Branched polyacrylic acid dispersant, and preparation method and application thereof

A branched polypropylene and dispersant technology, applied in chemical instruments and methods, transportation and packaging, textiles and papermaking, etc., can solve the problem of reducing the viscosity of the grinding slurry, reducing the agglomeration of calcium carbonate particles, and the unsatisfactory stabilization of the dispersant and other problems, to achieve the effect of stable reaction, less heat release and low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

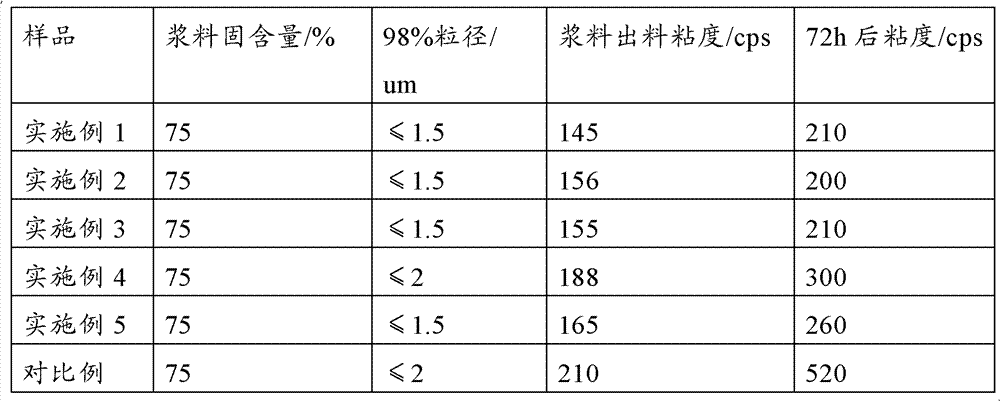

[0022] The method and advantages of the present invention will be further described in comparison with specific examples and comparative examples below.

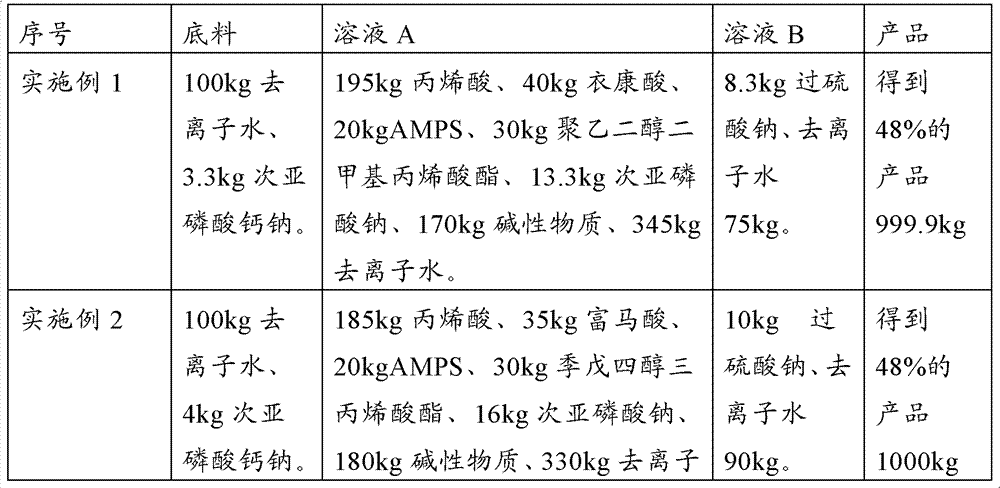

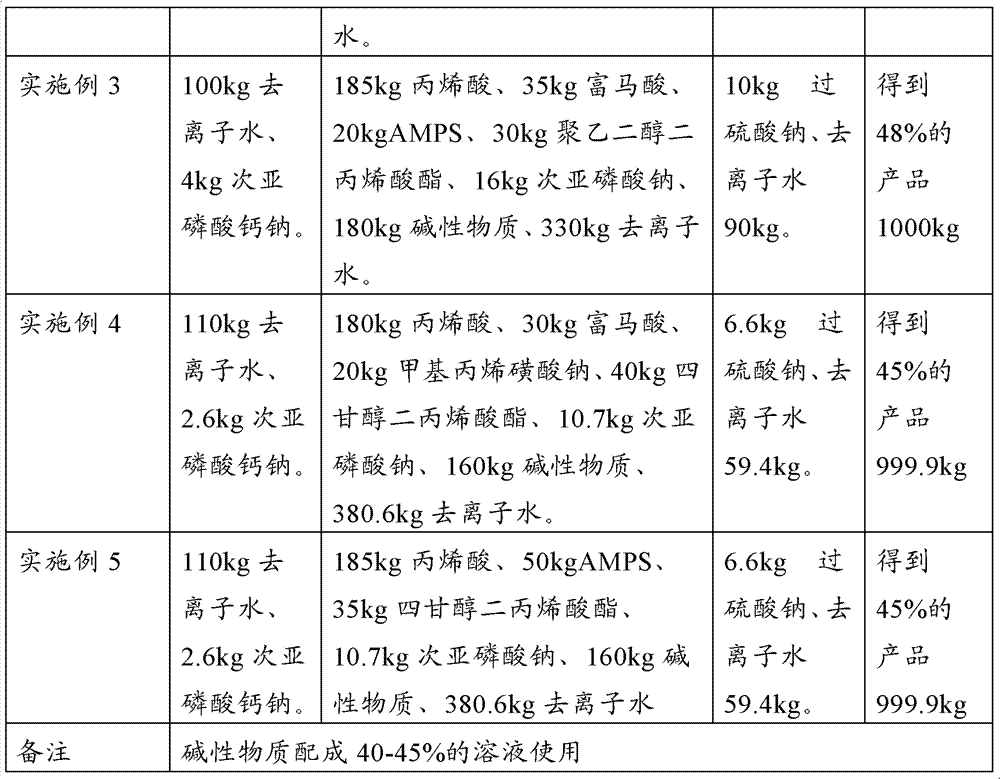

[0023] The preparation of novel branched polyacrylic acid dispersant is carried out as follows:

[0024] (1) Add a certain amount of water and the reductant of the initiation system into the reactor as the bottom material, stir and dissolve;

[0025] (2) Make a solution of acrylic acid monomer, comonomer, polyene monomer, and a certain amount of water, and neutralize it with an alkaline substance to a pH of about 4, and then add the remaining reducing agent of the initiating system to make a dropwise addition Liquid A;

[0026] (3) The oxidizing agent of initiating system, a certain amount of water are made into dripping liquid B;

[0027] (4) Add solutions A and B to the reactor described in step (1) at a certain temperature by means of dropwise addition within a certain period of time, then react for a period of time to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com