Wet rotary cage sand blasting machine

A sandblasting machine and rotary cage technology, applied in abrasive jet machine tools, used abrasive treatment devices, abrasives, etc., can solve problems such as large dust, environmental pollution, and environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to more clearly illustrate the technical solutions in the embodiments of the present invention or the prior art, the following will briefly introduce the drawings that need to be used in the description of the embodiments or the prior art. Obviously, the accompanying drawings in the following description are only These are some embodiments of the present invention. For those skilled in the art, other drawings can also be obtained according to these drawings without any creative effort.

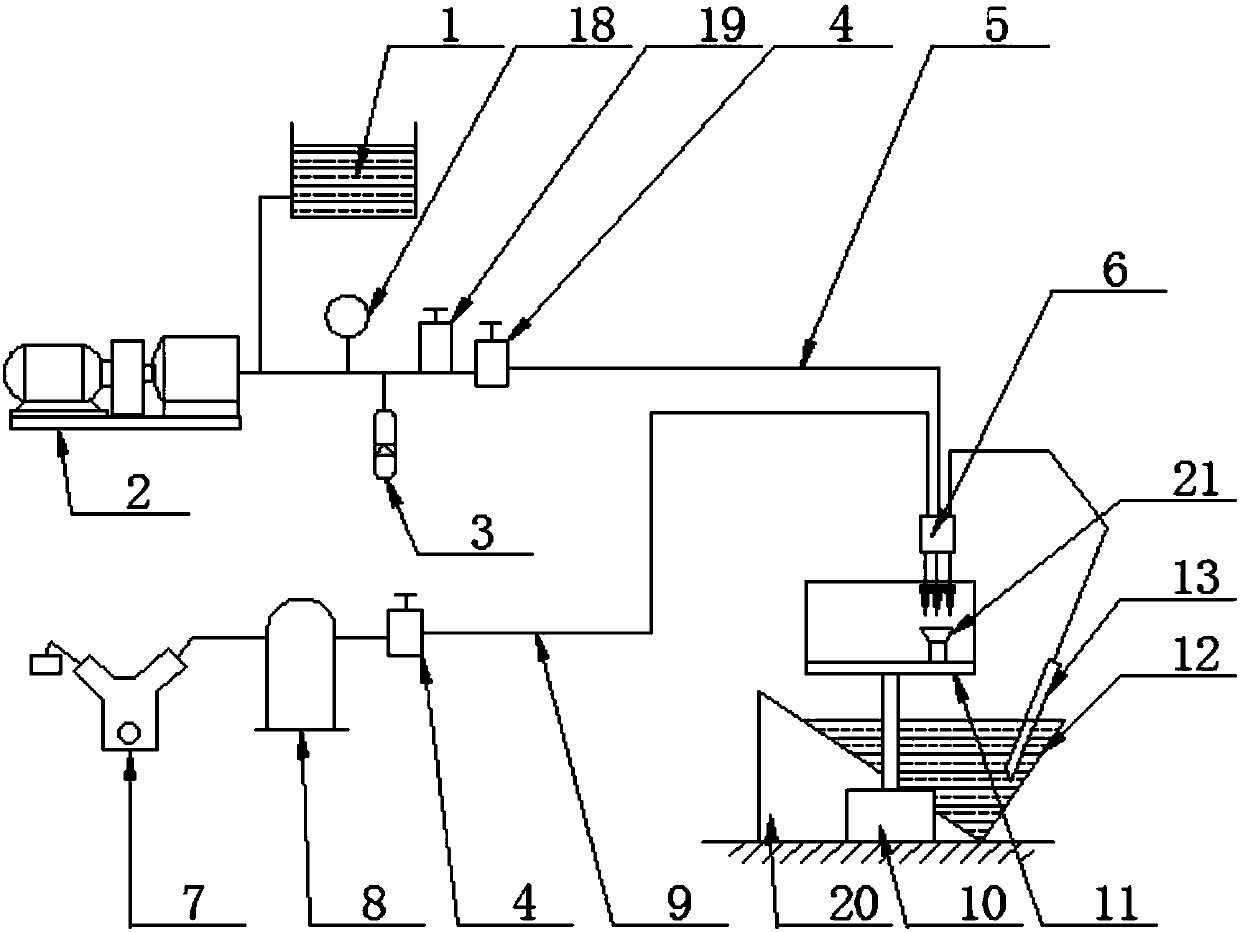

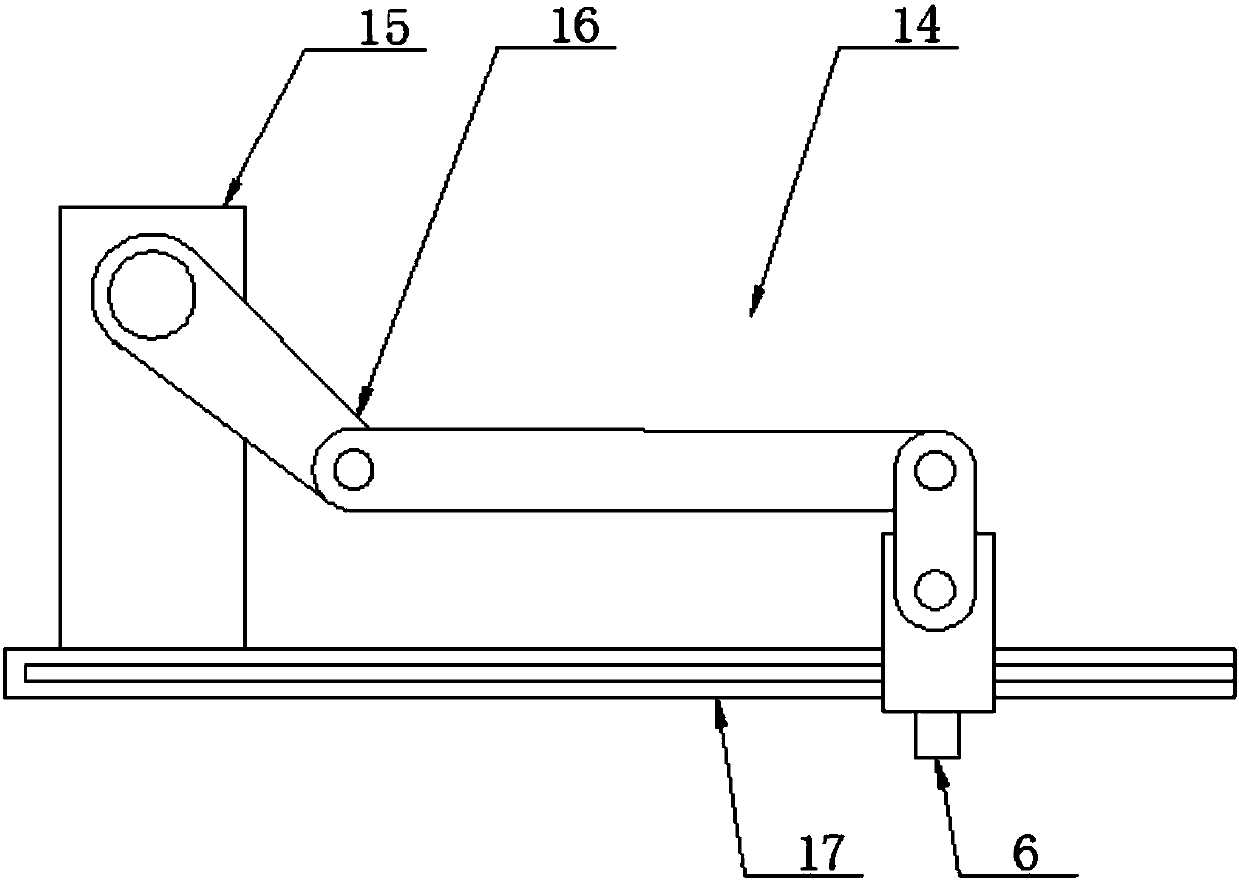

[0018] see as figure 1 — figure 2 As shown, this specific embodiment adopts the following technical scheme: it includes a pool 1, a high-pressure plunger pump 2, a voltage stabilizer 3, a pressure regulating valve 4, a high-pressure water pipe 5, a descaling nozzle 6, an air compressor 7, and a pressure regulator cylinder 8. High-pressure air duct 9, tumbler motor 10, tumbler 11, sand collecting bucket 12, sand suction head 13, swing mechanism 14; the pool 1 is connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com