Novel method for conformal plasma immersed ion implantation assisted by atomic layer deposition

a conformal plasma and ion implantation technology, applied in the field of semiconductor device fabrication, can solve the problems of increasing aspect ratio and shrinking devices, affecting the implantation process of dopant ions, and reducing the implantation efficiency of ions, so as to achieve the effect of maximizing the penetration of dopant ions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

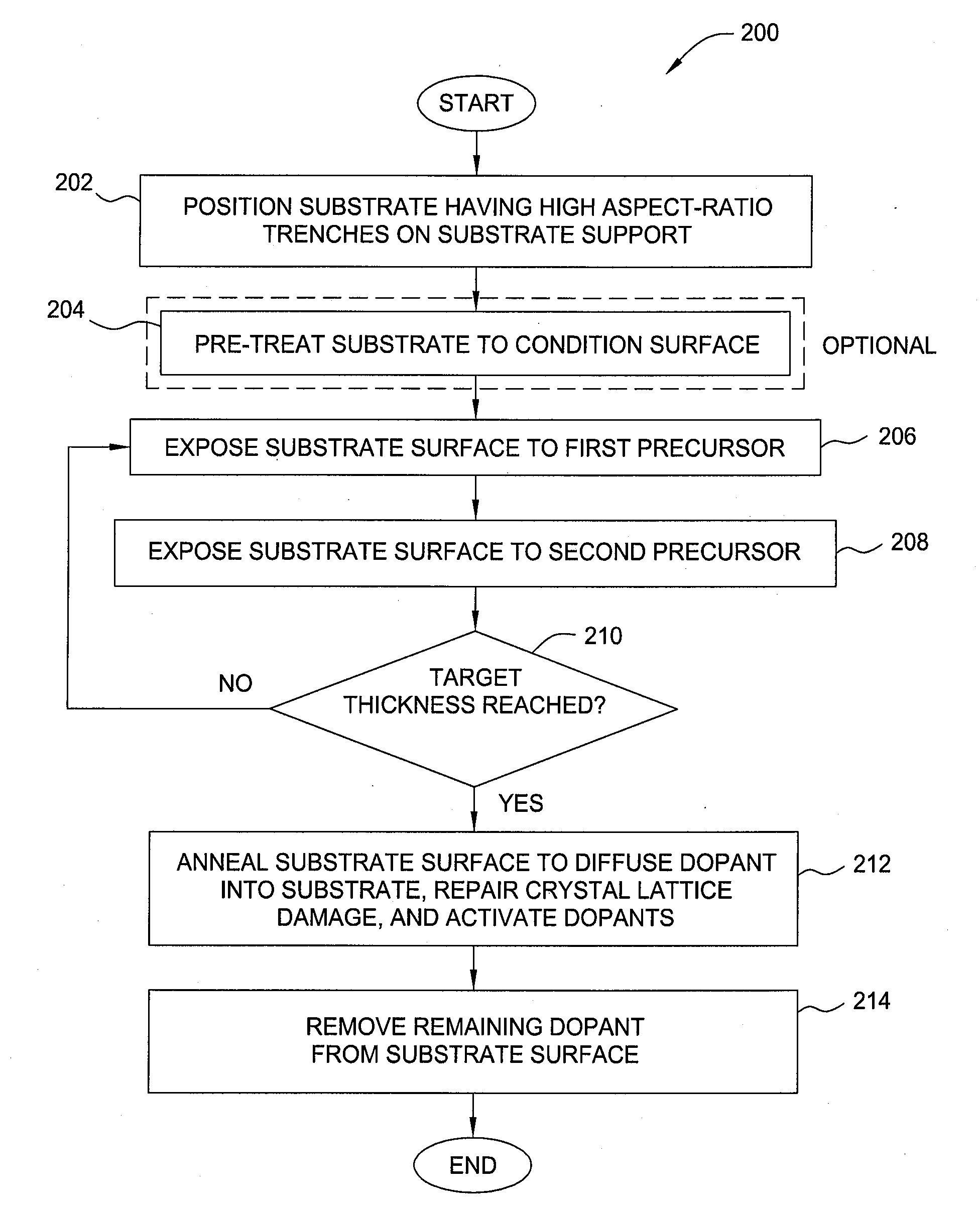

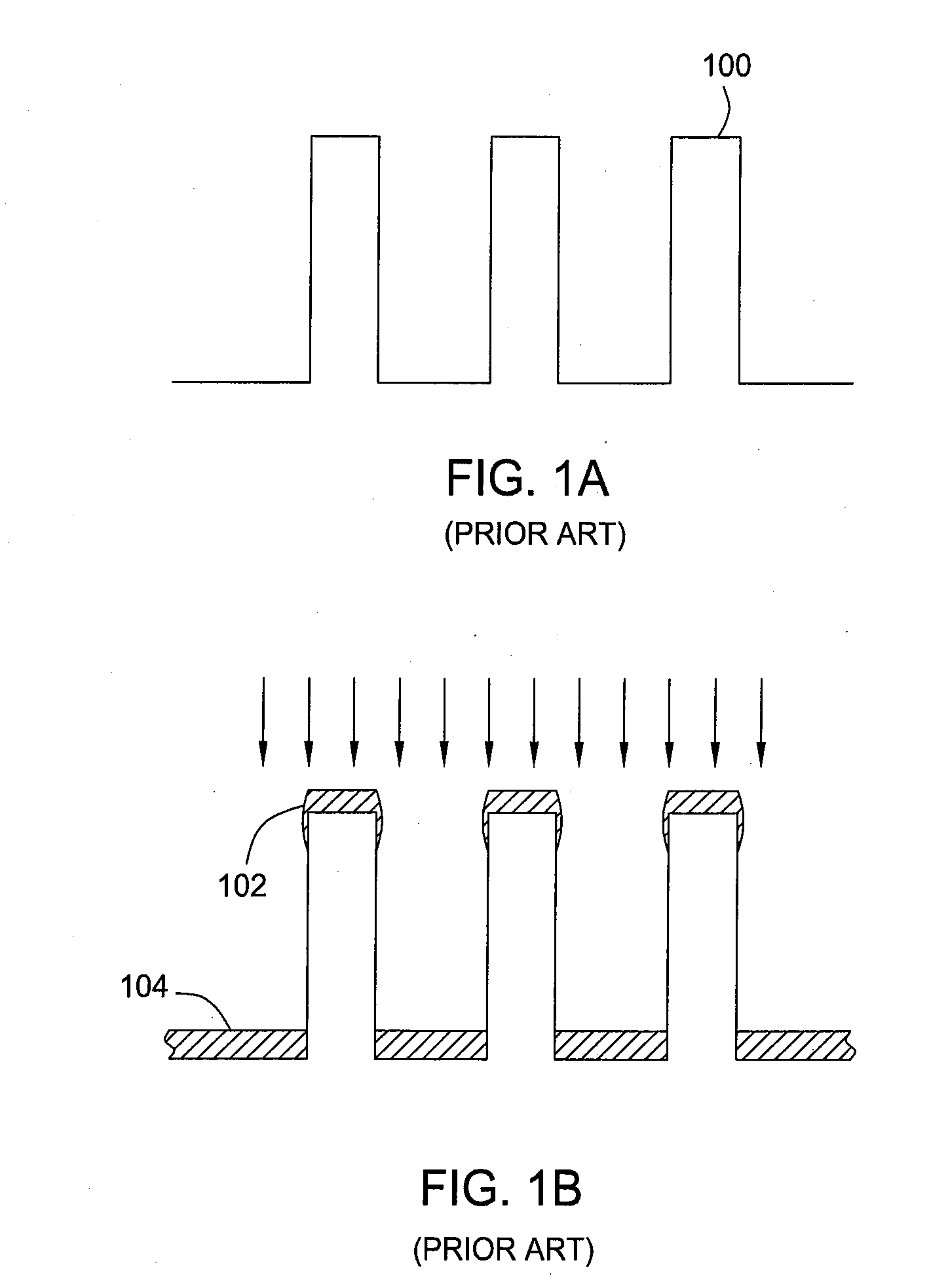

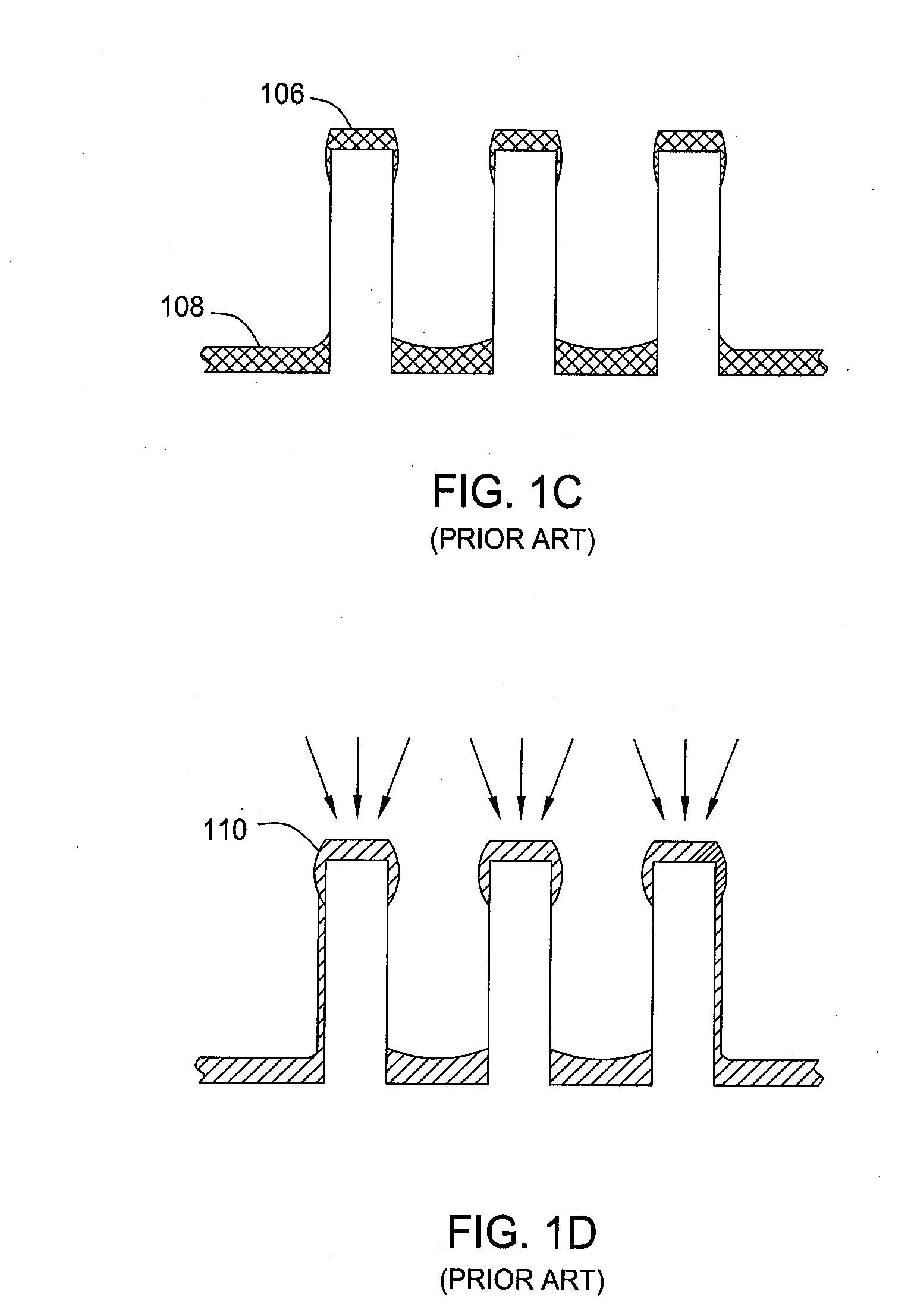

[0023]Embodiments of the invention contemplate methods of conformal doping of a substrate. Such methods generally provide for conformal deposition of a dopant source on a substrate followed by treatment with electromagnetic energy to diffuse the dopants into the substrate and activate them. Deposition may be by any process designed to achieve conformal deposition of thin dopant source layers on a substrate having high aspect ratio features, such as greater than about 3:1 by atomic layer deposition (ALD), chemical vapor deposition enhanced by weak plasma (WPCVD), or plasma-assisted atomic layer deposition (PAALD) of dopants on the substrate followed by anneal. Processes for manufacturing semiconductor devices are increasingly challenged to produce conformally doped regions on substrates with ultra-high aspect ratio holes or trenches formed in field regions. ALD is a successful procedure for forming conformal layers on high aspect ratio features heretofore used in metal and dielectric...

PUM

| Property | Measurement | Unit |

|---|---|---|

| RF power | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com