Paint curtain coating tool bit

A technology of knife head and paint spraying, which is applied in the field of paint spraying knife head, can solve the problems of poor defoaming effect, low control precision, inconvenient adjustment of paint curtain thickness, etc., and achieve the effect of solving uneven thickness and improving control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

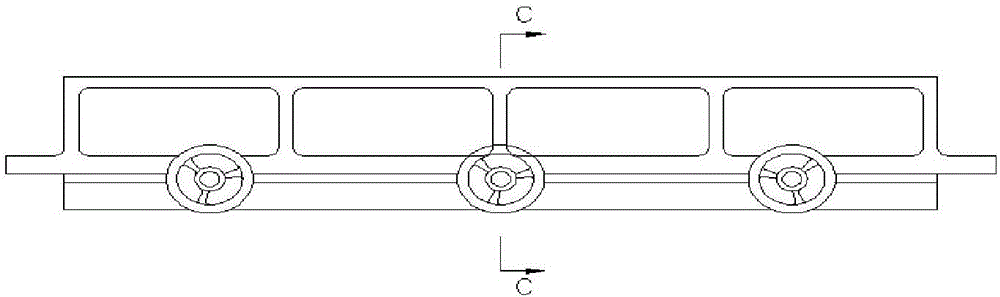

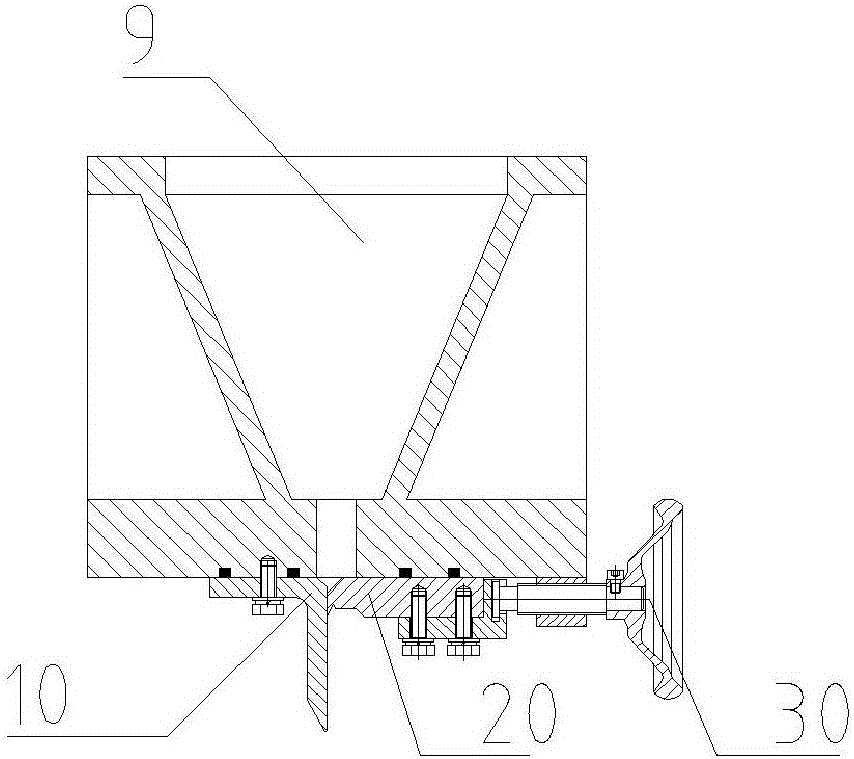

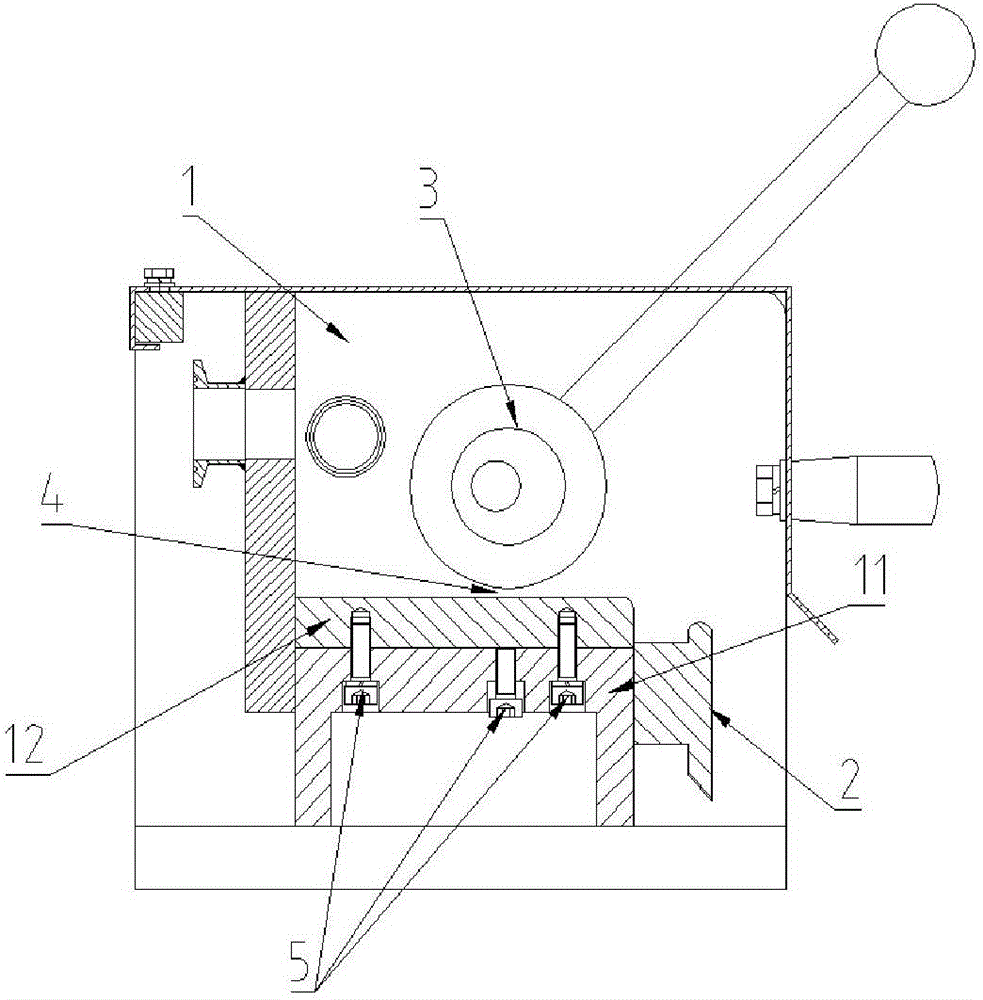

[0029] Now in conjunction with the accompanying drawings, the preferred embodiments of the present invention will be described in detail.

[0030] Such as image 3 As shown, the paint shower head of the present invention includes a paint storage room 1, a paint knife 2 located below the paint storage room 1, and a flow adjustment assembly 3 located inside the paint storage room 1. The flow adjustment A paint passing gap 4 is formed between the component 3 and the bottom of the paint storage room 1. The flow regulating component 3 can adjust the size of the paint passing gap 4. The bottom of the paint storage room 1 includes a beam 11 and a bottom plate 12. The bottom plate 12 is arranged above the crossbeam 11, and the crossbeam 11 is provided with several sets of floor fine-tuning assemblies 5 along the length direction. By setting the flow regulating assembly 3 that can adjust the size of the paint gap 4 inside the paint storage room 1, the thickness of the paint curtain ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com