Rotational flowcleaner

A technology of scale remover and transmission shaft, which is applied to cleaning appliances, wellbore/well components, earth-moving drilling, etc., can solve the problems of affecting water injection operation, high labor intensity and high cost, and achieves good descaling effect and labor intensity. Small, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

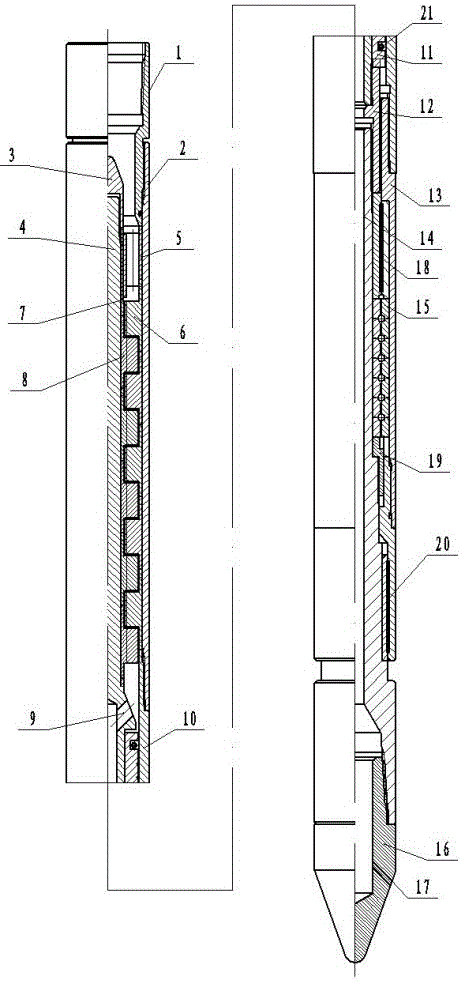

[0015] The cyclone descaler includes a turbine 8 motor, a transmission shaft assembly and a nozzle 16, the lower end of the turbine 8 motor is connected to the transmission shaft assembly, the lower end of the transmission shaft assembly is connected to the nozzle 16, and the nozzle 16 includes a water outlet.

[0016] The turbine 8 motor includes an upper joint 1, the lower outer wall of the upper joint 1 is connected to the outer cylinder 2, the lower end of the outer cylinder 2 is connected to the lower joint 10 of the outer cylinder, the lower end of the lower joint 10 of the outer cylinder is connected to the transmission shell 13, and the outer cylinder 2 is provided with a mandrel 4, the core The upper end of the shaft 4 is provided with a diversion cone 3, the lower end of the diversion cone 3 is connected to the bushing 7, the lower end of the bushing 7 is connected to the turbine 8, the bearing bush 5 is arranged between the mandrel 4 and the outer cylinder 2, the guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com