Patents

Literature

95 results about "Diethyl succinate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

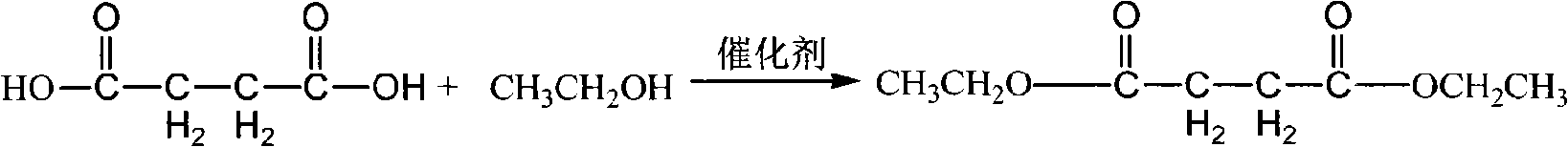

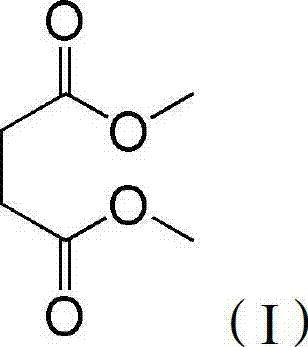

Diethyl succinate is the diethyl ester of succinate. It is a colorless liquid with the formula (CH₂CO₂Et)₂ (Et = ethyl). The organic molecule contains two ester groups. This ester is a versatile chemical intermediate. A colorless liquid, diethyl succinate is formed by Fisher esterification of succinic acid and ethanol.

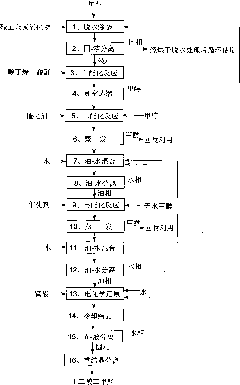

Preparation method of diethyl succinate

InactiveCN101323566AImprove protectionMild control conditionsOrganic compound preparationCarboxylic acid esters preparationAlcoholDistillation

The invention discloses a preparation method of butane diacid dimethyl ester. The preparation process comprises the following steps of: (1) the rate of raw materials and a catalyst and dosage quality rate thereof is: butane diacid : industrial ethanol : absolute ethyl alcohol : the catalyst is equal to 1 : 0.8 to 1.1 : 0.1 to 0 : 0.01 to 0.02; 1) putting butane diacid, industrial ethyl alcohol of 20 percent of total amount and the catalyst into an esterification kettle and increasing temperature to 120 DEG C; 2) inputting residual industrial ethanol continuously for 8 hours to 9 hours, maintaining the temperature of the kettle at 115 DEG C to 120 DEG C and the temperature of the top of distillation device less than 105 DEG C; 4) sampling to detect acid value and inputting absolute ethyl alcohol when the acid value is 40mgKOH / g to 48mgKOH / g; 5) sampling to detect acid value after an hour and stopping heating when the acid value is 10mgKOH / g to 15mgKOH / g; 6) reducing the temperature to 80 DEG C after ethyl alcohol is withdrawn from the kettle by opening vacuum; 7) separating the catalyst from the materials cooled to 80 DEG C and putting the catalyst into an alkaline washing kettle; 8) inputting alkali solution of proper amount and mixing for 20 minutes to 40 minutes under temperature of 60 DEG C to 70 DEG C; 9) placing stilly for layering and emitting the lower water layer; 10) adding crude product after the alkaline washing into a rectification kettle, raising the temperature to 150 DEG C to 170 DEG C and dehydrating; 11) opening vacuum and collecting distillate of 160 DEG C to 190 DEG C which is the final product.

Owner:SHENZHEN FEIYANG IND CO LTD

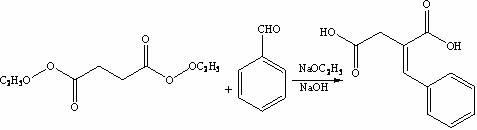

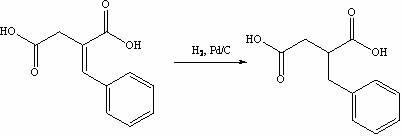

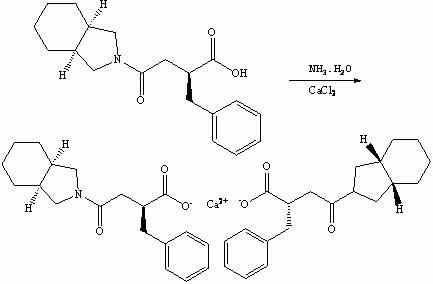

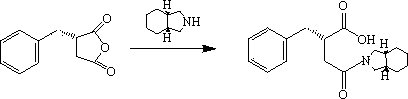

Preparation method of mitiglinide calcium

InactiveCN102101838ASave cis-hexahydroisoindoleHigh chiral separationOrganic chemistryAcetic anhydrideBenzaldehyde

The invention discloses a preparation method of mitiglinide calcium. The method comprises the following steps of: performing Stobble condensation on diethyl succinate and benzaldehyde serving as raw materials in ethanol by using sodium alcoholate; hydrolyzing to obtain toluenyl butane diacid; performing catalytic hydrogenation on the toluenyl butane diacid to obtain DL-2-benzyl butane diacid; resolving the DL-2-benzyl butane diacid with (R)-chiral amine to obtain (S)-2-benzyl butane diacid; reacting the (S)-2-benzyl butane diacid under the action of acetic anhydride to obtain acid anhydride ; reacting the obtained acid anhydride with cis-hexahydroisoindole to obtain mitiglinide acid; and reacting the mitiglinide acid with calcium chloride and ammonia water to generate a mitiglinide calcium bihydrate. The preparation method of the mitiglinide calcium has the advantages of saving of cis-hexahydroisoindole serving as a raw material and high chiral separating degree.

Owner:周玉莲

Red date brandy and production process thereof

InactiveCN102051307AQuick peelPromote dissolutionMicroorganism based processesAlcoholic beverage preparationFlavorDate Fruit

The invention discloses red date brandy and a production process thereof. The red date brandy is prepared by using red dates as raw materials through the processes of separating, cleaning, roasting, smoke curing, extruding, soaking, treating with steam, pulping, protecting colors, carrying out ultrasonic enzymolysis, regulating constituents, sterilizing, fermenting, distilling, adsorbing, storing, blending, ageing, and the like, wherein the processes of roasting and smoke curing with peat are used for increasing fragrance and the contents of phenols; the processes of extruding and soaking arebeneficial to extracting date juice; the composite method of treating with steam, protecting the color and carrying out ultrasonic enzymolysis is used for improving the juice yield and the date juicequality; the processes of supplementing a proper quantity of date juice and adding flavor-producing yeast in a later stage mainly aim to generate flavor constituents such as ethyl acetate, isoamyl acetate, diethyl succinate, and the like; the method for distilling for three times is used for collecting flavor constituents of aldehydes, esters, high-grade alcohols, and the like to obtain a high-quality distilled liquor; the adsorbing treatment is used for removing impurities with poor flavors and greatly improving the fragrance and the flavor of the wine; and through storing, blending and ageing, the wine is more mature, fine, smooth and soft. The obtained red date brandy has the advantages of rich and mellow mouthfeel, harmonious red date fruit fragrance, aged oak fragrance, elegant and strong bouquet and pure and mild as well as fine and smooth mouthfeel.

Owner:山西悦卜林创业投资有限公司

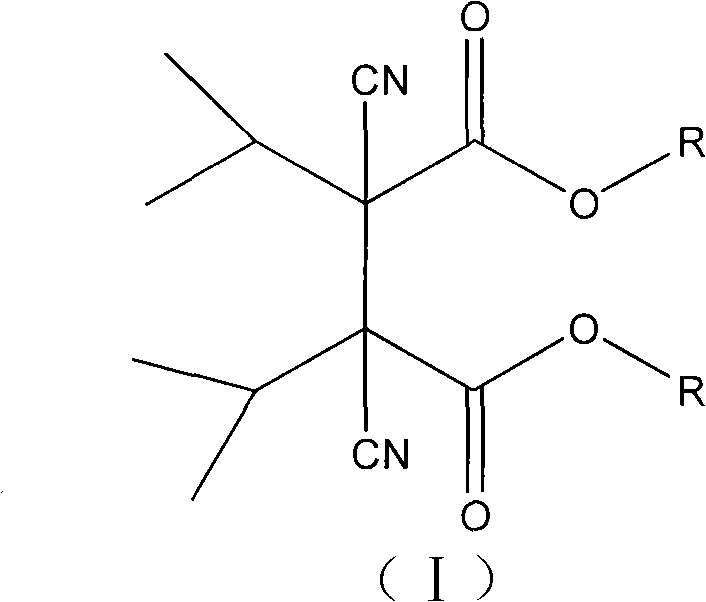

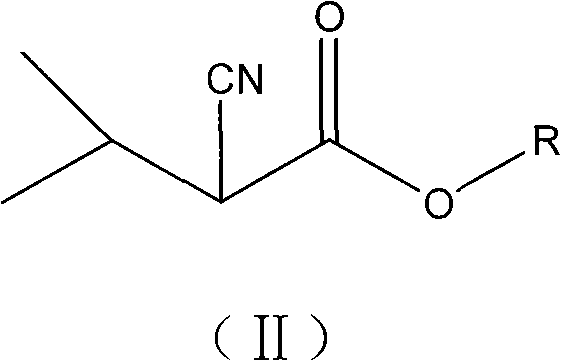

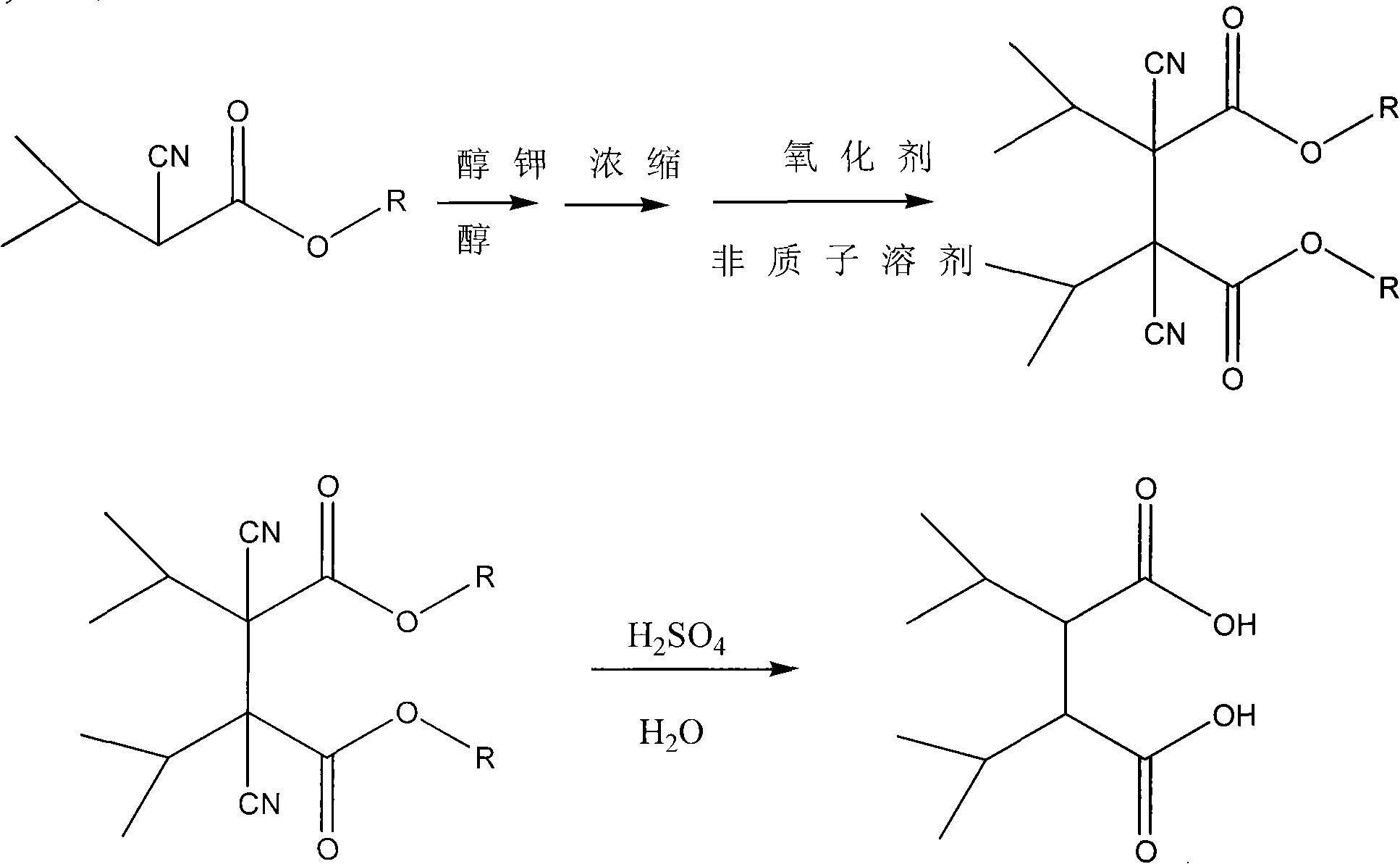

2,3-diisopropyl-2.3-dicyano-diethyl succinate compound, preparation method and application thereof

ActiveCN101811982AAvoid low temperature operationEasy to industrializeCarboxylic acid nitrile preparationOrganic compound preparationElectron donorPetrochemical

The invention relates to a preparation method of 2,3-diisopropyl succinate and ester compound thereof, which comprises the steps of: carrying out an oxidative coupling reaction of a 3-methyl-2-cyano butyrate compound for preparing a 2,3-diisopropyl-2.3-dicyano-diethyl succinate compound; carrying out a hydrolysis reaction and a decarboxylation reaction for preparing the 2,3-diisopropyl succinate;and further esterifying for preparing the 2,3-diisopropyl diethyl succinate compound. An intermediate of the 2,3-diisopropyl-2.3-dicyano-diethyl succinate compound and the preparation method thereof are beneficial to commercially producing 2,3-diisopropyl succinic ester which is an internal electron donor compound used capable of being used for preparing a Ziegler-Natta polypropylene catalyst. The invention can be used for the technical field of petrochemical polypropylene.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing dimethyl succinate

ActiveCN101824627AThorough responseLow production costElectrolysis componentsOrganic compound preparationEvaporationCis-Butenedioic Acid

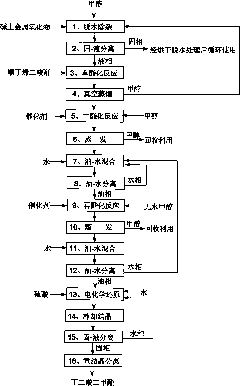

The invention relates to a method for preparing dimethyl succinate, which comprises the following steps that: (1) dehydration and decontamination: methanol and alkali-earth metal oxide are mixed, dehydrated and decontaminated; (2) separation of solid and liquid; (3) monoesterification reaction: maleic anhydride is added in the liquid-phase material which is obtained in the previous step; (4) vacuum distillation; (5) 2-esterification reaction; (6) evaporation; (7) mixing of oil and water; (8) separation of oil and water; (9) re-eesterification; (10) evaporation; (11) mixing of oil and water; (12)separation of oil and water; (13) electrochemical reduction: hydrogen is introduced to reduce dimethyl maleate to dimethyl succinate; (14) cooling and crystallization; (15) separation of solid and liquid: solid material enters the next step; (6) re-crystallization and separation: the product dimethyl succinate is obtained. The method is simple, and has reasonable process, low preparation cost, high product purity and good quality.

Owner:RUNTAI CHEM CO LTD

Synthetic method of plant growth regulator trinexapac-ethyl intermediate 3-carbethoxy-5-oxo-cyclohexane-1-enol cyclopropanecarboxylate

ActiveCN102911058ANo purification requiredShort reaction timeOrganic compound preparationCarboxylic acid esters preparationKetoneSodium salt

The invention provides a synthetic method of plant growth regulator trinexapac-ethyl intermediate 3-carbethoxy-5-oxo-cyclohexane-1-enol cyclopropanecarboxylate. The synthetic method comprises the following steps: (1) carrying out annulation reaction on 2-acetonyl-1,4-diethyl succinate and organic alkaline at the temperature of 20-120 DEG C for 0.5-5 hours in a non-polarity organic solvent to obtain 3,5-cyclohexanedione-1-ethyl formate; and (2) adding organic amine and cyclopropanecarboxylic acid chloride, and carrying out acylation reaction at the temperature of minus 5-50 DEG C, so as to obtain 3-ethoxycarbonyl-5-oxo-cyclohexane-1-enol cyclopropanecarboxylate in the presence of micromolecular alcohol, ether, ketone and nitrile the carbon atoms of which are below C8 and are used as additives. According to the method, special additives are added before acylation so that cyclopropanecarboxylic acid chloride can directly react with intermediate-state 3-ethoxycarbonyl-5-oxo-cyclohexane-1-enol sodium salt to obtain the trinexapac-ethyl precursor 3-ethoxycarbonyl-5-oxo-cyclohexane-1-enol cyclopropanecarboxylate, thereby shortening reaction time, simplifying synthesis process and improving yield; and the product is directly rearranged without purification so as to obtain the final product trinexapac-ethyl.

Owner:JIANGSU YOUJIA CHEM +1

Preparation method of diethyl succinate

ActiveCN102863335AGood for separation and refinementSimple production processOrganic compound preparationCarboxylic acid esters preparationSolubilityReaction rate

The invention provides a preparation method of dimethyl succinate. The method comprises the steps of mixing maleic anhydride, an alcohol compound, carbon dioxide, hydrogen and a hydrogenation catalyst and conducting esterification hydrogenation reaction to obtain the dimethyl succinate. According to the method, the maleic anhydride, the alcohol compound and hydrogen serve as raw materials, the carbon dioxide serves as a solvent and an acid catalyst, under catalysis of the hydrogenation catalyst, the esterification hydrogenation reaction is conducted, and the dimethyl succinate is obtained. The carbon dioxide serves as the solvent of the esterification hydrogenation reaction and the acid catalyst, high catalytic activity is achieved, and the reaction rate is improved; the carbon dioxide and water generated in the reaction process can form acid, and an obtained product has certain solubility in the carbon dioxide, so that the reaction can be conducted in a positive direction, and the conversion rate and the production rate of the dimethyl succinate are improved. Experimental results show that the yield rate of the obtained dimethyl succinate exceeds 99%.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

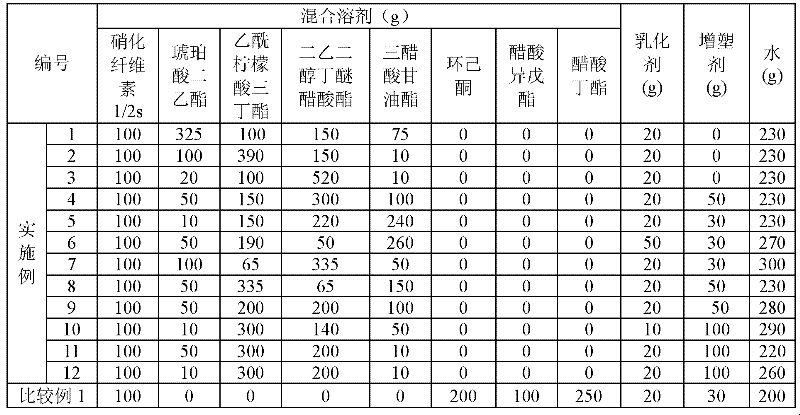

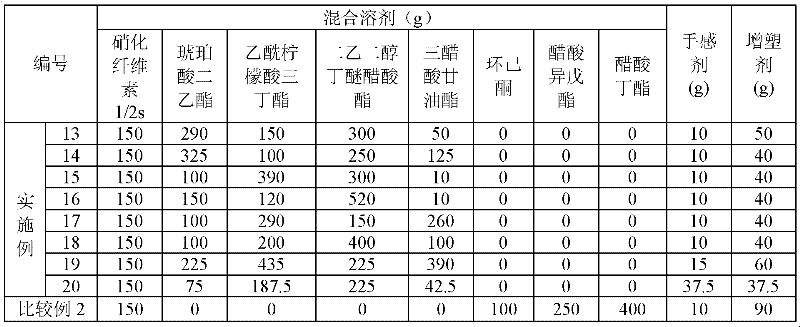

Mixed solvent used for dissolving nitrated cellulose and nitrated cellulose product containing mixed solvent

The invention provides a mixed solvent used for dissolving nitrated cellulose. The mixed solvent contains 1-50wt% of diethyl succinate, 10-60wt% of acetyl tributyl citrate, 10-80wt% of diethylene glycol butyl ether acetate and 1-40wt% of glycerol triacetate. The invention also provides a water-soluble nitrated cellulose product and a water-soluble nitrated cellulose product prepared by the mixed solvent provided by the invention. The nitrated cellulose product prepared by the mixed solvent is little in smell and low in toxicity, has good volatilization grade, and greatly improves the production environment of leather processing enterprises and alleviates the harm to the body health of workers on the basis of keeping the performances of the nitrated cellulose products.

Owner:德瑞(常州)特种材料有限公司

Descaling agent for water scale of condensing equipment and descaling method

The invention relates to a descaling agent for water scale of condensing equipment and a descaling method. The descaling agent comprises the following materials in percentage by weight: 15%-30% of dissolving agents, 2%-5% of permeating agents, 1%-5% of corrosion inhibitors, 10%-30% of cosolvents, 20%-30% of purified water and the balance of ethanol, wherein the dissolving agents are selected from oxalic acid, citric acid, ascorbic acid, salicylic acid and glacial acetic acid; the permeating agents are selected from diethyl succinate, butyl cellusolve and sulfonated dioctyl succinate sodium salt; the corrosion inhibitors are selected from urotropine, aniline and diethyl thiourea or rodine; the cosolvents are selected from para-benzoic acid, urea, cyclohexanone, acetamide and sodium salicylate. The descaling agent disclosed by the invention is obtained by blending the raw materials, has high descaling capacity and higher descaling speed by utilizing combined effect, is less in corrosion on equipment and low in price and can save a large amount of cleaning expense, enhance the equipment operation level, the energy utilization level and the production efficiency and greatly reduce the product production cost.

Owner:宁夏启元国药有限公司

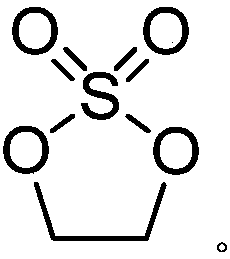

Preparation method of ethylene sulfate

ActiveCN108610324AEliminate potential safety hazardsEasy to makeOrganic chemistrySodium methoxideLithium hydroxide

The invention discloses a preparation method of ethylene sulfate. The method comprises the steps of: reacting ethylene glycol with diethyl sulfate in the presence of an alkaline catalyst to produce ethylene sulfate, wherein the alkaline catalyst is one of or a combination of several of lithium hydroxide, sodium methoxide, sodium ethoxide, potassium carbonate, sodium carbonate and lithium carbonate. The preparation method provided by the invention can reduce environmental pollution, is more environmental friendly, and has the advantages of simple operation, safety, ideal yield and the like.

Owner:SUZHOU HUAYI NEW ENERGY TECH CO LTD

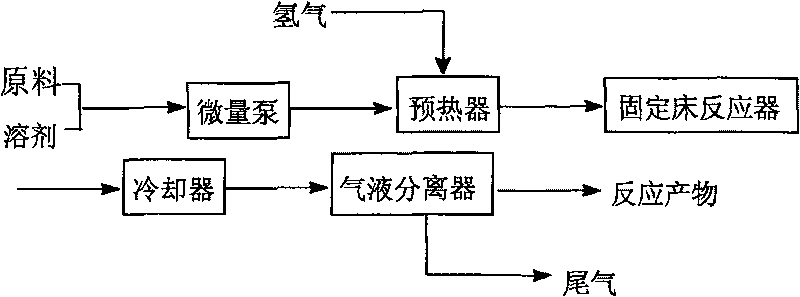

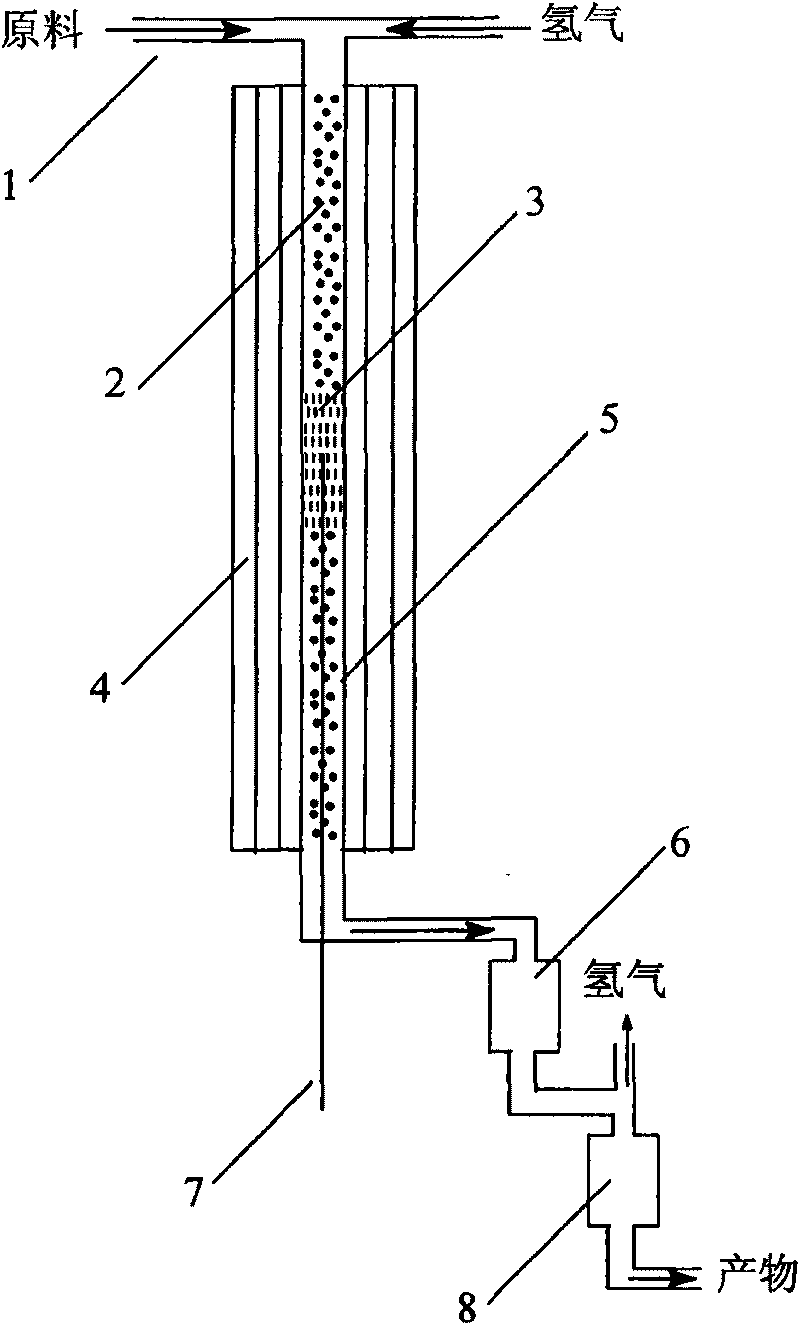

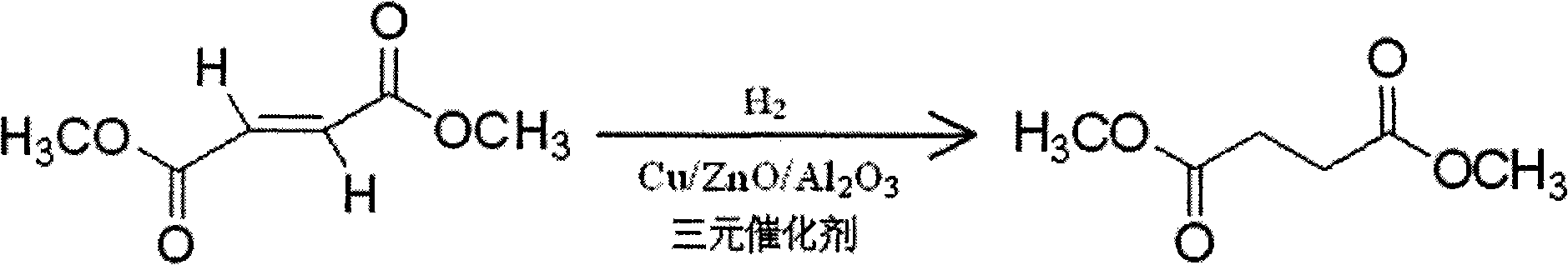

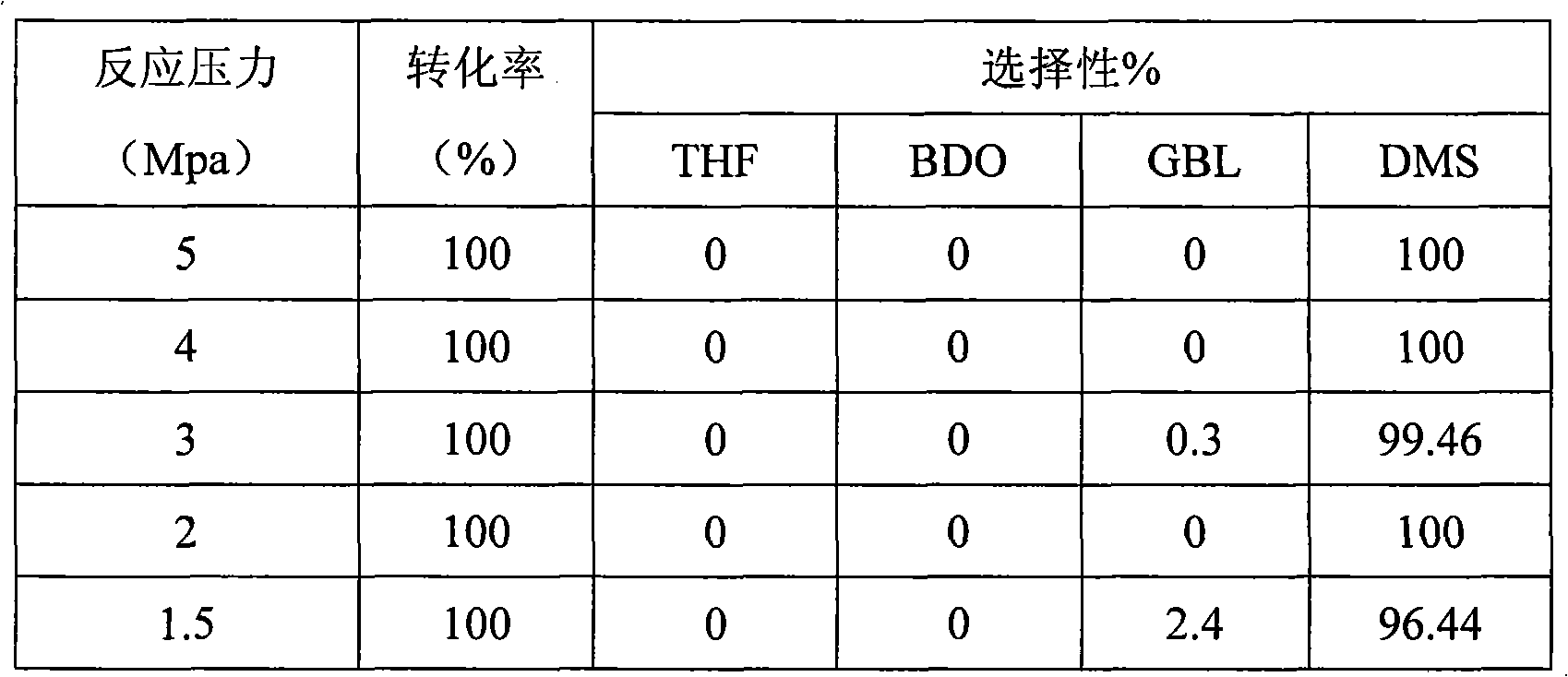

Method for preparing gamma-butyrolactone through catalytic hydrogenation of dimethyl succinate

InactiveCN101704805ARaise the pHHigh activityOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsFixed bedReaction temperature

The invention relates to a method for preparing gamma-butyrolactone through catalytic hydrogenation of dimethyl succinate, which belongs to the field of chemical technology. Gamma-butyrolactone is prepared by utilizing the catalytic hydrogenation of multicomponent metallic oxide catalyst through a fixed bed tubular reactor by adopting dimethyl succinate as raw material and carbinol as solvent. The multicomponent metallic oxide catalyst is prepared through a coprecipitation method, the major catalyst comprises 15 to 80 percent (Wt) of copper oxide and 10 to 50 percent (Wt) of zinc oxide, the catalyst accelerator comprises 0 to 10 percent (Wt) of one or a plurality of the oxides of calcium, barium, magnesium, manganese, nickel, molybdenum or cobalt, and a carrier comprises 5 to 30 percent (Wt) of one or a plurality of aluminium oxide, zirconium dioxide and silicon dioxide. When the reaction temperature is 200 to 300 DEG C, the reaction pressure is 2 to 4 MPa, the mol ratio of hydrogen to ester is 100 to 250, and the liquid hourly space velocity is 0.2 to 0.5 h per hour, the conversion rate of dimethyl succinate is larger than 95 percent, and the selectivity of gamma-butyrolactone is larger than 90 percent. The multicomponent metallic oxide catalyst has higher activity and is inexpensive, and both preparation and recovery of the catalyst can not pollute the environment.

Owner:JIANGSU POLYTECHNIC UNIVERSITY

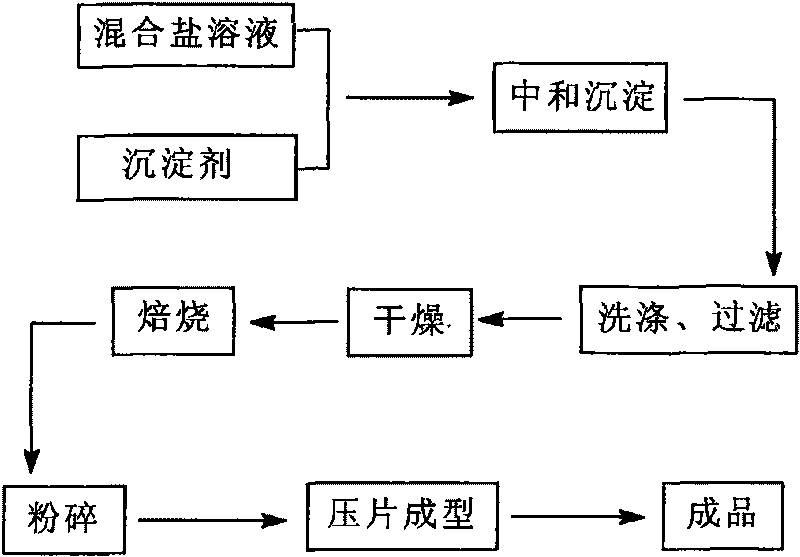

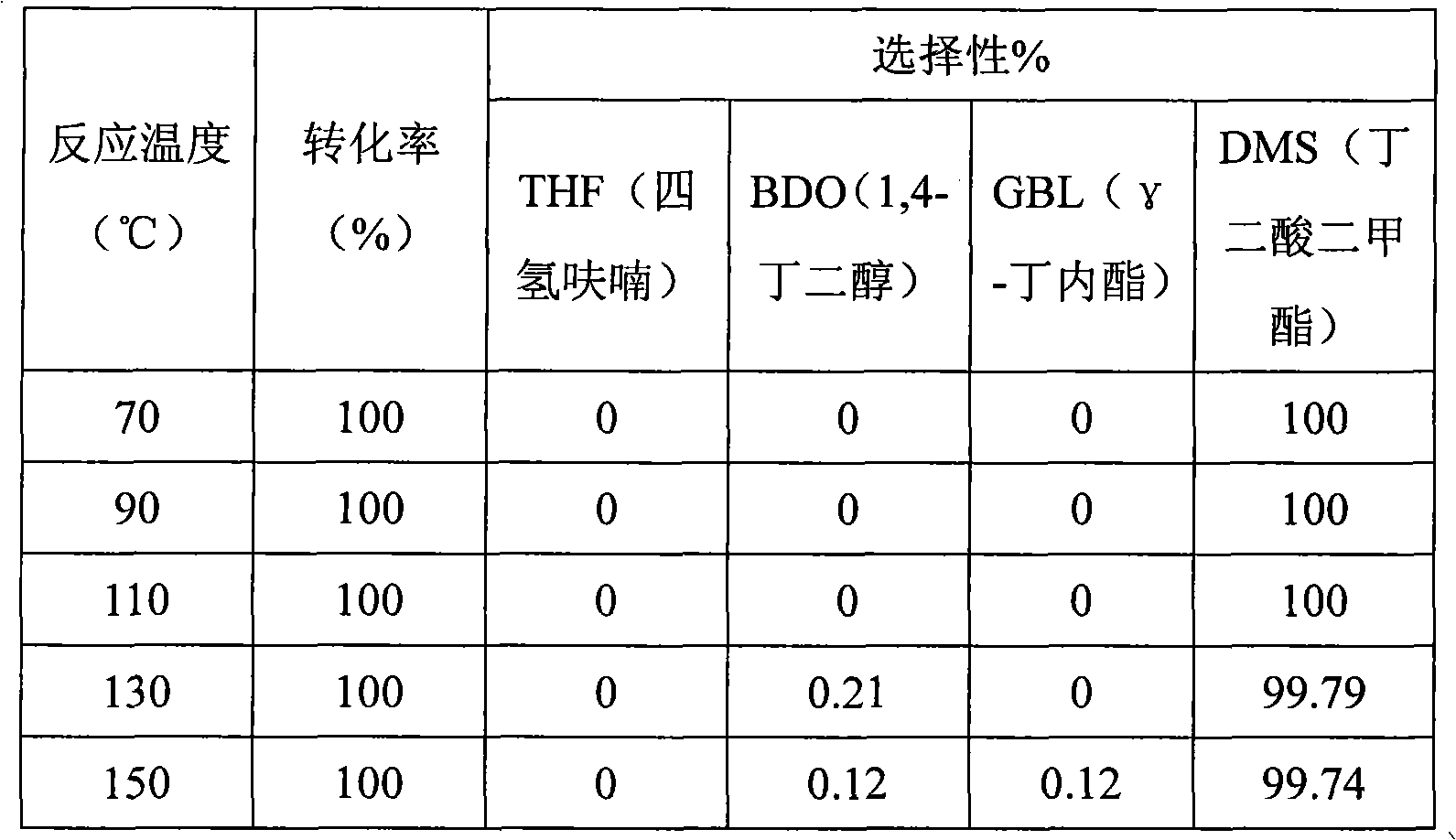

Catalyst for producing 1,4-butylediol and preparation method and use thereof

InactiveCN101422732AHigh activityGood choiceOrganic compound preparationHydroxy compound preparationWater bathsTitanium

The invention relates to a catalyst that is used for preparing 1,4-butanediol by diethyl succinate hydrogenation and a preparation method of the catalyst. In the total weight of the catalyst, cupric oxide accounts for 30 to 60 weight percent (Wt), zinc oxide accounts for 20 to 50 weight percent (Wt), and titanium oxide accounts for 5 to 20 weight percent (Wt). In the preparation, the dissoluble salts of copper, zinc and titanium are mixed according to the proportions thereof in the total weight of the catalyst and dissolved in deionized water, thus preparing a metallic ion mixture solution, under water-bath heated agitation, the metallic ion mixture solution and a precipitator are drop-added in current flow, the pH value of the solution is controlled between 7 and 8, the solution is agitated at constant temperature for 1 to 3 hours, temperature is raised to 70 to 80 DEG C for aging for 2 to 20 hours, precipitate is filtered, the precursor precipitate is rinsed by deionized water so as to remove impurity ions, and then the precipitate is dried at the temperature of 110 to 120 DEG C for 8 to 12 hours and baked in a muffle furnace at the temperature of 350 to 550 DEG C for 3 to 5 hours. The invention has the advantages that the provided catalyst has standardized pore structure, higher specific surface, higher activity, good selectivity, and the production and recycling without environmental pollution.

Owner:JIANGSU POLYTECHNIC UNIVERSITY

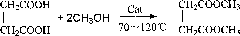

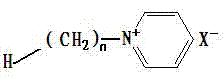

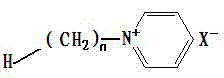

Method for preparing diethyl succinate catalyzed by pyridine ionic liquid

InactiveCN102267898AEasy to makeLow priceOrganic compound preparationCarboxylic acid esters preparationButanedioic acidPtru catalyst

The invention discloses a method for preparing diethyl succinate catalyzed by a pyridine ionic liquid. The method is to mix succinic acid and ethanol with a molar ratio of 1:3, add Brφnsted acidic pyridine ionic liquid catalyst, and the catalyst The amount is 5-8% of the mass of succinic acid, the reaction temperature is 60-70°C, the reaction time is 2-3h, and the catalyst and product are separated by ether extraction. The pyridine ionic liquid used in the present invention has high catalytic activity, good selectivity, low price, and stable properties, and can be reused after simple rotary evaporation and water removal treatment, which not only realizes green synthesis, but also reduces manufacturing costs and improves economic efficiency. benefit. The invention can be used for synthesizing butanediol diethyl ester and is suitable for large-scale industrial production.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

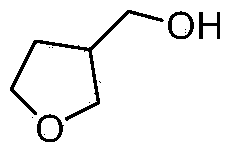

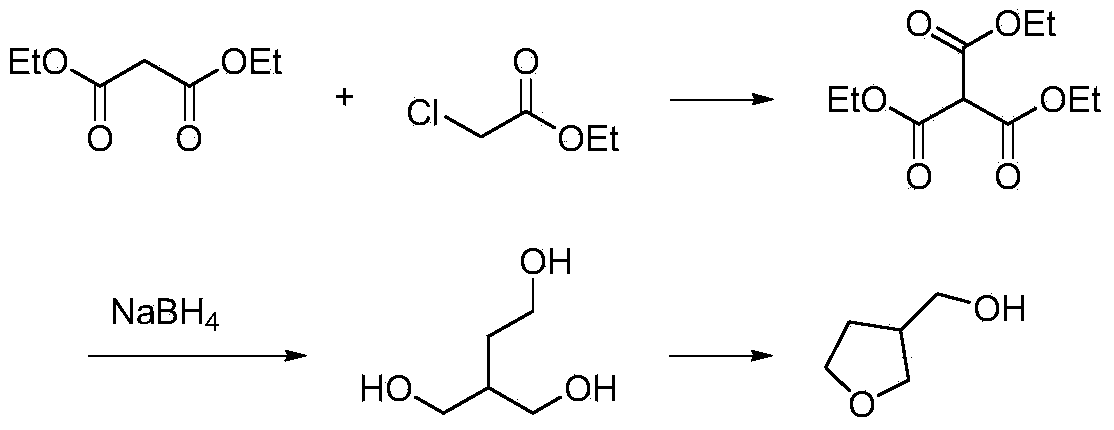

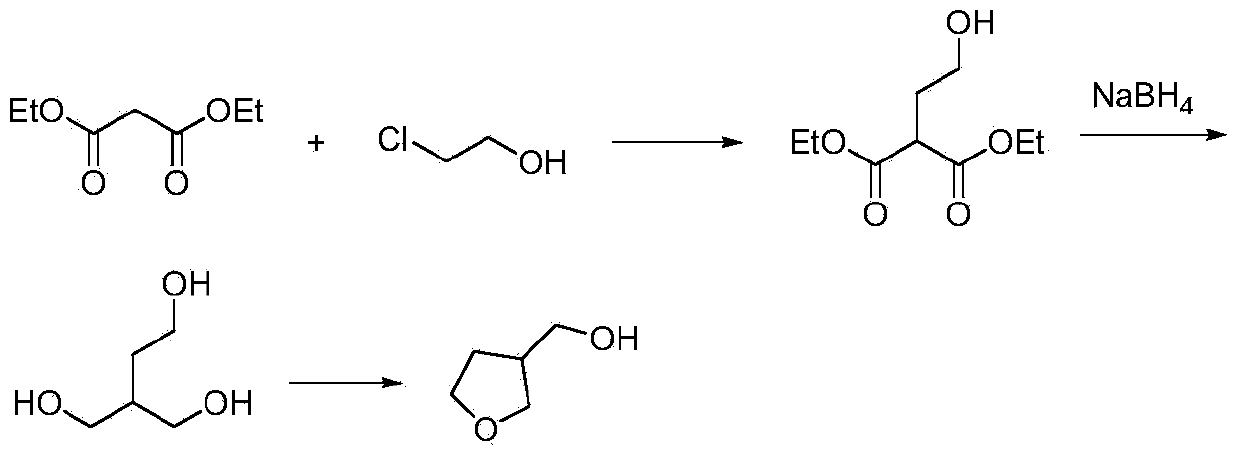

Synthetic method for 3-hydroxymethyl tetrahydrofuran

The invention discloses a synthetic method for 3-hydroxylmethal tetrahydrofuran. The synthetic method comprises the following steps: with 2-chloroethanol and diethyl malonate as raw materials, reacting under the action of alkaline in the presence of an organic solvent or in absence of a solvent to obtain an intermediate 2-ethoxy-diethyl succinate; then, reducing the intermediate 2-ethoxy-diethyl succinate by virtue of metal borohydride to obtain 2-hydroxymethyl-1,4-butanediol; and finally, producing 3-hydroxylmethal tetrahydrofuran under the action of a dehydrating agent. According to the synthetic method, the usage amount of the reducing agent metal borohydride is remarkably lowered, and yield of a byproduct sodium metaborate is reduced at the same time. The invention provides the synthetic method for the drug intermediate 3-hydroxylmethal tetrahydrofuran.

Owner:XIAN MODERN CHEM RES INST

Water-soluble polyamide, and preparation method and application thereof

InactiveCN102875803AGood water solubilityRich sourcesOther chemical processesWater/sewage treatment by sorptionMetal ions in aqueous solutionSolubility

The invention discloses a water-soluble polyamide, and a preparation method and an application thereof, and belongs to technical field of the synthetic methods of the polymers and applications thereof. The preparation method comprises the steps of mixing tributyl citrate and diethyl succinate according to the proportion of 1:2-3:1 and an equal amount to the total amount of the above substances; vacuum-heating the above mixture for 60 h at a temperature of 60 DEG C to obtain a prepolymer; heating the prepolymer to a temperature of 160 DEG C; reacting for 4 h; then heating the prepolymer to a temperature of 200 DEG C; heating continuously for 4 h to obtain a polymer; and hydrolyzing the polymer under a strong alkali condition to obtain the water-soluble polyamide. The preparation method is simple and has easily obtained raw materials. The polymerized product has the characteristic of good water-solubility, and can chelate metal ions in a water solution.

Owner:SHAOXING UNIVERSITY

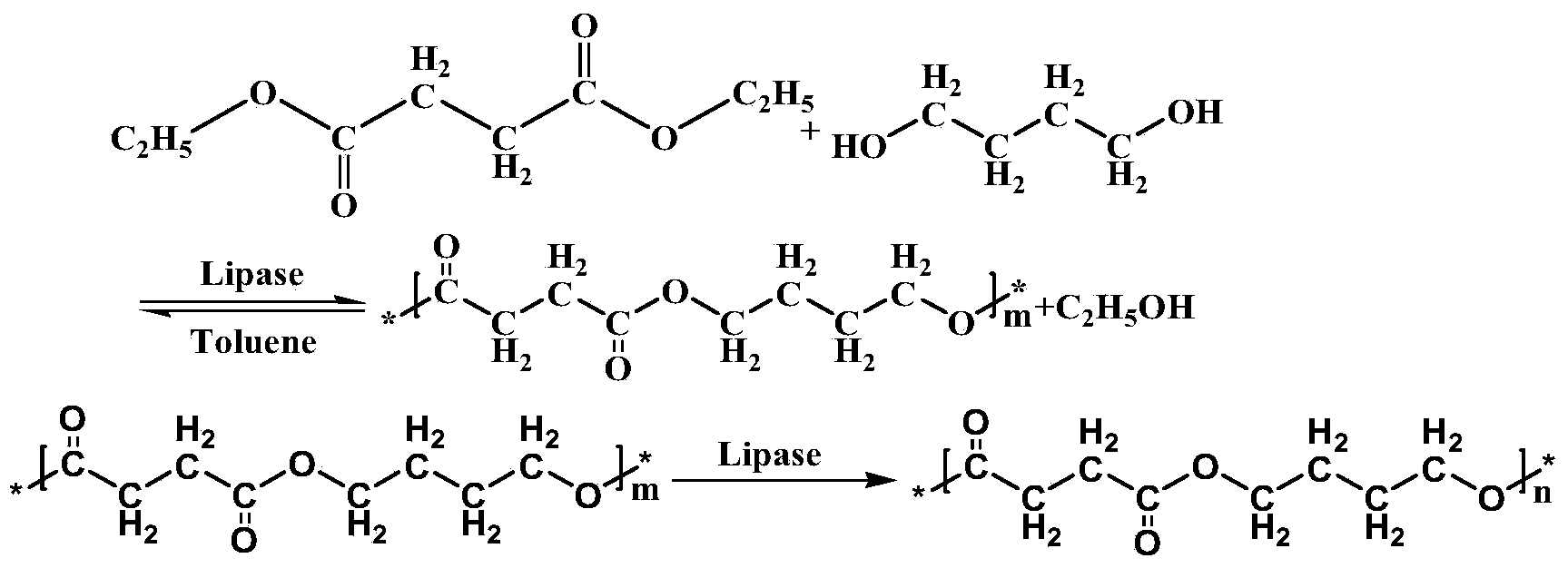

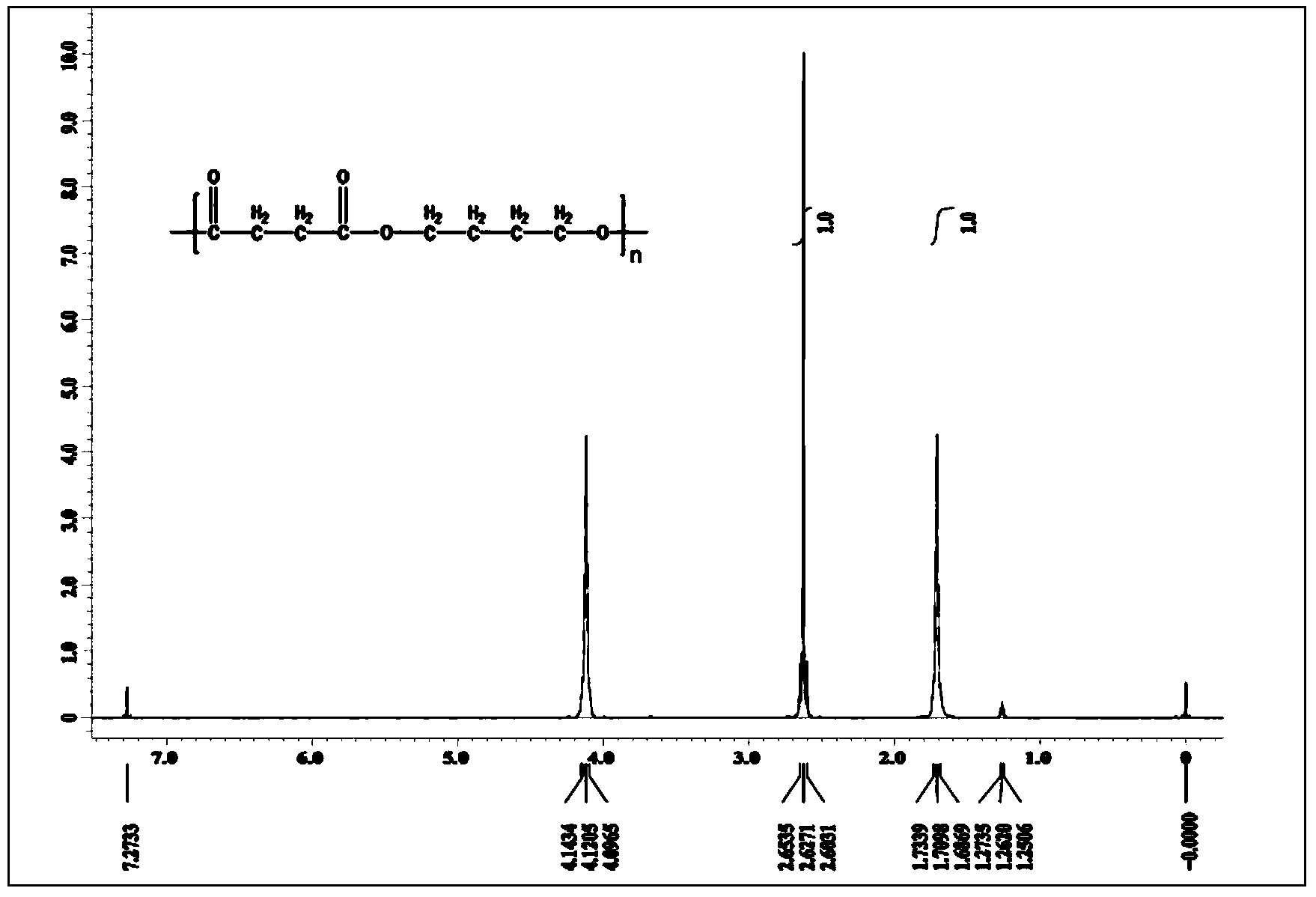

Preparation method of poly(butylene succinate)

The invention discloses a preparation method of poly(butylene succinate). The preparation method comprises the following steps: (1), under catalytic action of lipase, polymerizing an acyl donor and 1,4-butanediol through liquor to obtain a prepolymer, wherein the acryl donor is at least one of succinic acid, dimethyl succinate and diethyl succinate; (2), under the catalytic action of the lipase, polymerizing the prepolymer by virtue of a main body to obtain poly(butylene succinate). The invention provides the preparation method of poly(butylene succinate) with high molecular weight. Compared with the existing technology of synthesizing polyesters in an enzymatic manner, under the condition that material ingredients are the same, the method disclosed by the invention can be used for greatly reducing consumption of energy and dosage of the organic solvent in the processing process, and improving the molecular weight and material performance of a product. Moreover, the method can be used for overcoming a bottleneck of short-chain aliphatic monomer polymerization in an enzymatic manner, obtaining a high molecular product which can be put into practical application; meanwhile, the production cost is lowered by virtue of normal-pressure polymerization, and a basis is provided for industrially producing the polyesters by virtue of an enzyme process.

Owner:TSINGHUA UNIV

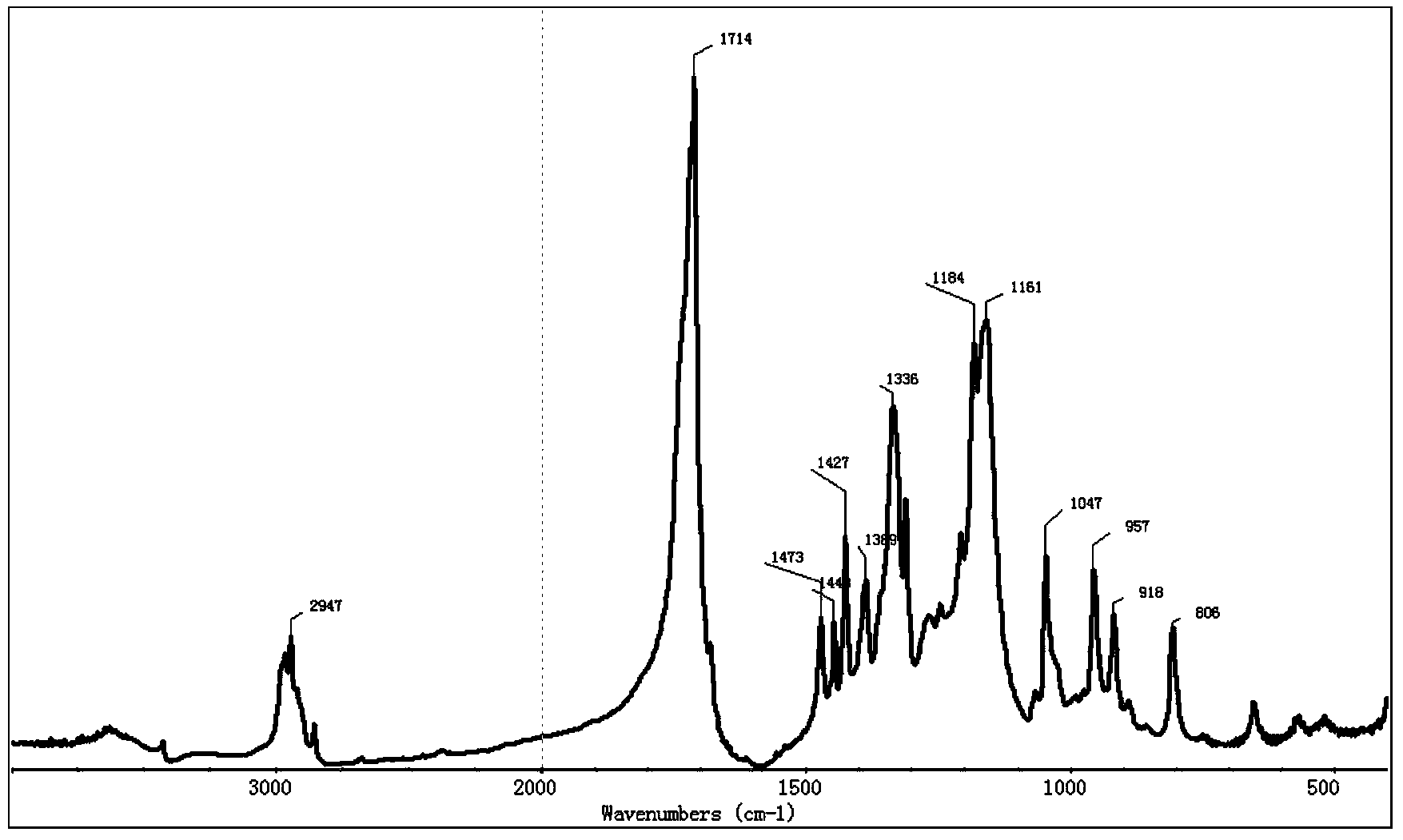

Catalyst for use in synthesis of dimethyl succinate and application thereof

InactiveCN101905160ALarge specific surface areaGood choiceOrganic compound preparationCarboxylic acid esters preparationChemical industryPore distribution

The invention relates to a catalyst for use in the synthesis of dimethyl succinate and application thereof, which belong to the field of chemical industry. The catalyst consists of copper, zinc oxide and alumina serving as active ingredients, and the application of the catalyst in synthesizing dimethyl succinate is also disclosed. Meanwhile, the invention also discloses a method for synthesizing the dimethyl succinate. In the method, the dimethyl succinate is prepared by using monomethyl maleinate as raw material and by hydrogenation in the presence of the catalyst of the invention. Compared with a copper-based catalyst prepared by using traditional methods, the catalyst of the invention has the advantages of neater pore distribution, larger specific surface area, and excellent hydrogenation activity and selectivity, and the target product has the advantages of specific selectivity and good thermal stability. By using the new catalyst, the synthesis method of the invention overcomes the problems of high pressure and high cost and the like of the prior art, and has the advantages of simple process and easily controlled conditions and the like. Therefore, the synthesis method has a good industrial application prospect.

Owner:SHANGHAI HUAYI ENERGY CHEM

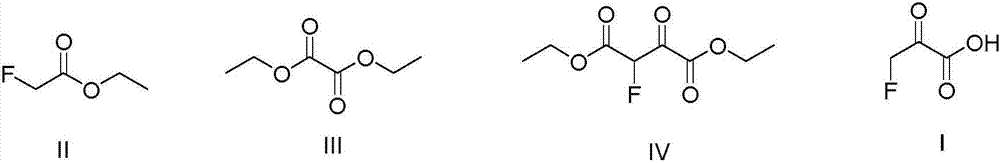

Preparing method of 3-fluoroacetone acid

ActiveCN107056606AThe reaction process conditions are simpleSimple and fast operationOrganic compound preparationCarboxylic acid esters preparationDistillationGas phase

The invention relates to a preparing method of 3-fluoroacetone acid. Diethyl oxalate and fluoro ethyl acetate are adopted as raw materials, NaH is adopted as a strong base catalyst to conduct an ester condensation reaction to obtain 2-fluo-3-oxo diethyl succinate, wherein the yield rate is 84.6%, and the gas phase chromatographic detection purity is 99.9%. 2-fluo-3-oxo diethyl succinate is put into an acid solution, and then through hydrolysis and decarboxylation reactions, and then through distillation and water removal, a coarse product is obtained, and finally through a sublimation method, 3-fluoroacetone acid is obtained, the yield rate is 85.4%, the liquid phase chromatographic detection purity is 99.9%, and the total yield through the two steps is 72%. The reaction technology is simple in condition, reactions are all conventional reactions under the normal pressure, the operation is simple and convenient, the raw materials are easy to obtain, and the product cost is low.

Owner:ZHEJIANG UNIV OF TECH

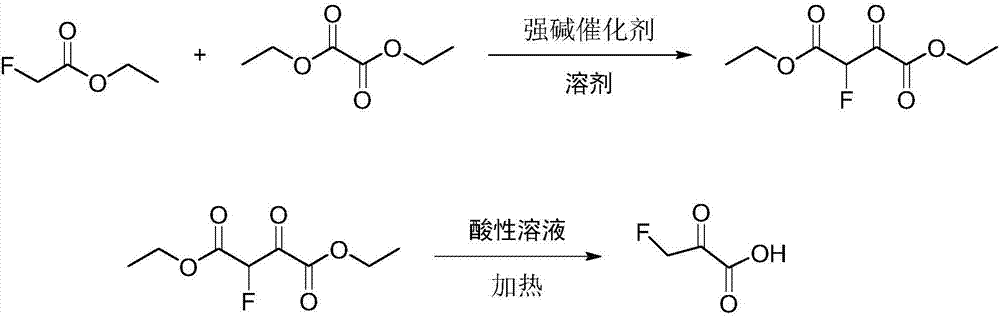

Fibroin shampoo and preparation method thereof

InactiveCN104622711AImprove performanceImprove heat resistanceCosmetic preparationsHair cosmeticsVitamin E AcetateGlycerol

The invention discloses a fibroin shampoo and a preparation method thereof. The shampoo comprises the following components: guar gum, octadecyl trimethyl ammonium chloride, hydroxyethyl cellulose, lecithin, glycerol, propylene glycol, fibroin, vitamin E acetate, essence, diethyl succinate, menthol and deionized water. The preparation method comprises the steps of adding the guar gum, hydroxyethyl cellulose, lecithin, propylene glycol, fibroin, vitamin E acetate, essence, diethyl succinate and menthol into a reactor, adding 30-40 weight parts of deionized water, stirring and mixing uniformly, and then heating and stirring to obtain a mixture I; adding the octadecyl trimethyl ammonium chloride and the glycerol into the mixture I, heating and stirring under vacuum, then adding the remaining deionized water, continuously stirring the mixture, and homogenizing with a high pressure homogenizer to obtain the fibroin shampoo. The shampoo has good stability and hair washing and nourishing performance.

Owner:WUXI CANMEI TECH

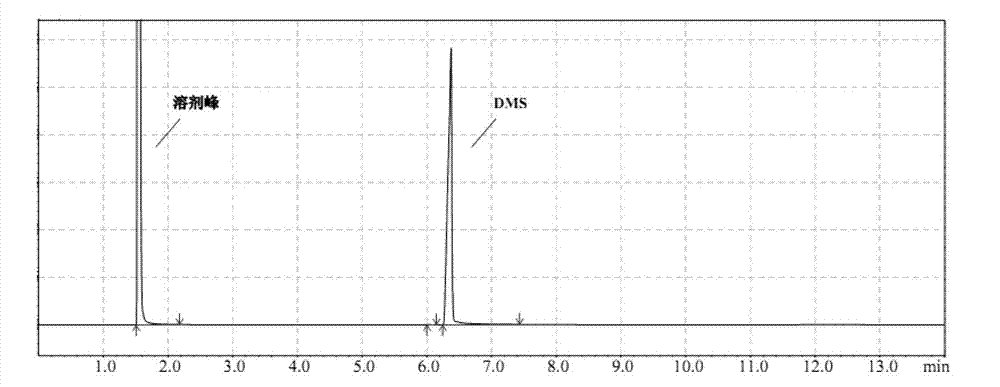

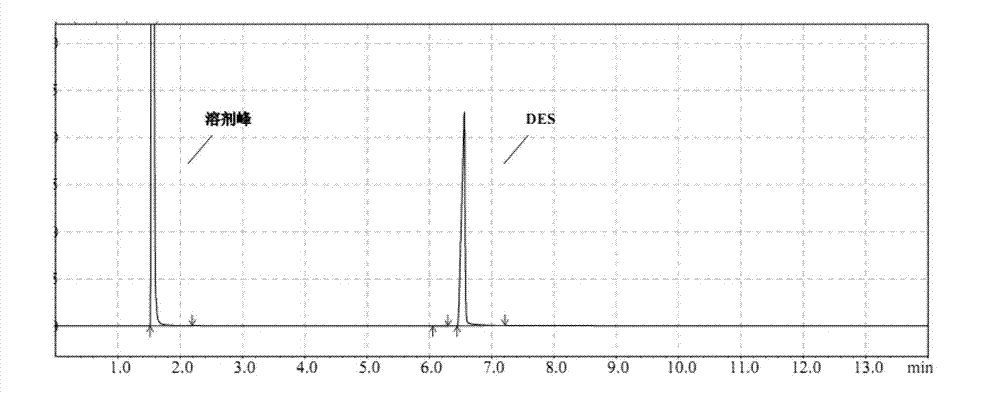

Method for determining dimethyl sulfate and diethyl sulfate in electronic and electric products

InactiveCN103592377AEasy to separateAccurate measurementComponent separationInjection volumeHplc method

The invention discloses a method for determining dimethyl sulfate and diethyl sulfate in electronic and electric products. The method comprises the following steps: adding a certain amount of acetone into a prepared sample, carrying out ultrasonic extraction to obtain the target compounds, deriving the target compounds with p-nitrophenol under alkaline conditions, extracting the derivation products with diethyl ether, and separating and detecting the ethyl ether extraction solution with a high performance liquid chromatography (HPLC) system. The chromatographic column uses an octadecyl bonded silica gel as the filler; the detector is a diode array detector; the mobile phase is a mixed solvent composed of 40-60 vol% of methanol and 60-40 vol% of water; the detection wavelength is 305nm; the column temperature is 40-60 DEG C; and the sample injection volume is 5-20 muL. After the systemic comparative studies, the invention establishes an HPLC method for determining contents of dimethyl sulfate and diethyl sulfate in electronic and electric products for the first time; and the method has the technical characteristics of favorable separating effect, high determination accuracy, high sensitivity, high specificity, simple and quick analysis and the like.

Owner:青岛谱尼测试有限公司

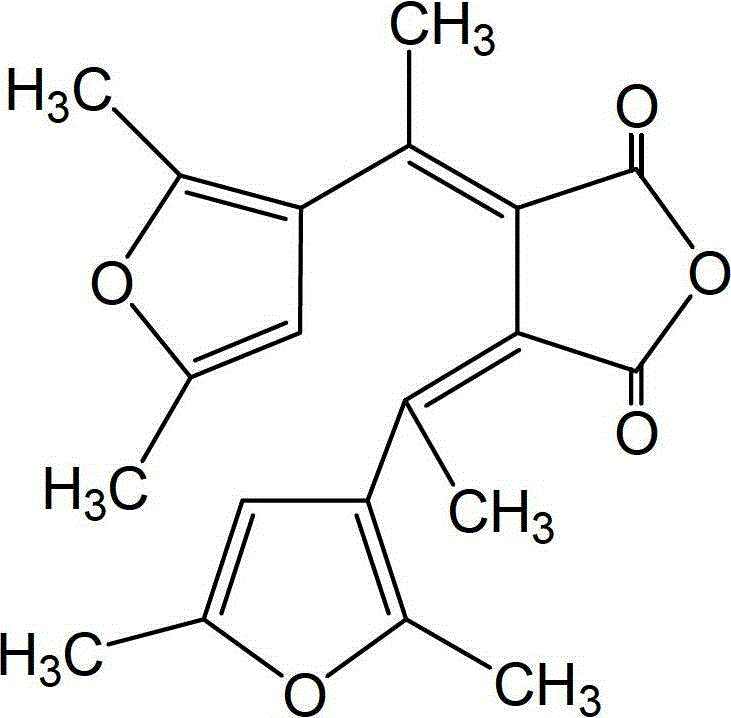

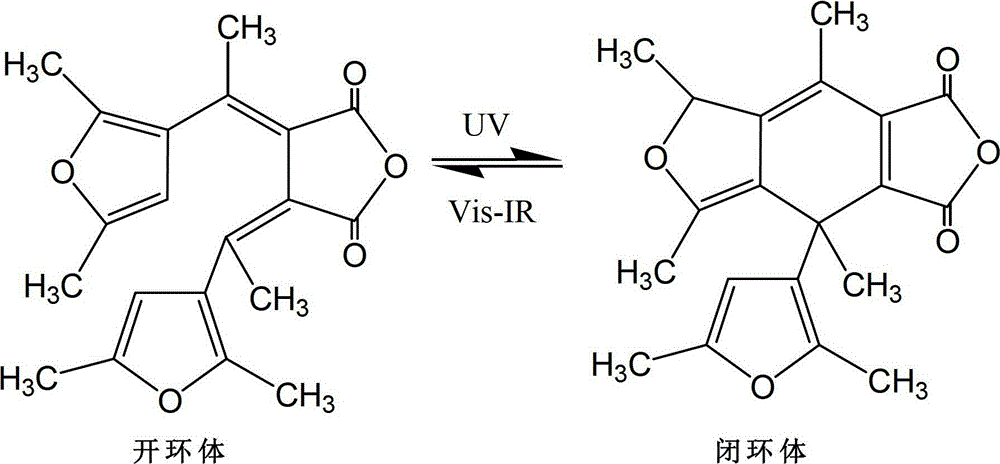

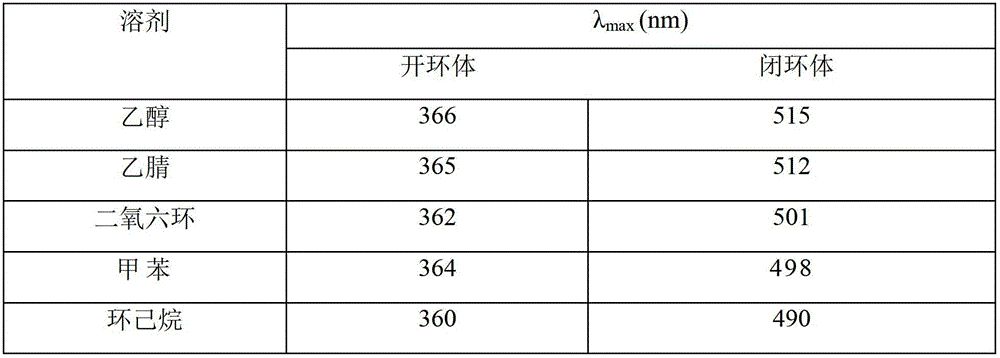

Synthetic method of dual-furan substituted fulgide photochromic compound

The invention relates to a synthetic method of dual-furan substituted fulgide photochromic compound, the method comprises the steps of taking potassium tert-butoxide as organic alkali; enabling 2, 5-dimethyl-3-acetylfuran and diethyl succinate to generate monoacid ester by Stobbe condensation reaction; then generating diester by methanol and acetylchloride; enabling diester and 2, 5-dimethyl-3-acetylfuran to generate monoacid ester by Stobbe condensation reaction; finally, saponifying the monoacid ester in alcohol solution of potassium hydroxide to obtain dual-acid; dewatering the dual-acid, obtaining dual-furan substituted fulgide. The dual-furan substituted fulgide photochromic compound can change into pink (closed loop body) from yellow (open loop body) in a solid or liquid state under irradiation of the ultraviolet light with wavelength of 360-370nm. Compared with the mono-furan substituted fulgide photochromic compound, the molecule of the furan substituted fulgide photochromic compound has two functional groups capable of cyclization reaction, which better facilitates photochromism.

Owner:浙江阿克迈新材料有限公司

Method used for preparing diethyl sulfate

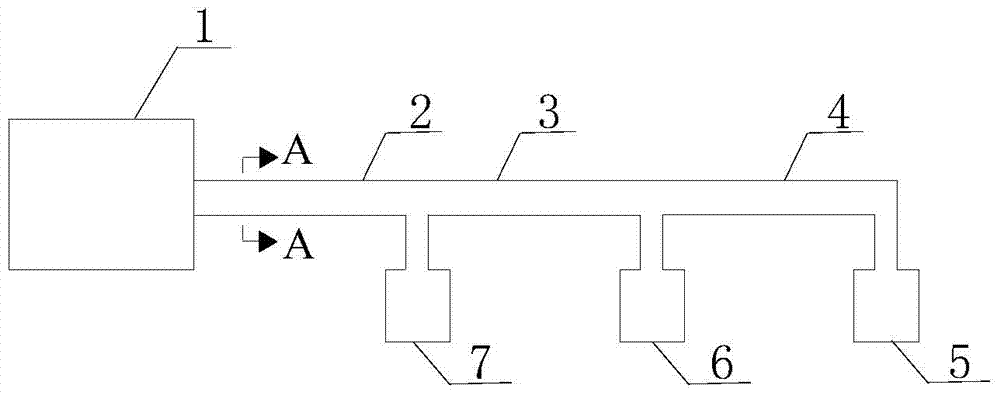

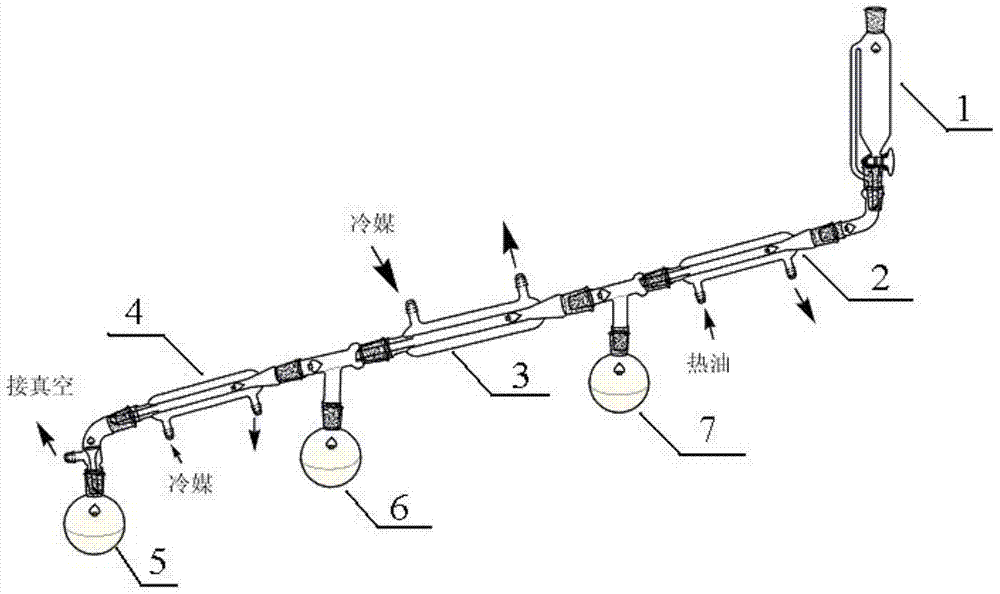

ActiveCN104774162AIncrease evaporation areaHigh yieldOrganic compound preparationSulfuric acid esters preparationHydrogen SulfateReactive distillation

The invention provides a method used for preparing diethyl sulfate. According to the method, a mixed solution containing ethyl hydrogen sulfate and / or diethyl sulfate is delivered through reaction distillation surface at a certain temperature, and at the same time, reduced pressure distillation is carried out, so that diethyl sulfate in the mixed solution and generated on the reaction distillation surface is separated rapidly, waste sulfuric acid in the mixed solution and generated on the reaction distillation surface is collected in a waste liquid collector, and ethanol is collected in a tail gas collector. Recycling of waste sulfuric acid and collected ethanol can be realized; the method is low in cost; and no waste acid is discharged.

Owner:TAIAN HAVAY CHEM

Preparation method of mitiglinide calcium

InactiveCN103450069AFew reaction stepsShort reaction timeOrganic chemistryChemical recyclingButanedioic acidPtru catalyst

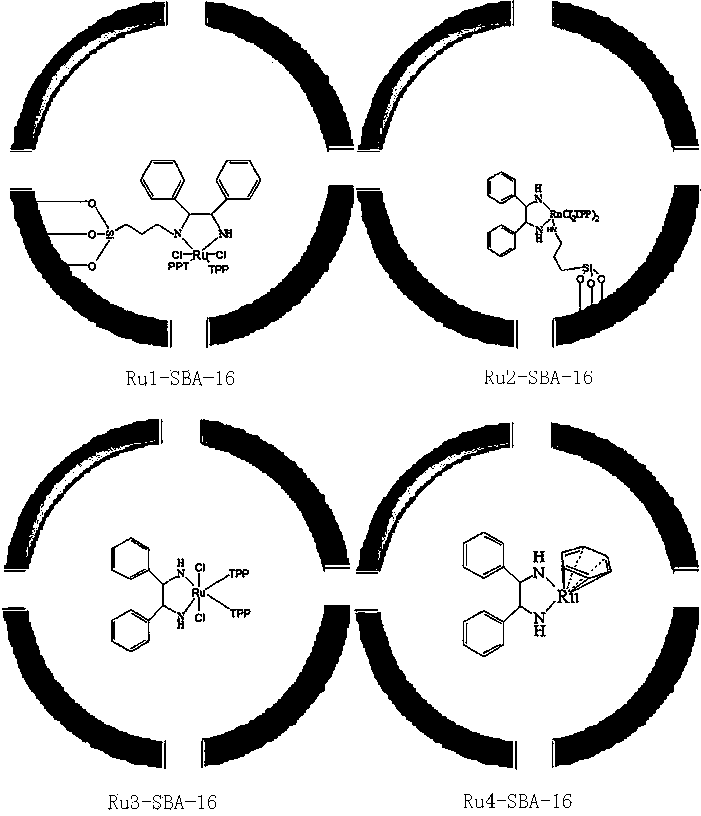

The invention discloses a preparation method of mitiglinide calcium. The preparation method comprises the following steps: (I) by taking diethyl succinate and benzaldehyde as raw materials, carrying out a reaction in a sodium ethoxide solution, and then, under the action of a multiphase asymmetric catalyst Ru-SBA-16, carrying out asymmetric hydrogenation to obtain a (S)-2-benzylsuccinic acid; (II) reacting the (S)-2-benzylsuccinic acid with perhydro-isoindole so as to generate mitiglinide; and (III) complexing the mitiglinide and calcium chloride so as to obtain a target compound mitiglinide calcium. According to the method, the reaction steps can be reduced, the reaction time can be shortened, and the chiral purity of mitiglinide calcium can be improved.

Owner:SHANXI DATONG UNIV

Aluminium alloy surface acid degreasing agent

The invention discloses an aluminium alloy surface acid degreasing agent which is characterized by comprising the following components in part by weight: 25 to 35 parts of concentrated sulphuric acid, 3 to 5 parts of sodium dodecyl sulfate, 0.1 to 2 parts of diethyl succinate sodium sulfonate and 1,000 parts of water. The aluminium alloy surface acid degreasing agent can be used for an acid pretreatment tank of products such as an aluminium section, an aluminium alloy and the like, has strong effects of removing oil stain and removing oxide, has slight corrosion to an aluminium base and has good gloss. The aluminium alloy surface acid degreasing agent can be operated at normal temperature, energy is saved and the acid mist overflowing and the acid pickle discharge are reduced, so that the damage to human bodies and the pollution to the environment are reduced in the production link.

Owner:CHONGQING WANLI LIANXING IND GROUP

Sepiolite-fiber-added compound waterborne coating for outer wall and manufacturing method of coating

The invention discloses a sepiolite-fiber-added compound waterborne coating for an outer wall. The coating is characterized by being made from the following raw materials, by weight part, 26-29 of a VAE emulsion, 11-14 of a wax emulsion, 1-2 of an aziridine cross-linking agent, 3-4 of calcium-magnesium powder, 1-2 of sodium diethyl succinate sulfonate, 8-10 of maifan stone, 2-4 of fluorinated graphite, 3-4 of ceramic cellucotton, 3-5 of sepiolite fibers, 0.3-0.5 of sodium fluoride, 6-8 of modified round-grained mortar and 25-30 of water. The formula is scientific and reasonable; through cooperation of the VAE emulsion with the aziridine cross-linking agent, the viscosity and water resistance of the coating is improved; through addition of sepiolite fibers, the coating has an excellent absorption effect and high temperature resistance and the coating film is not prone to crack; and through addition of the modified round-grained mortar which is light in weight and good in dispersion, the brightness, viscosity and strength of the coating is improved. The coating can meet different decoration requirements.

Owner:HEXIAN MINGSHENG ENVIRONMENTAL PROTECTION MATERIAL

Antibacterial coating material additive and preparation method thereof

InactiveCN106560492AImprove water resistanceHigh hiding powerAntifouling/underwater paintsPaints with biocidesEpoxySilanes

The present invention discloses an antibacterial coating material additive and a preparation method thereof. The coating material additive comprises the following raw materials by weight: 33-45 parts of maifanite, 20-28 parts of tourmaline, 5-10 parts of silver ion, 1-5 parts of polyurethane, 5-10 parts of sodium sulfonate diethyl succinate, 1-5 parts of diphenyl dihydroxy silane, 1-3 parts of epoxy sodium carboxymethylcellulose, 10-17 parts of titanium dioxide, and 40-50 parts of water. The preparation method comprises: mixing the raw materials excluding silver ions, carrying out ball milling, adding water to the powder obtained after the ball milling, heating to a temperature of 45 DEG C, carrying out sealed stirring, adding the silver ions, continuously carrying out sealed stirring, and cooling to a room temperature to obtain the product. According to the present invention, after the antibacterial coating material additive is added to an aqueous coating material, the obtained aqueous coating material has advantages of good water resistance, high hiding power and scrub resistance, and has effects of oxygen ion releasing and sterilizing; and the antibacterial coating material additive further can be used in the ceramic tile field, and further has effects of oxygen ion releasing, sterilizing and environmental pollution reducing, wherein the performance of the ceramic tile can be improved, the concave-convex texture of the ceramic tile is clear, the three-dimensional effect of the ceramic tile is strong, the ceramic tile body is effectively protected, and the gloss is enhanced.

Owner:赖永建

Glass fiber yarn composite material and preparation method thereof

The invention discloses a glass fiber yarn composite material and a preparation method thereof. The glass fiber yarn is composed of the following raw materials in parts by weight: 50 parts of glass fiber, 8 parts of polyacrylamide, 10 parts of tolyltriazole, 6 parts of aminopropyltrioxysilane, 2-6 parts of sodium tetraborate, 2-8 parts of sulfamic acid, 3-9 parts of diethyl succinate, 4-12 parts of glycerol, hydroxyethylidene diphosphine 4‑8 parts of acid. Under the synergistic effect of various raw materials, the present invention has high strength, large elastic modulus, high tensile strength, high temperature resistance, good tensile resistance, good impact resistance, and good chemical stability compared with ordinary alkali-free glass fibers. Good fatigue resistance and high performance. At the same time, the invention not only has reasonable formula components, stable performance, simple and easy-to-operate process, high production efficiency, but also can improve the toughness of glass fiber, is not easy to break, has good water blocking effect, and low production cost. , suitable for industrial production.

Owner:旌德县源远新材料有限公司

Method for preparing 2-(1-methylalkyl) succinic acid

ActiveCN103980108AMild reaction conditionsFew reaction stepsOxygen-containing compound preparationOrganic compound preparationTricarboxylic acidCarbon chain

The invention discloses a method for preparing a 2-(1-methylalkyl) succinic acid. The method comprises the following steps: (1) producing 1,1,2-ethane tricarboxylic acid triethyl ester from ethyl bromoacetate and diethyl malonate by condensation reaction; (2) producing 3-methyl alkane-1,1,2-tricarboxylic acid triethyl ester from the 1,1,2-ethane tricarboxylic acid triethyl ester and 2-bromoalkane; (3) mixing 3-methyl alkane-1,1,2-tricarboxylic acid triethyl ester with LiCl / H2O, heating and carrying out decarboxylation to obtain 2-(1-methylalkyl) diethyl succinate; and (4) hydrolyzing the 2-(1-methylalkyl) diethyl succinate in a strong alkali solution to obtain the 2-(1-methylalkyl) succinic acid. The method is wide in reaction material source, low in price, mild in reaction condition, complete in reaction, and less in side reaction, and a 2-(1-methylalkyl) succinic acid homologous compound of which the alkyl carbon chain is 3-16 carbons in length can be prepared.

Owner:EAST CHINA UNIV OF SCI & TECH

Synthetic method of plant growth regulator trinexapac-ethyl intermediate 3-carbethoxy-5-oxo-cyclohexane-1-enol cyclopropanecarboxylate

ActiveCN102911058BNo purification requiredShort reaction timeOrganic compound preparationCarboxylic acid esters preparationKetoneSodium salt

The invention provides a synthetic method of plant growth regulator trinexapac-ethyl intermediate 3-carbethoxy-5-oxo-cyclohexane-1-enol cyclopropanecarboxylate. The synthetic method comprises the following steps: (1) carrying out annulation reaction on 2-acetonyl-1,4-diethyl succinate and organic alkaline at the temperature of 20-120 DEG C for 0.5-5 hours in a non-polarity organic solvent to obtain 3,5-cyclohexanedione-1-ethyl formate; and (2) adding organic amine and cyclopropanecarboxylic acid chloride, and carrying out acylation reaction at the temperature of minus 5-50 DEG C, so as to obtain 3-ethoxycarbonyl-5-oxo-cyclohexane-1-enol cyclopropanecarboxylate in the presence of micromolecular alcohol, ether, ketone and nitrile the carbon atoms of which are below C8 and are used as additives. According to the method, special additives are added before acylation so that cyclopropanecarboxylic acid chloride can directly react with intermediate-state 3-ethoxycarbonyl-5-oxo-cyclohexane-1-enol sodium salt to obtain the trinexapac-ethyl precursor 3-ethoxycarbonyl-5-oxo-cyclohexane-1-enol cyclopropanecarboxylate, thereby shortening reaction time, simplifying synthesis process and improving yield; and the product is directly rearranged without purification so as to obtain the final product trinexapac-ethyl.

Owner:JIANGSU YOUJIA CHEM +1

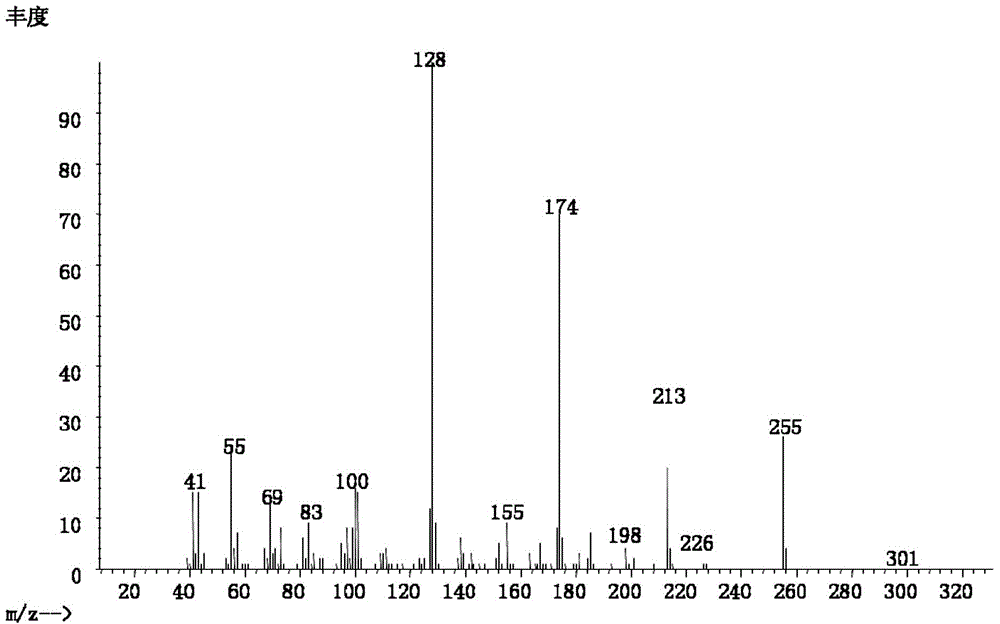

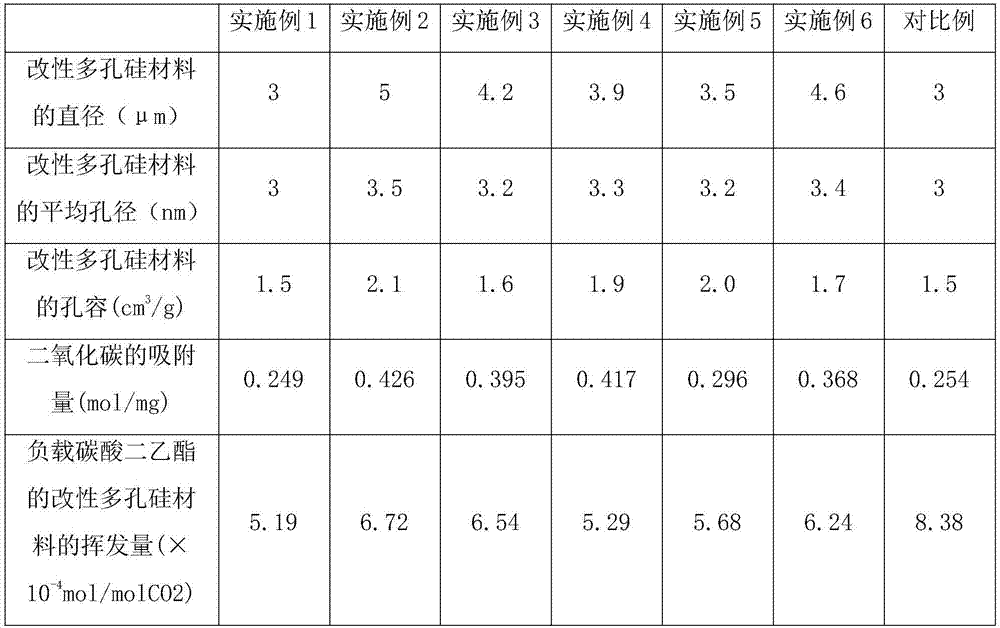

Preparation method of modified porous silicon material loaded with diethyl succinate and application thereof to carbon dioxide capturing and sealing storage

InactiveCN107469777AIncrease the areaHigh pore volumeGas treatmentOther chemical processesSilicic acidSuccinic acid

The invention provides a preparation method of a modified porous silicon material loaded with diethyl succinate and application thereof to carbon dioxide capturing and sealing storage. The preparation method concretely comprises the following steps of adding polyoxyethylene and magnesium chloride into a hydrochloric acid water solution; performing sealed stirring to complete dissolution; adding tetraethoxysilane; performing heating stirring at 40 to 50 DEG C; performing vacuum drying at 100 DEG C; performing natural cooling, filtering and washing; performing sintering for 450 to 600 DEG C to obtain the modified porous silicon material; adding ethanol into the mixture of the diethyl carbonate and diethyl succinate; after the uniform mixing, adding the modified porous silicon material; performing ultrasonic treatment; performing stirring backflow for 2h at 80 DEG C; performing water bath processing at 70 DEG C until the ethanol is completely volatilized; obtaining the modified porous silicon material loaded with diethyl succinate. According to an application method, in heating and pressurizing environment, raw materials containing carbon dioxide and the modified porous silicon material loaded with the diethyl succinate are subjected to reverse flow contact to generate absorption mass transfer; then, temperature reduction and pressure reduction are performed for gas liquid separation.

Owner:DONGGUAN LIANZHOU INTPROP OPERATION MANAGEMENT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com