A jet descaling device and method for removing scales on the inner wall of metal pipes

A technology for removing metal and descaling equipment, which is applied in the direction of metal rolling, metal rolling, metal processing equipment, etc., can solve problems such as the technology for removing surface scales that has not been proposed, and achieve green descaling technology, strong competitive advantages, The effect of stabilizing the descaling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

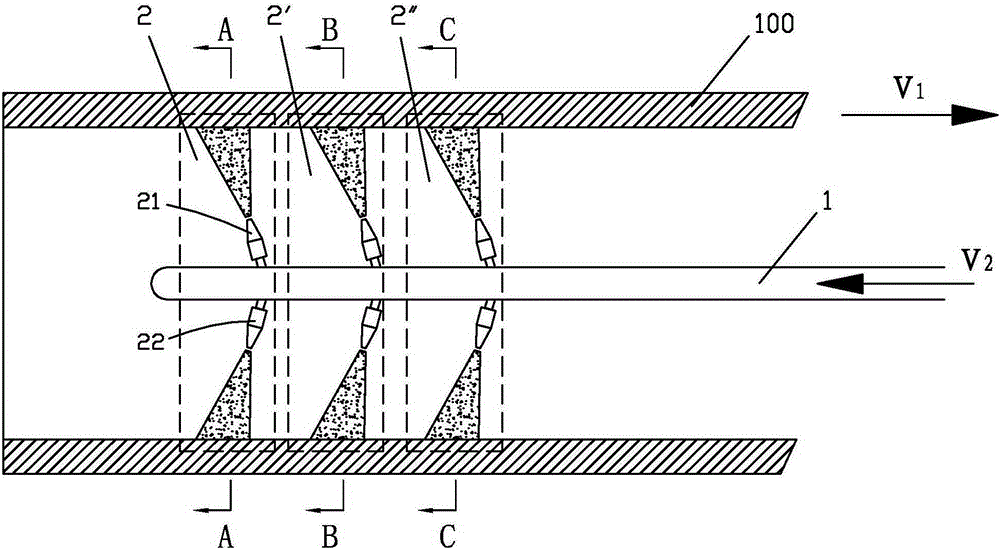

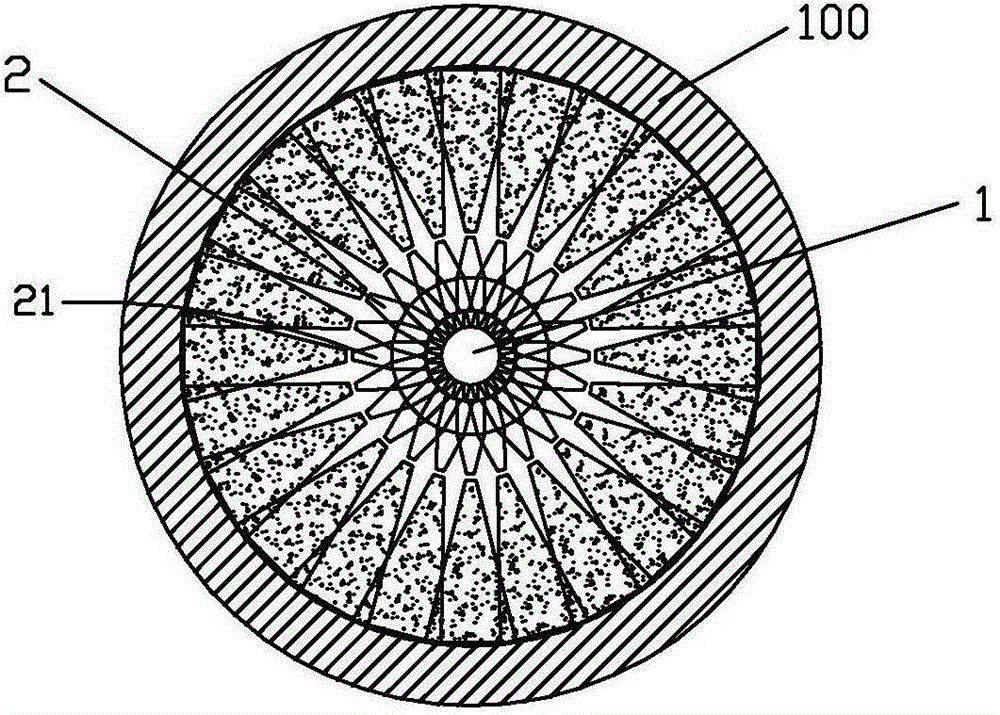

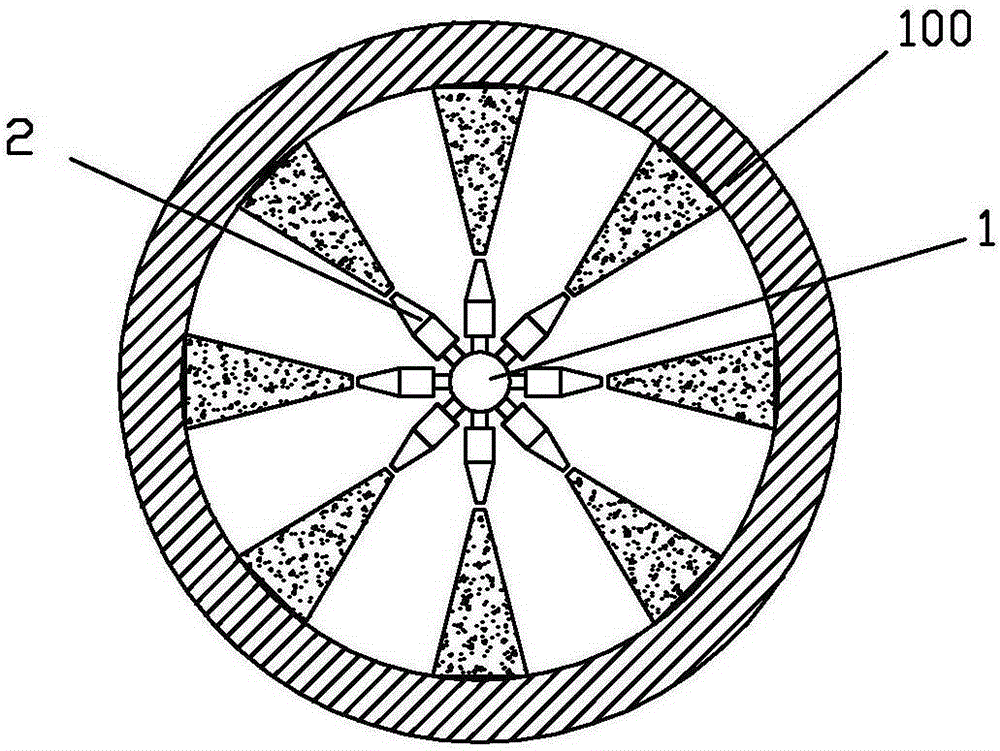

[0025] see Figure 1 to Figure 5 , a jet descaling device for removing scales on the inner wall of a metal pipe according to the present invention, which includes a support rod 1 arranged along the central axis of the metal pipe 100; three nozzle units 2, 2', 2", along the The length direction of the support rod 1 is arranged front and back, and each nozzle unit 2 (nozzle unit 2 is taken as an example, the same below) is provided with two mixed jet nozzles 21, 22, which diverge along the circumference of the support rod 1 with the axis of the support rod 1 as the center of the circle. Evenly arranged, and the mixed jet nozzles of the nozzle units 2, 2', 2" arranged in front and back are staggered in the circumferential direction to form a matrix of mixed jet nozzles, forming a closed circle that can cover the inner wall of the metal pipe for effective descaling Area.

[0026] Further, the angle of divergence between the mixed jet nozzles 21 and 22 in the nozzle unit 2 is 5°-1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com