Method for preparing multifunctional nanometer protective coating through high-duty-cycle pulse discharge

A multi-functional, pulse discharge technology, applied in the direction of coating, metal material coating process, gaseous chemical plating, etc., can solve the problems of slow coating deposition speed, loose coating structure, low production efficiency, etc., to improve the resistance Acid/alkali corrosion performance, reducing exhaust gas emissions, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

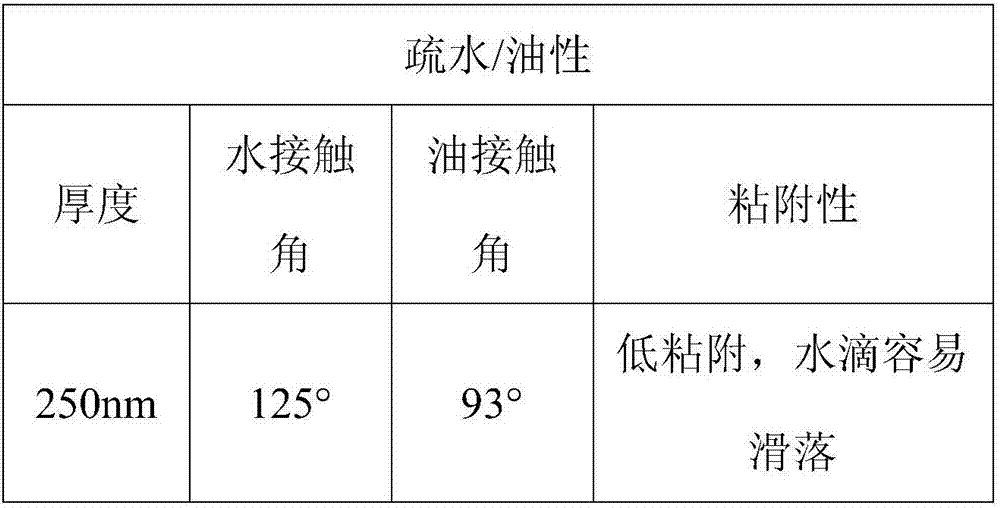

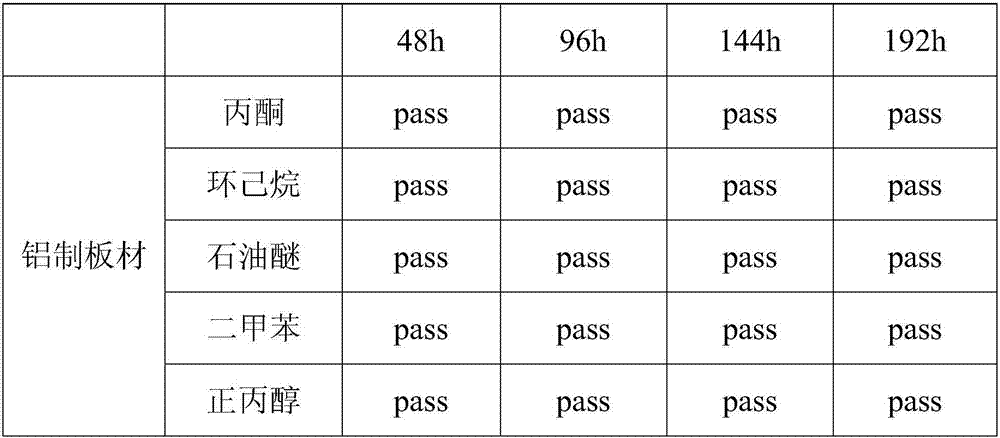

[0064] A method for preparing a multifunctional nano protective coating by pulse discharge with a large duty ratio, comprising the following steps:

[0065] (1) The base material is placed in the reaction chamber of the nano-coating preparation equipment, the reaction chamber is closed and the reaction chamber is continuously evacuated, the vacuum degree in the reaction chamber is evacuated to 10 millitorr, and the inert gas Ar is passed into, Turn on the motion mechanism to make the base material move in the reaction chamber; in step (1), the base material is a solid material, the solid material is a block aluminum material, and the surface of the base material is prepared to be resistant to immersion in organic solvents and cosmetics After coating, any interface can be exposed to the organic solvent test environment.

[0066] The volume of reaction chamber is 50L in the step (1), and the temperature of reaction chamber is controlled at 30 ℃, and the flow that feeds inert gas...

Embodiment 2

[0086] A method for preparing a multifunctional nano protective coating by pulse discharge with a large duty ratio, comprising the following steps:

[0087] (1) Place the substrate in the reaction chamber of the nano-coating preparation equipment, close the reaction chamber and continuously evacuate the reaction chamber, pump the vacuum in the reaction chamber to 60 millitorr, feed inert gas He, and start Motion mechanism to make the base material move;

[0088] In step (1), the base material is a solid material, and the solid material is a block aluminum alloy material, and any interface of the base material surface can be exposed to acid and alkali test environments after preparing an acid-resistant and alkaline environmental coating .

[0089] The volume of reaction chamber is 250L in the step (1), and the temperature of reaction chamber is controlled at 40 ℃, and the flow that feeds inert gas is 15 sccm.

[0090] In step (1), the base material performs planetary motion, ...

Embodiment 3

[0109] A method for preparing a multifunctional nano protective coating by pulse discharge with a large duty ratio, comprising the following steps:

[0110] (1) Place the substrate in the reaction chamber of the nano-coating preparation equipment, close the reaction chamber and continuously evacuate the reaction chamber, pump the vacuum in the reaction chamber to 130 millitorr, feed inert gas Ar, and start Motion mechanism to make the base material move;

[0111] In step (1), the base material is a solid material, and the solid material is a block aluminum material and a PCB board, and any interface of the base material surface can be exposed to cold and heat after the cold and heat cycle impact coating is prepared. in a loop test environment.

[0112] The volume of reaction chamber is 480L in the step (1), and the temperature of reaction chamber is controlled at 50 ℃, and the flow that feeds inert gas is 60sccm,.

[0113] In step (1), the base material performs circular mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com