Chromium nitride aluminum-titanium composite coating, cutter deposited with same, and preparation method

A composite coating, chromium-aluminum nitride technology, used in chemical instruments and methods, coatings, metal material coating processes, etc., can solve the problem of not meeting the needs of manufacturing development, hindering the pace of manufacturing To solve the problems of friction and wear, huge economic and social benefits, and good high temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

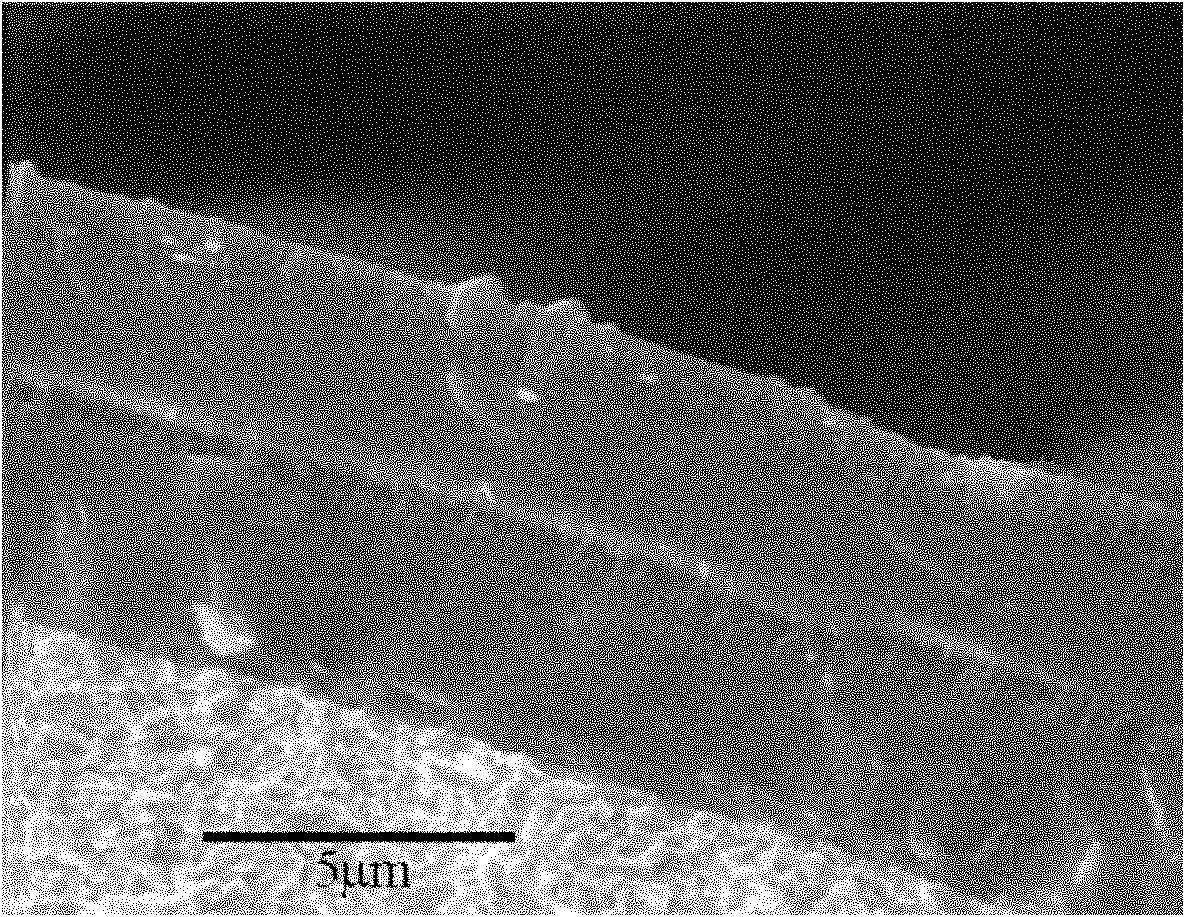

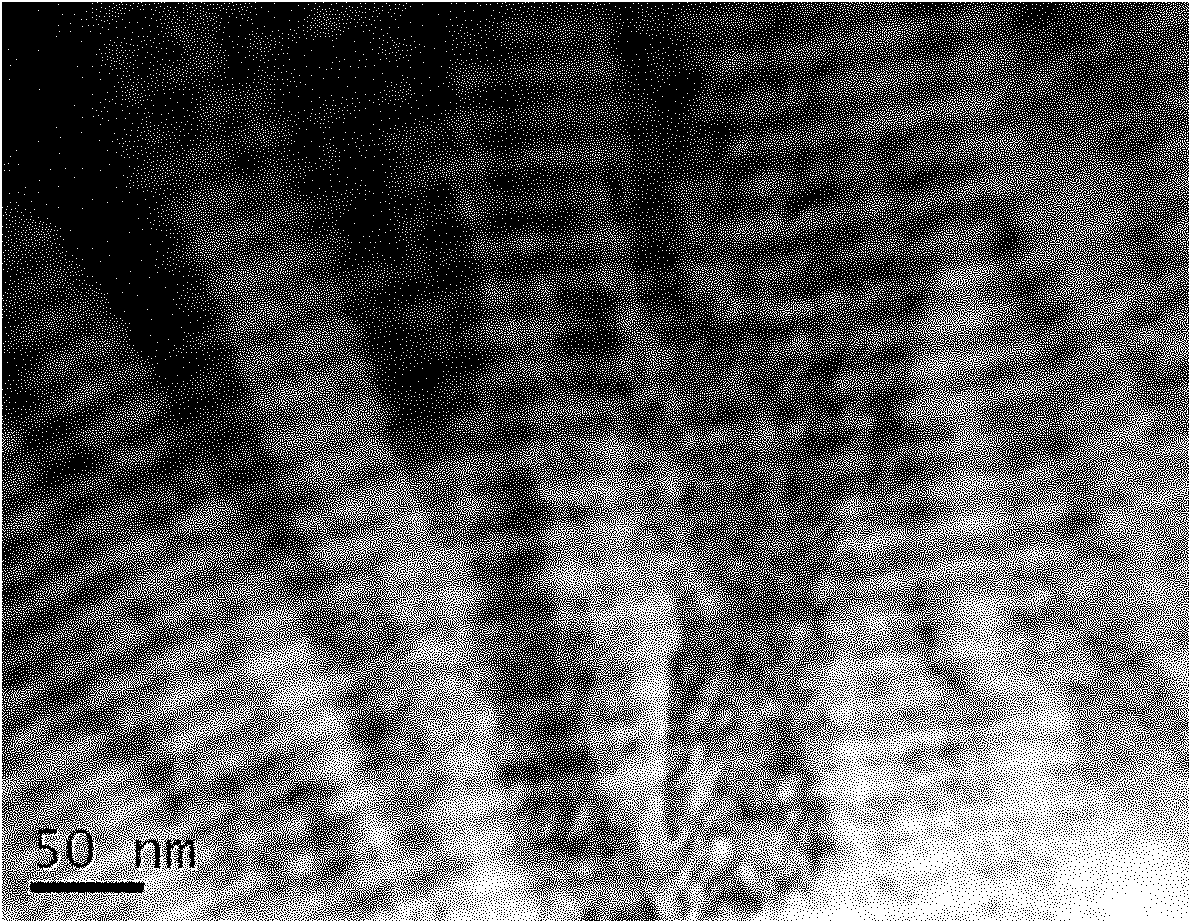

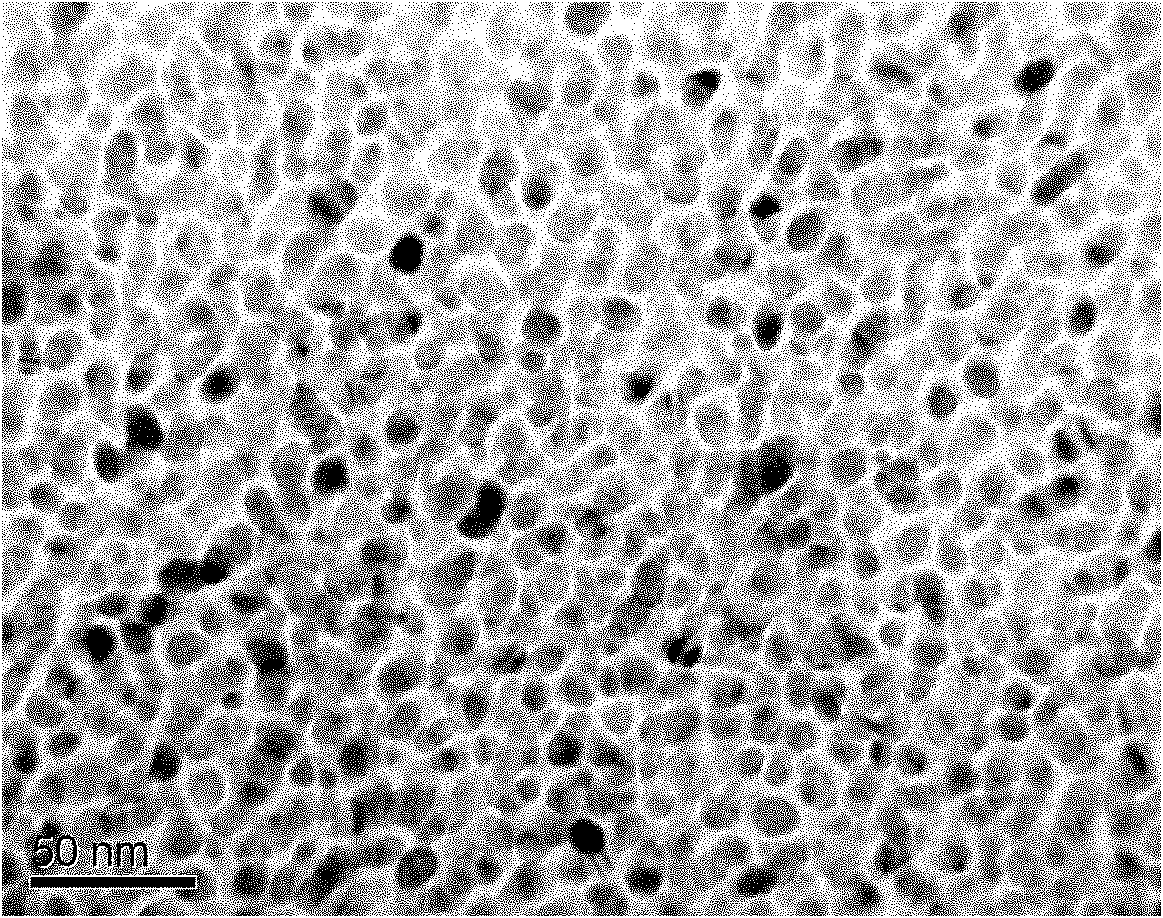

[0028] First, clean the carbide tool, clamp it on the workpiece frame, and start vacuuming. When the vacuum degree is higher than 5×10 -3 At Pa, start heating and degassing, the temperature is controlled at 200°C, and the revolution speed of the workpiece holder is 3 rpm. When the vacuum degree is 5×10 -3 At Pa, Ar gas is introduced, the temperature is controlled at 200°C, the bias power is turned on, and the bias voltage is controlled at -800V, and the tool substrate is glow-cleaned. After the glow cleaning is finished, the vacuum degree is adjusted to 2×10 -2 Pa, the bias voltage is kept at -800V, the temperature is controlled at 200°C, the Cr target is opened, and the tool substrate is bombarded to obtain a Cr bonding layer with a thickness of 70 nm; after the bombardment is completed, the bias voltage is adjusted to -200V, and the Ar gas is turned off. channel, into N 2 The vacuum degree was adjusted to 2.0 Pa, the temperature was 300°C, and a CrN support layer with a t...

Embodiment 2

[0030] Clean the hard alloy tool, clamp it on the workpiece frame, and start vacuuming. When the vacuum degree is higher than 5×10 -3Pa, start heating and degassing, control the temperature at 300°C, keep the revolution speed of the workpiece holder at 9 rpm, when the vacuum degree is 5×10 -3 At Pa, Ar gas is introduced, the temperature is controlled at 300°C, the bias power is turned on, and the bias voltage is controlled at -800V, and the tool substrate is glow-cleaned. After glow cleaning, in a vacuum of 1.5×10 -2 Pa, at a temperature of 300°C and a bias voltage of -800V, open the Cr target, and bombard the tool substrate to obtain a 100 nm thick Cr bonding layer; after the bombardment, close the Ar gas channel, 2 The vacuum degree was adjusted to 2.0Pa, the bias voltage was adjusted to -150V, the temperature was controlled at 300°C, and a 100nm-thick CrN support layer was deposited on the Cr bonding layer. After the deposition of the CrN support layer, adjust the N 2 Co...

Embodiment 3

[0032] Clean the hard alloy tool, clamp it on the workpiece frame, and start vacuuming. When the vacuum degree is higher than 5×10 -3 Pa, start heating and degassing, control the temperature at 350°C, keep the revolution speed of the workpiece holder at 12 rpm, when the vacuum degree is 5×10 -3 At Pa, Ar gas is introduced, the temperature is controlled at 350°C, the bias power is turned on, and the bias voltage is controlled at -800V, and the tool is glow cleaned. After glow cleaning, the vacuum degree is adjusted to 2.2×10 -2 Pa, the temperature is controlled at 350°C, and the bias voltage is maintained at -900V. Open the Cr target and bombard the tool substrate to obtain a 50nm thick Cr bonding layer; after the bombardment is completed, the bias voltage is reduced to -200V. Into N 2 The vacuum degree was adjusted to 2.0Pa, the temperature was controlled at 350°C, and a 200nm-thick CrN support layer was deposited on the Cr bonding layer. After the deposition of the CrN sup...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com