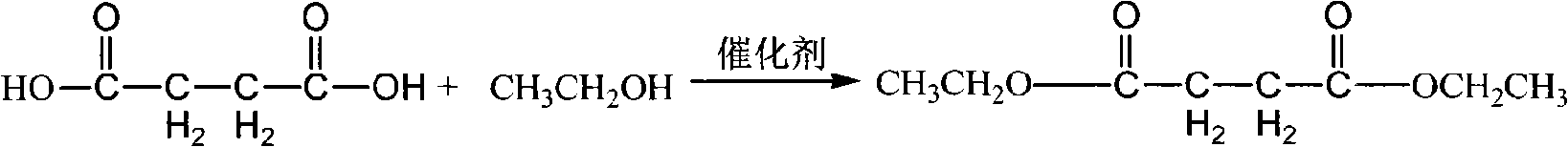

Preparation method of diethyl succinate

A technology of diethyl succinate and succinic acid, which is applied in the field of preparation of diethyl succinate, can solve the problems of difficulty in popularization and application, harsh reaction conditions, and high equipment requirements, and achieve environmental protection and mild control conditions , the effect of easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Raw materials and dosage: 1000 kg of succinic acid, 950 kg of industrial ethanol (95% ethanol content), 100 kg of absolute ethanol, 15 kg of solid super acid phosphotungstic acid.

[0040] According to succinic acid, 20% of the total amount of methanol and solid acid, the temperature is raised to 120 ° C, wherein the ethanol feed pipe is passed under the liquid level at the bottom of the kettle, so that the ethanol alcohol stays in the reactant for a long time, the distribution effect is good, and the ethanol is increased. utilization rate. Continuously feed remaining ethanol (80% of the total amount) in about 8 hours to maintain the kettle temperature at 115-120° C., and the top temperature is less than 105° C. Sampling was taken to measure the acid value, the acid value was 42mgKOH / g, the industrial ethanol was stopped, and absolute ethanol was introduced, and the acid value was detected to be 12.5mgKOH / g after one hour, and the absolute ethanol was stopped. In the e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com