Exhaust gas purification device for diesel engine using heavy-oil or lower quality fuel

A diesel engine and exhaust gas technology, which is applied in the direction of exhaust devices, combustion engines, internal combustion piston engines, etc., can solve the problems of not being able to fully improve PM capture efficiency, achieve NOx reduction, suppress the formation of nitrogen oxides, and reduce The effect of combustion temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1、2

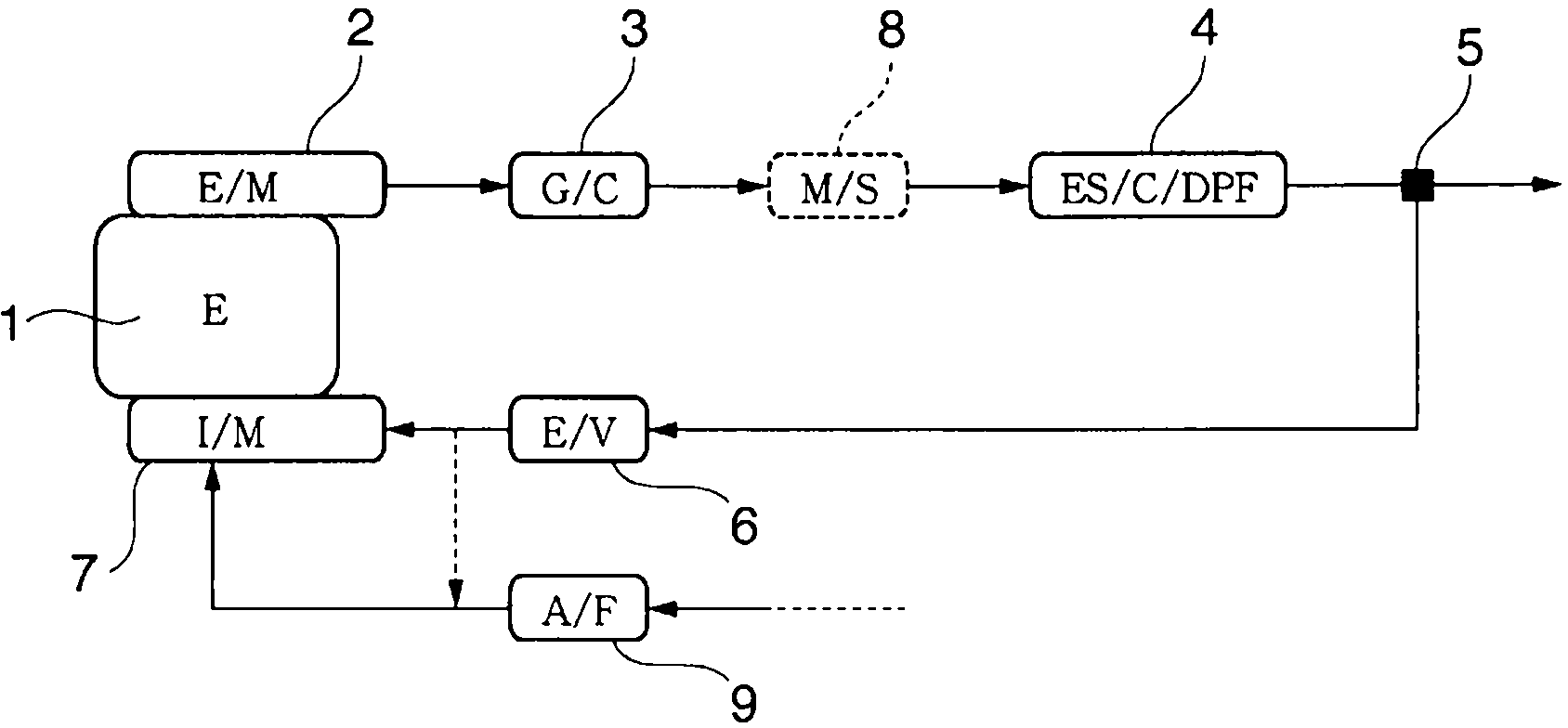

[0117] The present embodiment corresponding to the present invention 1, 2 is above-mentioned Figure 12 In the device of the twelfth embodiment shown, that is, in the exhaust gas purification device having the following structure, the temperatures of exhaust gas and EGR gas, PM, and SO are measured at positions i, i, and h. x , NO x In the above-mentioned exhaust gas purification device, the exhaust gas after the turbocharger 12 is cooled by the exhaust gas cooler 3 in advance, and then the exhaust gas purification device 4 in the electrostatic cyclone dust collector After the purification process, the EGR gas split out is processed at the scrubber 11, and then it is sent by the blower 13 through the gas-liquid separator 8, and the flow rate is controlled by the EGR valve 6 to return to the intercooler. 14 front intake pipe.

Embodiment 3、4

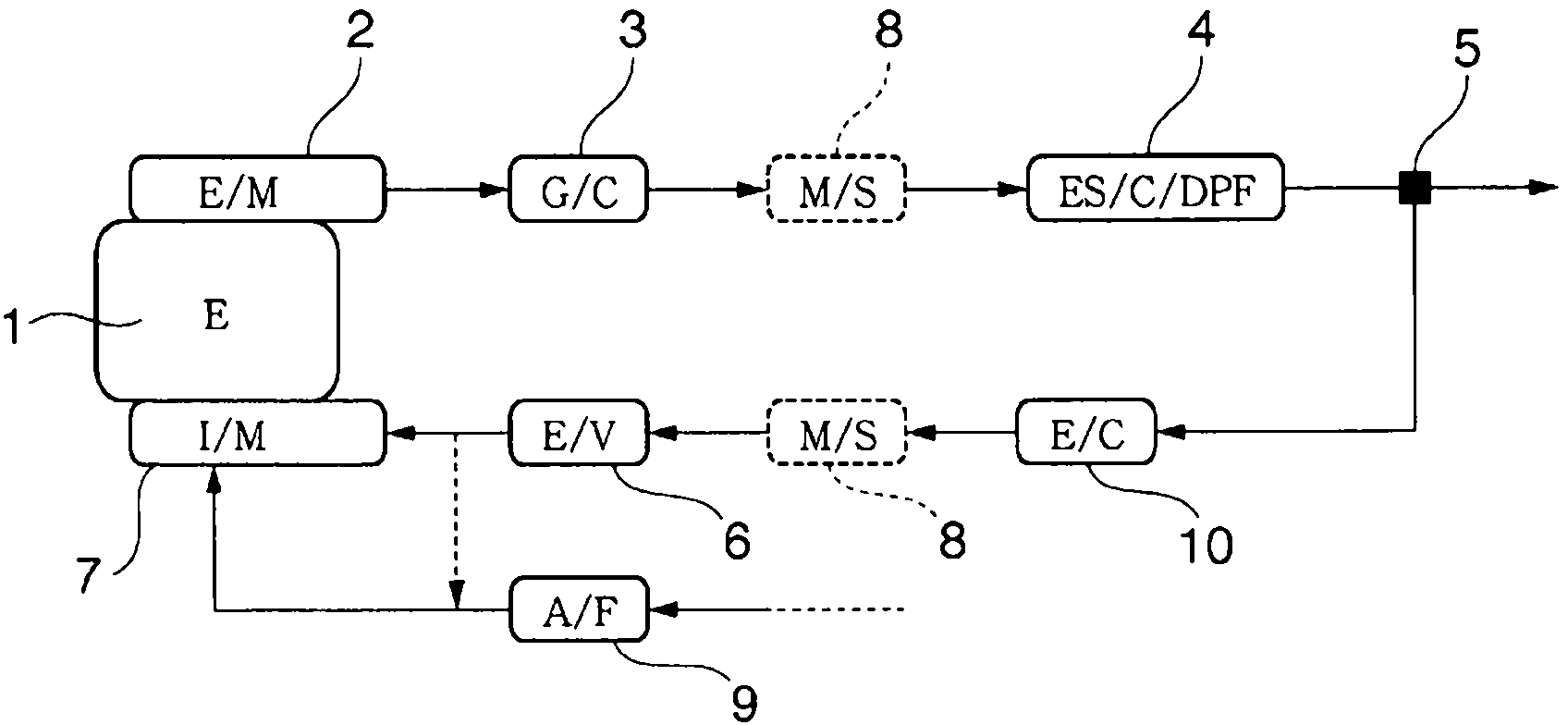

[0119] The present embodiment that is equivalent to the present invention 3,4 is above-mentioned Figure 13 In the device of the thirteenth embodiment shown, that is, the exhaust gas purifying device having the following structure, the temperatures of exhaust gas and EGR gas, PM and SO at positions 2, 4 and 1 are measured. x , NO x In the above-mentioned exhaust gas purification device, the exhaust gas after the turbocharger 12 is divided from the exhaust pipe in an untreated state to become EGR gas, and only the EGR gas is passed through the exhaust gas. The gas cooler 3, the electrostatic cyclone dust collector exhaust gas purification device 4, the scrubber 11, and the gas-liquid separator 8 are processed. After that, the EGR gas is sent by the blower 13 and controlled by the EGR valve 6 to make it return Into the intake duct before the intercooler 14.

[0120] basic features

[0121] Without exhaust gas purification device Figure 18 In the device with the structure sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com