Efficient descaling method for square billets

A high-efficiency, blank technology, applied in the field of descaling technology, can solve the problems of large spray distance and small striking force, and achieve the effect of ensuring interchangeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

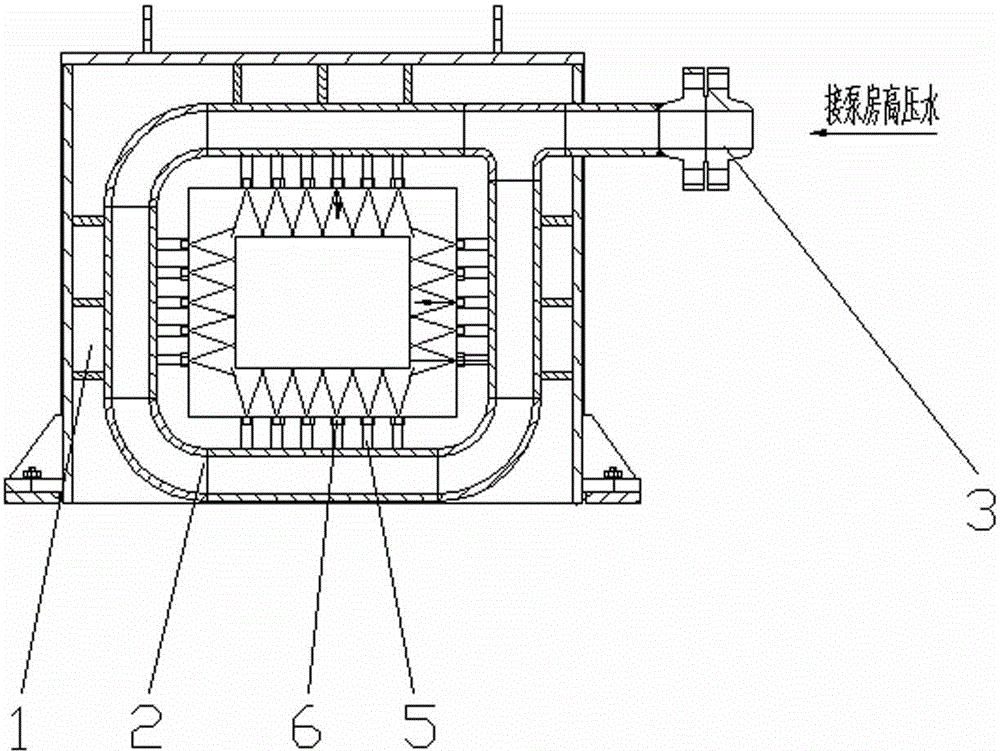

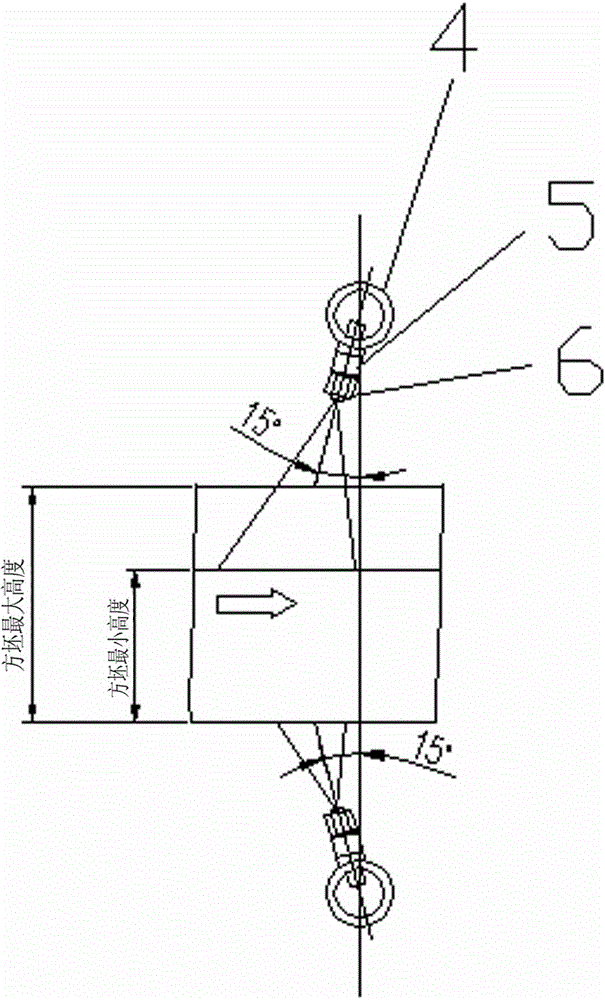

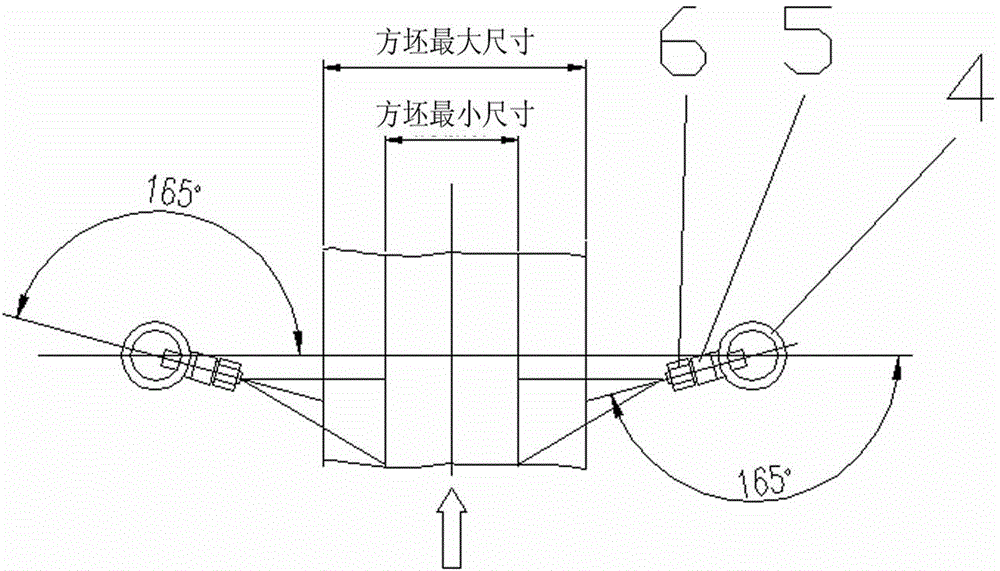

[0025] see Figure 4~6 , the descaling ring device selection adaptation method, including a descaling ring frame 1, a descaling ring 2 is arranged in the descaling ring frame 1, and the protruding part of the descaling ring frame 1 is connected with a high-pressure hose 7 and a high-pressure hose protective cover 8 is arranged on the outside of the high-pressure hose 7, wherein the descaling ring 2 is composed of an annular high-pressure water pipe 4, a nozzle adapter 5 and a nozzle 6; the selection requirements of the descaling ring device are as follows: ① The descaling ring device has a modular design, and its external dimensions and installation dimensions are exactly the same to ensure its interchangeability; ②The connection between the descaling ring device and the high-pressure water pipeline in the workshop adopts a flexible connection of high-p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com