Online cleaning method of tubular reactor fouling in ammonium phosphate production

A technology for tubular reactors and ammonium phosphate, applied in cleaning methods and appliances, chemical instruments and methods, ammonium orthophosphate fertilizers, etc., can solve problems affecting the normal operation of tubular reactors, restrict stable operation of tubular reactors, and consume Time-consuming tube reactor and other problems, to achieve the effect of eliminating product quality, obvious descaling, and improving operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

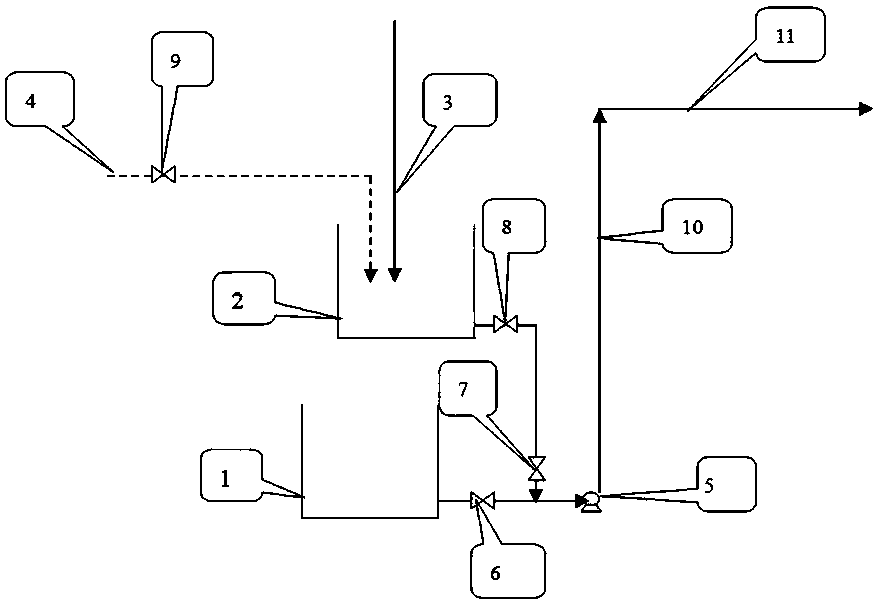

[0017] An on-line cleaning method of tubular reactor fouling in ammonium phosphate production, comprising:

[0018] (1) Preparation of cleaning solution

[0019] The cleaning liquid used is made up of two kinds of raw materials of sulfuric acid and water, and the mass fraction and mass ratio of two kinds of raw material liquids are as follows:

[0020] 60%~98% sulfuric acid

[0021] The mass ratio of sulfuric acid and water is 1:25~30

[0022] The two kinds of raw materials are mixed uniformly in a container to become a cleaning solution for use; the container is a storage tank with a capacity of 4t, and the amount of cleaning solution for each storage tank is 3.5t.

[0023] (2) The container of diluted sulfuric acid is used as the storage tank of the cleaning solution at the same time, the storage tank is provided with a cleaning solution outlet pipe, the cleaning solution outlet pipe is connected to the inlet of the tubular reactor delivery pump, and a control valve is ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com