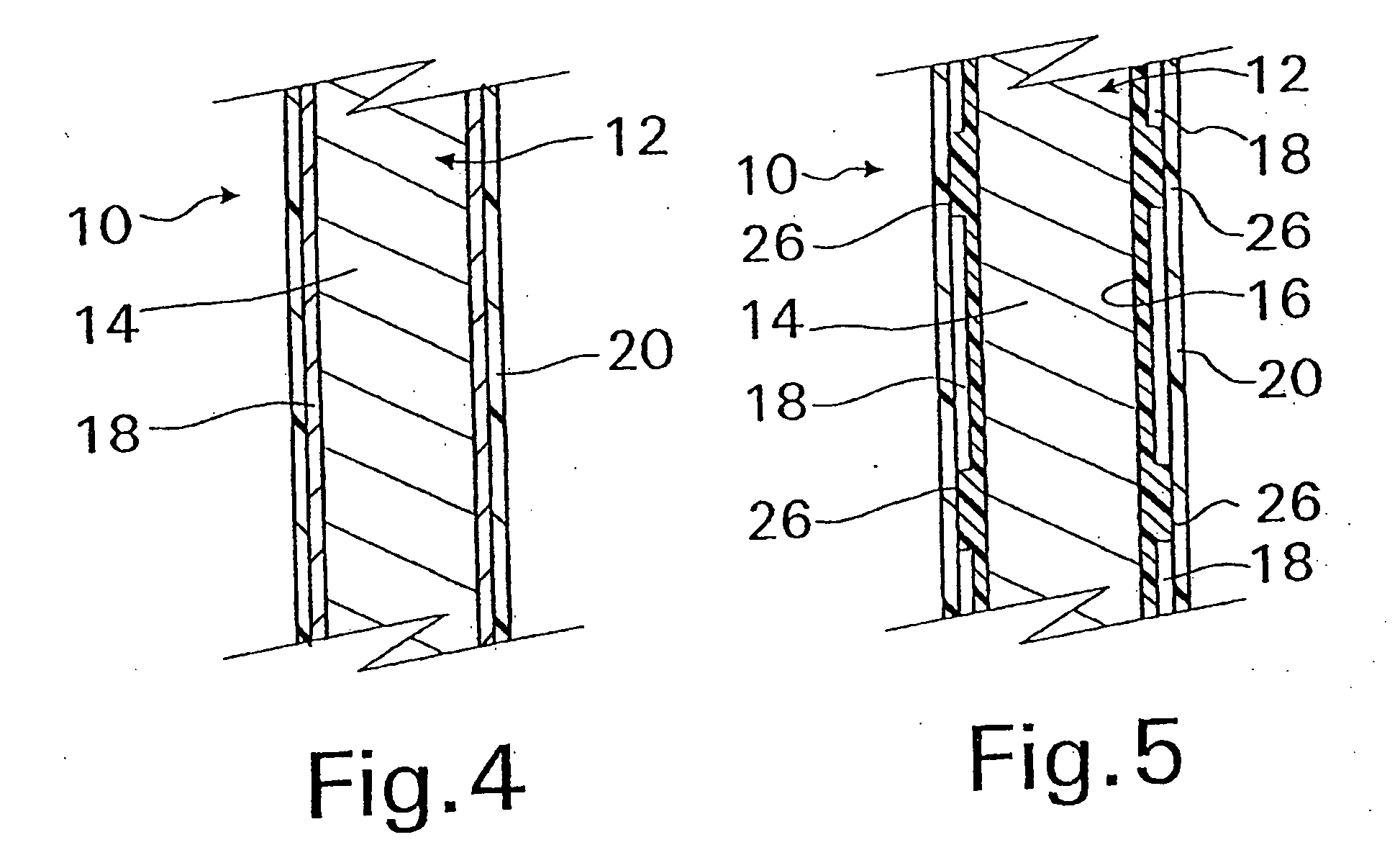

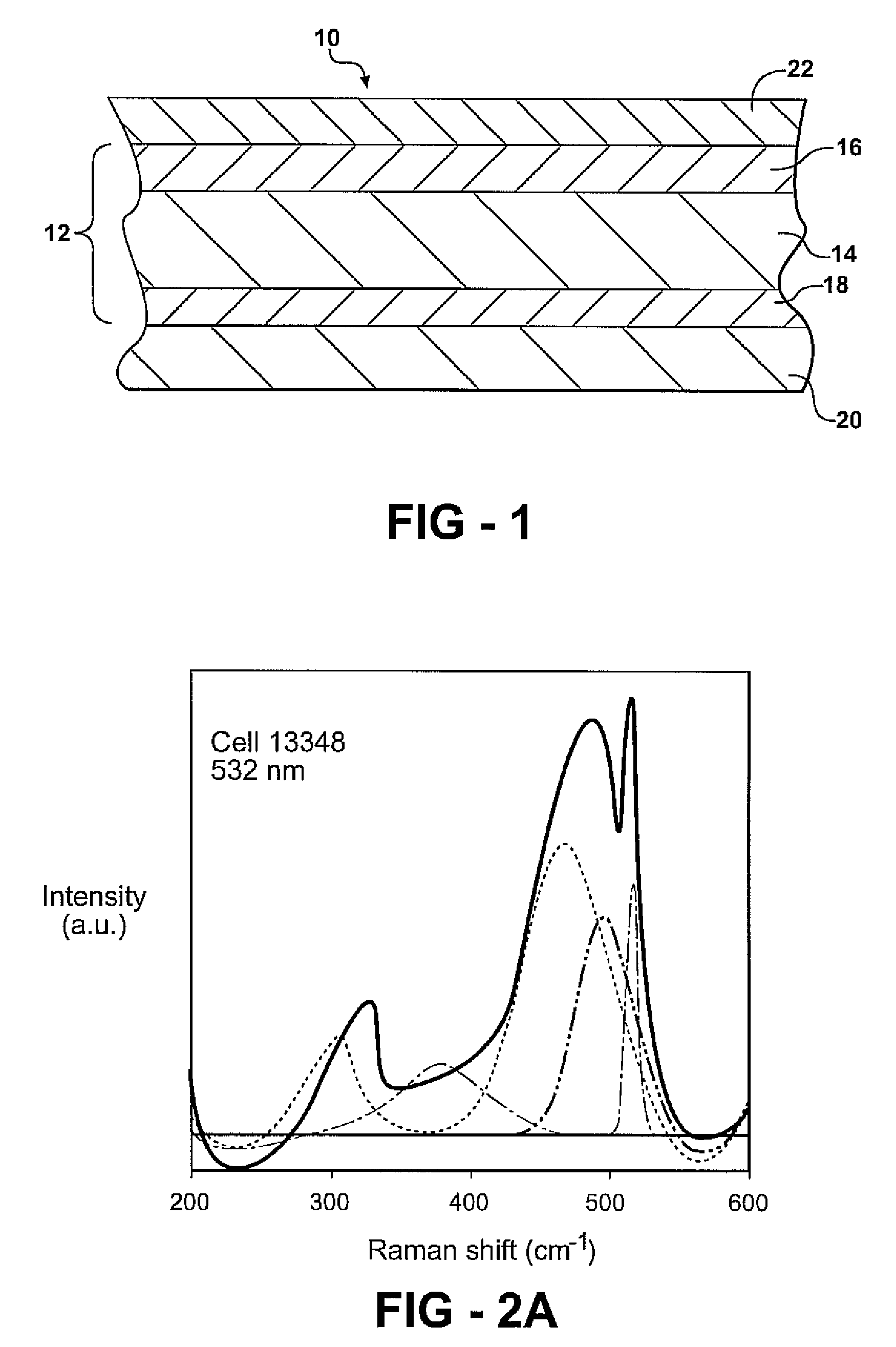

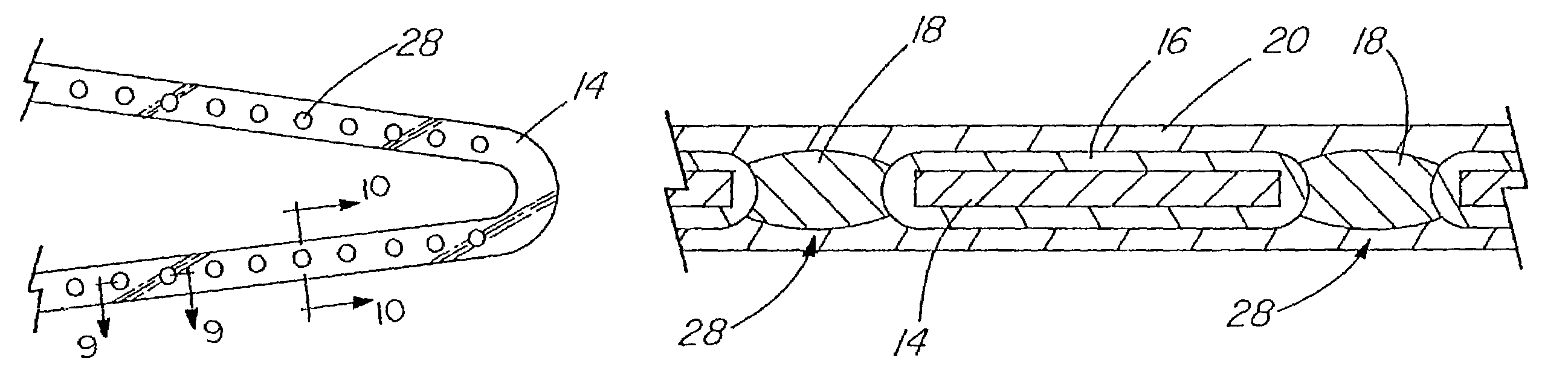

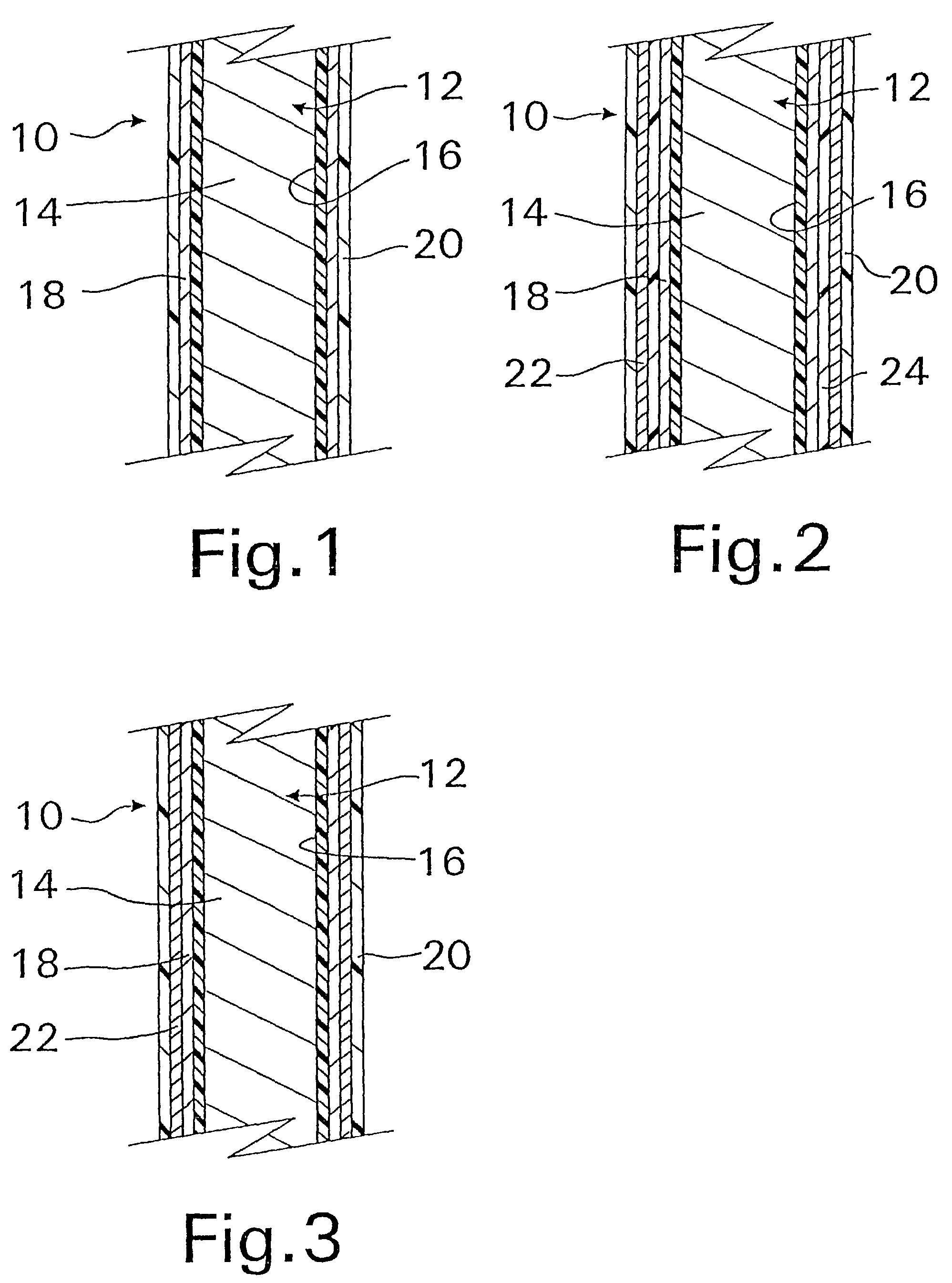

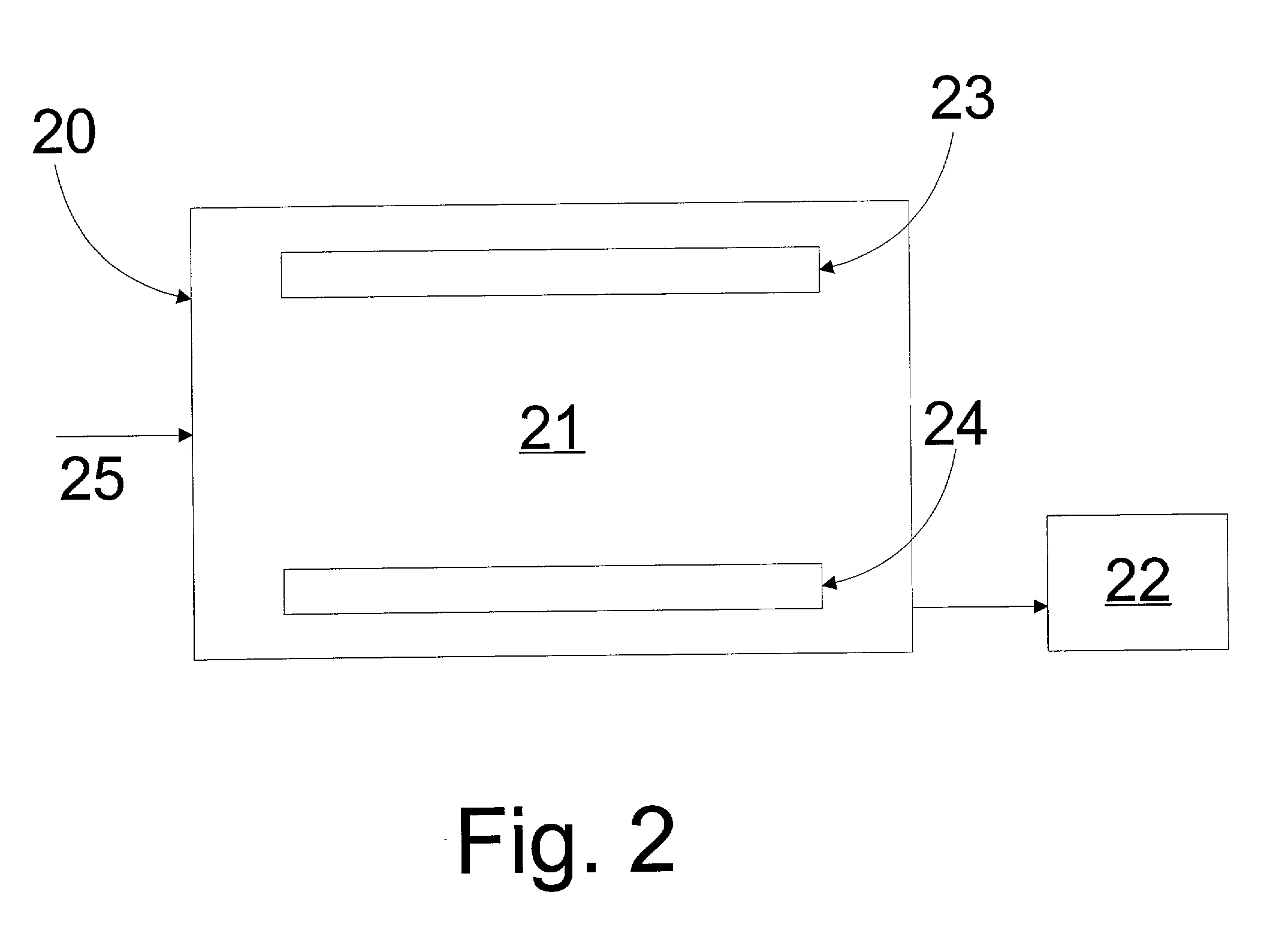

Coated implantable medical device

InactiveUS20070050010A1Prevent degradationIncrease release rateStentsIn-vivo radioactive preparationsParyleneGas phase

A coated implantable medical device 10 includes a structure 12 adapted for introduction into the vascular system, esophagus, trachea, colon, biliary tract, or urinary tract; at least one coating layer 16 posited on one surface of the structure; and at least one layer 18 of a bioactive material posited on at least a portion of the coating layer 16, wherein the coating layer 16 provides for the controlled release of the bioactive material from the coating layer. In addition, at least one porous layer 20 can be posited over the bioactive material layer 18, wherein the porous layer includes a polymer and provides for the controlled release of the bioactive material therethrough. Preferably, the structure 12 is a coronary stent. The porous layer 20 includes a polymer applied preferably by vapor or plasma deposition and provides for a controlled release of the bioactive material. It is particularly preferred that the polymer is a polyamide, parylene or a parylene derivative, which is deposited without solvents, heat or catalysts, and merely by condensation of a monomer vapor.

Owner:COOK MEDICAL TECH LLC

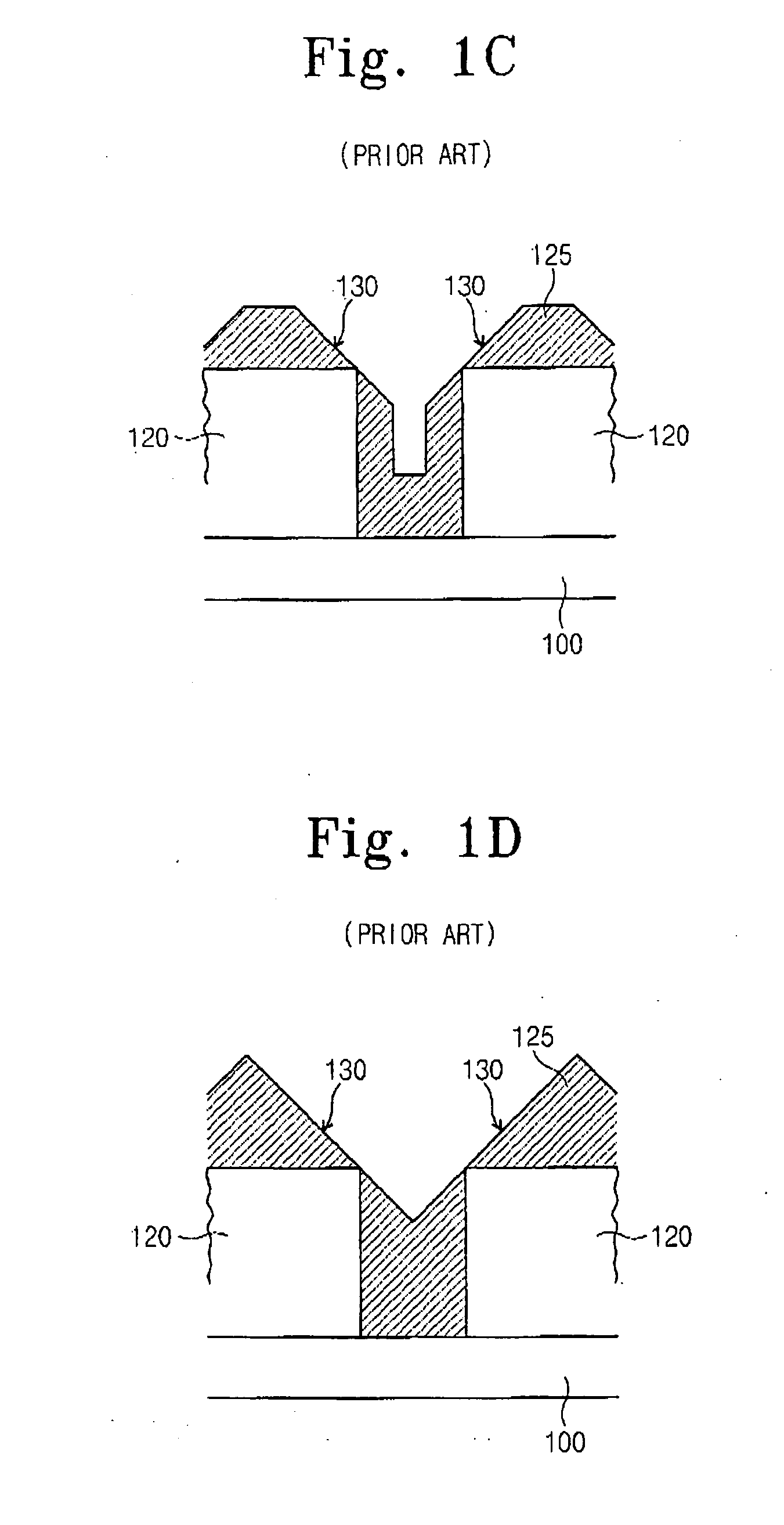

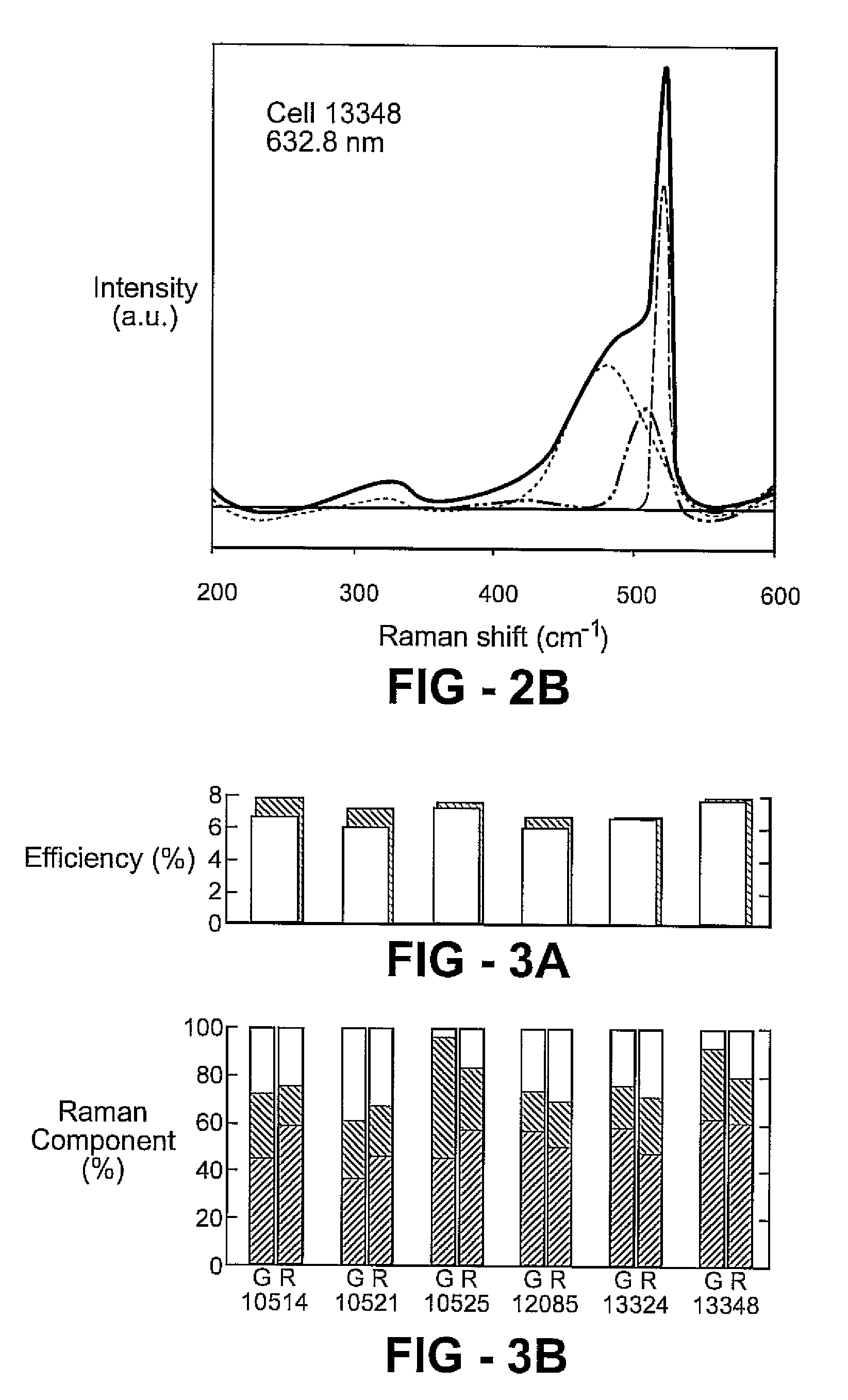

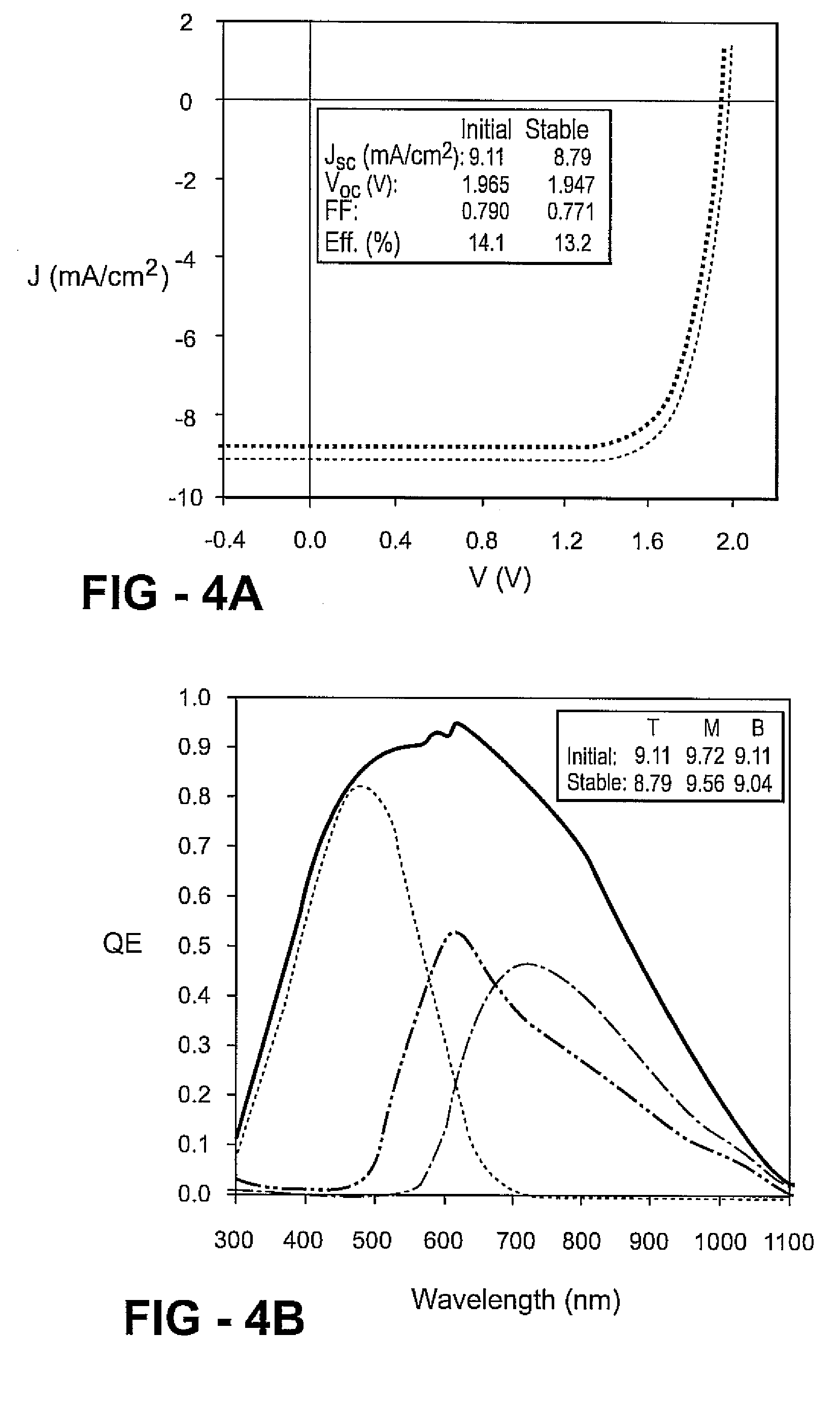

Stabilized photovoltaic device and methods for its manufacture

InactiveUS20070256734A1NanoinformaticsPhotovoltaic energy generationSemiconductor materialsPlasma deposition

A semiconductor device of p-i-n type configuration includes a p layer which is comprised of a p-doped semiconductor material, an n layer comprised of an n-doped semiconductor material and an i layer comprised of a substantially intrinsic, nanocrystalline semiconductor material interposed therebetween. The crystalline volume in the i layer decreases as the thickness of said layer increases from its interface with the n layer to its interface with the p layer. The grain size of the substantially intrinsic nanocrystalline semiconductor material may also decrease as the thickness of the i layer increases from its interface with the n layer to its interface with the p layer. The volume of regions of intermediate range order in a portion of the i layer commencing at the interface of the i layer and the p layer, and comprising no more than 50% of the thickness thereof, is greater than is the volume of regions of intermediate range order in the remainder of the i layer. Devices of this type may be used as photovoltaic devices, and may be fabricated by a plasma deposition process.

Owner:UNITED SOLAR OVONIC

Plasma deposition to increase adhesion

ActiveUS20100237043A1Improve adhesionLamination ancillary operationsDecorative surface effectsPlasma depositionFluoropolymer

Plasma etching of a polymeric dielectric material such as polyurethane results in volatile byproducts that are deposited onto the surface of an inert substrate. The surface treatment increases adhesiveness so that the surface of the inert material may be bonded to another material. Portions of a medical device comprising an inert substrate such as a fluoropolymer may therefore be securely affixed to other portions of the medical device formed of polymeric, metallic, or ceramic materials.

Owner:MEDTRONIC INC

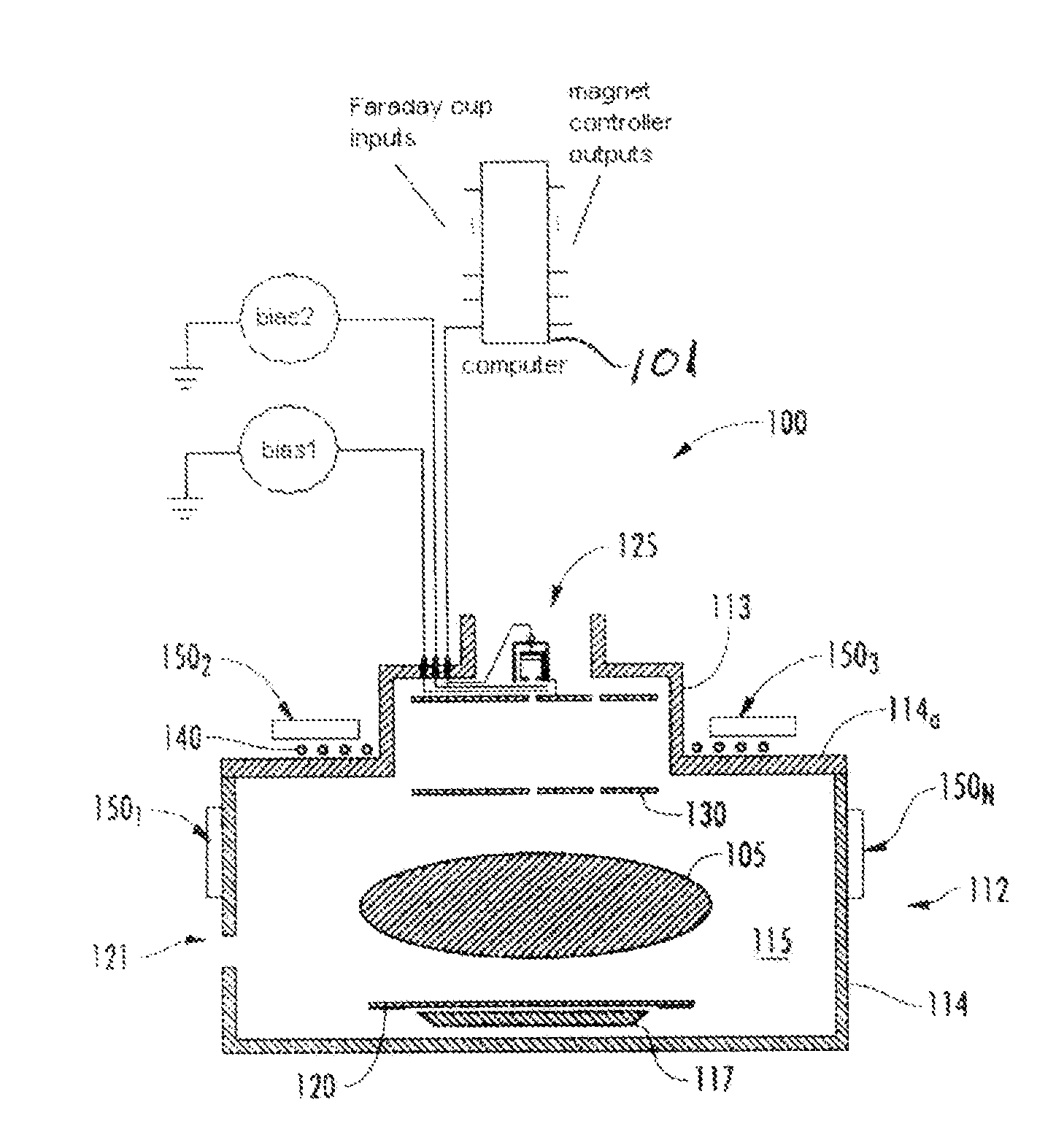

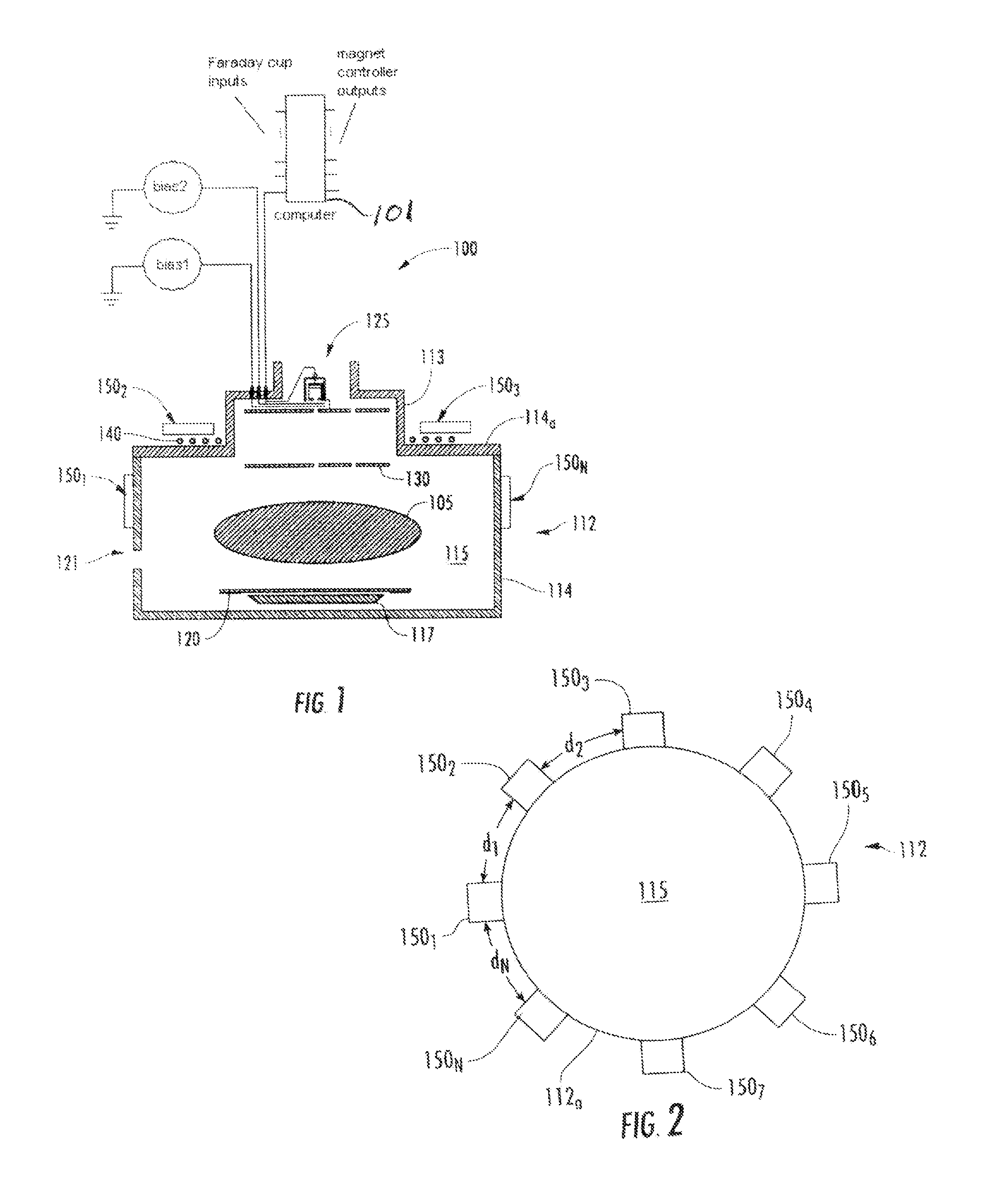

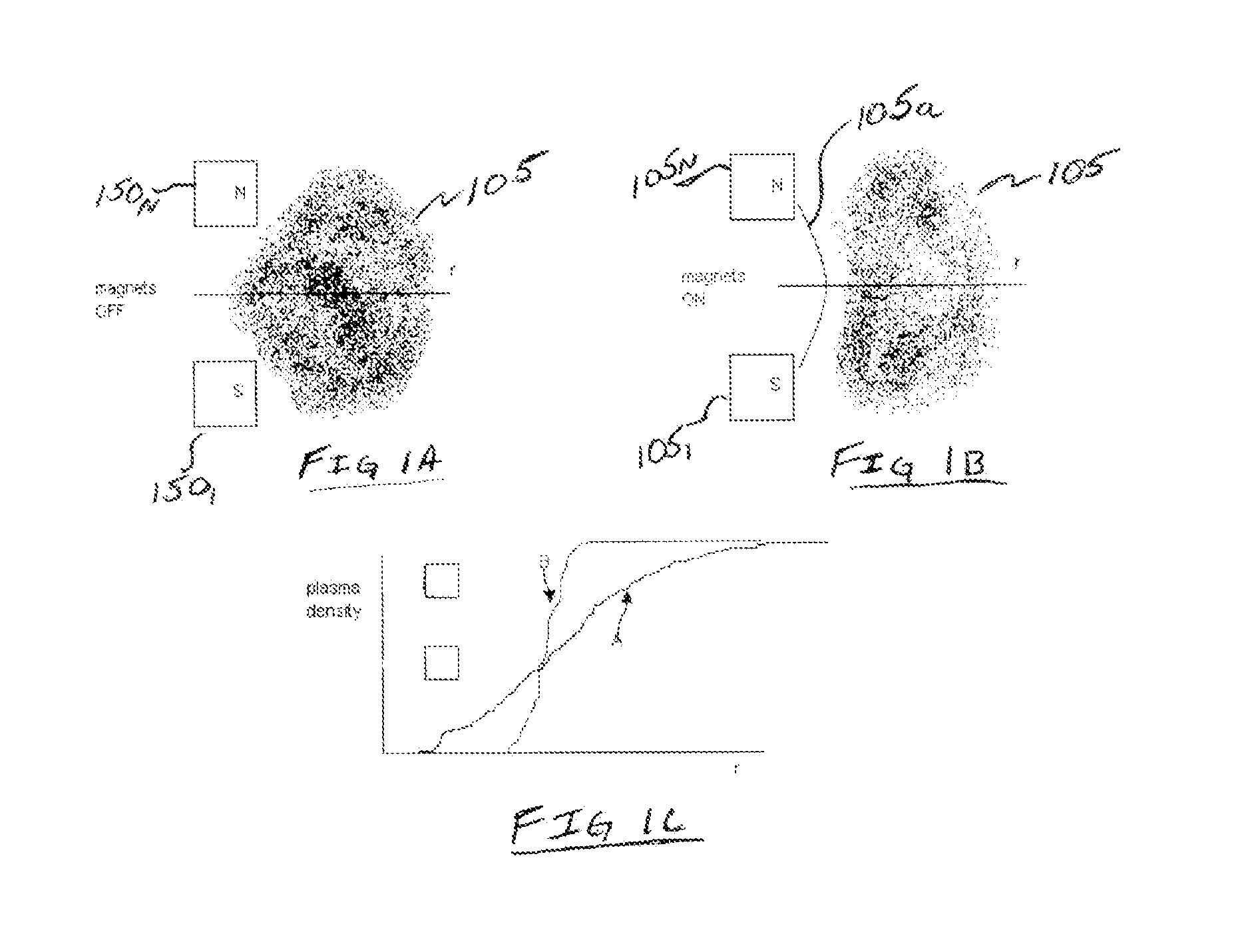

System and method for controlling plasma deposition uniformity

InactiveUS20120021136A1Electric discharge tubesVacuum evaporation coatingPlasma depositionEngineering

A plasma process uniformity control apparatus comprises a plasma chamber defined by chamber walls and a plurality of magnetic elements disposed on the outside of the chamber walls. Each of the plurality of magnets is configured to supply a magnetic field directed at respective portions of the plasma inside the chamber to control the uniformity of the plasma directed toward the target substrate.

Owner:VARIAN SEMICON EQUIP ASSOC INC

Use of Plasma in Formation of Biodegradable Stent Coating

Metallic stents are treated with a gaseous species in a plasma state under conditions causing the species to polymerize and to be deposited in polymerized form on the metallic stent surface prior to the application of a drug-polymer mixture, which is done by conventional non-plasma deposition methods. The drug-polymer mixture once applied forms a coating on the stent surface that releases the drug in a time-release manner and gradually erodes, leaving only the underlying plasma-deposited polymer. In certain cases, the plasma-deposited polymer itself erodes or dissolves into the physiological medium over an extended period of time, leaving only the metallic stent. While the various polymers and drug remain on the stent, the plasma-deposited polymer enhances the adhesion of the drug-polymer anchor coating and maintains the coating intact upon exposure to the mechanical stresses encountered during stent deployment.

Owner:JW MEDICAL SYSTEMS LTD

Coated implantable medical device

InactiveUS7550005B2Prevent degradationIncrease release rateStentsHeart valvesParylenePlasma deposition

A coated implantable medical device 10 includes a structure 12 adapted for introduction into the vascular system, esophagus, trachea, colon, biliary tract, or urinary tract; at least one coating layer 16 posited on one surface of the structure; and at least one layer 18 of a bioactive material posited on at least a portion of the coating layer 16, wherein the coating layer 16 provides for the controlled release of the bioactive material from the coating layer. In addition, at least one porous layer 20 can be posited over the bioactive material layer 18, wherein the porous layer includes a polymer and provides for the controlled release of the bioactive material therethrough. Preferably, the structure 12 is a coronary stent. The porous layer 20 includes a polymer applied preferably by vapor or plasma deposition and provides for a controlled release of the bioactive material. It is particularly preferred that the polymer is a polyamide, parylene or a parylene derivative, which is deposited without solvents, heat or catalysts, and merely by condensation of a monomer vapor.

Owner:COOK MEDICAL TECH LLC

Methods for surface modification

InactiveUS20030163198A1Affecting its functionPrevent uniform property characteristicSurgeryGlovesReactive gasPlasma deposition

A method of modifying surfaces of a device, for example, a medical device, is disclosed. The method includes modifying a surface of a device by providing a device, exposing the device to a reactive gas and plasma energy to create a plasma deposited surface on the device, and quenching the device with the reactive gas. The device exhibits changes in its surface properties thereby making it more desirable for an intended use.

Owner:HORIZON TECH FUNDING CO LLC

Integrated process modulation (IPM) a novel solution for gapfill with HDP-CVD

InactiveUS7524750B2Reduce moistureAvoid attackElectric discharge tubesSemiconductor/solid-state device manufacturingHalogenIon density

Owner:APPLIED MATERIALS INC

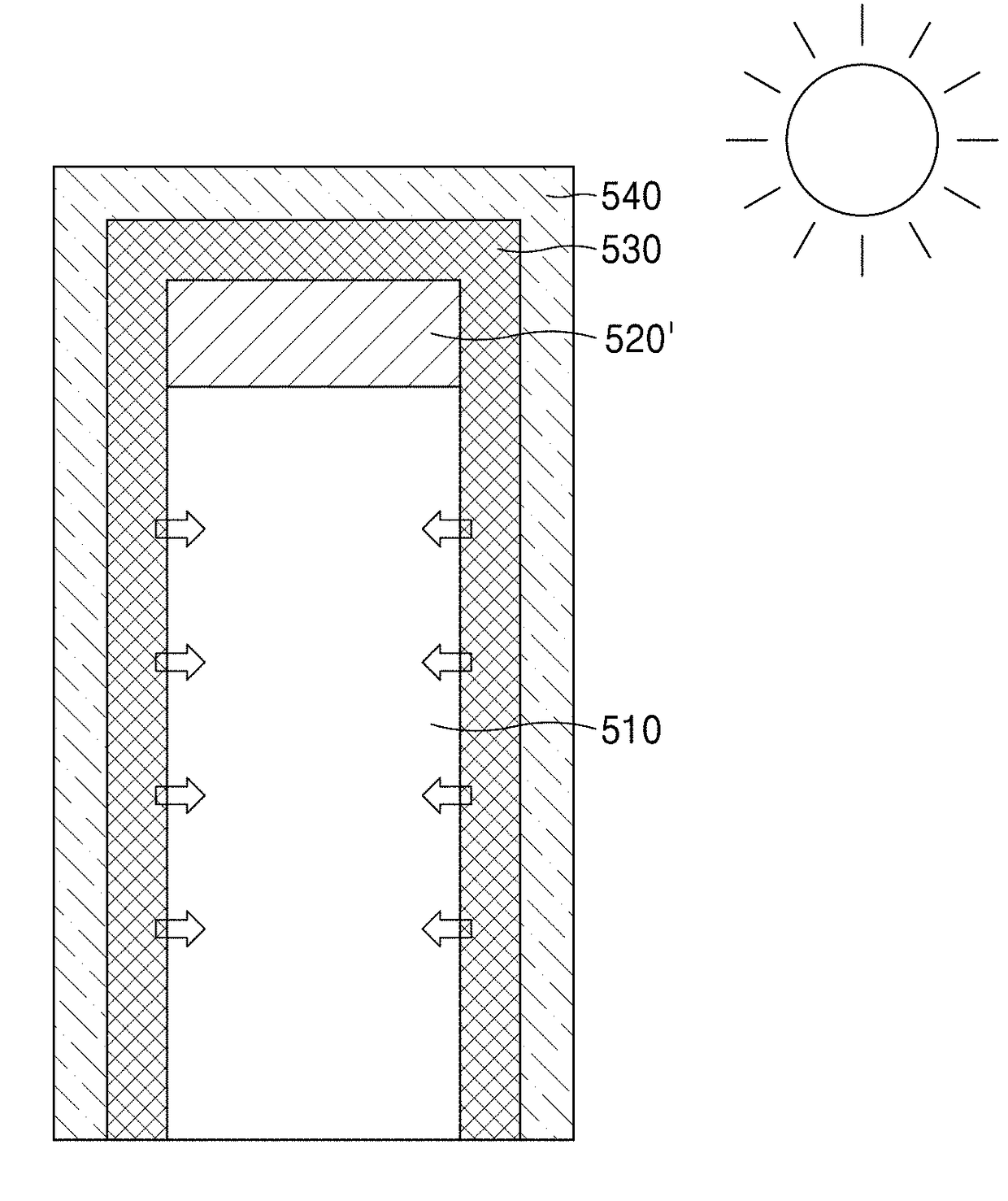

Seed Layers and Process of Manufacturing Seed Layers

InactiveUS20100193664A1Cost per unit volumeHigh purityFrom solid stateFrom frozen solutionsAmorphous siliconPlasma deposition

This invention relates seed layers and a process of manufacturing seed layers for casting silicon suitable for use in solar cells or solar modules. The process includes the step of positioning tiles with aligned edges to form seams on a suitable surface, and the step of joining the tiles at the seams to form a seed layer. The step of joining includes heating the tiles to melt at least a portion of the tiles, contacting the tiles at both ends of at least one seam with electrodes, using plasma deposition of amorphous silicon, applying photons to melt a portion of the tiles, and / or layer deposition. Seed layers of this invention include a rectilinear shape of at least about 500 millimeters in width and length.

Owner:AMG IDEAL CAST SOLAR

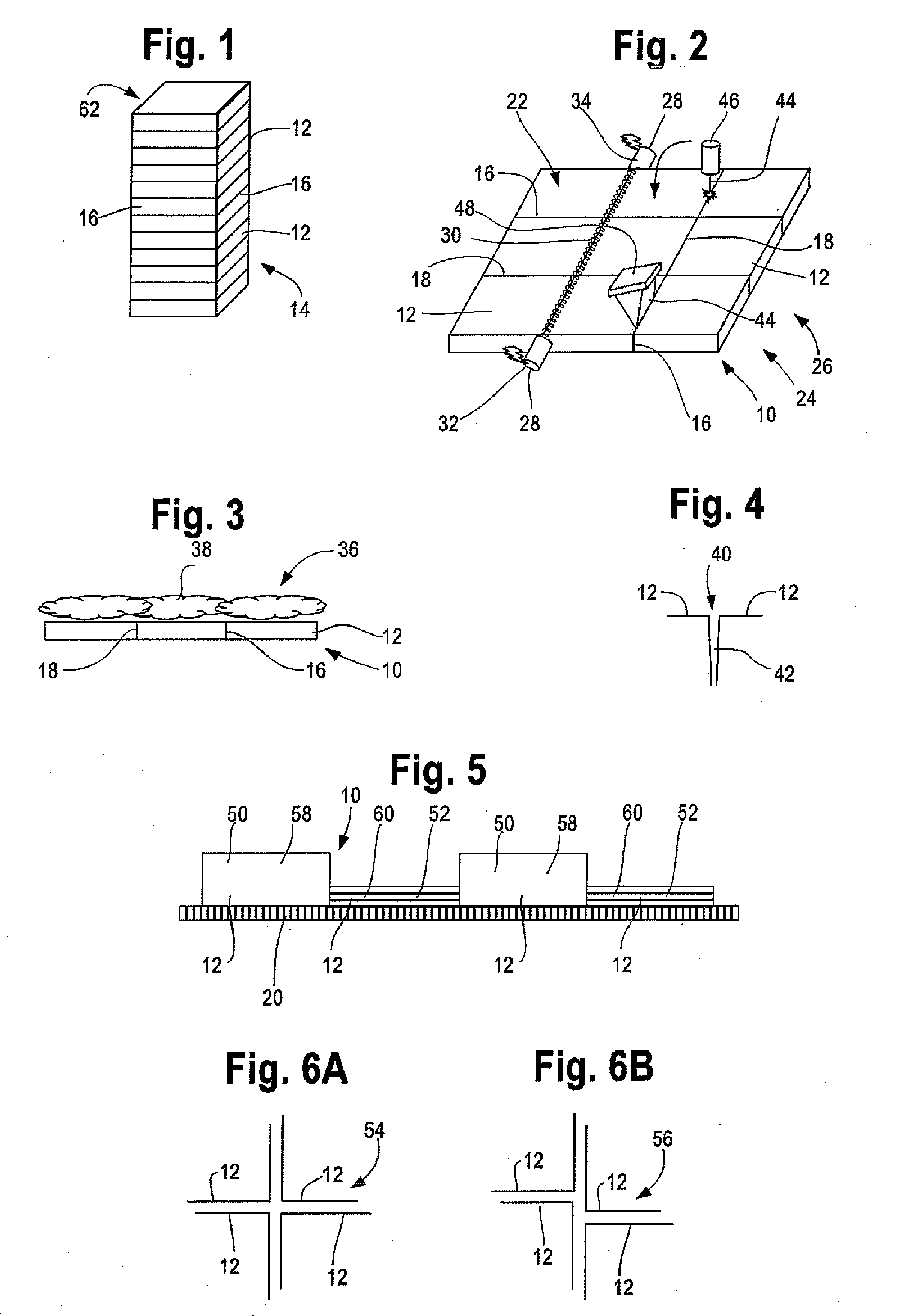

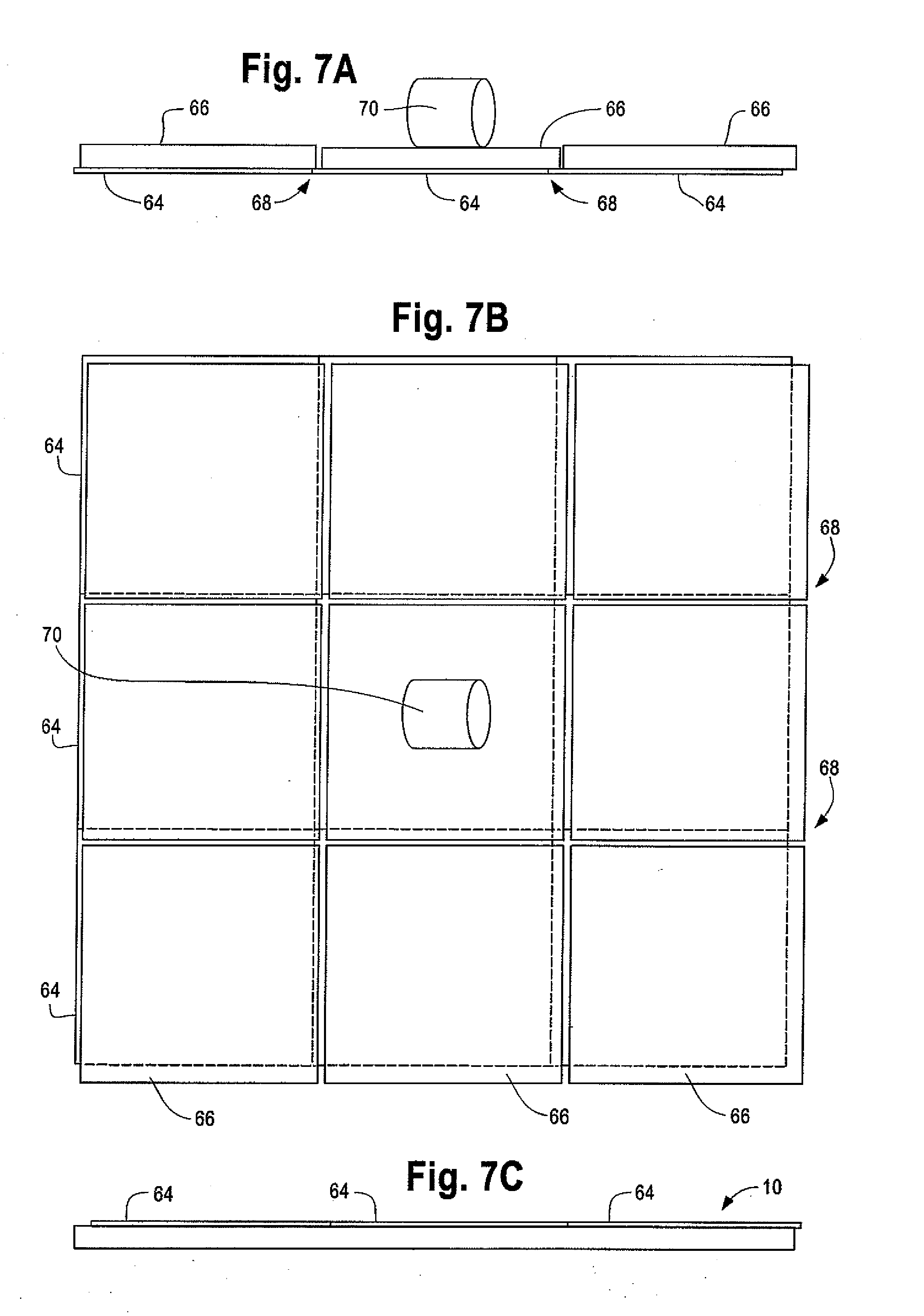

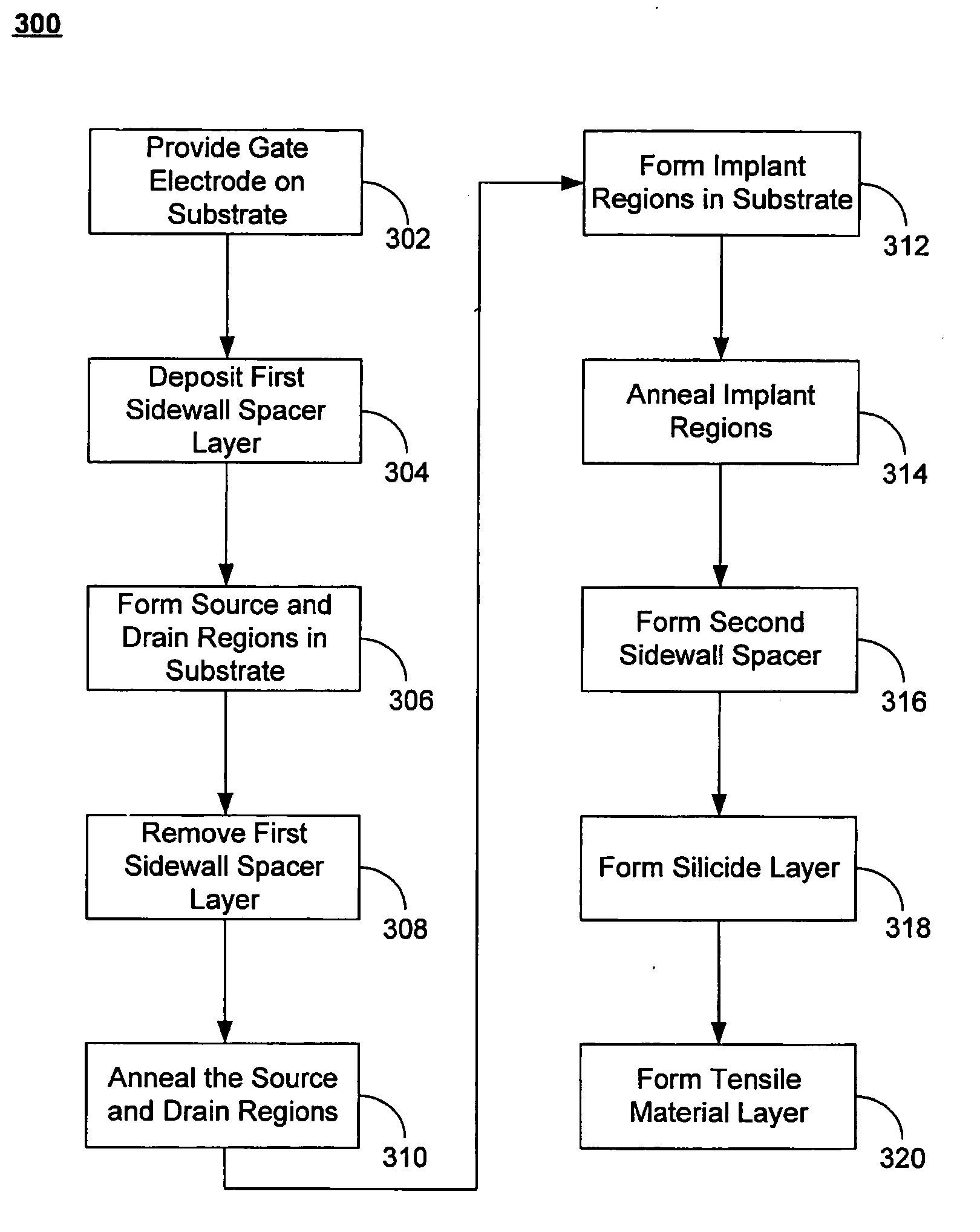

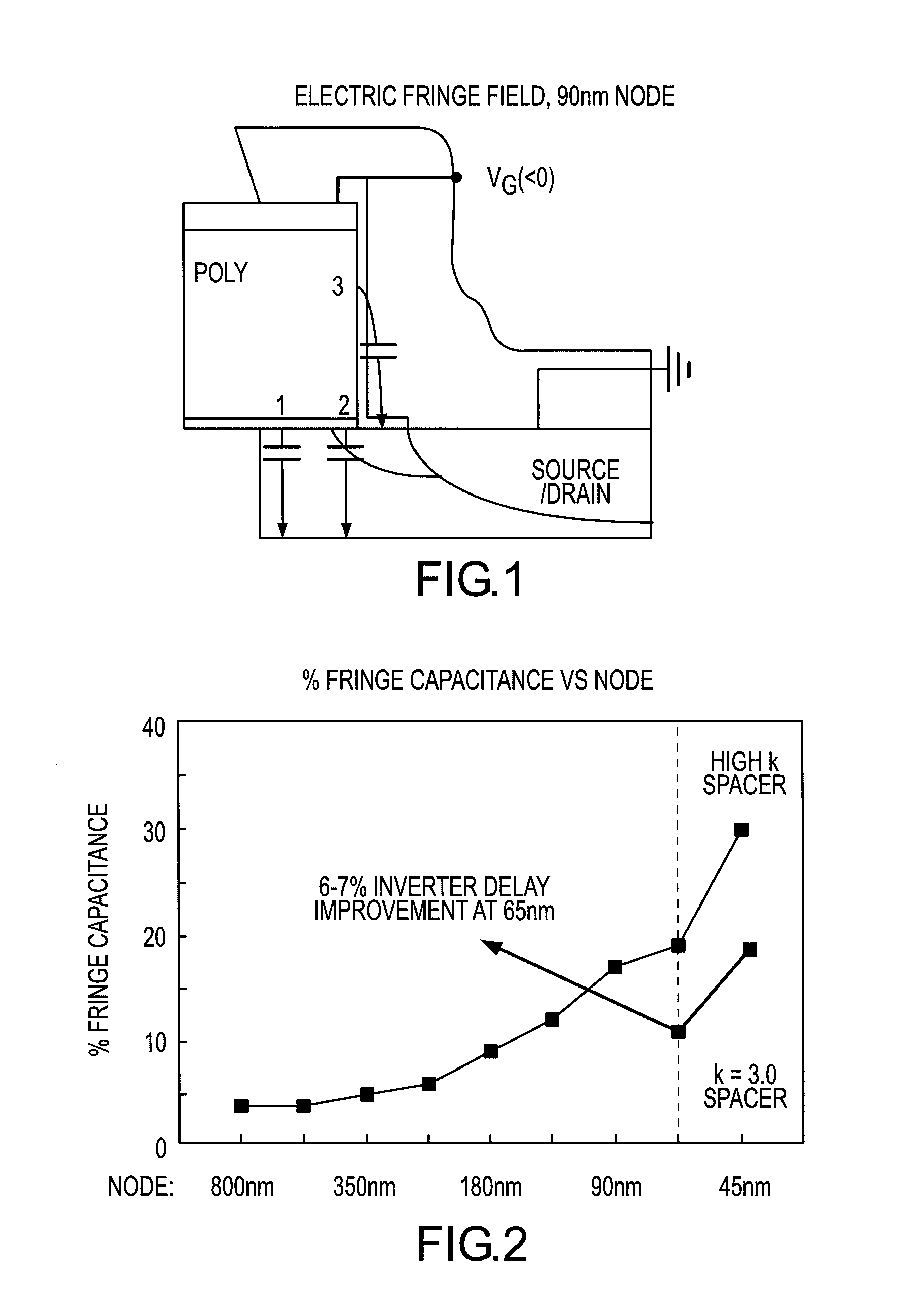

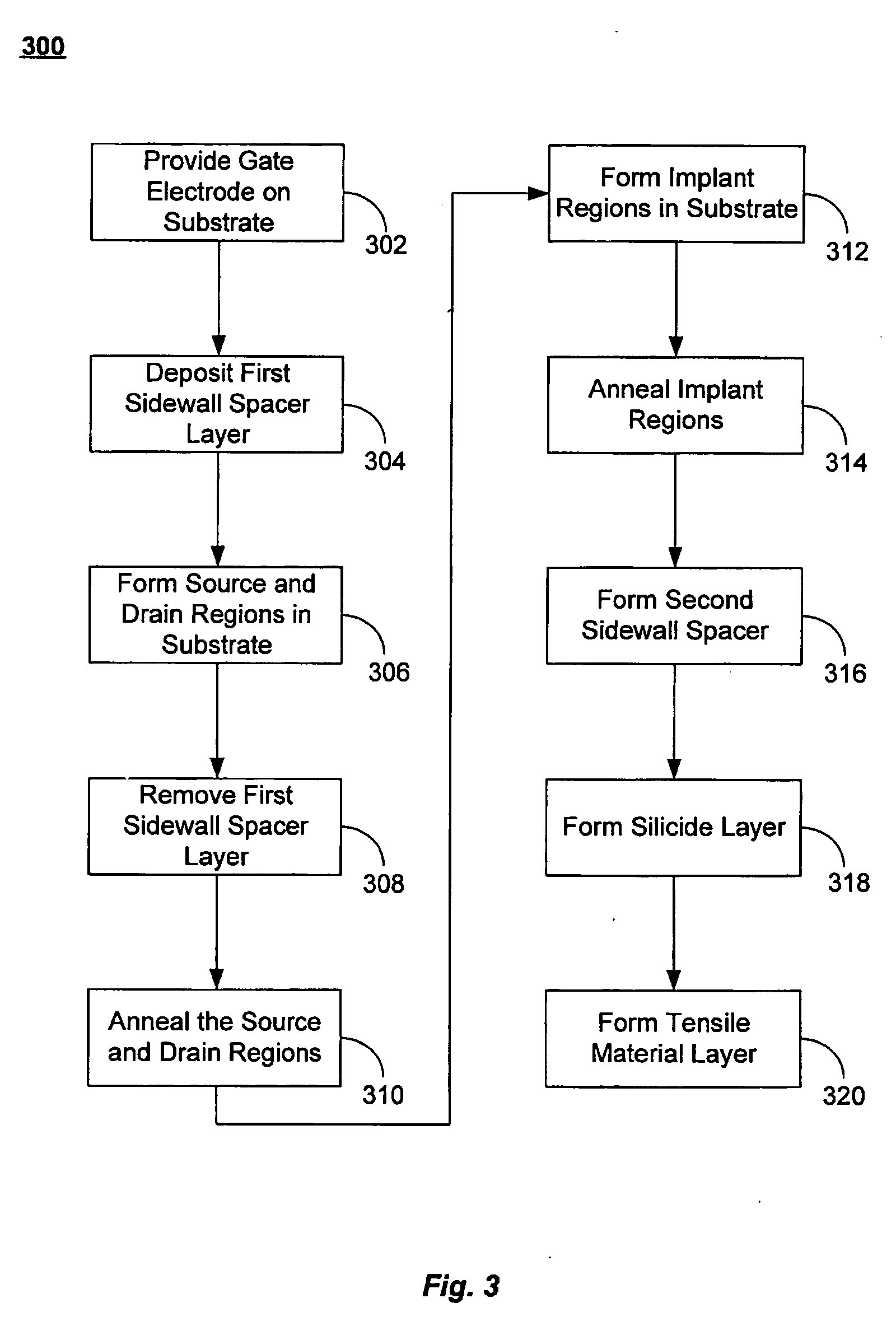

Low-k spacer integration into CMOS transistors

InactiveUS20070202640A1Semiconductor/solid-state device manufacturingSemiconductor devicesCMOSPlasma deposition

A method of forming source and drain regions in a semiconductor transistor. The method includes the steps of forming a first sidewall spacer on sidewall surfaces of a gate electrode that is formed on an underlying substrate, where the first sidewall spacer includes amorphous carbon. The method may also include implanting the source and drain regions in the semiconductor substrate, and removing the first sidewall spacer before annealing the source and drain regions. The method may still further include forming a second sidewall spacer on the sidewall surfaces of the gate electrode, where the second sidewall spacer has a k-value less than 4. Also, a method to enhance conformality of a sidewall spacer layer. The method may include the steps of pulsing a radio-frequency power source to generate periodically a plasma, and depositing the plasma on sidewall surfaces of a gate electrode to form the sidewall spacer layer.

Owner:APPLIED MATERIALS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com