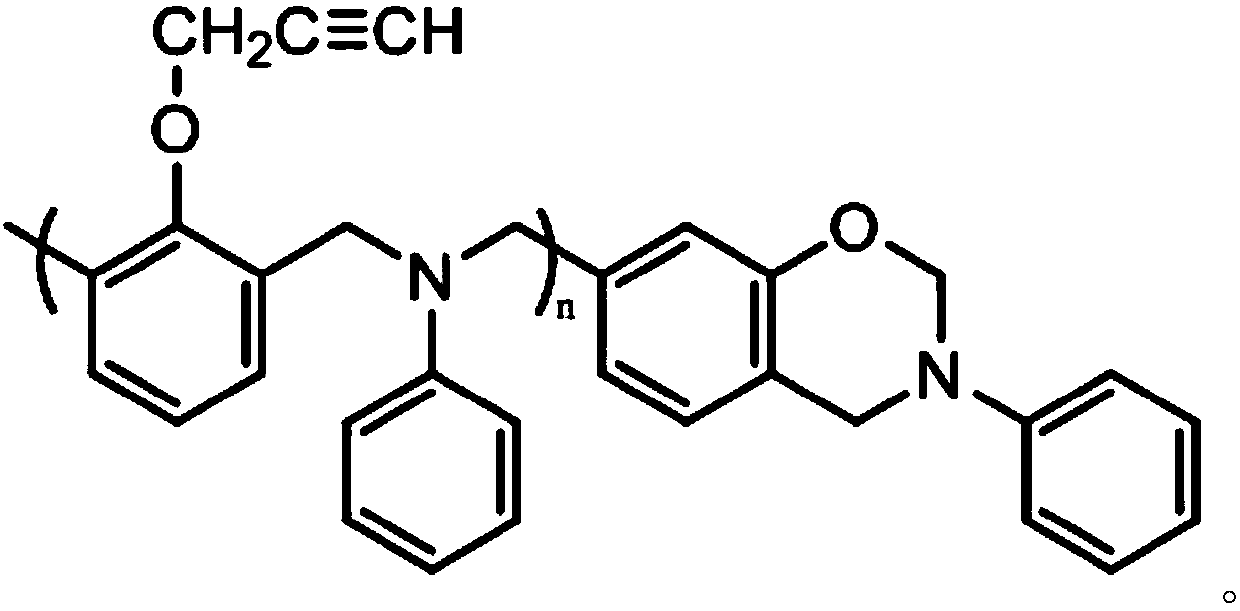

Thermosetting resin containing propargyl ether and preparation method of thermosetting resin

A technology of propargyl ether and thermosetting, applied in the field of thermosetting resin with propargyl ether and its preparation, to achieve the effects of improving processability, good environmental stability, and low hygroscopicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

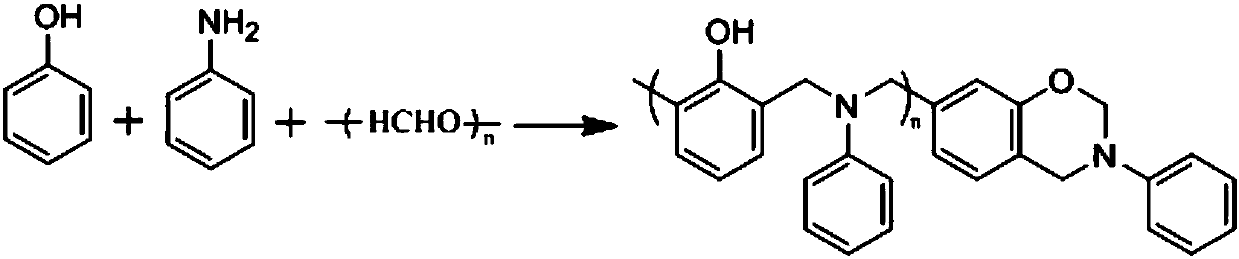

[0028] Add 5g of phenol, 4.947g of aniline, and 3.192g of paraformaldehyde into a three-necked flask, connect a condenser and a stirring device, slowly raise the temperature to 110°C, react for 6 hours, and take out the reactant to obtain 12.027g of benzoxazine resin.

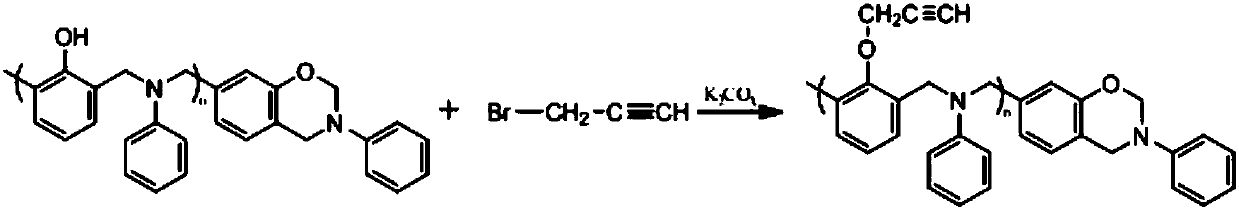

[0029] Put 5g of benzoxazine resin, 1.8g of 4-nitrophthalonitrile, and 1g of anhydrous potassium carbonate into a three-necked flask, add 30ml of N-methylpyrrolidone, and react at room temperature for 24h under the protection of nitrogen. The reacted substance was filtered, the filtrate was poured into a large amount of water, the solid was filtered out with suction, washed with water several times, and dried in a vacuum oven at 50° C. for 24 hours.

Embodiment 2

[0031] Add 3g of phenol, 2.968g of aniline, and 2.106g of paraformaldehyde into a three-necked flask, connect a condenser and a stirring device, slowly raise the temperature to 110°C, react for 6 hours, and take out the reactant to obtain 7.304g of benzoxazine resin.

[0032] Put 5g of benzoxazine resin, 2g of 4-nitrophthalonitrile, and 1.2g of anhydrous potassium carbonate into a three-necked flask, add 30ml of N-methylpyrrolidone, and react at room temperature for 24h under the protection of nitrogen. The reacted substance was filtered, the filtrate was poured into a large amount of water, the solid was filtered out with suction, washed several times with water, and dried.

Embodiment 3

[0034] Add 2.5g of phenol, 2.473g of aniline, and 1.755g of paraformaldehyde into a three-necked flask, connect a condenser and a stirring device, slowly raise the temperature to 110°C, react for 3 hours, and take out the reactant to obtain 6.215g of benzoxa oxazine resin.

[0035] Put 3g of benzoxazine resin, 1g of 4-nitrophthalonitrile, and 1g of anhydrous potassium carbonate into a three-necked flask, add 25ml of N-methylpyrrolidone, and react at room temperature for 24h under the protection of nitrogen. The final substance was filtered, the filtrate was poured into a large amount of water, the solid was filtered out with suction, washed several times with water, and dried.

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com