Patents

Literature

116results about How to "Solve uneven thickness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

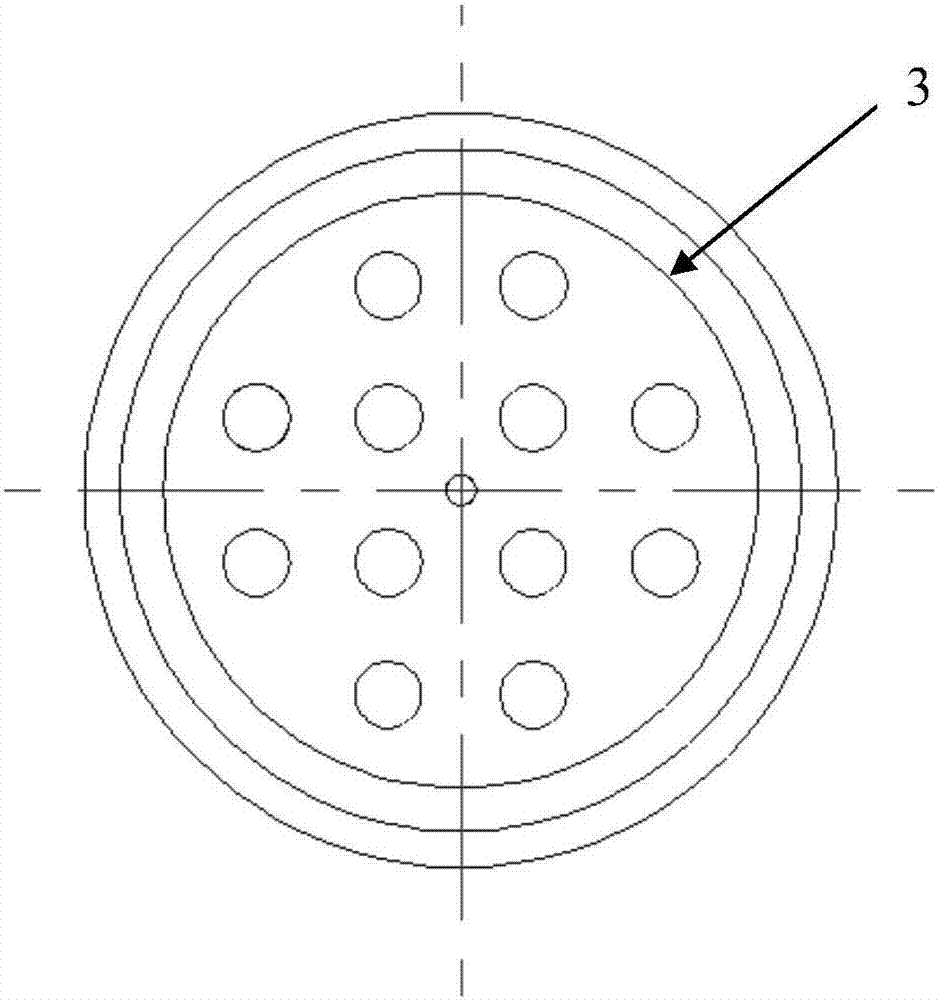

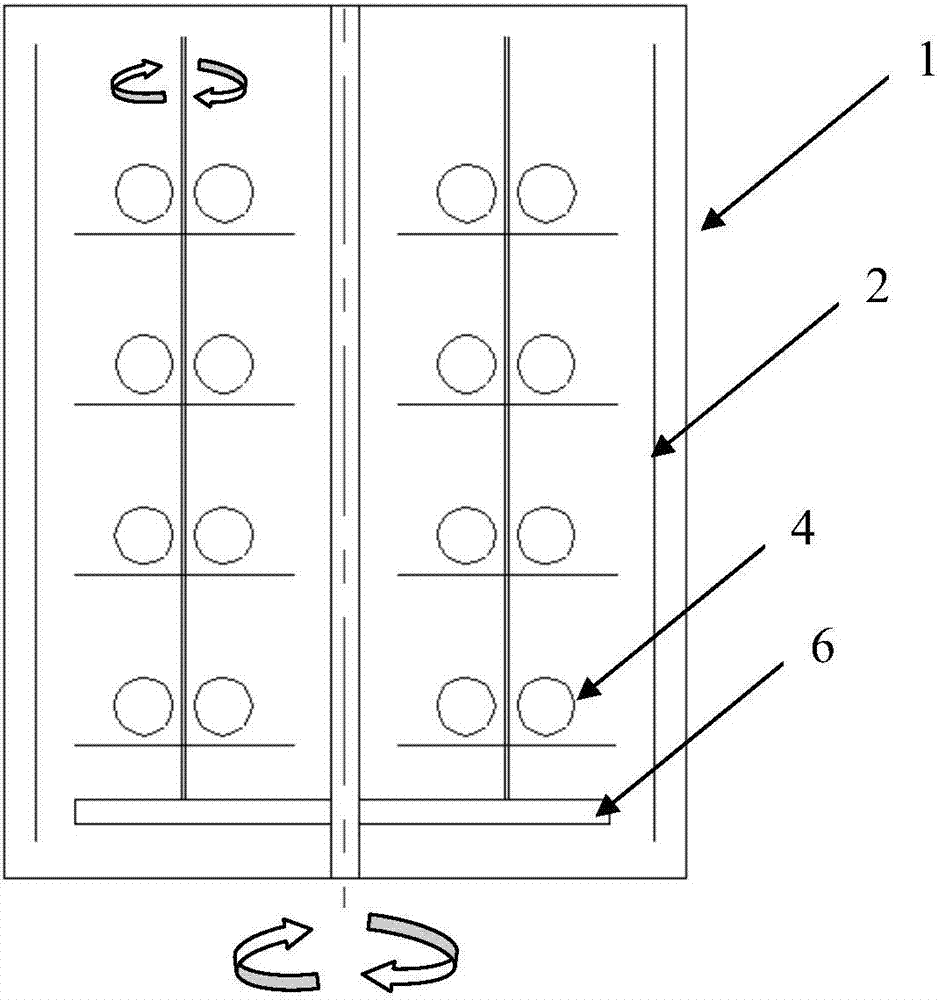

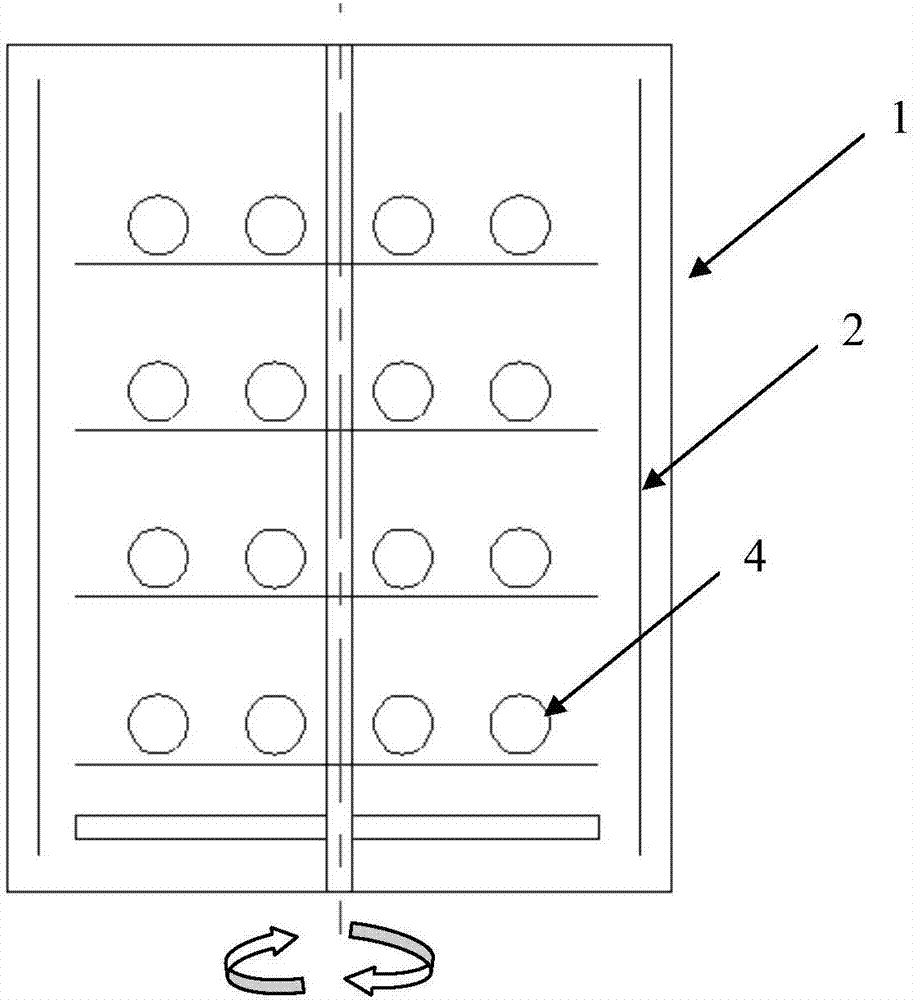

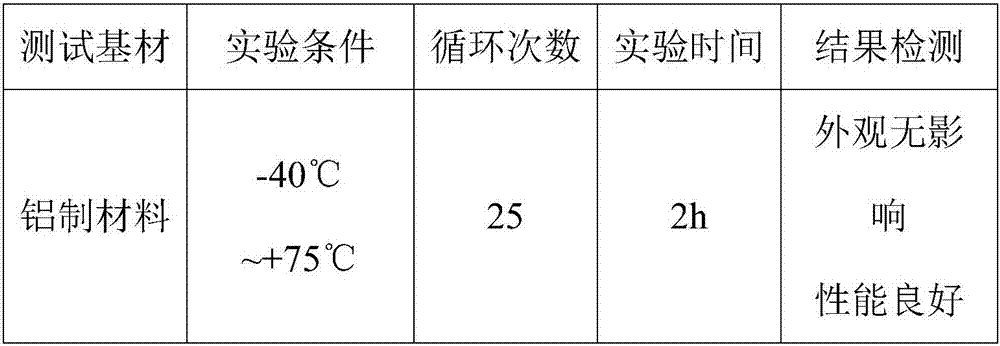

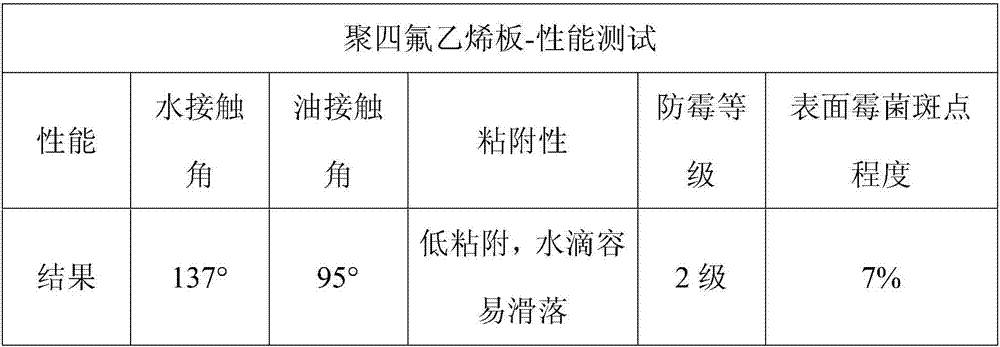

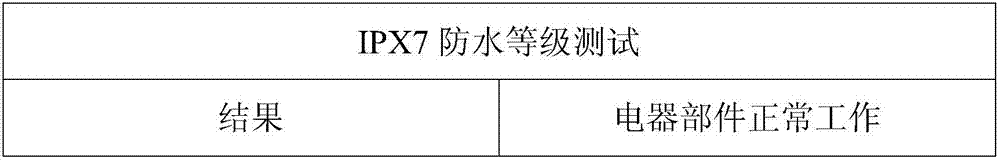

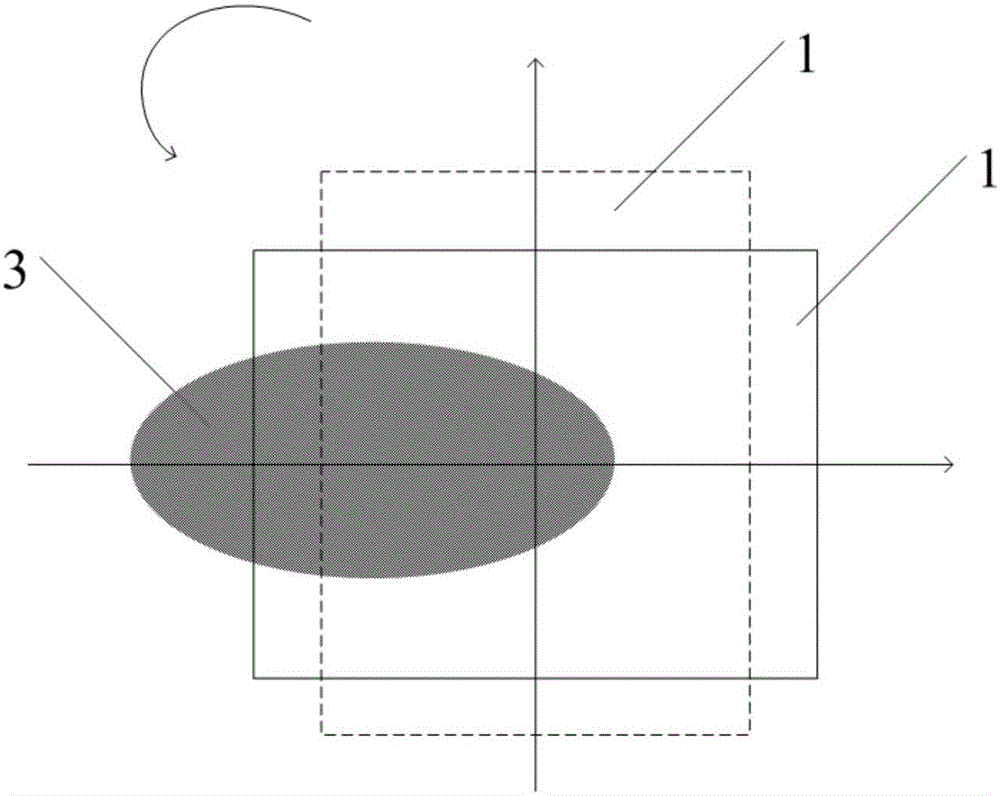

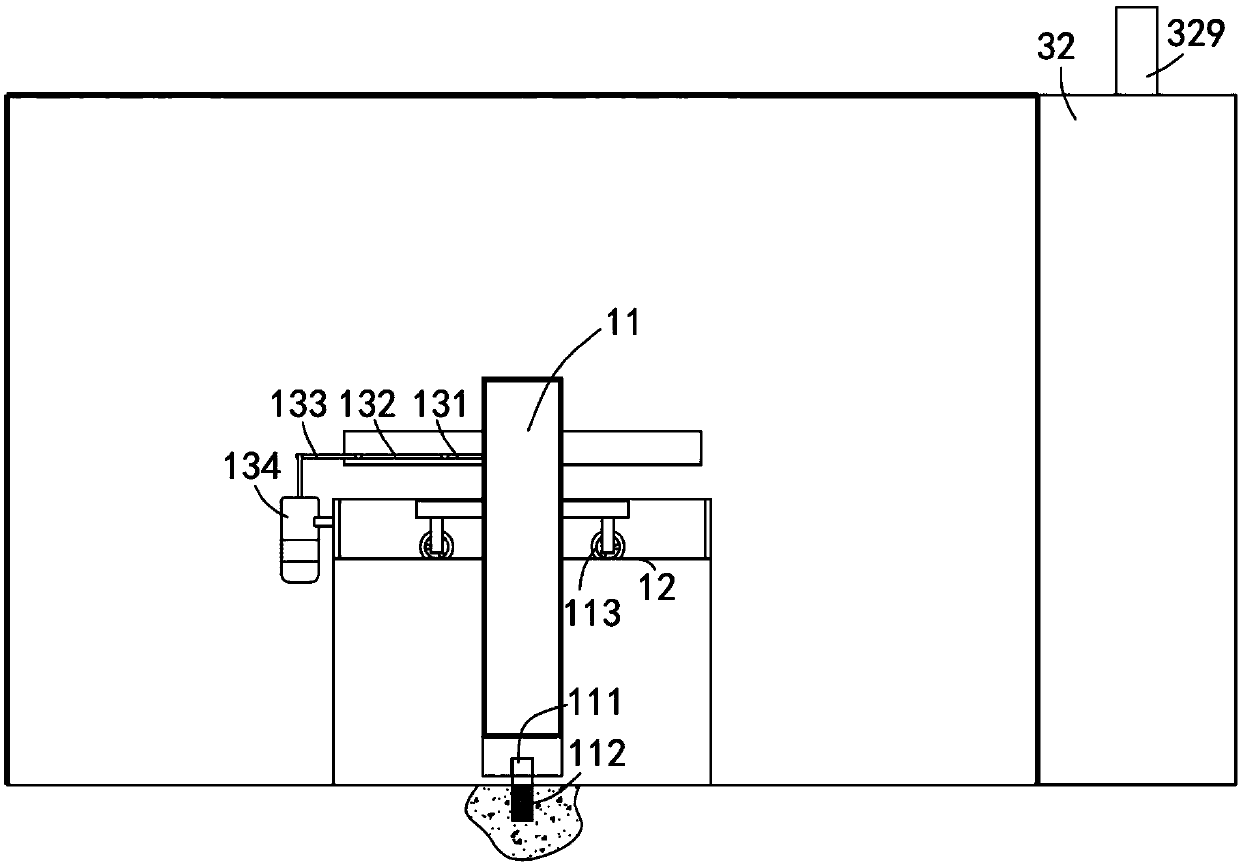

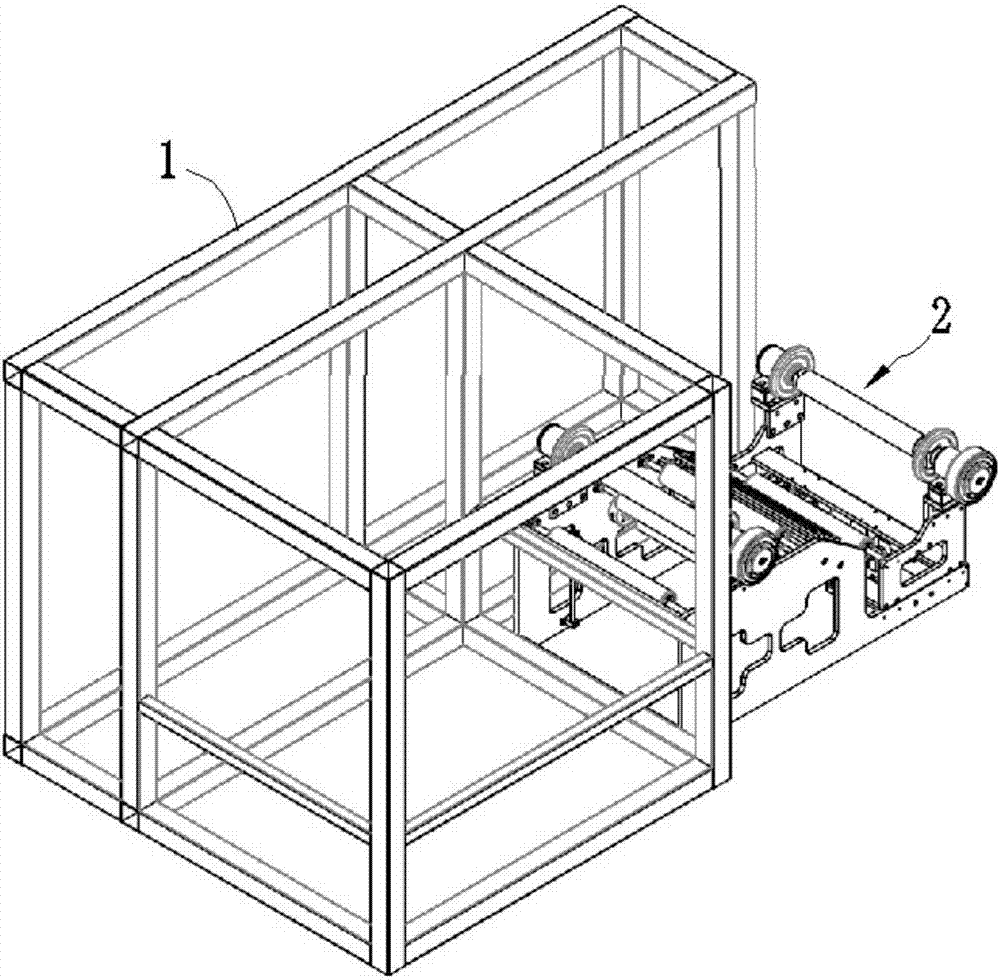

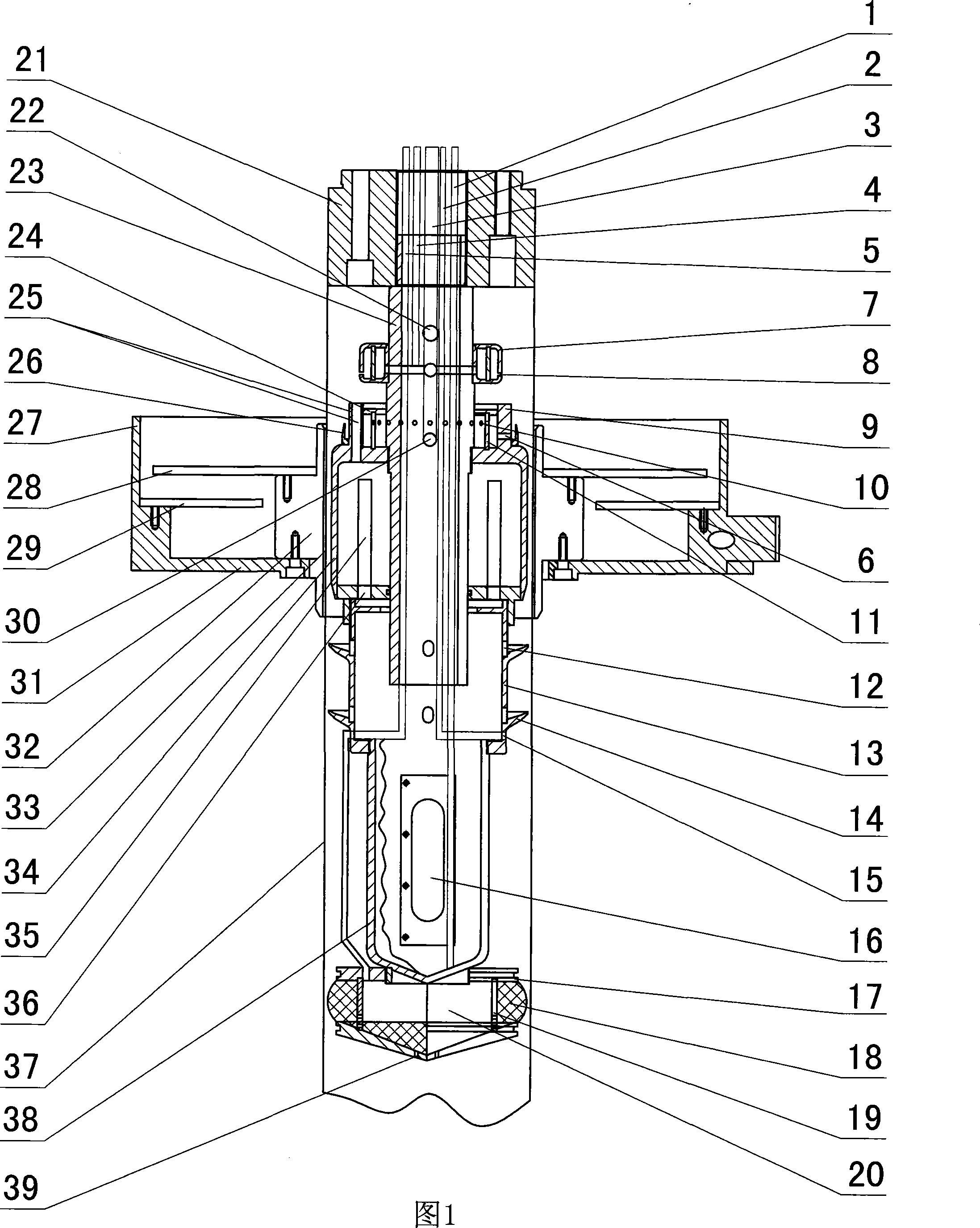

Base material motion type device and method for preparing nano coating through plasma discharge

PendingCN106958012APlay an active roleSolve uneven thicknessElectric discharge tubesNanotechnologySolventDeposition process

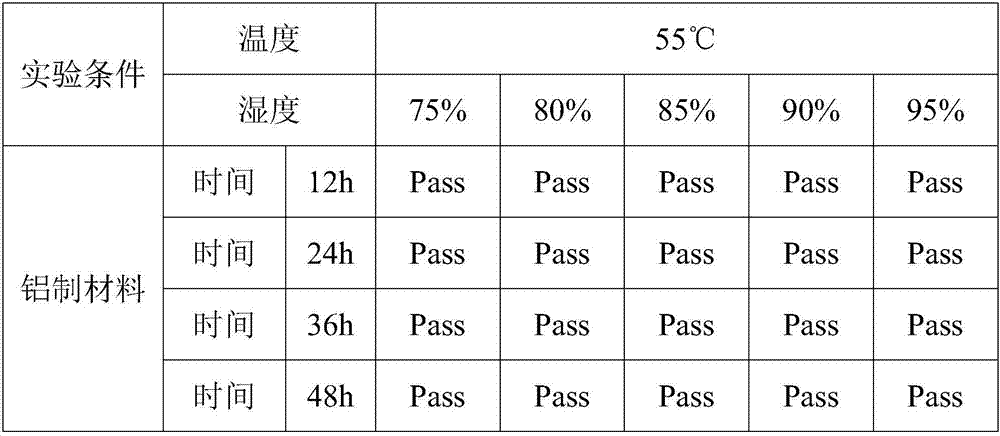

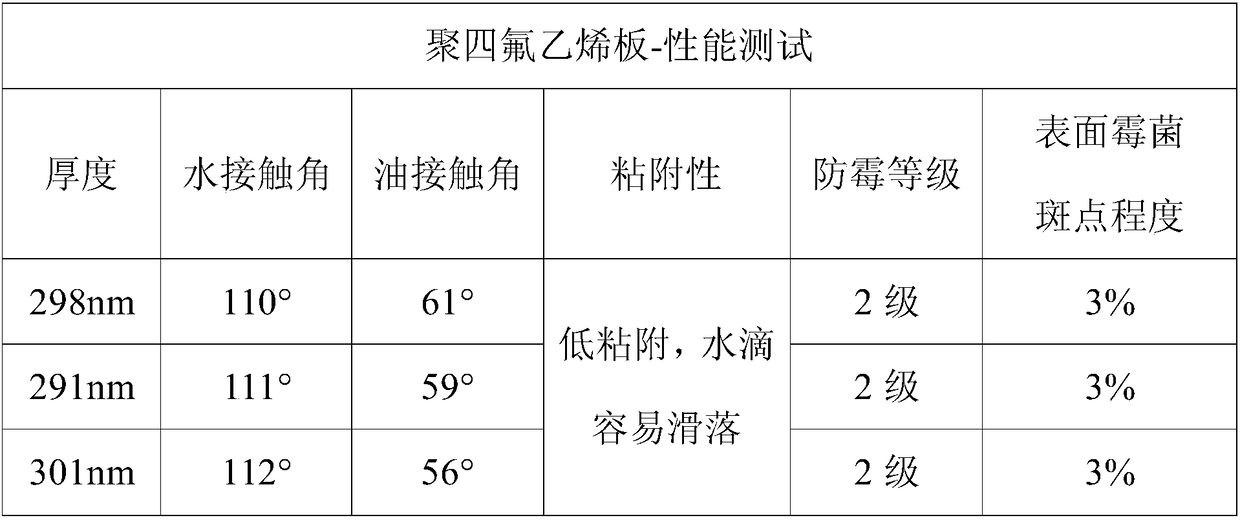

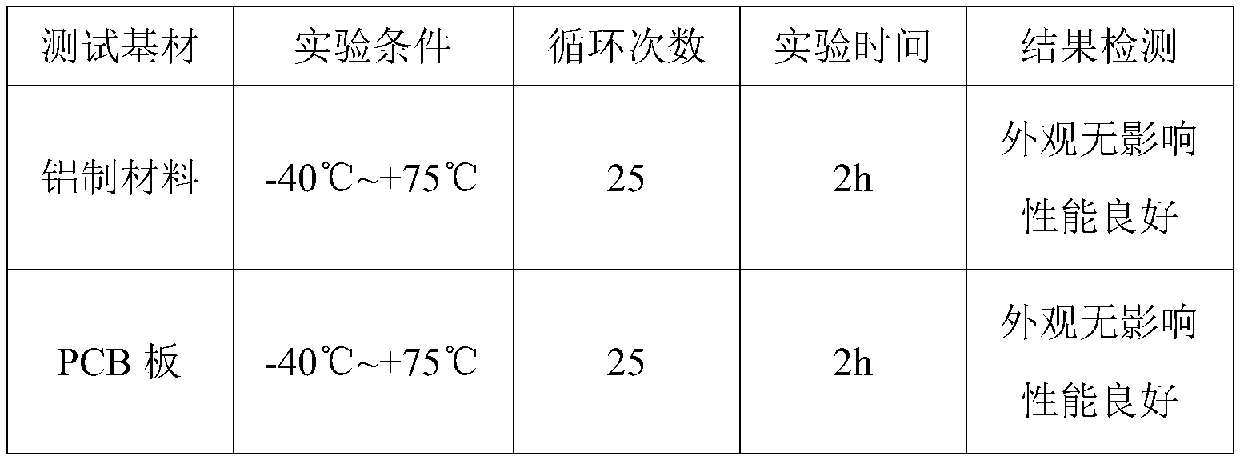

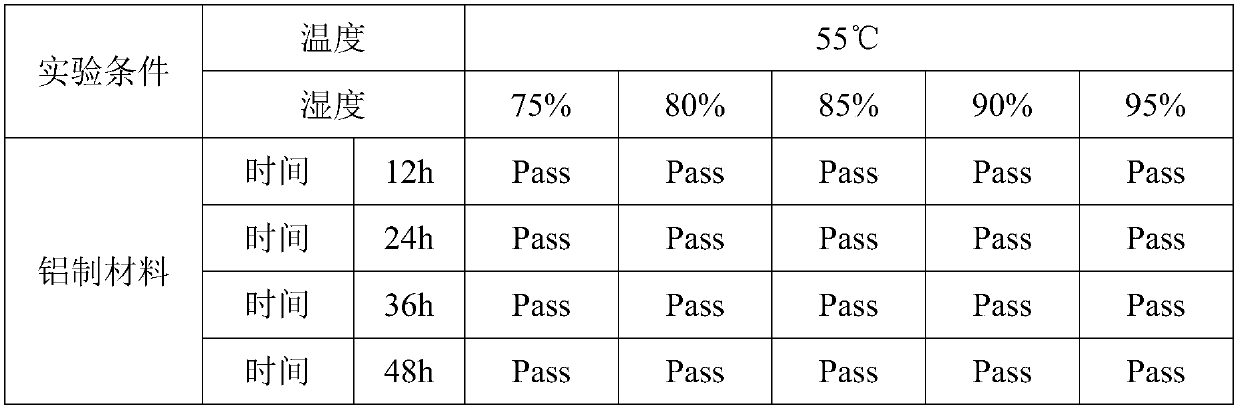

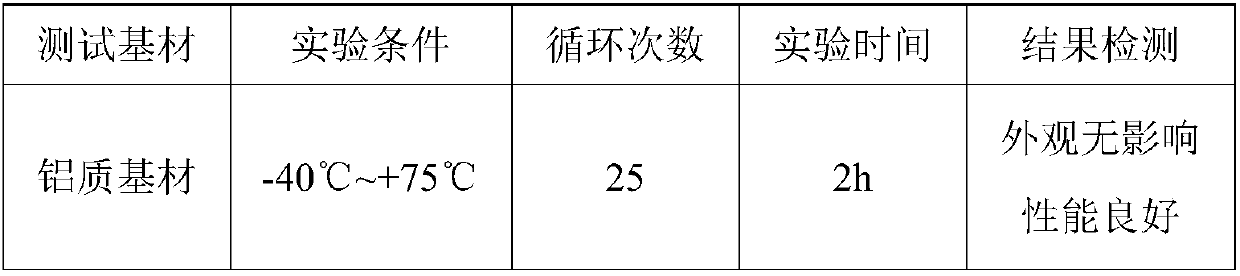

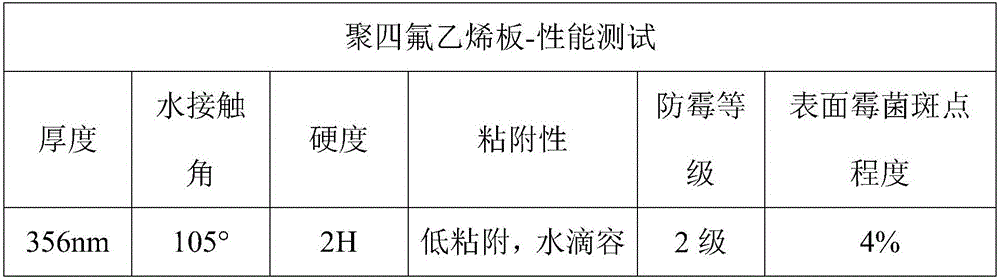

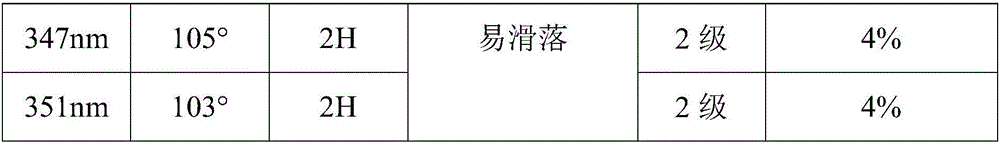

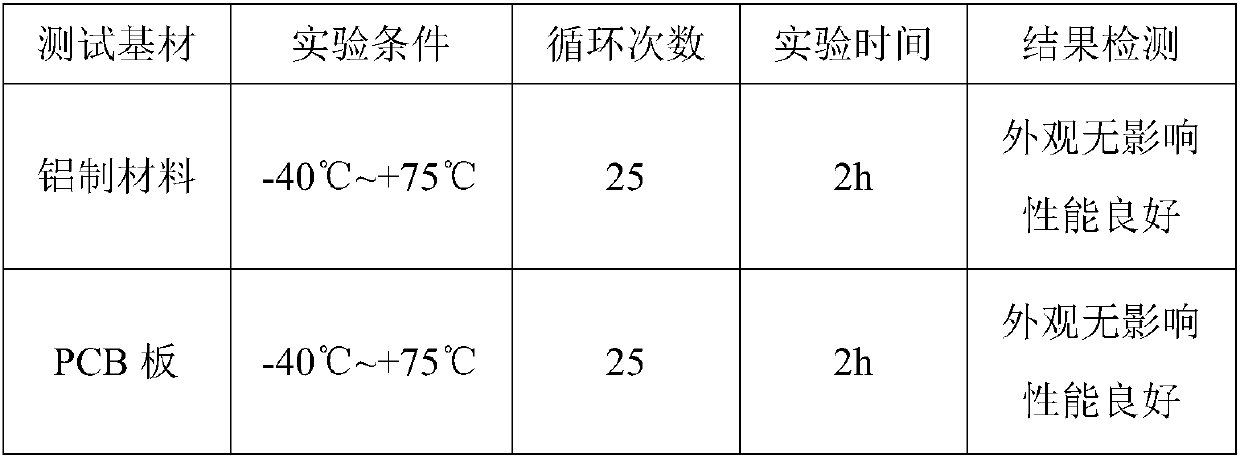

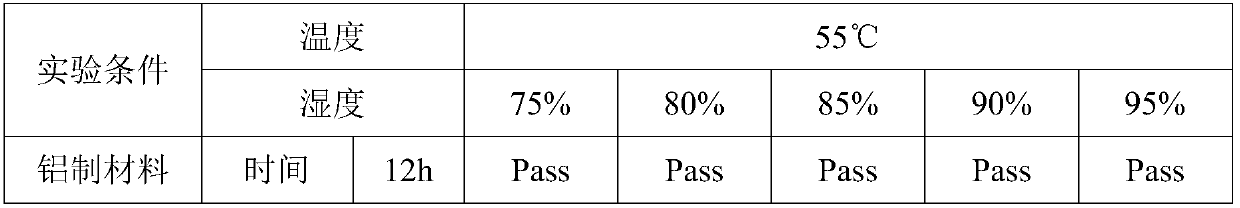

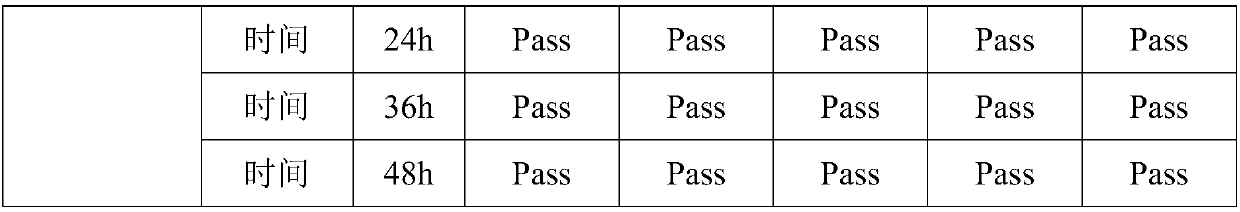

The invention discloses a base material motion type device and method for preparing a nano coating through plasma discharge, and belongs to the technical field of plasmas. The device comprises electrodes, a vacuum exhaust device, a gas pipeline and a base material fixing device; and the method comprises the following steps that the base material fixing device can do motions in the space formed by the electrodes under the driving of a moving mechanism, and monomer steam is introduced into a reaction chamber to carry out plasma chemical vapor deposition, wherein the deposition process comprises a pretreatment stage and a coating stage, the plasma discharge mode in the pretreatment stage is high-power continuous discharge and the plasma discharge mode in the coating stage is small-power continuous discharge. In the preparation process of the coating, the movement characteristic of the base material and the plasma discharge energy are combined and linked; the base material does motions while the plasma discharge occurs, so that the coating deposition efficiency is improved, and the uniformity and compactness of the thickness of the coating are improved; and the coating prepared by the method has the characteristics of being waterproof, moisture-proof, and anti-fungus, and has acid solvent resistance, alkaline solvent resistance, acid salt mist resistance, alkaline salt mist resistance and the like.

Owner:JIANGSU FAVORED NANOTECHNOLOGY CO LTD

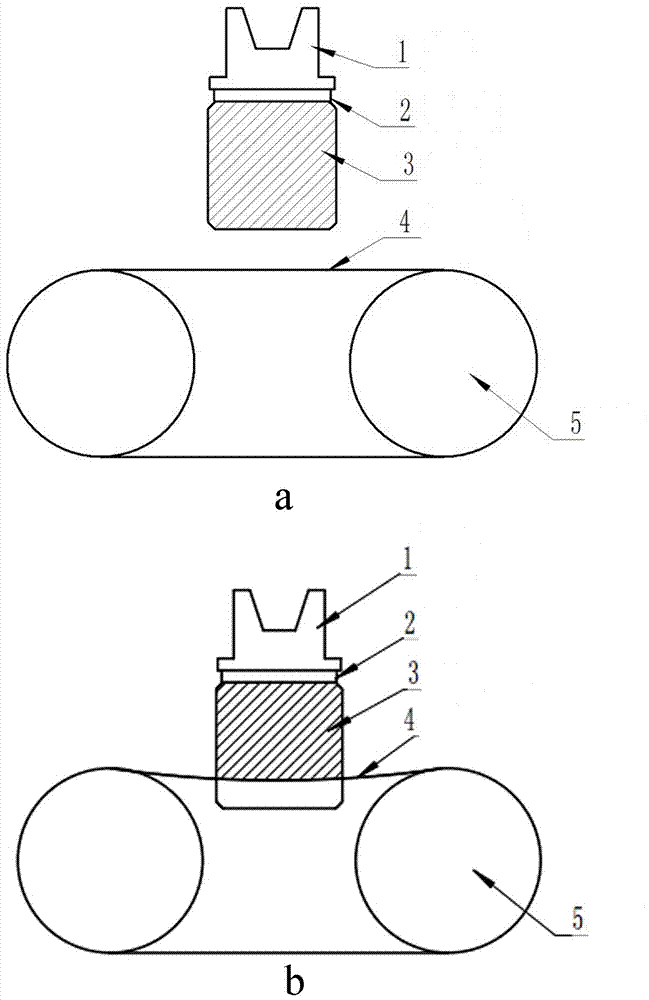

Method for efficiently cutting silicon slice by electroplated diamond wires

ActiveCN107116712AImprove yieldIncrease feed cutting speedGrinding machinesFine working devicesCrystalline siliconReciprocating motion

The invention provides a method for efficiently cutting a silicon slice by electroplated diamond wires. The method comprises the following steps of (1) gluing a rod; (2) performing feeding; (3) compounding cutting liquid; (4) performing cutting, wherein the cutting is realized in a manner that a silicon rod is driven by a cutting machine frame to move towards an electroplated diamond wire net and at the same time, the electroplated diamond wire net is driven by a main roll to be in reciprocating motion, the density of diamond grains on the electroplated diamond wires is 200-350 grains / mm, in the cutting process, the cutting tension of the electroplated diamond wires is 6-16N, the linear speed of the electroplated diamond wires is 1200-1800m / min, the cutting speed of a work piece is 0.8-3.5 mm / min, the temperature of cutting liquid is 18-23 DEG C, and in the cutting process, the electroplated diamond wires adopt a gradual progressive method or a manner of performing supplying in a reverse direction first and then performing supplying in a forward direction; (5) performing blanking; (6) performing ungluing, and performing washing; and (7) performing detecting and packaging. Through the cutting method disclosed by the invention, the smooth cutting of the crystalline silicon rod of 8.4inch and 650-700mm can be completed in two hours.

Owner:杨凌美畅新材料股份有限公司

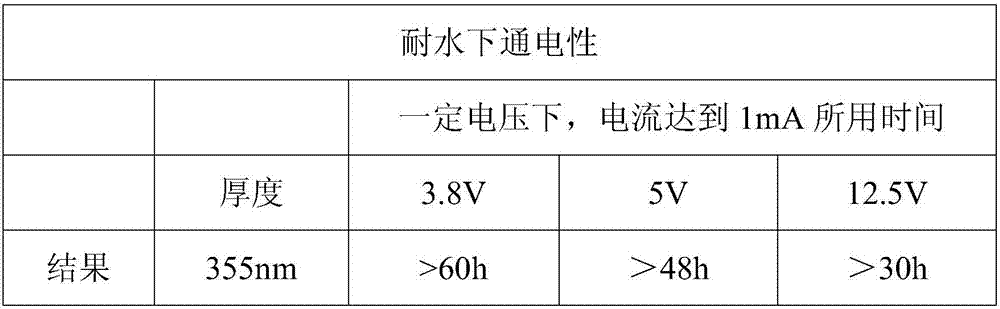

Preparation method of high-insulating nanometer protective coating

InactiveCN107699868AImprove controllabilityOptionalChemical vapor deposition coatingParyleneGas phase

The invention relates to a preparation method of a high-insulating nanometer protective coating, and belongs to the technical field of plasmas. According to the method, a reaction cavity is vacuumized, inert gas is led in to enable a base material to move, monomer steam is led into the reaction cavity, plasma discharging is started, chemical vapor deposition is carried out, and the high-insulatingnanometer protective coating is prepared by conducting chemical vapor deposition on the surface of the base material; the monomer steam is a mixture of at least one kind of low dipole moment organicmatter monomer and at least one kind of polyfunctional unsaturated hydrocarbon and hydrocarbon ramification; and according to the method, the organic matter monomers with the low dipole moment and thehigh chemical inertia are screened out, the free volume and the compactness of the coating are regulated and controlled through the polyfunctional monomer, due to the fact the plasma chemical vapor deposition method can be suitable for many monomers and can be high in controllability on the ingredient and the structure of the formed coating, the deposited coating has the more excellent protectionperformance and insulation performance compared with existing coatings like parylene under the condition that the thickness is the same.

Owner:JIANGSU FAVORED NANOTECHNOLOGY CO LTD

Preparation method of coating with thiol compound as transition layer

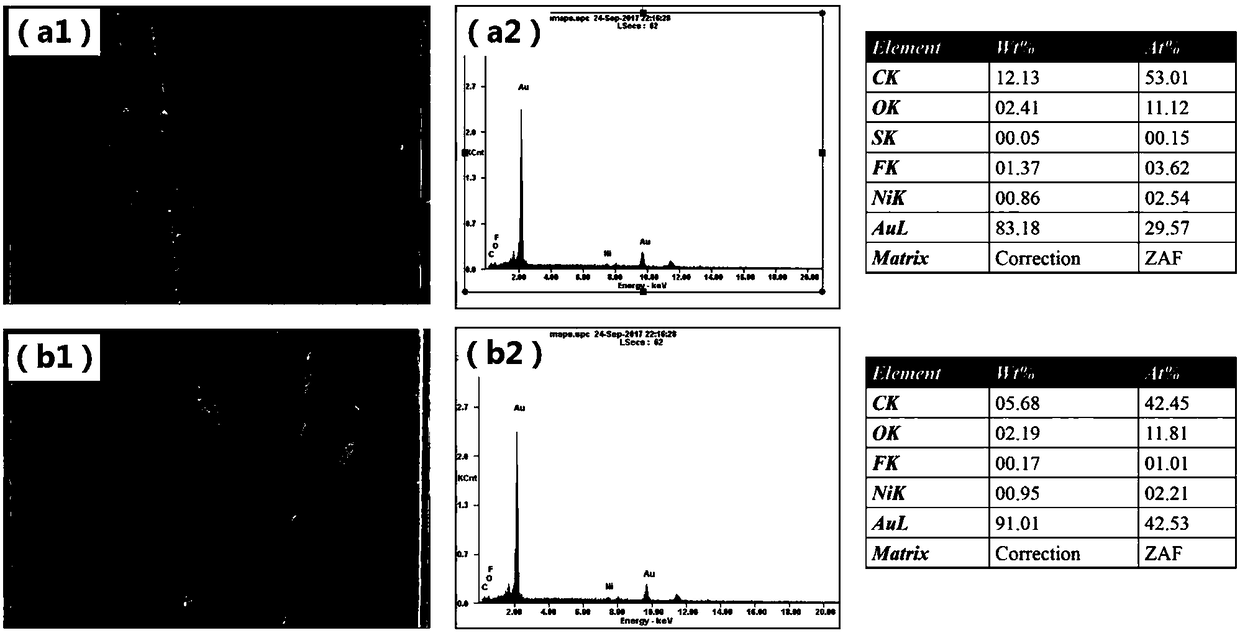

ActiveCN108425104AImprove controllabilityOptionalChemical vapor deposition coatingEpoxyBound property

The invention discloses a preparation method of a coating with a thiol compound as a transition layer, and belongs to the technical field of plasmas. According to the method, a sulfydryl-containing thin layer is adopted as the transition layer between the coating and a substrate; before the coating is deposited, the thin layer of 1-10 nm is deposited on the surface of the substrate by using a sulfydryl-containing monomer, wherein the sulfydryl at one end of the monomer reacts with the surfaces of copper, gold, nickel, epoxy resin and the like, so that a chemical bond is formed, the excellent binding property is kept, and the other end of the monomer is polymerized, and has the excellent binding property with the coating on the upper layer. According to the method for depositing the transition layer, the binding force of the coating and the substrate is greatly improved; according to the method , the environmental protection property is high, the deposition temperature is low, the speedis higher, and the controllability of the coating structure and the composition is high, and the selectivity of the monomer is high; the deposition efficiency is high, and the compactness of the obtained organic silicon nano-protection coating is remarkably improved; and the binding force obtained by the coating on different substrates can be improved by 30-50%.

Owner:JIANGSU FAVORED NANOTECHNOLOGY CO LTD

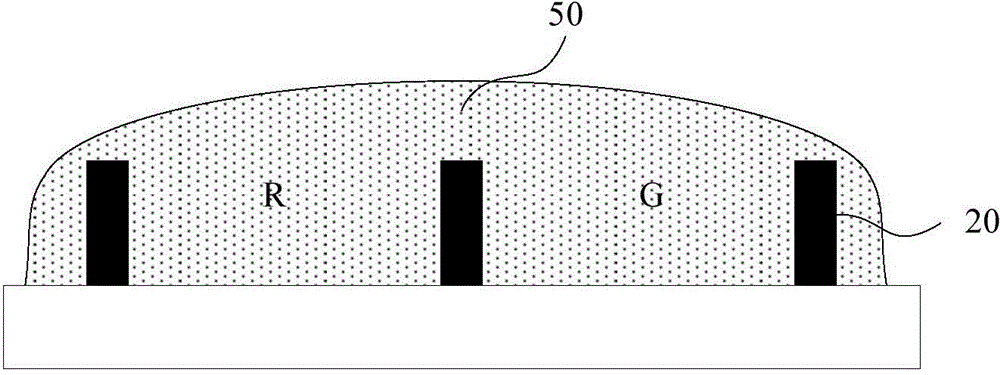

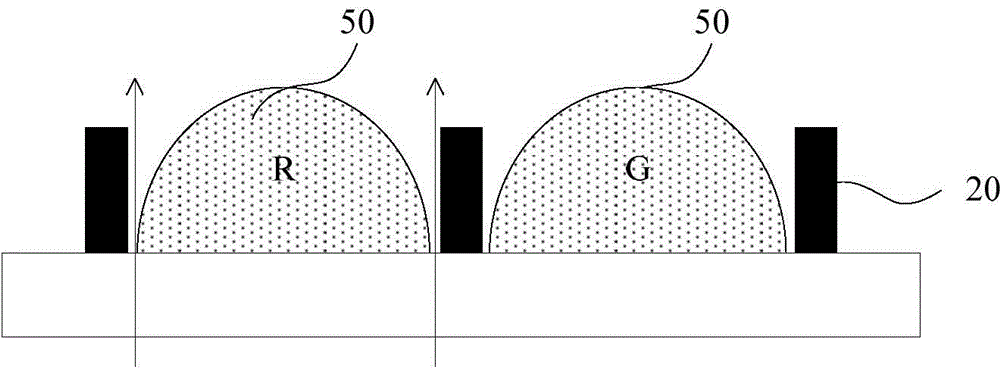

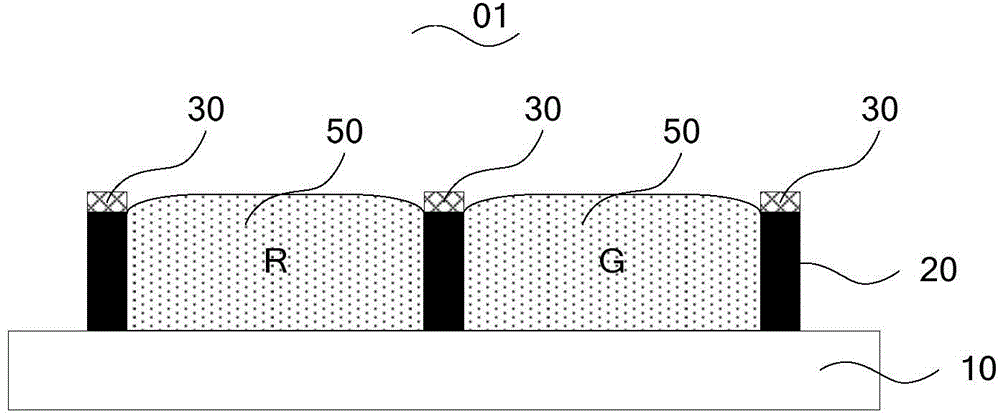

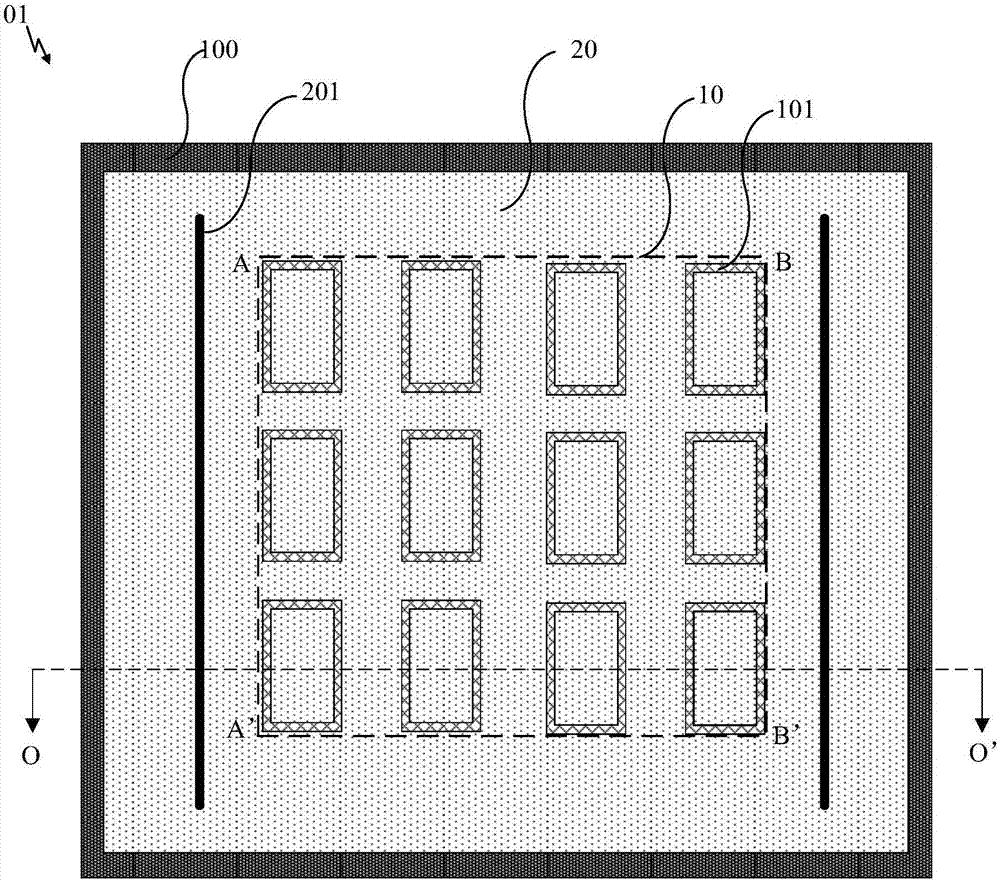

Color filter, manufacturing method thereof and display device

InactiveCN104090419AUniform thicknessImprove brightness uniformityNon-linear opticsIsolation layerDisplay device

The embodiment of the invention provides a color filter, a manufacturing method of the color filter and a display device and relates to the technical field of display. The color filter can effectively solve the problem that when a color filter unit is manufactured through the ink jet method, ink with different colors in sub-pixel units partitioned by the black matrix is mixed or the ink is uneven in thickness. When the color filter is applied to color display, the evenness of the brightness of a displayed image can be effectively improved, and light leak is prevented. The color filter comprises a substrate, a black matrix arranged on the surface of the substrate, color filter units arranged in sub-pixel units and further comprises an isolating layer arranged on the upper surface of the black matrix, wherein the black matrix defines the multiple sub-pixel units, each color filter unit is composed of color ink, the black matrix and the color ink have the same hydrophilicity and hydrophobicity, and hydrophilicity and hydrophobicity of the isolating layer are opposite to those of the black matrix and the color ink. The color filter and the display device comprising the color filter can be manufactured through the method.

Owner:BOE TECH GRP CO LTD

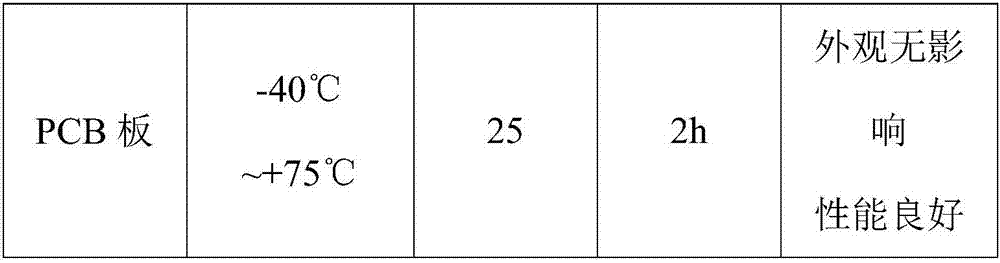

Method for preparing multifunctional nanometer protection coating through circulation small-power continuous discharge

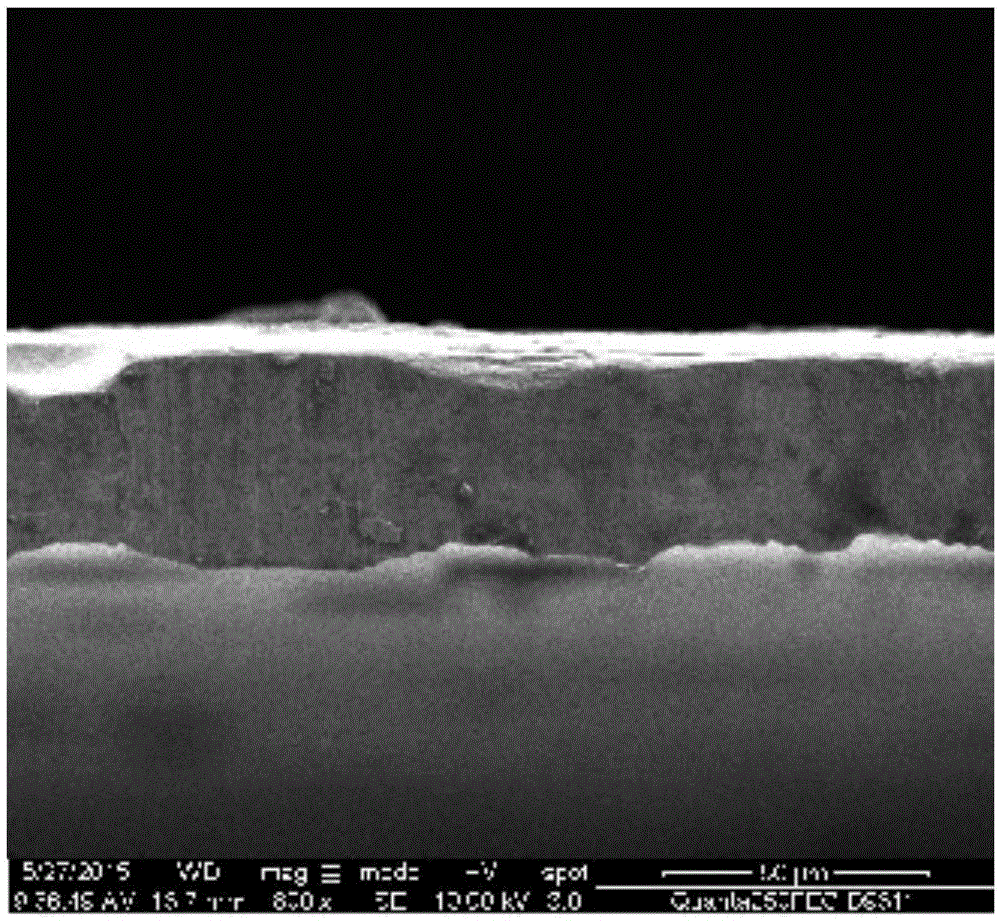

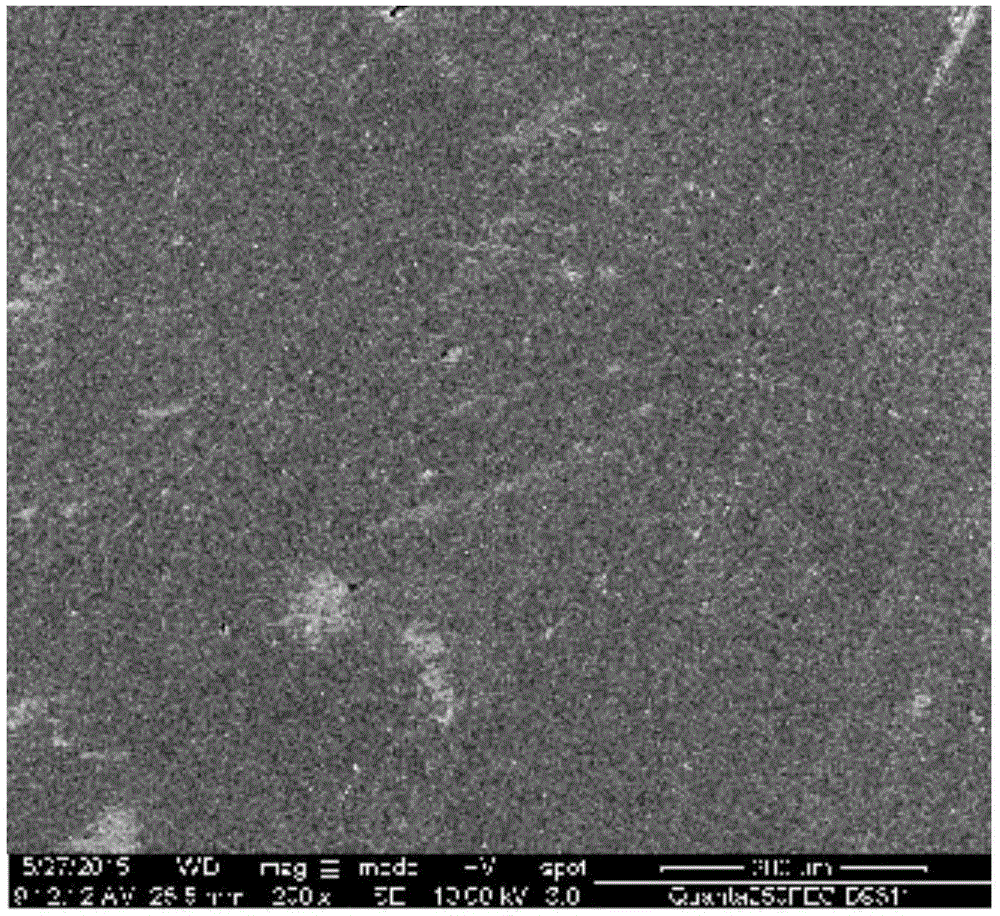

ActiveCN107142465AImprove the protective effectCoating increaseNanotechnologyChemical vapor deposition coatingChemical vapor depositionMoisture

The invention discloses a method for preparing multifunctional nanometer protection coating through circulation small-power continuous discharge, and belongs to the technical field of multifunctional nanometer protection coating through circulation small-power continuous discharge. The method comprises the steps that a reaction cavity is vacuumized, inert gas is introduced into the reaction cavity, a base material moves in the reaction cavity, monomer steam is introduced into the reaction cavity, chemical vapor deposition is carried out and comprises a pretreatment stage and a film coating stage, the plasma discharge mode is large-power continuous discharge in the pretreatment stage, the plasma discharge mode is small-power continuous discharge in the film coating stage, the pretreatment stage and the film coating stage are cycle and repeated at least one time, more active sites more introduced to the surface of the base material in a circulation mode in the film coating technological process, effective film coating is added, the film structure is more compact, the nanometer coating with of the multi-layer composite structure is obtained, multiple layers of protection are provided for the product, the more compact coating structure is shown microscopically, and excellent hydrophobicity, adhesive force, acid and base resistance, mechanical performance and moisture and heat resistance are shown macroscopically.

Owner:JIANGSU FAVORED NANOTECHNOLOGY CO LTD

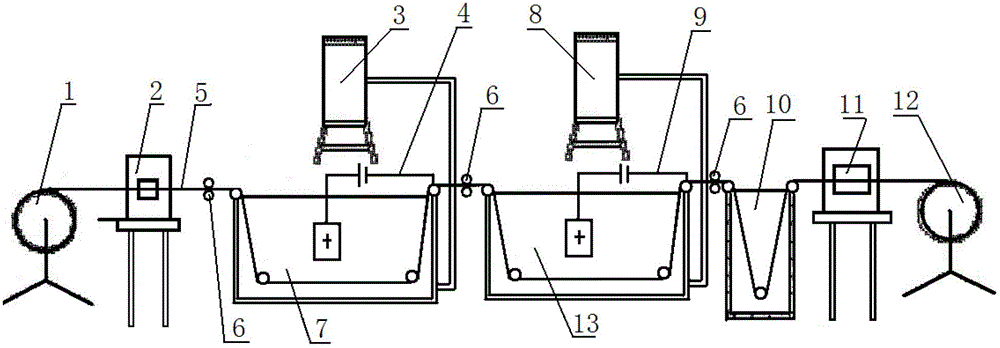

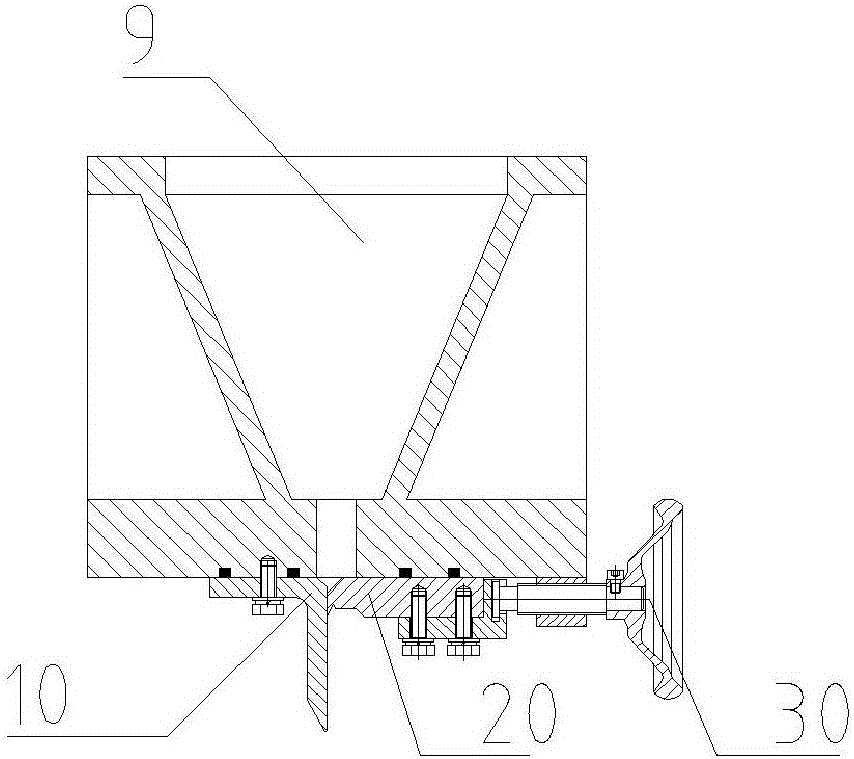

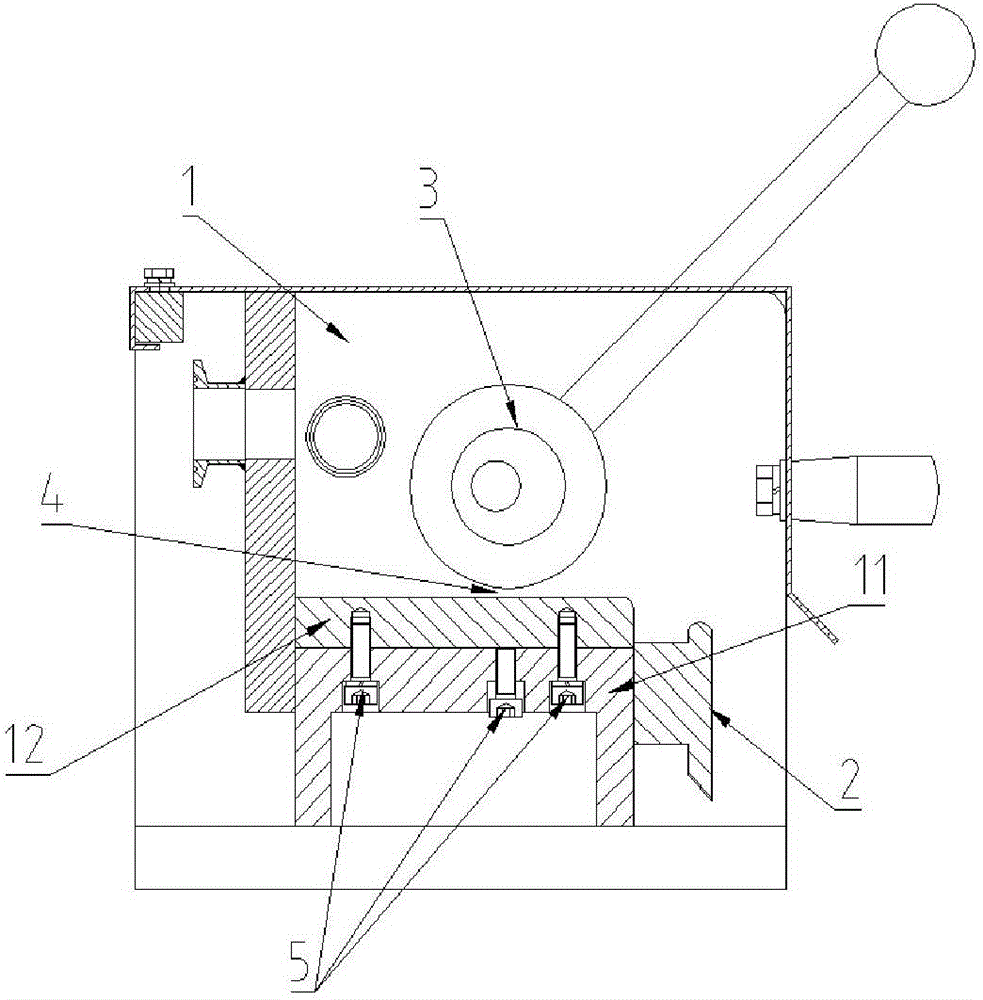

Device for plating metal by multiple beams of continuous long carbon fibers simultaneously and method thereof

The invention discloses a method for plating metal by multiple beams of continuous long carbon fibers simultaneously. At least 16 beams of continuous carbon fibers are connected in parallel, the spacing distance of the beams is 0.5-3 cm, and after being degummed and cleaned, all the continuous long carbon fibers are soaked in a plating bath for surface plating synchronously through two stages of electrolytic deposition, and are washed and dried after the second stage of surface plating; the continuous long carbon fibers enter and pass by a metal electric conduction roller at the front end of each stage of plating bath at the same time, the electric contact conditions of the continuous long carbon fibers are consistent, and the continuous long carbon fibers proceed at the same linear speed; at the same time the metal electric conduction roller is connected with a cathode of a power source to realize the connection of the continuous long carbon fibers and the cathode; and each beam of long carbon fiber is powered up by an independent power source, the current of the long carbon fiber is regulated and controlled independently, the problem of fiber winding caused by the nonuniform speed can be avoided, continuous plating is ensured, and the production efficiency of carbon fiber plating is improved.

Owner:TIANJIN UNIV

Preparation method for high-insulation hard nanometer protection coating of composite structure

ActiveCN107587119AHigh hardnessImprove insulation performanceChemical vapor deposition coatingPlasma technologyWear resistant

The invention provides a preparation method for a high-insulation hard nanometer protection coating of a composite structure, belonging to the field of plasma technology. According to the method, a reaction cavity is vacuumized and inert gas is introduced to allow a substrate to move, so organosilicon monomers with low dipole moment and high chemical inertia are screened out; the free volume and compactness of a coating are regulated and controlled through multifunctionality monomers, so the coating is allowed to have insulating properties and excellent protection performance and wear resistance at the same time; and an organosilicon coating is deposited on the coating with high insulating properties, and surface hard treatment is carried out so as to form a hard coating with a compact structure. The high-insulation hard nanometer protection coating provided by the invention has more excellent protection performance, insulating properties and wear resistance compared with conventionalcoatings such as parylene under the condition of same thickness. The preparation method provided by the invention overcomes the problems of poor wear resistance, too great thickness, low production efficiency and the like of conventional parylene coatings; and through hard treatment, a composite wear-resistant silica structure is increased in the coating, and the hardness and wear resistance of the coating are effectively improved.

Owner:JIANGSU FAVORED NANOTECHNOLOGY CO LTD

High-flatness paint-free simulation ecological plate and manufacturing method thereof

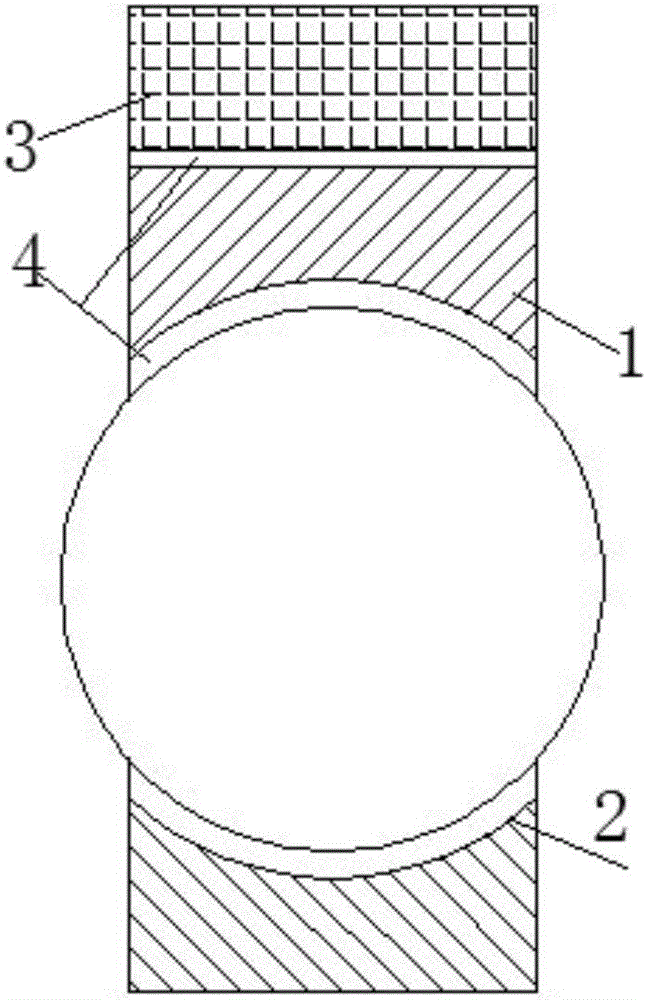

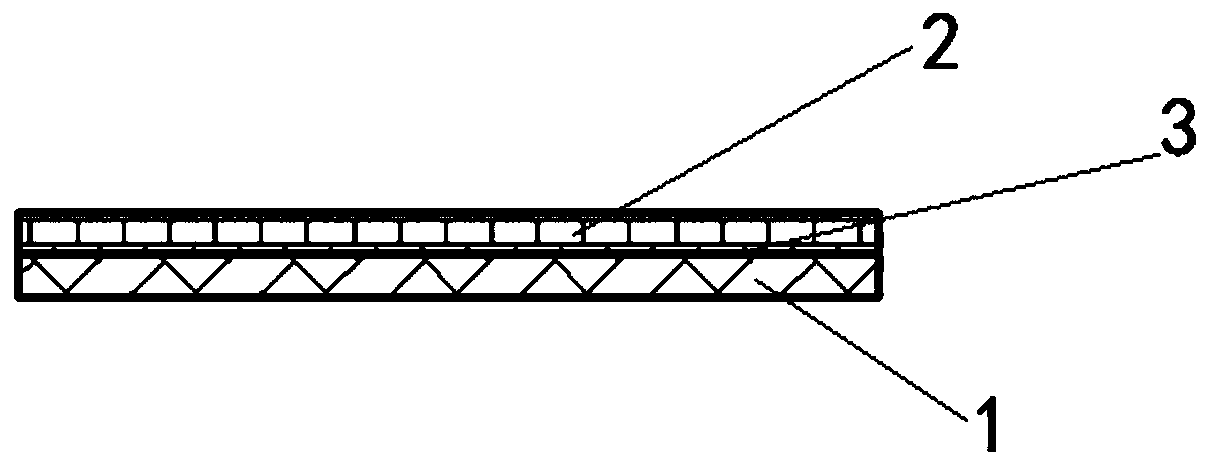

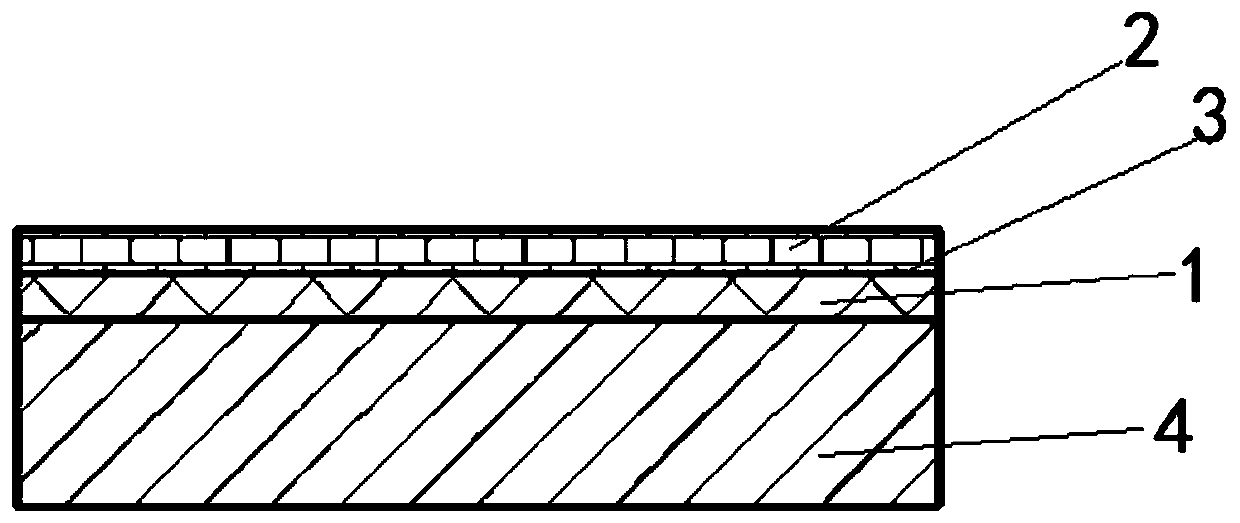

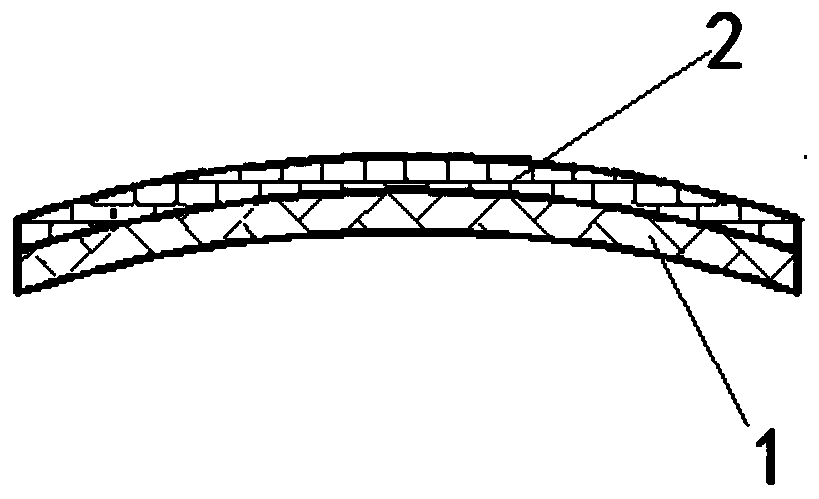

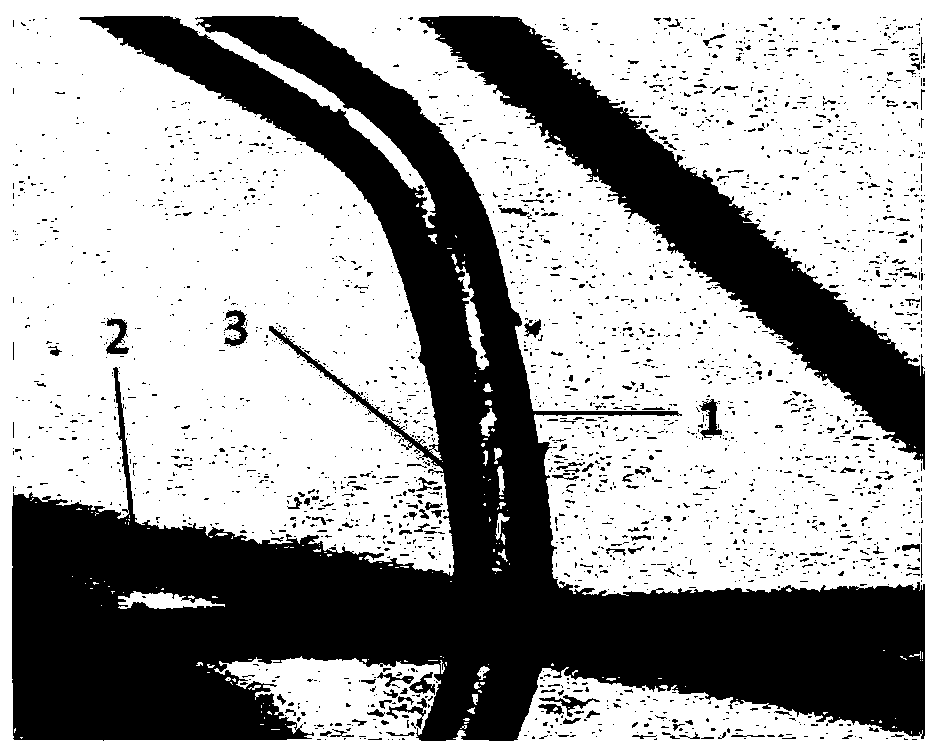

InactiveCN103231422AImprove flatnessSolve uneven thicknessLaminationLamination apparatusLacquerAdhesive

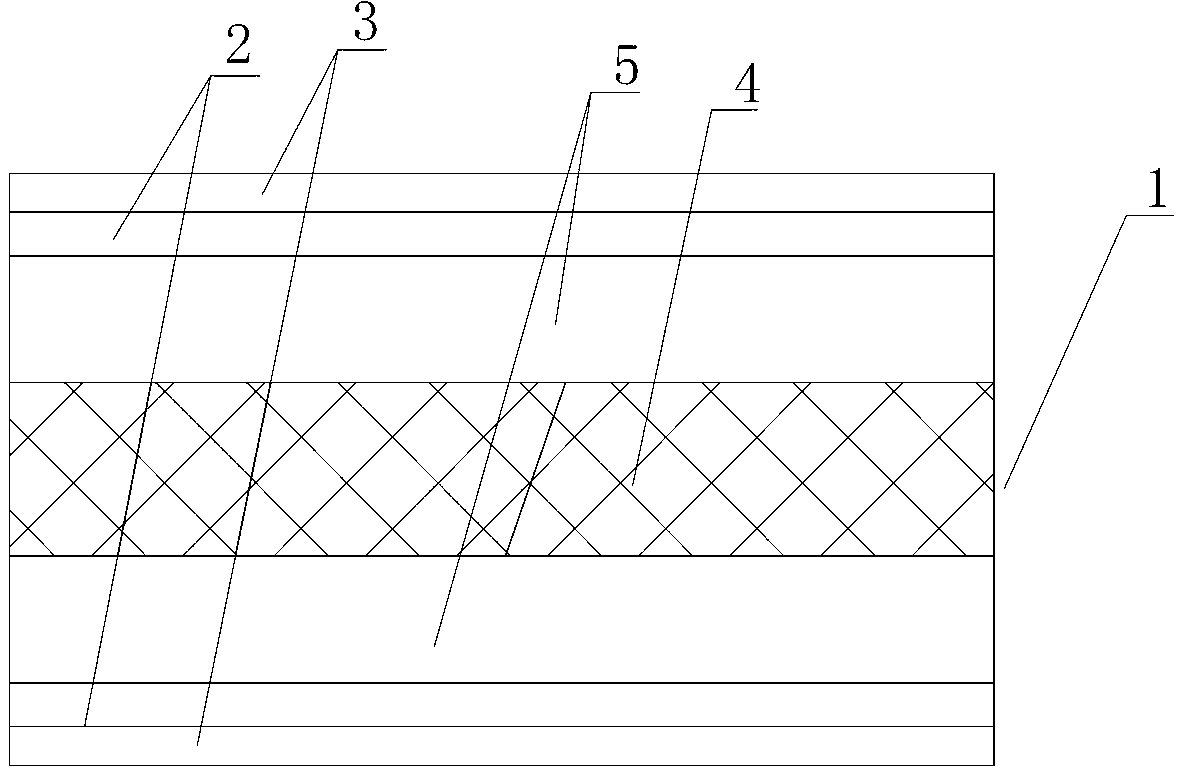

The invention relates to a high-flatness paint-free simulation ecological plate and a manufacturing method thereof. The ecological plate comprises a base plate layer (1), at least one of upper and lower sides of the base plate layer is provided with a layer of technical wood sheet (2), melamine impregnated paper (3) is pasted outside the technical wood sheet (2), and the technical wood sheet (2) and the base plate layer (1) are bonded by an adhesive. According to the high-flatness paint-free simulation ecological plate and the manufacturing method thereof, the problem of drying (partial brown) caused by uneven partial thicknesses of base plates and uneven moisture content in production of paint-free ecological plate products is solved, and the product percent of pass is improved to above 99.9% from around 90%.

Owner:TREEZO NEW MATERIAL TECH GRP CO LTD

Method for preparing LaB6/Si-Mo gradient high-temperature anti-oxidation coating

The invention relates to a method for preparing a LaB6 / Si-Mo gradient high-temperature anti-oxidation coating. According to the method, a SiC internal coating is prepared on the surface of a C / C composite material to relieve the problem of concentrated thermal stress caused by thermal expansion coefficient difference between a matrix and the coating; the intermediate layer is a SiC-MoSi2 transition coating and serves as a transition layer of internal and external coatings, cracks, pores and other defects of the external coating generated under a high-temperature condition can be effectively reduced, the excellent high-temperature oxidation resistance of the coating can be achieved, and the resistance adaptability of the C / C composite material under high-temperature aerobic relieving condition is further improved; the LaB6 / Si-Mo coating is prepared by utilizing a plasma spraying method, so that the thickness of the coating can be accurately controlled, and the problem of uneven thickness of the coating is solved. Gradient is sequentially formed among the coatings, so that generation of thermal stress is reduced, and the binding force among the coatings is improved. Advantages of the plasma spraying method and an embedding method are combined, so that the high-temperature oxidation resistance of the coating can be greatly improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Preparation method for organic silicon nanometer hard protective coating

ActiveCN107523809AAvoid wasting waterAvoid wastingChemical vapor deposition coatingGas phaseWater vapor

The invention discloses a preparation method for an organic silicon nanometer hard protective coating, and belongs to the technical field of plasmas. In the method, a reaction chamber is vacuumized, an inert gas is charged to enable a base material to move, monomer steam is charged, chemical vapor deposition is carried out, and an organic silicon nanometer coating is prepared on the surface of the base material through the chemical vapor deposition; and the component of the monomer steam is the mixture of at least one organic silicon monomer containing double bonds and a Si-Cl structure or a Si-O-C structure or a Si-N-Si structure or a Si-O-Si structure or a cyclic structure, and at least one polyfunctional unsaturated hydrocarbon and hydrocarbon derivative, charging for the monomer steam is stopped, oxygen and / or vapor is charged, and hard treatment is carried out on the surface of the organic silicon nanometer coating. According to the preparation method disclosed by the invention, the traditional organic carbonate hydroxide compound monomer is replaced by the organic silicon monomer, each silicon atom at least provides 1-4 active sites, high activity is achieved, a part of oxygen is introduced into the monomer, organic silicon can be oxidized into nanometer silicon dioxide, and the hardness of the coating can be greatly increased due to a dispersion strengthening effect.

Owner:JIANGSU FAVORED NANOTECHNOLOGY CO LTD

Preparation method for high-insulation nanometer protection coating with modulation structure

ActiveCN107587120ANot easy to penetratePrevent vertical spreadVacuum evaporation coatingSputtering coatingToughnessDislocation

The invention provides a preparation method for a high-insulation nanometer protection coating with a modulation structure, belonging to the technical field of plasma. According to the method, a reaction cavity is vacuumized and inert gas is introduced to allow a substrate to move; a low dipole moment-organosilicon / fluorocarbon modulated multilayer compact structure is formed through a manner of alternative preparation of a low dipole moment organic coating and an organosilicon coating or an organic fluorocarbon coating, so the stress of the coating can be reduced while the toughness of the coating is improved; meanwhile, since the low dipole moment-organosilicon / fluorocarbon structure has a transverse interface, when a corrosion medium is used for corrosion of the coating, corrosion develops along a transverse direction when the corrosion medium encounters the transverse interface, so longitudinal corrosion penetrating the coating is hard to form and the corrosion medium is preventedfrom penetrating the coating and corroding protected materials and device; moreover, the modulated nanometer layered structure has superlattice effect, and dislocation accumulation formed among layers, so the coating is more unlikely to breakdown and has improved resistance to underwater energization.

Owner:JIANGSU FAVORED NANOTECHNOLOGY CO LTD

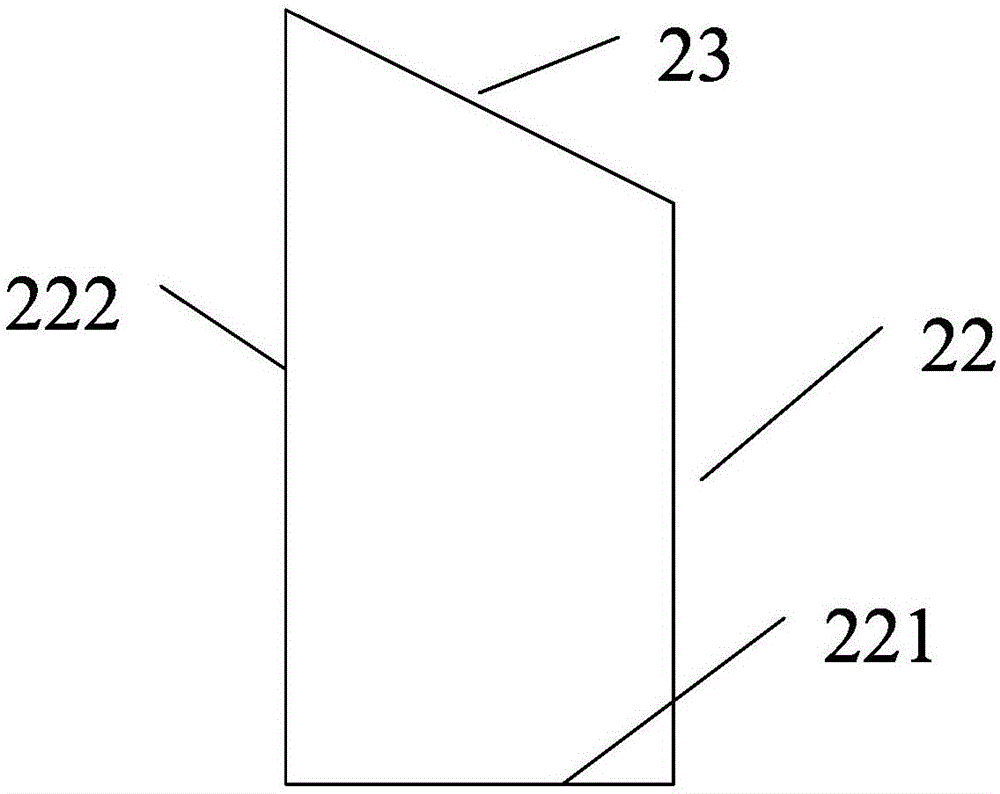

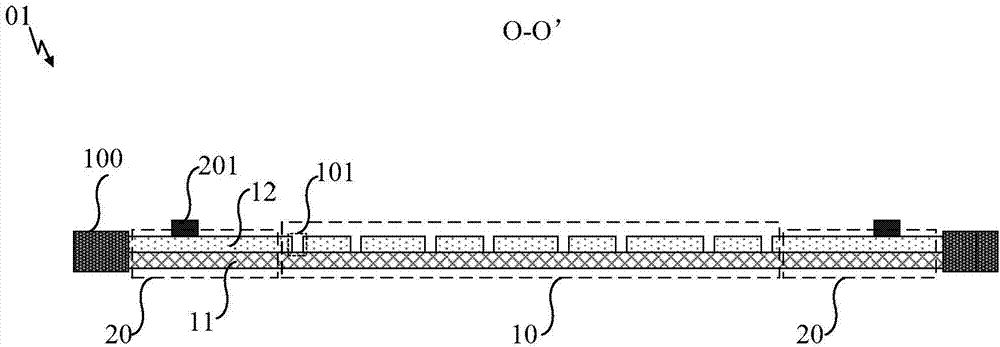

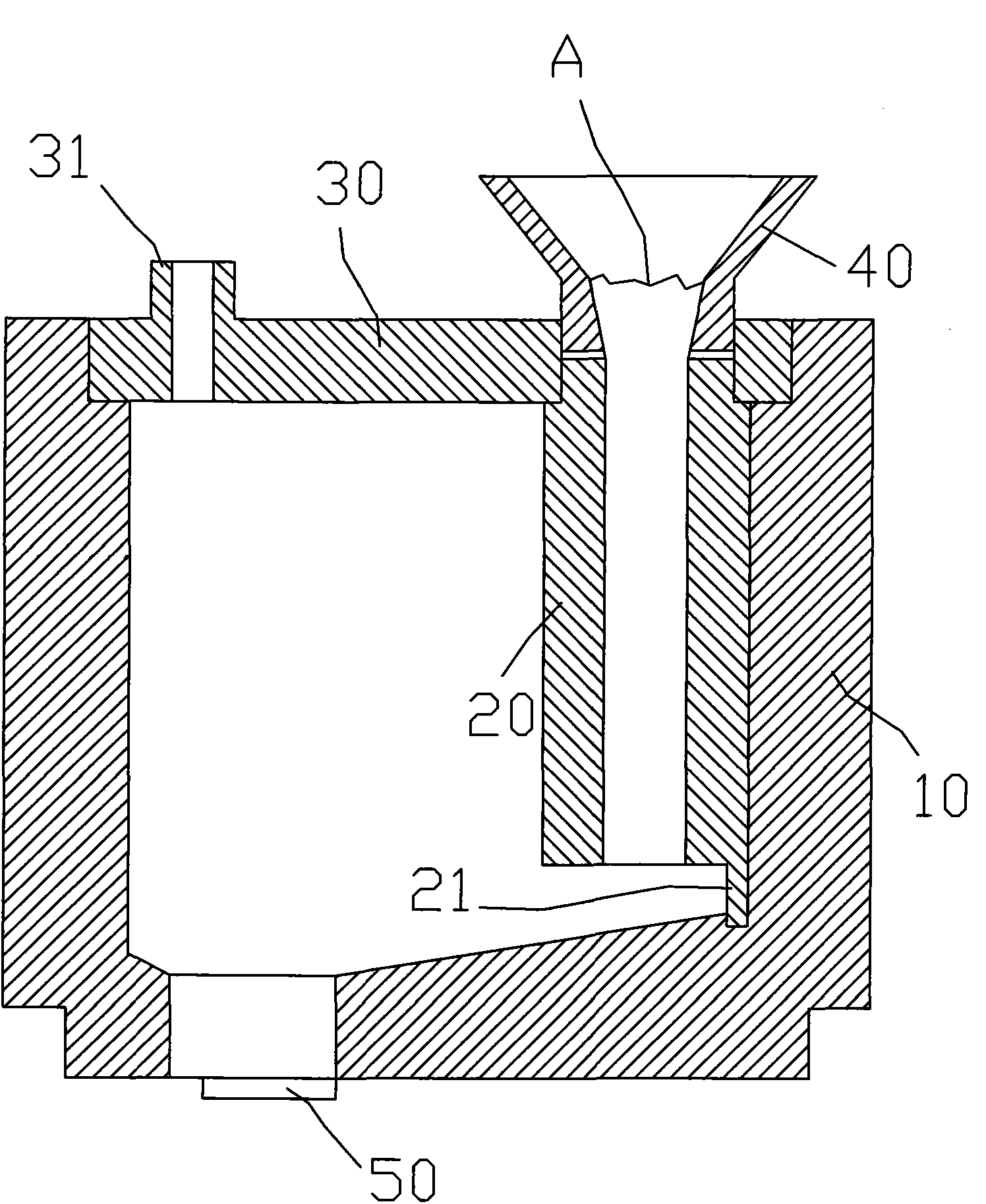

Crucible structure

ActiveCN105088147ASolve uneven thicknessVacuum evaporation coatingSputtering coatingCrucibleAcute angle

The invention relates to a crucible structure. The crucible structure comprises a crucible body and a crucible cover; the crucible body comprises a bottom wall and a crucible lateral wall, one end of the crucible lateral wall is connected with the crucible bottom wall, and the crucible cover is arranged at the other end of the crucible lateral wall; and an acute angle is formed between the crucible cover and the axis direction of the crucible, and an opening structure is arranged on the crucible cover. By means of the crucible, the evaporation area can be effectively enlarged, and the evaporation uniformity is improved.

Owner:BOE TECH GRP CO LTD

Method for coating reflection cup of car lamp

InactiveCN102560402ASolve uneven thicknessImprove bindingVacuum evaporation coatingSputtering coatingMicrometerEvaporation

The invention discloses a method for coating a reflection cup of a car lamp. The method is characterized in that the method comprises the following steps: (1) activation and cleaning treatment: carrying out activation and cleaning treatment on the surface of the reflection cup, wherein the treatment time lasts for 80-120 S, the vacuum degree in a vacuum chamber reaches 45-60 Pa, and the voltage of a coating electric cabinet output to the vacuum chamber through voltage transformation is 3,000V; (2) evaporation coating of an aluminum film: the aluminizing thickness is not more than 300nm; and (3) coating of a protective film: the voltage of a coating electric cabinet output to the vacuum chamber through voltage transformation is 3,000V, and the thickness of the coated protective film is 2.5-3.0 micrometers. As the method is used, the protective film has acid resistance and alkali resistance and does not fall off after being dipped in hydrochloric acid of concentration 1% or sodium hydroxide of concentration 1% and in water of 50 DEG C for 24h; and as a vacuum coating technology is used, the problem of nonuniform film thickness caused by manual spraying is effectively solved and the quality of the car lamp is greatly improved.

Owner:GUANGDONG ZHENHUA TECH CO LTD

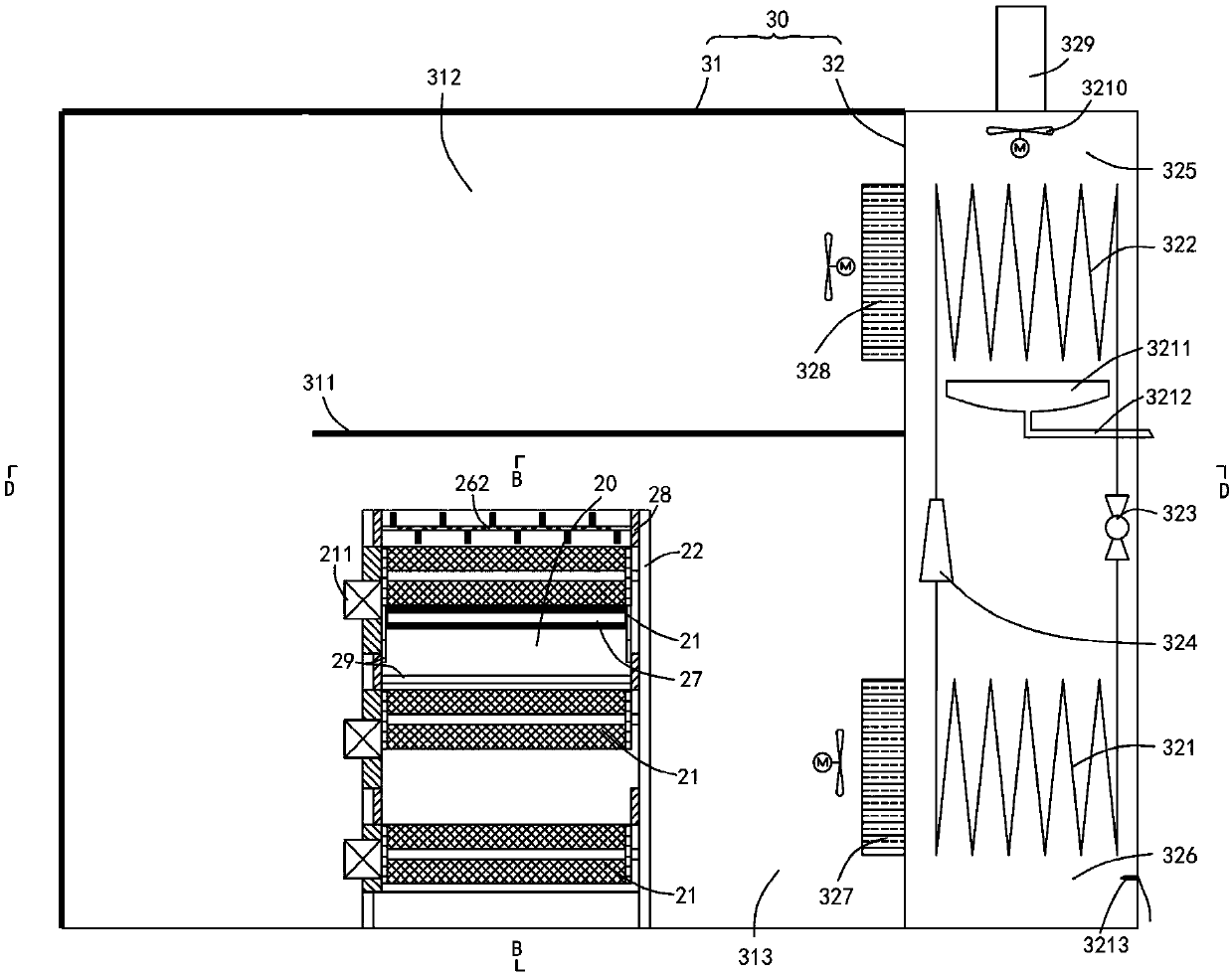

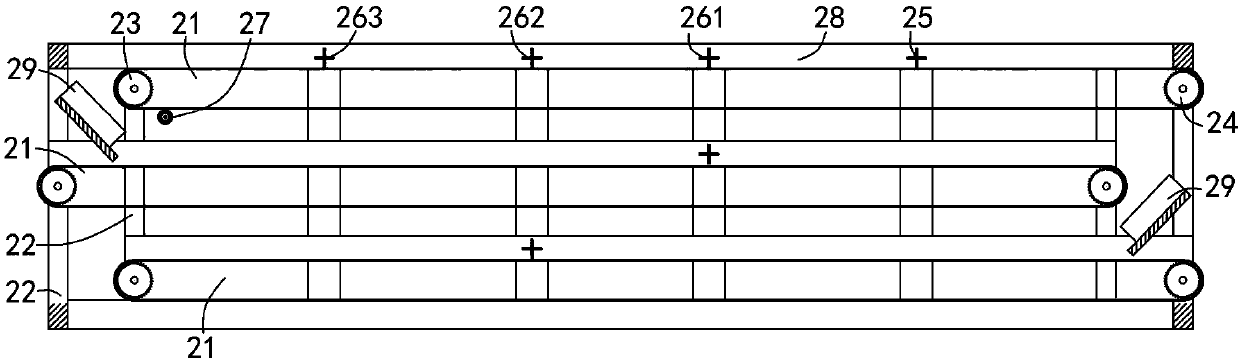

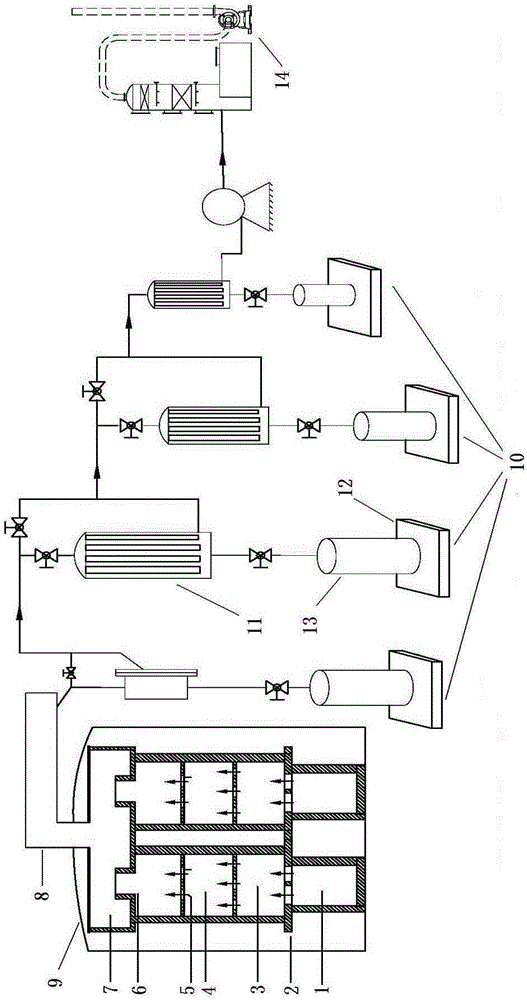

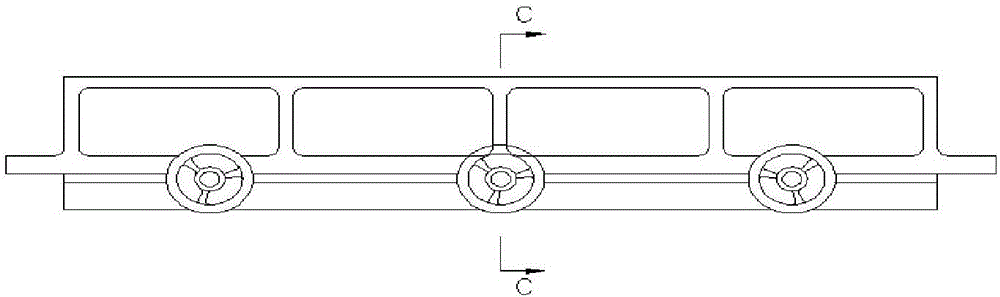

Multi-layer chain combined continuous drying system

PendingCN107647450ASolve ventilation problemsEvenly distributedFood processingFood treatmentAir volumeProduct gas

The invention relates to a multi-layer chain combined continuous drying system. The multi-layer chain combined continuous drying system comprises a swinging charging machine, a chain type multi-layermesh belt and a heat pump drying room, wherein a material shifting mechanism, a material overturning mechanism and a brush roller; the heat pump drying room comprises a closed drying chamber and a heat pump machine set; and the drying chamber is divided into an upper layer wind chamber and a lower layer wind chamber by a partition board which is horizontally arranged. According to the multi-layerchain combined continuous drying system disclosed by the invention, the swinging charging machine and the material shifting mechanism are arranged, so that the problem that the thickness of a materiallayer on the transporting mesh belt is uneven can be effectively solved; the ventilation problem of the material layer is solved from an inner respect and an outer respect by the material overturningmechanism and the brush roller of the drying system, so that the dehumidifying effect is strengthened; through the specific arrangement of the chain type multi-layer mesh belt and the direction of ahot air current of the heat pump, and a recycle gas loop separated by the partition board of the drying chamber, the purpose that the wind speed and wind capacity of hot gas in the drying chamber areuniformly distributed is guaranteed; the quality of the dried materials is guaranteed by the heat pump machine set in the heating manner of being close to natural drying; and the heat pump machine sethas the excellent properties of being energy-saving and environmental-friendly.

Owner:NINGXIA FATUFA VEGETABLE IND GRP CO LTD

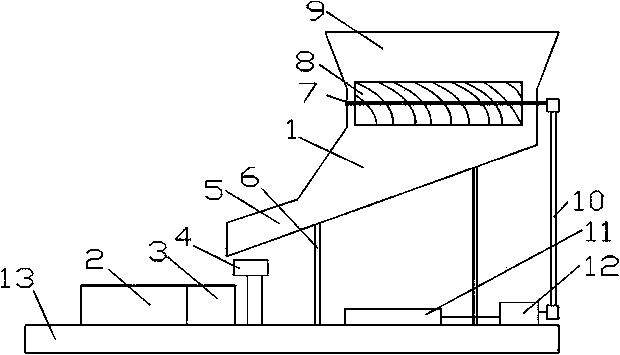

Modified traditional Chinese medicine slicer

InactiveCN103507101ASolve uneven thicknessAvoid problems such as missed cuts caused by insufficient widthGas current separationMetal working apparatusEngineeringChinese herbology

The invention discloses a modified traditional Chinese medicine slicer. The modified traditional Chinese medicine slicer comprises a supporting base, a supporting frame, a cutting machine box body, a feeding hopper and a rotation shaft, wherein the rotation shaft is provided a cutter base, the cutter base is provided with a cutter and a transmission mechanism, and the cutter is two sets of spiral rotary cutter blades. A screening net is installed at a discharging port of the cutting machine box body, and an opening is formed in the cutting machine box body under the screening net. The modified traditional Chinese medicine slicer further comprises a sealing cover matched with the opening, and a receiving bucket corresponding to the sealing cover is installed on the supporting base. The cutting edges of the spiral rotary cutter blades are continuous, so that the problems like cutting omission caused by the insufficient width are avoided. The screening net intercepts long raw materials mixed in cut medicine slices, and accumulates the raw materials which are not cut. When enough raw materials are accumulated, the cutting motion is stopped, the sealing cover is opened, and the raw materials are leaked out of the sealing cover and fall into the receiving bucket. After the raw materials are cleaned, the sealing cover is closed, and the slicing function continues.

Owner:DUJIANGYAN SHENDU TRADITIONAL CHINESE MEDICINE

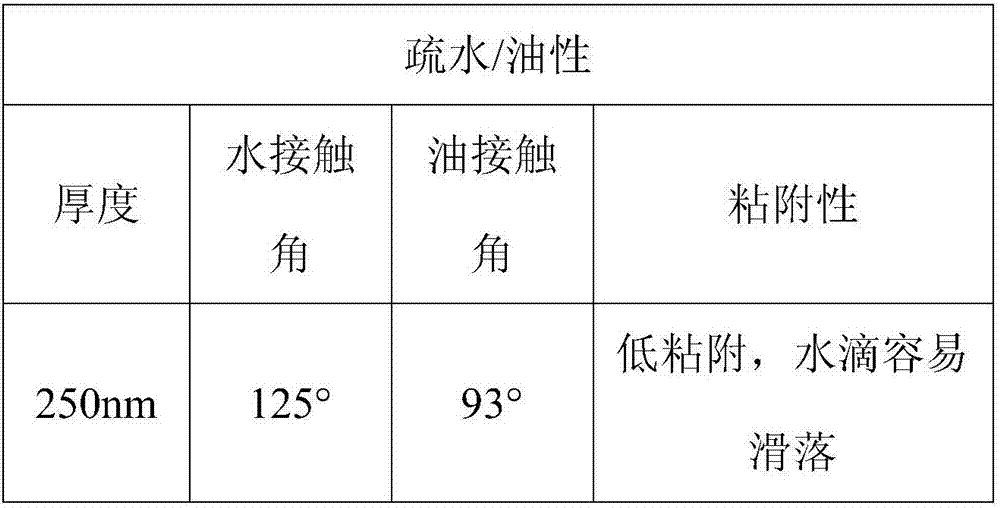

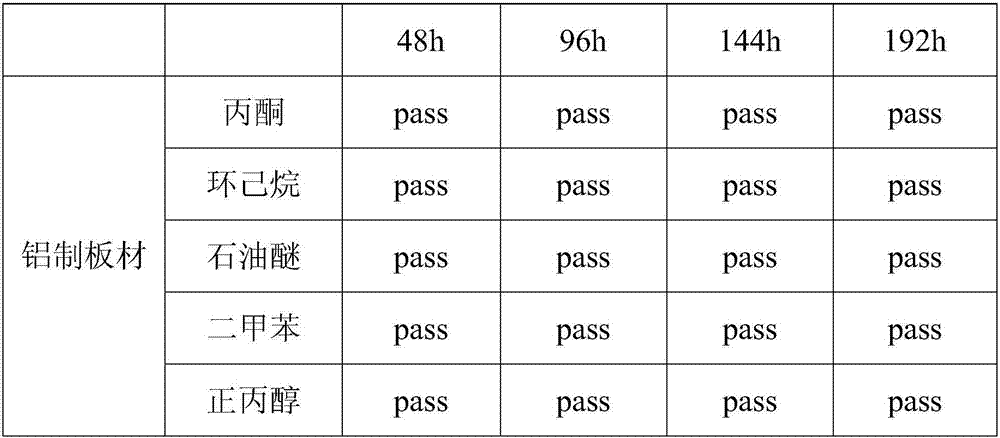

Method for preparing multifunctional nanometer protective coating through high-duty-cycle pulse discharge

ActiveCN107217243ADense network cross-linked structureSolve uneven thicknessChemical vapor deposition coatingSolventPulse discharge

The invention discloses a method for preparing a multifunctional nanometer protective coating through high-duty-cycle pulse discharge, and belongs to the technical field of plasmas. In the method, the interior of a reaction chamber is vacuumized until a vacuum degree is 10-200 millitorrs, inert gas He or Ar is charged, a movement mechanism is started to enable a base material to move in the reaction chamber, monomer steam is charged into the reaction chamber, plasma discharge is carried out, chemical vapor deposition is carried out, a deposition process comprises a pretreatment phase and a film-coating phase, a plasma discharge manner in the pretreatment phase is high-power continuous discharge, and a plasma discharge manner in the film-coating phase is the high-duty-cycle pulse discharge. During a preparation process for the coating, the movement characteristic of the base material and the high-duty-cycle pulse discharge energy of plasmas form combined linkage. The base material moves during the plasma discharge, so that the deposition efficiency of the coating is increased, and the thickness uniformity and compactness of the coating are improved. The prepared coating has the characteristics of being waterproof and moistureproof, mouldproof, resistant to acidic and basic solvents, resistant to acidic and basic salt mist, and the like.

Owner:JIANGSU FAVORED NANOTECHNOLOGY CO LTD

Silk-screen printing mask, drilling crew, equipment and silk-screen printing method

InactiveCN107031175ASolve uneven thicknessScreen printersOther printing apparatusScreen printingElectrical and Electronics engineering

An embodiment of the invention provides a silk-screen printing mask, a drilling crew, equipment and a silk-screen printing method, relates to the silk-screen printing field and can solve the problem of uneven thicknesses of pattern layers formed through the silk-screen printing process. The silk-screen printing mask is divided into a printing area and a non-printing area, and the printing area is surrounded by the non-printing area. The silk-screen printing mask comprises a silk-screen layer and a cement film layer located on one side of the silk-screen layer, a plurality of hollowed-out portions are arranged at the position, located in the printing area, of the cement film layer, and the printing layer is formed by defining outer contours of the peripheral hollowed-out portions; the silk-screen printing mask further comprises magnetic adsorption portions at least arranged at the positions, on the two opposite sides of the printing area, of the non-printing area.

Owner:BOE TECH GRP CO LTD +1

Wide double row cultivation technique for beans odd ridge

InactiveCN101283651AIncrease productionSolve uneven thicknessFertilising methodsWeed killersLand preparationRidge

The invention relates to a single-ridge wide-top double-row cultivation method of beans. The prior narrow-row dense-planting high-yield cultivation of soybean fails in shoveling, temperature rise and drought, water-logging resistance, etc. The ridge three-row cultivation method of soybean has narrow on-ridge spacing and is bad for soybean growth. The technical proposal is that the method comprises the steps of land selection, land preparation, deep soil loosening, deep fertilizer application, ridging and seeding, level land seeding, equipment preparation, weeding, fertilizer supplementation, pesticide spray and harvesting. The ridge spacing is 62-70 cm. Each ridge has two rows with a row spacing of 16-24 cm. The method is used for bean cultivation in agriculture.

Owner:崔生

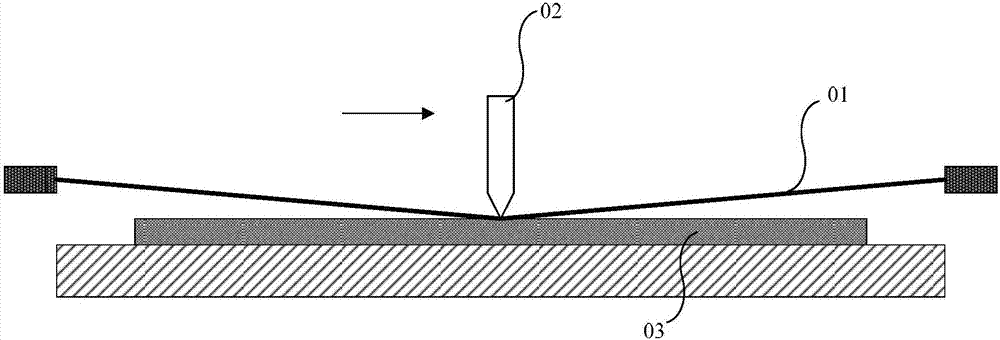

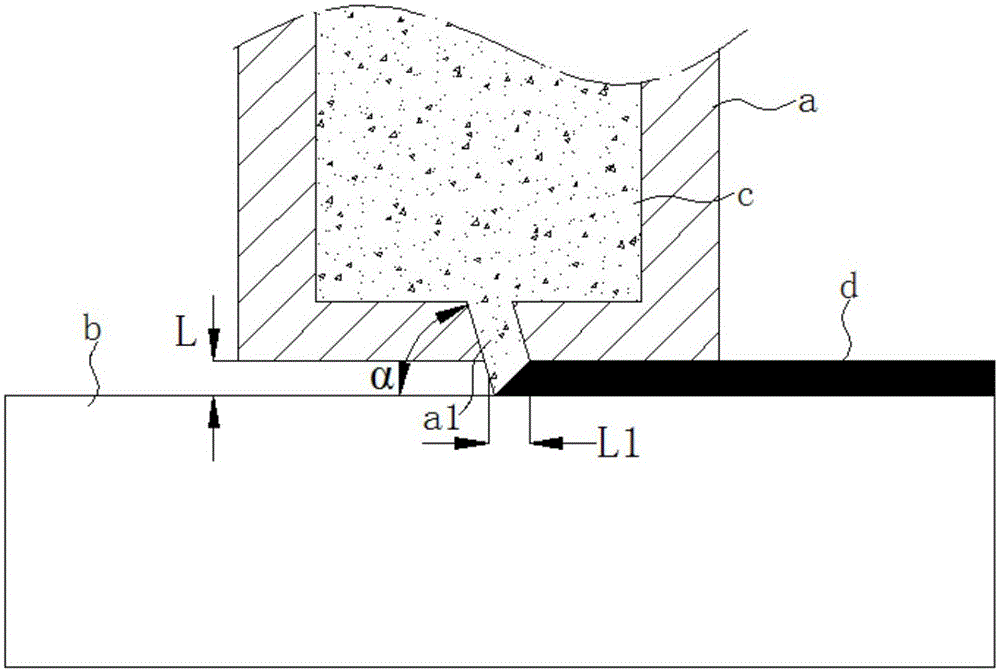

Preparing method of ultrathin amorphous alloy strip

The invention relates to a preparing method of an ultrathin amorphous alloy strip. Molten steel obliquely sprays the surface of a cooling body, and the spraying direction of the molten steel is opposite to the rotating direction of the cooling body. Meanwhile, the distance between the lower end face of a nozzle and the cooling body is reduced, and therefore the scraping pressing and correcting functions on molten steel laminar flow from the lower end face of the nozzle are improved, and the prepared amorphous alloy strip is thin and even. Meanwhile, the smoothness and density of the free surface of the amorphous alloy strip are improved. The acute angle formed between a nozzle runner and the surface of the cooling body is set in the range of 15-85 degrees, the transverse disturbance of the amorphous alloy strip to the laminar flow molten liquid is small in cooperation with the scraping pressing and correcting functions of the lower end face of the nozzle, and therefore the surface stress of the strip is reduced, and the transverse radian of the strip is reduced; and the quality and the finished product performance of the amorphous alloy strip are improved.

Owner:CHINA WEAPON SCI ACADEMY NINGBO BRANCH

Semiconductor monocrystalline silicon multi-wire cutting clamping device and method

InactiveCN106079126AReduced slice thickness variationSolve the uneven thickness of silicon waferWorking accessoriesFine working devicesWire cuttingSlice thickness

The invention discloses a semiconductor monocrystalline silicon multi-wire cutting clamping device. The device comprises a set of clamping plates. Each clamping plate is provided with an arc-shaped groove. The surface of each groove is provided with adhesives. A fixture is connected to any one clamping plate through the adhesives and located at the end, away from the groove, of the clamping plate. According to the semiconductor monocrystalline silicon multi-wire cutting clamping device, the shape of a monocrystalline silicon rod to be cut is changed by using the clamping plates; meanwhile, the difference between the impact state of mortar and the aggregation state of the mortar on side faces during cutting is changed, and the purpose that cutting states in all positions in the vertical direction are equivalent during cutting is achieved; and the thickness deviation of slices can be effectively reduced, the problem of uneven thicknesses of silicon slices is solved, and the device has good application value.

Owner:XIAN ZHONGJING SEMICON MATERIALS CO LTD

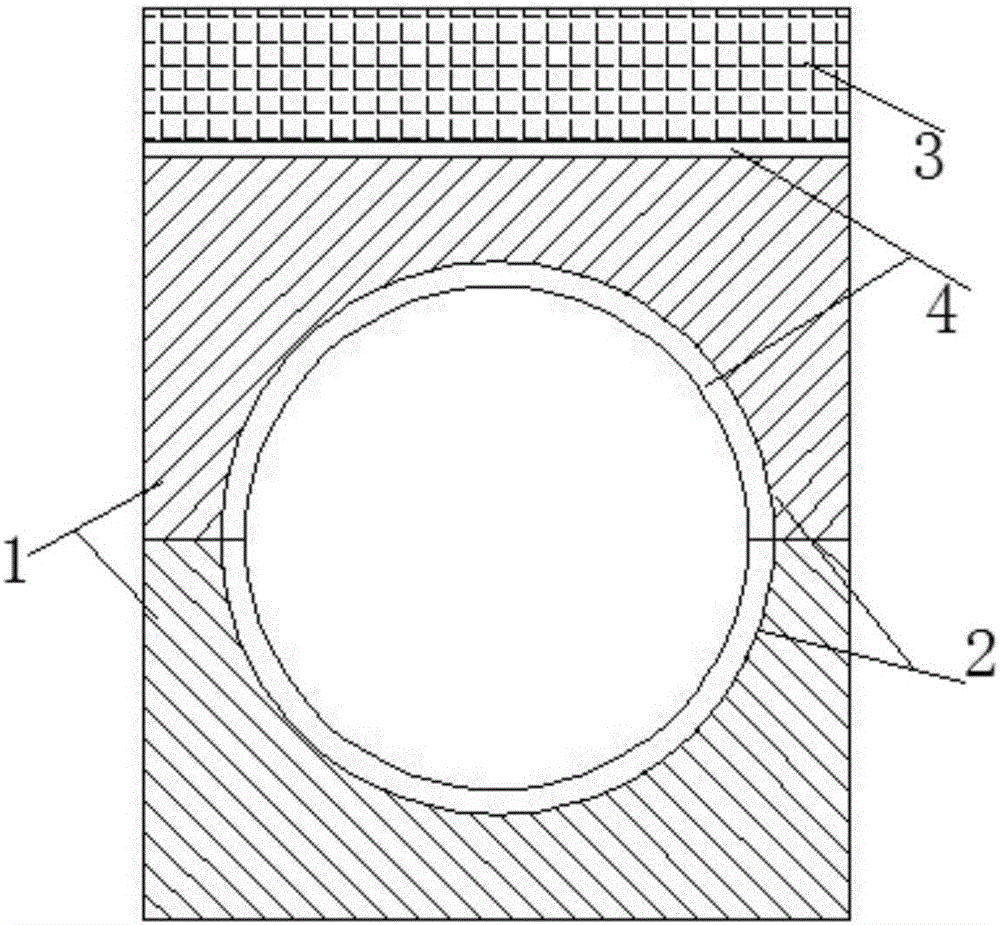

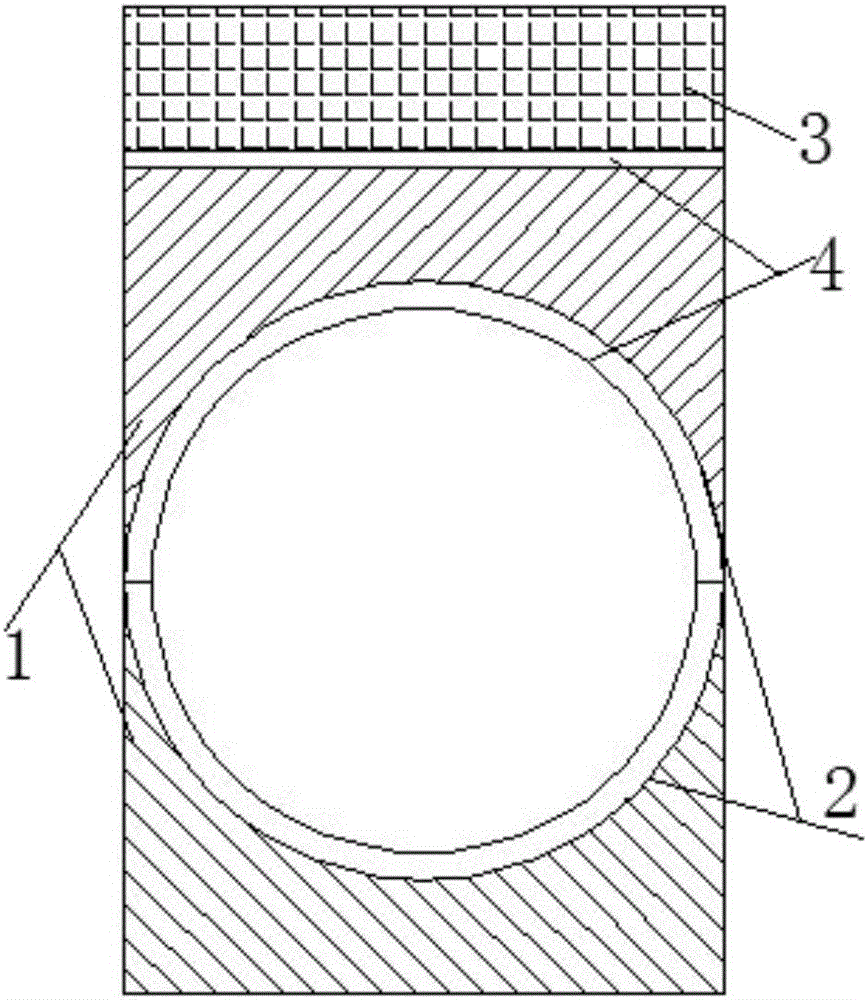

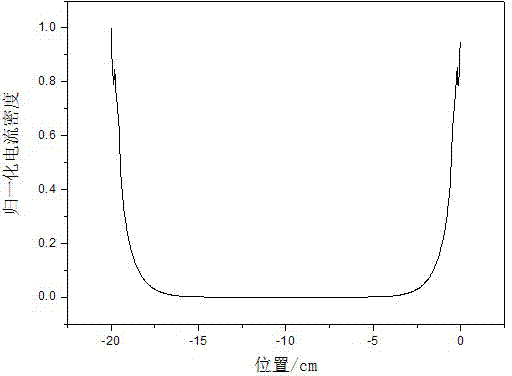

Homogeneous electrochemical treatment method of inner surface of tubular workpiece

InactiveCN103924270AImprove uniformityImproved current density distributionElectrochemistryMaterials science

The invention discloses a homogeneous electrochemical treatment method of an inner surface of a tubular workpiece, aiming at solving the general problem that a uniform-thickness coating can not be prepared or homogeneous electrochemical treatment can not be carried out when the inner surface of the tubular workpiece is subjected to electrochemical treatment currently. The method disclosed by the invention comprises the following steps that a counter electrode is inserted into the tubular workpiece, the counter electrode and the tubular workpiece are used as two poles for electrochemical treatment, the counter electrode and the tubular workpiece do relative axial motion along the axis of the tubular workpiece in the process of electrochemical treatment. The method disclosed by the invention can effectively solve the above problem, a coating with good homogeneity can be prepared on the inner surface of the tubular workpiece, and the homogeneity of the coating is improved remarkably; meanwhile, the method disclosed by the invention is simple to operate, low in equipment and low in cost, and can meet industrial production demands; meanwhile, through measures such as control of relative movement speed, arrangement of subsidiary conduit and series connection of multiple counter electrodes, the homogeneity of the coating is further improved, and the preparation requirement of super-long tubular workpiece coating can be met.

Owner:SICHUAN INST OF MATERIALS & TECH

Traditional Chinese medicine slicer

InactiveCN103507102ASolve uneven thicknessAvoid problems such as missed cuts caused by insufficient widthGas current separationMetal working apparatusEngineeringChinese herbology

The invention discloses a traditional Chinese medicine slicer which comprises a supporting base. A support is arranged on the supporting base, a cutter box is installed on the support, a feed hopper is installed on the upper portion of the cutter box, a rotating shaft is installed in the feed hopper, a cutter base is installed on the rotating shaft, and a cutter is installed on the cutter base. The traditional Chinese medicine slicer further comprises a transmission mechanism installed on the supporting base and drives the rotating shaft, the cutter is provided with two sets of spiral rotary knife strips, and the knife strips are spirally and uniformly distributed on the rotating shaft in the axial direction at intervals. The spiral knife strips are distributed on the cutter base, so traditional Chinese medicinal materials can be subjected to force in two directions at the same time, adjustment of the thickness of sheets is completed when cutting is finished, medicinal material sheets of uniform thicknesses are formed, and the problem of uneven thickness is solved; meanwhile, knife edges of the spiral knife strips are continuous in shape, and the problem of leaked cutting caused by the insufficient thickness is solved.

Owner:DUJIANGYAN SHENDU TRADITIONAL CHINESE MEDICINE

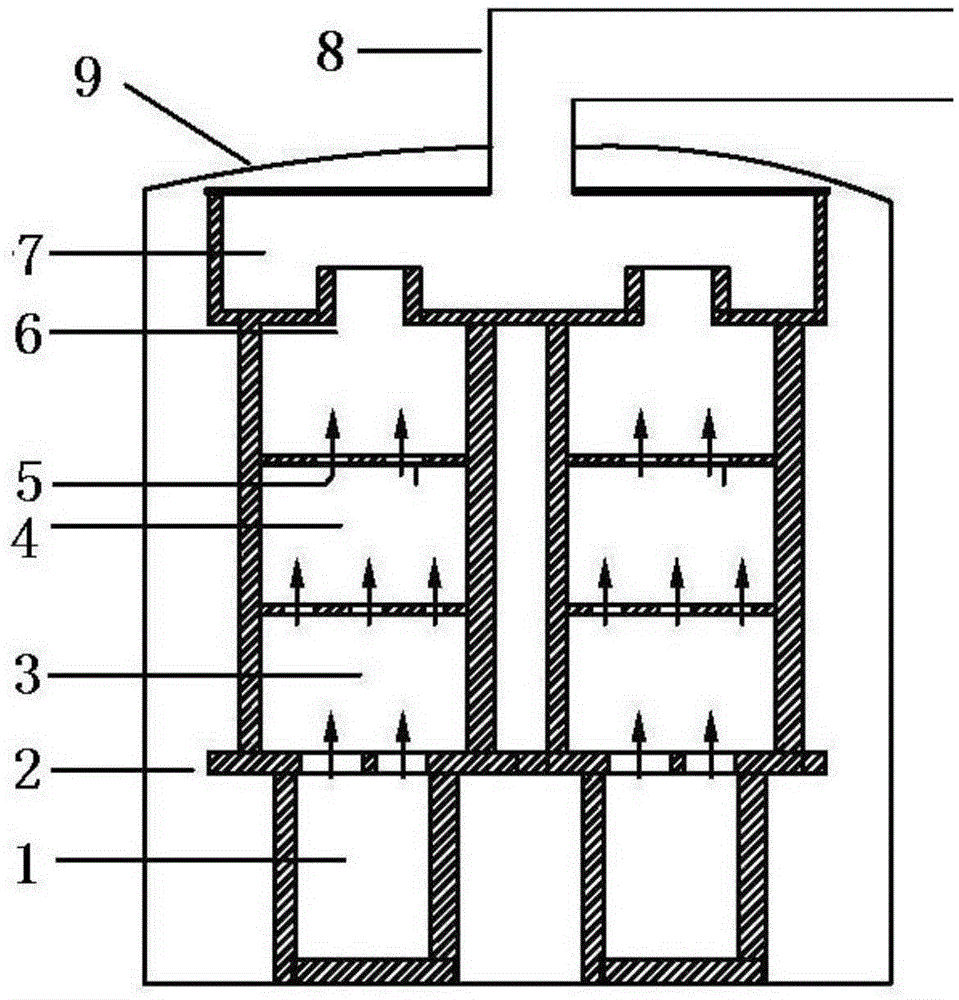

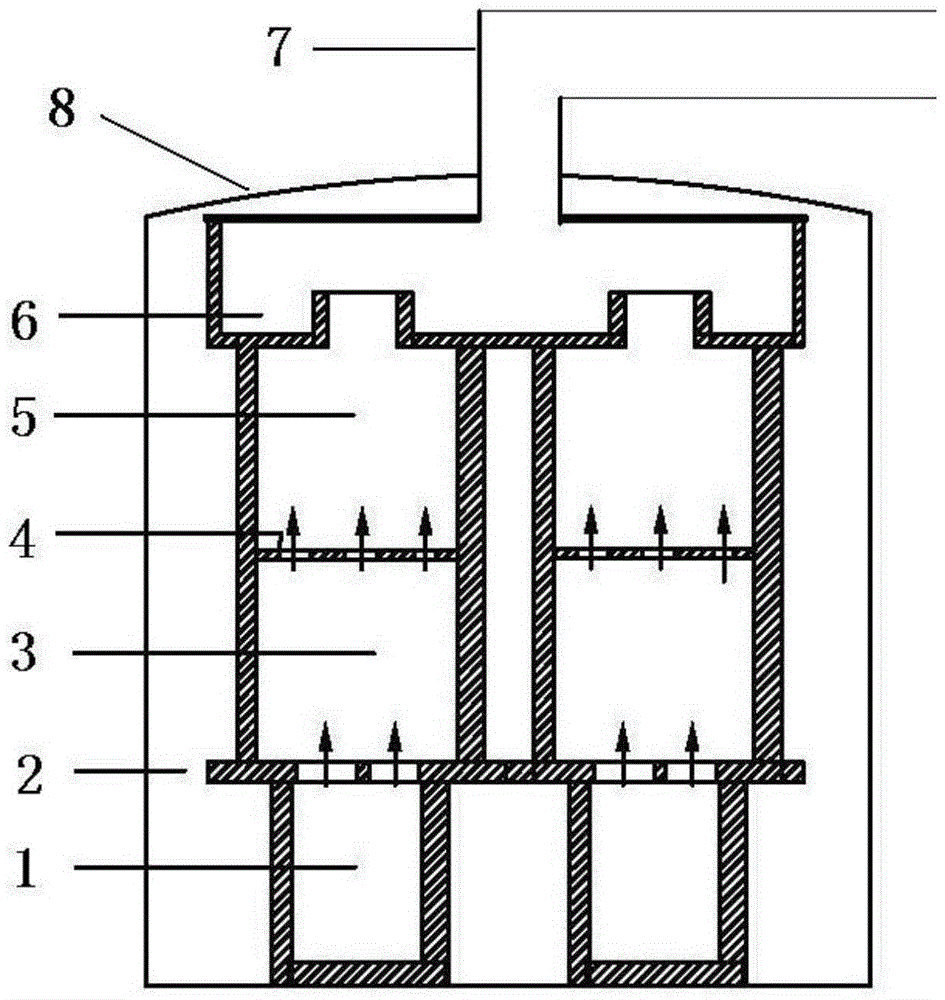

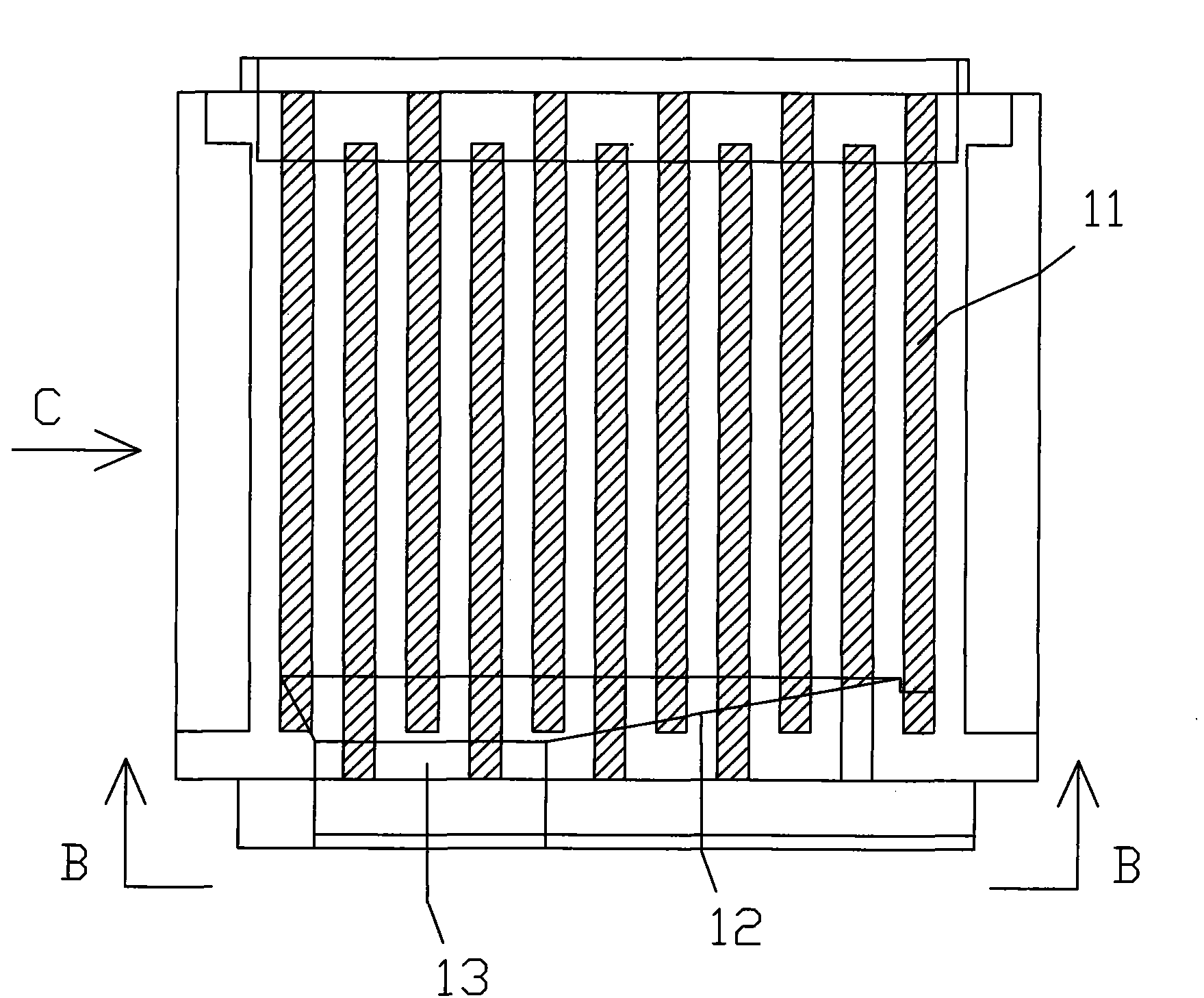

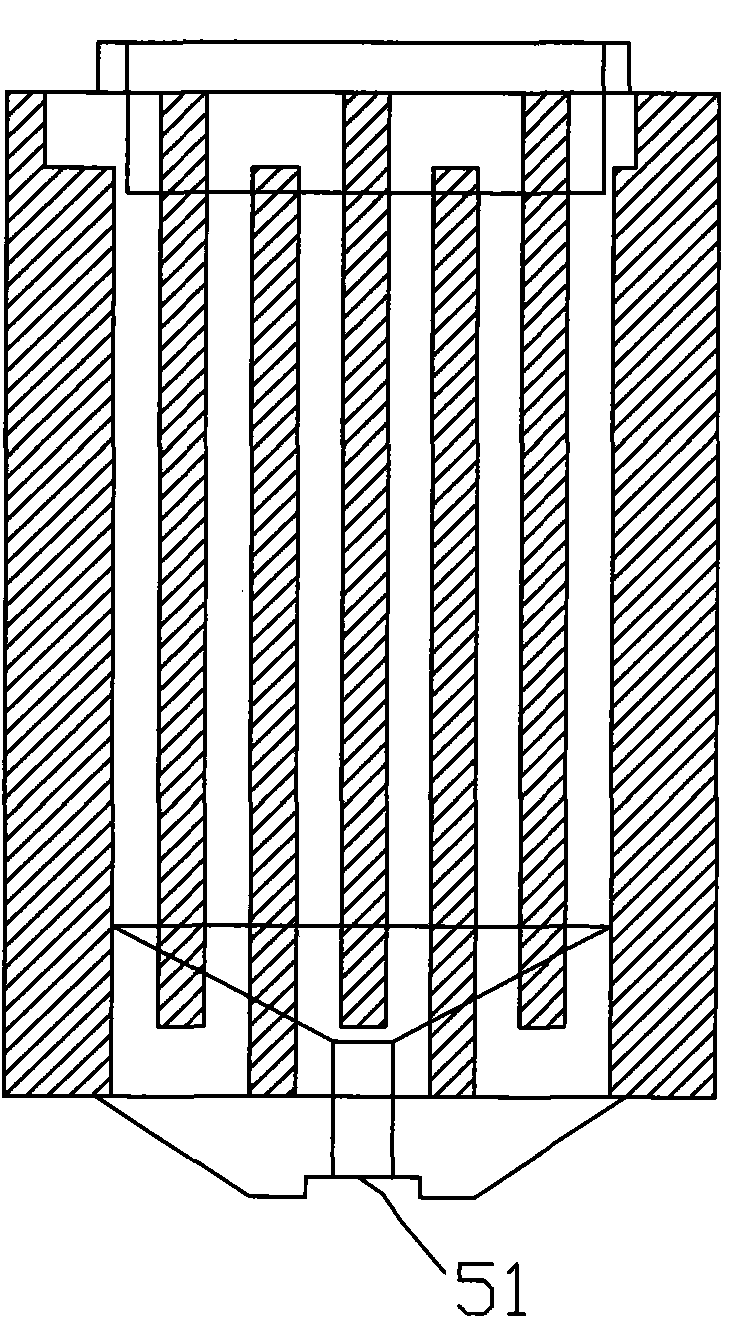

Graphite depositing device for chemical vapor deposition furnace

ActiveCN105420686AImprove conversion rateUniform thicknessChemical vapor deposition coatingGraphiteEngineering

The invention provides a graphite depositing device for a chemical vapor deposition furnace. The device comprises a solid raw material containing device, a cover plate, a depositing mechanism with at least two longitudinally-arranged depositing chambers, and a dust collecting chamber located above the depositing chambers. The cover plate is arranged at the top of the solid raw material containing device. Airflow holes are formed in the cover plate. The depositing mechanism is arranged at the top of the cover plate. The cover plate serves as a bottom plate of the depositing mechanism. A separation plate is arranged between the depositing chambers. Airflow holes are formed in the separation plate. The bottom of the dust collecting chamber is communicated with the uppermost depositing chamber through a dust collecting channel. The separation plate is additionally arranged between the depositing chambers, the whole chambers are divided, the thickness of products deposited in the different chambers is more even and gradient, the conversion rate of the products is increased, subsequent processing efficiency is greatly improved, processing difficulty is lowered, the overall utilization rate of the products is increased, and the problem that the thickness of a large-size depositing chamber is uneven in the depositing process is effectively solved.

Owner:安徽光智科技有限公司

Method for airborne thin-walled metal part and nonmetal part bonding

The invention provides a method for airborne thin-walled metal part and nonmetal part bonding, and belongs to the technical field of aviation product bonding. The method comprises the steps of bonding, deformation amount measuring, metal thin-walled part pre-correcting, bonding tool mold finishing, bonding after pre-correcting and finishing and finished product detecting. According to the method for airborne thin-walled metal part and nonmetal part bonding, a metal part is pre-corrected in the reverse direction of the bonding part deformation tendency, increment or decrement supplement machining is conducted on a bonding tool mold in the reverse direction of the deformation tendency, the metal thin-walled part and a nonmetal thin-walled part are completely attached to a tool in a vacuumizing mode when bonding is conducted, vacuumizing is kept in the whole process, bonding curing is conducted through a drying box or a hot-pressing tank, after pressure maintaining treatment is conducted,and the bonding part approaching the ideal state is obtained through counteracting and compensating of the deformation amount and the pre-correction amount of the parts.

Owner:SICHUAN JIUZHOU ELECTRIC GROUP

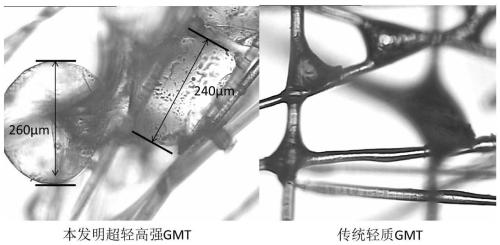

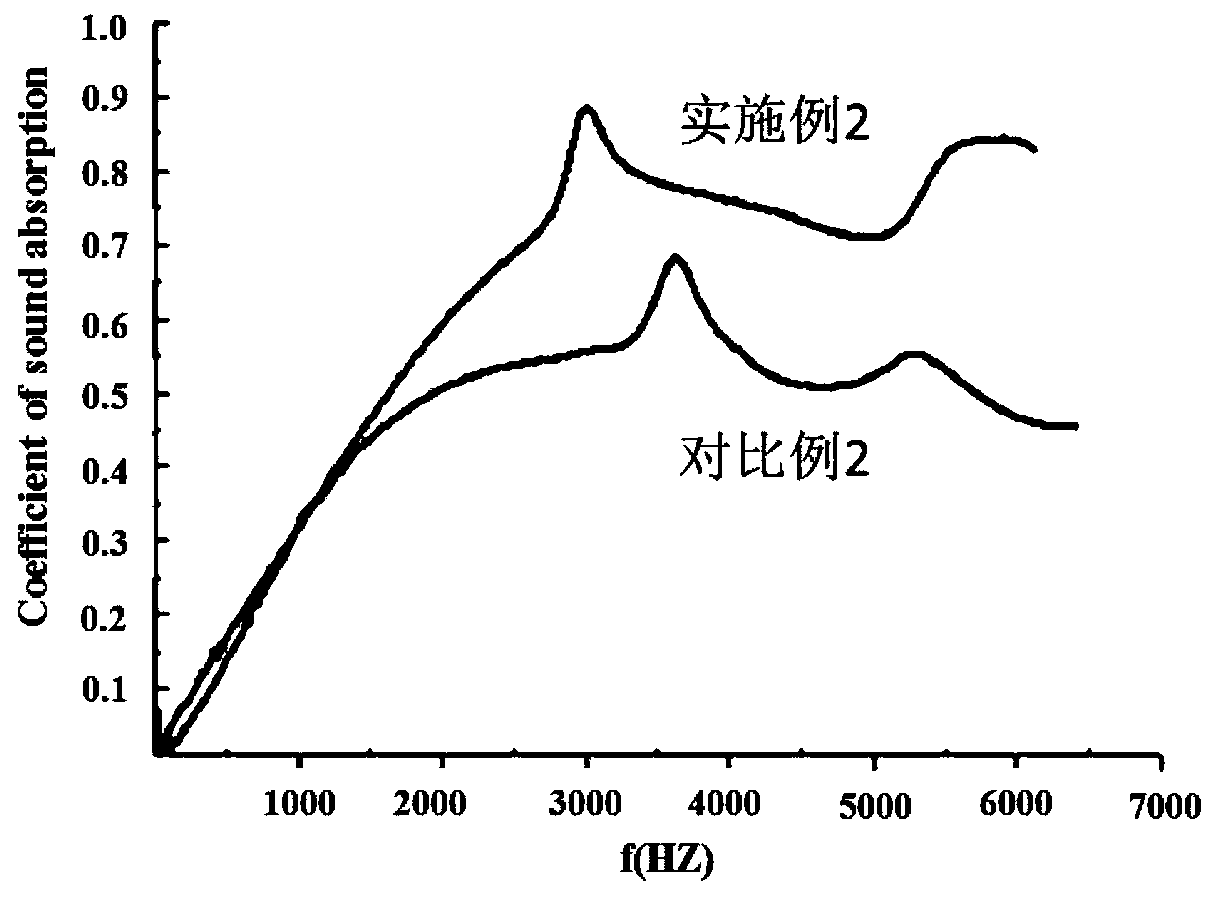

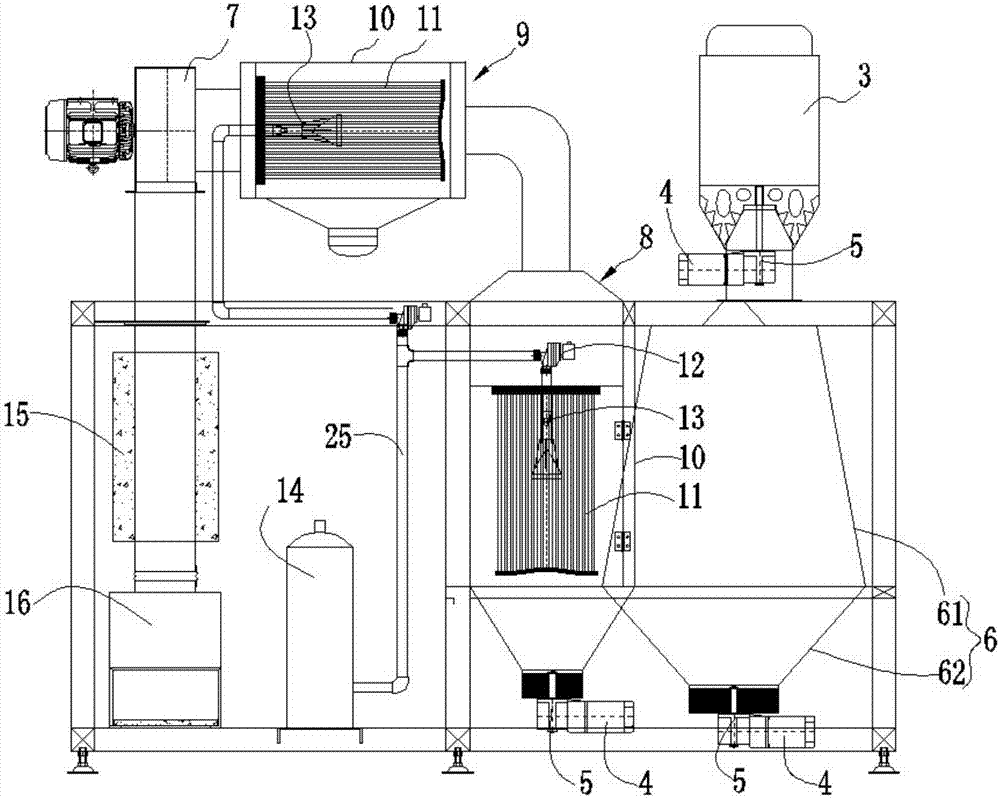

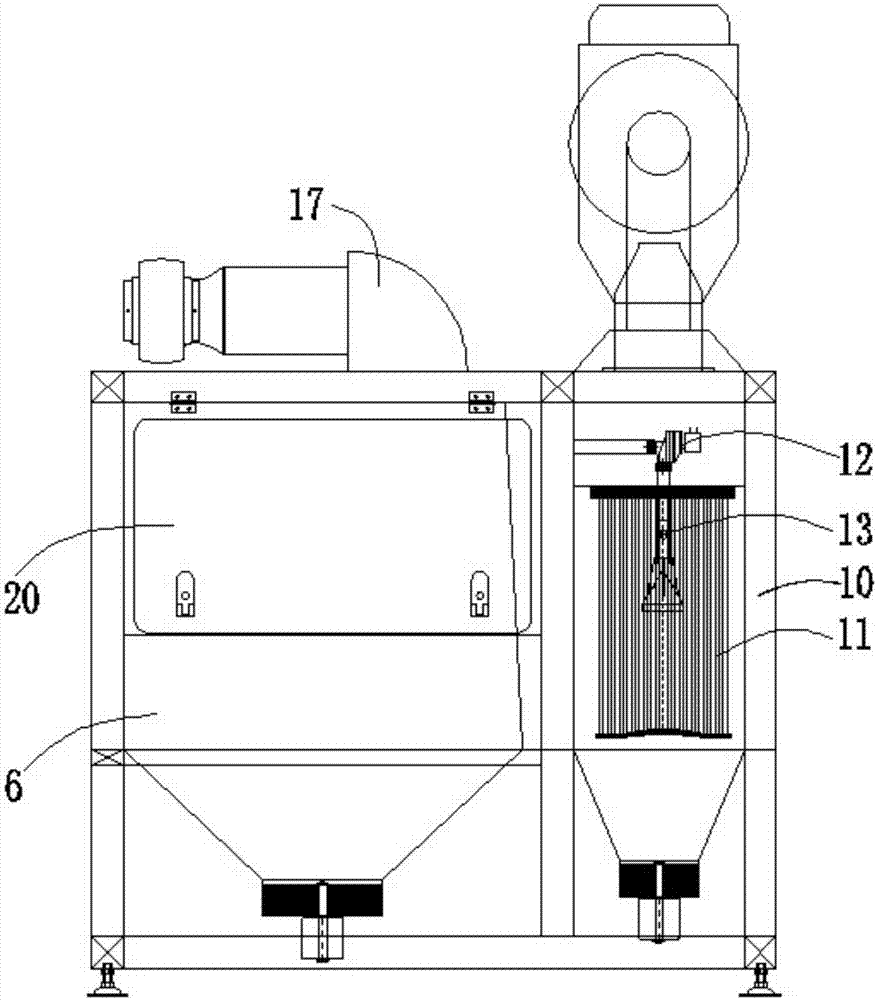

Ultra-light high-strength high-sound-absorption fiber-reinforced thermoplastic foamed composite board and preparation method thereof

InactiveCN111038042ALow manufacturing costSolve uneven thicknessSynthetic resin layered productsLaminationThermoplasticSynthetic fiber

The invention discloses an ultra-light high-strength high-sound-absorption fiber-reinforced thermoplastic foamed composite board and a preparation method thereof, wherein the ultra-light high-strengthhigh-sound-absorption fiber-reinforced thermoplastic foamed composite board is prepared by using a binder uniformly containing a forming agent and a fiber reinforcement body through a non-woven and continuous board-making composite process. According to the invention, plastic synthetic fibers uniformly containing a microsphere foaming agent are prepared by blending the microsphere foaming agent and thermoplastic resin powder as raw materials through a melt spinning procedure; the advantages of a non-woven process can be fully utilized to stably, continuously and efficiently produce the ultra-light high-strength GMT composite board; and the microsphere foaming agent does not fall off in a felt making link, so that the high-quality composite felt containing the microsphere foaming agent canbe prepared safely in batches without increasing additional investment such as newly increased equipment, personnel training and the like, and the manufacturing cost of the section is remarkably reduced.

Owner:浙江华江科技股份有限公司

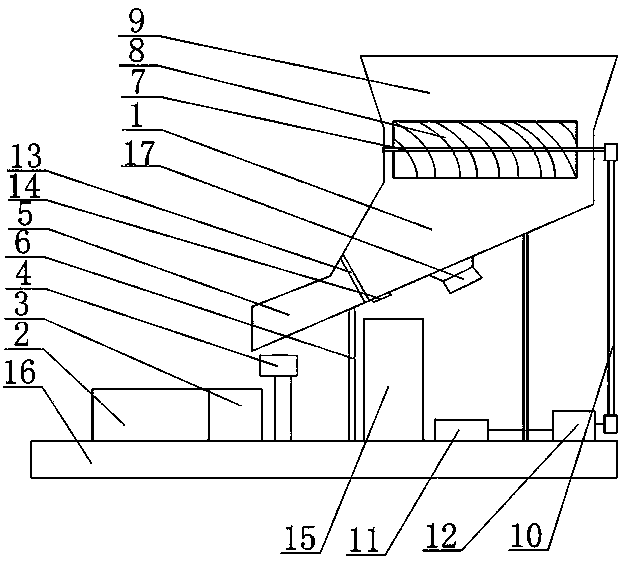

Graphene heat conduction film automatic material spraying and rolling device and material spraying rolling process

InactiveCN107876343ASolve the problem of low thermal conductivity parametersSolve uneven thicknessLiquid surface applicatorsCoatingsGraphiteCopper foil

The invention discloses a graphene heat conduction film automatic material spraying and rolling device and a material spraying and rolling process. The material spraying and rolling device comprises amaterial spraying device and a rolling device connected with the spraying device; the spraying device is used for spraying graphene powder to the copper foil surface in a penetrating-in manner, the rolling device comprises a roller dual servo motor device and a copper foil receiving device, and the roller dual servo motor device is connected with the spraying device and is used for rolling and winding the copper foil sprayed by the graphene powder. The spraying method is combined with the rolling technology to enable the graphene powder to be evenly sprayed to the surface of copper foil, through rolling, a high heat conduction film is made, the heat conduction parameter of the heat conduction film is improved, a large amount of electric energy consumption is saved, and the problem that the occupied site of the device is large is solved.

Owner:张龙远

Paint curtain coating tool bit

ActiveCN106111442AAdjustable thicknessSolve uneven thicknessLiquid surface applicatorsCoatingsEngineeringMechanical engineering

The invention relates to the field of curtain coating equipment, in particular to a paint curtain coating tool bit. The paint curtain coating tool bit comprises a paint storage chamber, a paint knife arranged on the lower portion of the paint storage chamber, and a flow adjusting assembly arranged inside the paint storage chamber, wherein a paint pass gap is formed between the flow adjusting assembly and the bottom of the paint storage chamber, the size of the paint pass gap can be adjusted through the flow adjusting assembly, the bottom of the paint storage chamber comprises a beam and a base plate, the base plate is arranged on the top of the beam, and a plurality of base plate fine adjustment assemblies are arranged on the beam in the length direction. Because the flow adjusting assembly through which the size of the paint pass gap can be adjusted is arranged inside the paint storage chamber, the thickness of a paint curtain can be conveniently adjusted through the flow adjusting assembly; because the base plate fine adjustment assemblies are arranged on the beam in the length direction, fine adjustment can be carried out on the base plate through the base plate fine adjustment assemblies, it is achieved that fine adjustment can be carried out on the partial position of the paint pass gap so that fine adjustment can be carried out on the thickness of the paint curtain, the accuracy of control is greatly improved, and the problem that the thickness of a paint curtain is not uniform is effectively solved.

Owner:肇庆市德信真空设备有限公司

Film cooling forming device of film-blowing machine

The invention discloses a film cooling molding apparatus for the film blower, which comprises an intake plate, an inner cooling water diversion barrel, an outer cooling water ring, a water-scraping barrel, a water-collecting barrel and a water absorption container. The intake plate is arranged on the upper of the inner water diversion cooling barrel; the intake plate is connected with an inlet pipe; the upper end of the outer cooling water ring is open and is covered out of the inner water diversion cooling barrel; a water inlet hole is arranged at upper part of the inner water diversion cooling barrel; a water inlet pipe is arranged at the water inlet hole; the water-scraping barrel and the water-collecting barrel are arranged in sequence under the inner water diversion cooling barrel and the water-scraping barrel; the water-collecting barrel and the inner water diversion cooling barrel are communicated with each other; a pumping pipe is connected with the water-collecting barrel; the water absorption container is arranged under the water-collecting barrel; the water absorption container is provided with a water absorption sponge and the water absorption container is connected with a suction pipe. With simple structure and low production cost, the invention has the advantages that the inside and outside water is contacted with the film base directly; the fast and even cooling is achieved; the problems of poor cooling and non-uniform thickness of the film base in prior art are solved.

Owner:李志淮

Pressure spray bag for use in pressured making of amorphous strip and amorphous strip making method

The invention relates to strip making equipment for an amorphous strip, in particular to a pressure spray bag for use in pressured making of the amorphous strip and an amorphous strip making method. The pressure spray bag comprises a spray bag shell and a conveying mechanism for conveying molten steel into the spray bag, wherein a prism-shaped liquid guide cavity which is larger on the upper portion and smaller on the lower portion is formed in the bottom in the spray bag shell; the liquid guide cavity is communicated with a jet cavity below; the bottom of the jet cavity is connected with a nozzle. Molten steel enters the pressure spray bag from a liquid guide hopper through a flow guide pipe, nitrogen is added into the pressure spray bag through an air inlet nozzle, and the molten steel flows towards the nozzle under the actions of own dead weight and the pressure of nitrogen, meets a hollow structure and a copper roller into which cooling water is introduced continuously after flowing out of the nozzle, is condensed into solid momentarily, and is molded into the amorphous strip. By adopting the pressure spray bag and the amorphous strip making method, the flowing degree of molten steel is increased, molten steel flowing into the spray bag can be sprayed completely at one time, high density, uniform thickness and a small quantity of rough edges are realized, and the quality of the amorphous strip is improved.

Owner:安徽众恒复合材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com