Polybenzoxazine composition

Technology of a polymer composition, benzoxazine, applied in the field of preparation of polymer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0158] All parts, percentages, ratios, etc. in the examples are by weight unless otherwise indicated.

[0159] The amount of catalyst used in the binder is determined by equivalents (eq) based on the number of moles of reactive groups per mole of reactant molecules, for example, 2 equivalents of a difunctional reactant represents one mole of that reactant, and one A mole of trifunctional reactant would represent 3 equivalents of that reactant. The catalyst was treated as a monofunctional catalyst.

[0160] A double dash symbol in the table indicates that the sample was not tested.

[0161] Materials were purchased from Sigma-Aldrich, Milwaukee, WI unless otherwise stated.

[0162] testing method

[0163] Differential Scanning Calorimetry (DSC Analysis) of Curing

[0164] The thermal properties of the composition during curing were determined by placing an amount of the composition in an open aluminum pan in a differential scanning calorimeter (DSC) and heating from 25°...

example 1

[0215] Powders of finely ground BZ-1 (23.1) and sulfur (3.2 grams) were mixed in an equimolar ratio and stirred and shaken in a Wig-L-Bug shaker for approximately 1 minute. Approximately 15.4 milligrams (mg) of the mixture was heated to 320°C in a DSC (Seiko) as described above. The DSC trace showed an exotherm with a high temperature peak at about 211°C, a cure onset temperature of about 140°C, and a total energy released during cure of 221 J / gram. The trace also shows a less sharp endotherm with a peak at about 113°C, which corresponds to the recorded melting point of sulfur.

example 2

[0217] BZ-2 (33.3 grams) and finely ground sulfur (3.2 grams) were mixed in an equimolar ratio and stirred vigorously for about 1 minute. Approximately 20.3 mg of the mixture was heated to 320°C in DSC as described in Example 1. The DSC trace shows an exotherm with double high temperature peaks at about 170°C and 225°C and a cure onset temperature of about 130°C. The total energy released during curing was 221 J / gram. The trace also shows a less sharp endotherm with a peak at about 113°C, which corresponds to the recorded melting point of sulfur.

[0218] Comparative Examples C1–C2

[0219] About 4.4 mg of BZ-1 (C1 ) and about 12.0 mg of BZ-2 (C2) were heated to 320° C. in DSC as described in Example 1 . The respective DSC traces of C1 and C2 showed peak exothermic temperatures of 240°C and 246°C, curing onset temperatures of 190°C and 190°C, and energy released during curing of 323 and 113 J / g, respectively.

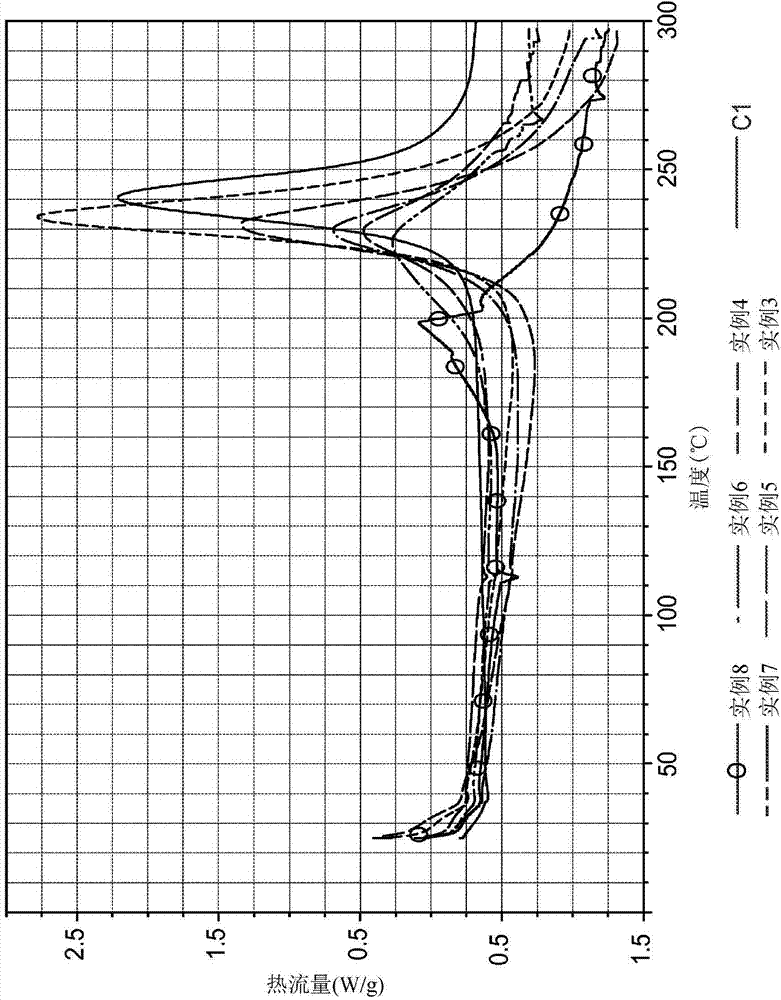

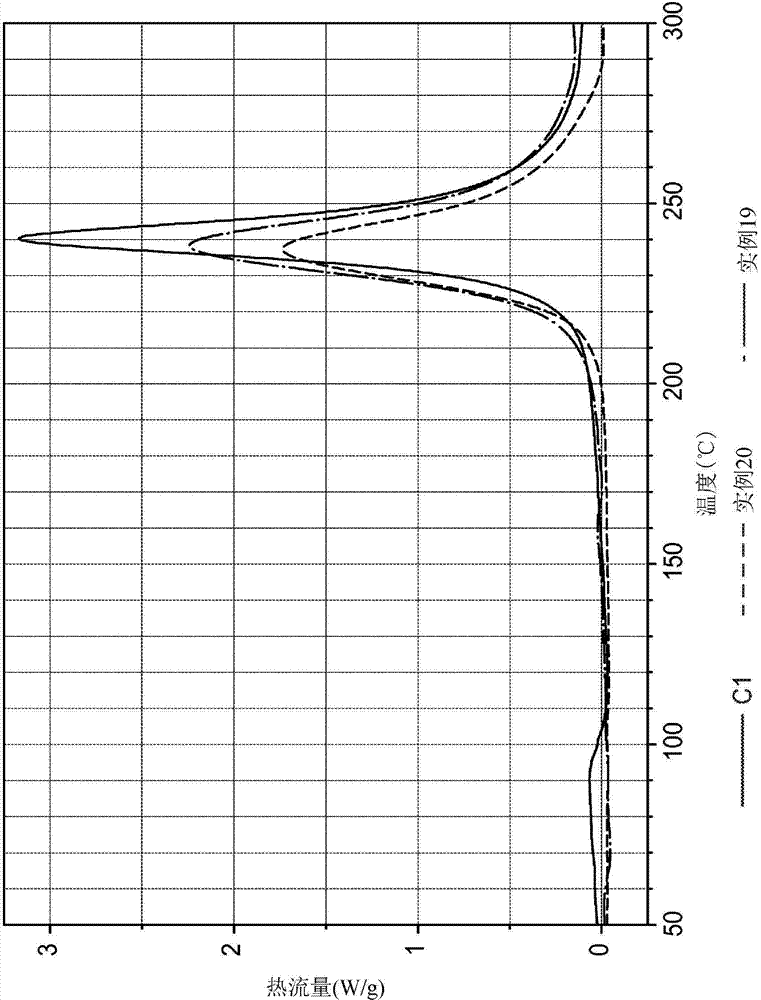

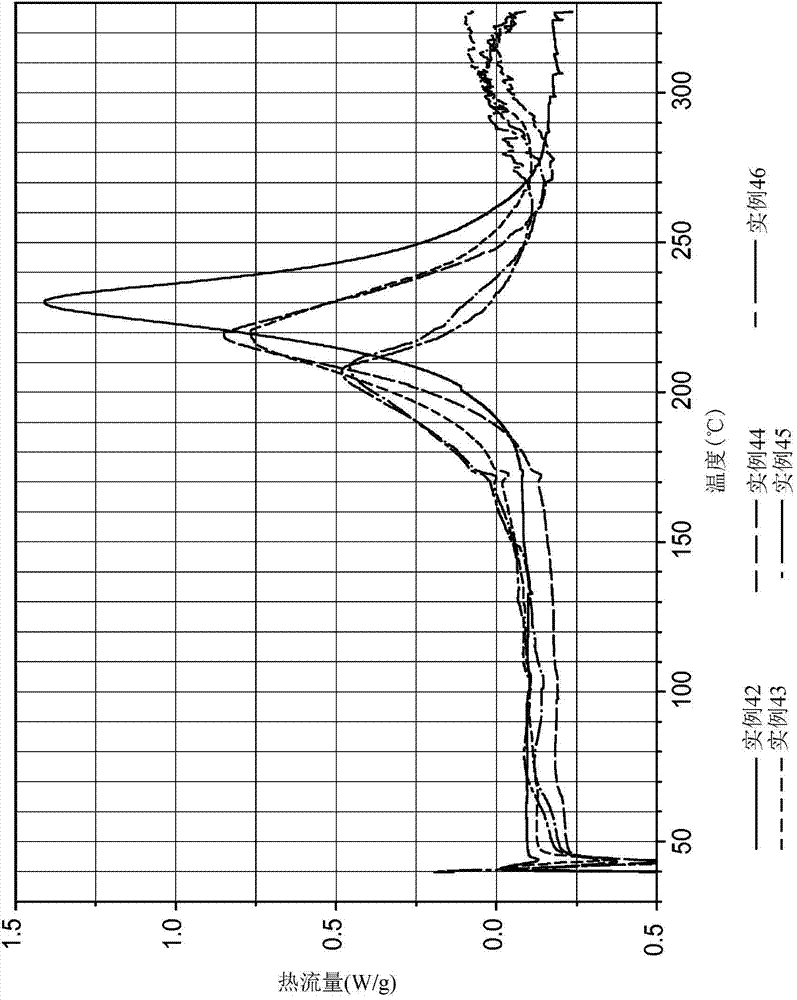

[0220] Examples 3-8, Comparative Example C1A

[0221] Fin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com