Jet de-scaling system and method for surfaces of metal bars and wires

A descaling system and a technology for metal bars, which are applied in the technical field of metal surface cleaning according to the present invention, can solve the problems of slow descaling speed, poor working environment of process production workshops, inconsistent descaling effects, etc. The effect of green descaling process and high descaling capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

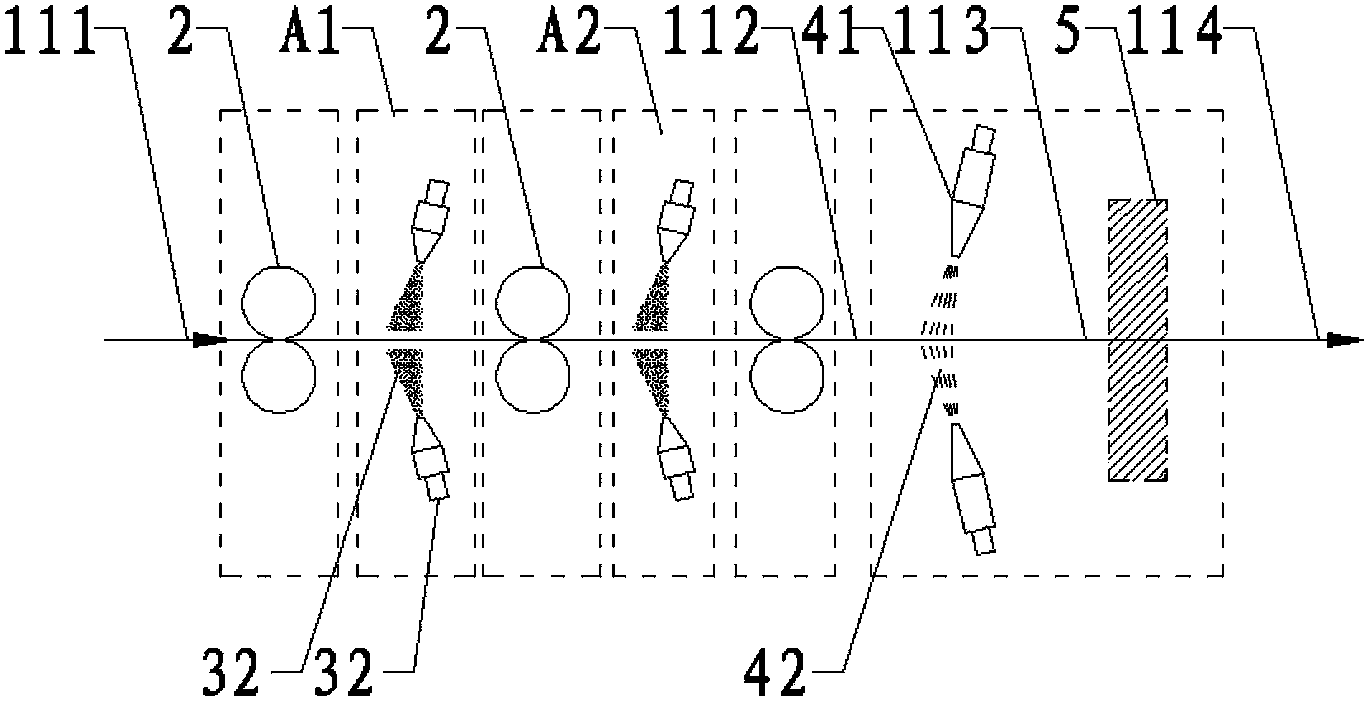

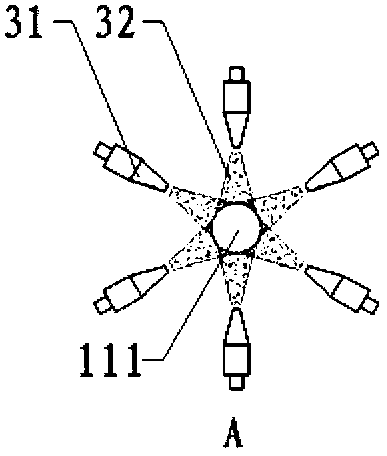

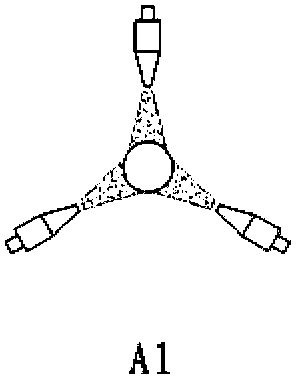

[0062] Embodiment 1: The cold steel wire rod 111 is conveyed to the entrance of the subunit A1 arranged with three mixing nozzles 32 through the roller table 2, and the three nozzles 32 in the subunit A1 are centered around the central axis of the wire rod 111 Divergent, centrally symmetrical arrangement. The included angles of the three nozzles 32 are 120° (see Figure 2). After passing through the A1 subunit, the scales of the three arcs on the section of the wire 111 have been removed, and the remaining three arcs have not been removed. In this way, when the wire 111 enters the second sub-unit A2 from the support roller table 2, the nozzles 32 of the sub-unit A2 are also circumferentially arranged at an angle of 120°, but the overall arrangement form is exactly 60° misaligned with the overall arrangement form of A1, That is to say, the compensation on the circumference is realized, and the unscaled three-section arc surface of the wire 111 is guaranteed to be descaled just a...

Embodiment 2

[0063] Embodiment 2: Referring to Figure 3, the difference between this embodiment and the above embodiment is that the descaling unit B in this embodiment is composed of three subunits B1, B2, B3, and each subunit B1, B2, B3 The arrangement of nozzles inside is also 120°circumferentially dispersed, but the difference in the arrangement of the three sub-units B1, B2, and B3 is that the misalignment angle between them is 40°.

Embodiment 3

[0064] Embodiment 3: Referring to Figure 4, the difference between this embodiment and the above embodiments is that the descaling unit C in this embodiment is composed of four subunits C1, C2, C3 and C4, and each subunit C1, C2 The arrangement of the nozzles in , C3 and C4 is also a 120° circumferential divergent arrangement, but the difference in the arrangement of the four subunits C1, C2, C3 and C4 is that the misalignment angle between them is 30°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com