Large-diameter metal bar surface jet flow descaling system and method

A technology of metal bar and descaling system, applied in the direction of metal rolling, metal rolling, metal processing equipment, etc., can solve the problems that have not been raised

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

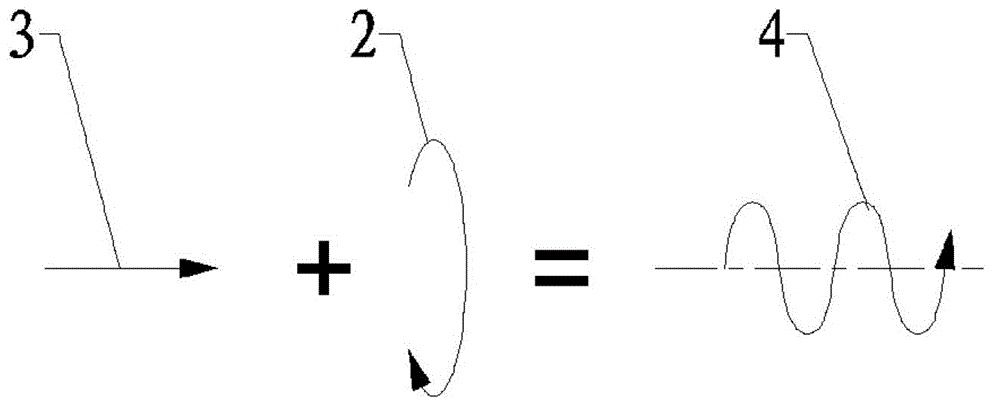

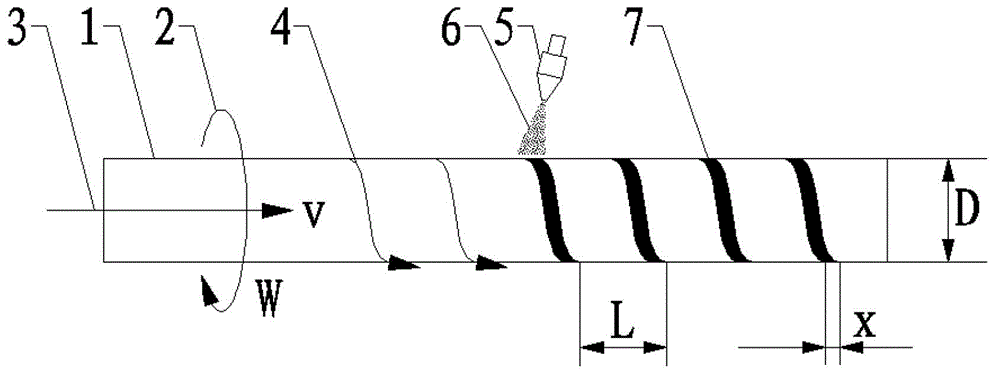

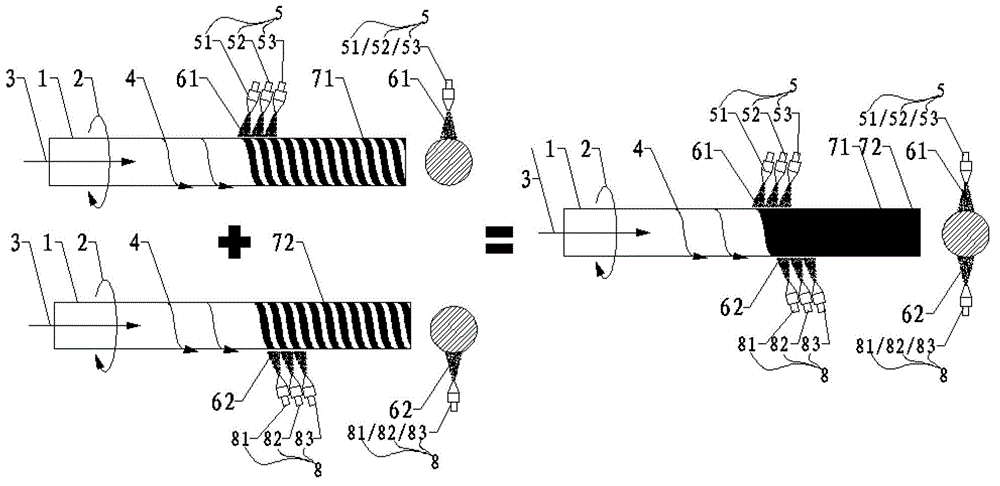

Method used

Image

Examples

Embodiment 1

[0079] Embodiment 1: The cold steel bar 1 is conveyed to a mixed jet descaling area composed of a plurality of nozzle subunits 5, 8, 9, 10, 11, 12 through a roller table, and the nozzle subunits 5, 8, Each subunit of 9, 10, 11, and 12 contains three nozzles, the nozzle models are exactly the same, and the vertical spraying distance between all nozzles and the outer circumferential surface of bar 1 is 5cm, and the inclination angle is 10°. At the same time, all subunits 5, 8, 9, 10, 11, 12 are uniformly arranged in a divergent shape along the circumferential direction of the circular section of the bar 1, and between each two subunits 5, 8, 9, 10, 11, 12 along the circumferential direction of the section The misalignment angle value is 60°. In this way, the bar model is a solid steel bar with an outer diameter of 150 mm. When the bar 1 is fed forward at a horizontal speed of 5 m / min and an axial rotational angular speed of 5 round / min, all nozzle subunits 5, 8, and 9 , 10, 11,...

Embodiment 2

[0080] Embodiment 2: The cold steel bar 1 is conveyed to a mixed jet descaling area composed of a plurality of nozzle subunits 5, 8, 9, 10, 11, 12, the nozzle subunits 5, 8, Each subunit of 9, 10, 11, and 12 contains three nozzles, the nozzle models are exactly the same, and the vertical spraying distance between all nozzles and the outer circumferential surface of bar 1 is 5cm, and the inclination angle is 10°. At the same time, all subunits 5, 8, 9, 10, 11, 12 are arranged on a straight line parallel to the axis of bar 1, and each subunit 5, 8, 9, 10, 11, 12 presents a certain amount of misalignment along the direction of the straight line, The amount of misalignment is 5cm. In this way, the bar model is a solid steel bar with an outer diameter of 150 mm. When the bar 1 is fed forward at a horizontal speed of 5 m / min and an axial rotational angular speed of 5 round / min, all nozzle subunits 5, 8, and 9 , 10, 11, and 12 are all sprayed at a pressure of 50Mpa, so that the one-...

Embodiment 3

[0081]Embodiment 3: The cold steel bar 1 is conveyed to a mixed jet descaling area composed of a plurality of nozzle subunits 5, 8, 9, 10, 11, 12 arranged by a roller table, and the nozzle subunits 5, 8, Each subunit of 9, 10, 11, and 12 contains three nozzles, the nozzle models are exactly the same, and the vertical spraying distance between all nozzles and the outer circumferential surface of bar 1 is 5cm, and the inclination angle is 10°. At the same time, subunit 5 , 8 are arranged on a straight line parallel to the axis of the bar 1, and there is a certain amount of misalignment between the subunits 5, 8 along the direction of the line, and the amount of misalignment is 5 cm; On a straight line parallel to the axis, there is a certain amount of misalignment between the subunits 5 and 8 along the direction of the line, and the amount of misalignment is 5 cm; 1 Axial arrangement with different angles in the direction of the outer circumference, and the angle between two str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com