Degradable environment-friendly dirt remover

A stripping agent, an environmentally friendly technology, applied in the field of degradable and environmentally friendly dirt stripping agents, can solve the problems of single function, narrow application area, non-environmental friendly, etc., and achieve the effect of simple production process and safe transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1: 100kg of degradable environment-friendly dirt stripping agent was prepared, and the raw materials used were all industrial products. 70kg of citric acid, 18kg of sulfamic acid, 6kg of sodium gluconate, 3kg of sodium polyaspartate, 1.4kg of thiourea and 1.6kg of 2,2-dibromo-3-azapropionamide. Put the above-mentioned raw materials into the conical mixer, and mix evenly to obtain the finished product.

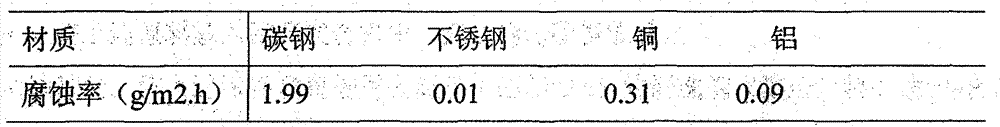

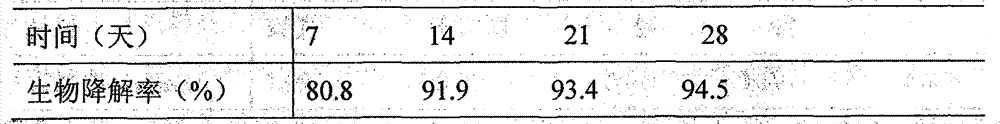

[0035] Corrosion test: The above-mentioned dirt stripping agent is prepared into a 5% cleaning agent aqueous solution with deionized water, and the above-mentioned 5% cleaning agent aqueous solution is placed in a 500ml conical flask, and the test pieces of different materials are respectively suspended in a container containing 5% of the cleaning agent. % cleaning agent aqueous solution in a Erlenmeyer flask, and then place the Erlenmeyer flask in a constant temperature water bath at 50°C for a static test for 12 hours. The corrosion rate was determined with re...

Embodiment 2

[0042] Example 2: 100kg of degradable and environmentally friendly dirt stripping agent was prepared, and the raw materials used were all industrial products. 75kg of citric acid, 14kg of sulfamic acid, 5kg of sodium gluconate, 2.8kg of sodium polyaspartate, 1.6kg of thiourea and 1.6kg of 2,2-dibromo-3-azatrilopropanamide. Put the above-mentioned raw materials into the conical mixer, and mix evenly to obtain the finished product.

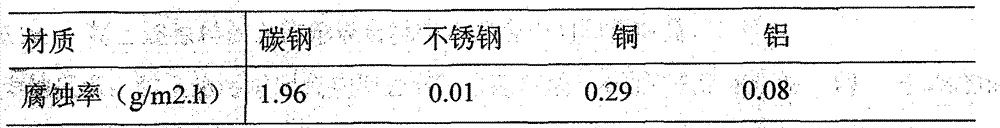

[0043] Corrosion test: The above-mentioned dirt stripping agent is prepared into a 5% cleaning agent aqueous solution with deionized water, and the above-mentioned 5% cleaning agent aqueous solution is placed in a 500ml conical flask, and the test pieces of different materials are respectively suspended in a container containing 5% of the cleaning agent. % cleaning agent aqueous solution in a Erlenmeyer flask, and then place the Erlenmeyer flask in a constant temperature water bath at 50°C for a static test for 12 hours. The corrosion rate was dete...

Embodiment 3

[0050] Example 3: 100kg of degradable and environmentally friendly dirt stripping agent was prepared, and the raw materials used were all industrial products. 73kg of citric acid, 16kg of sulfamic acid, 5kg of sodium gluconate, 2.9kg of sodium polyaspartate, 1.5kg of thiourea, and 1.6kg of 2,2-dibromo-3-azepamide. Put the above-mentioned raw materials into the conical mixer, and mix evenly to obtain the finished product.

[0051] Corrosion test: The above-mentioned dirt stripping agent is prepared into a 5% cleaning agent aqueous solution with deionized water, and the above-mentioned 5% cleaning agent aqueous solution is placed in a 500ml conical flask, and the test pieces of different materials are respectively suspended in a container containing 5% of the cleaning agent. % cleaning agent aqueous solution in a Erlenmeyer flask, and then place the Erlenmeyer flask in a constant temperature water bath at 50°C for a static test for 12 hours. The corrosion rate was determined wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com