Patents

Literature

36results about How to "Fast descaling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

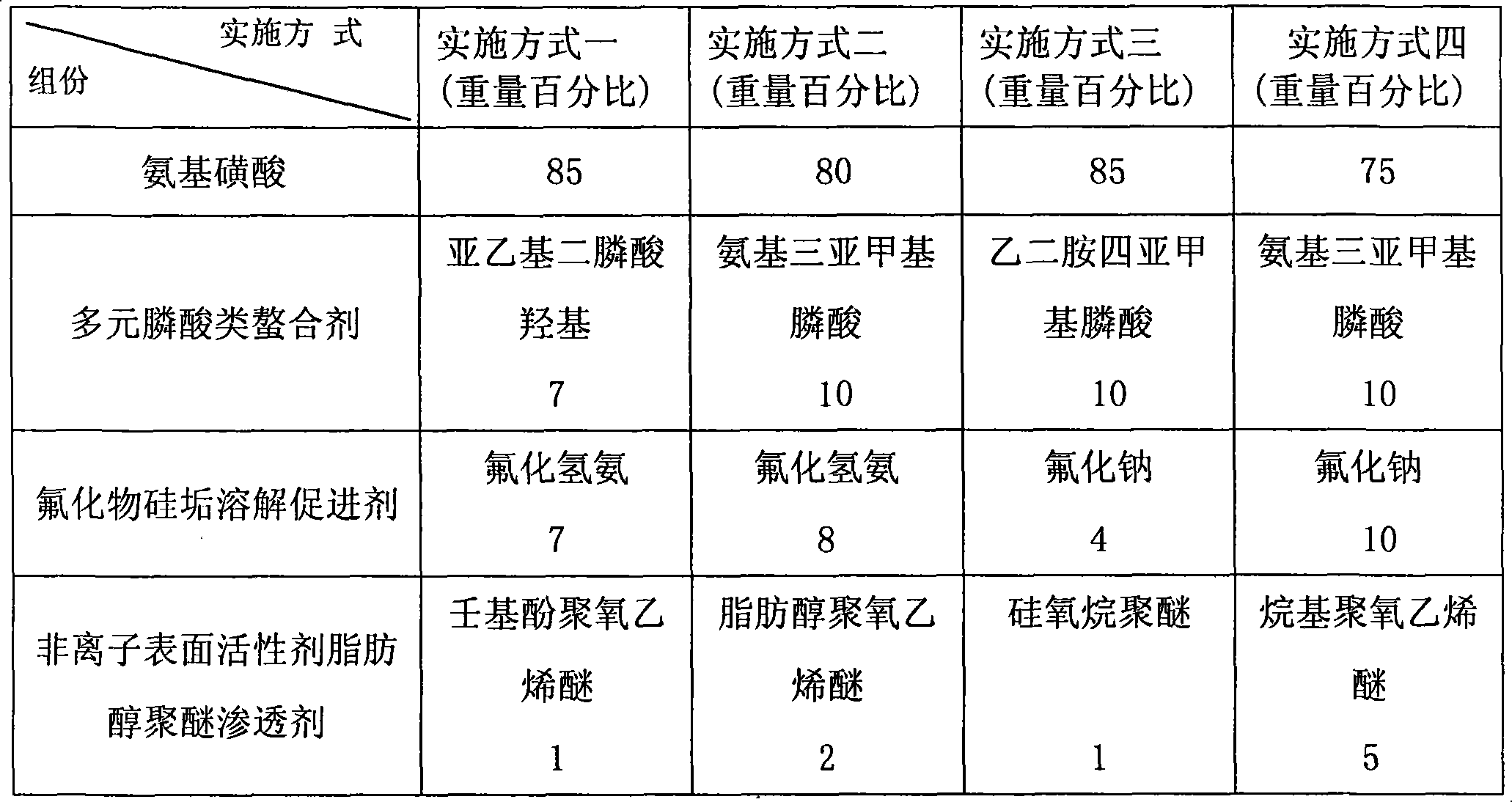

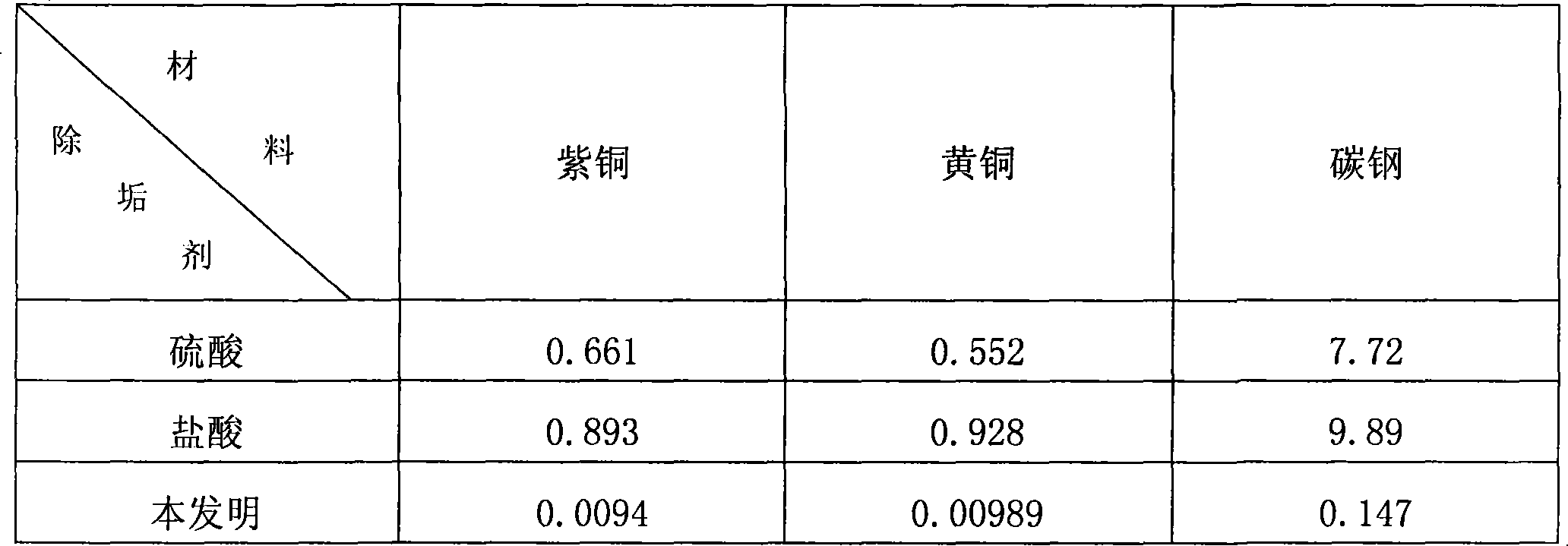

Descaling agent for cleaning central air conditioner main machine

InactiveCN101086065ASolve cleaning problemsStrong acidity of solid organic acidPolyesterHexamethylenetetramine

The invention relates to a scale and rust remover used for cleaning main frame of central air-conditioner. It is characterized in that it comprises solid mixture and liquid inhibitor; said solid mixture comprises amidosulfonic acid, polyphosphinic acid chelating agent, silicofluoride scale and rust dissolution promotor, non-ionic surface activator aliphatic alcohol polyester penetrant, their weight proportions in order are as follows: 75%-85%, 5%-10%, 5%-10%, 1%-5%; said inhibitor is liquid and comprises hexamethylene tetramin, aniline and methyl azimido-benzene according to weight proportion of 2: 2: 1. Said inhibitor is added into acidic washing solution with its weight amount being 0.3% of that of water amount. The product can dissolve carbonate, silicate, sulfate and iron oxide, the descaling speed at room temperature is fast, and is increased within 60 Deg. C, the corrosive rate to metal is pretty low, and there is no acid mist and harmful gas generation during desaling process.

Owner:长沙科惠洁水质处理服务有限公司

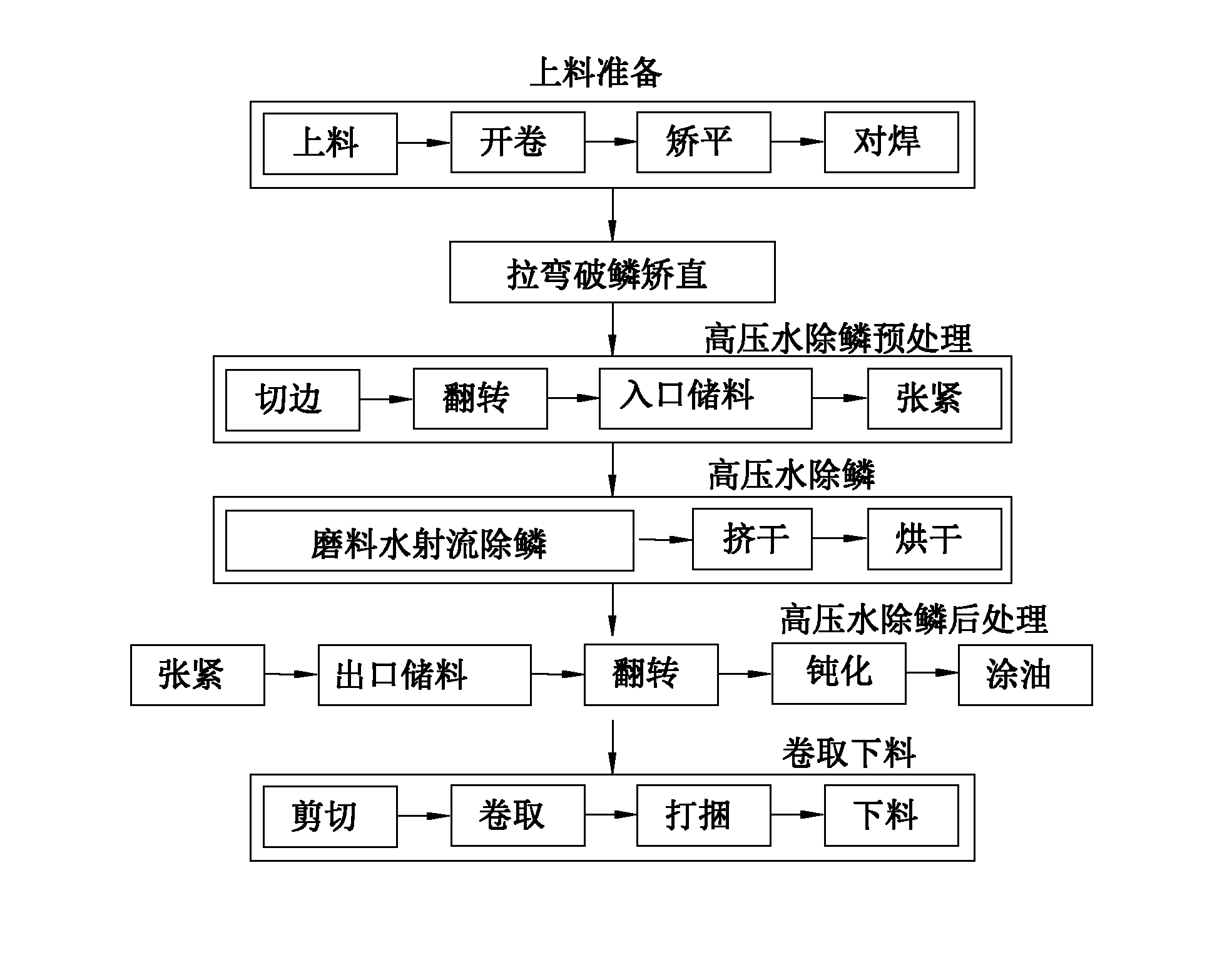

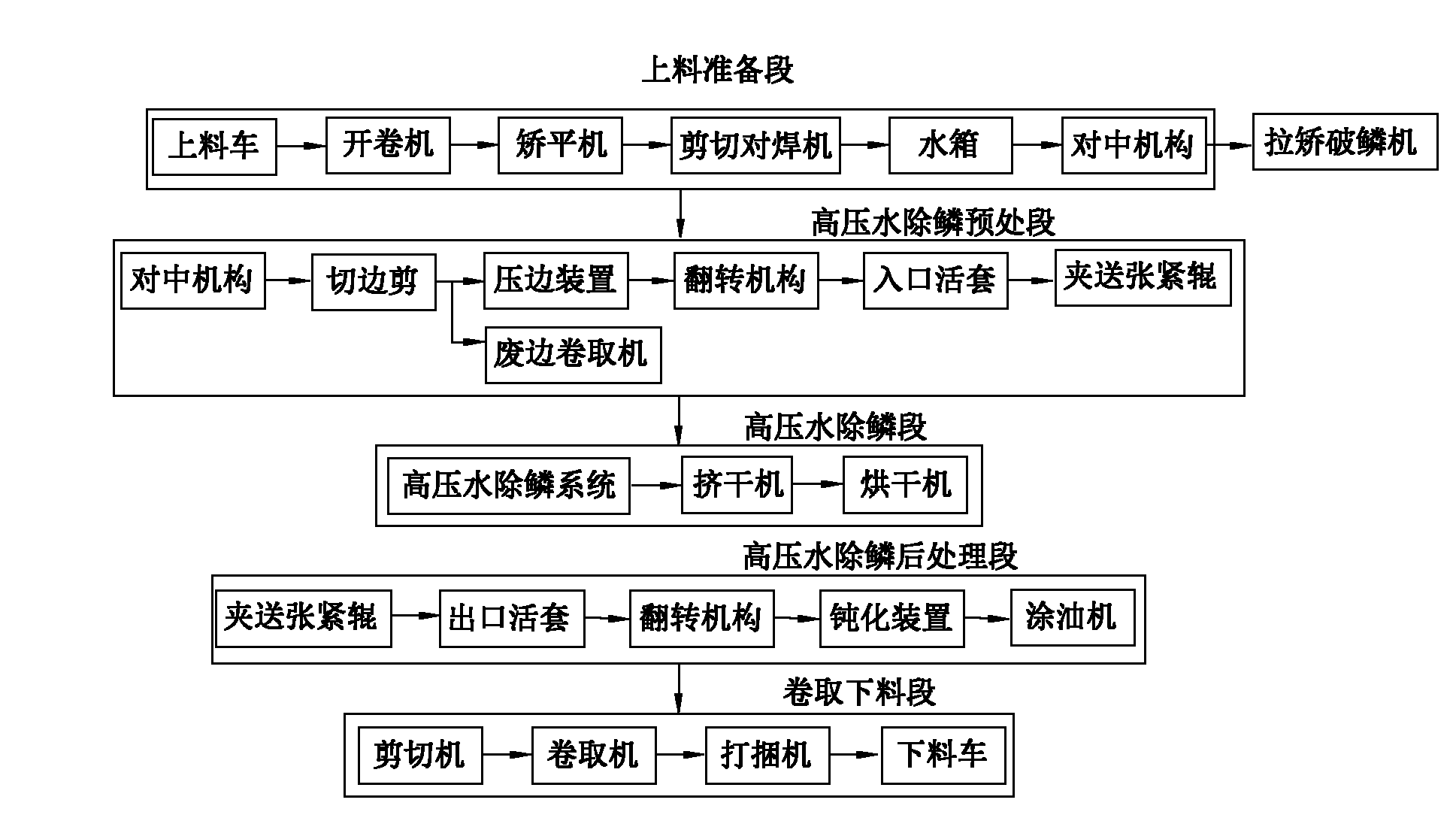

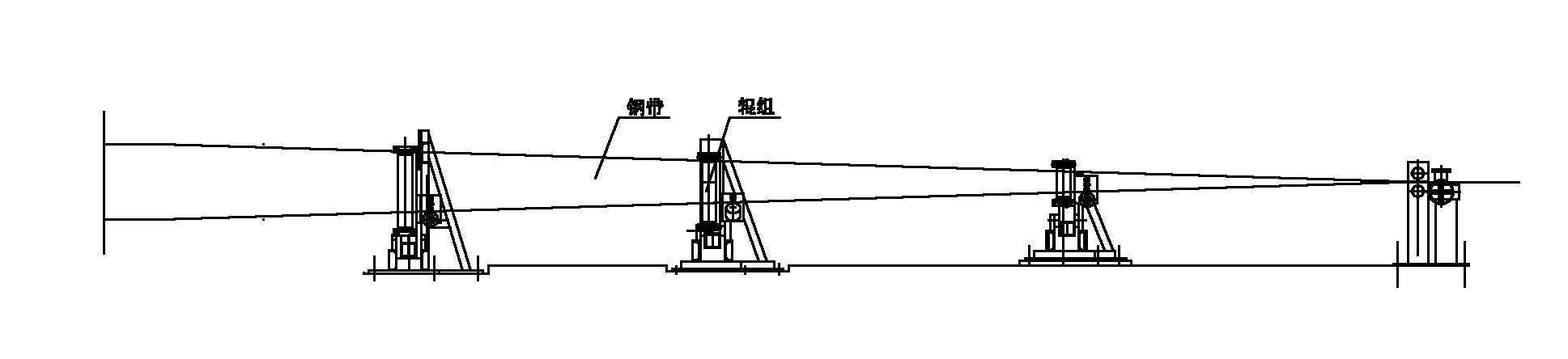

Cold-state stainless steel band or plate descaling process

InactiveCN102836890ANo damageNo pollution in the processWork treatment devicesMetal rolling arrangementsAcid washingHigh pressure water

The invention discloses a cold-state stainless steel band or plate descaling process, which mainly and sequentially comprises the following six process steps of: preparing for feeding; performing stretch bending, scale breaking and straightening; performing high-pressure water descaling pretreatment; performing high-pressure water descaling; performing high-pressure water descaling post-treatment; and coiling. According to the cold-state stainless steel band or plate descaling process, after the former two treatment steps are performed, the steel band or plate is turned from a horizontal state into a vertical state, then subsequent two processes are performed, and the steel band or plate is turned into the horizontal state and the subsequent treatment processes are performed. The cold-state stainless steel band or plate descaling process is combined application of a stainless steel acid washing continuous descaling process and a high-pressure water descaling system in the prior art, and continuous descaling production of an abrasive high pressure water jet descaling technology on the cold-state stainless steel band or plate is realized. Compared with the conventional stainless steel acid washing descaling process, a shot blasting step and an acid washing step are reduced, the abrasive high pressure water jet descaling technology is adopted, the descaling speed and the efficiency are high, the effect is good, no damage is caused to the surface of the stainless steel band or plate, and the environment is not polluted.

Owner:HUNAN NONFERROUS HEAVY MACHINERY

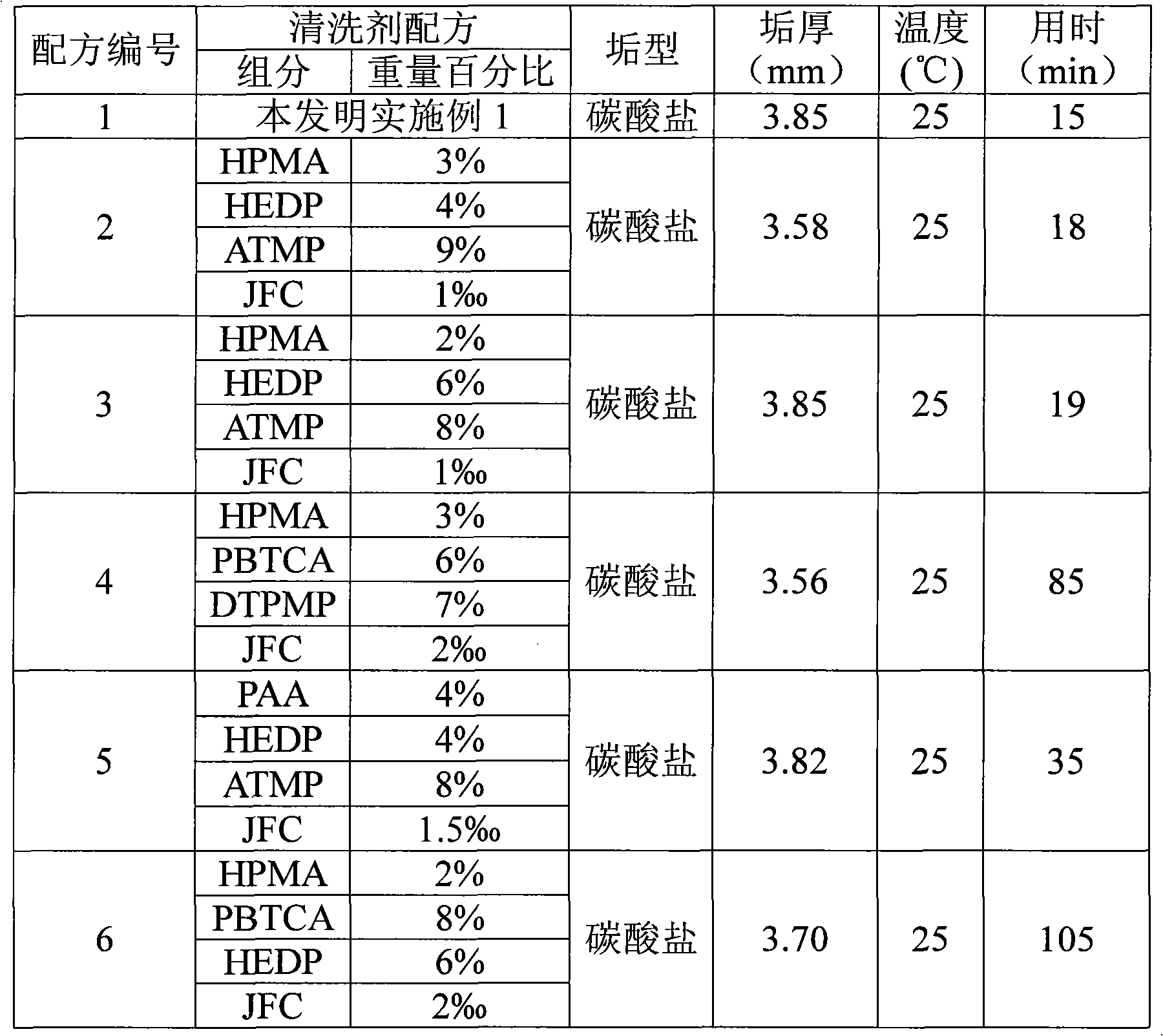

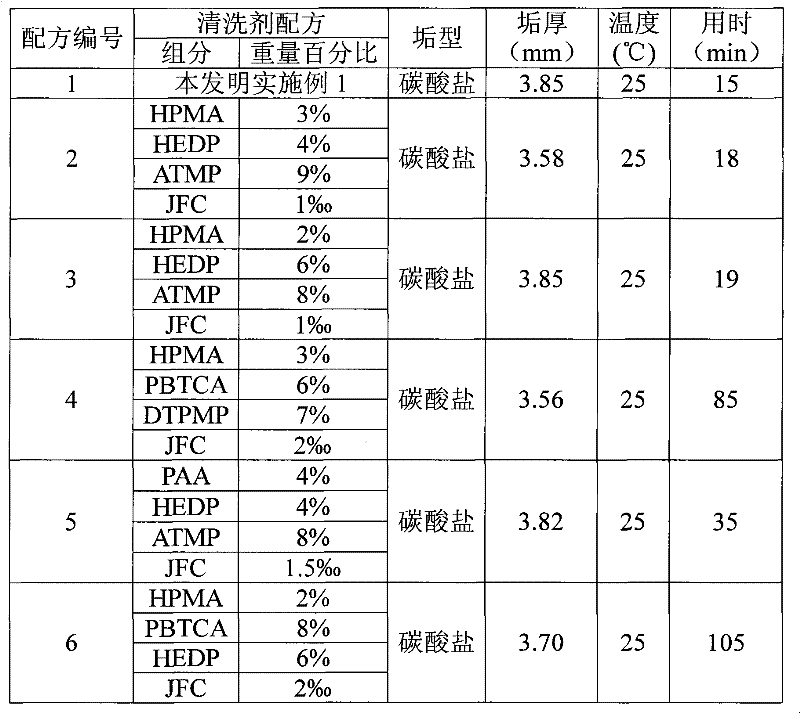

Organic descaling composition, preparation method and application thereof

ActiveCN101565660AStrong chelationGood dispersionHollow article cleaningOrganic non-surface-active detergent compositionsReaction speedCleansing Agents

The invention provides an organic descaling composition, which includes an organic cleaning agent and a corrosion inhibitor CM-911, and the weight ratio of the organic cleaning agent and the corrosion inhibitor is 100:0.1-0.3. The organic cleaning agent includes the follow components by weight: 1%-15% of maleic acid-crylic acid copolymer (MA-AA), 1%-25% of 1-hydroxyethylidene-1,1-diphosphonic acid (HEDP), 2%-30% of amino trimethylene phosphonic acid (ATMP), 0.03%-0.5% of penetrating agent JFC and balance of water. The organic descaling agent provided by the present invention has advantages of fast reaction speed, small corrosivity for material and high descaling efficiency.

Owner:河南伯淼水处理有限公司

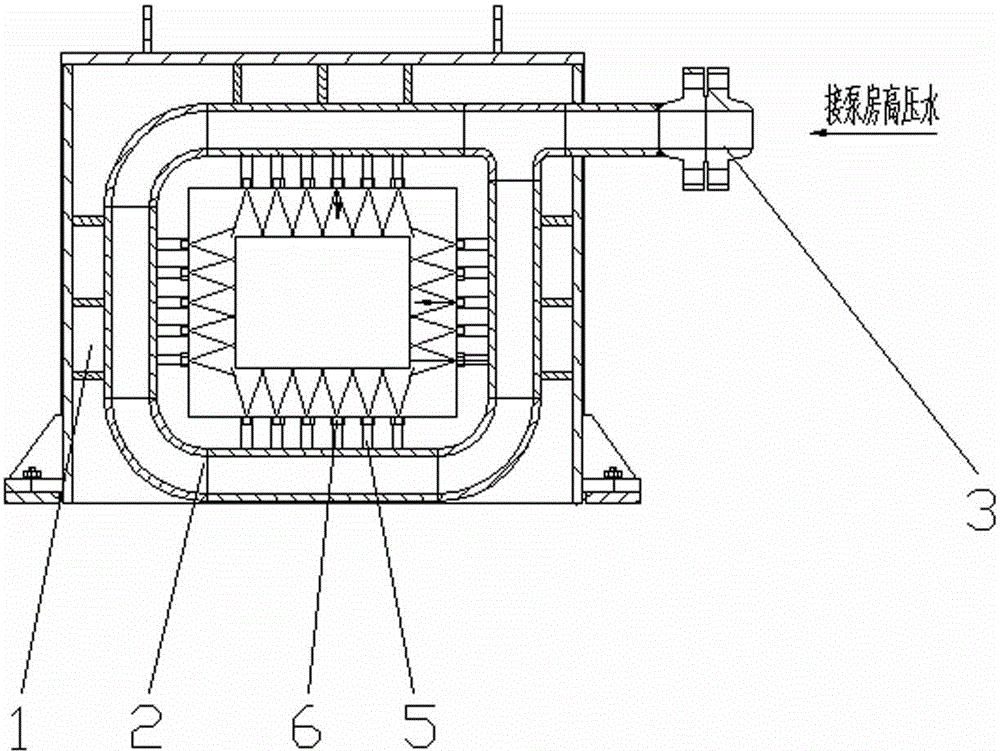

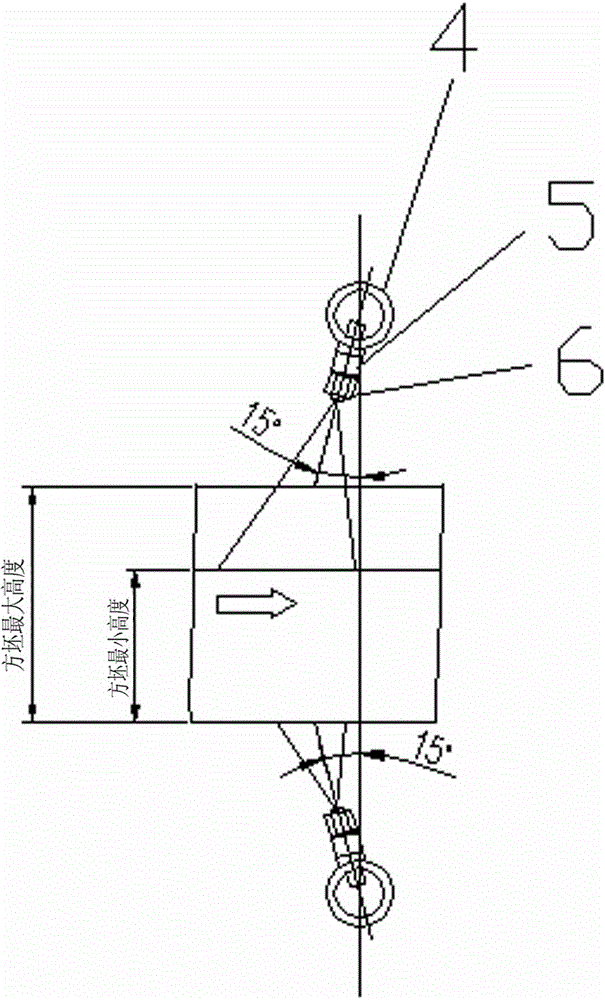

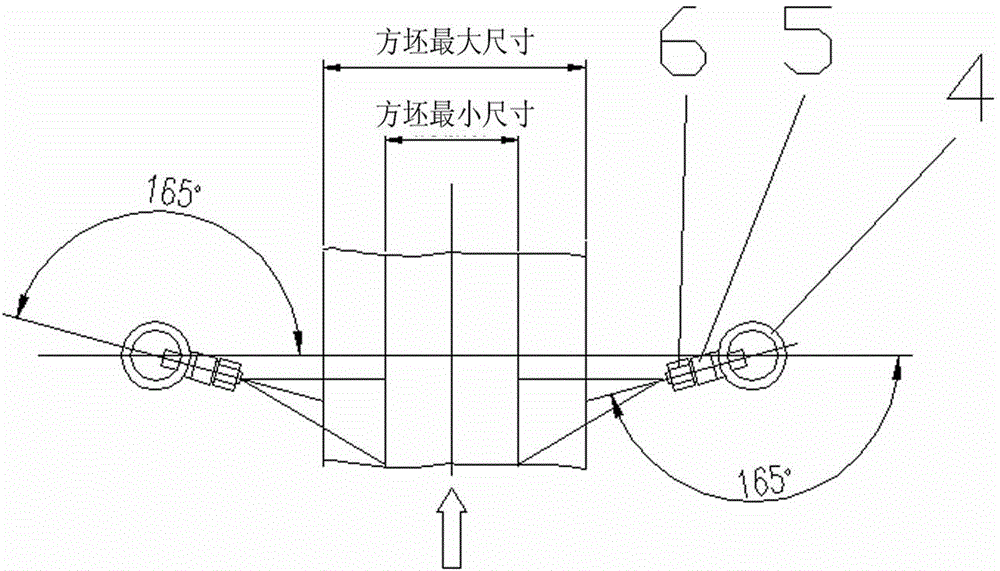

Efficient descaling method for square billets

InactiveCN104801555AEfficient descalingFast descalingWork treatment devicesMetal rolling arrangementsRing deviceWater source

The invention relates to an efficient descaling method for square billets. The efficient descaling method comprises a descaling ring device selective adaptability method and a descaling nozzle selective adaptability method. According to the efficient descaling method, the problem that the conventional square billet scaling ring is incapable of descaling thoroughly can be solved; meanwhile, the problems that nozzles on two sides idly spray water and the water source is wasted can also be avoided; efficient descaling can be conducted on all different-sized billets. The efficient descaling method is convenient to use, thorough in descaling, energy-saving, environmental-friendly and the like.

Owner:SGIS SONGSHAN CO LTD

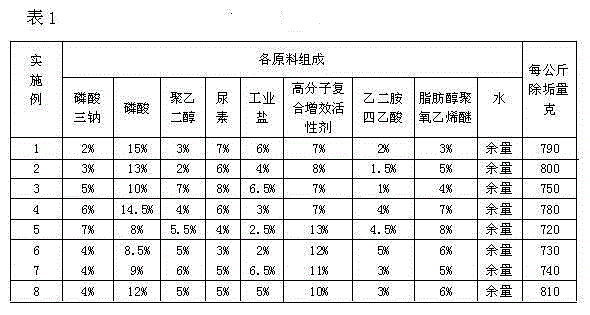

Environment-friendly multi-purpose descaling liquid

The invention discloses environment-friendly multi-purpose descaling liquid. The environment-friendly multi-purpose descaling liquid is used for removing water scales, oil scales, dirt and urine scales, and the key is that the environment-friendly multi-purpose descaling liquid is prepared from the following raw materials in percentage by weight: 2-7% of trisodium phosphate, 8-15% of phosphoric acid, 2-7% of polyethylene glycol, 3-8% of urea, 2-7% of industrial salt, 7-13% of a polymer composite synergistic active agent, 1-5% of ethylene diamine tetraacetic acid, 3-8% of fatty alcohol polyoxyethylene ether and the balance of water. The multi-purpose descaling liquid can rapidly remove the scales and has the advantages of good descaling effect, no irritation and no harm to human bodies, safety, no toxicity and no environmental pollution.

Owner:石家庄正仁环保科技有限公司

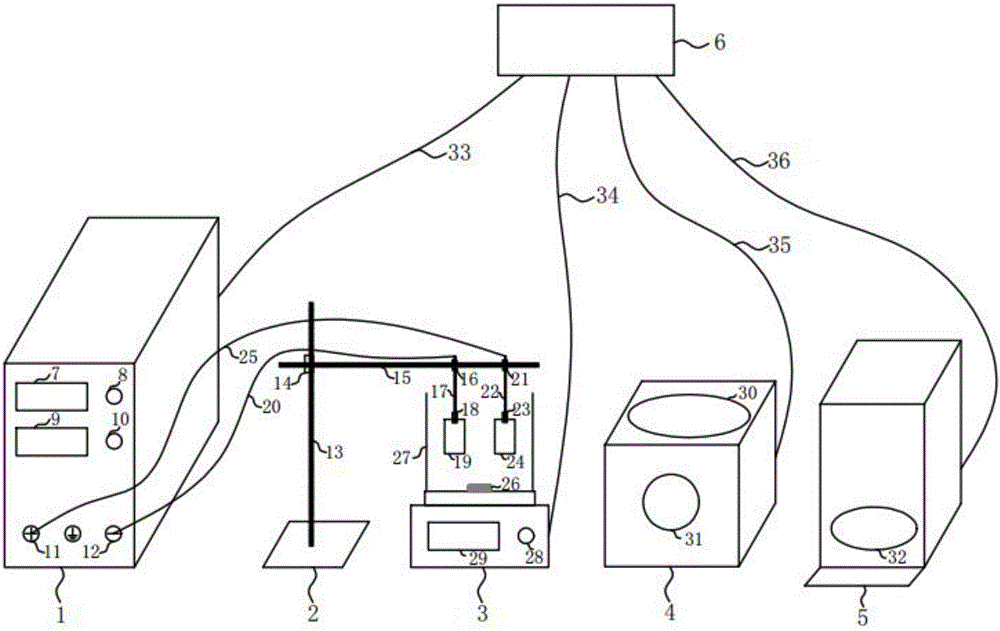

System and method for measuring scale amount of furnace tube of boiler of thermal power plant

PendingCN107525061ALow blank lossAvoid damageBoiler indication operationsBoiler cleaning apparatusBoiler furnaceMegasonic cleaning

The invention relates to a system and a method for measuring a scale amount of a furnace tube of a boiler of a thermal power plant, wherein the system comprises an electrolytic stripping and descaling device, an ultrasonic cleaner for degreasing the furnace tube of the boiler before and after descaling and an electronic scale for weighing the masses of the furnace tube of the boiler before and after descaling; the electrolytic stripping and descaling device comprises a direct current electrolyser and an electrolytic tank accommodating an electrolytic stripping agent; the direct current electrolyser comprises a cathode and an anode which are separately connected to a platinum electrode and the furnace tube of the boiler; the platinum electrode and the furnace tube of the boiler are arranged in the electrolytic tank; direct current electrolysis is performed under the action of the electrolytic stripping agent to strip scales on the furnace tube of the boiler. The system provided by the invention has the technical effects of being high in descaling speed, short in consumed time and low in blank wastage of a matrix metal; damage on the matrix metal of the furnace tube is very small and blank correction is not performed commonly; the matrix can keep the original shape of the furnace tube under scales; and the system and method are quite beneficial for observing the corrosive shape of the metal under the scales of the furnace tube of the boiler.

Owner:DATANG DONGBEI ELECTRIC POWER TESTING & RES INST

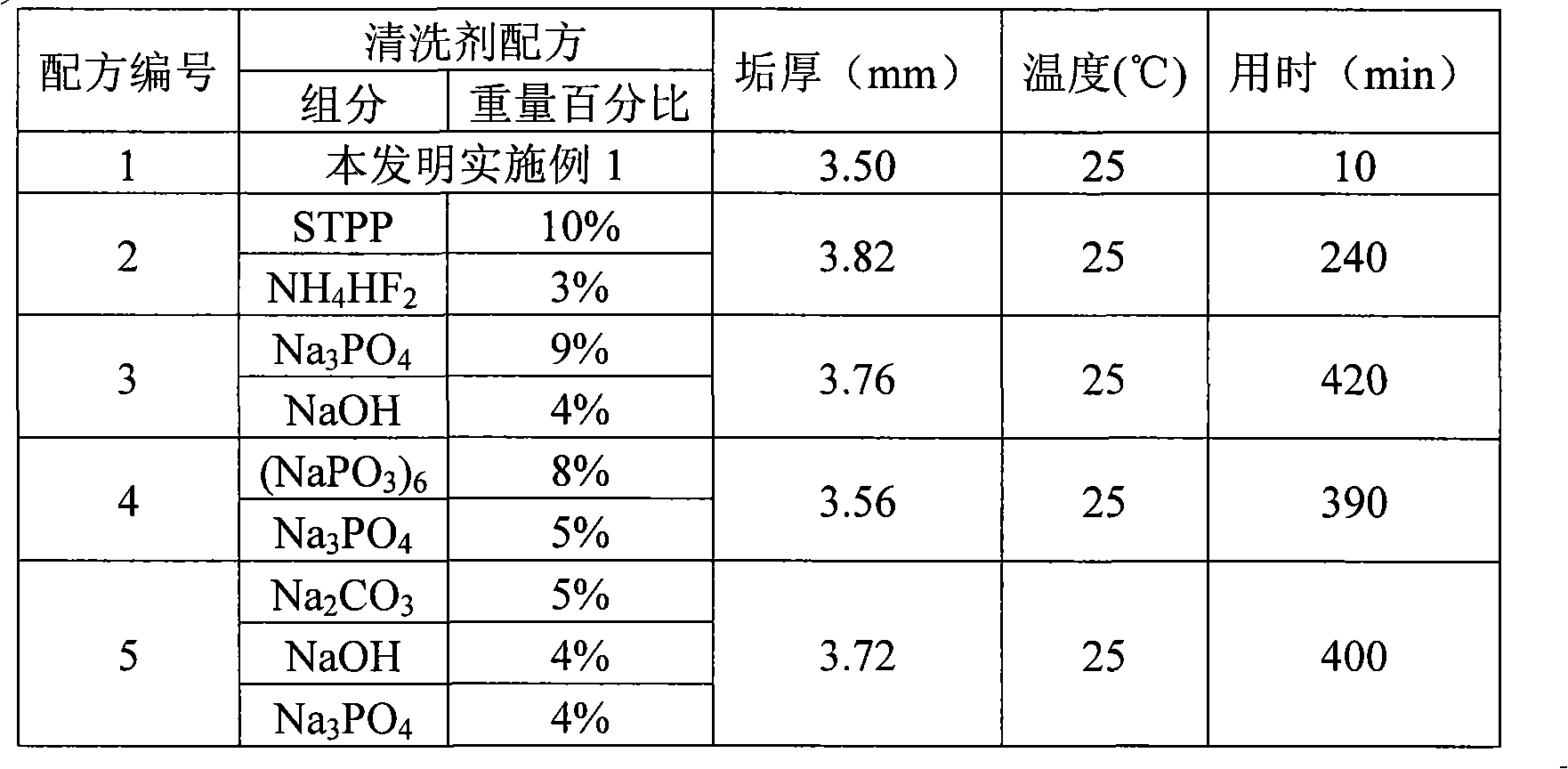

Composition for removing scale, preparation method and applications thereof

InactiveCN101555075AImprove solubilityViolent reactionTreatment using complexing/solubilising chemicalsCleaning processes and apparatusSodium phosphatesPhysical chemistry

The invention provides a composition for removing scale. The composition comprises the following ingredients by weight: 2 to 50 percent of aminosulfonic acid (NH2SO3H), 1 to 10 percent of sodium tripolyphosphate (STPP) and 0.5 to 5 per thousand of penetrating agent (JFC). The invention also provides a preparation method and applications of the composition. The composition has fast reaction velocity for removing scale, little corrosion to the material and high scale-removing rate.

Owner:董宇新

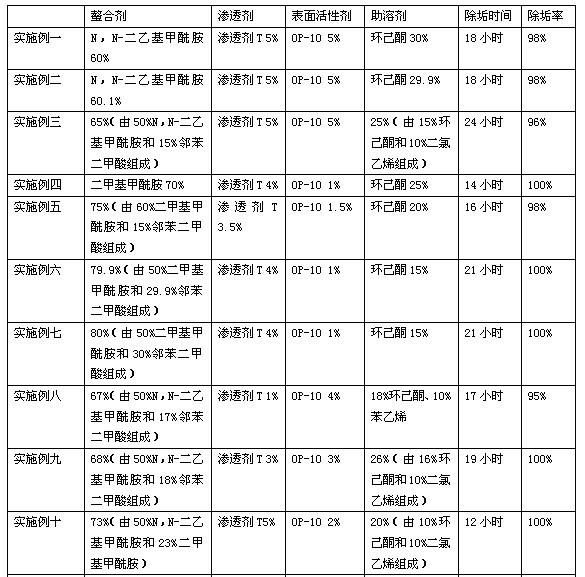

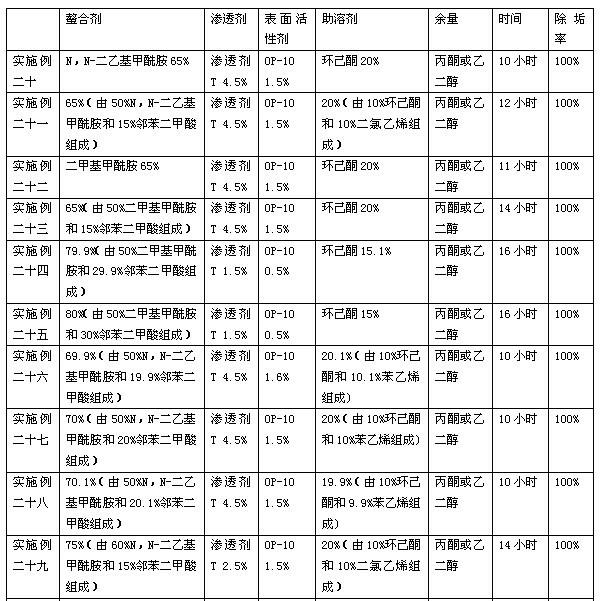

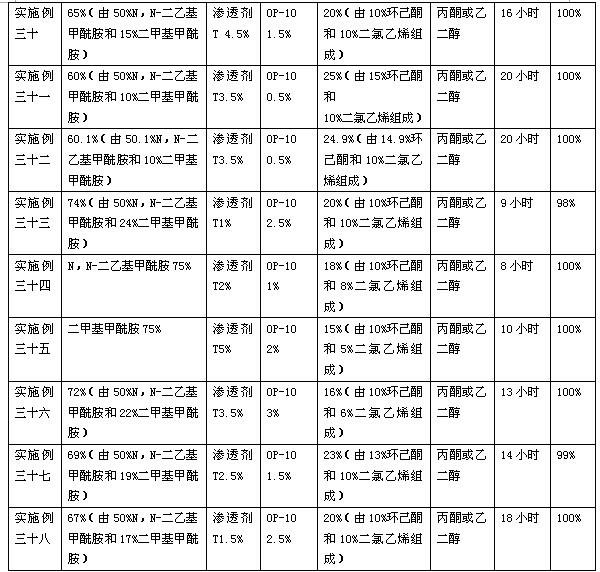

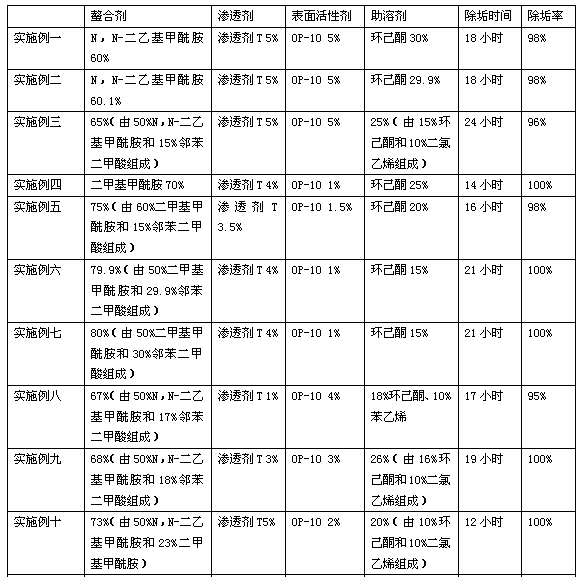

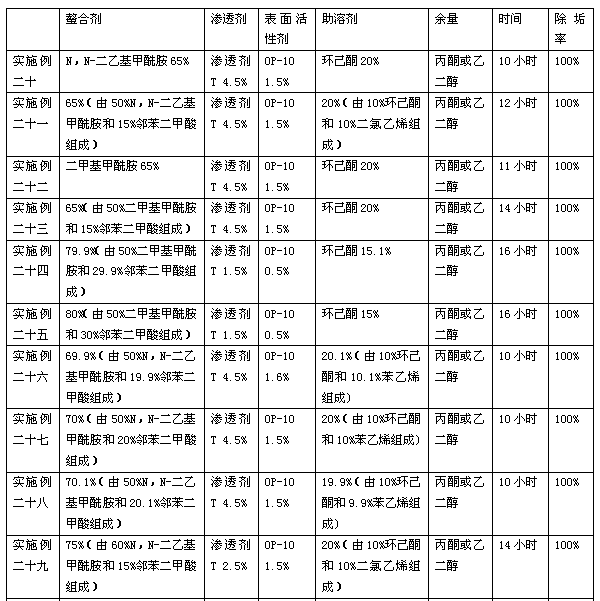

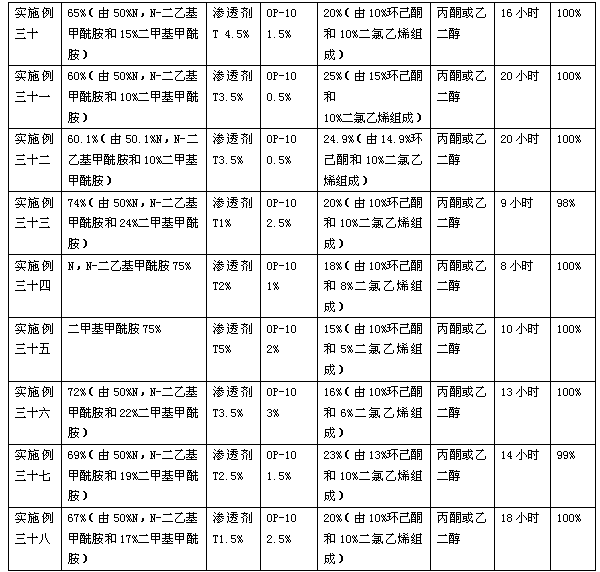

Scavenger for clearing away PVC (polyvinyl chloride) polymer in top condenser of polymerization kettle

ActiveCN102604762ARemove completelyStrong descaling abilityNon-surface-active detergent compositionsSurface-active non-soap compounds and soap mixture detergentsPolymer scienceScavenger

The invention discloses a scavenger for clearing away PVC (polyvinyl chloride) polymer in a top condenser of a polymerization kettle, which comprises the following components by weight percentage: 60-80% of a chelator, 1-5% of a penetrant, 0.5-3% of a surfactant, 15-25% of a cosolvent and the balance of acetone or glycol. The scavenger is prepared by the steps of adding raw materials such as the chelator, the penetrant, the surfactant, the cosolvent and the like in a reactor, stirring, adding acetone or glycol after the raw materials are fully dissolved, and stirring uniformly; and finally filling. The scavenger for clearing away PVC polymer provided by the invention has strong chelation dissolving capacity, high dissolving rate, almost no corrosion to all metals and high descaling capacity, is convenient to use and fast in action, and does not affect the continuous normal production of enterprises. The scavenger has remarkable social and economic benefits.

Owner:HENAN CHEM IND RES INST

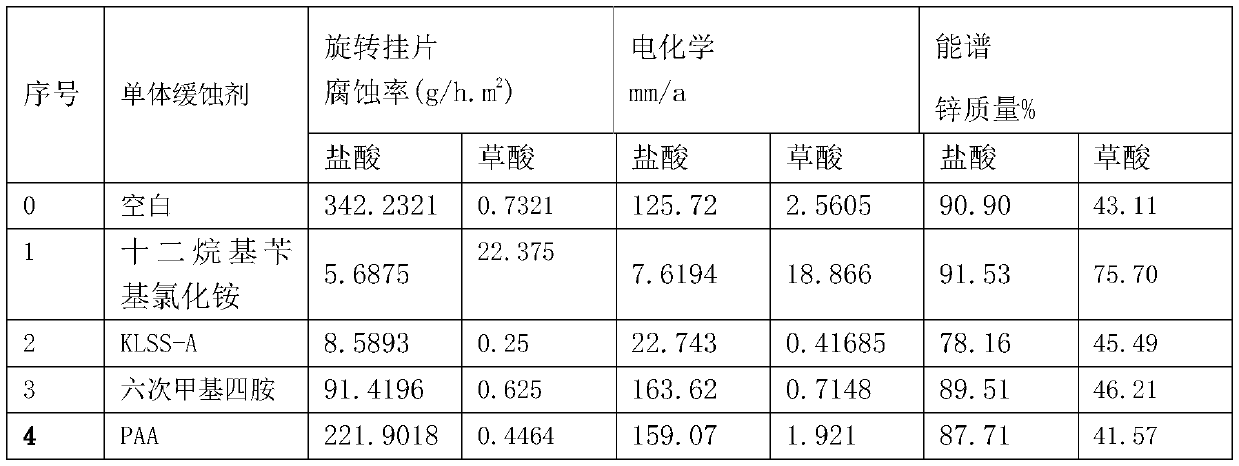

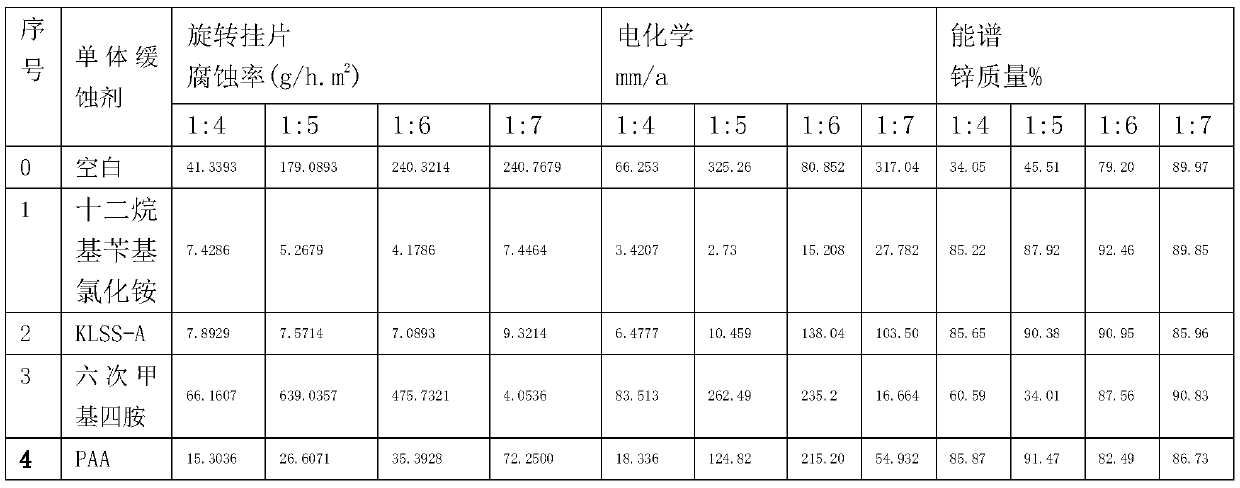

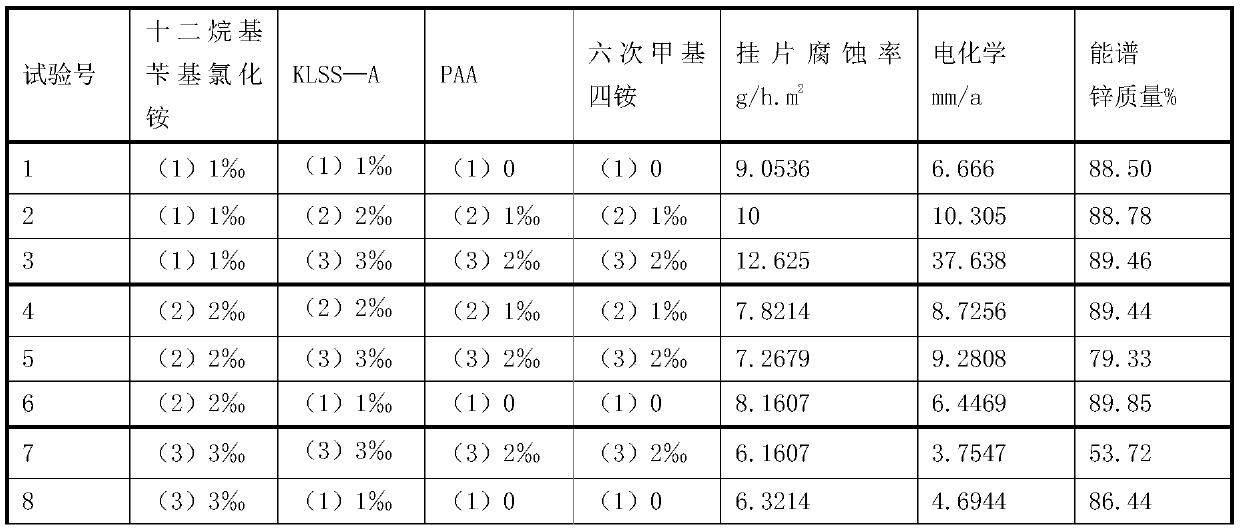

Galvanizing equipment descaling cleaner

ActiveCN110257178AFast descalingSlow descalingInorganic/elemental detergent compounding agentsCationic surface-active compoundsOrganic acidSurface-active agents

The invention discloses a chemical cleaner for galvanizing equipment, and belongs to the technical field of chemical cleaning. The chemical cleaner is prepared from, in weight percent, 0.3-1.2% of surface active agents, 0.1-1.2% of imidazoline inhibitors, 0.1-0.8% of dispersing agents, 0.2-0.8% of additives, 7-8% of oxalic acid, 12-14% of hydrochloric acid and the balance water. According to the cleaner, inorganic acid and organic acid are mixed together through best distribution ratio, so that the cleaner has descaling and inhibiting functions, the inorganic acid, the organic acid, dodecyl benzyl ammonium chloride, the amphoteric imidazoline inhibitor and additives are compounded together, the dodecyl benzyl ammonium chloride has a good corrosion inhibition effect on zinc, so that the chemical cleaner for the galvanizing equipment is prepared, and the cleaner has low metal zinc corrosion rate, is high in descaling speed and meets descaling and corrosion inhibition requirements of the industrial galvanizing equipment.

Owner:ENERGY RES INST CO LTD HENAN ACADEMY OF SCI

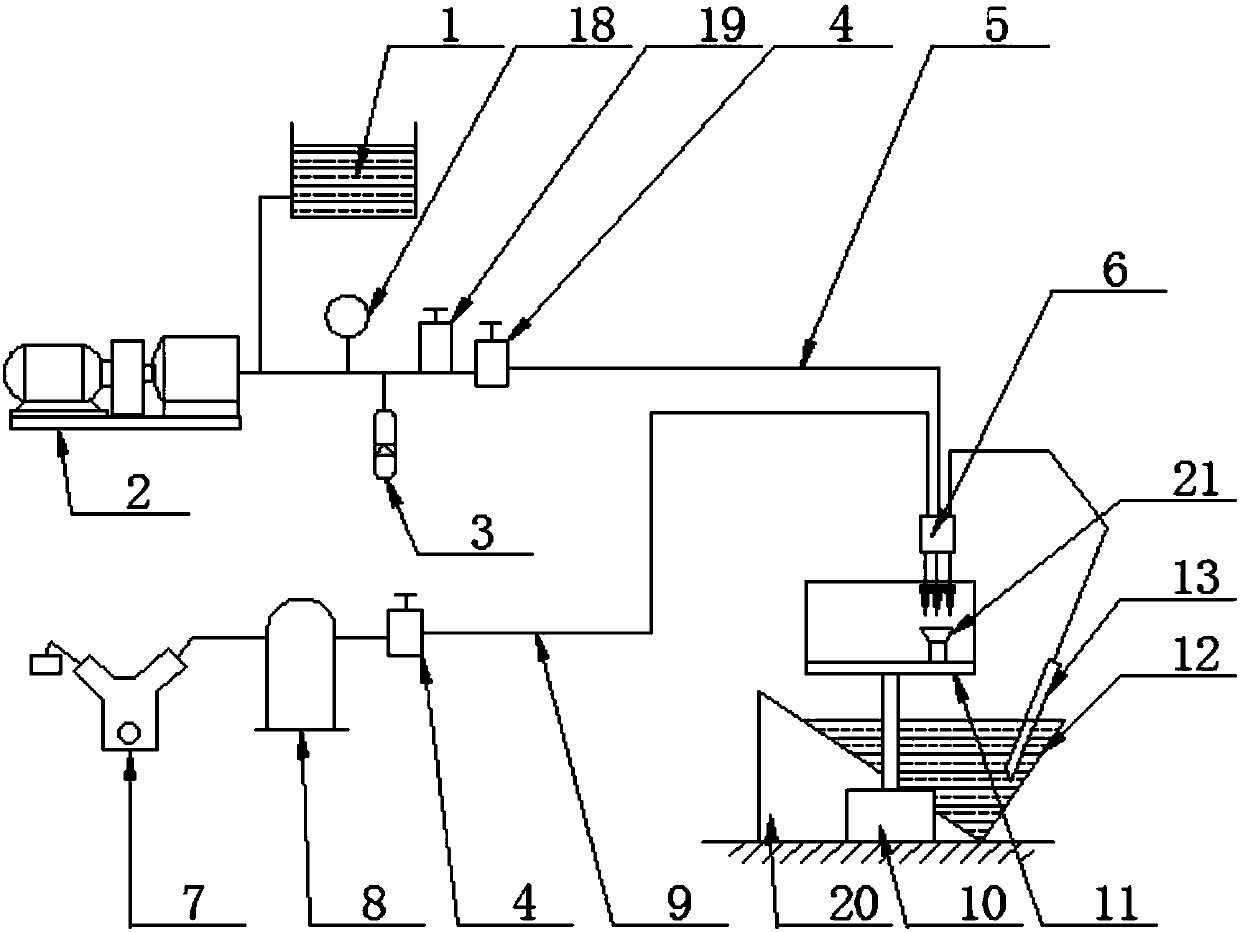

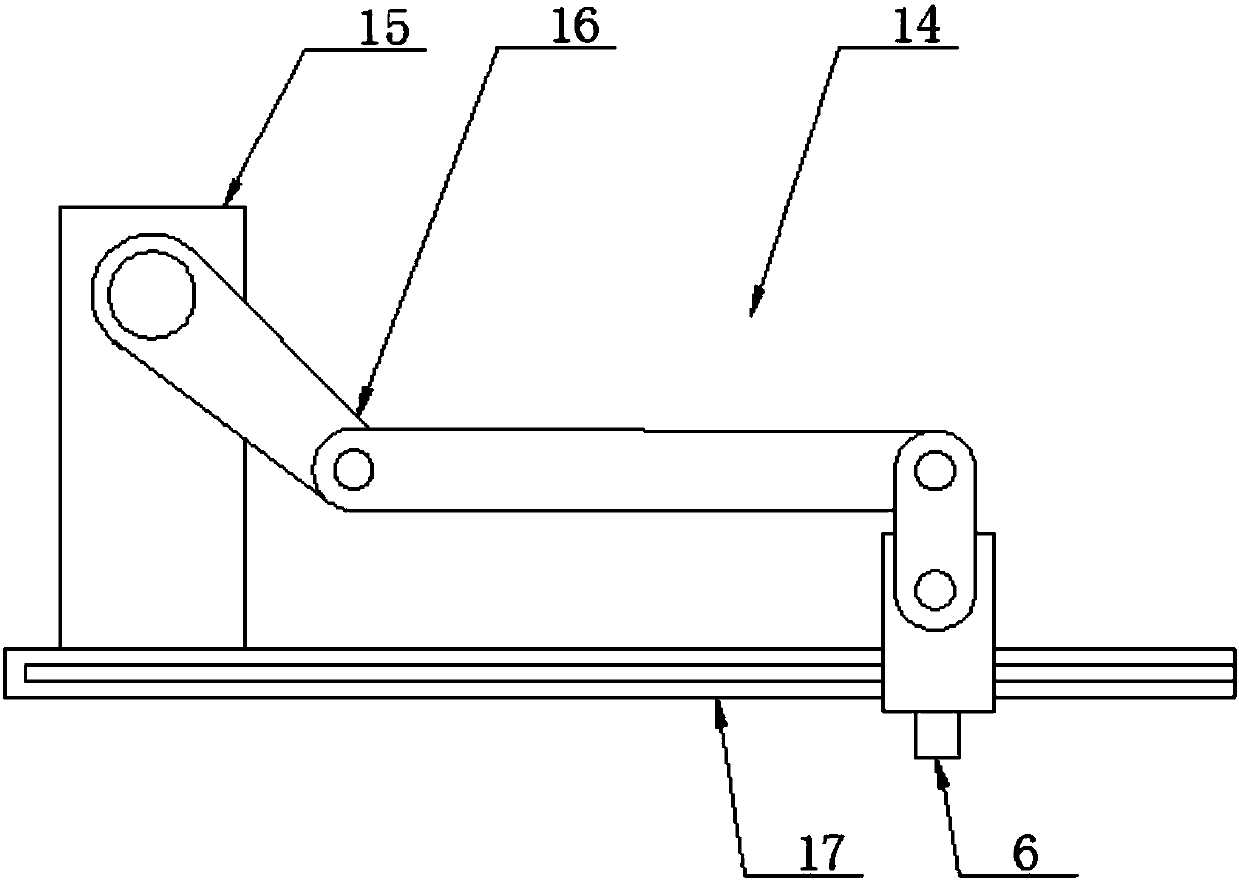

Wet rotary cage sand blasting machine

InactiveCN110153903AGuaranteed particle size rangeNo pollution in the processAbrasive feedersAbrasive machine appurtenancesSand blastingEngineering

The invention discloses a wet rotary cage sand blasting machine, and relates to the technical field of casting production equipment. The wet rotary cage sand blasting machine comprises a water tank, ahigh-pressure plunger pump, a pressure stabilizer, a pressure regulating valve, a high-pressure water pipe, a descaling nozzle, an air compressor, a pressure stabilizing cylinder, a high-pressure airpipe, a rotating cage motor, a rotating cage, a sand collecting hopper, a sand suction head and a swinging mechanism; the water tank is connected with the high-pressure plunger pump; the high-pressure plunger pump is connected with the descaling nozzle through the high-pressure water pipe; the high-pressure water pipe is provided with the pressure stabilizer and the pressure regulating valve; theair compressor is connected with the descaling nozzle through the high-pressure air pipe; the pressure stabilizing cylinder is arranged on the high-pressure air pipe; the rotating cage motor is in driving connection with the rotating cage; the sand collecting hopper is arranged below the rotating cage; the sand suction head is arranged in the sand collecting hopper; the sand suction head is connected with the descaling nozzle; and the swinging mechanism is in driving connection with the descaling nozzle. According to the wet rotary cage sand blasting machine, dust is not generated during descaling and pollution is avoided; mortar is recycled under negative pressure, and the consumption is low; and the utilization rate of the nozzle is high, the descaling speed is high, and the surface quality of a descaled workpiece is good.

Owner:霍山县忠福机电科技有限公司

Descaling agent for toilet

InactiveCN105482927AFast descalingStrong pungent smellOrganic non-surface-active detergent compositionsInorganic non-surface-active detergent compositionsStiphra robustaPolyethylene glycol

The invention discloses a descaling agent for a toilet. The descaling agent for the toilet is characterized by comprising the components in percentage by weight: 5-9% of oxalic acid, 3-5% of sodium silicate, 8-15% of polyethylene glycol, 3-5% of citric acid, 10-15% of hydrochloric acid and the balance of water. The product has the advantages that the descaling agent for the toilet is fast in descaling speed and free of strong pungent smell, the time for maintaining the cleaning effect is long after descaling, and the descaling agent is easy to manufacture.

Owner:湖北荆楚卓美文化传媒有限责任公司

Boiler descaling agent and preparation process thereof

InactiveCN105886150AFast descalingGood descaling effectOrganic non-surface-active detergent compositionsNon-surface-active detergent solventsIonChemistry

The invention discloses a boiler descaling agent and a preparation process thereof. The boiler descaling agent is prepared from, by weight, 30-40 parts of organic acid, 15-20 parts of ethanol, 5-10 parts of an organic solvent, 8-12 parts of 8-hydroxyquinoline, 2-6 parts of a corrosion inhibitor and 12-40 parts of deionized water. The preparation process comprises the steps that S1, 8-hydroxyquinoline is dissolved in an ethanol solution to obtain the ethanol solution of 8-hydroxyquinoline; S2, the organic acid, the organic solvent, the deionized water and the ethanol solution of 8-hydroxyquinoline are mixed, the corrosion inhibitor is added, and then a finished product solution is obtained; S3, the finished product solution is bottled and packaged to obtain the boiler descaling agent. The boiler descaling agent is high in descaling speed, good in descaling effect, convenient to use, wide in application range and capable of effectively removing scale, oil dirt and rust scale, protecting equipment after descaling and prolonging the service life of the equipment, the preparation process is simple, raw materials are easy to obtain, and cost is low.

Owner:ZHENJIANG WEIFU BOILER CO LTD

Surface treatment technique for aluminum

InactiveCN105671536ASimple processAvoid damageMetallic material coating processesRoom temperatureDistilled water

The invention discloses a surface treatment technique for aluminum. The surface treatment technique is characterized by comprising the following steps that (1) degreasing treatment is conducted, and the aluminum is dipped in a degreasing agent for 10-20 min; (2) after degreasing is finished, the aluminum is placed into a solution composed of sodium fluoride, concentrated nitric acid and water and dipped for 5-8 min at the room temperature; (3) the aluminum is placed into a solution composed of concentrated sulfuric acid, sodium dichromate and water and dipped for 2-3 min at the room temperature; and (4) the aluminum is washed in cold water for 5-8 min, washed through distilled water for 3-5 min and then dried at the temperature of 50-60 DEG C. According to the surface treatment technique for the aluminum, the technique is simple, through strict technological parameter control, the oxide skin removal speed is high, the damage of part base bodies can be reduced, and removal is more thorough.

Owner:CHONGQING JIEWEI DIE & MOLD

Washing agent for removing scale of cold-rolling acid-pickling regeneration set pipeline and using method thereof

The invention provides a washing agent for removing scale of a cold-rolling acid-pickling regeneration set pipeline and a using method thereof. The washing agent is prepared from the following components in parts by weight: 40-60 parts of ammonium hydrogen fluoride, 5-25 parts of sodium fluoride, 10-30 parts of trichloroethylene, 20-40 parts of ethyl ether, 20-50 parts of nitric acid, 10-30 partsof polyvinylpyrrolidone K30, 5-25 parts of acrylic acid-2-acrylamide-2-methylpropanesulfonic acid and 60-80 parts of water. The washing agent is suitably used for washing and removing scale of the cold-rolling acid-pickling regeneration set pipeline, is excellent in washing effect, relatively low in harm on human body, high in safety, low in pollution after being discharged, rapid in scale removing speed, high in scale removing efficiency and excellent in effect of washing iron salt scale and silicate scale, can replace hydrofluoric acid for use, and is capable of thoroughly washing the acid regeneration pipeline in 10 hours.

Owner:鞍钢栗田(鞍山)水处理有限公司

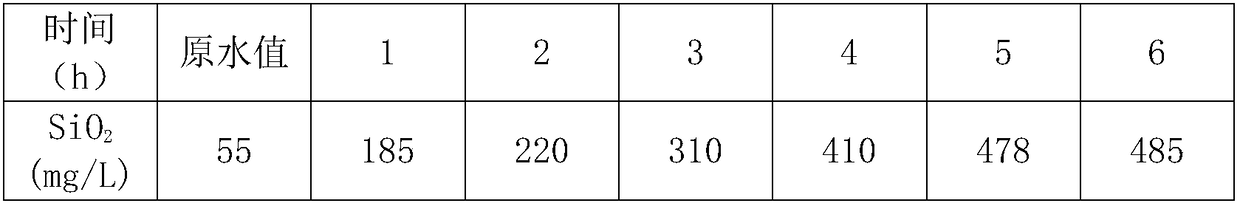

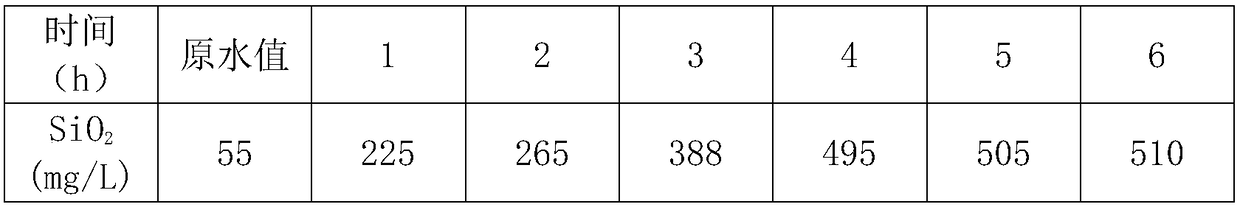

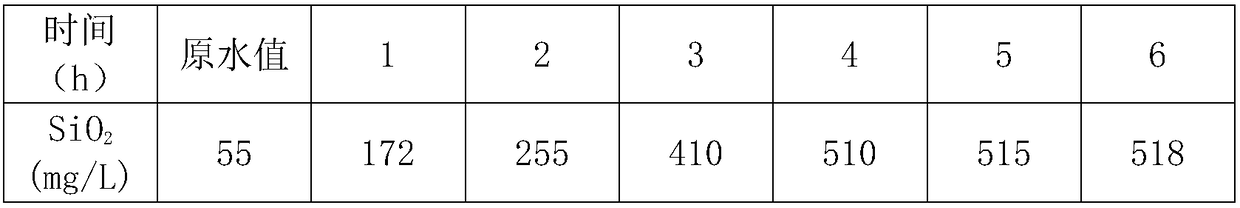

Organic descaling composition, preparation method and application thereof

ActiveCN101565660BFast descalingDescaling speed comparisonHollow article cleaningOrganic non-surface-active detergent compositionsMeth-Diphosphenes

The invention provides an organic descaling composition, which includes an organic cleaning agent and a corrosion inhibitor CM-911, and the weight ratio of the organic cleaning agent and the corrosioninhibitor is 100:0.1-0.3. The organic cleaning agent includes the follow components by weight: 1%-15% of maleic acid-crylic acid copolymer (MA-AA), 1%-25% of 1-hydroxyethylidene-1,1-diphosphonic acid(HEDP), 2%-30% of amino trimethylene phosphonic acid (ATMP), 0.03%-0.5% of penetrating agent JFC and balance of water. The organic descaling agent provided by the present invention has advantages offast reaction speed, small corrosivity for material and high descaling efficiency.

Owner:河南伯淼水处理有限公司

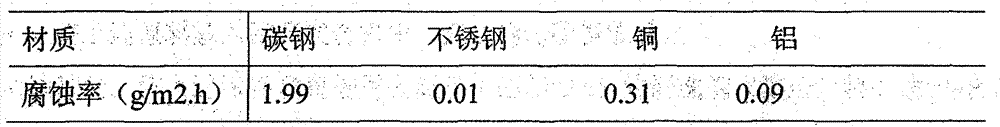

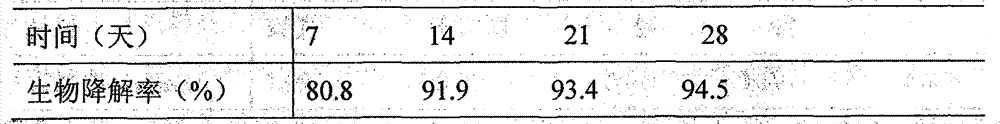

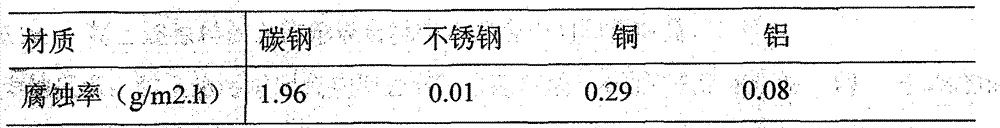

Degradable environment-friendly dirt remover

The invention relates to a degradable environment-friendly dirt remover which is characterized by comprising the following components in percentage by weight: 70-75% of citric acid, 14-18% of sulfamic acid, 5.0-6.0% of sodium gluconate, 2.8-3.0% of sodium polyaspartate, 1.4-1.6% of thiocarbamide and 1.4-1.6% of 2,2-dibromo-3-nitrilopropionamide. In the invention, environment-friendly solid organic acids are used as the main components, and degradable corrosion inhibitor, dispersant, slime remover and chelator are used as auxiliary components, therefore, the degradable environment-friendly dirt remover is applicable to various types of dirt and various metal materials, and has excellent descaling and corrosion-inhibiting properties. The degradation rate of the degradable environment-friendly dirt remover can be higher than 93% after 28 days, thus, the degradable environment-friendly dirt remover belongs to an environment-friendly product. The product can be used for preferably overcoming the defects of single function, narrow applicability and non-environment-friendliness in the current cleaning agent.

Owner:SHIJIAZHUANG HIGH TECH ZONE HUAKE ENVIRONMENTAL PROTECTION TECH

Process agent for oil dirt cleaning industrial water and method of producing the same

InactiveCN100526447CImprove permeabilityFast descalingSurface-active detergent compositionsDetergent compounding agentsHexamethylenetetraminePhysical chemistry

The invention relates to an industrial water treatment agent for oil stain cleaning and a preparation method thereof, which is prepared by preparing the following components according to the weight ratio: pull-off powder: 10%-25%, sodium dodecylbenzenesulfonate: 6%-12% , Ethanol: 3% to 6%, isopropanol: 10% to 20%, benzotriazole: 0.7% to 1.2%, rotropine: 1% to 2%, and the balance is deionized water. The preparation method comprises the following steps: 1) putting ethanol and isopropanol into a reaction kettle, stirring evenly and raising the temperature to 30°C-60°C; 2) adding pull-off powder into the kettle and stirring until dissolved; 3) adding Add sodium dodecylbenzenesulfonate and stir until dissolved; 4) Add deionized water into the kettle and stir well; 5) Add benzotriazole into the kettle and stir evenly; 6) Add urethane into the kettle Tropin, stir evenly; 7) discharge, measure and pack after cooling to normal temperature. The invention has the advantages of thorough scale dissolution, strong penetration, fast scale removal speed, no need to stop the car during cleaning, and can complete cleaning and corrosion inhibition at one time.

Owner:南京市第一精细化工公司精细化工厂(普通合伙)

Pipeline dredging deodorant and preparation method thereof

InactiveCN108048243AProduct raw materials are green and environmentally friendlyAvoid secondary pollutionInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsSodium acetateButanedioic acid

The invention discloses a pipeline dredging deodorant which is prepared from the following raw materials in parts by weight: 6 to 9 parts of sodium persulfate, 4 to 7 parts of potassium citrate, 10 to14 parts of potassium carbonate, 3 to 5 parts of sodium silicate, 8 to 10 parts of potassium ethoxide, 2 to 5 parts of stearyl alcohol sodium sulfovinate, 3 to 5 parts of polypropylene glycol, 2 to 4parts of oleyl alcohol sodium sulfovinate, 6 to 9 parts of ethyoxyl sodium acetate, 3 to 6 parts of alkylphenol polyoxyethylene ether, 2 to 5 parts of di-lauroyl tartaric acid ester, 6 to 9 parts ofpolyethylene glycol, 10 to 15 parts of potassium carboxylate, 3 to 6 parts of sodium n-alkyl sulfate and 5 to 8 parts of hydroxy-butanedioic acid. The dredging deodorant disclosed by the invention caneliminate odor of a sewer line in several minutes in the kitchen and bathroom and catering industries, completely clear obstructions in the sewer line within ten minutes, fulfills the aims of havingno toxicity or odor and rapidly removing odor and dredging the sewer line, and is poisonless and harmless for an operator and the kitchen and bathroom environment. The invention further discloses a preparation method of the pipeline dredging deodorant.

Owner:刘音希

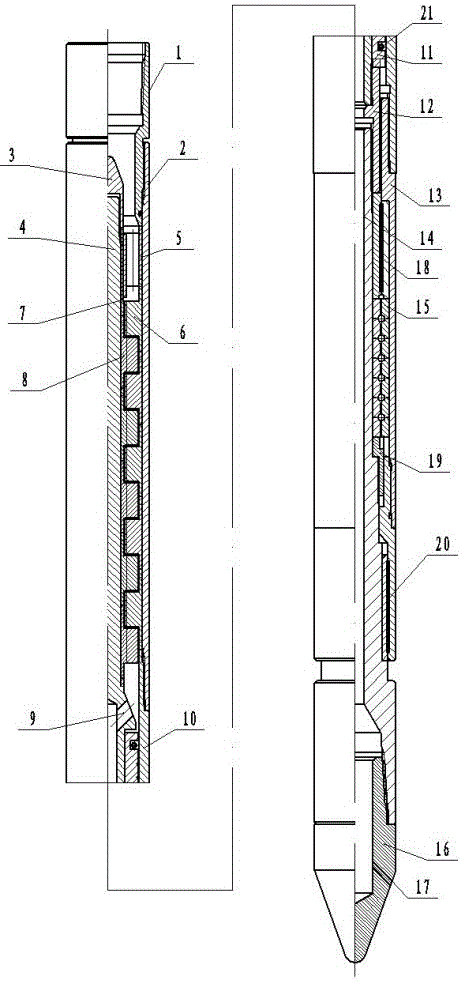

Rotational flowcleaner

The invention relates to the technical field of oil casing washing, in particular to a rotational flowcleaner. The rotational flowcleaner comprises a turbine motor, a drive shaft assembly and a sprayer, the lower end of the turbine motor is connected to the drive shaft assembly, and the lower end of the drive shaft assembly is connected to the sprayer; the turbine motor comprises an upper contact, the outer wall of the lower portion of the upper contact is connected to an outer canister, the lower end of the outer canister is connected to a lower contact of the outer canister, the lower end of the lower contact of the outer canister is connected to the drive shaft assembly, the outer canister is internally provided with a core shaft, the upper end of the core shaft is provided with a stream guidance cone, a bearing bush is arranged between the core shaft and the outer canister, the lower portion of the bearing bush is provided with a guide wheel, the upper and lower ends of the guide wheel are connected to the bearing bush and the lower contact of the outer canister in an inserting mode respectively, the outer wall of the core shaft is sleeved with a turbine, the lower portion of the core shaft is provided with a flushing port, the flushing port is located at the lower portion of the turbine, and the lower end of the core shaft is connected to the drive shaft assembly through a lower contact of the core shaft. The rotational flowcleaner is simple in structure, during oil casing washing, an oil outlet pipe does not need lifting, the labor intensity is low, the required time is short, the cleaning speed is high, the cleaning effect is good, and the cost is low.

Owner:DONGHAO MECHANICAL & ELECTRONICS

Condensing equipment scale descaling agent and descaling method

The invention relates to a scale remover for condensation equipment and a preparation method thereof. The scale remover is composed of 15% to 30% of a dissolving agent, 2% to 5% of a penetrating agent, 1% to 5% of a corrosion inhibitor, and a cosolvent 10% to 30%, purified water 20% to 30%, and the rest is ethanol, in terms of mass percentage; the dissolving agent is selected from oxalic acid, citrate, ascorbic acid, salicylic acid and glacial acetic acid, and the penetrant is selected from diethyl succinate Among esters, ethylene glycol monobutyl ether and dioctyl sulfosuccinate sodium salt, the corrosion inhibitor can be hexamethamine, aniline, diethylthiourea or rhodin, and the cosolvent can be p-benzoic acid, urea, Cyclohexanone, acetamide and sodium salicylate. The invention combines the above-mentioned raw materials and utilizes the combination effect to make them have strong descaling ability and fast descaling speed, less corrosion to equipment, low price, can save a lot of cleaning costs, and improve equipment operation level and energy utilization The level and production efficiency have greatly reduced the cost of producing products.

Owner:宁夏启元国药有限公司

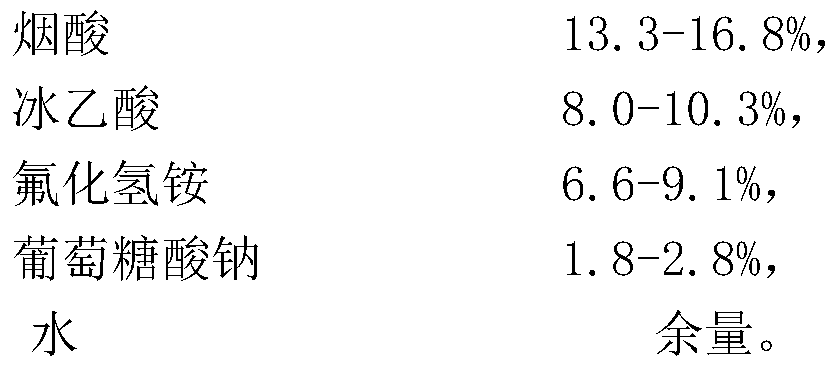

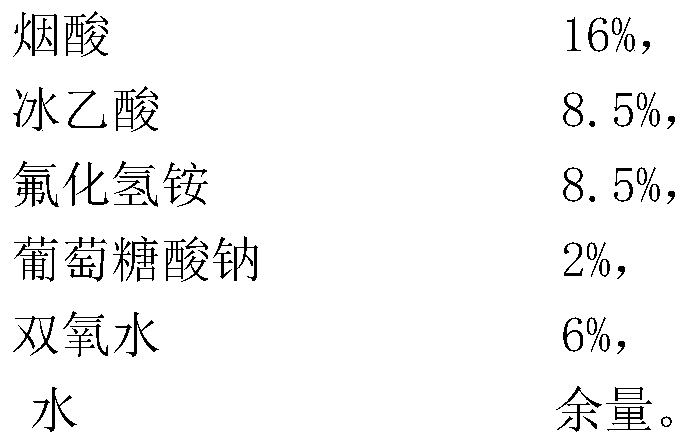

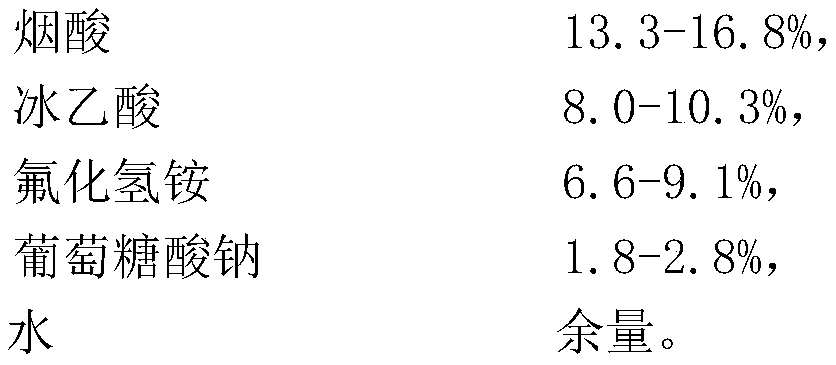

Precise water system descaling agent and preparation method thereof

InactiveCN110734817AFast descalingNo smellDetergent compounding agentsOrganic non-surface-active detergent compositionsAcidum NicotinicumAmmonium bifluoride

The invention discloses a precise water system descaling agent, which comprises the following components in percentage by weight: 13.3 to 16.8 percent of nicotinic acid, 8.0 to 10.3 percent of glacialacetic acid, 6.6 to 9.1 percent of ammonium bifluoride, 1.8 to 2.8 percent of sodium gluconate and the balance of water. The precise water system descaling agent does not corrode equipment, is odorless, high in descaling rate and high in descaling speed, and does not corrode a human body.

Owner:HUNAN JINYU ENVIRONMENTAL PROTECTION TECH CO LTD

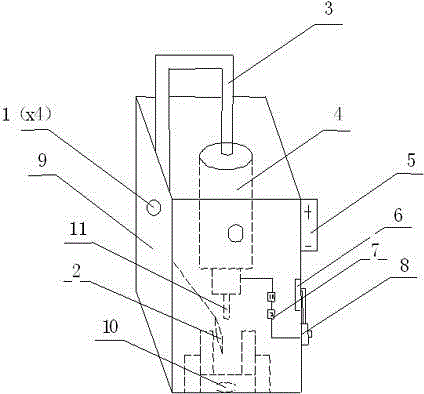

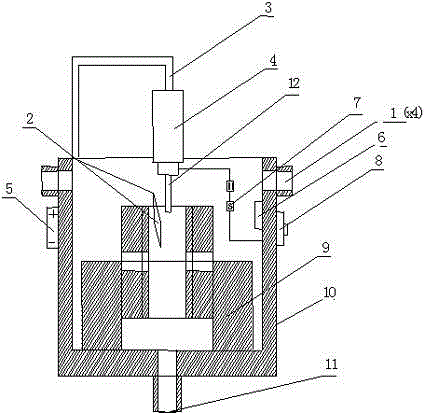

High-efficiency and stable ultrasonic electrolytic descaling device

InactiveCN105236595AFast descalingEfficient descalingScale removal and water softeningElectrolysisTransducer

The present invention discloses a high-efficient and stable ultrasonic electrolytic descaling device. The high-efficient and stable ultrasonic electrolytic descaling device is characterized in that an electrolyte circulating inlet is arranged in each of the four walls of an electrolytic bath; a circulating outlet is arranged in the bottom of the electrolytic bath; a multi-stage centrifugal pump provides pressure for electrolyte; an ultrasonic generator is mounted at the center position of the electrolytic bath, and the ultrasonic generator is connected with a transducer and an oscilloscope; the oscilloscope is connected with electrode plates of a positive electrode and a negative electrode of an electrolysis power supply; a demountable vertical adsorption plate is arranged below the oscilloscope for dividing the electrolytic bath into a left chamber and a right chamber; a heater is arranged on the inner wall of the electrolytic bath; the transducer and the heater are separately controlled by a controller to heat the electrolyte in the electrolytic bath. The descaling device disclosed by the present invention can refresh streams in a descaling process; by utilizing ultrasonic high-frequency vibration and a heating function of the heater, water in a circulating system can be efficiently descaled; and the descaling process produces no pollution, and is high in efficiency and high in safety.

Owner:QINGDAO LANNONGGU AGRI PROD RES & DEV

Treatment process for surface of magnesium

The invention discloses a treatment process for the surface of magnesium. The treatment process is characterized by comprising the following steps that 1, dipping degreasing treatment is conducted in a degreasing agent; 2, after degreasing is conducted, a part is put into a solution composed of sodium hydroxide and water and is washed in alkali liquor for 5-15 min; 3, the part is washed in cold water for 5-7 min and is dipped in a solution composed of chromium oxide, calcium nitrate and the water for 5-15 min; 4, the part is washed in cold water for 2-5 min and is dipped in a solution composed of chromium oxide, sodium phosphate and the water for 3-12 min; and 5, the part is washed in cold water for 2 min and then dried. According to the treatment process for the surface of the magnesium, the process is simple, the oxide skin removing speed can be high and part matrix damage can be reduced through strict process parameter control, and removing is more thorough.

Owner:CHONGQING JINSHENG MACHINERY PARTS MFG CO LTD

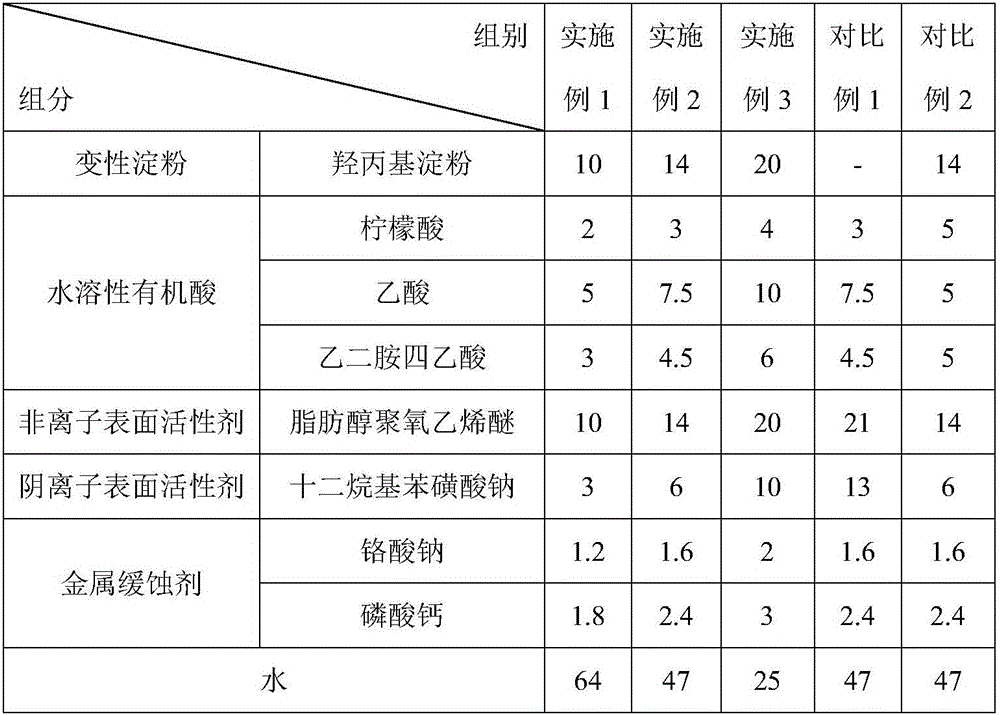

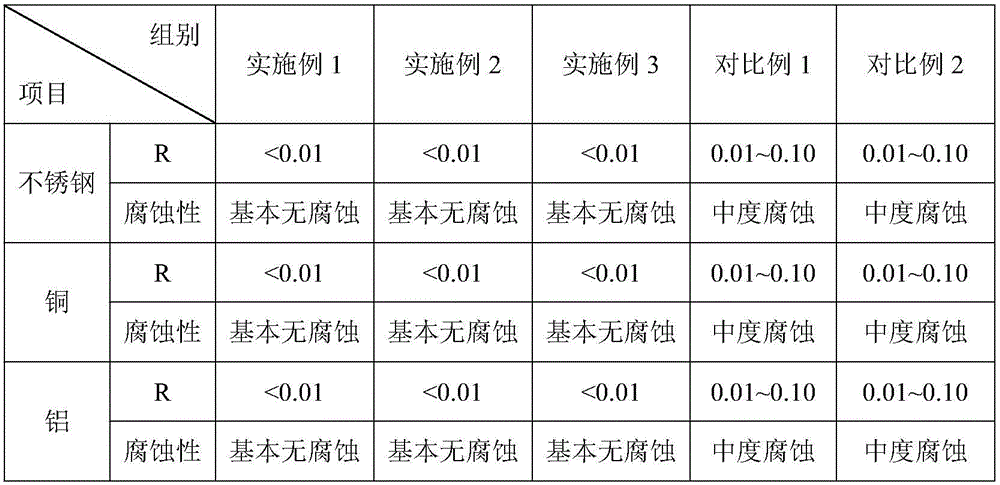

Scale scavenging agent and preparation method thereof

The invention belongs to the technical field of daily chemical products and particularly relates to a scale scavenging agent and a preparation method thereof. The scale scavenging agent provided by the invention comprises the following components in percentages by mass: 10-20% of modified starch, 10-20% of organic acid, 10-20% of a nonionic surfactant, 3-10% of an anionic surfactant, 3-5% of a metal corrosion inhibitor and 25-64% of water. The scale scavenging agent provided by the invention is fast in scale removal speed, high in scale removal rate and small in metal corrosion.

Owner:叶宗瑞

A safe water tank descaling agent

ActiveCN106381246BImprove securityEasy to removeSurface-active detergent compositionsSurface-active non-soap compounds and soap mixture detergentsIron saltsMagnesium salt

Owner:XINGAN ANHUI ELECTRIC LTD BY SHARE LTD

Scavenger for clearing away PVC (polyvinyl chloride) polymer in top condenser of polymerization kettle

ActiveCN102604762BRemove completelyEnhanced descaling abilitySurface-active non-soap compounds and soap mixture detergentsPolymer scienceScavenger

The invention discloses a scavenger for clearing away PVC (polyvinyl chloride) polymer in a top condenser of a polymerization kettle, which comprises the following components by weight percentage: 60-80% of a chelator, 1-5% of a penetrant, 0.5-3% of a surfactant, 15-25% of a cosolvent and the balance of acetone or glycol. The scavenger is prepared by the steps of adding raw materials such as the chelator, the penetrant, the surfactant, the cosolvent and the like in a reactor, stirring, adding acetone or glycol after the raw materials are fully dissolved, and stirring uniformly; and finally filling. The scavenger for clearing away PVC polymer provided by the invention has strong chelation dissolving capacity, high dissolving rate, almost no corrosion to all metals and high descaling capacity, is convenient to use and fast in action, and does not affect the continuous normal production of enterprises. The scavenger has remarkable social and economic benefits.

Owner:HENAN CHEM IND RES INST

Process for treating metal oxide layer

InactiveCN105586586ASimple processAvoid damageMetallic material coating processesSulfateRoom temperature

The invention discloses a process for treating a metal oxide layer. The process is characterized by comprising the following steps that metal to be treated is placed in a solution formed by sodium dichromate, magnesium sulfate, manganese sulfate and water, dipping is conducted for 10-20 min under the room temperature condition, and then the metal is flushed with cold water; afterwards, the metal is washed with distilled water for 5-10 min; and finally the metal is dried at the temperature of 60-70 DEG C. The process for treating the metal oxide layer is simple, and through strict control over process parameters, the descaling speed is high, part base body damage can be reduced, and removal is more thorough.

Owner:CHONGQING CHUNGU MACHINERY MFG CO LTD

Sulfide scale descaling and deodorizing passivation agent composition and preparation method thereof

ActiveCN108034953BEfficient removalNo corrosionMetallic material coating processesEthylenediaminePolyethylene glycol

The invention discloses a descaling and deodorant passivator composition for sulfide scale. The passivator is made of, by weight, 5-8 parts of urotropine, 4-7 parts of sodium citrate, 3-6 parts of lauroyl peroxide, 16-20 parts of sodium carbonate, 3-5 parts of sodium silicate, 9-11 parts of dodecanoyl aspartic acid, 4-7 parts of potassium sorbate, 3-5 parts of polyethylene glycol, 3-5 parts of alkylphenol ethoxylates, 6-9 parts of dilauryl tartrate, 9-11 parts of sulfosuccinic acid, 1-3 parts of sodium methacrylate, 6-9 parts of lauramine, 10-14 parts of sodium carboxylate, 2-4 parts of hydroxyethyl ethylenediamine and 4-6 parts of sodium cetyl sulfate. The descaling and deodorant passivator composition for sulfide scale is used for descaling and deodorization of ferrous sulfide scale, sulfur-containing dirt, organic material scale and asphalt scale generated in the production process of petrochemical industry, mine and metallurgy industry; while the descaling is being carried out, a sulfur-containing wastewater and a waste gas can be deodorized and carried out passivation treatment; and the passivation treatment is not needed after the descaling. The method has the advantages thatthe removal speed of FeS scale is high, and the descaling rate is larger than 98% in 4 hours.

Owner:GANSU HEIMA PETROCHEM ENG

Acid pickling treatment process of stainless steel

The invention discloses an acid pickling treatment process of stainless steel. The acid pickling treatment process comprises the following steps: (1) preparing materials according to weight percentage: 20-22% of nitric acid, 5-7% of hydrofluoric acid and the balance of water; (2) preparing a solution, namely, uniformly mixing and stirring the prepared materials according to the mass proportion; (3) loosening an oxidation film: soaking stainless steel to be treated in sulfuric acid with the volume concentration of 10-15% at the temperature of 800 DEG C for 20-25 minutes; (4) removing the oxidation film: soaking the stainless steel to be treated in the prepared solution, performing normal temperature treatment for 10-15 minutes and then taking out, thoroughly cleaning the surface of the stainless steel with water, cleaning with an alkaline liquor for neutralizing, and finally airing after thorough cleaning. According to the acid pickling treatment process of stainless steel provided by the invention, through the strict control over technological parameters, the oxide scale removing speed and efficiency are high, the corrosion to the matrix is little, the corrosion inhibition rate is high, and no acid mist is produced during the cleaning operation process.

Owner:芜湖华普汽车部件有限公司

Process agent for oil dirt cleaning industrial water and method of producing the same

InactiveCN101130716AImprove permeabilityFast descalingSurface-active detergent compositionsDetergent materialsBenzeneProcedure Agents

The invention discloses a treating agent of industrial water after cleaning oil dirt and making method, which comprises the following parts: 10%-25% zipper powder, 6%-12% sodium dodecylbenzene sulfonate, 3%-6% alcohol, 10%-20% isopropanol, 0. 7%-1. 2% azimido-benzene, 1%-2% tropyl and residual deionized water. The preparing method comprises the following steps: 1) putting alcohol and isopropanol into autoclave; stirring to heat to 30-60 deg. c; 2) adding zipper powder into the autoclave to stir until dissolving; 3) adding sodium dodecylbenzene sulfonate into the autoclave to stir until dissolving; 4) adding deionized water in the autoclave to stir evenly; 5) adding azimido-benzene to stir evenly; 6) adding tropyl to stir evenly; 7) cooling to normal temperature; discharging; gauging; packing. The invention dissolves dirt thoroughly with strong penetrability and rapid speed to strip dirt, which needn't stop car during cleaning course to do cleaning and inhibiting within one time.

Owner:南京市第一精细化工公司精细化工厂(普通合伙)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com