Method for preparing graphene membrane

A graphene film and layer graphene technology, applied in the field of graphene film preparation, can solve problems such as harshness, difficulty in obtaining the number of layers, random shape of graphene film, etc., and achieve easy size control, excellent optoelectronic properties, and methods. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

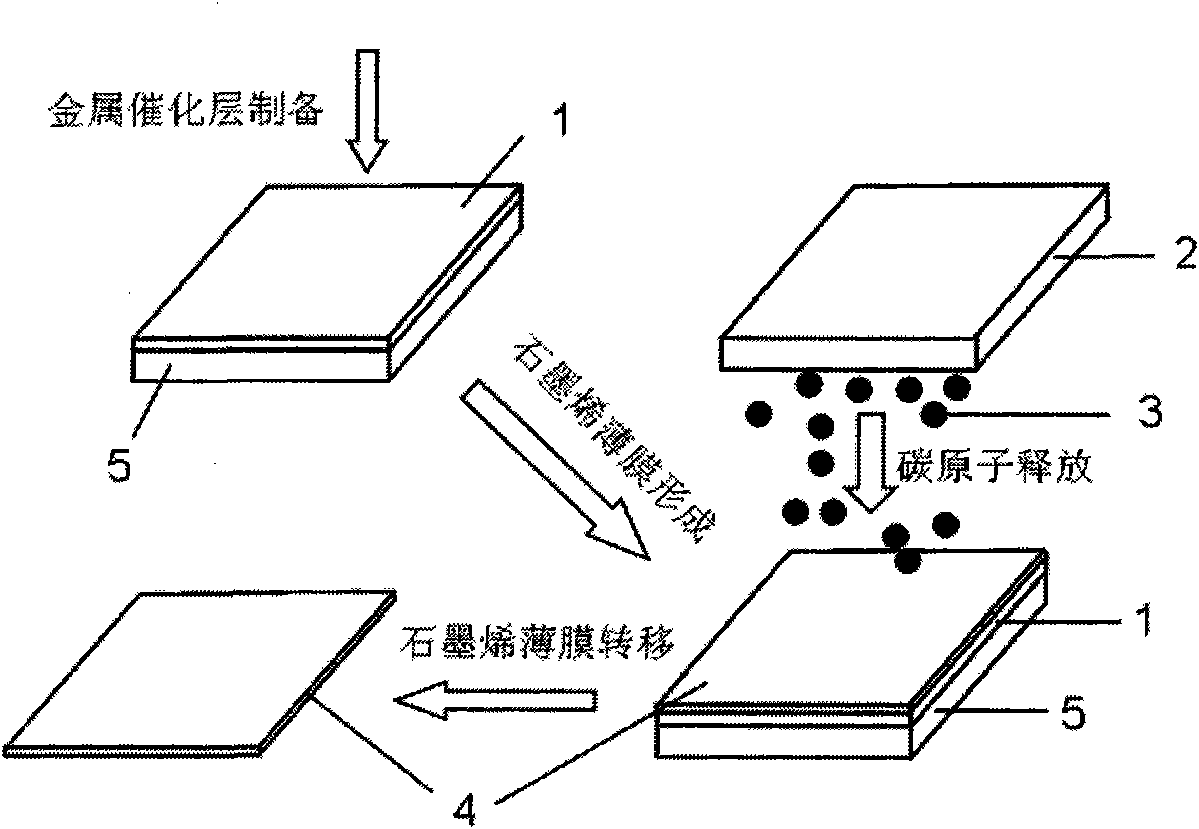

[0020] Embodiment 1: adopt highly oriented pyrolysis graphite to prepare graphene film on Ni film

[0021] In SiO 2 (300nm) / Si(500μm) prepared 300nm Ni film, and placed it together with pyrolysis graphite in high vacuum (5.0×10 -8 torr) was heat-treated at 950°C for 12 hours; then, the temperature was raised to 650°C and maintained for 10 minutes, and finally lowered to room temperature, thereby preparing a graphene film on the Ni film.

[0022] Effect: High-temperature heat treatment is used to release carbon atoms from highly oriented cracked graphite, thereby forming a graphene film on the Ni film, and a high-quality graphene film can be grown on Ni. The thickness of the graphene film is about 0.31nm, that is, a single layer graphene (#1).

Embodiment 2

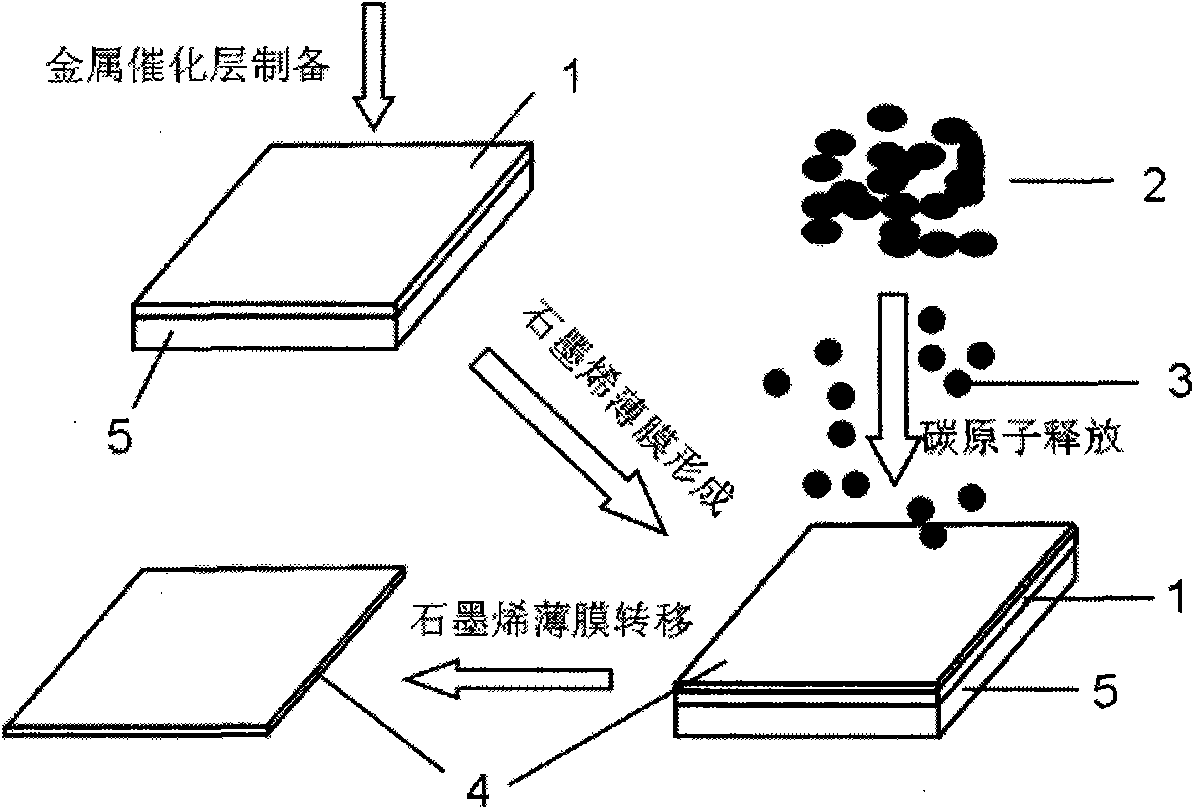

[0023] Embodiment 2: adopt highly oriented pyrolysis graphite to prepare graphene film on Ni film

[0024] A 20nm Ni film was prepared on mica, and it was placed in an ultra-high vacuum (5.0×10 -9 torr); then carry out heat treatment at 850° C. for 18 hours in a hydrogen atmosphere (10 Pa), and then heat it to 600° C. and keep it for 60 minutes, and finally drop to room temperature, thereby preparing a graphene film on Ni.

[0025]Effect: High-temperature heat treatment is used to release carbon atoms from highly oriented cracked graphite, and a single-crystal Ni film is easily formed on mica, and a graphene film is prepared in a hydrogen atmosphere. The thickness of the graphene film is about 0.31nm, that is, a single layer Graphene (#2).

Embodiment 3

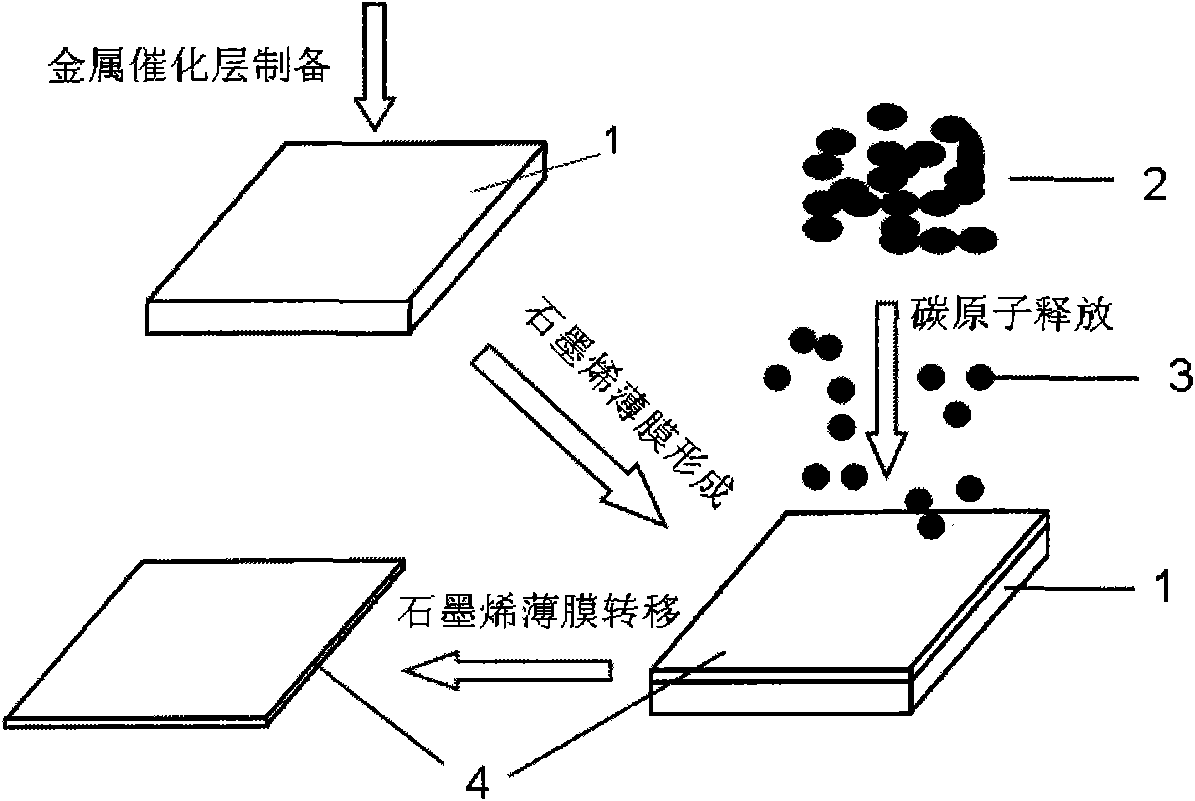

[0026] Embodiment 3: adopt graphite powder to prepare graphene film on Ni film

[0027] A 300nm Ni film was prepared on sapphire, and it was placed together with graphite powder in an ultra-high vacuum (1.0×10 -10 torr); then in a mixed atmosphere of hydrogen and argon (5Pa) after heat treatment at 450° C. for 30 hours, the temperature was lowered to room temperature, thereby preparing a graphene film on Ni.

[0028] Effect: High-temperature heat treatment is used to release carbon atoms from graphite powder, and a graphene film is prepared in a mixed atmosphere of hydrogen and argon. The thickness of the graphene film is about 0.94nm, that is, the number of layers of graphene is 3(# 3).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com