Patents

Literature

201results about How to "Less heat release" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

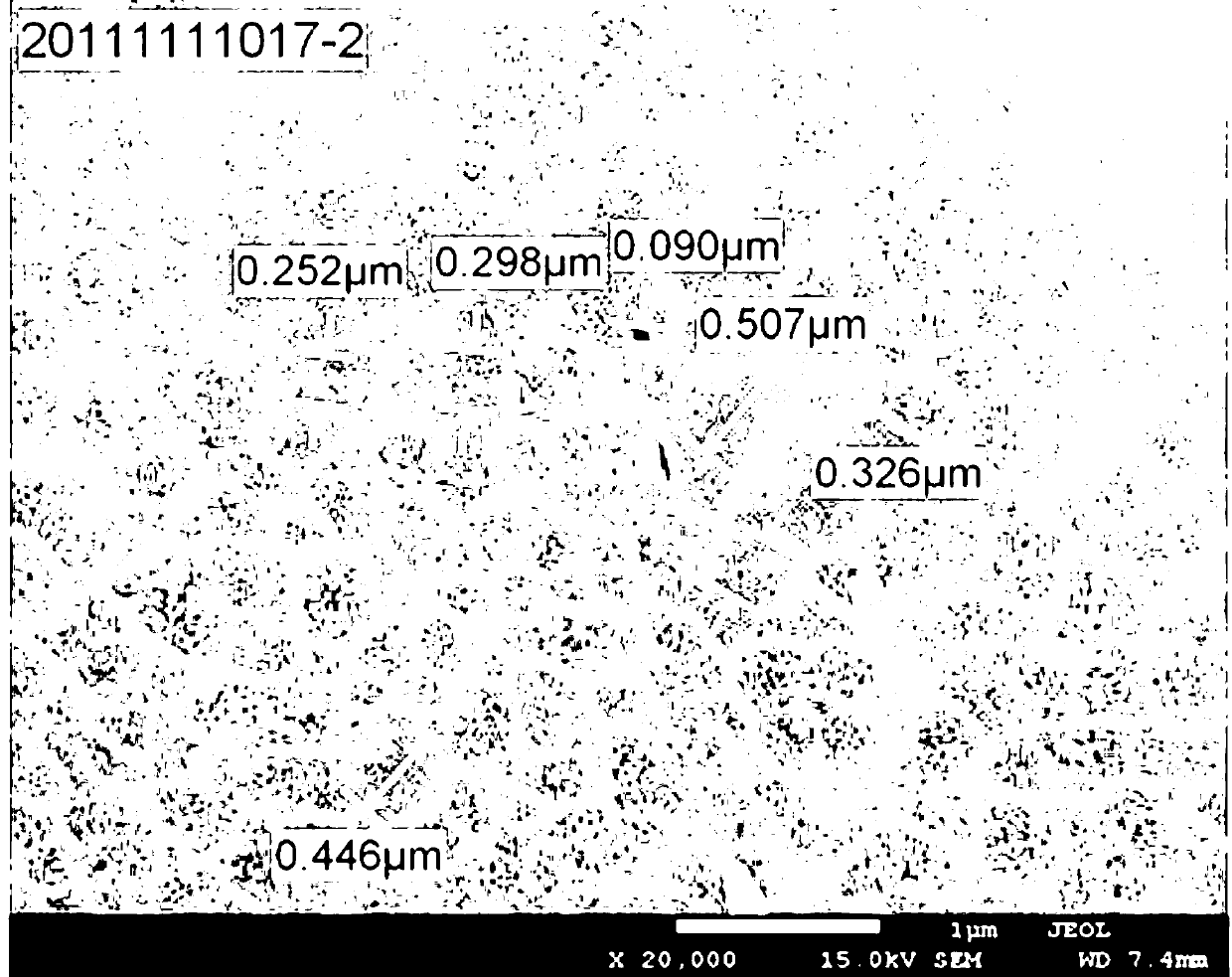

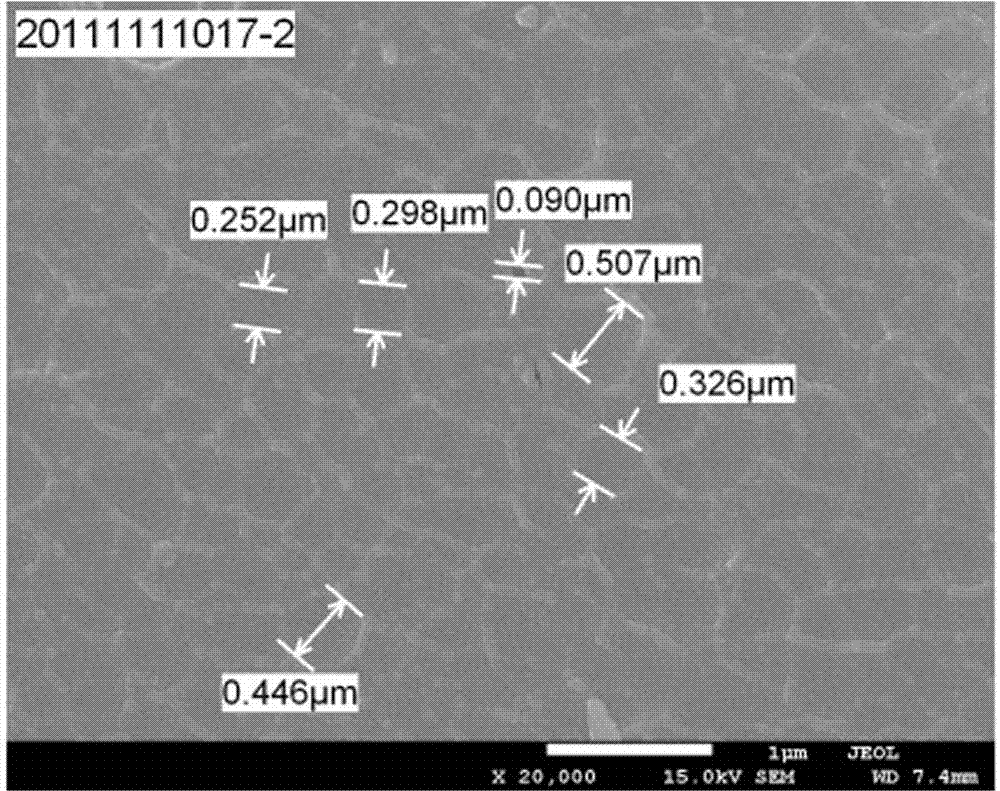

Mobile phone shell and preparation method thereof

ActiveCN103297565AImprove corrosion resistanceAppearance has no effectAnodisationSmall component housingsMobile phoneNanotechnology

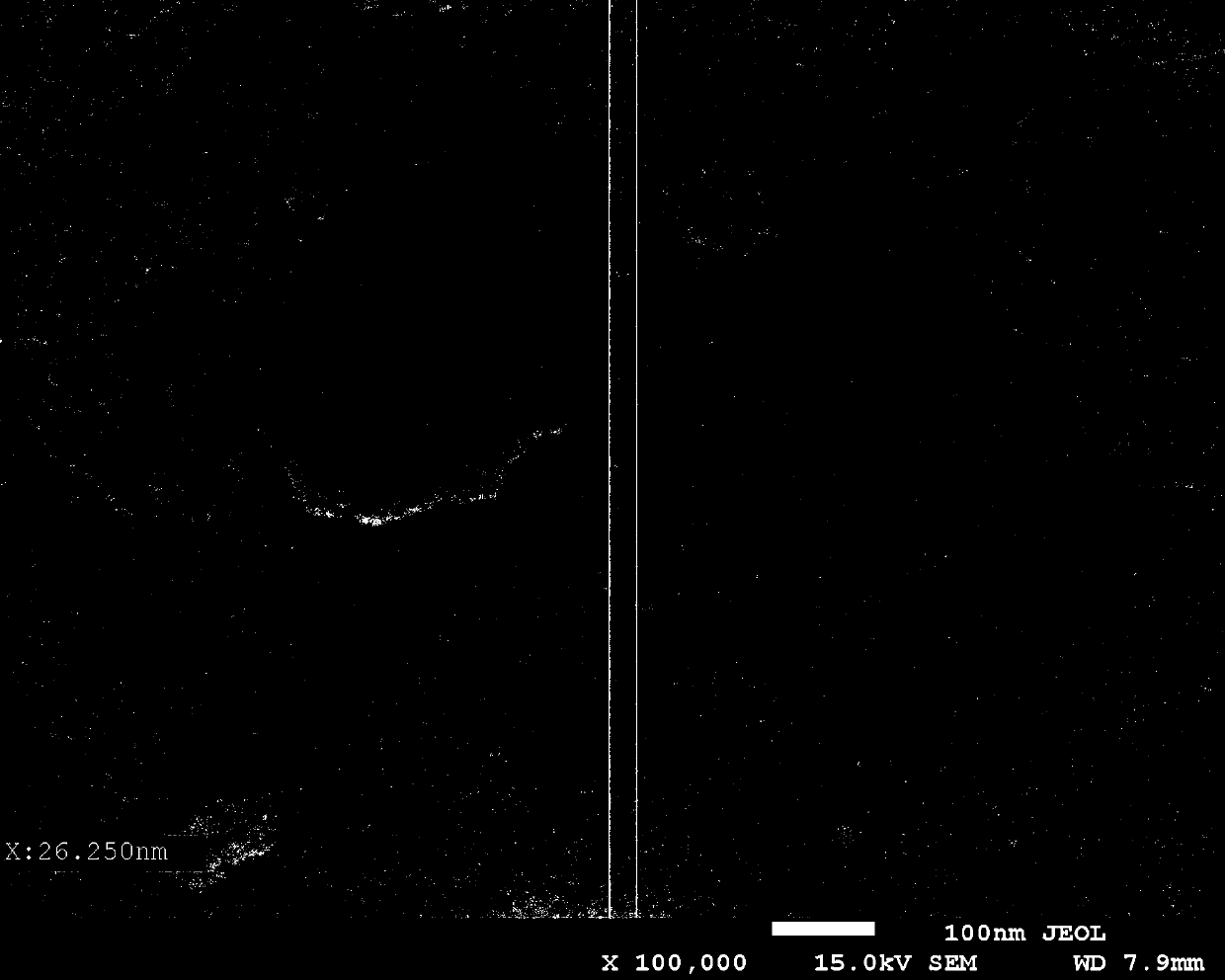

The invention provides a mobile phone shell and a preparation method of the mobile phone shell. The mobile phone shell comprises a plastic piece and a metal shell body which is combined with the plastic piece, wherein the surface of a face, combined with the plastic piece, of the metal shell body is provided with an oxidation film layer, corrosion holes are formed in the surface layer of a face, opposite to the plastic piece, of the oxidation film layer, the hole diameter of each corrosion hole is 200 nanometers to 2000 nanometers, nanometer micro holes are formed in the inner layer of the oxidation film layer, the hole diameter of each nanometer micro hole is 10 nanometers to 100 nanometers, and resin compositions of the plastic piece are filled in the nanometer micro holes and the corrosion holes. The prepared mobile phone shell is resistant to abrasion, falling and corrosion.

Owner:BYD CO LTD

Wafer processing method

InactiveUS7138606B2Improve temperature distributionUniform temperatureDrying solid materials with heatMuffle furnacesEngineeringLiquid circulation

A wafer processing method for use with a wafer processing apparatus having a liquid cooling jacket with a built-in coolant liquid circulation path and a ceramic plate as attached onto the liquid cooling jacket and having therein a heater and an electrode for an electrostatic chuck. The method enables performance of wafer processing while letting a wafer be mounted on the ceramic plate by a wafer transport. The method includes causing the wafer transport to transport the wafer onto the ceramic plate, pre-heating the wafer while the wafer is held on the ceramic plate for a predetermined length of time, and mounting the preheated wafer on the ceramic plate.

Owner:HITACHI HIGH-TECH CORP

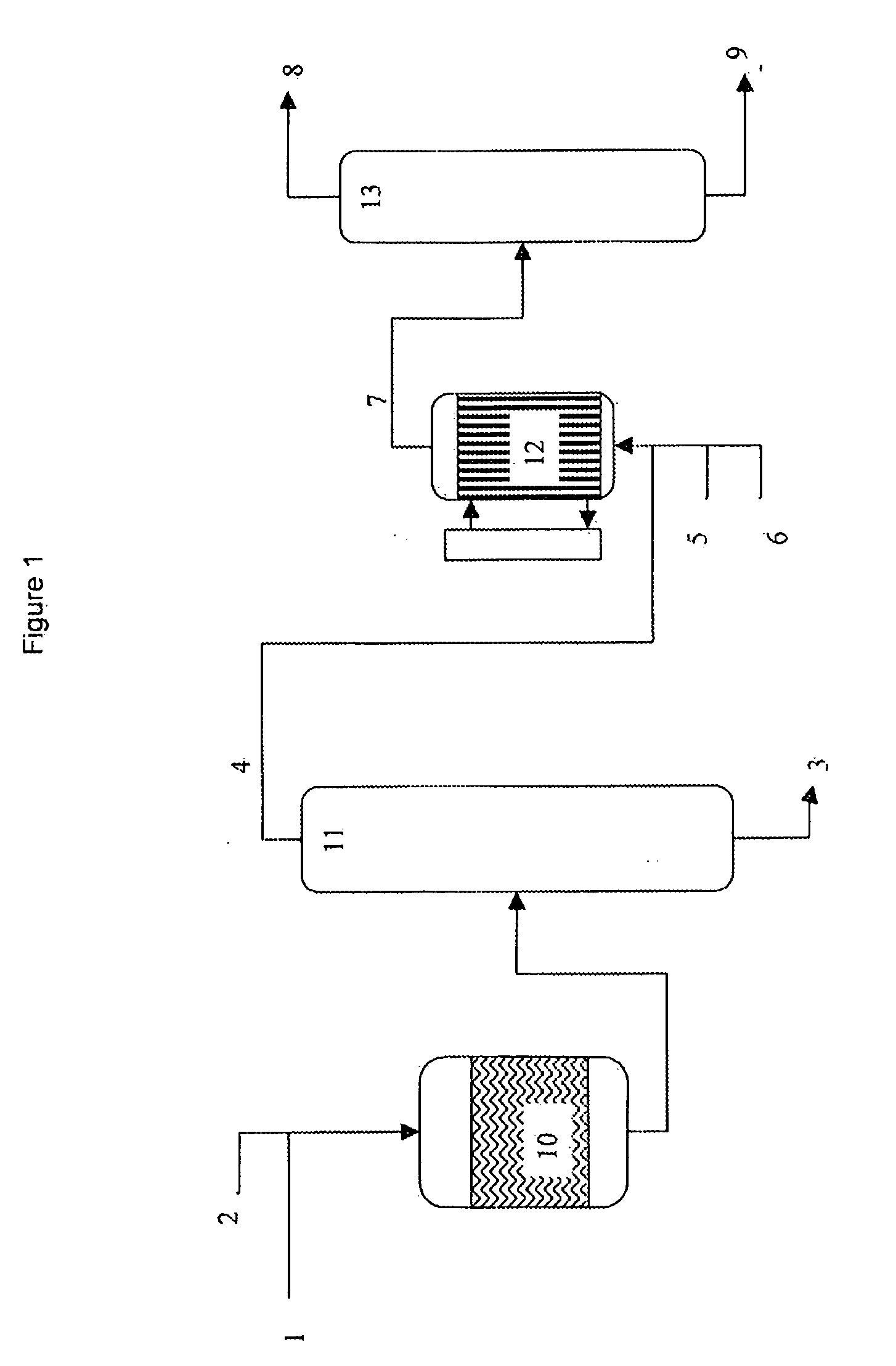

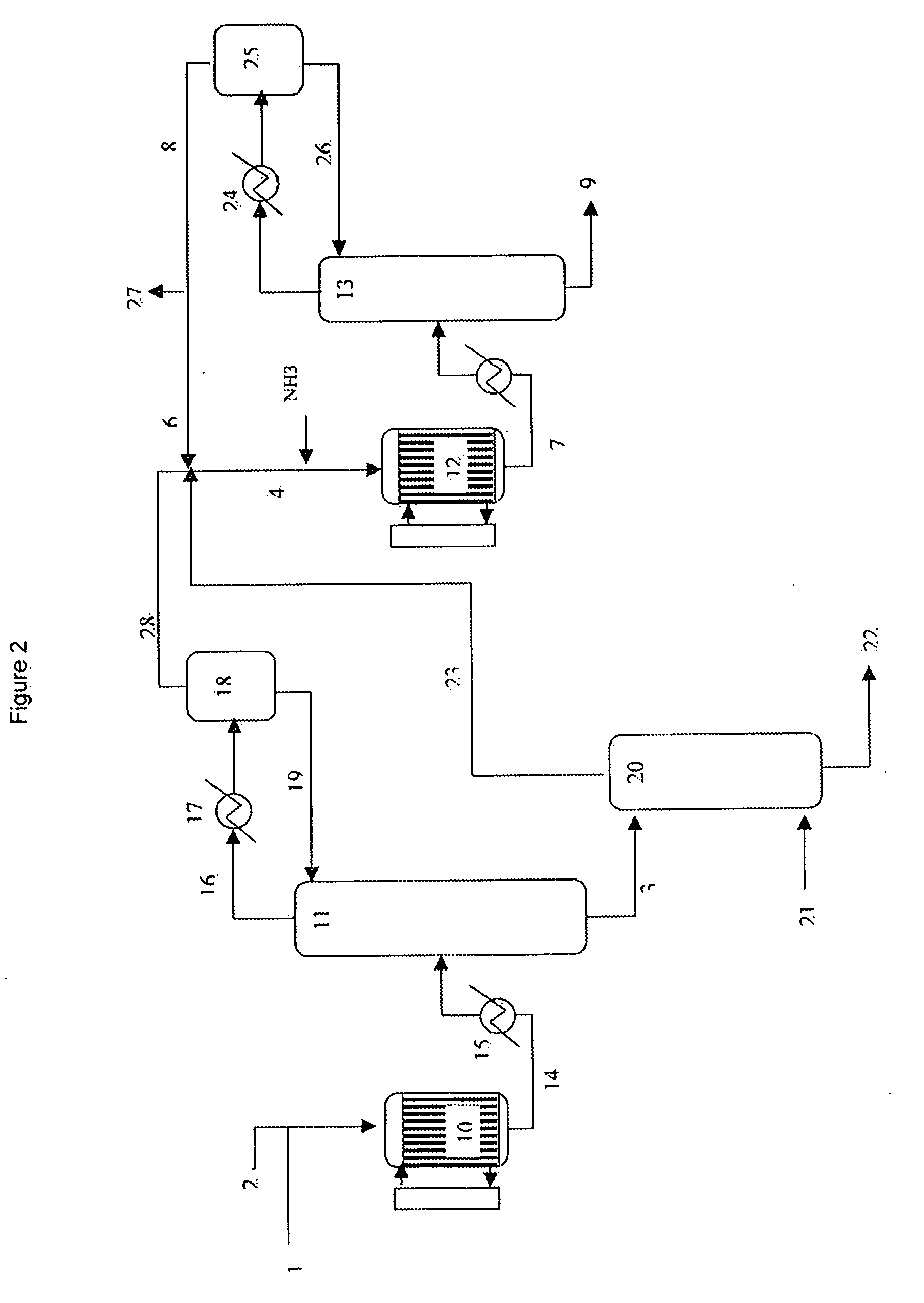

Method for the synthesis of acrylonitrile from glycerol

InactiveUS20100048850A1Less heat releaseIncrease partial pressureOrganic compound preparationPreparation by hydrocarbon ammoxidationGas phaseGlycerol

The invention relates to a novel way to synthesize acrylonitrile from a renewable raw material and more particularly relates to a method for producing acrylonitrile by the ammoxidation of glycerol in gaseous phase. The method can be implemented in a single step, or the glycerol can be previously submitted to a dehydration step. The acrylonitrile thus obtained meets the requirements of green chemistry.

Owner:ARKEMA FRANCE SA

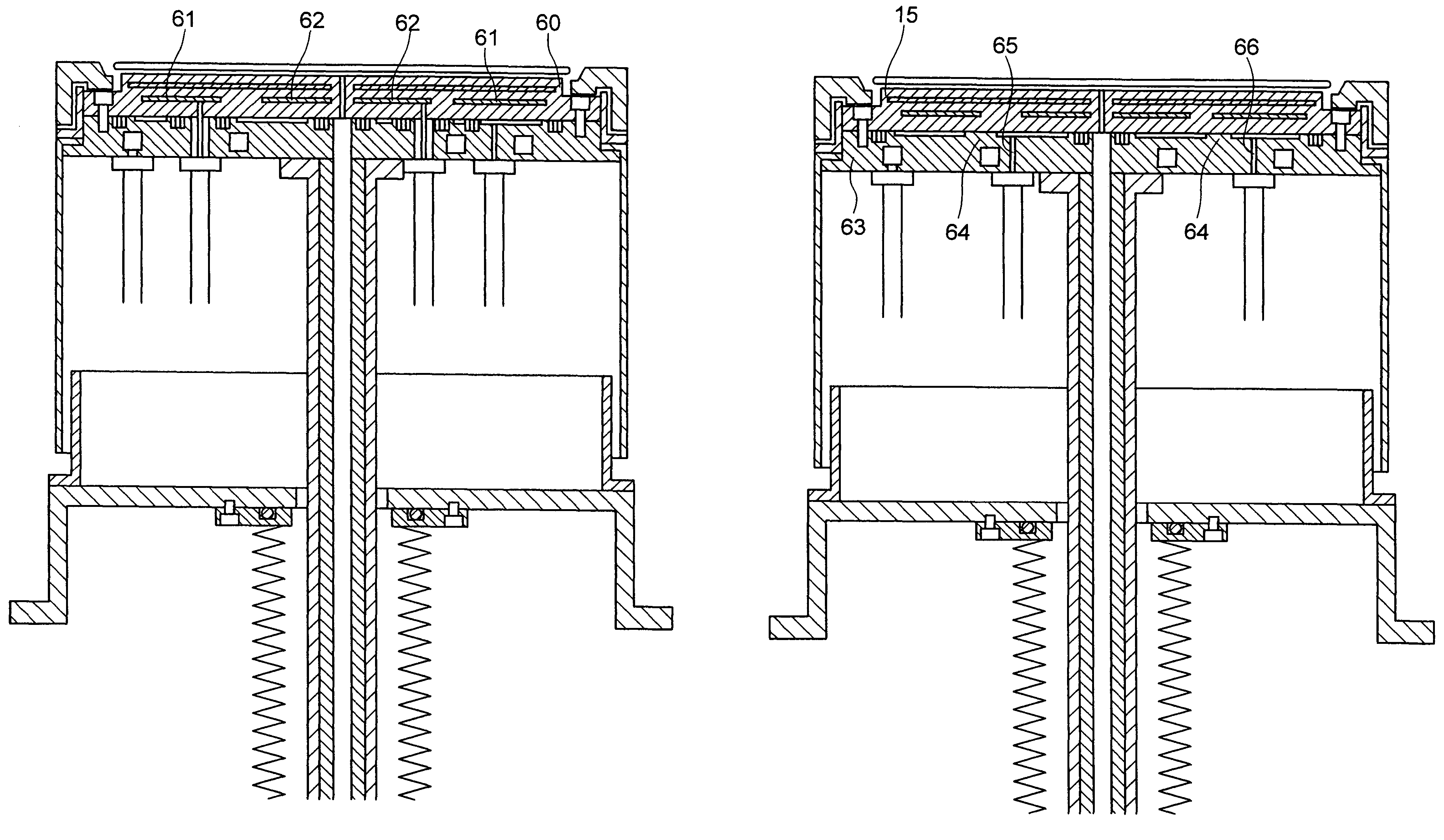

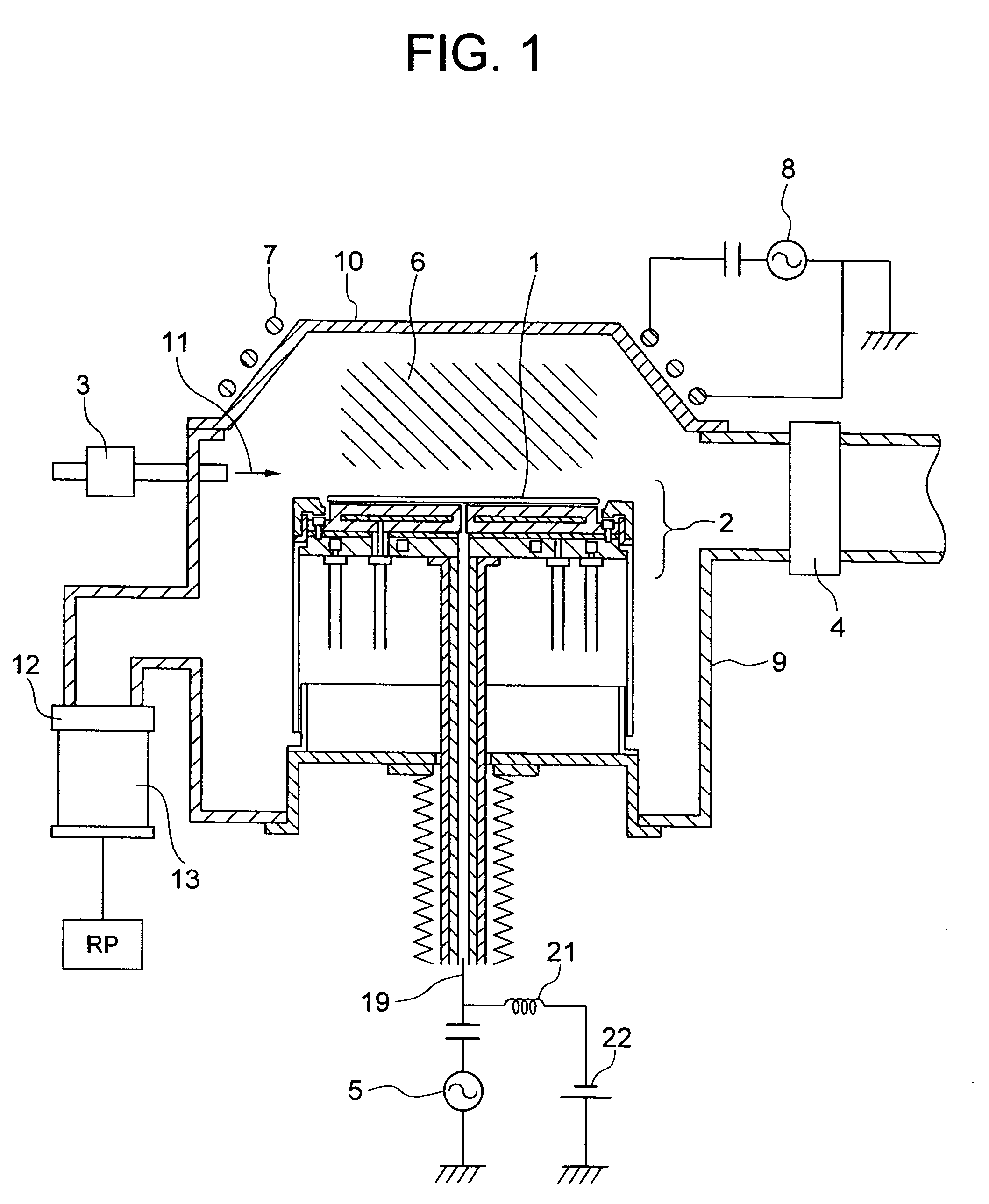

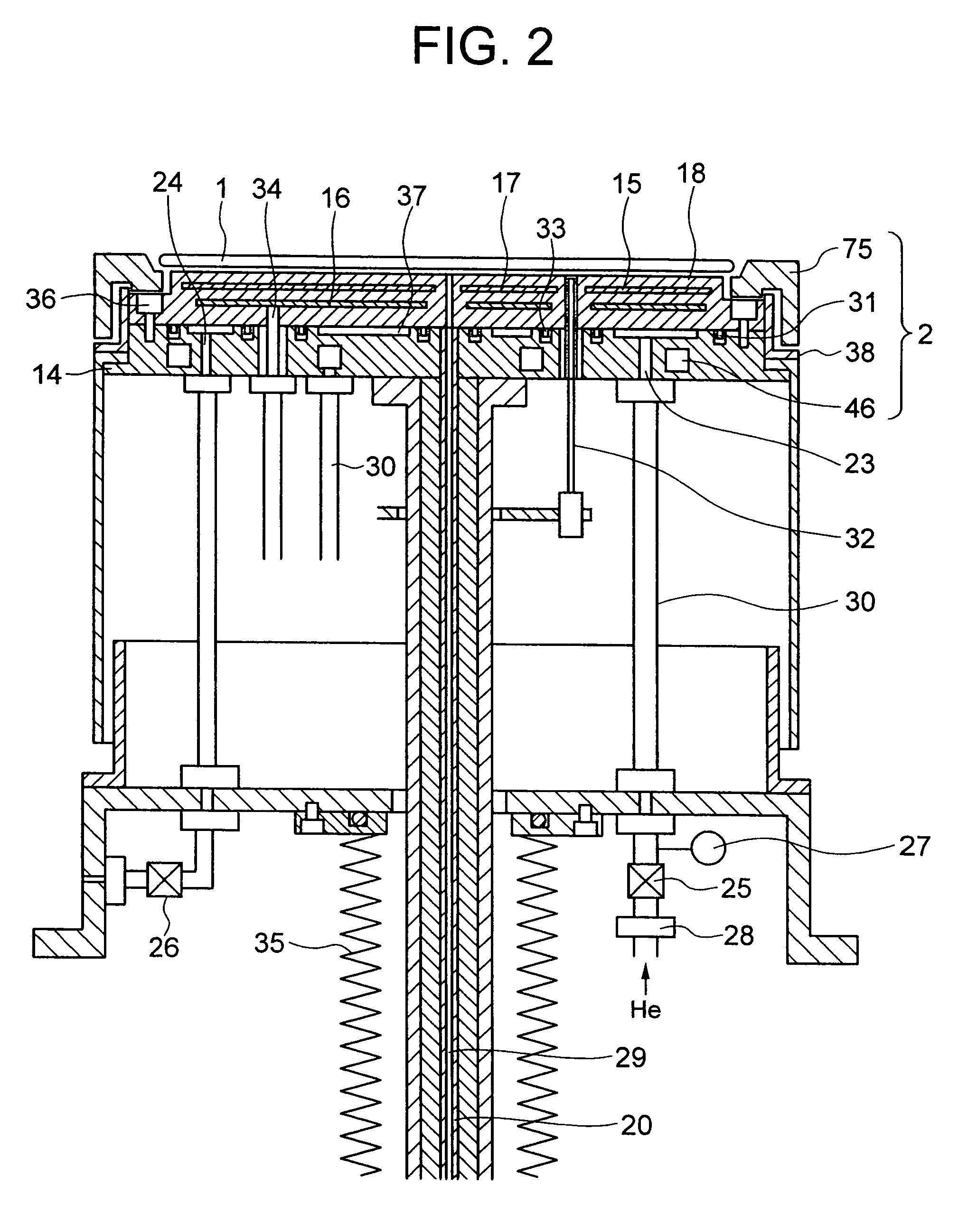

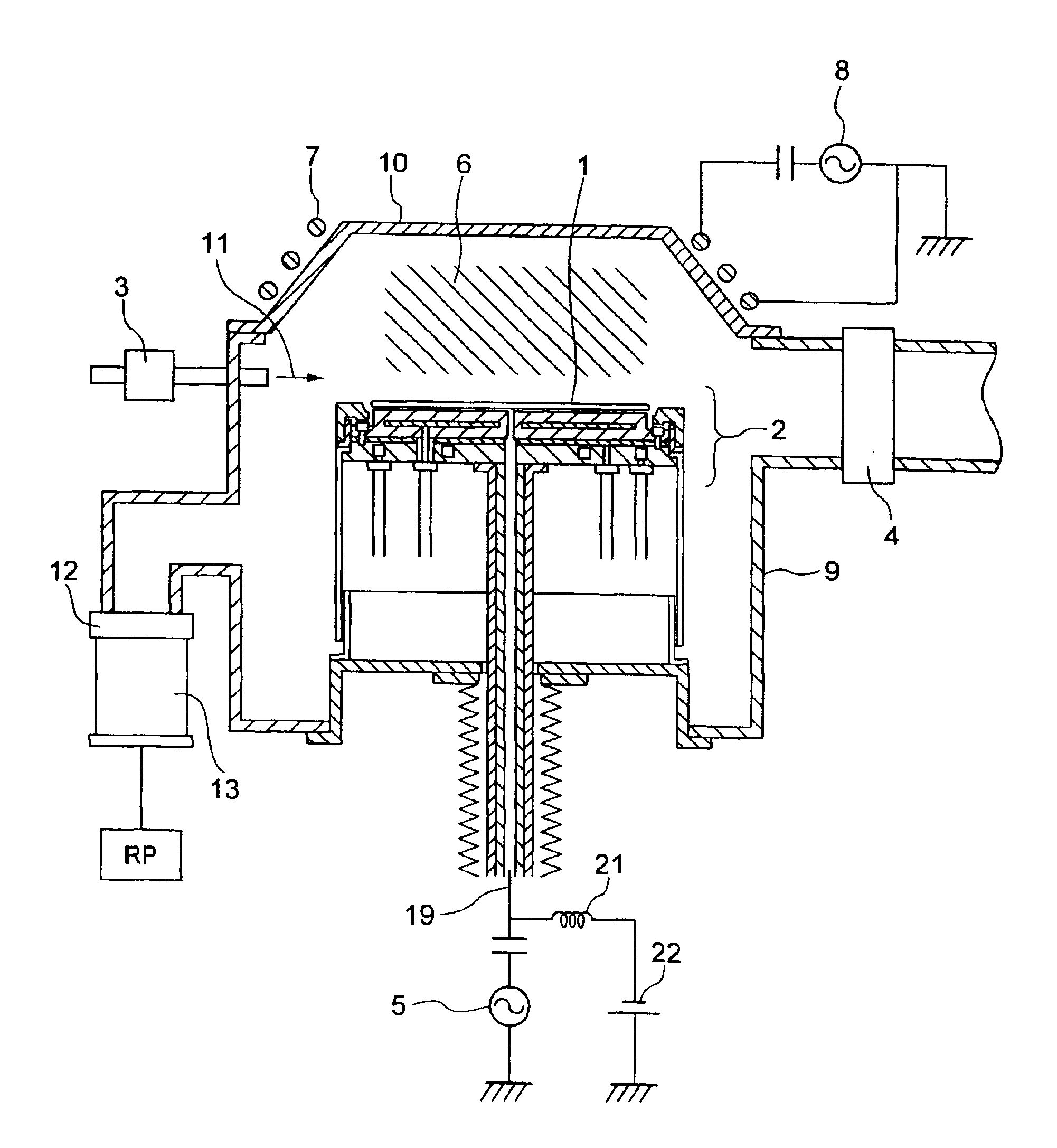

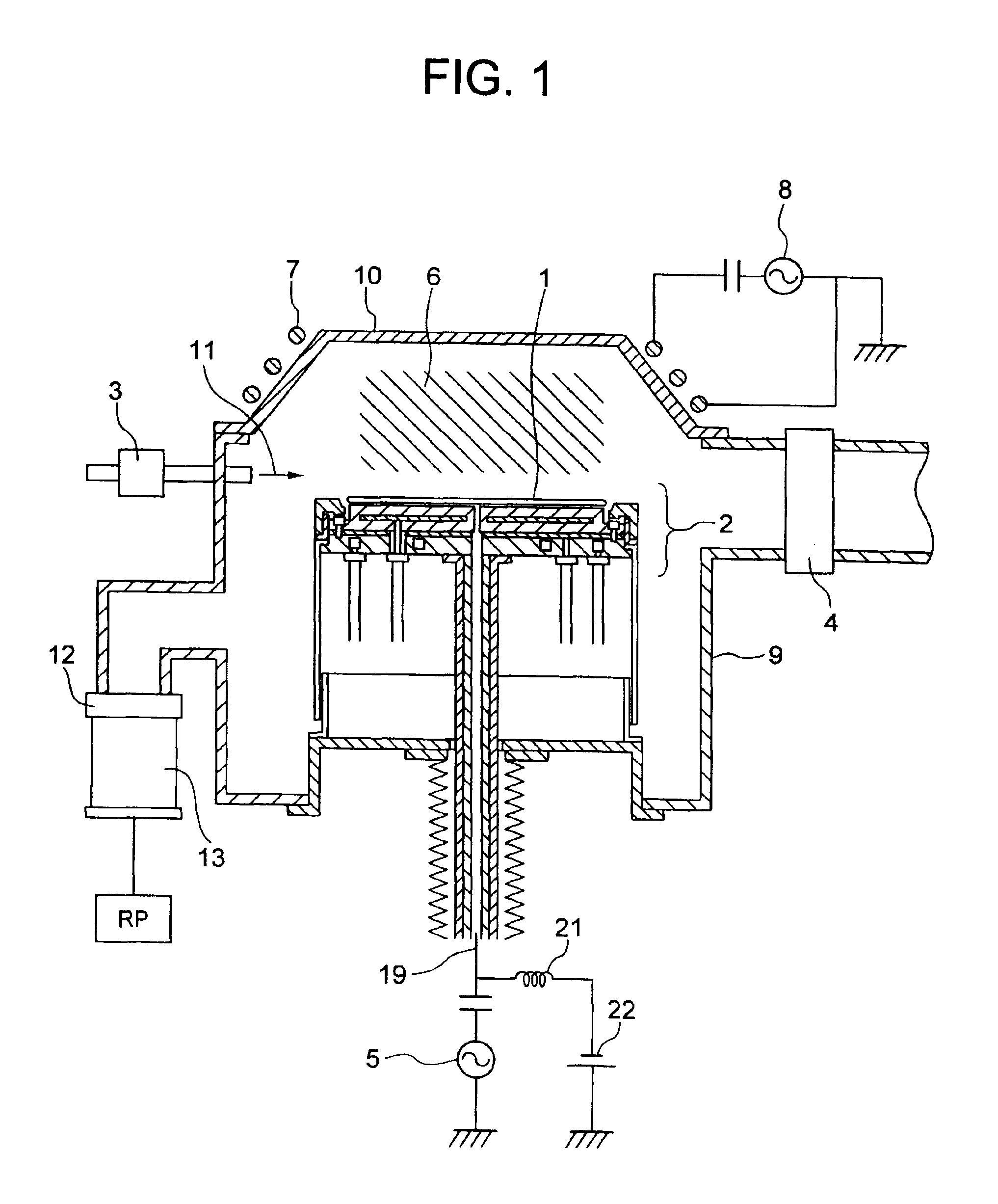

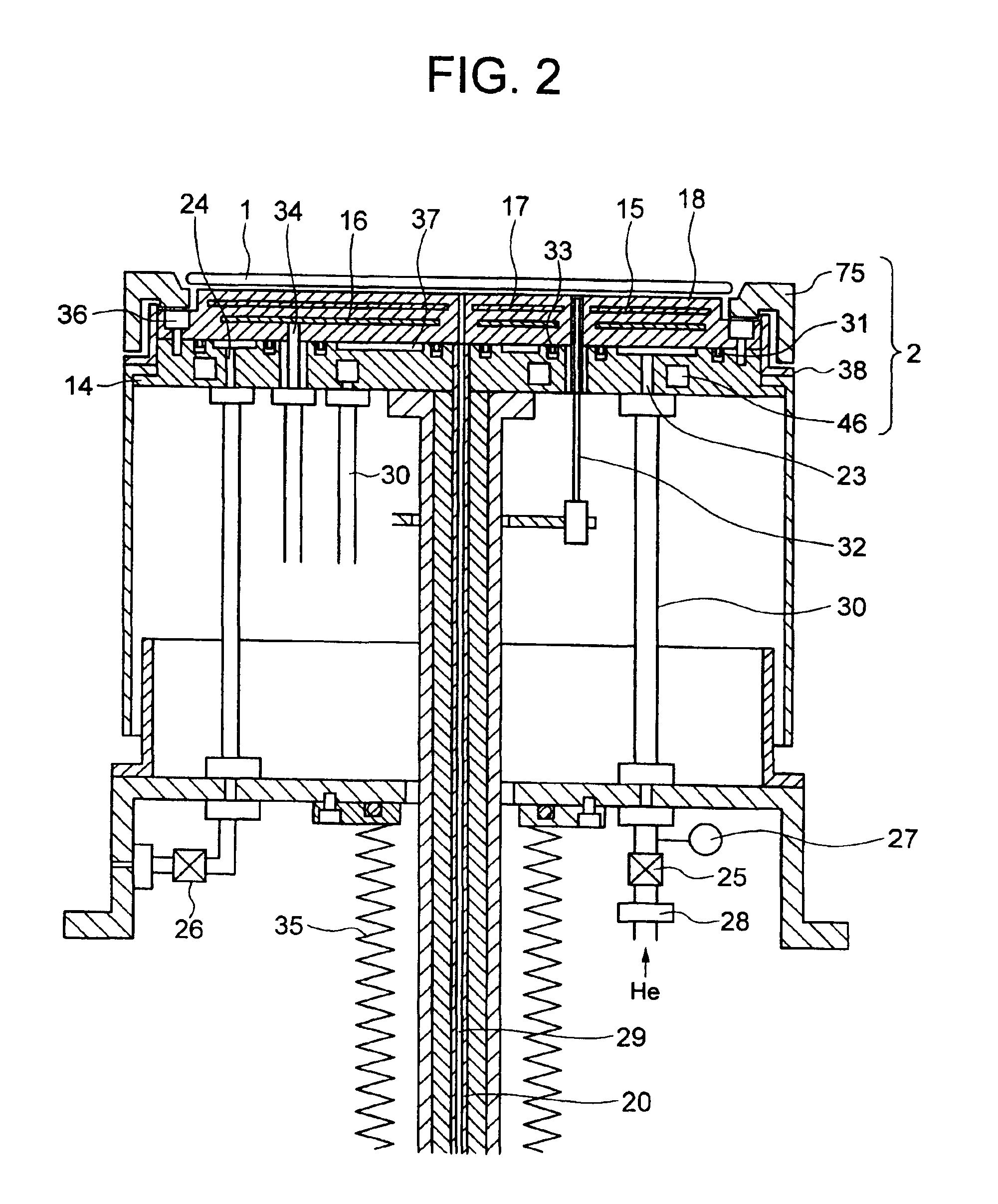

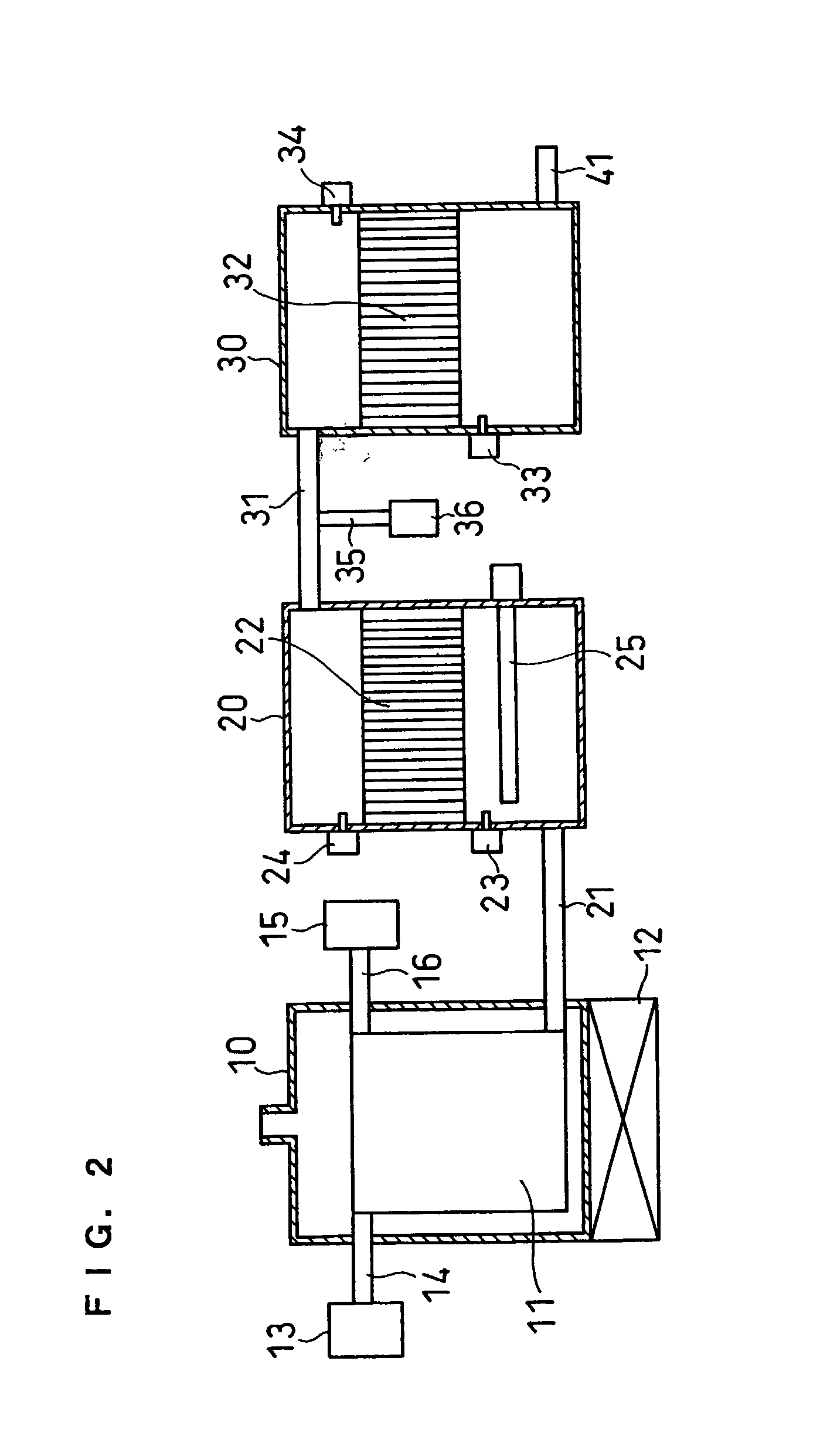

Wafer stage for wafer processing apparatus

InactiveUS6895179B2Improve temperature distributionUniform temperatureDrying solid materials with heatMuffle furnacesElastomerEngineering

A wafer stage for use in a wafer processing apparatus having a liquid cooling jacket with a built-in coolant liquid circulation path and a ceramic plate as attached onto the liquid cooling jacket and having therein a heater and an electrode for an electrostatic chuck. The wafer stage enables performance of wafer processing while letting a wafer be mounted on the ceramic plate. The liquid cooling jacket enables attachment of the ceramic plate through a gap for circulation of a coolant gas as formed over the liquid cooling jacket, and a heat resistant seal material containing therein an elastic body for sealing the coolant gas between the liquid cooling jacket and the ceramic plate.

Owner:HITACHI HIGH-TECH CORP

Preparation method of metal resin complex and metal resin complex prepared thereby

ActiveCN103448202AEasy accessSize has little effectAnodisationLaminationAlloy substrateWater soluble

The invention provides a preparation method of a metal resin complex and the metal resin complex prepared thereby. The preparation method of the metal resin complex comprises the following steps: S1, micropores are formed on the surface of a pretreated metal substrate, and the metal substrate is an aluminum alloy substrate or aluminum substrate; S2, the metal substrate having the micropores on the surface thereof and obtained by the step S1 is soaked in a water-soluble polymer solution for modification; and S3, the surface of the treated metal substrate modified by soaking in the step S2 is coated with a resin composition, and after molding the metal resin complex is obtained. In the metal resin complex, the binding force between metal and resin is strong, and the process is simple, is easy for large-scale production, and has no pollution.

Owner:BYD CO LTD

Injectable-porous-drug loaded polymethyl methacrylate-based composite scaffold bone transplant material and preparation method thereof

ActiveCN104906637AEasy to prepareGood biocompatibilityProsthesisReaction temperaturePolymethyl methacrylate

The present invention discloses an injectable-porous-drug loaded polymethyl methacrylate-based composite scaffold bone transplant material and a preparation method thereof, and belongs to the field of organic functional materials preparation. The polymethyl methacrylate-based composite scaffold bone transplant material uses polymethyl methacrylate (PMMA) as a scaffold for providing mechanical supporting, and a chitosan-based thermosensitive hydrogel as a pore forming agent and an osteoconductive material and a drug carrier, and the polymethyl methacrylate (PMMA) and the chitosan-based thermosensitive hydrogel are mixed with each other to form an injectable-porous three-dimensional structural bone cement composite. The scaffold bone transplant material is simple in preparation method, suitable in reaction temperature, and good in biocompatibility, has matched mechanical properties, good biological mineralization and corresponding anti-bacterial, anti-inflammatory or anti-tumor capabilities, and has broad prospects in clinical application of reconstruction of bone tissues in future.

Owner:WUHAN UNIV

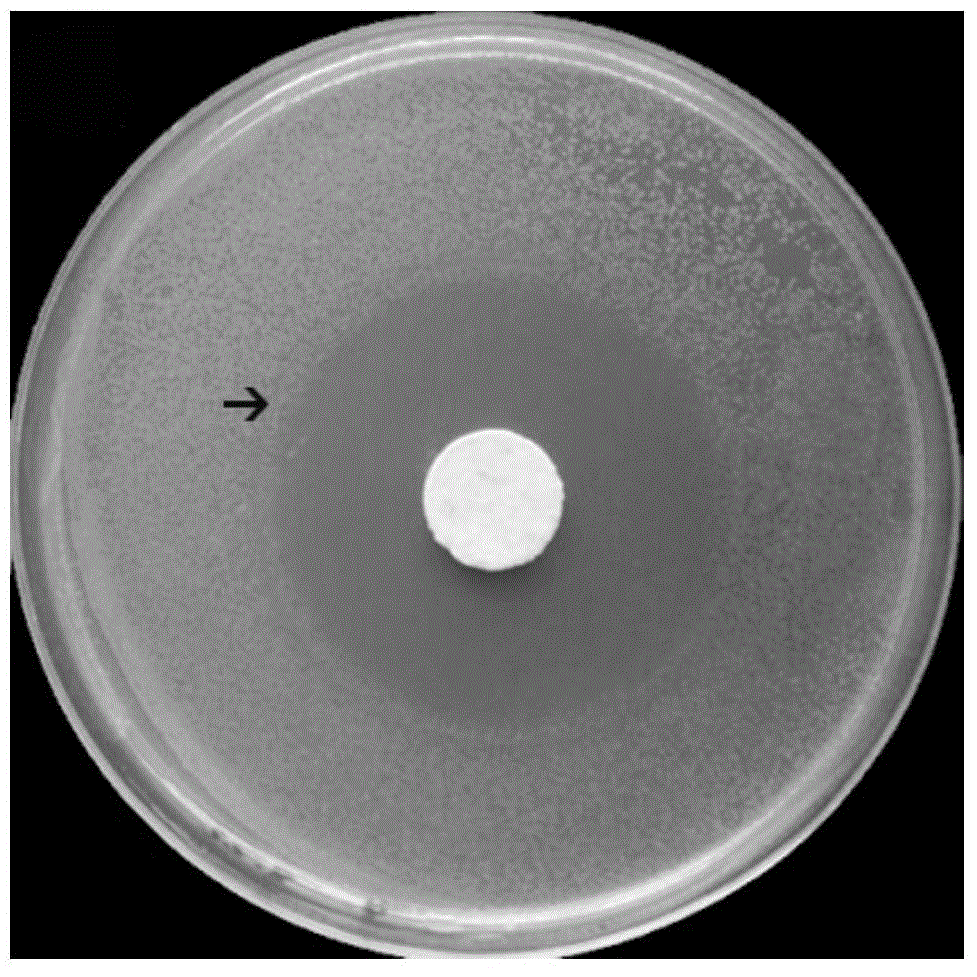

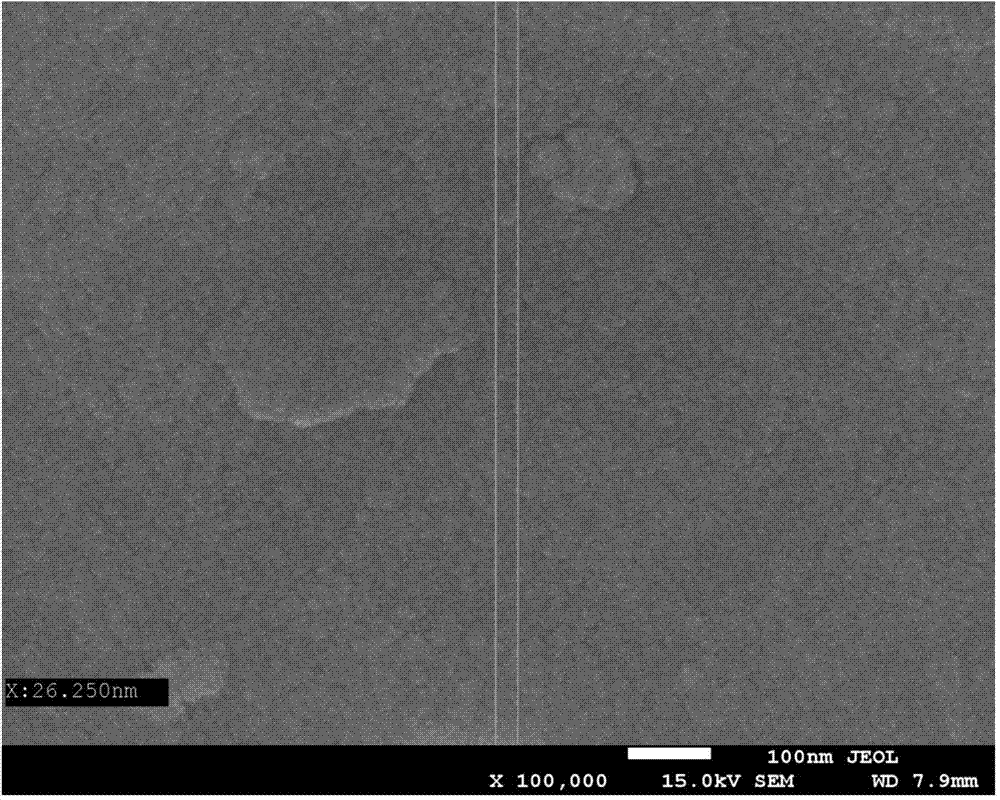

Preparation method of aluminum alloy-resin composite and aluminum alloy-resin composite prepared by using same

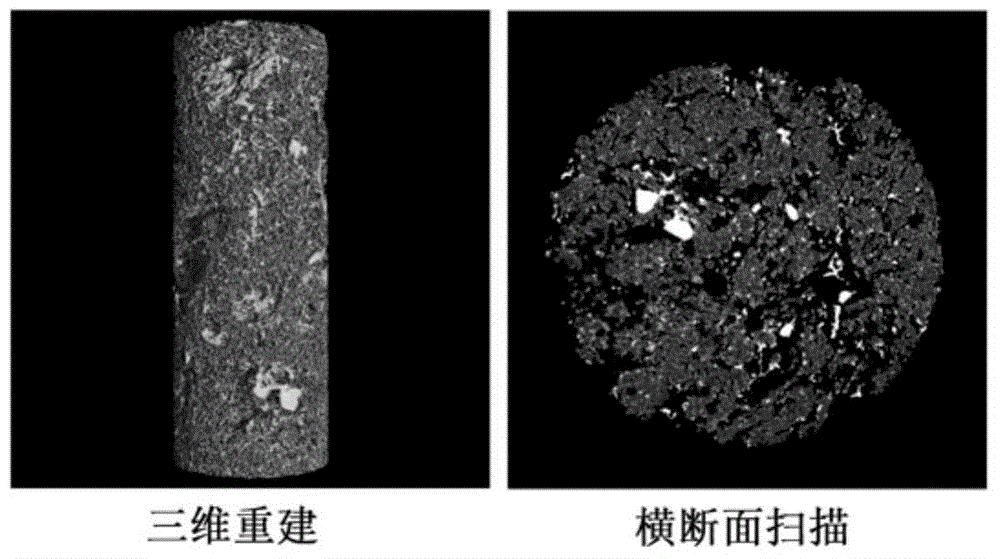

ActiveCN103286995AHigh strengthUnique structureAnodisationAutomatic/semiautomatic turning machinesAlloy substrateAnodic oxidation

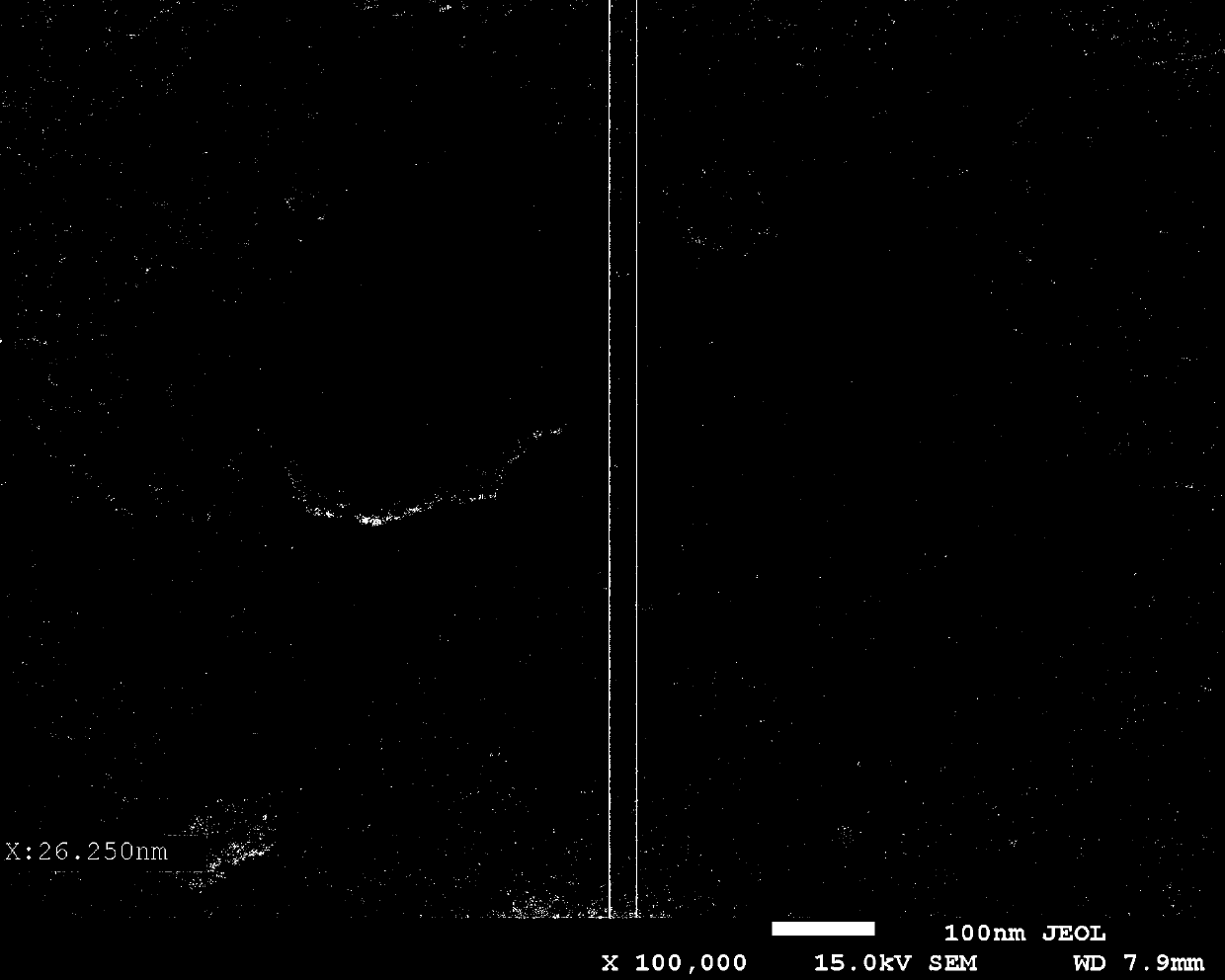

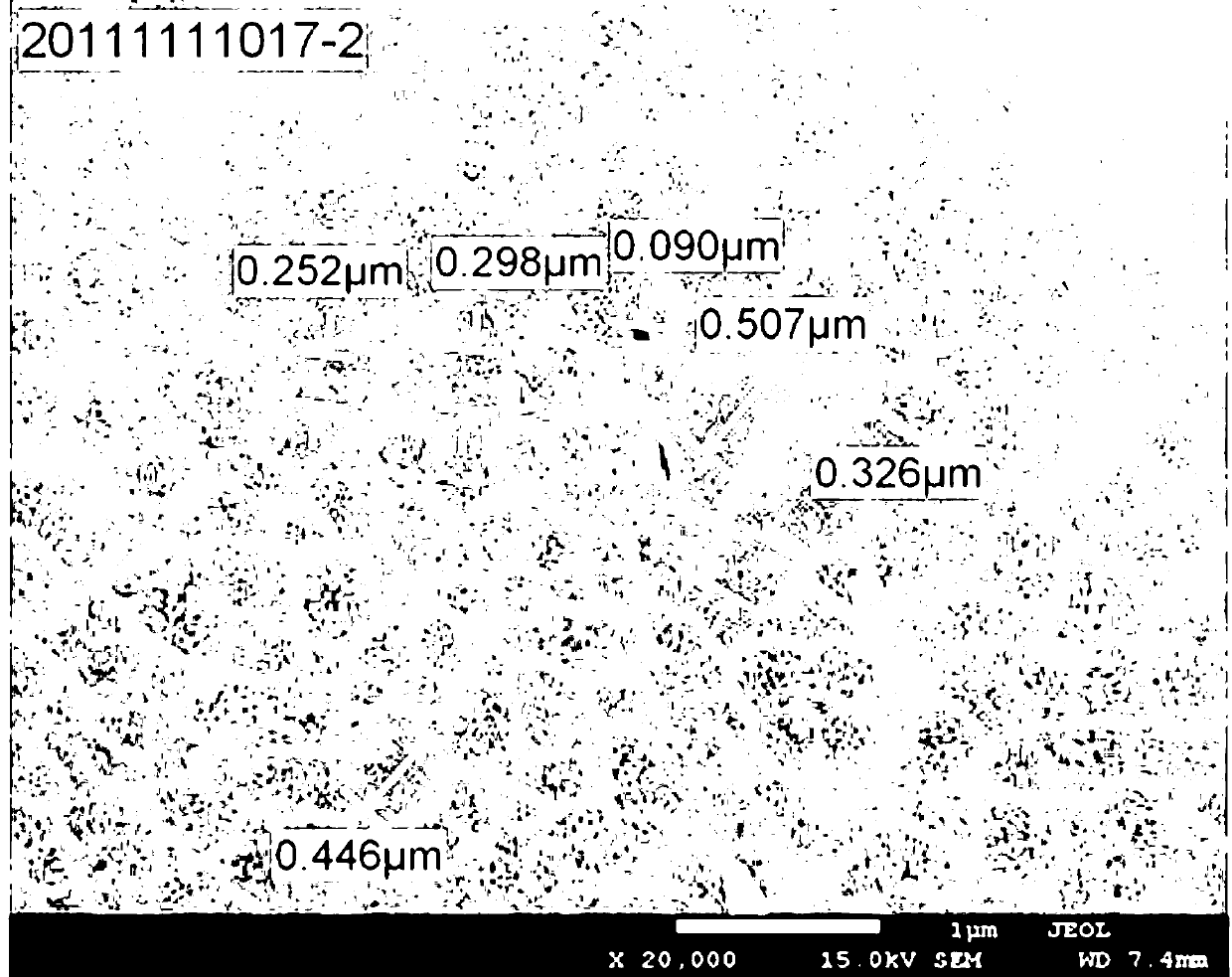

The invention provides a preparation method of an aluminum alloy-resin composite and an aluminum alloy-resin composite prepared by using the same. The preparation method comprises the following steps: S1. anodizing a pretreated aluminum alloy substrate to obtain an aluminum alloy of which the surface contains a nanoporous oxide film layer; S2. soaking the aluminum alloy containing the nanoporous oxide film layer obtained in the step S1 in an alkaline solution with the pH value of 10-13 to form corrosion pores on the outer surface layer of the oxide film layer, thereby obtaining the surface-treated aluminum alloy substrate; and S3. putting the surface-treated aluminum alloy substrate in a mold, injecting a resin composition into the mold to be combined with the surface-treated aluminum alloy substrate, and forming to obtain the aluminum alloy-resin composite. A unique double-layer stereoscopic porous structure can be formed on the surface of the aluminum alloy to enhance the binding force between the resin and the aluminum alloy; and the invention has the advantages of easier formation, basically no influence on the appearance of the aluminum alloy, wider application range and no environment pollution, and is more suitable for large-scale production.

Owner:BYD CO LTD

Mobile phone case

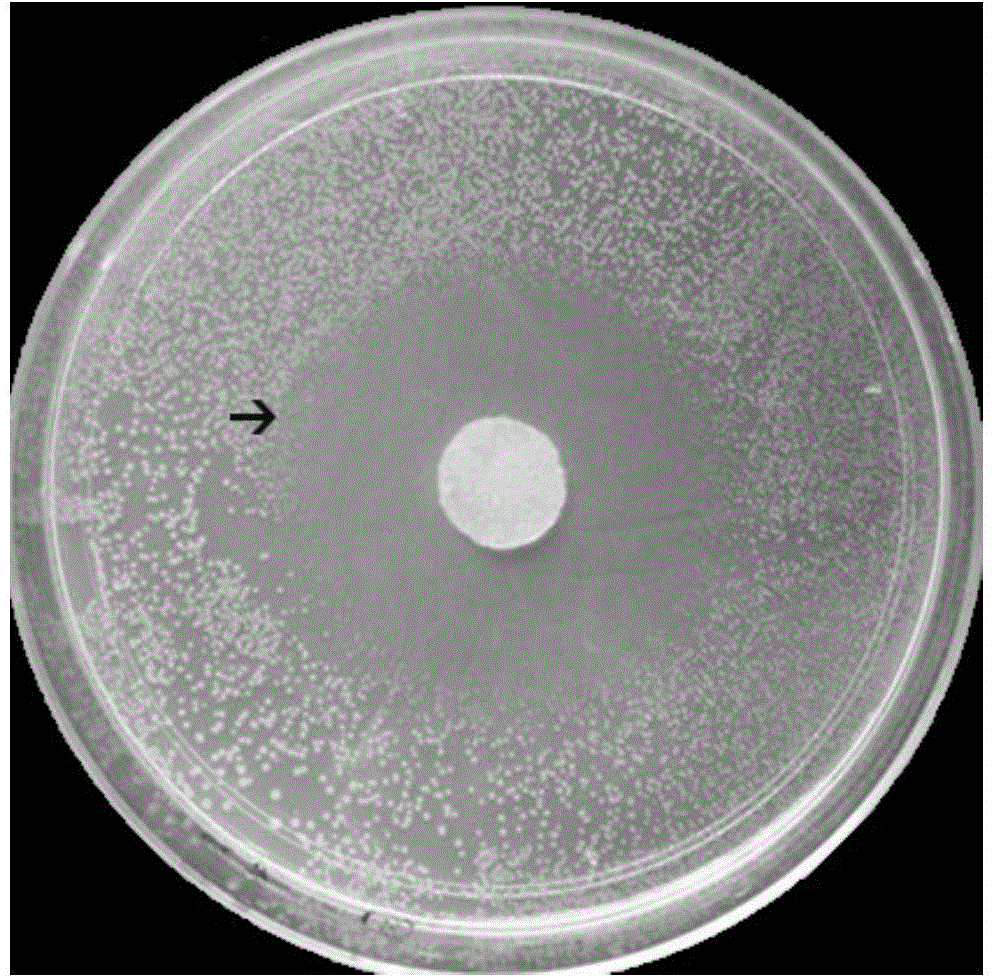

ActiveCN104780241AImprove corrosion resistanceAppearance has no effectAnodisationSynthetic resin layered productsNanometreNanopore

A shell, a method of preparing the shell and an electronic product comprising the shell are provided. The shell may comprise: a metal shell body, a plastic part made of a resin, and an oxide layer formed between the metal body and the plastic part, joining the plastic part to the metal shell body, wherein the oxide layer contains corrosion pores having an average diameter of about 200 nm to about 2000 nm in the surface contacting the plastic part, and nanopores having a diameter of about 10 to 100 nm in the surface contacting the metal shell body, and a part of the resin is filled in the corrosion pore and corrosion pore.

Owner:BYD CO LTD

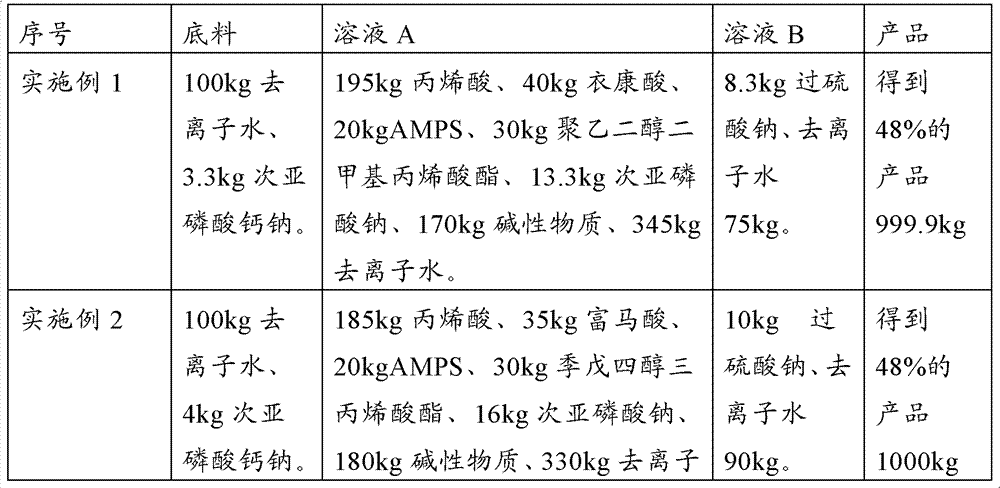

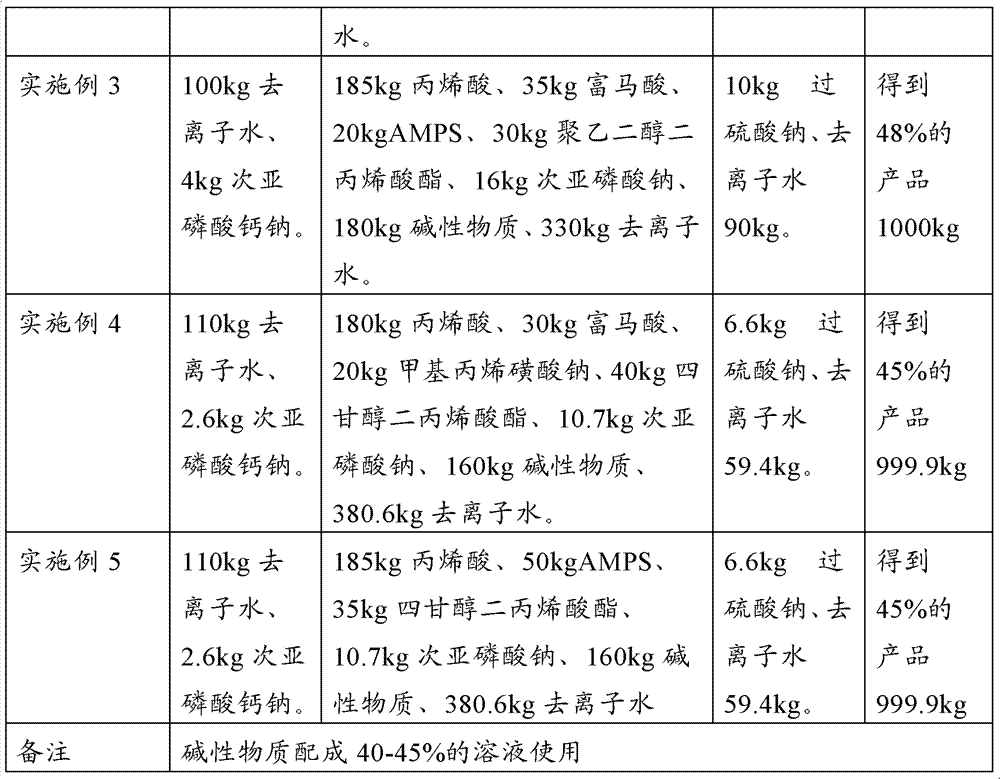

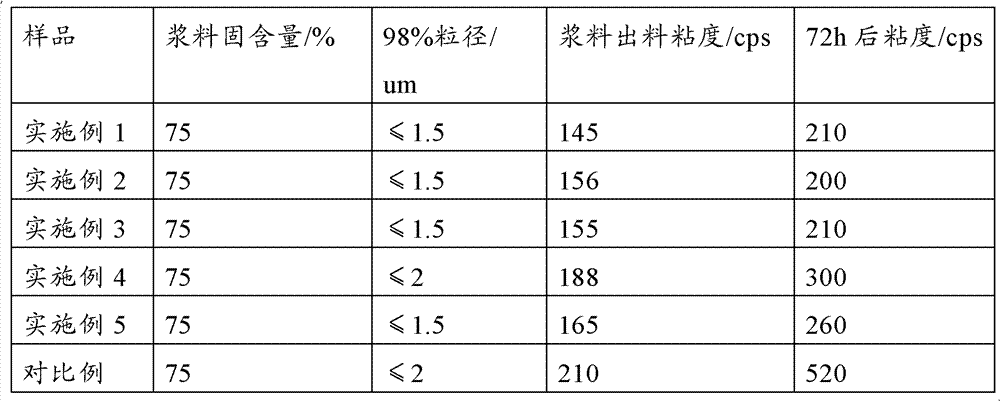

Branched polyacrylic acid dispersant, and preparation method and application thereof

ActiveCN102775546ALess heat releaseSmooth responseTransportation and packagingPaper coatingMaleic anhydrideSodium polyacrylate

The invention discloses a branched polyacrylic acid dispersant, and a preparation method and application thereof. According to the invention, polyene monomers are introduced into molecular chains of a linear sodium polyacrylate dispersant so as to obtain a branched dispersant structure which allows the branched polyacrylic acid dispersant to better clad cross sections newly occurred after grinding, and therefore, grinding and dispersing efficiency is improved; furthermore, methacrylic acid, maleic anhydride, fumaric acid, itaconic acid, sodium methylacrylsulfonate, 2-acrylamide-2-methylpropanesulfonic acid (AMPS) and the like are introduced and can provide monomers with stronger negative charges, improve electrostatic repulsion action of double electric layers, mitigate agglomeration among calcium carbonate particles and reduce the viscosity of ground slurry. The dispersant provided by the invention enables high efficiency in grinding of calcium carbonate to be obtained and the slurry to have the characteristics of low viscosity, good dispersibility and stability.

Owner:SHAOXING SIHUIER NEW MATERIALS CO LTD

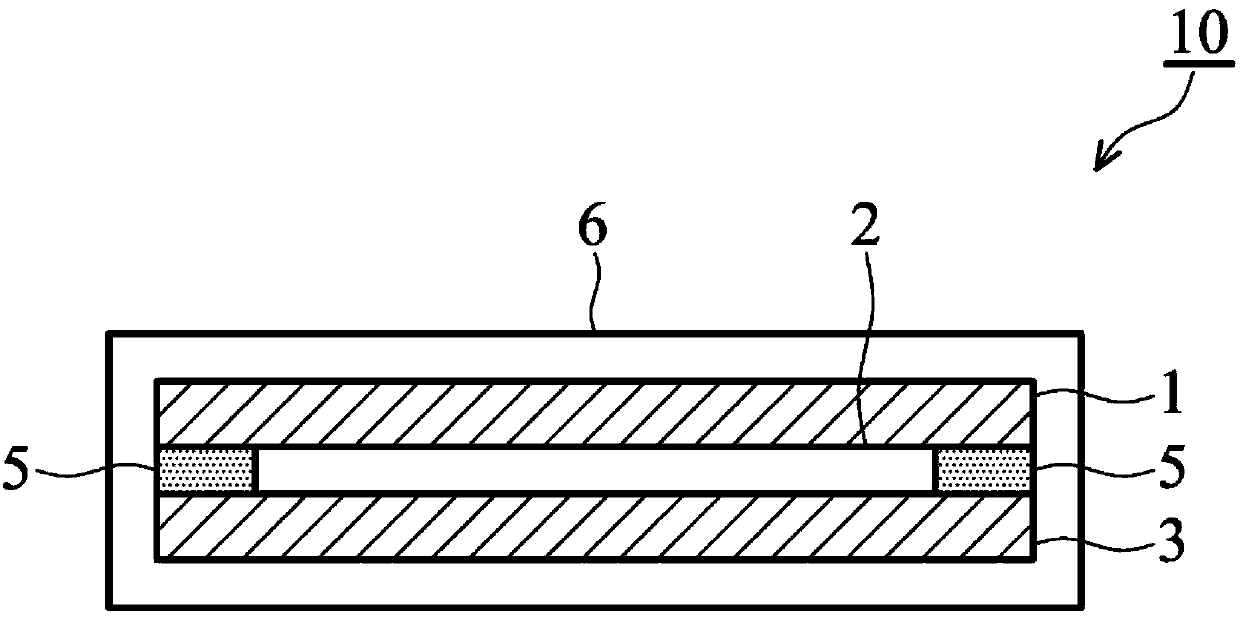

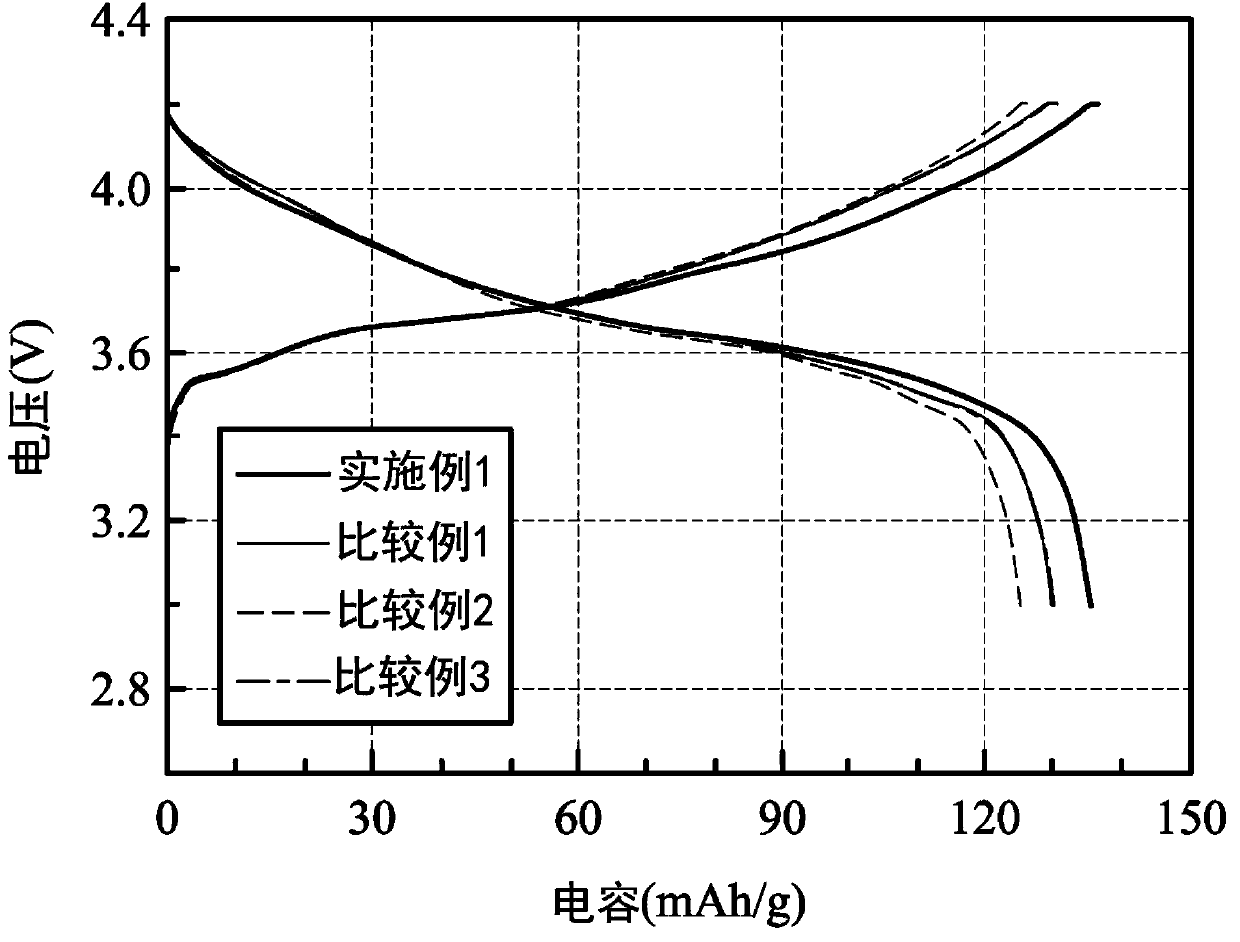

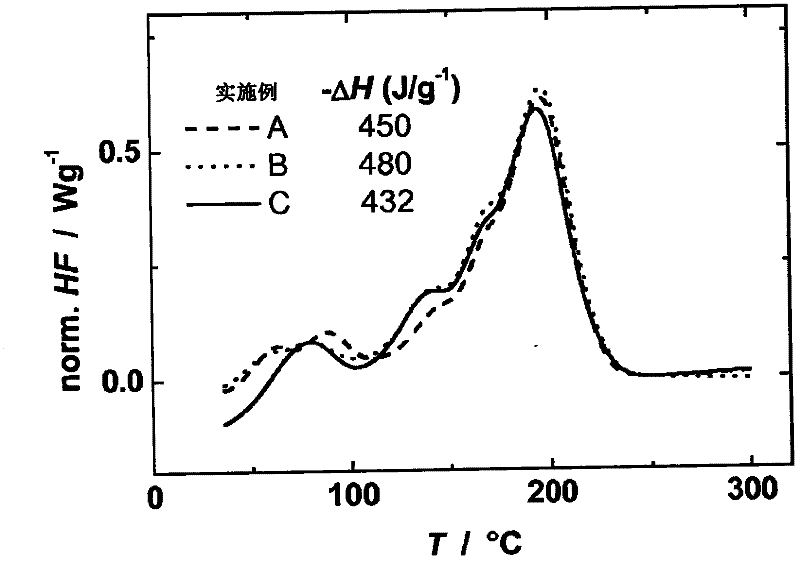

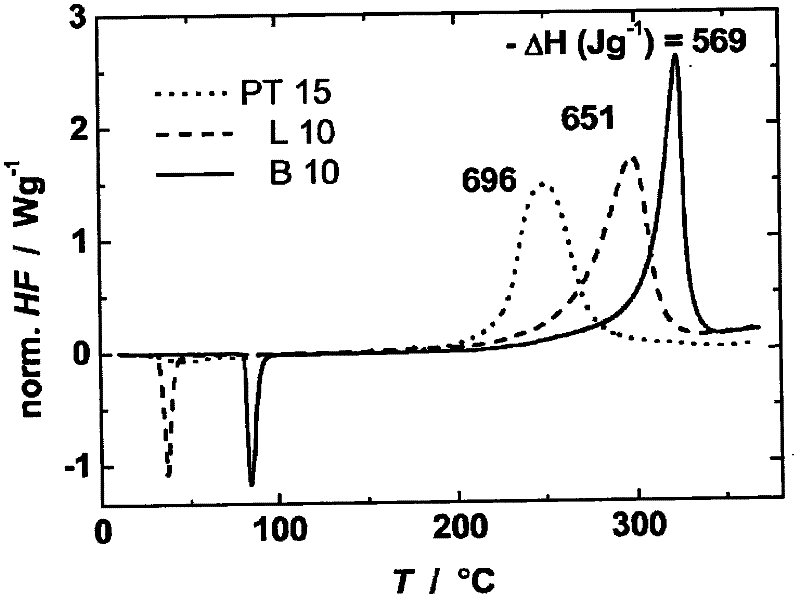

Lithium battery and forming method therefor

ActiveCN103872373AIncrease capacitanceLess heat releaseFinal product manufactureNon-aqueous electrolyte accumulator electrodesNitrogenPhysical chemistry

The invention provides a lithium battery. The lithium battery comprises a positive pole plate, a negative pole plate, an isolating membrane arranged between the positive pole plate and the negative pole plate for defining a holding region, and an electrolyte solution located in the holding region. The positive pole plate is a mixture of lithium transition metal oxides, binders and conducting particles. The surfaces of the lithium transition metal oxides are modified with nitrogen-containing macromolecules and transition-metal-containing cyano complexes. The invention relates to a forming method for the lithium battery.

Owner:IND TECH RES INST

Catalyst for producing maleic anhydrid(e) by benzene gas-phase oxidation with high load and high yield

InactiveCN101284242AReduce production power consumptionIncrease production capacityOrganic chemistryPhysical/chemical process catalystsRare-earth elementGas phase

The invention relates to a catalyst for manufacturing maleic anhydride through the high-load and high-yield benzene gas-phase oxidation. A fixed-bed tubular reactor sequentially comprises an A section and a B section which are composed of catalysts with different performances along the inlet direction of reaction mixture gas; the A section is 40 to 60 percent of the total bed height, and the B section is 60 to 40 percent of the total bed height. The catalyst in the A section has the active phase composition that the ratio of V2O5:MoO3:P2O5:Na2O:NiO:Re2O3 equals to 1:(0.4 to 0.9):(0.01 to 0.08):(0.05 to 0.100):(0.005 to 0.500):(0.0001 to 0.0010), wherein, Re is any two of following rare earth elements that are Nd, Pm, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb or Lu. The catalyst in the B section has the active phase composition that the proportion of the Re2O3 is 2 to 3 times of that of the Re2O3 in the A section, the proportion of the P2O5 is (0.005 to 0.040)mol, and the proportions of other oxides are the same with that in the A section. The catalyst can lead maleic anhydride production equipment to increase about 25 percent production capacity without increasing any investment, and the benzene consumption and the energy consumption can be obviously reduced.

Owner:TIANJIN BOHUA ZHONGHE CHEM +1

Thermofusion welding agent for welding copper covered steel grounded screen

ActiveCN101412167AHigh strengthReduce consumptionWelding/cutting media/materialsSoldering mediaDetonatorLow noise

The invention provides a hot-melt welding flux for copper-clad steel grounding net welding, which belongs to the field of metal welding. The prior hot-melt welding flux for copper-clad steel grounding net welding has the problems of violent reaction, huge heat release, high noise, poor corrosion resistance and the like. The hot-melt welding flux consists of hot-melt solder and detonator, wherein the hot-melt solder consists of the following materials in weight percentage: 30 to 40 percent of copper oxide powder, 8 to 11 percent of metal aluminum powder, 20 to 35 percent of metal copper powder, 5 to 10 percent of fluorite powder, 4 to 10 percent of tin powder and 5 to 10 percent of nickel powder. The hot-melt welding flux has the advantages of proper reaction speed, low heat release, low noise, good corrosion resistance and the like.

Owner:CHINA ELECTRIC POWER RES INST +1

Hybrid polymers made of cyanates and silazanes, method for the production and use thereof

InactiveCN102449035AImprove featuresImprove fracture toughnessGlass/slag layered productsThin material handlingPolymer scienceHigh fracture

The invention relates to hybrid pre-polymers and polymers produced by converting difunctional, oligofunctional and / or polyfunctional cyanates and / or pre-polymers thereof with monomer, oligomer and / or polymer silazanes. The polymers are duromers having high glass transition temperature and very high fracture toughness from the respective cyanate output materials. They can be dissolved in a pre-polymerized state in solvents and are therefore suitable as impregnating resins for prepregs, for example. In addition, they can be processed to moulded articles. The fire characteristics thereof are particularly exceptional.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV +1

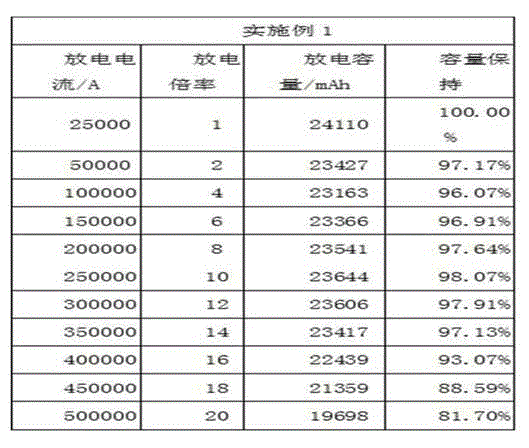

Flexible-packaged high-power lithium iron phosphate power battery

InactiveCN104577130AImprove conductivityLower internal resistanceElectrode carriers/collectorsLi-accumulatorsPower batteryHigh rate

The invention relates to the technical field of a lithium ion power battery, and particularly relates to a flexible-packaged high-power lithium iron phosphate power battery. The flexible-packaged high-power lithium iron phosphate power battery comprises a positive electrode plate, a negative electrode plate, a diaphragm, an electrolyte, tabs, and an aluminum plastic film, wherein the surface of a current collector of the positive electrode plate is pre-coated with a conductive coating and then coated with a positive electrode material. Each of both the positive electrode material and a negative electrode material comprises the following compositions in percentage by weight: 88-92% of active substances, 3-6% of a binder and 4-8% of a conducting agent. Through applying the modified positive electrode material, the surface of a current collector of the positive electrode plate is pre-coated with the conductive coating, so that the conductivity performance of the positive electrode material can be improved, the internal resistance of the battery can be effectively reduced, and heat release of the battery when in high-rate discharge is reduced. A mixture formed by mesophase carbon microbeads, artificial graphite and hard carbon according to certain ratio is adopted as the negative electrode material, so that a good solid electrolyte membrane is favorably formed, and the high-rate cycle performance of the battery can be improved through adding a certain amount of hard carbon.

Owner:SHANDONG SHENGONGHAITE ELECTRONICS TECH

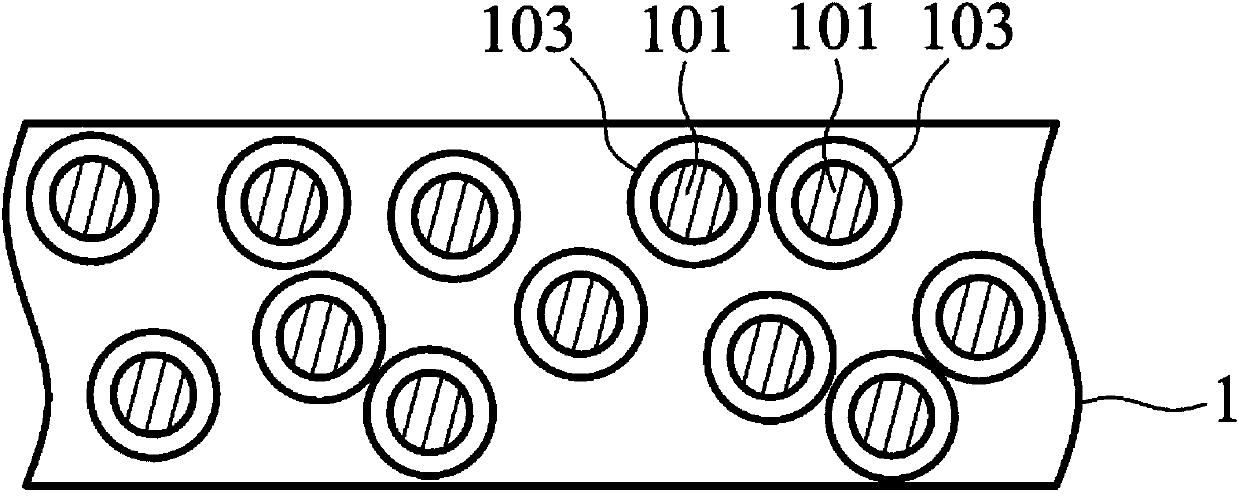

Surface treated metal and surface treatment method thereof and metal resin complex and preparation method of metal resin complex

ActiveCN103451701AIncrease corrosion rateReduce corrosion rateAnodisationPore diameterAnodic oxidation

The invention provides a surface treated metal and a surface treatment method thereof and a metal resin complex and a preparation method of the metal resin complex. The surface treated metal comprises a metal body and an anodic oxidation film layer which is located on the surface of the metal body, the anodic oxidation film layer includes a barrier layer which is in contact with the metal body and a loose layer located on the outer surface of the barrier layer, the loose layer contains anodic oxidation film micropores, the pore diameter of the anodic oxidation film micropores is 10 nm-800 mum, the barrier layer contains barrier layer corrosion pores, the pore diameter of the barrier layer corrosion pores is 10 nm-800 mum, the metal body includes a corrosion layer which is in contact with the barrier layer, the corrosion layer contains metal corrosion pores, the pore diameter of the metal corrosion pores is 10 nm-1 mm, the metal is aluminum alloy or aluminum, the bonding force between the metal and resin is strong, and the surface treated metal is simple in process, is easy for large-scale production, and has no pollution.

Owner:BYD CO LTD

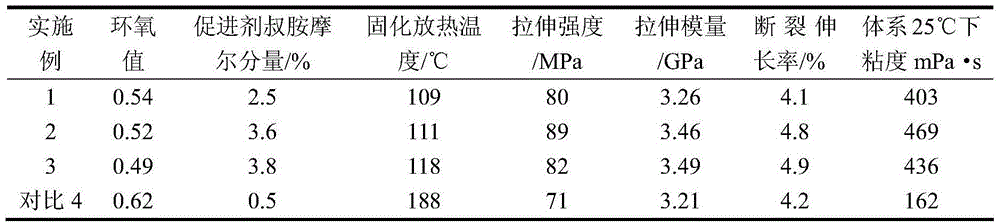

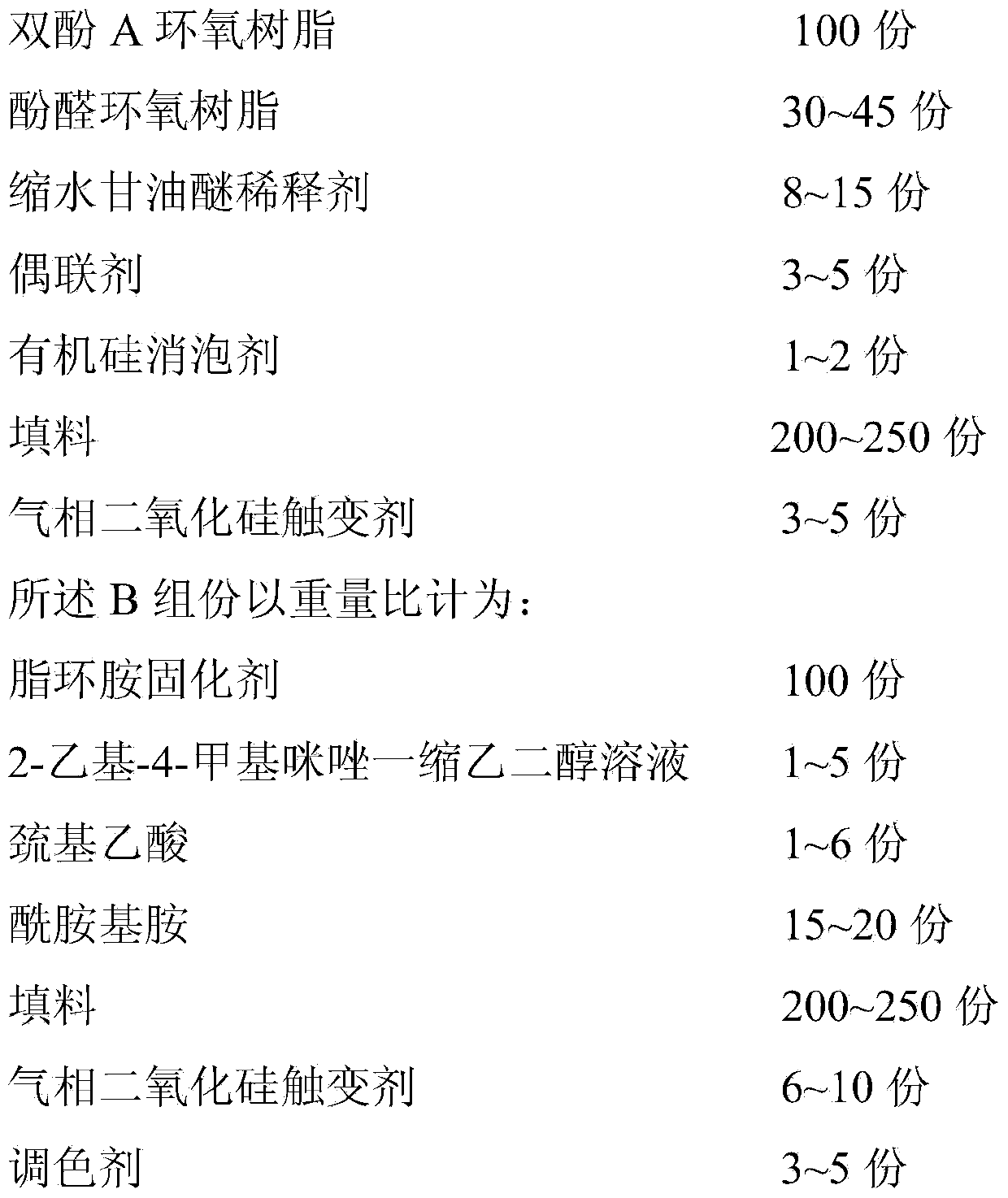

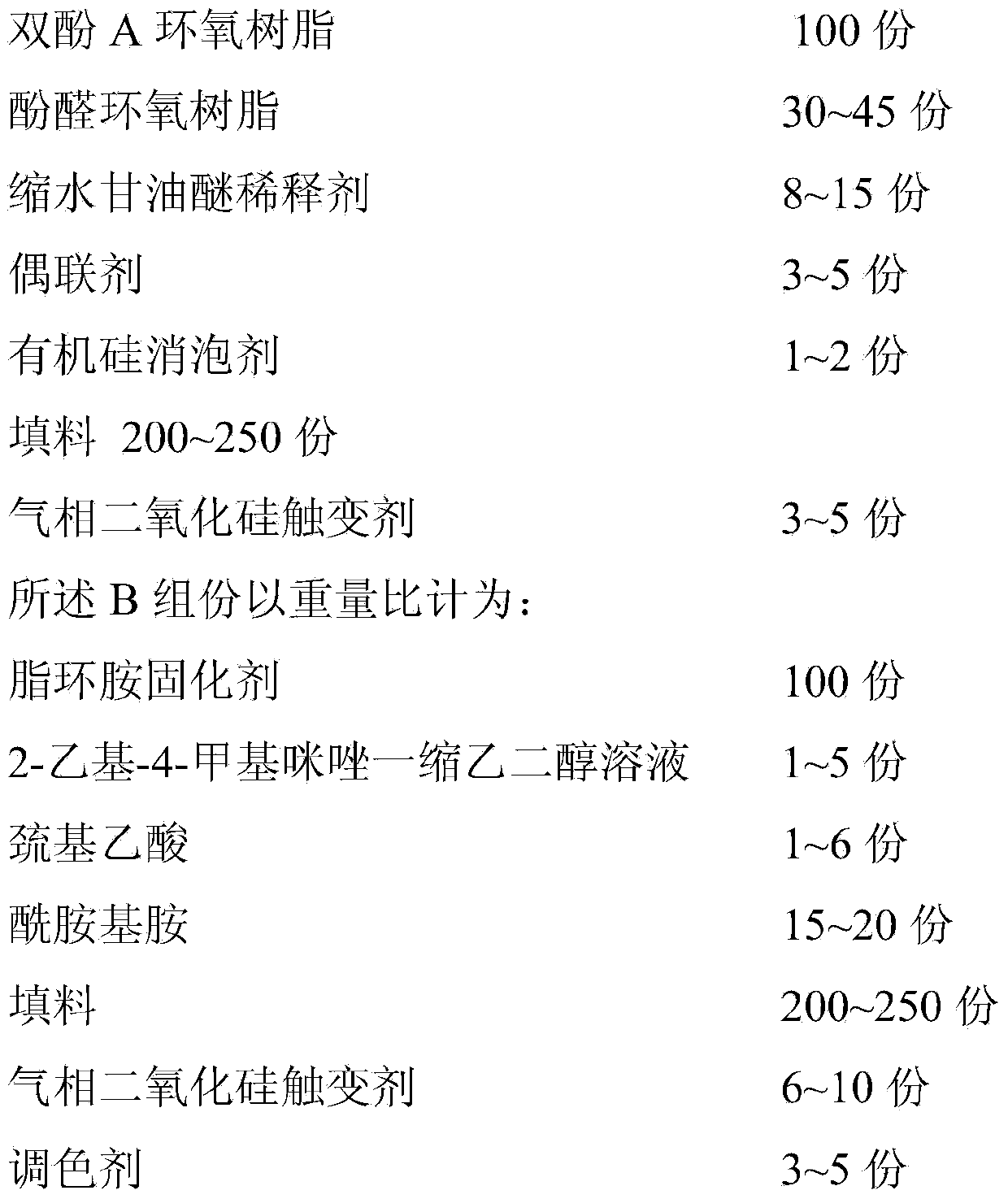

Low-viscosity, low-exothermicity, high-strength, high-toughness epoxy resin/curing agent system for liquid infusion molding of composite material

The invention discloses a low-viscosity, low-exothermicity, high-strength, high-toughness epoxy resin / curing agent system for liquid infusion molding of a composite material and relates to the technical field of epoxy resin. The epoxy resin / curing agent system comprises the following components in percentages by mass: 39%-65% of an epoxy resin component, 34%-60% of a curing agent component and 0.1%-1.5% of a curing accelerator component, wherein the epoxy resin component is prepared by uniformly mixing amine-modified epoxy resin and an epoxy resin active diluents; the curing agent component is acid anhydride, the curing accelerator component is a curing accelerator and the total mass of the components is 100%. The low-viscosity, low-exothermicity, high-strength, high-toughness epoxy resin / curing agent system for liquid infusion molding of a composite material has low viscosity of 100-500mPa.s at 25 DEG C, low curing exothermic peak temperature of 90-120 DEG C, tensile strength of 80-90MPa, tensile modulus of 3.2-3.4GPa and elongation at break of 4%-5% and can be used in liquid infusion molding of large-size composite material parts.

Owner:BEIJING UNIV OF CHEM TECH

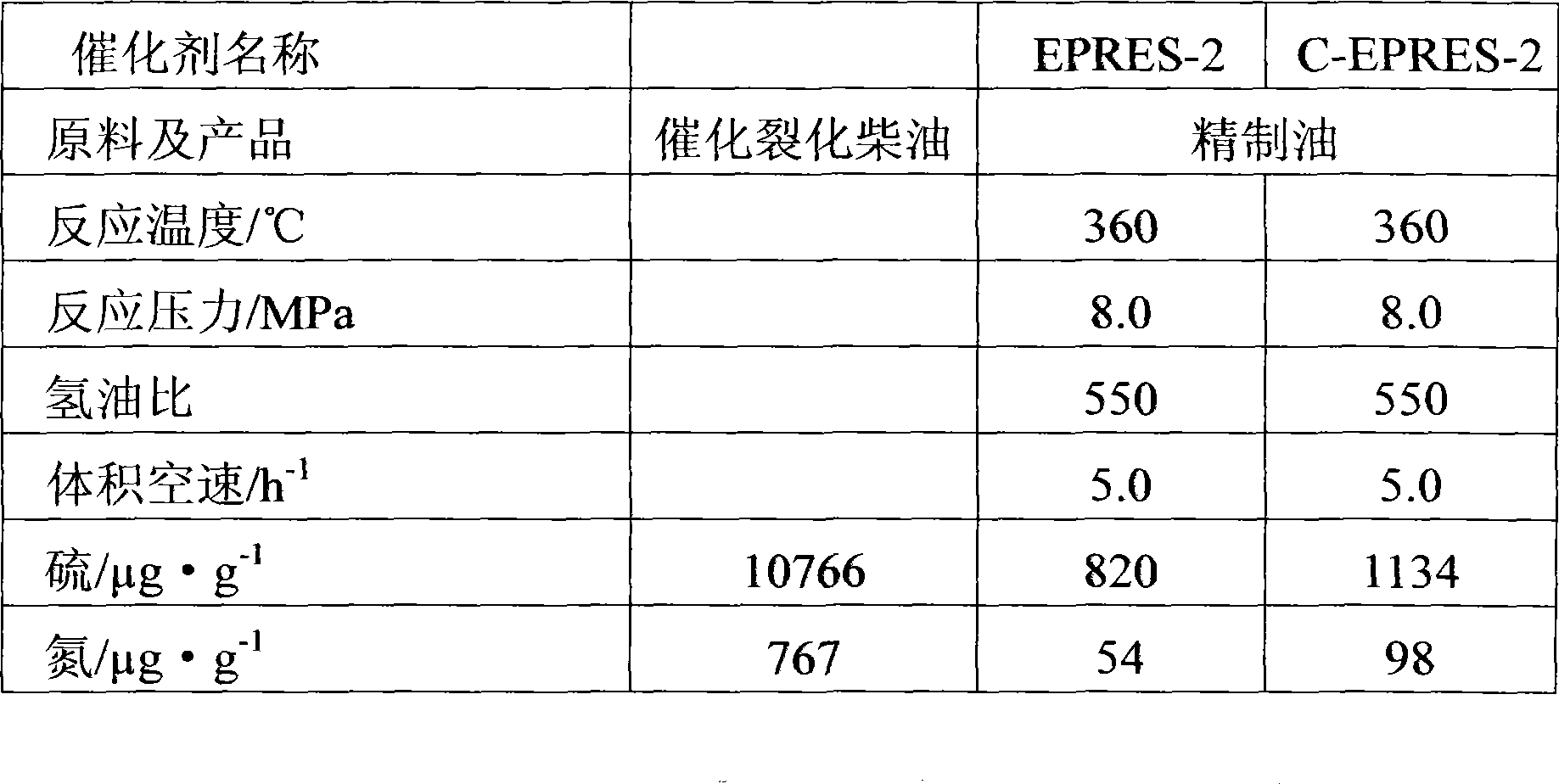

Processing method before using hydrogenation catalyst

ActiveCN101417246AEasy to useIncrease profitCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsOrganic solventWater vapor

The invention relates to a processing method before the application of hydrogenation catalyst, comprising the detailed process as follows: organic solvent, elemental sulfur and water are introduced in oxidated hydrogenation catalyst; subsequently, heating predisposal is carried out under a certain condition. The processing method before the application of the hydrogenation catalyst loads the sulfur-contained substance such as the elemental sulfur to the hydrogenation catalyst; a certain interaction is generated and little heat is discharged; and the water vapor which is generated during the heat disposal process of the added water adjusts the interaction of the sulfur and the catalyst and reduces the heat discharging degree during the heat disposal process. Compared with the prior art, the catalyst obtained by the method has the advantages of high utilization ratio of the sulfur-contained matter, gradual increment of the temperature of the catalyst bed and high activity of the catalyst when the activation is applied. The method can be used for processing before the application of various hydrogenation catalysts.

Owner:CHINA PETROLEUM & CHEM CORP +1

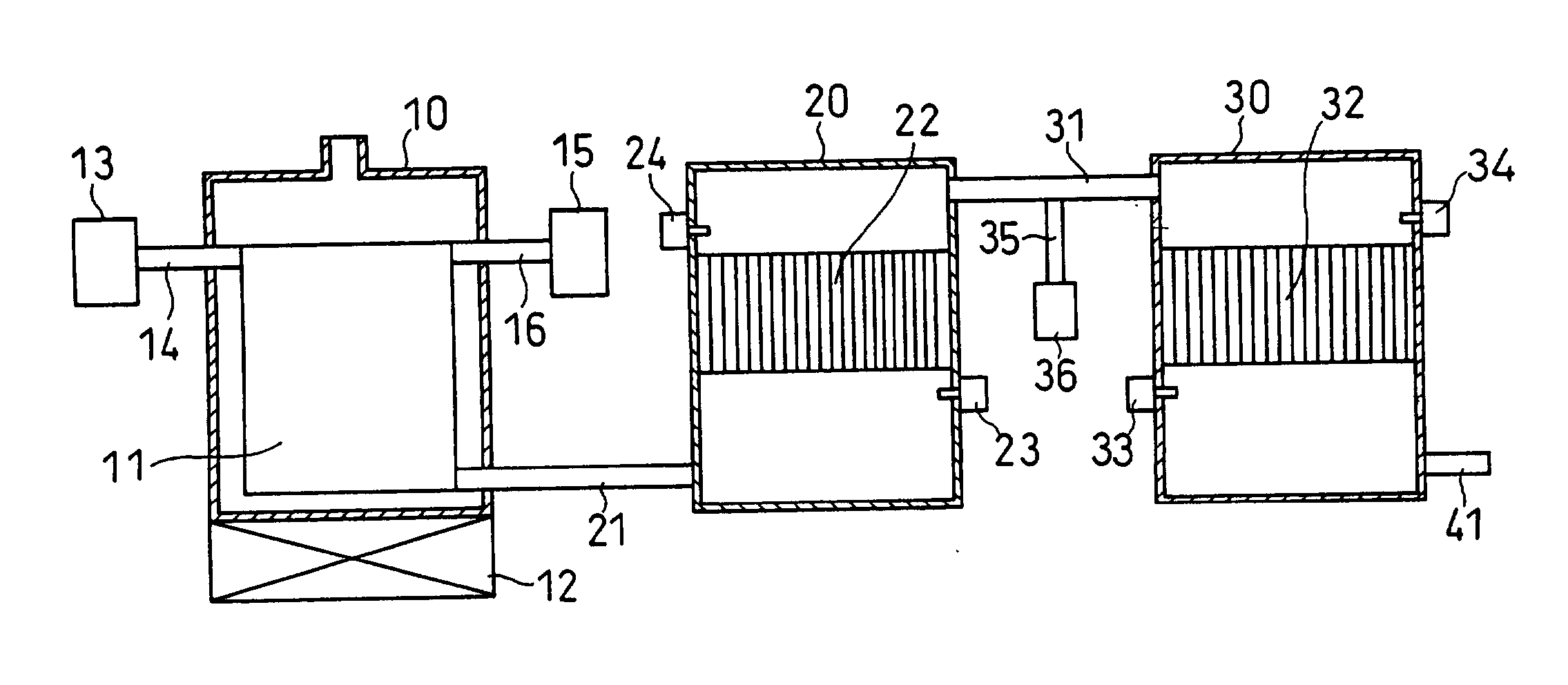

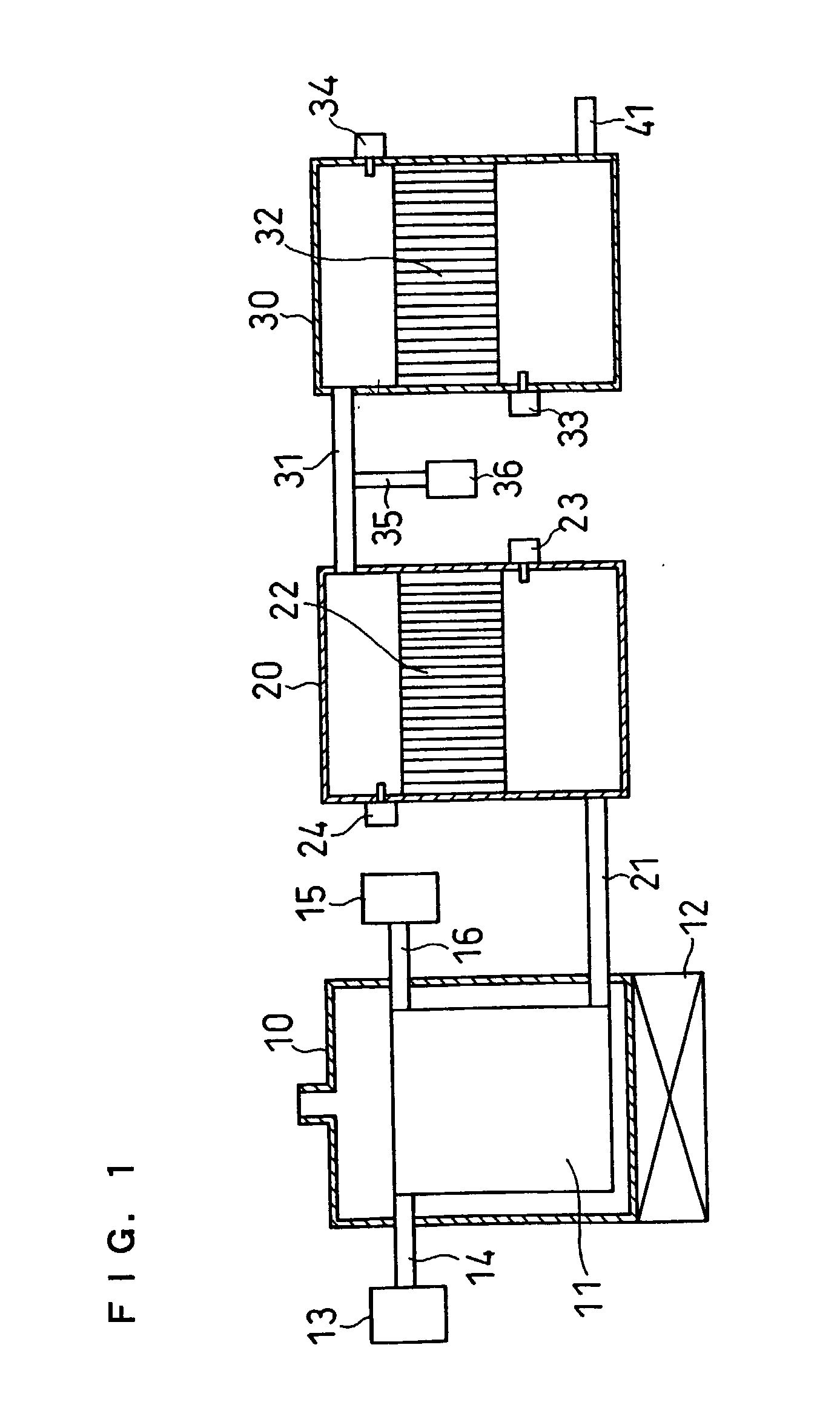

Apparatus for forming hydrogen

InactiveUS20030003033A1Decrease high concentration of carbon monoxideActivity of catalystTemperatue controlCombustible gas catalytic treatmentMethanationProduct gas

A hydrogen producing apparatus comprising: a reforming section having a reforming catalyst which causes a reaction between a carbon-containing organic compound as a feedstock and water; a feedstock supply section for supplying the feedstock to the reforming section; a water supply section for supplying water to the reforming section; a heating section for heating the reforming catalyst; a shifting section having a shift catalyst which causes a shift reaction between carbon monoxide and water contained in a reformed gas supplied from the reforming section; and a purifying section having a purifying catalyst which causes oxidation or methanation of carbon monoxide contained in a gas supplied from the shifting section, wherein the shift catalyst comprises a platinum group metal and a metal oxide.

Owner:PANASONIC CORP

Preparation method of metal resin complex and metal resin complex prepared thereby

The invention provides a preparation method of an aluminum alloy resin complex and the aluminum alloy resin complex prepared thereby. The preparation method of the aluminum alloy resin complex comprises the following steps: S1, anodic oxidation: a metal substrate with a surface comprising an anodic oxidation film layer is obtained by anodic oxidation of a pretreated metal substrate, and the metal substrate is an aluminum alloy substrate or aluminum substrate; S2, treatment with an etching liquid: the metal substrate containing the anodic oxidation film layer and obtained by the step S1 is immersed in the etching liquid for treatment to obtain a surface treated metal substrate; S3, injection: the surface of the surface treated metal substrate is injected with a resin composition, and then the metal resin complex is obtained after molding; and the etching liquid contains HCl and a soluble halogen acid salt, or contains H3PO4 and a soluble phosphate. In the metal resin complex, the binding force between aluminum alloy and resin is strong, and the process is simple, and is easy for large-scale production.

Owner:BYD CO LTD

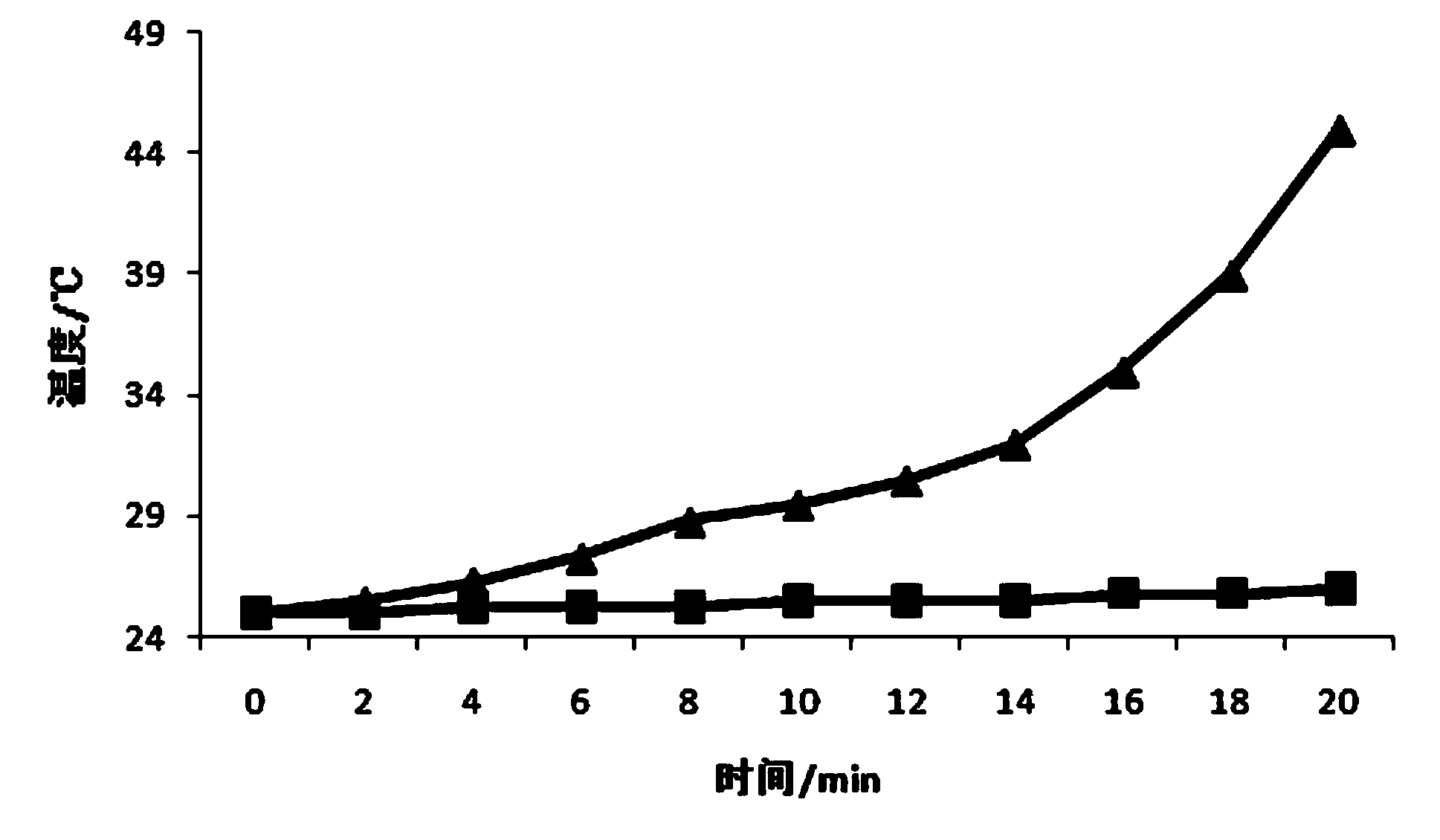

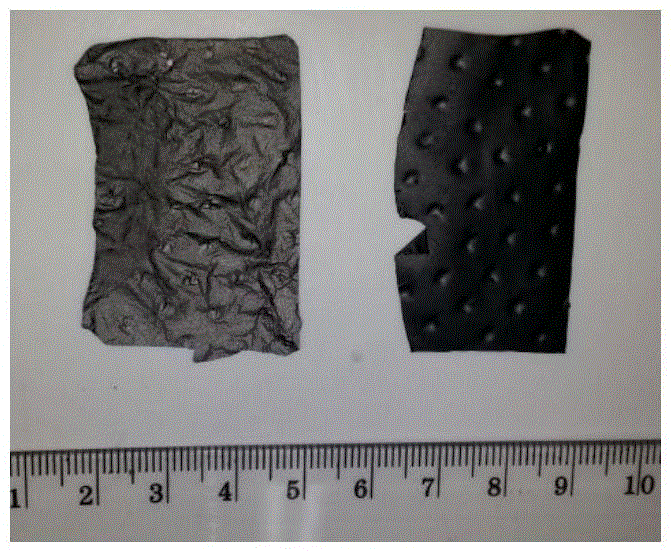

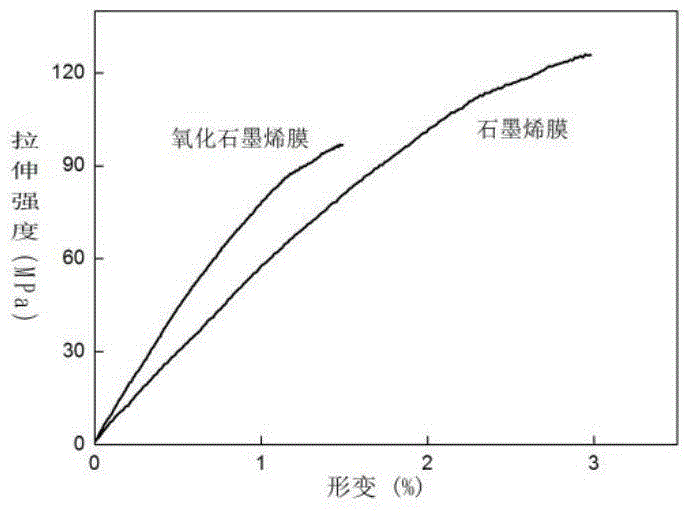

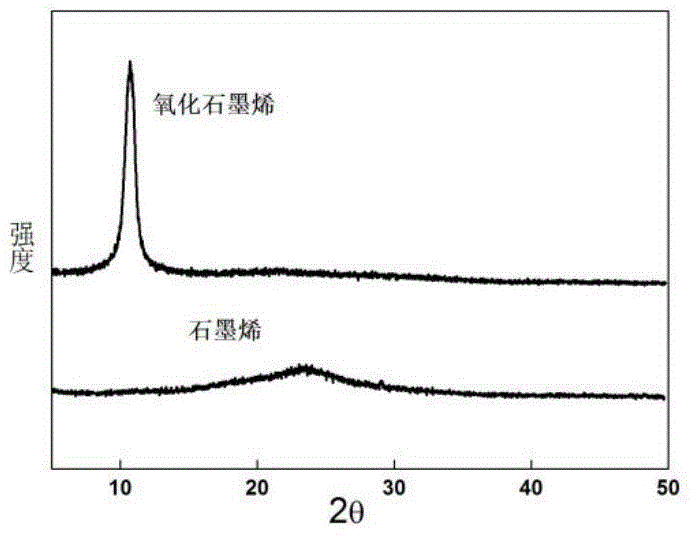

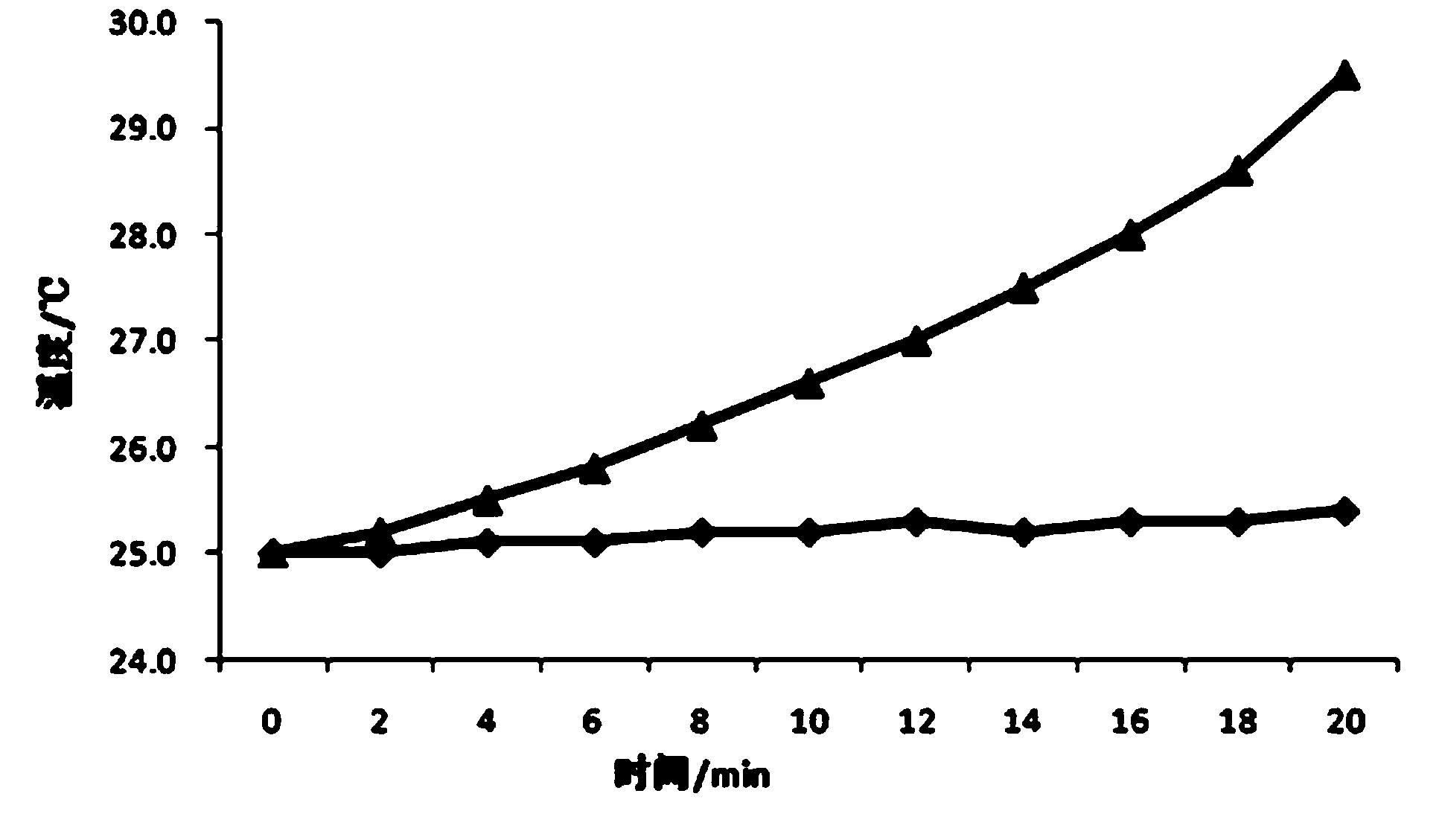

Preparation method of high-conductivity graphene membrane

The invention belongs to the technical field of preparation of graphene materials, and particularly relates to a preparation method of a high-conductivity graphene membrane. The preparation method comprises the following steps: preparing graphene oxide through an improved Hummer method in the presence of phosphoric acid protective agent, filtering through a polyester fiber filter membrane to obtain a graphene oxide membrane, and reducing the obtained graphene oxide membrane in a hydriodic acid-ethanol mixed solution to obtain the graphene membrane. The preparation method is simple and convenient to operate, has simple requirements for equipment and technology, and is cheap in raw materials and low in cost; and the prepared graphene membrane has few defects and high conductivity. The preparation method is easy to realize large-scale industrial production.

Owner:QINGDAO UNIV OF SCI & TECH

Preparation method of metal resin complex and metal resin complex prepared thereby

ActiveCN103451704AReduce reaction exothermImprove bindingSurface reaction electrolytic coatingAlloy substratePhosphoric acid

The invention provides a preparation method of a metal resin complex and the metal resin complex prepared thereby. The preparation method of the metal resin complex comprises the following steps: S1, anodic oxidation: a metal substrate with a surface comprising an anodic oxidation film layer is obtained by anodic oxidation of a pretreated metal substrate, and the metal substrate is an aluminum alloy substrate or aluminum substrate; S2, treatment with phosphoric acid: the metal substrate containing the anodic oxidation film layer and obtained by the step S1 is immersed in a phosphoric acid solution for treatment to obtain a surface treated metal substrate; and S3, injection: the surface of the surface treated metal substrate is injected with a resin composition, and then the metal resin complex is obtained after molding. In the metal resin complex, the binding force between metal and resin is strong, and the process is simple, is easy for large-scale production, and has no pollution.

Owner:BYD CO LTD

Supercritical low-temperature air energy power generator

InactiveCN102146814ALess heat releaseImprove thermal efficiencySteam engine plantsHigh energyEngineering

The invention relates to a new solar energy thermal supercritical low-temperature air energy power generator which comprises a heat absorber, an expansion generator unit, a heat regenerator, a cooler, a booster pump, a refrigerator and pipeline accessories thereof and a detection and control device; and a nitrogen or mixed working medium is filled in a closed system. The working medium becomes high-pressure supercritical fluid through passing through the heat absorber, also becomes a working medium in the supercritical state through the work application and power generation of the expansion generator unit, is pressed into the heat regenerator by the booster pump for heat exchange through being condensed by the heat regenerator and the cooler and then is thermally absorbed by the heat absorber to form a closed cycle power generation system. The power generator also can be used for low-temperature heat source power generation in excess heat, waste heat, terrestrial heat and the like; and the working medium adopts carbon dioxide or mixed working medium. The supercritical low-temperature air energy power generator can generate cool air. With the adoption of the supercritical low-temperature air energy power generator, the working medium is condensed under the supercritical state, release a small quantity of heat and can circularly utilize the condensation heat. Therefore, the supercritical low-temperature air energy power generator has high thermoelectric efficiency, high energy conversion density, low unit power investment and low cost and uses less power during the cool air generation process. The supercritical low-temperature air energy power generator successfully breaks through the key technical difficulty of low thermal efficiency during the low-temperature solar energy thermal power generation.

Owner:罗良宜

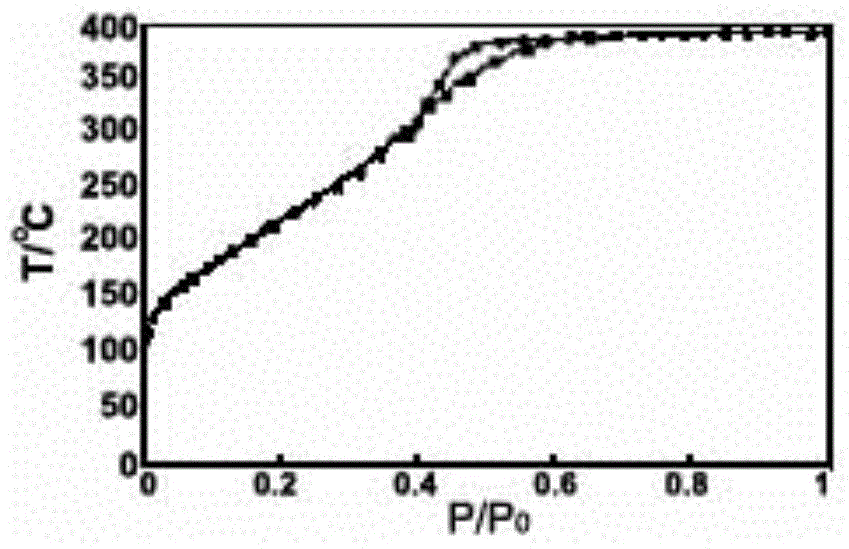

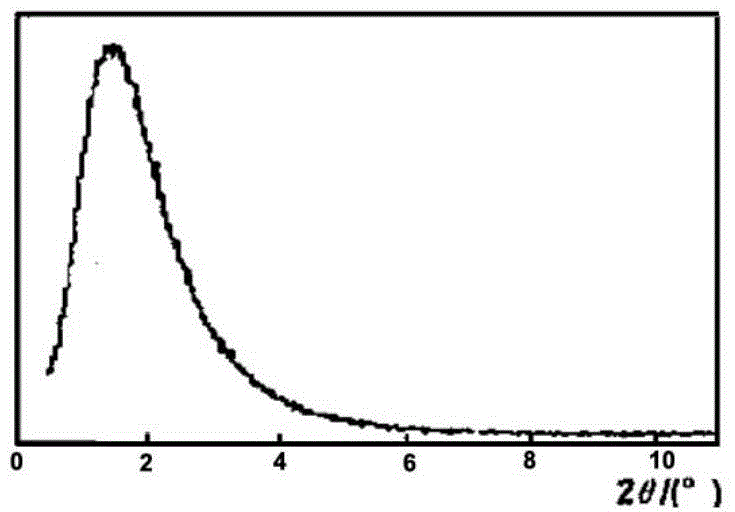

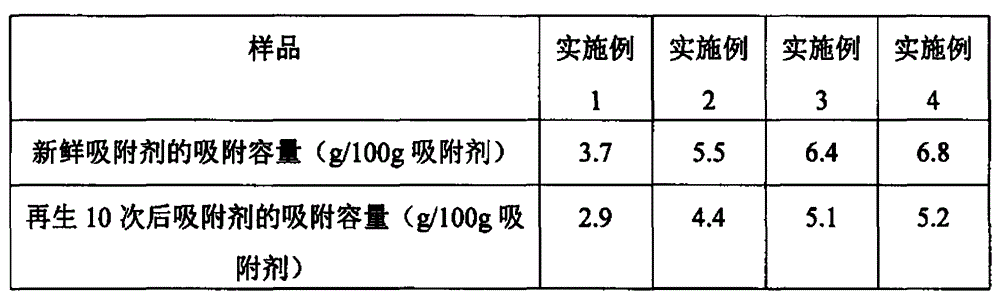

Purification adsorbent based on mesoporous molecular sieve material and preparation method and application of purification adsorbent based on mesoporous molecular sieve material

InactiveCN104383874AAvoid the disadvantages of high temperature resistanceRealize industrial applicationIon-exchange process apparatusGas treatmentMolecular sieveGas phase

The invention relates to a purification adsorbent based on a mesoporous molecular sieve material and a preparation method and application of the purification adsorbent based on the mesoporous molecular sieve material. The purification adsorbent based on the mesoporous molecular sieve material is characterized by comprising the following components in percentage by weight: 20%-60% of a mesoporous molecular sieve, 35%-75% of activated aluminum oxide and 3%-20% of metal components. The preparation method of the purification adsorbent based on the mesoporous molecular sieve material is characterized by comprising the following steps: firstly, mixing the mesoporous molecular sieve material, the activated aluminum oxide and the metal components, then carrying out extruding or disc granulation, and finally aging and activating so as to obtain an adsorbent product which is applicable to a temperature variation adsorption or pressure variation adsorption technology, and can work under a gas phase or liquid phase condition. Compared with the prior art, the prepared adsorbent containing the mesoporous molecular sieve has the advantages of being large in adsorption material duct, more beneficial to the adsorption of macromolecular impurities (such as disulphide), uniform in adsorption duct distribution, low in heat adsorption effect, and the like and has the deep adsorption function.

Owner:SHANGHAI LVQIANG NEW MATERIALS CO LTD +1

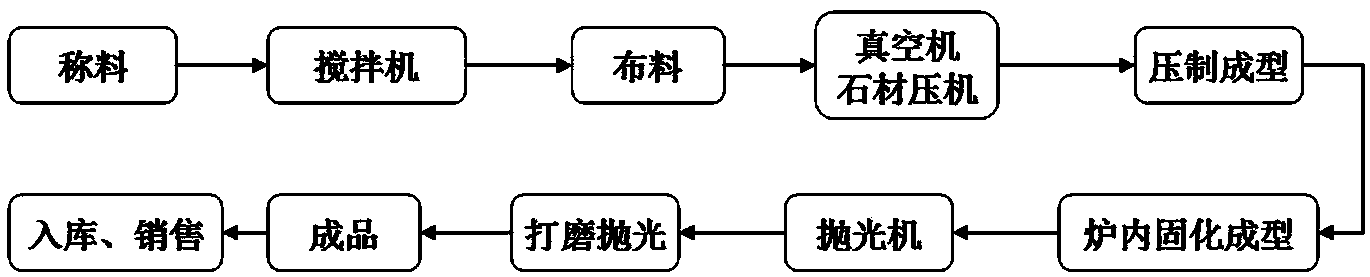

Artificial stone and preparation method thereof

The invention discloses an artificial stone and a preparation method thereof. The artificial stone comprises the following raw materials in percentage by weight: 30-60% of quartz, 30-60% of crushed glass, 5-10% of alloy resin, 0.01-3% of alloy powder, 0.01-0.5% of pigment, 0.01-0.5% of a coupling agent and 0.01-0.5% of a curing agent. The artificial stone has the characteristics of art attractiveness, health and environment-friendliness. Due to addition of the alloy powder and the alloy resin in the formula, the artificial stone has an outstanding antibacterial function, is relatively high in anti-permeability and moisture resistance, long in service life and relatively good in glossiness, fullness and moisturizing property, the waste glass and the waste gel can be utilized again, thus being energy-saving and environmentally friendly; flowers can be also made according to demands, and thus artificial stone with patterns can be manufactured.

Owner:GUOJIA NEW MATERIAL HUBEI ENVIRONMENTAL PROT GEL IND PARK CO LTD

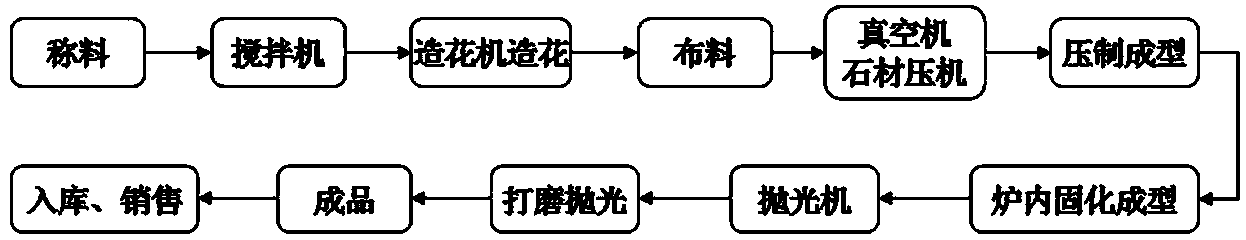

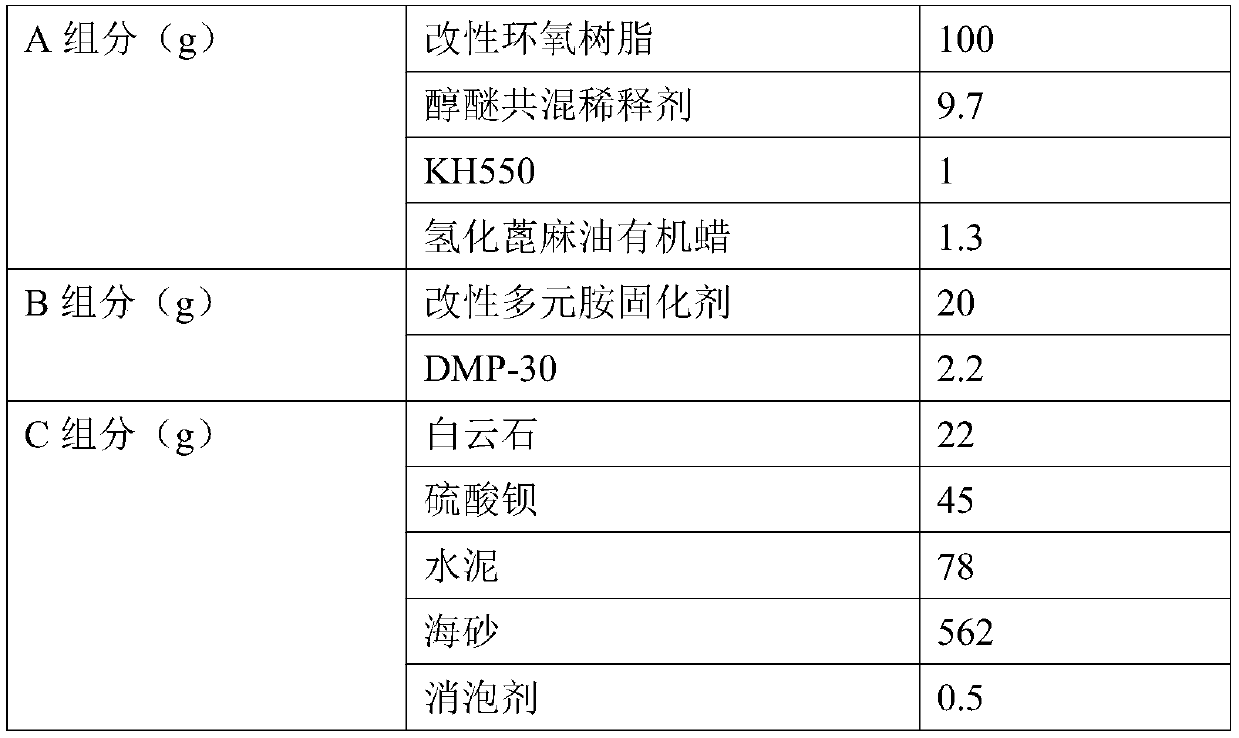

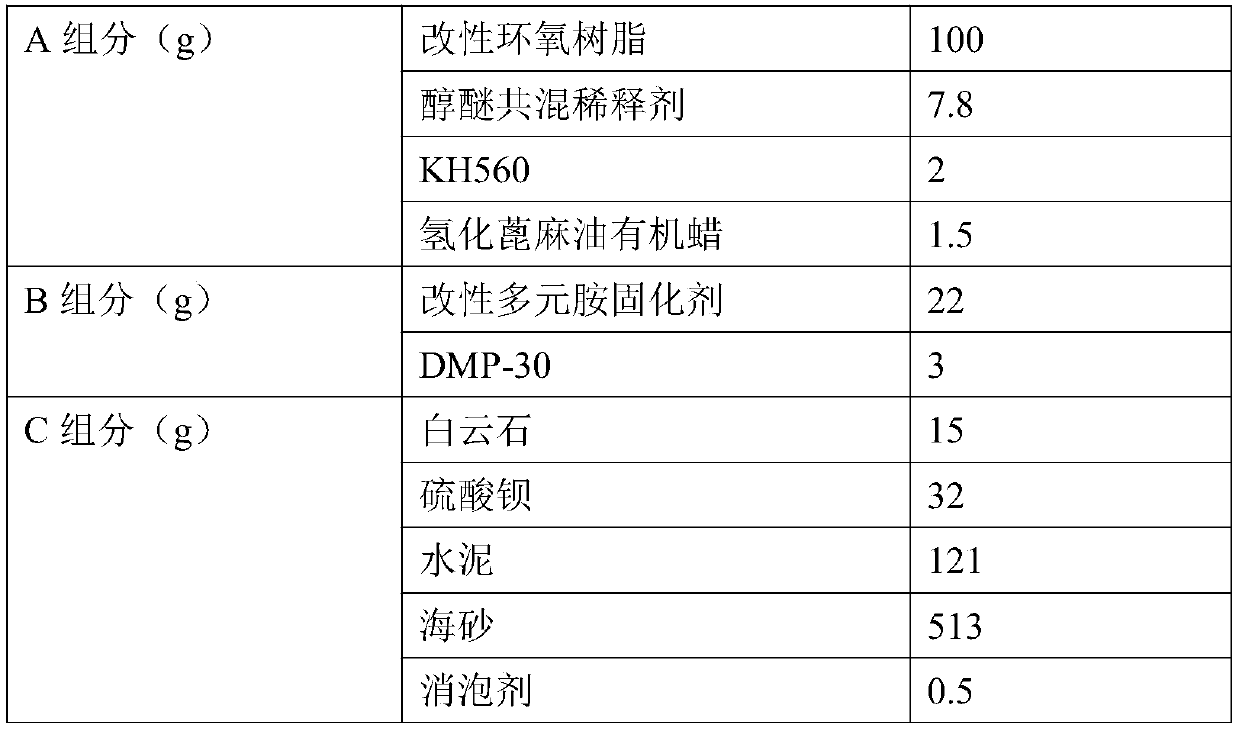

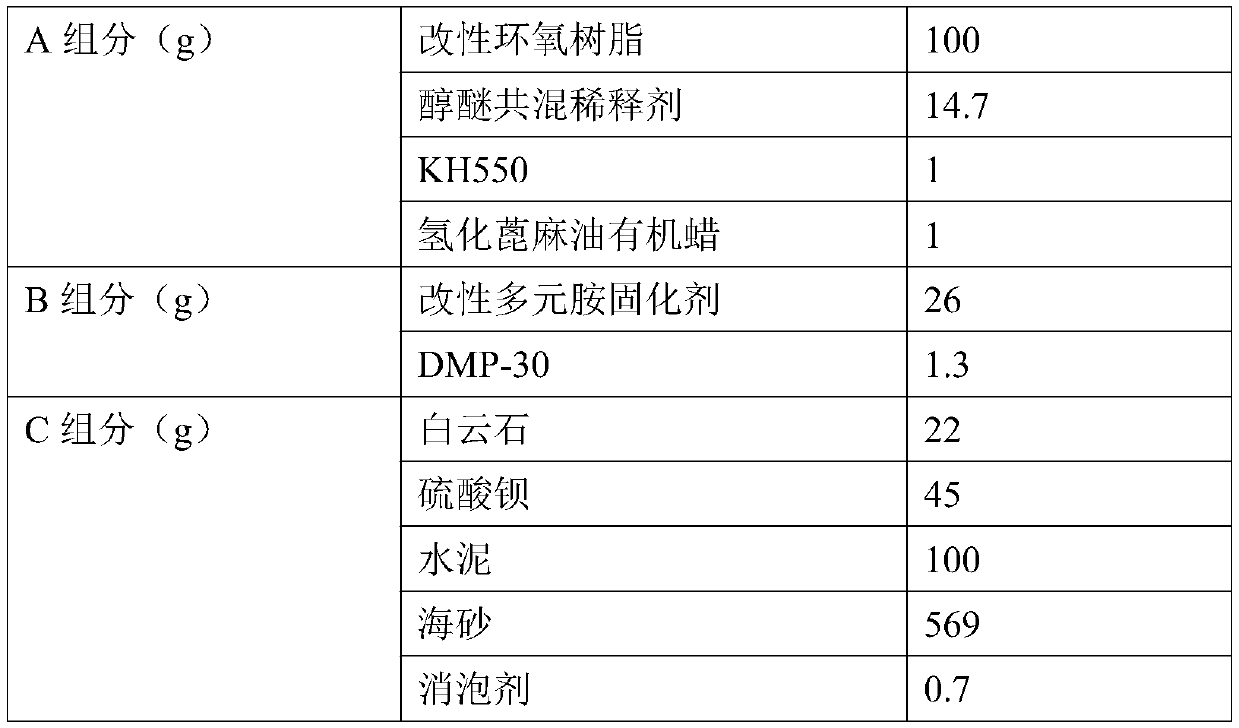

Quick-setting epoxy grouting mortar suitable for summer first-aid repair construction

The invention discloses a quick-setting epoxy grouting mortar suitable for summer first-aid repair construction. The quick-setting epoxy grouting mortar is formed by mixing of a resin component A, a curing agent component B and a bone powder component C in a mass ratio of 1:(0.2-0.26):(5-7) during use. Specifically, the component A comprises the following components by weight: 100 parts of modified epoxy resin, 1-15 parts of an alcohol ether composite diluent, 1-3 parts of a coupling agent, and 0.5-3 parts of a rheological agent; the component B comprises the following components by weight: 16-23 parts of a modified polyamine curing agent, and 1-3 parts of an accelerator; and the component C comprises the following components by weight: 1-23 parts of dolomite powder, 15-46 parts of bariumsulfate powder, 10-121 parts of cement, 385-588 parts of sea sand, and 0.1-1.5 parts of a defoamer. The quick-setting epoxy grouting mortar provided by the invention has the technical characteristicsof short curing time, high hour strength, and no flash polymerization during high temperature construction, at the same time is non-toxic and harmless, and is simple to prepare, and is widely applicable to concrete structure repair with quick-setting and early strength requirements and construction of installation and anchoring projects, especially suitable for summer repair construction.

Owner:中冶武汉冶金建筑研究院有限公司

Preparation method of stainless steel-resin composite and stainless steel-resin composite prepared by same

ActiveCN103895160ADoes not affect appearanceAppearance has no effectMolten spray coatingLamination ancillary operationsAl powderPolymer science

Provided are stainless steel-resin composite and method of preparing the same. The method comprises steps of: providing a stainless steel substrate; spraying aluminum particles onto a first surface of the stainless steel substrate via thermal spraying to form an aluminum layer on the first surface of the stainless steel substrate; removing the aluminum layer via dipping the stainless steel substrate into an alkaline solution with a p H value greater than or equal to 10 so as to form a porous surface; and injecting a resin composition onto the porous surface of the stainless steel substrate so as to form a resin layer.

Owner:BYD CO LTD

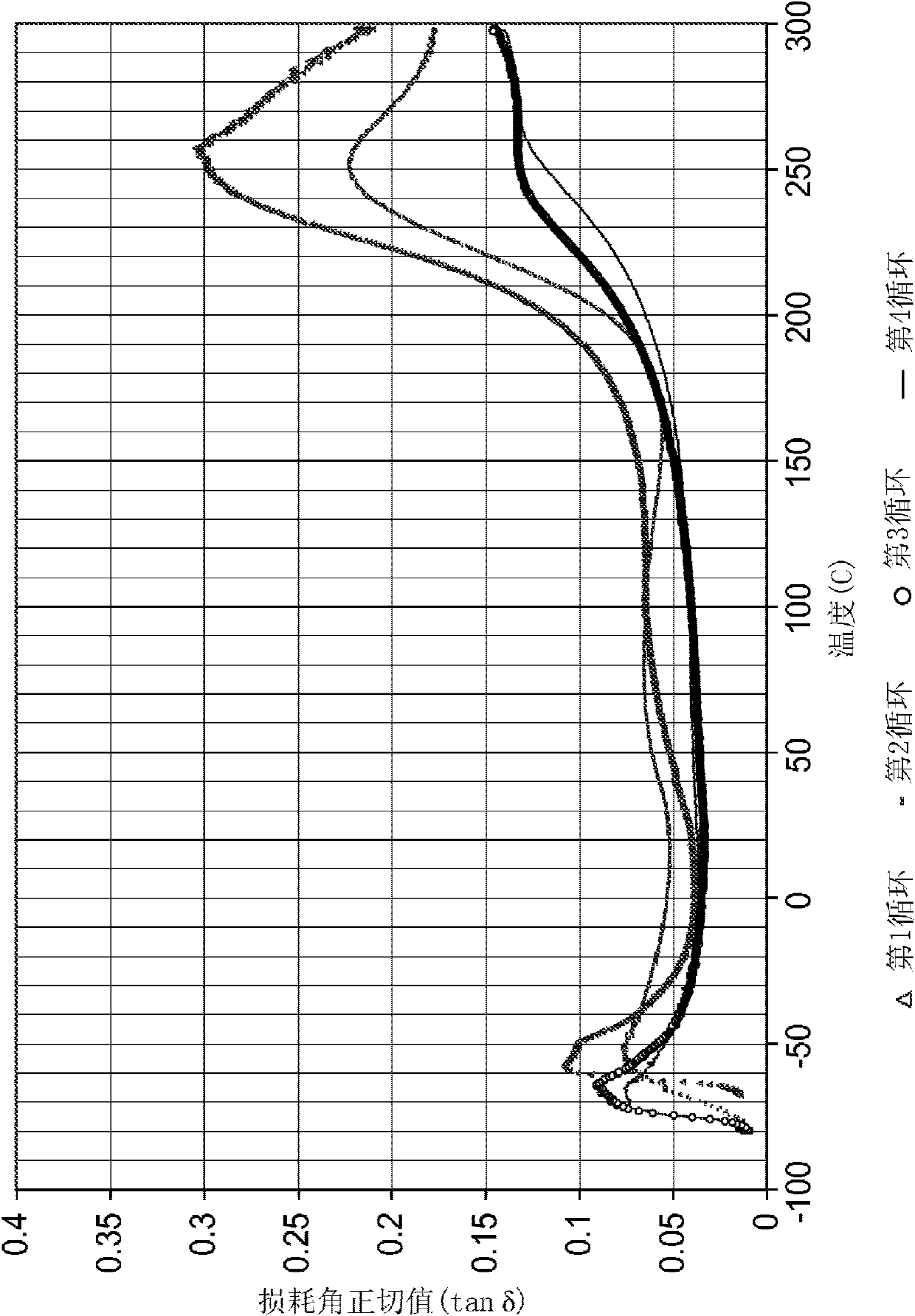

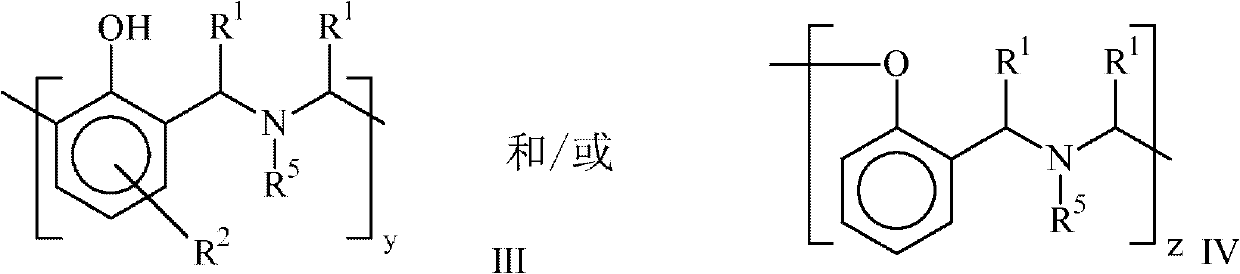

Polybenzoxazine composition

InactiveCN102575006AOvercome significant drawbacks of aggregationImprove thermal stabilityChemical recyclingCoatingsSealantCoating

Owner:3M INNOVATIVE PROPERTIES CO

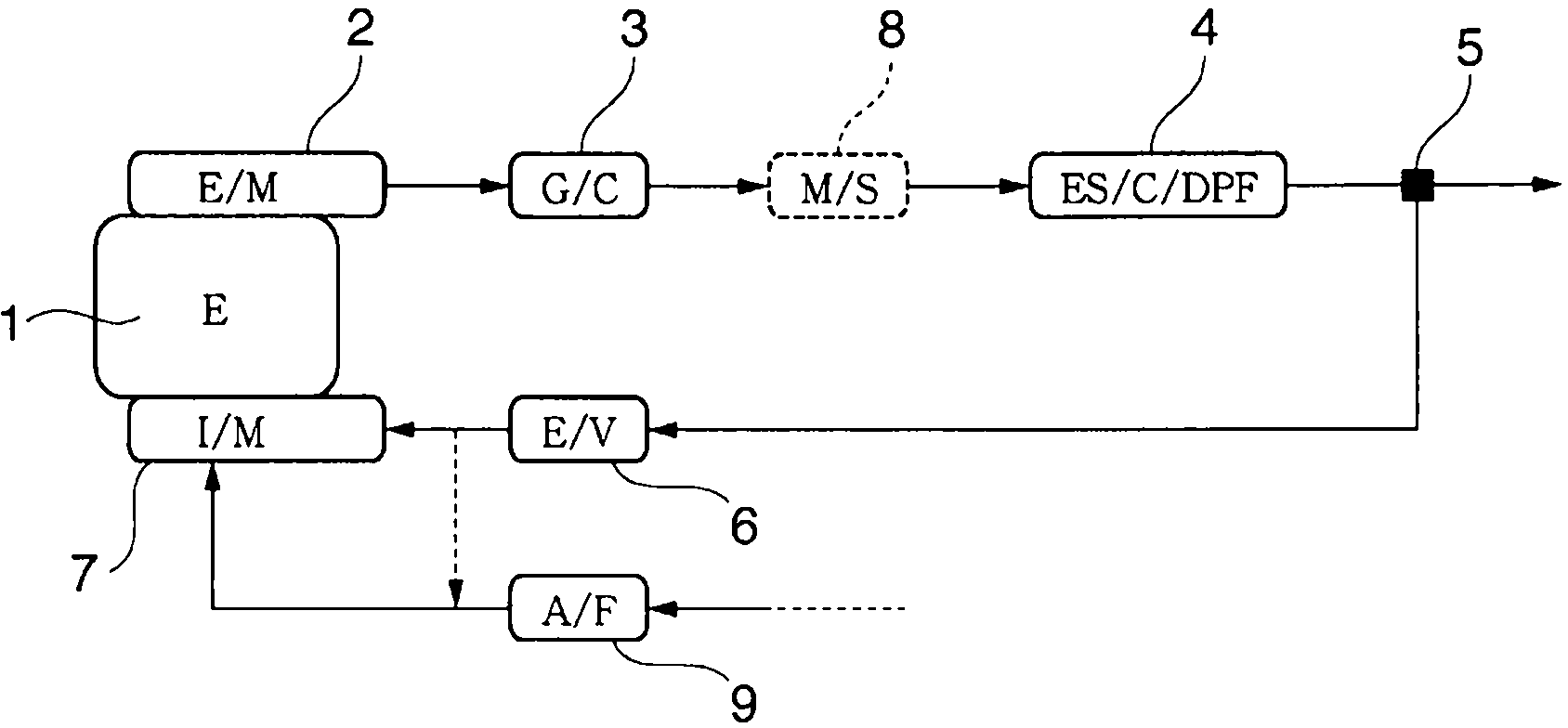

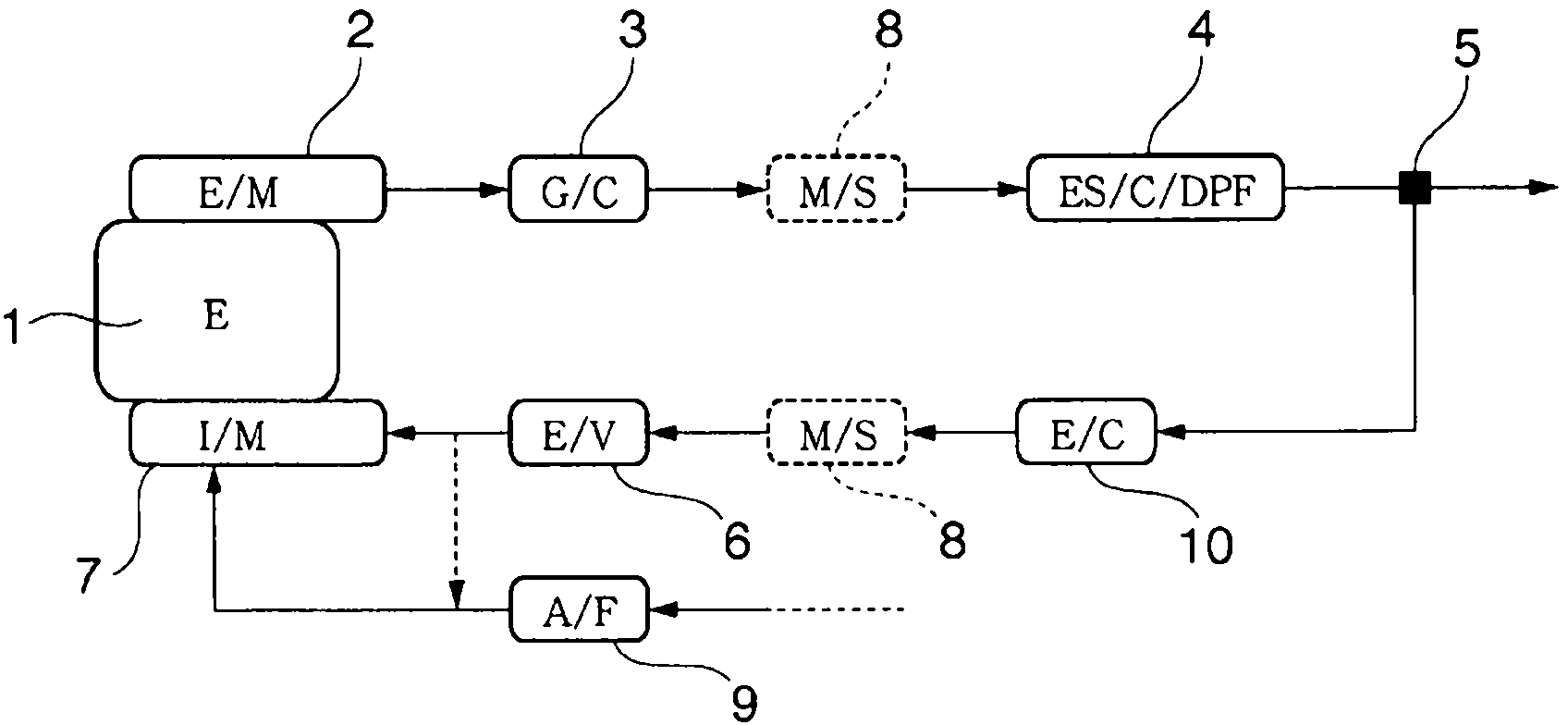

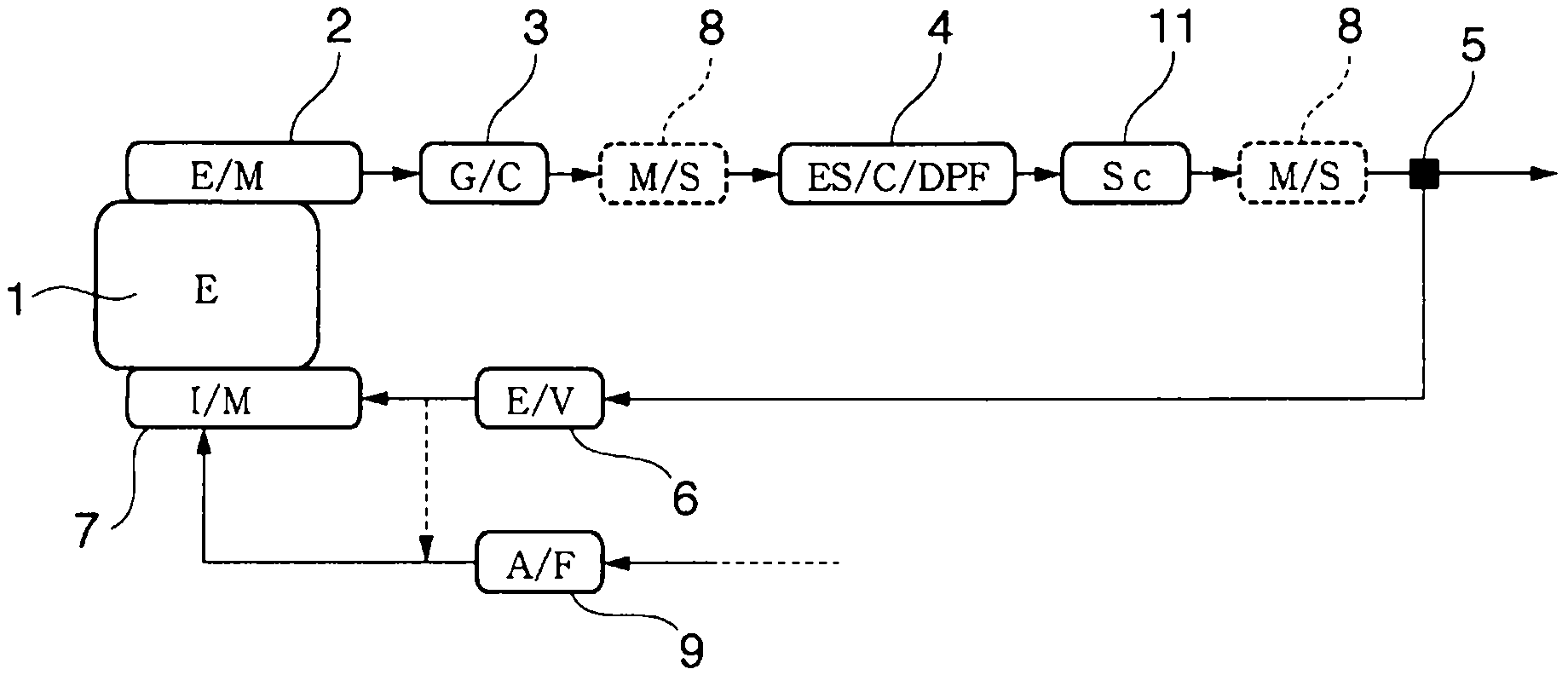

Exhaust gas purification device for diesel engine using heavy-oil or lower quality fuel

InactiveCN103261595ANO

<sub>x</sub>

reduceSuppress generationNon-fuel substance addition to fuelInternal combustion piston enginesElectricityFuel oil

Owner:USUI KOKUSAI SANGYO KAISHA LTD

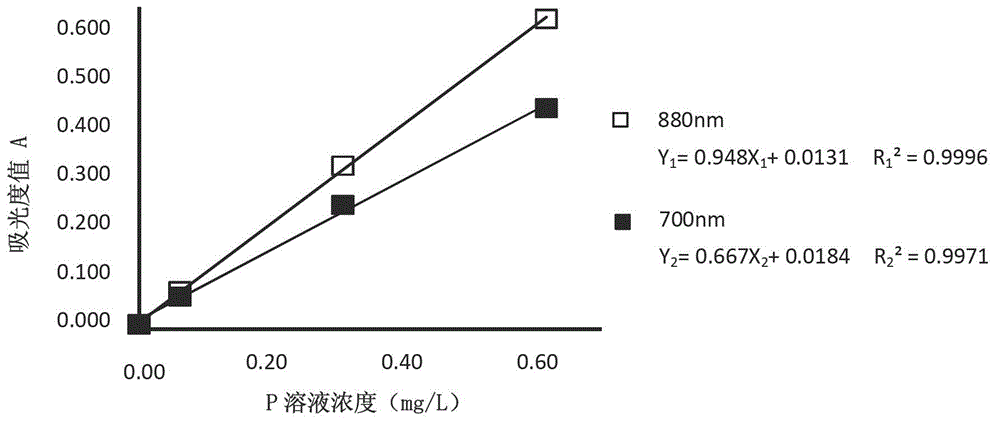

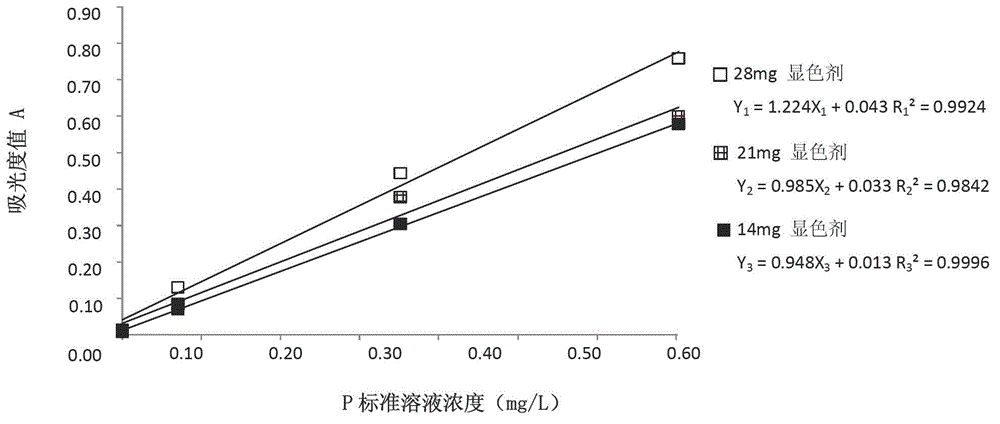

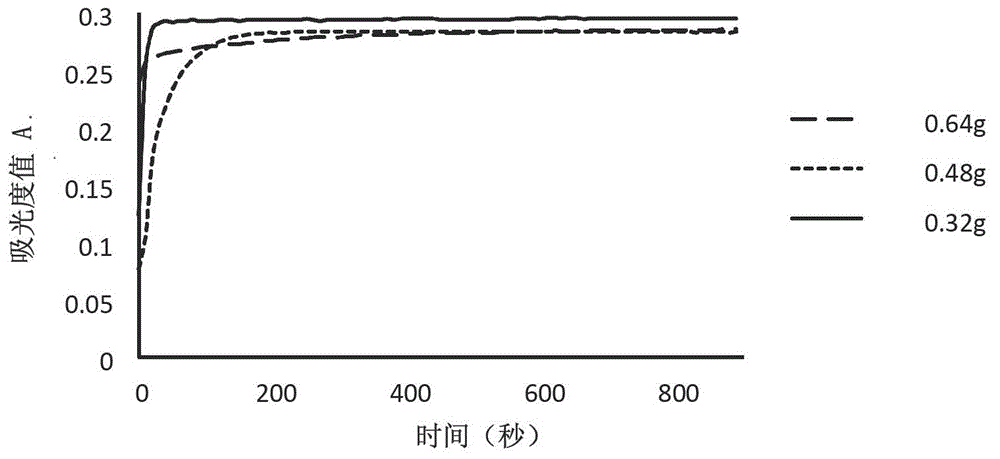

Method and kit for utilizing Mo-Sb antiluminosity method to detect content of orthophosphate in water

InactiveCN102914539AImprove work efficiencyEasy to operateMaterial analysis by observing effect on chemical indicatorStrong acidsAntimony potassium tartrate

The invention discloses a method and kit for utilizing a Mo-Sb antiluminosity method to detect a content of orthophosphate in water. The method comprises blending ammonium molybdate, antimony potassium tartrate and ascorbic acid to make a color developing agent, adding the color developing agent into a to-be-measured water sample to blend the color developing agent, then adding benzene sulfonic acid to enable the pH to be 0-1, fully blending and standing for over 3min, utilizing a spectrophotometer to measure the absorbance at the position of 880nm, and obtaining the content of orthophosphate in the to-be-measured water sample through an absorbance value according to a pre-measured standard curve. According to the method, by improving a strong acid medium, operation in measuring orthophosphate in the Mo-Sb antiluminosity method is simplified, danger is lowered, the detection speed is improved, and field operation is facilitated.

Owner:PEKING UNIV

Structural adhesive for building of bridge with precast segmental matching method

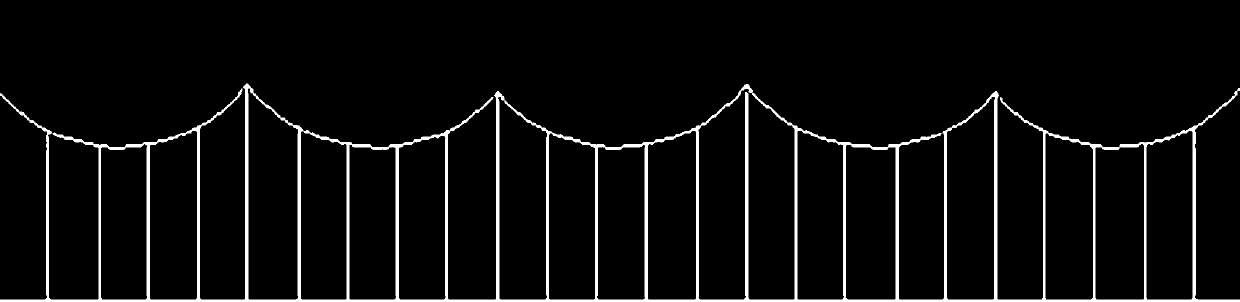

InactiveCN103468189ALess heat releaseMeet the matching construction process requirementsNon-macromolecular adhesive additivesEpoxynovolac adhesivesAdhesiveMercaptoacetic acid

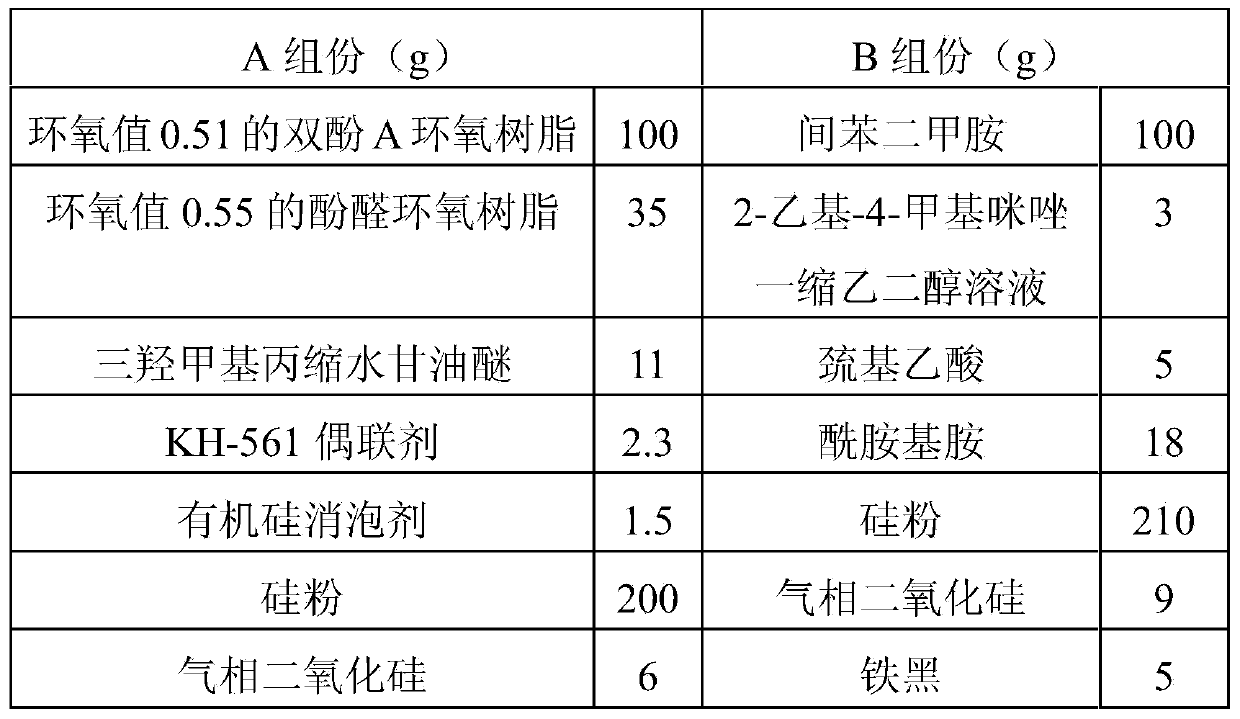

The invention relates to a structural adhesive for building of a bridge with a precast segmental matching method. Novolac epoxy resin and bisphenol A epoxy resin are matched via a certain proportion to form an epoxy resin system, an alicyclic amine hardener, amido amine, a 2-ethyl-4-methyl imidazole recoiled glycol solution and mercaptoacetic acid are adopted as accelerants to prepare a curing system, and the structural adhesive which is prepared from the epoxy resin system and the curing system according to the weight ratio of 3:1 has the characteristics that the low heat release and high early strength are realized, and the operable time is not less than 40 min, and meanwhile, in the use process of the structural adhesive, the colour and lustre are stable, and the technological requirements for matching construction of the bridge are met.

Owner:WUHAN JIANQIAO NEW MATERIAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com