A kind of biodiesel and preparation method thereof

A biodiesel and oleic acid technology, applied in the field of fuel oil, can solve the problems of cost performance defects, insufficient clarity, low cetane number, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

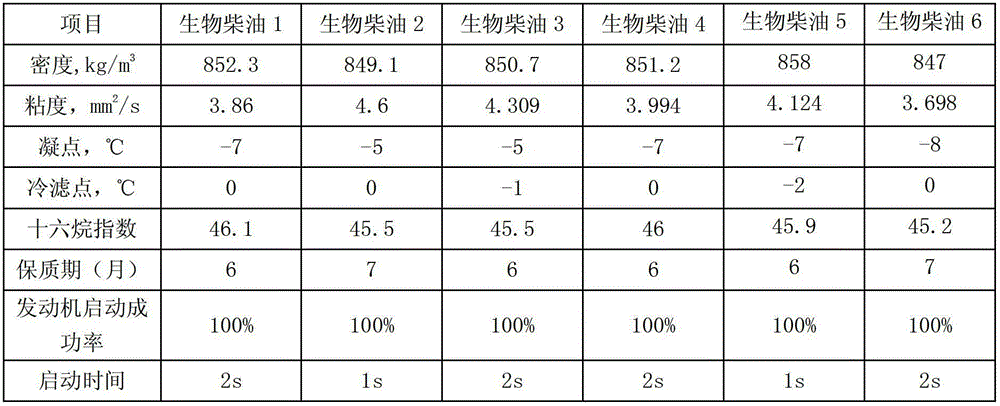

Examples

Embodiment 1

[0062] To prepare a high-clean biodiesel 1, the conventional 0# diesel is designed to account for 30% by weight in biodiesel, and methanol-based fuel oil accounts for 62.9%. Measure 480g of methanol, 400g of oleic acid and 420g of conventional 0# diesel oil (purchased from Sinopec). The additive formula includes the following components and contents:

[0063] Span-80 emulsifier 18g, OP-10 emulsifier 6g;

[0064] 20g of pH buffering agent, including 11g of sodium petroleum sulfonate and 9g of barium petroleum sulfonate;

[0065] Isobutanol 21g;

[0066] Tricresyl phosphate 11g;

[0067] Toluene 13g;

[0068] Isooctyl nitrate 8g;

[0069] The auxiliary emulsifying dispersant is combined with 1.0g of dimethyl succinate and 1.0g of T161A product of polyisobutylene derivative series;

[0070] Antioxidants were selected from N-phenyl-α-naphthylamine (T531) and 0.5 g each of 2,6-di-tert-butyl-α-dimethylamino-p-cresol.

[0071] The above-mentioned raw materials are 100g in total...

Embodiment 2

[0082] Another kind of biodiesel is prepared, and conventional diesel is designed to account for 70% by weight of biodiesel, and methanol-based fuel accounts for 27.6%. Measure 738.0g of methanol and 2075g of conventional 0# diesel oil, 82.0g of oleic acid, and change the composition of additives to:

[0083] Span-80 emulsifier 16g, Tween-60 emulsifier 8g;

[0084] pH buffering agent 18g, of which sodium petroleum sulfonate 10.0g, barium petroleum sulfonate 8.0g;

[0085] Isobutanol 30g;

[0086] Tricresyl phosphate 9.95g;

[0087] 13g of tert-butyl methyl ether;

[0088] Isooctyl nitrate 4g;

[0089] The auxiliary emulsifying dispersant is combined with 0.35g of diethyl succinate and 0.35g of T161A product of polyisobutylene derivative series;

[0090] The antioxidant is 0.35 g of N-phenyl-α-naphthylamine (T531).

[0091]The preparation process is similar to Example 1. The prepared biodiesel is a dark yellow transparent liquid biodiesel 2, and its specific parameters a...

Embodiment 3

[0093] To prepare another biodiesel, the conventional diesel is designed to account for 40% by weight in the biodiesel, and the amount of methanol-based fuel added is 54%. Measure 60g of methanol and 400g of conventional 0# diesel oil, 480g of oleic acid, and change the additive components for:

[0094] 20 parts by weight of emulsifier, wherein 15 parts by weight of SP-80 emulsifier, 5 parts by weight of OP-10 emulsifier;

[0095] 21 parts by weight of pH buffering agent, including 11 parts by weight of sodium petroleum sulfonate and 10 parts by weight of barium petroleum sulfonate;

[0096] Tricresyl phosphate, 10 parts by weight;

[0097] Isooctyl nitrate, 6 parts by weight;

[0098] As an emulsifying dispersant, 1.0 parts by weight of dimethyl succinate and 1.0 parts by weight of T161A (polyisobutenyl succinimide) products of the polyisobutylene derivative series are combined;

[0099] Antioxidant, use N-phenyl-α-naphthylamine (T531) and 2,6-di-tert-butyl α-dimethylamino...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com