Inner surface and outer surface jet flow descaling system and method for big-diameter metal pipe wall

A technology for internal and external surfaces and descaling systems, applied in metal rolling, metal rolling, metal processing equipment, etc., can solve problems that have not been raised

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

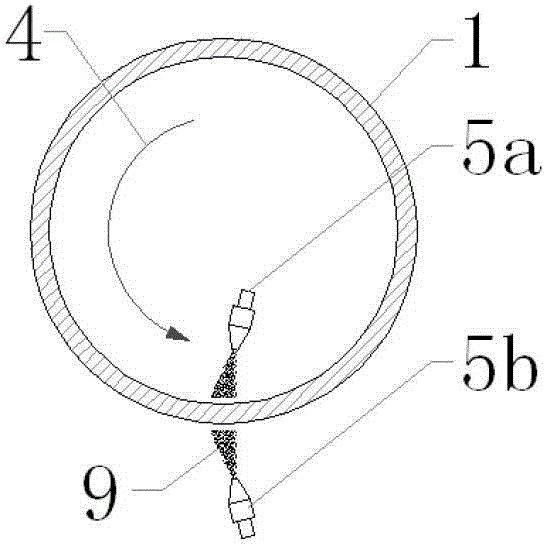

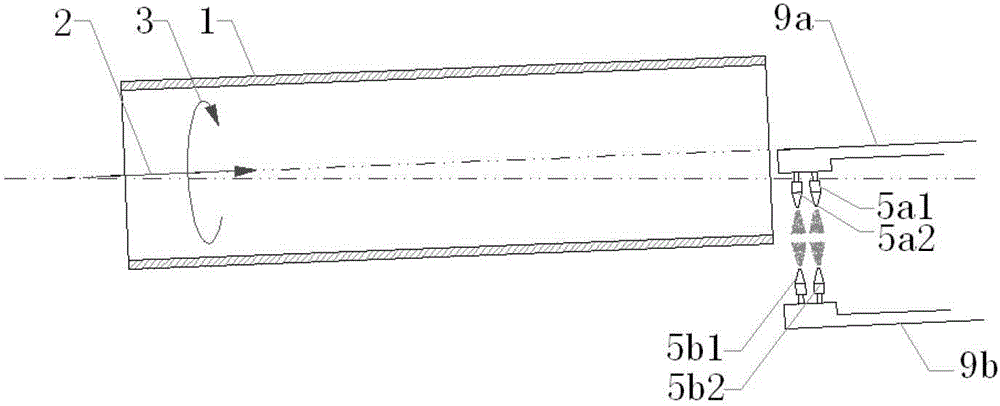

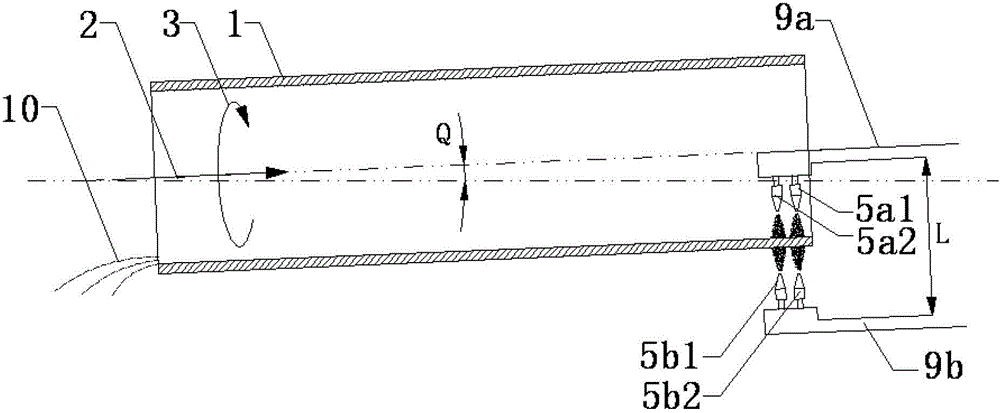

[0076]Embodiment 1: The pipe wall of the cold steel metal pipe 1 is transported by rollers to the mixed jet descaling area composed of a plurality of spray subunits 5, 6, 7, 8. The spray subunits 5, 6, 7, Each subunit of 8 includes two mixing nozzles, the nozzle models are exactly the same, and the vertical spraying distance between all nozzles and the inner and outer circumferential surfaces of the metal pipe 1 is 5cm, and the inclination angle is 10°, and all subunits 5, 6, 7, and 8 are uniformly arranged in a divergent shape along the circumferential direction of the circular section of the metal pipe 1, and the misalignment angle between each two subunits 5, 6, 7, and 8 along the circumferential direction of the section is 60 °. In this way, the model of the metal pipe wall is a hollow steel pipe 1 with an outer diameter of 800mm and an inner diameter of 600mm. The injection subunits 5, 6, 7, and 8 are all sprayed at a pressure of 50 MPa, so that the outer surface of the ...

Embodiment 2

[0077] Embodiment 2: The pipe wall of the cold steel metal pipe 1 is transported to the mixed jet descaling area composed of a plurality of spray subunits 5 and 6 through the roller table, and each subunit of the spray subunits 5 and 6 contains Two mixing nozzles, the nozzle models are exactly the same, and the vertical spray distance between all nozzles and the inner and outer peripheral surfaces of the metal pipe 1 is 5cm, and the inclination angle is 10°, and all subunits 5 and 6 are arranged in a parallel On a straight line on the wall axis of the metal pipe 1 , the distance between the subunits 5 and 6 is 5 cm on the straight line. In this way, the model of the metal pipe wall is a hollow steel pipe 1 with an outer diameter of 800mm and an inner diameter of 600mm. Both the injection sub-units 5 and 6 are sprayed at a pressure of 50 MPa, so that the outer surface of the metal pipe 1 can be descaled at one time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com