Galvanizing equipment descaling cleaner

A technology of galvanizing equipment and cleaning agent, applied in the field of chemical cleaning, which can solve the problems of reducing the service life of equipment, leakage of coolant, corrosion of radiator heat pipes, etc., and achieves fast descaling speed, slow descaling speed, and high corrosiveness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

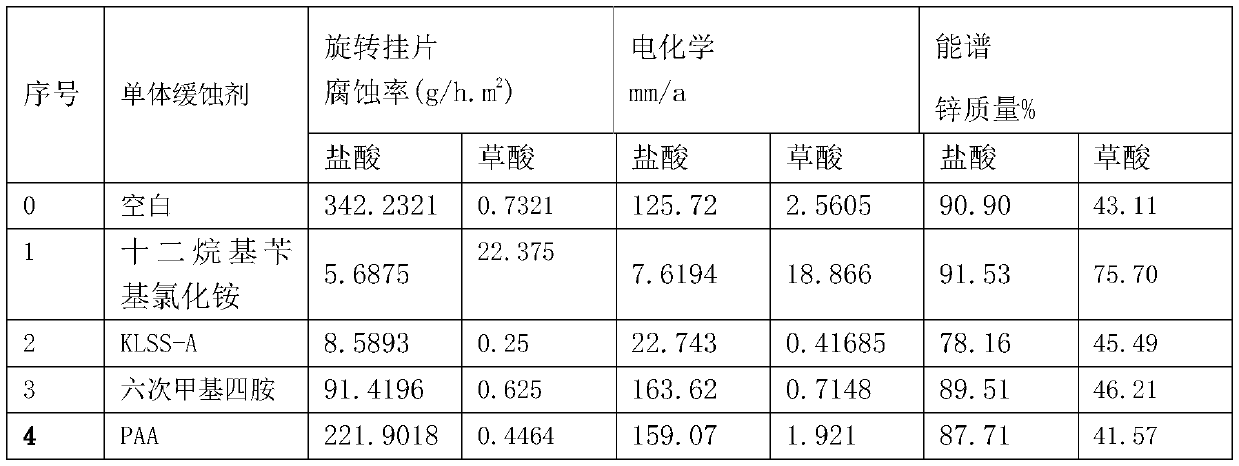

[0019] Add 2‰ of the single-component corrosion inhibitor monomer, add it to 1 g equivalent / L HCL and oxalic acid solution respectively, and do the corrosion test on Zn metal with a rotary coupon at 25°C for 2 hours; electrochemical Corrosion experiment, and using electron microscope and energy dispersive spectrometer to scan and observe the surface micro-morphology and element composition of the corrosion test piece after the corrosion test, see Table 1.

[0020] Table 1, 1 gram equivalent / L (oxalic acid) solution + 2‰ monomer corrosion inhibitor + pure Zn corrosion rotating coupon, electrochemical, energy spectrum experimental data

[0021]

[0022] It can be seen from Table 1 that in the oxalic acid solution of zinc, the corrosion rate of the corrosion coupons of zinc is generally lower than that in the hydrochloric acid solution of the same concentration. Among them, KLSS-A, hexamethylenetetramine, and PAA have relatively low corrosion rates to metal zinc in the two aci...

Embodiment 2

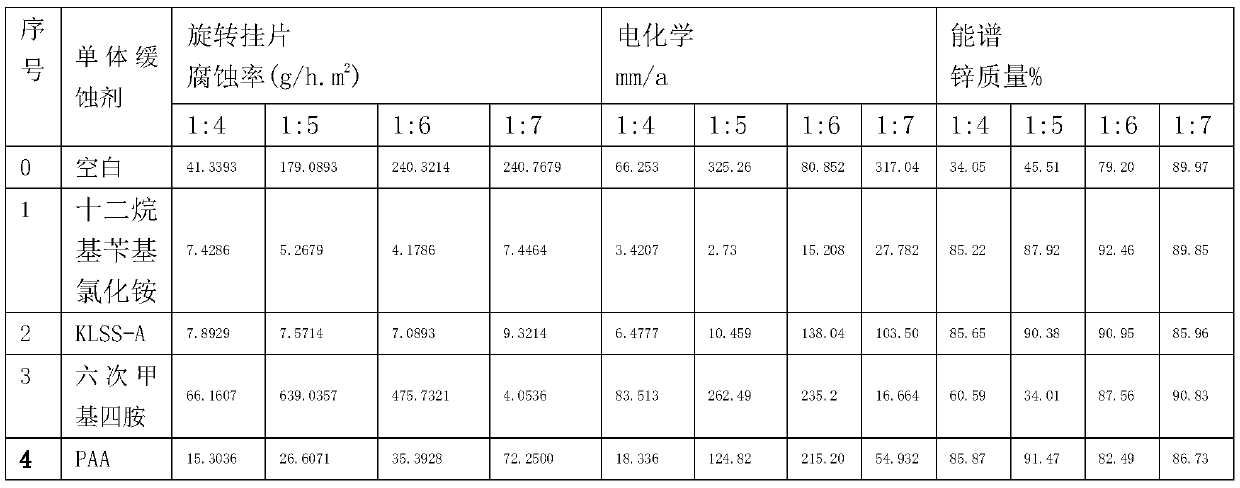

[0024] The one-component corrosion inhibitor monomer was added in an amount of 2‰, respectively added to the mixed solution of 1 g equivalent / L HCL and oxalic acid, and at 25 ° C, the test time was 2 hours, and the corrosion test of Zn metal was carried out on a rotary coupon; Electrochemical corrosion experiment, and using electron microscope and energy dispersive spectrometer to scan and observe the microscopic appearance of the surface of the corrosion test piece after the corrosion test, the change of element composition, see Table 2.

[0025] Table 2. 1 gram equivalent / L (equivalent ratio oxalic acid: HCL=1:4; 1:5; 1:6; 1:7) + 2‰ monomer corrosion inhibitor + pure Zn corrosion rotary coupon, electrochemical, Energy spectrum experiment data

[0026]

[0027] From the corrosion coupon test data of each corrosion inhibitor monomer in Table 2, combined with the comprehensive judgment of electrochemical analysis and electronic scanning analysis, the corrosion inhibitor mono...

Embodiment 3

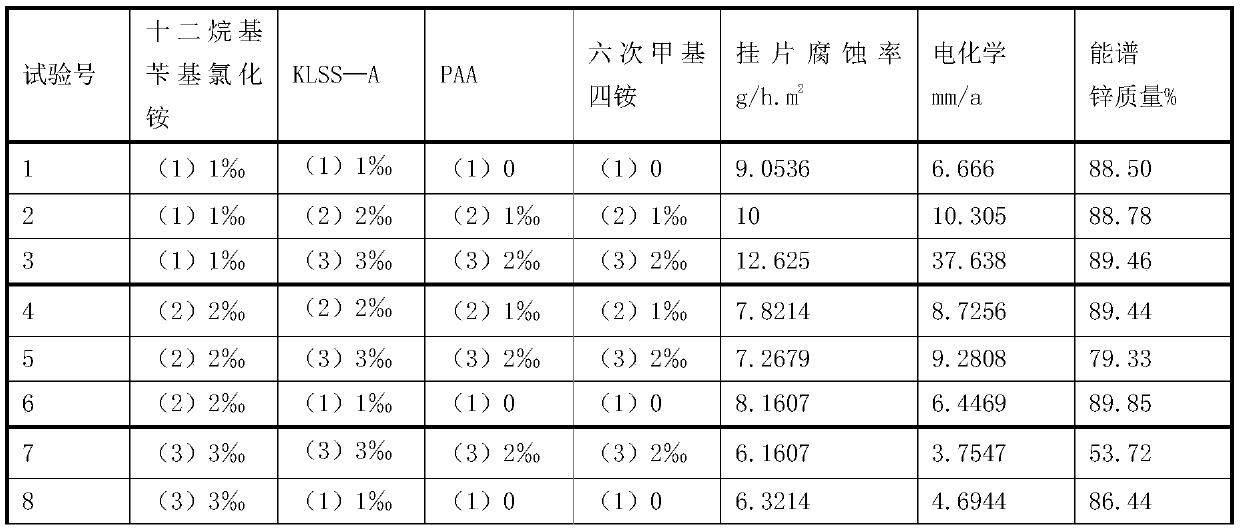

[0029] Add different amounts of multi-corrosion inhibitor monomers to the mixed acid of 1 gram equivalent / LHCL and oxalic acid solution (1:6) for compounding. At 25°C, the test time is 2 hours, and the corrosion test of Zn metal is carried out on a rotary coupon; Electrochemical corrosion experiment, and use electron microscope and energy dispersive spectrometer to scan and observe the microscopic appearance of the surface of the corrosion test piece after the corrosion test, and the change of element composition, see Table 3.

[0030] Table 3: 1 gram equivalent / L mixed acid solution (equivalent ratio oxalic acid: HCL=1:6) + different amounts of monomer corrosion inhibitor + pure Zn corrosion rotating coupon, electrochemical, energy spectrum orthogonal experiment results

[0031]

[0032]

[0033] According to the K of different corrosion inhibitor monomers in the experiment of Table 3 1 、K 2 、K 3 It is concluded that the best combination ratio of corrosion inhibitor m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com